Patents

Literature

35results about How to "Shorter lift time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

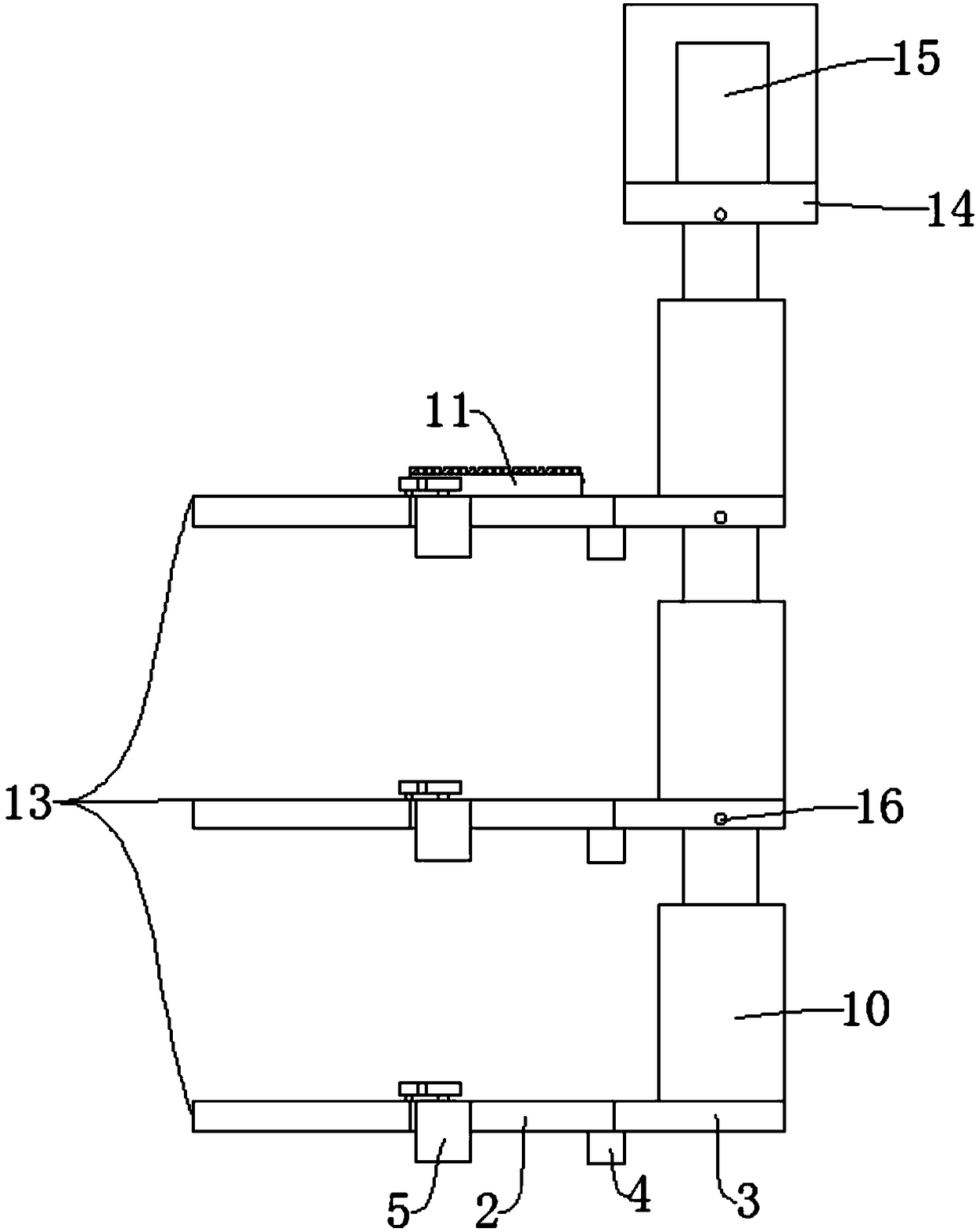

