Lifting process of upper structure of FPSO crane

A crane and hoisting technology, which is applied in the direction of transportation and packaging, load hanging components, cranes, etc., can solve the problems of difficult hoisting accuracy, long construction period, and high difficulty, so as to reduce the number of hoisting times, reduce potential safety hazards, and control The effect of hoisting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

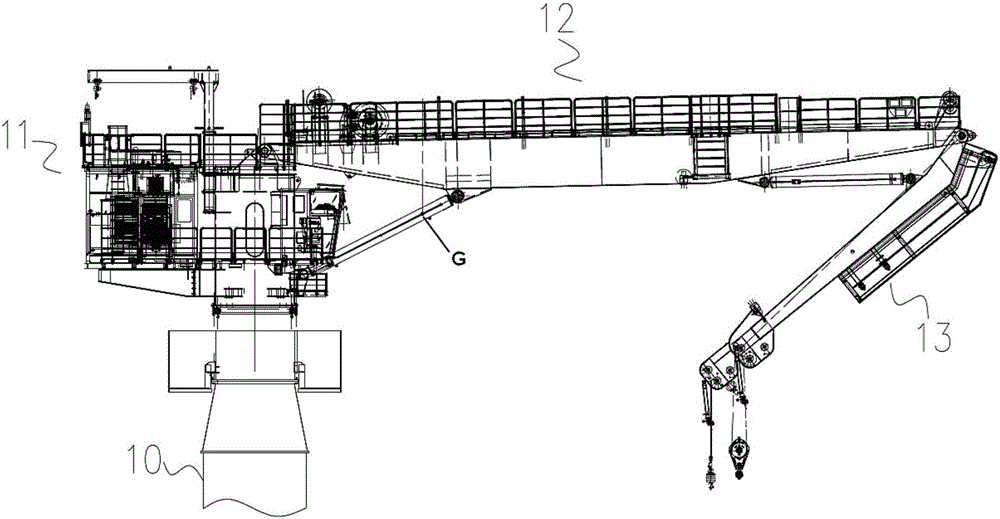

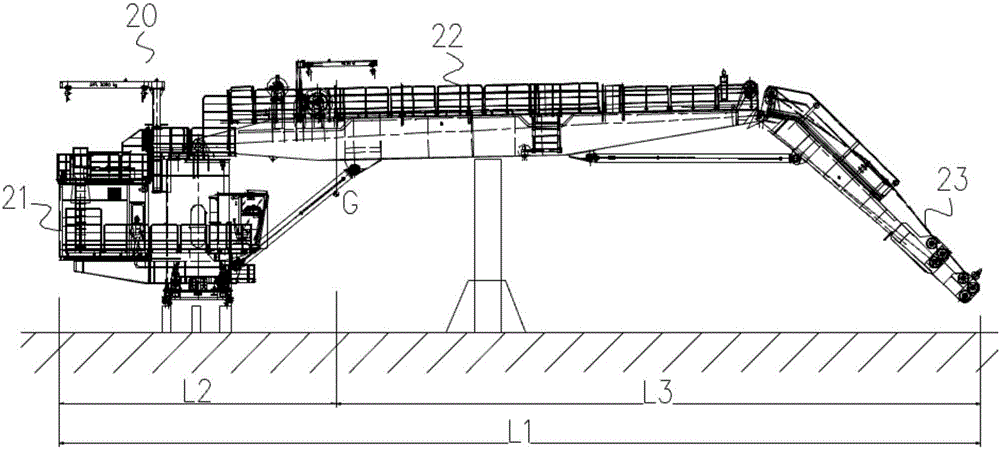

[0020] see figure 2 , which is a structural schematic diagram of the upper structure 20 of the FPSO crane in this case. The FPSO crane superstructure 20 includes an operation platform 21, a main boom 22 and a joint boom 23, the operation platform 21 is connected transversely to the main boom 22, and the main boom 22 is connected transversely to the joint boom 23 And the initial angle α2 of the main boom and the joint boom is an obtuse angle, the total length of the superstructure 20 is 41531mm (L1), and its center of gravity divides the superstructure into left and right parts of 12531mm (L2) and 29000mm (L3).

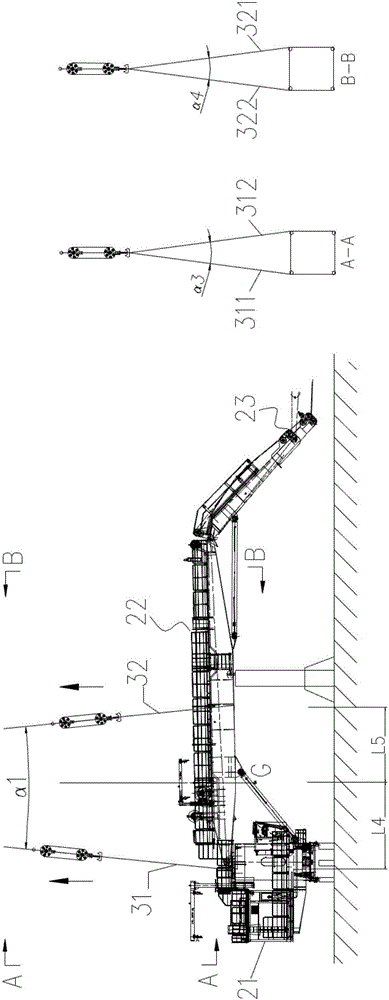

[0021] Please also see Figure 3 to Figure 5 , image 3 It is a schematic diagram of the installation of the main suspension rope of the hoisting process of the upper structure of the FPSO crane of the present invention, Figure 4 It is the hoisting schematic diagram of the hoisting process of the FPSO crane superstructure of the present invention, Figure 5 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com