Prefabricated bay window component, assembly type bay window panel point construction and construction method thereof

A prefabricated, bay window technology, applied in building construction, construction, building material processing, etc., can solve the problems of poor construction, poor fixation, increased difficulty and cost in production, etc., to strengthen connections and ensure structural safety. The effect of improving the overall stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

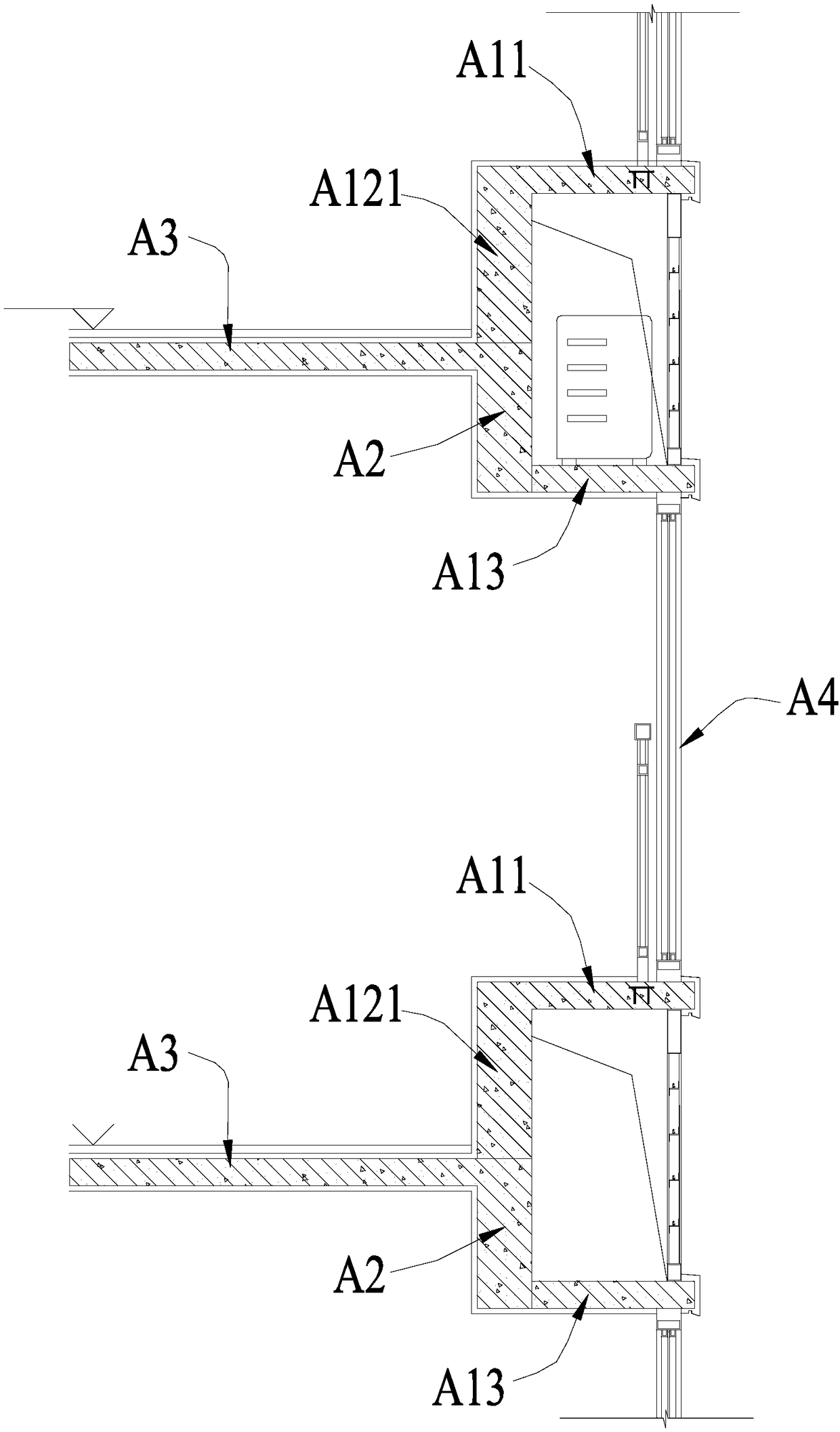