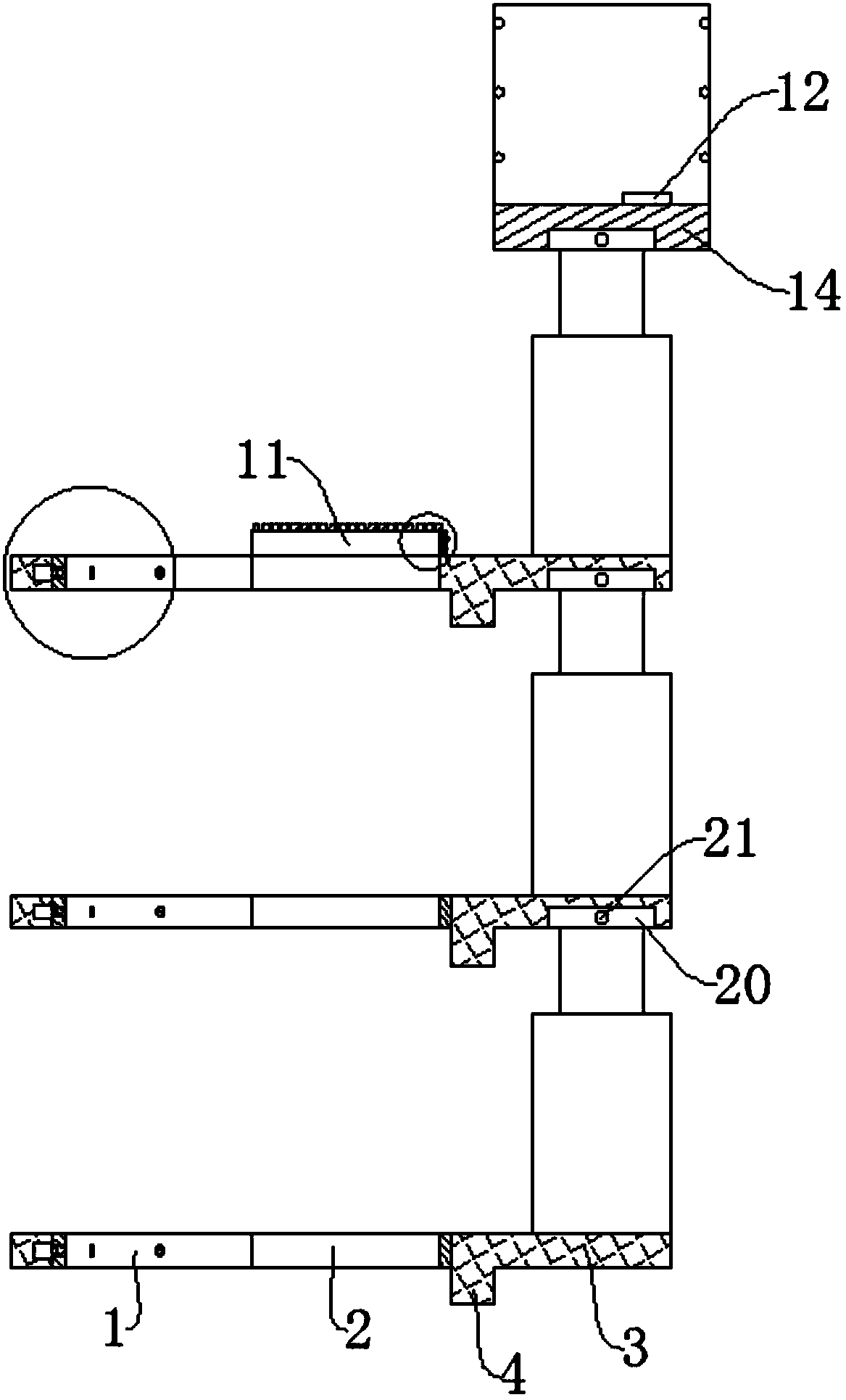

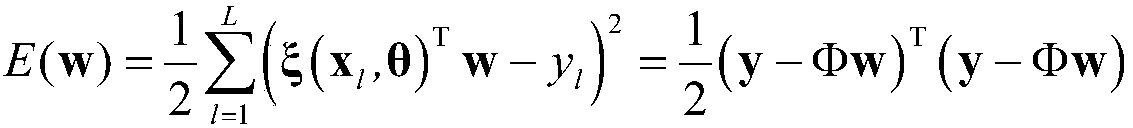

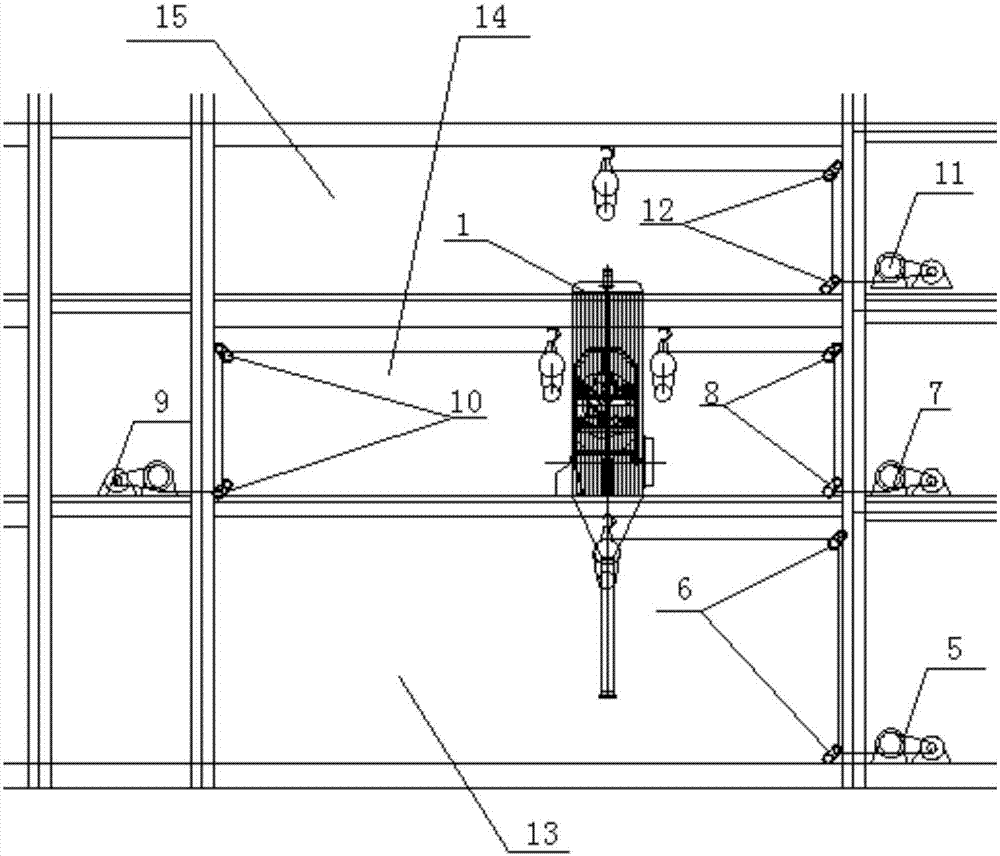

Fabricated type building intelligent hoisting method and system based on machine vision

ActiveCN106966298AImprove hoisting efficiencyImprove accuracyImage enhancementImage analysisIntelligent lightingMachine vision

