Broaching tool handle assembly

A tool handle and component technology, applied in the field of broach tool handle components, can solve the problems of reducing the diameter of the tool handle neck, poor accuracy and stability, and easy breakage of the tool handle, so as to reduce the radial runout value, improve the accuracy, and improve the safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

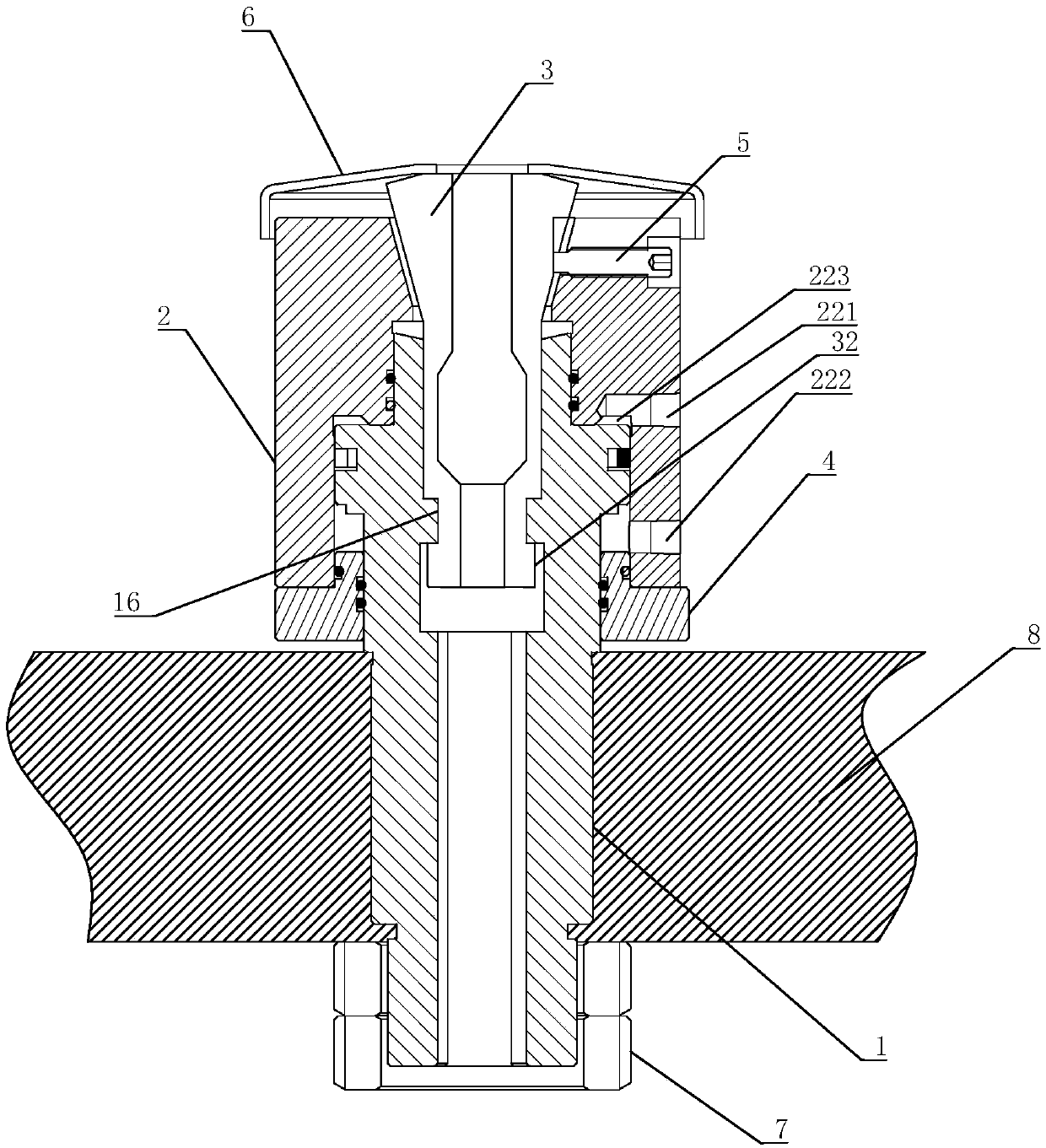

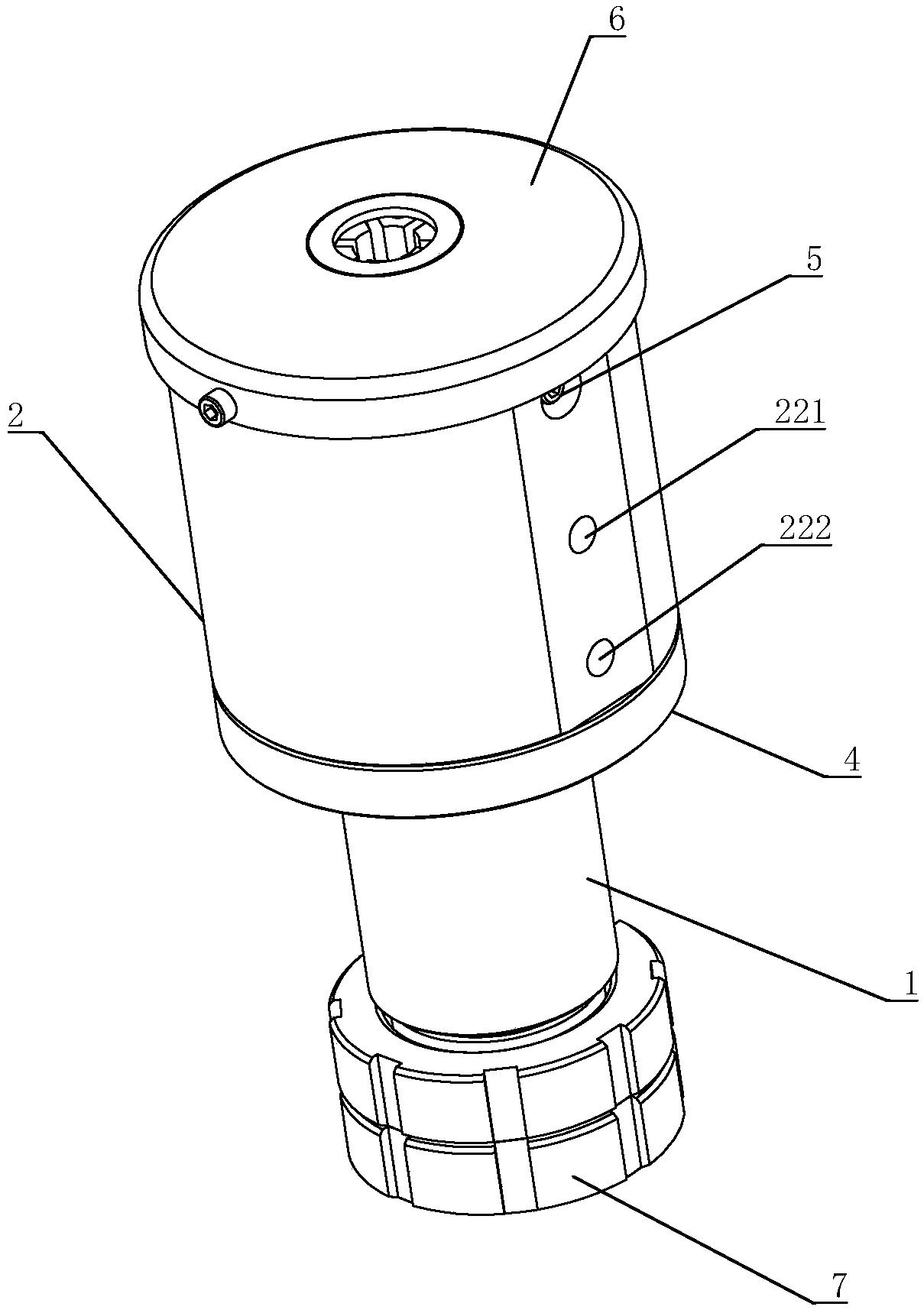

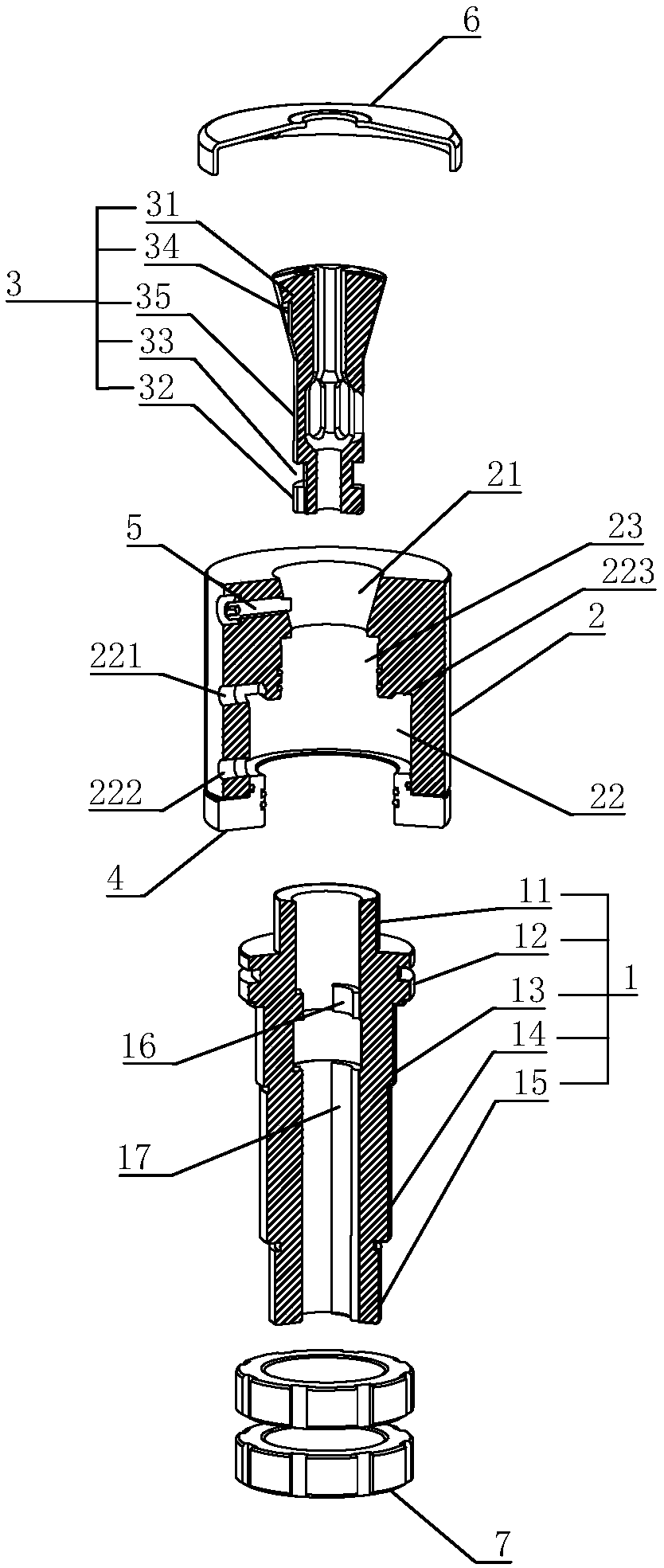

[0034] The present invention will be described in detail below in conjunction with the drawings and embodiments.

[0035] Reference Figure 1 to Figure 14 , A broach handle assembly of the present invention includes a broach 9 and a handle clamping device; the broach 9 includes a broach handle 91, the broach handle 91 has a tapered strip pull The knife handle 93, the strip broach shank 93 has a circular, elliptical or polygonal vertical axial section, and this embodiment is preferably a circular cross section; the knife handle clamping device is used to clamp the strip broach 93 to achieve opposite pulling The clamping of the knife 9 is fixed. Specifically, the tapered angle (the angle between the generatrix and the center line) of the strip broach 93 is β, and the value range of β is [-5°, 15°]; When the end extends and the radius becomes larger, β is a positive value, such as Picture 9 Shown is a positive angle, the taper that extends from the inside to the outside and incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com