Water filtration structure

A water filtration and filter tube technology, applied in filtration separation, membrane filter, filtration treatment and other directions, can solve the problem of ineffective removal of toxic and harmful substances, and achieve the effects of simple structure, low cost and good breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

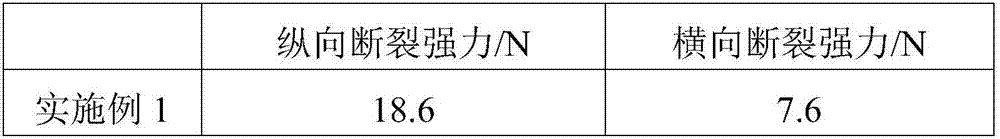

Embodiment 1

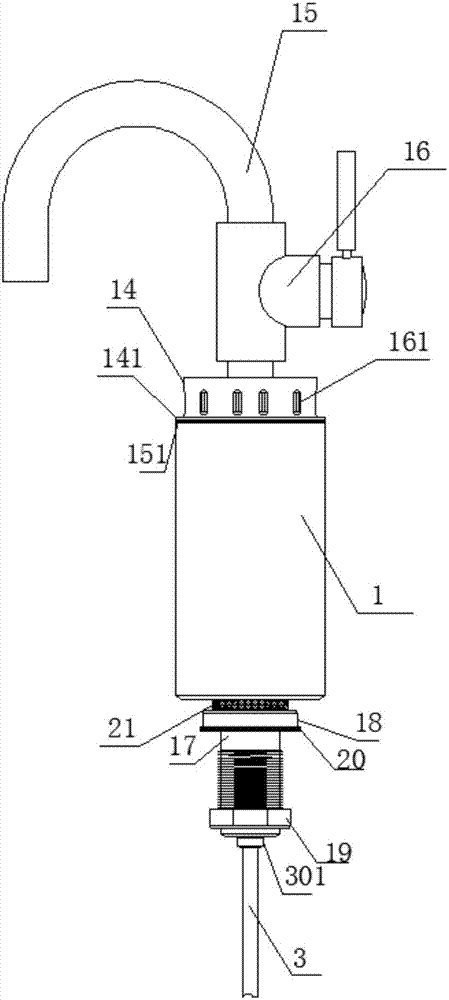

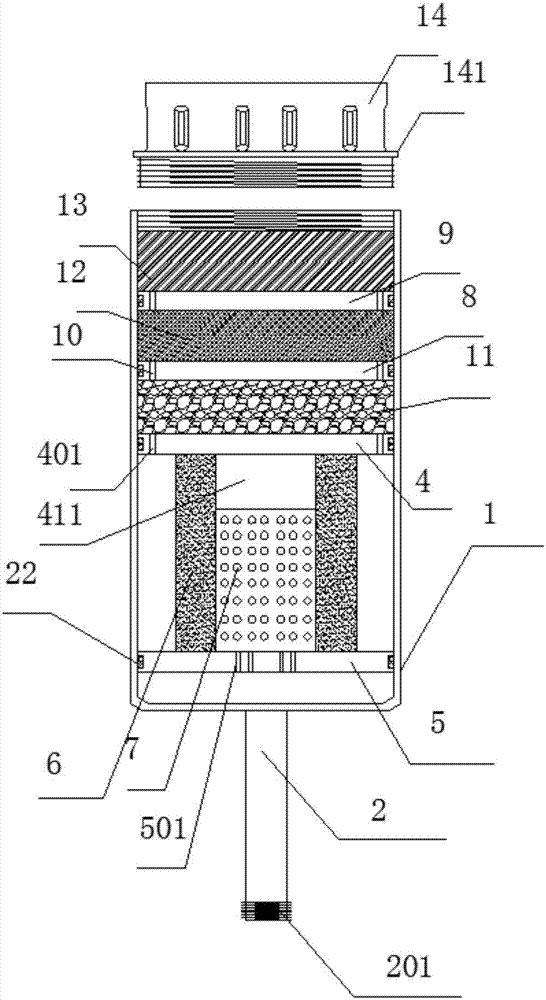

[0048] refer to figure 1 and figure 2 The shown water filtration structure includes a filter pipe 1, a water inlet pipe 2 is arranged at the axial center of the lower end of the filter pipe 1, and a water inlet pipe 2 is arranged at the outer wall of the end far away from the filter pipe 1 There is an external thread 201, and through the external thread 201, it is matched with a hose 3 for connecting to the water network. The hose 3 has a threaded sleeve 301 matching the external thread 201, and an upper end cap is arranged inside the filter pipe 1 4 and the lower end cover 5, the bottom of the upper end cover 4 is provided with a core 411, between the upper end cover 4 and the lower end cover 5 is fitted with PP cotton 6, between the PP cotton 6 and the core 411 The transition fit between the PP cotton 6 is provided with granular carbon 7, the lower surface of the lower end cover 5 is evenly distributed with water inlet holes 501, the water inlet pipe 2 is opposite to the w...

Embodiment 2

[0053] refer to figure 1 and figure 2 The shown water filtration structure includes a filter pipe 1, a water inlet pipe 2 is arranged at the axial center of the lower end of the filter pipe 1, and a water inlet pipe 2 is arranged at the outer wall of the end far away from the filter pipe 1 There is an external thread 201, and through the external thread 201, it is matched with a hose 3 for connecting to the water network. The hose 3 has a threaded sleeve 301 matching the external thread 201, and an upper end cap is arranged inside the filter pipe 1 4 and the lower end cover 5, the bottom of the upper end cover 4 is provided with a core 411, between the upper end cover 4 and the lower end cover 5 is fitted with PP cotton 6, between the PP cotton 6 and the core 411 The transition fit between the PP cotton 6 is provided with granular carbon 7, the lower surface of the lower end cover 5 is evenly distributed with water inlet holes 501, the water inlet pipe 2 is opposite to the w...

Embodiment 3

[0059] refer to figure 1 and figure 2 The shown water filtration structure includes a filter pipe 1, a water inlet pipe 2 is arranged at the axial center of the lower end of the filter pipe 1, and a water inlet pipe 2 is arranged at the outer wall of the end far away from the filter pipe 1 There is an external thread 201, and through the external thread 201, it is matched with a hose 3 for connecting to the water network. The hose 3 has a threaded sleeve 301 matching the external thread 201, and an upper end cap is arranged inside the filter pipe 1 4 and the lower end cover 5, the bottom of the upper end cover 4 is provided with a core 411, between the upper end cover 4 and the lower end cover 5 is fitted with PP cotton 6, between the PP cotton 6 and the core 411 The transition fit between the PP cotton 6 is provided with granular carbon 7, the lower surface of the lower end cover 5 is evenly distributed with water inlet holes 501, the water inlet pipe 2 is opposite to the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com