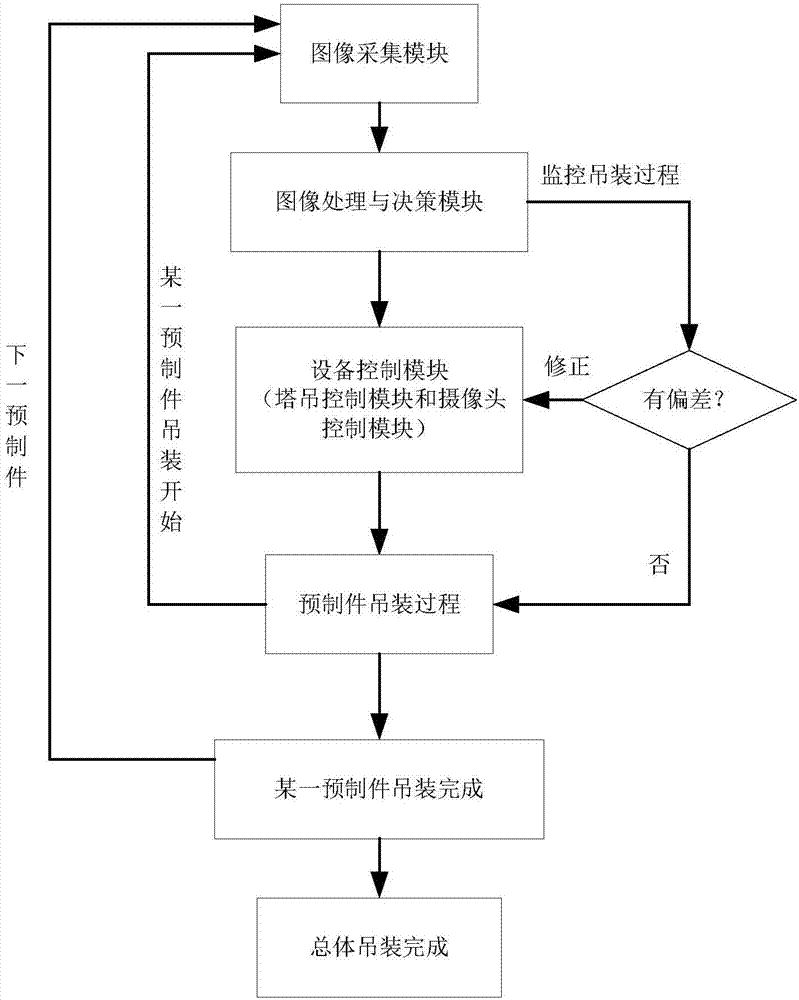

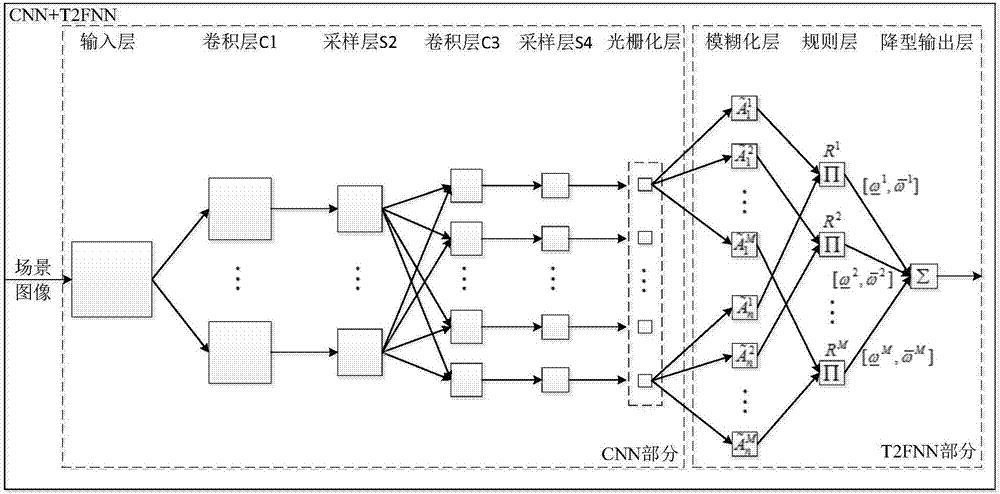

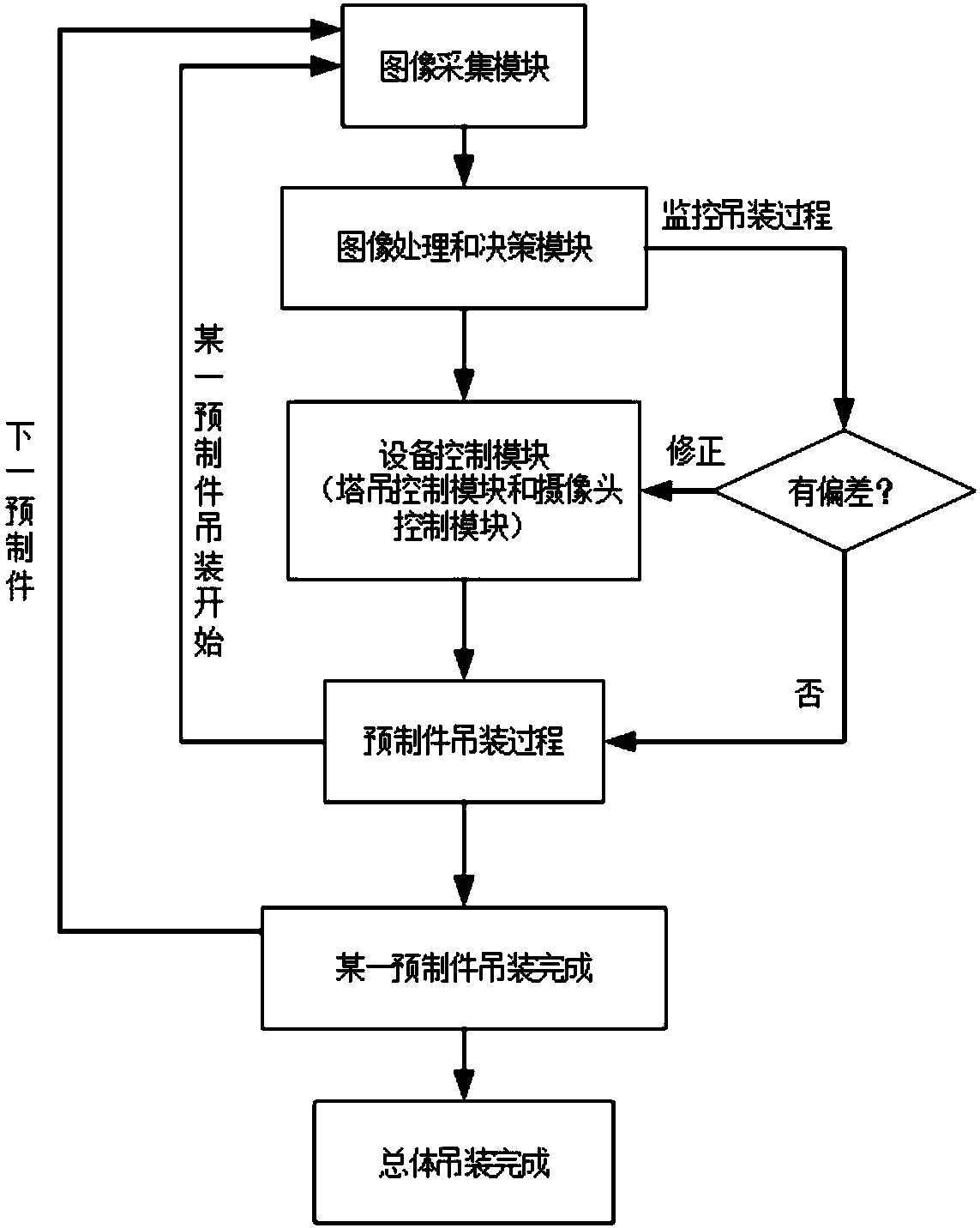

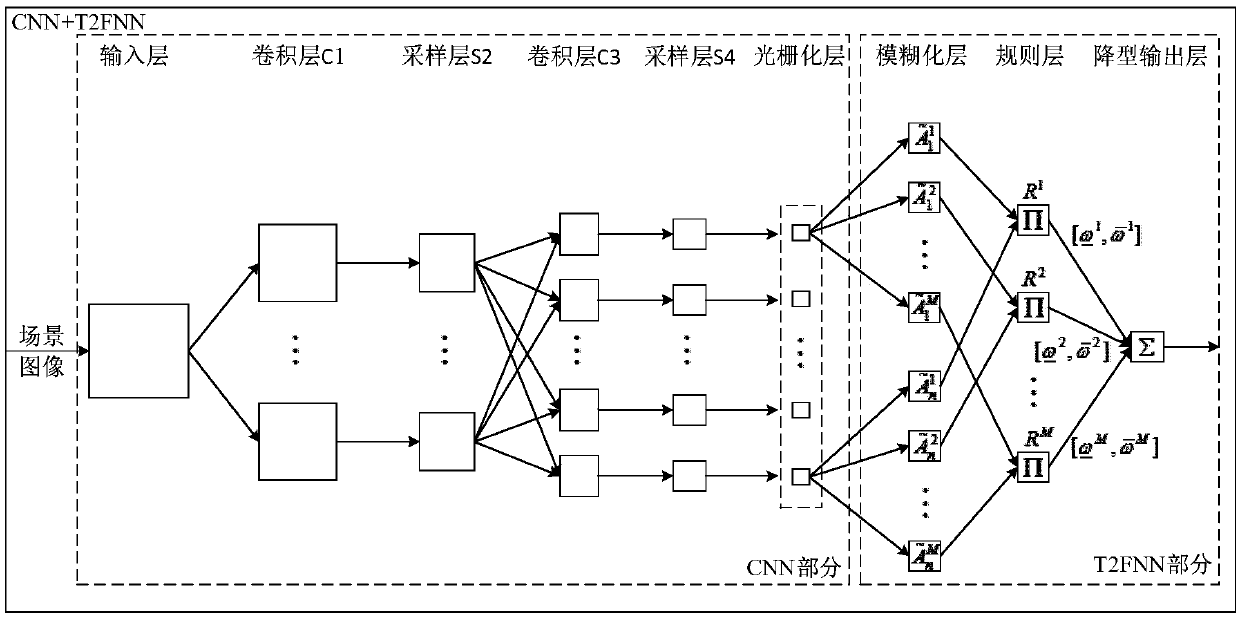

The invention discloses a fabricated type building intelligent hoisting method and a system based on machine vision. The fabricated type building intelligent hoisting system based on the machine vision comprises an image gathering module, an image processing and decision module and a device control module, the image processing and decision module and the image gathering module are communicated, and the device control module and the image processing and decision module are communicated. According to the fabricated type building intelligent hoisting method and the system based on the machine vision, the machine vision replaces the reliance on human vision in the hoisting process of the fabricated type building. Obstacle recognition is conducted in a complex fabricated scene through a deep learning model of a convolutional neural network and a type-II fuzzy neural