Novel flue gas waste heat recycling device

A flue gas waste heat and recovery device technology, which is applied to heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems that waste heat utilization equipment cannot generate hot air and hot water at the same time, and the heat exchange efficiency is low , to achieve the effects of reducing production costs, less steel consumption, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

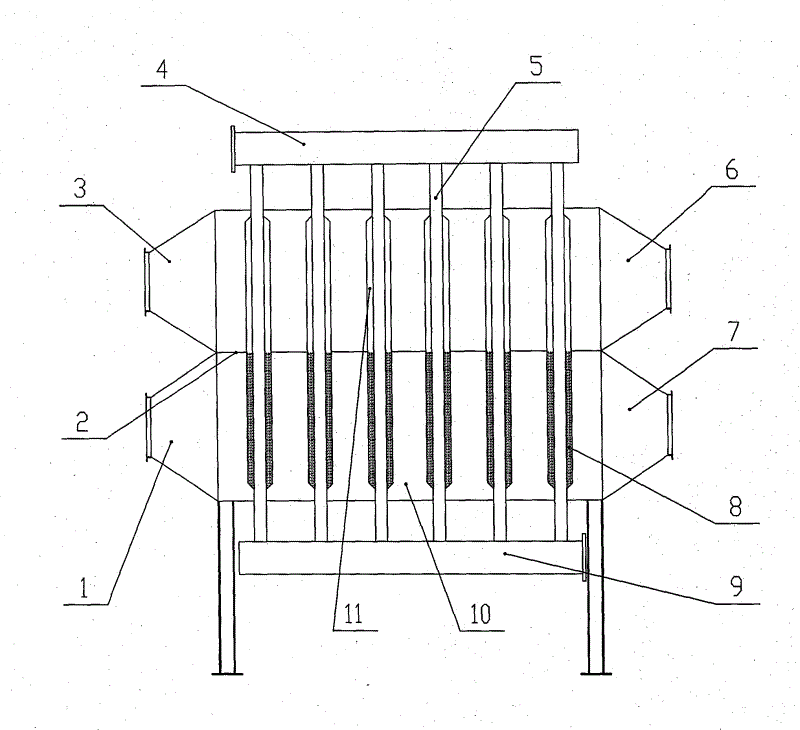

[0011] Referring to the accompanying drawings, the present invention includes 4 water inlet headers located on the upper part of the 10 shell side, connected to the 4 water inlet headers are the 5 heat exchange tube assemblies located inside the 10 shell side, and 11 closed chambers outside the 5 heat exchange tube assemblies The body contains half of the 8 superconducting liquid, and the other half is a vacuum. The lower part of the 5 heat exchange tube assembly is connected to the 9 water outlet header, and the 10 shell side is connected to the 1 smoke inlet, 7 smoke outlet, 3 hot air outlet and 6 Cold air inlet, 2 partitions divide 10 shells into flue gas channel and air channel.

[0012] The working principle of the present invention: high-temperature flue gas enters the interior of shell side 10 from smoke inlet 1, and quickly scours 5 heat exchange tube assemblies, 5 heat exchange tube assemblies 11 contain half of 8 superconducting liquid in the external airtight cavity,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com