Fabricated building frame hollow column joint structure and construction method thereof

A hollow-column, prefabricated technology, applied in building construction, construction, and building material processing, can solve the problems of difficult assembly, low installation efficiency, long welding time, etc., and achieve the effect of shortening the installation period and improving the installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-8 The application is described in further detail.

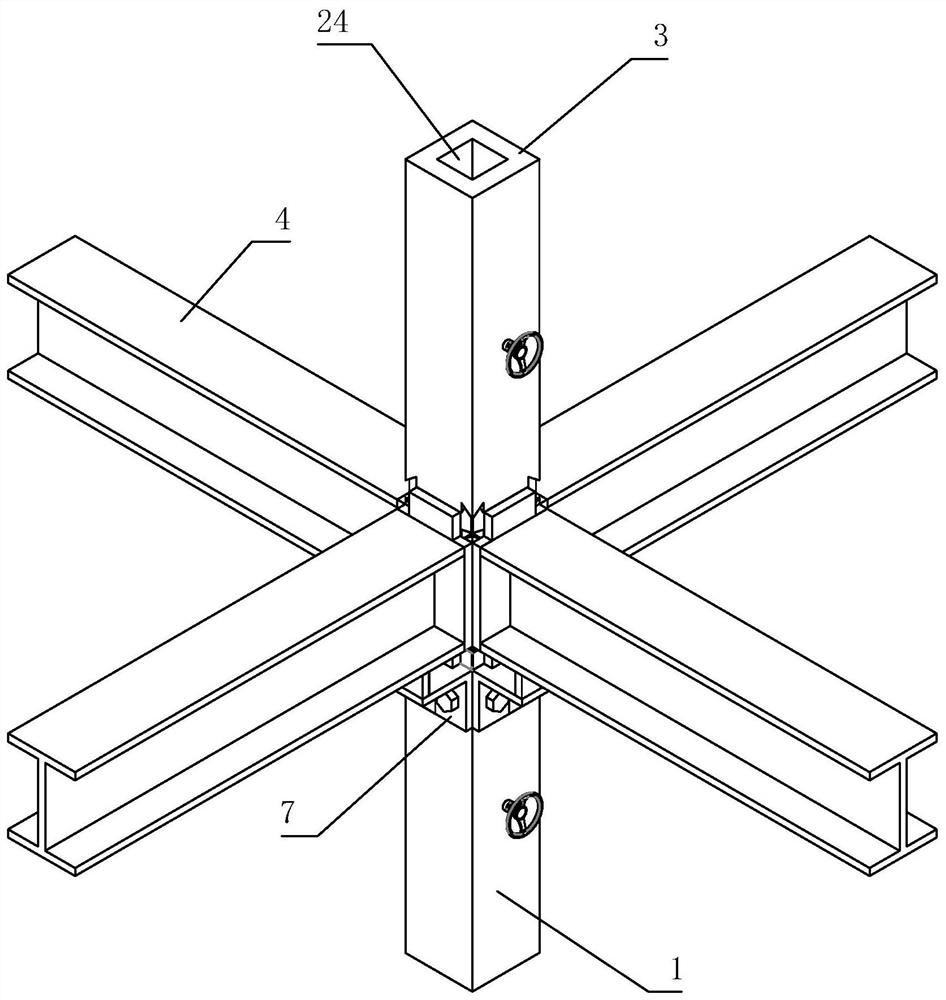

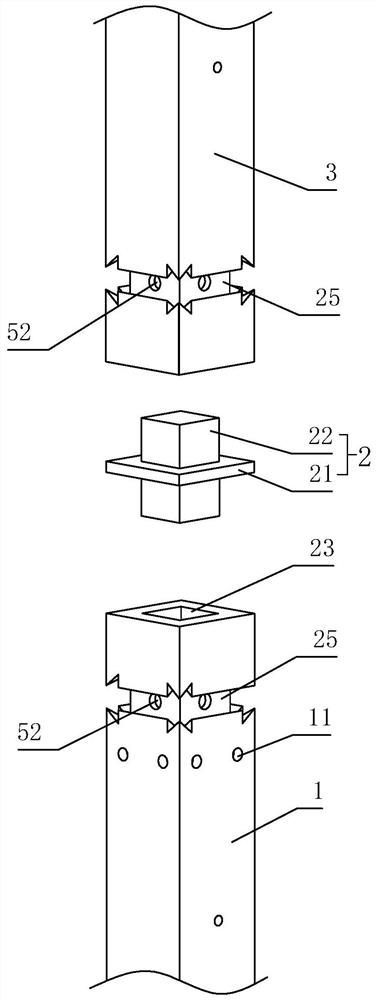

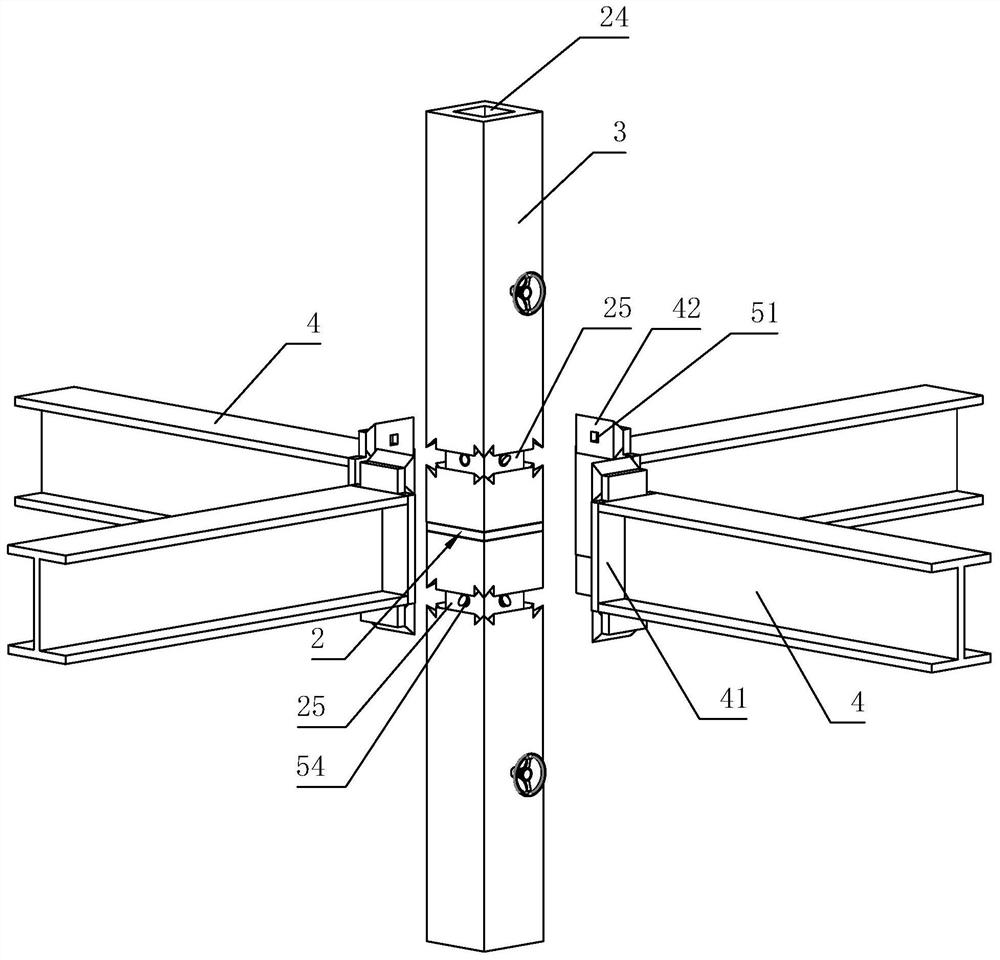

[0046] The embodiment of the present application discloses a hollow column node structure of a prefabricated building frame, referring to figure 1 , figure 2 , including a lower prefabricated column 1 with a square cross section, a connecting column 2 inserted on the upper part of the lower prefabricated column 1, an upper prefabricated column 3 sleeved on the upper part of the connecting column 2 with a square cross section, and the end is installed on the The lower side wall of the upper prefabricated column 3 and the crossbeam 4 of the upper side wall of the lower prefabricated column 1 .

[0047] The connecting cylinder 2 includes a limiting portion 21 and two inserting portions 22 fixedly connected to the upper end and the lower end of the limiting portion 21. The cross-sectional dimension of the limiting portion 21 is larger than that of the inserting portion 22. And the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com