network by using the machine vision, prefabrication hoisting path planning is conducted by using ant colony algorithm, and consequently, the movement of equipment on the scene is controlled according to the decision result. The fabricated type building intelligent hoisting method and the system based on the machine vision analyze and obtain the best scheme from the complex scene by using the camera instead of the human eye, can better plan the prefabrication hoisting path, greatly improve the hoisting efficiency and accuracy of the fabricated type building, realize the intelligent hoisting of the fabricated type building, and improve the shortcomings of artificial hoisting.

Owner:日照安泰科技发展有限公司

Installing method for bridge crane in enclosed environment workshop

The invention discloses an installing method for a bridge crane in an enclosed environment workshop, and belongs to the technical field of hoisting device installing. The installing method includes the steps that a crane beam rail in the original workshop is retested, and a main beam supporting frame used for containing and assembling a main beam is manufactured; devices on the main beam are assembled through an auxiliary crane, the main beam is hoisted through a large crane, after the main beam is installed, end beams of the main beam are not connected, two large cranes are located on the two sides of the end beams, and hoisting lugs of two truck-mounted cranes are arranged at the ends of a main trolley; after the main trolley is evenly hoisted to be in place, assembling is carried out; and installing of the main beam bridge crane is completed. According to the installing method, the requirement for a site in the workshop is not high, the roof of the workshop does not need to be dismantled, the large crane is not used, ground assembling is rapid, hoisting is once achieved, the working efficiency is high, and the upper-air operational quantity is small; and the installing method has the beneficial effects that the practical hoisting time is short, the practicability is high, and the like.

