Boiler steel frame combination and installation process of sintering machine circular cooler

A boiler and chiller technology, applied in the direction of boiler support/positioning devices, etc., can solve the problems of shortened steel frame period, long construction period, long steel frame construction period, etc., achieve high installation stability, shorten installation period, and solve long construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

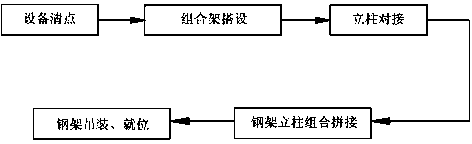

[0033] Such as figure 1 As shown, the sintering machine annular cooler boiler steel frame assembly and installation process includes the following steps,

[0034] Combination and assembly of columns: (a) Name the six columns Z1, Z2, Z3, Z4, Z5, Z6 in turn, where Z1 and Z2 form a group, Z3 and Z4 form a group, Z5 and Z6 form a group, in each The left and right centerlines are drawn on the upper and lower sections of the root column, and the two sides of the interface are respectively padded and leveled when docking. First, the butt joint between the columns is welded, and then the web is welded. The total length of the column is 4mm longer than that before welding, and the single column After welding, check the straightness of the column, the straightness error is 8mm, the deviation of the butt center line is 1.5mm, the total length deviation is -8mm, the column curvature is 1 / 1000, and is 10mm, and the column torsion value is 1 / 1000, and 10mm, the bracket height deviation is...

Embodiment 2

[0043] Such as figure 1 As shown, the sintering machine annular cooler boiler steel frame assembly and installation process includes the following steps,

[0044] Combination and assembly of columns: (a) Name the six columns Z1, Z2, Z3, Z4, Z5, Z6 in turn, where Z1 and Z2 form a group, Z3 and Z4 form a group, Z5 and Z6 form a group, in each The left and right centerlines are drawn on the upper and lower sections of the root column, and the two sides of the interface are respectively padded and leveled when docking. First, the butt joint between the columns is welded, and then the web is welded. The total length of the column is 4mm longer than that before welding, and the single column After welding, check the straightness of the column, the straightness error is 6mm, the deviation of the butt center line is 1.2mm, the total length deviation is -4mm, the column curvature is 1 / 1200, and it is 8mm, and the column torsion is 1 / 1200, and 8mm, bracket height deviation is -1mm;

...

Embodiment 3

[0058] Such as figure 1 As shown, the sintering machine annular cooler boiler steel frame assembly and installation process includes the following steps,

[0059] Combination and assembly of columns: (a) Name the six columns Z1, Z2, Z3, Z4, Z5, Z6 in turn, where Z1 and Z2 form a group, Z3 and Z4 form a group, Z5 and Z6 form a group, in each The left and right centerlines are drawn on the upper and lower sections of the root column, and the two sides of the interface are respectively padded and leveled when docking. First, the butt joint between the columns is welded, and then the web is welded. The total length of the column is 4mm longer than that before welding, and the single column After welding, check the straightness of the column, the straightness error is 5mm, the deviation of the center line of the butt joint is 1.0mm, the deviation of the total length is +2mm, the curvature of the column is 1 / 1500, and ≤5mm, and the torsion of the column is 1 / 1500, and 5mm, bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com