Turning hoisting method for vertical type apparatus

A hoisting method and technology of vertical equipment, applied in transportation and packaging, load hanging components, cranes, etc., can solve the problems of high cost of foundation treatment, and achieve the effects of simple anti-tilt facilities, convenient operation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

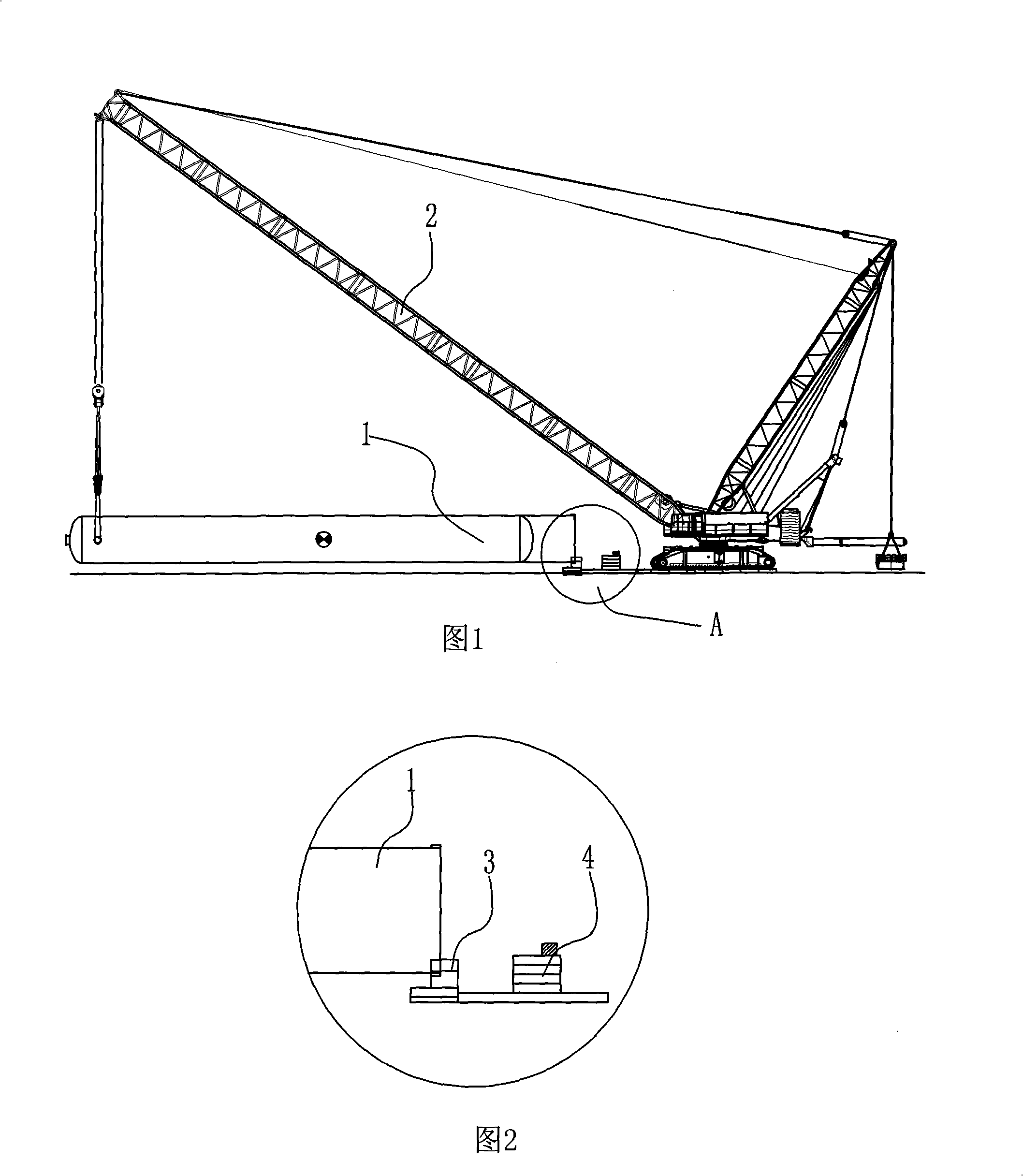

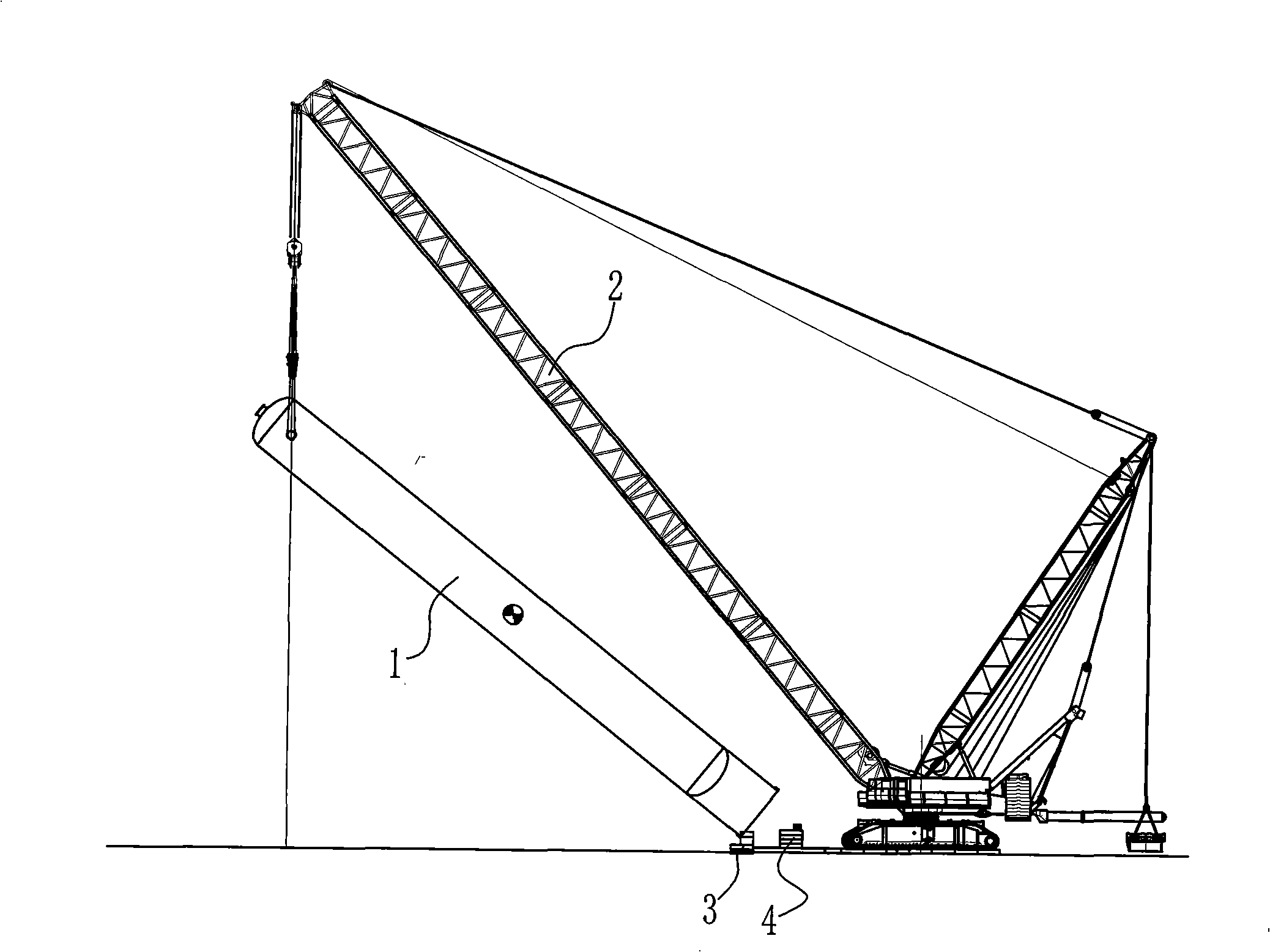

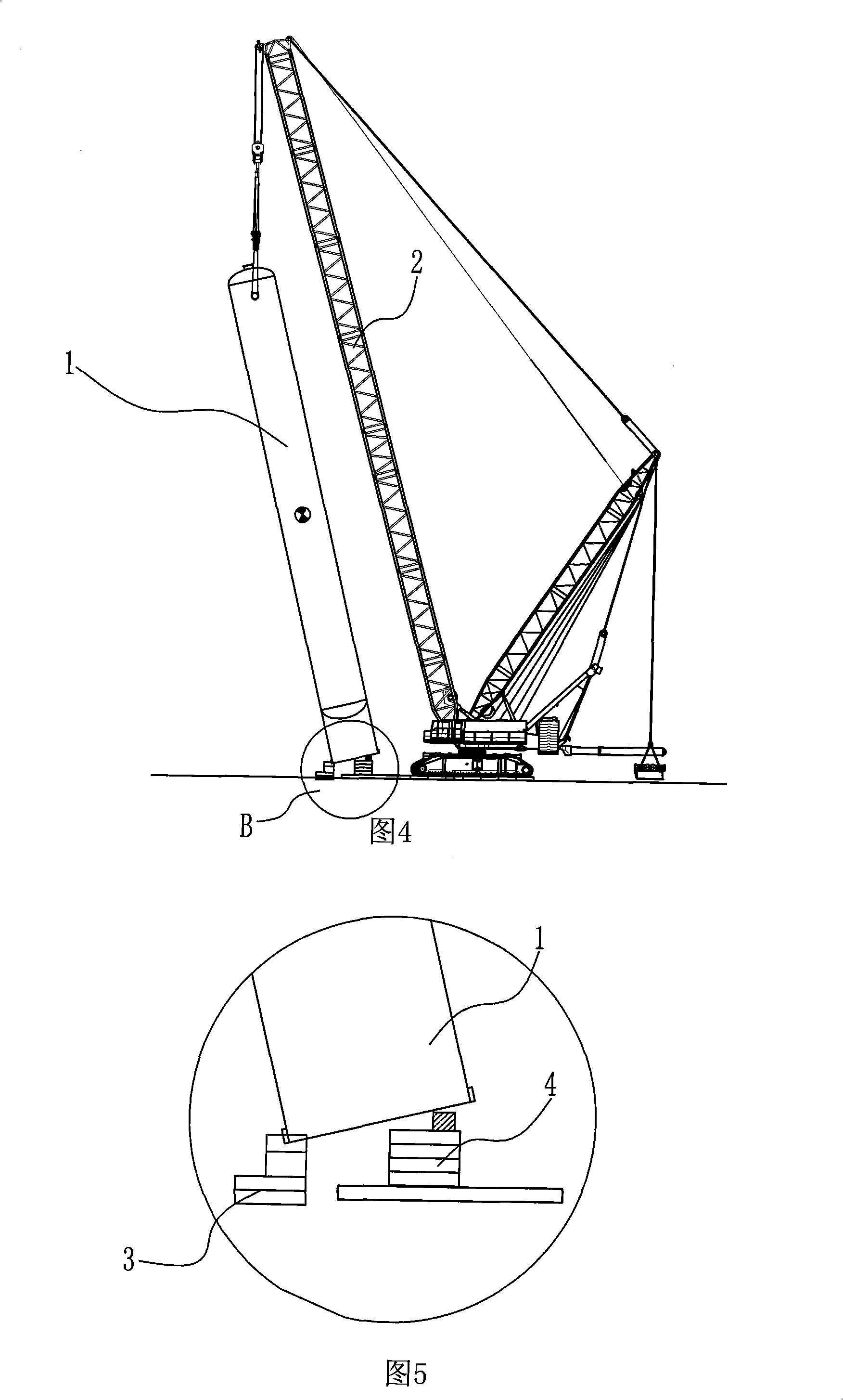

[0046] First set the rotating shaft system 3 and the anti-tilt facility 4, such as figure 1 and figure 2 shown. The rotating shaft system 3 can be the rotating shaft system in the current turning method, pushing method and rolling tail method, and can also be a rotating shaft system developed for this hoisting process. This embodiment adopts