Owner:CHINA MCC17 GRP

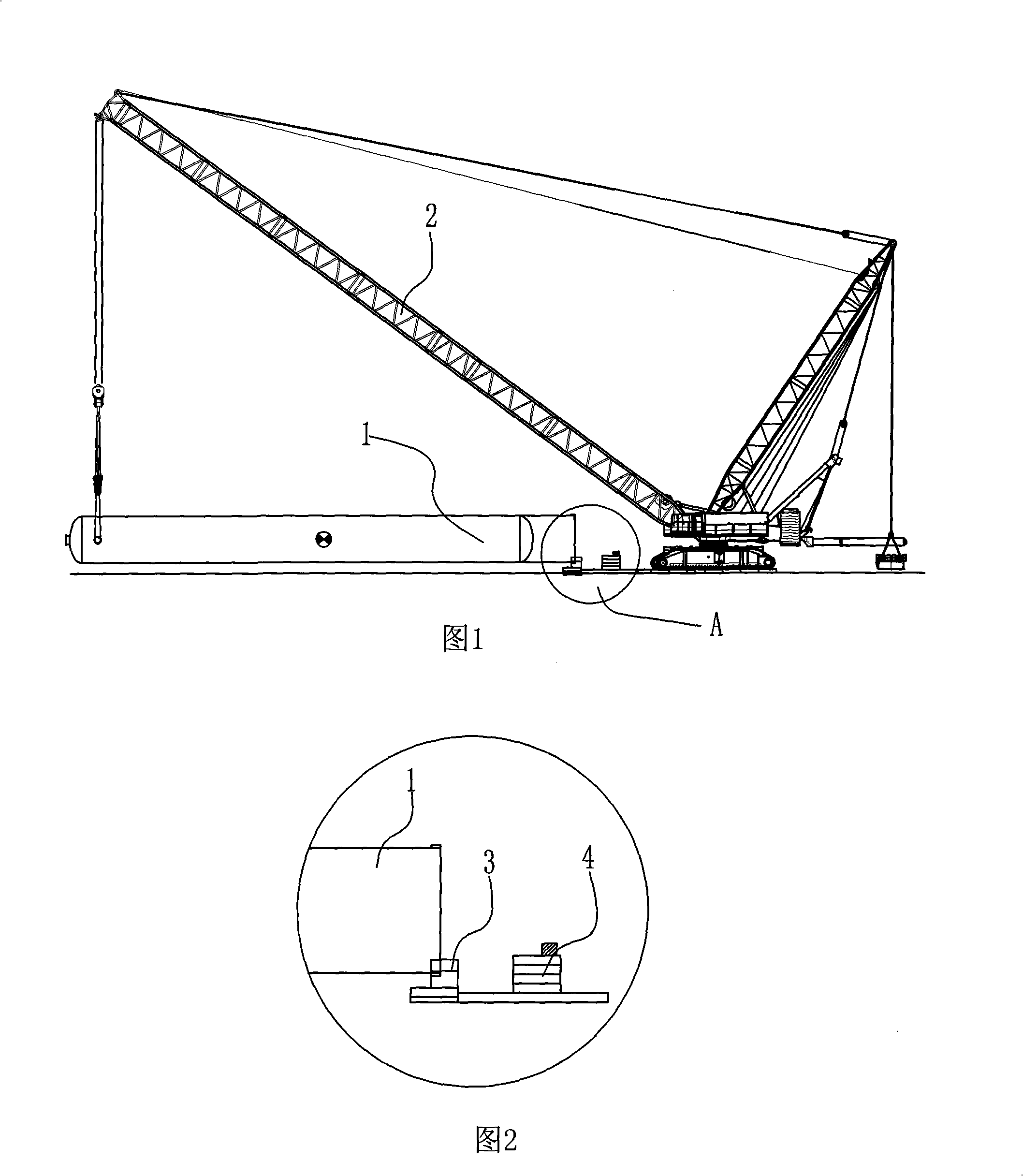