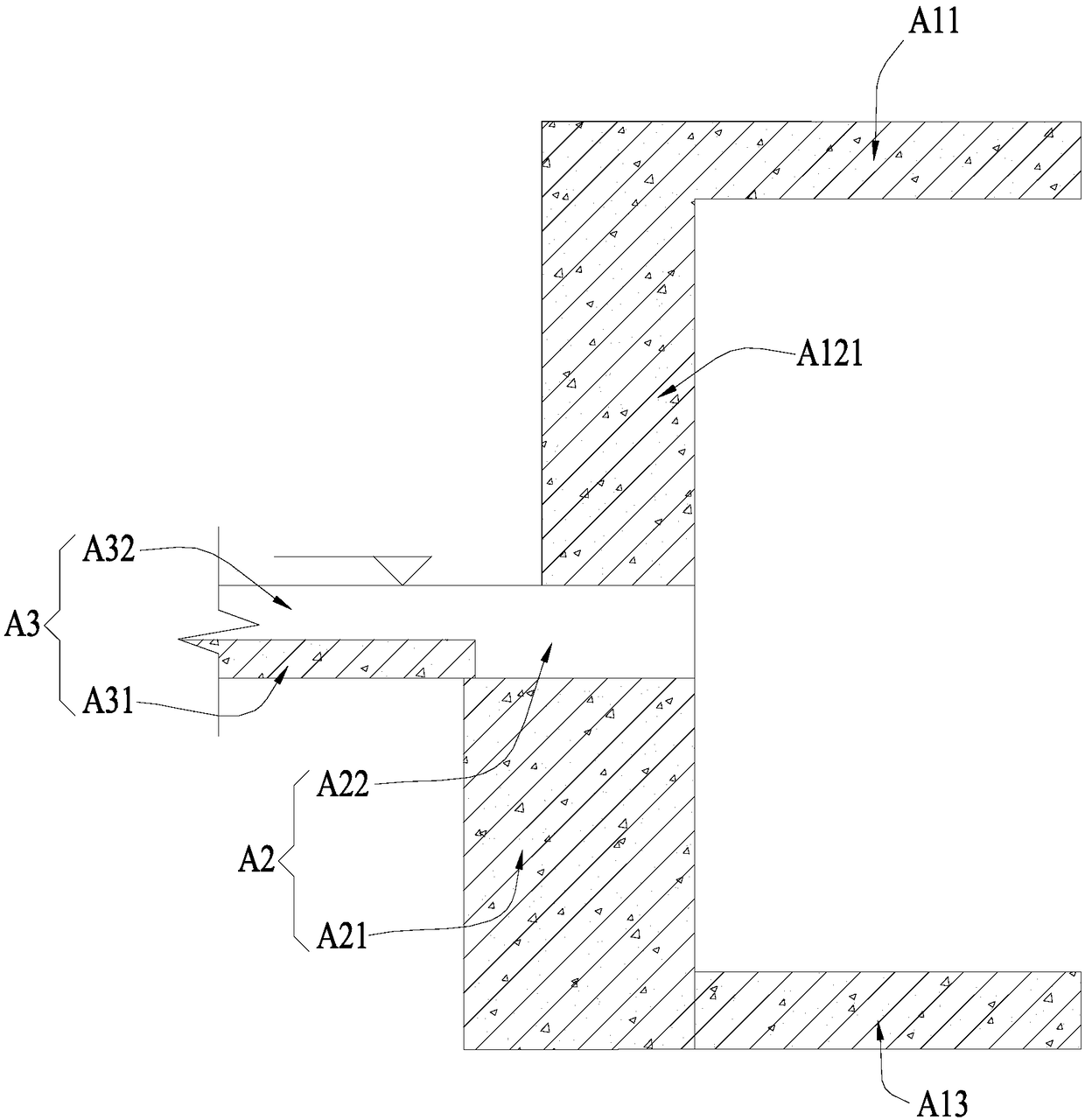

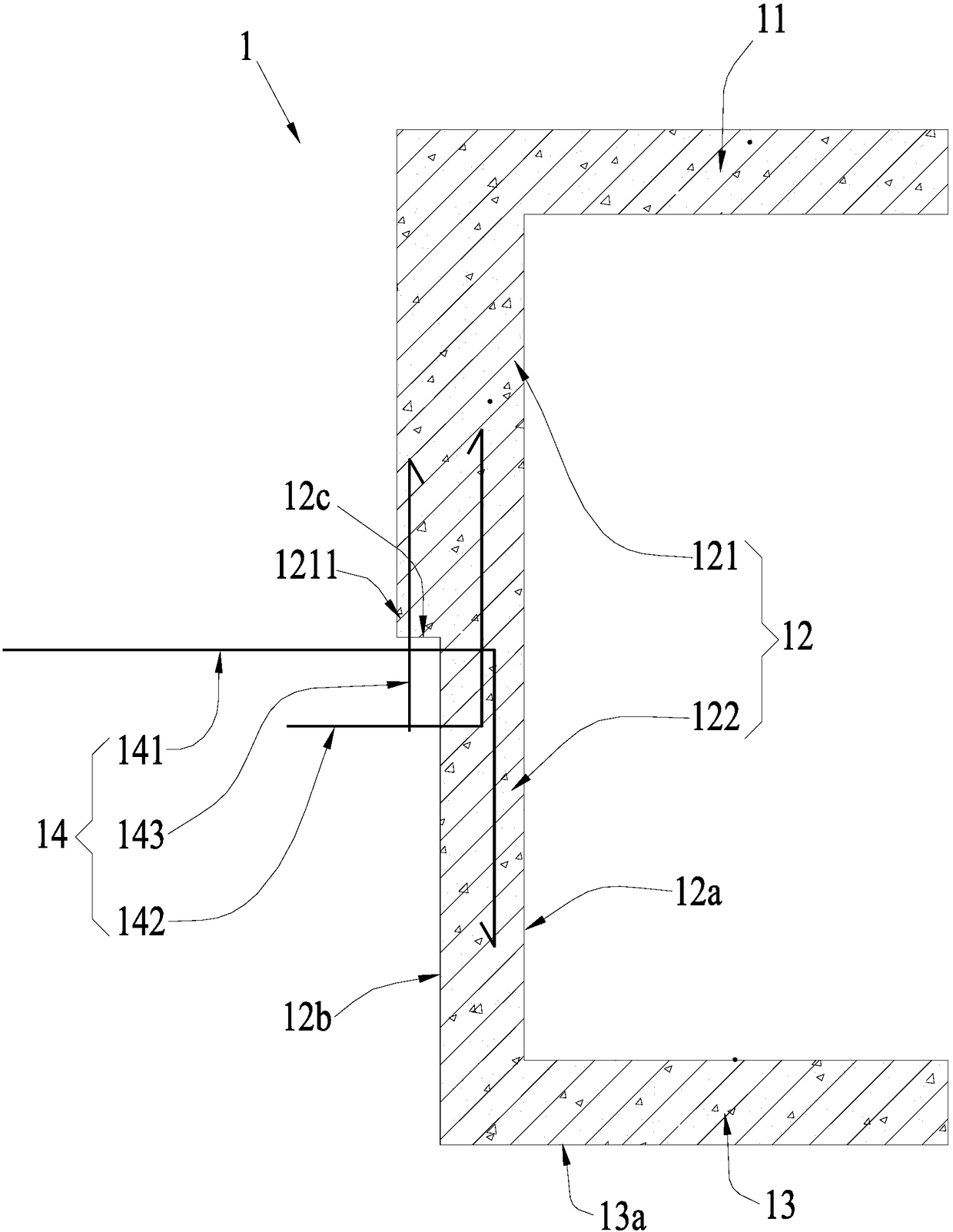

[0044] As a preferred embodiment of the present invention: the anchor piece 14 of the prefabricated bay window component 1 includes multiple groups of embedded steel bars, and each group of embedded steel bars is partially buried in the concrete of the second panel 12, and partially embedded in the concrete of the second panel 12. The rear side of the slab protrudes, and each group of pre-embedded steel bars is arranged at intervals.

[0045] Applied in the prefabricated bay window node structure, the part of each group of pre-embedded steel bars protruding from the rear side of the second plate 12 is bound to the steel bars of the cast-in-place part 22 of the structural beam and the steel bars of the cast-in-place part 32 of the floor slab, And anchored in the concrete of the cast-in-place part 22 of the structural beam and the concrete of the cast-in-place part 32 of the floor slab.

[0046] In order to ensure the connection strength between the prefabricated bay window comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com