Energy-saving wall with functions of heat preservation and heating

An energy-saving, wall-based technology, applied in thermal insulation, walls, home appliances, etc., can solve the problems of low heat medium temperature requirements, restricting the utilization rate of heat energy, and low utilization rate of heat energy, so as to facilitate heat conduction and reduce heat Bridge effect, the effect of improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

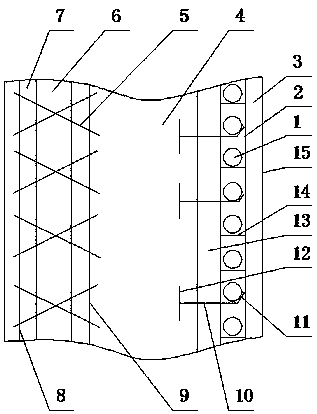

[0011] like figure 1 As shown, the energy-saving wall of the present invention has the functions of heat preservation and heating, and includes a composite sandwich steel wire grid insulation board. The inner steel mesh sheet 9 and the outer steel mesh sheet 8 on the side, a number of abdominal wires 5 pass through the heat preservation board 6 and the two ends are respectively connected to the inner steel mesh sheet 9 and the outer steel mesh sheet 8, thereby being connected with the inner The steel wire mesh sheet 9 and the outer steel mesh sheet 8 are connected to form a steel wire mesh frame structure, and a main body layer 4 is arranged close to the inner side of the insulation board 6, and the main body layer 4 adopts a cast-in-place reinforced concrete layer, and the inner steel wire mesh sheet 9 is consolidated in the main body layer 4, and an outer protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com