the rotating shaft system developed for this hoisting process. Firstly, an underground foundation 31 is installed underground. The turntable 38 is circular and includes an upper turntable and a lower turntable, the lower turntable is fixed on the chassis 32, the lower turntable is fixed on the carrier plate 33 above it, and the upper turntable and the lower turntable are formed by bearing connection A matching structure that can rotate around the vertical axis of rotation 36. Two horizontal shaft bearings 34 are fixedly installed on the bearing plate 33, and a shaft hole 39 is formed on the top of the horizontal shaft bracket 34, and t...

Embodiment 2

[0050] This embodiment is only different from the embodiment in the shaft system used, and the others are the same as embodiment 1.

[0051] The present embodiment adopts the more commonly used rotating shaft system and anti-tilt facilities in the crane rolling tail in the conventional technology. First be provided with as the platform 5 for placing the rotating shaft system 6 and the anti-tilt facility 7. Platform 5 can use the subgrade box of crane to lay and form, and this platform 5 can be connected with the subgrade box under the crawler belt of crane, and platform 5 is fixed by the gravity of crane self. A rotating shaft system 6 is set at the end of the platform 5 away from the crane, and an anti-tilt facility 7 is set at the end of the platform 5 close to the crane. The rotating shaft system 6 is composed of a roadbed box 63 , a rotating shaft base 62 and a rotating shaft 63 . The roadbed box 63 is welded and fixed with the platform 5, and the lower end of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com