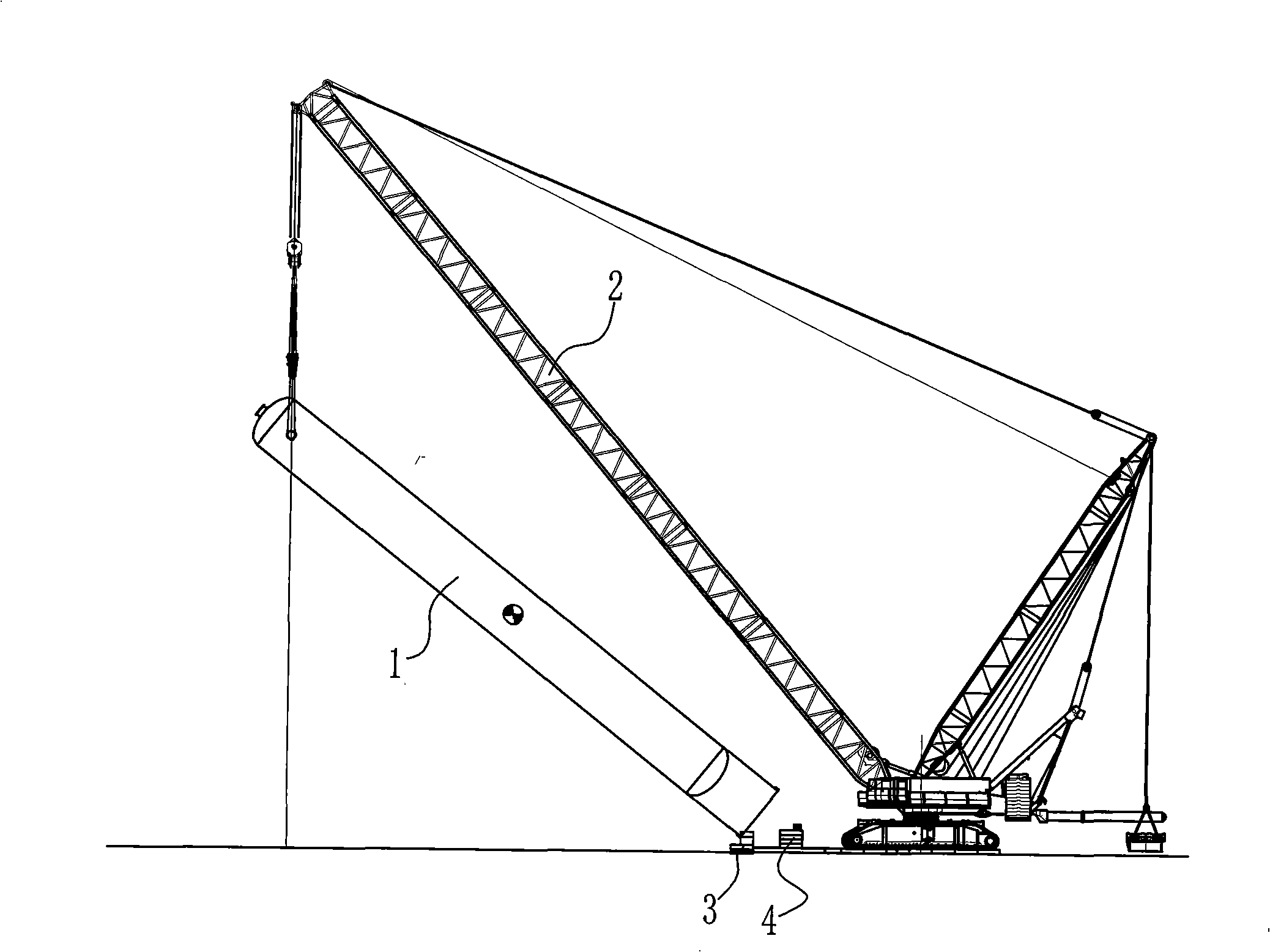

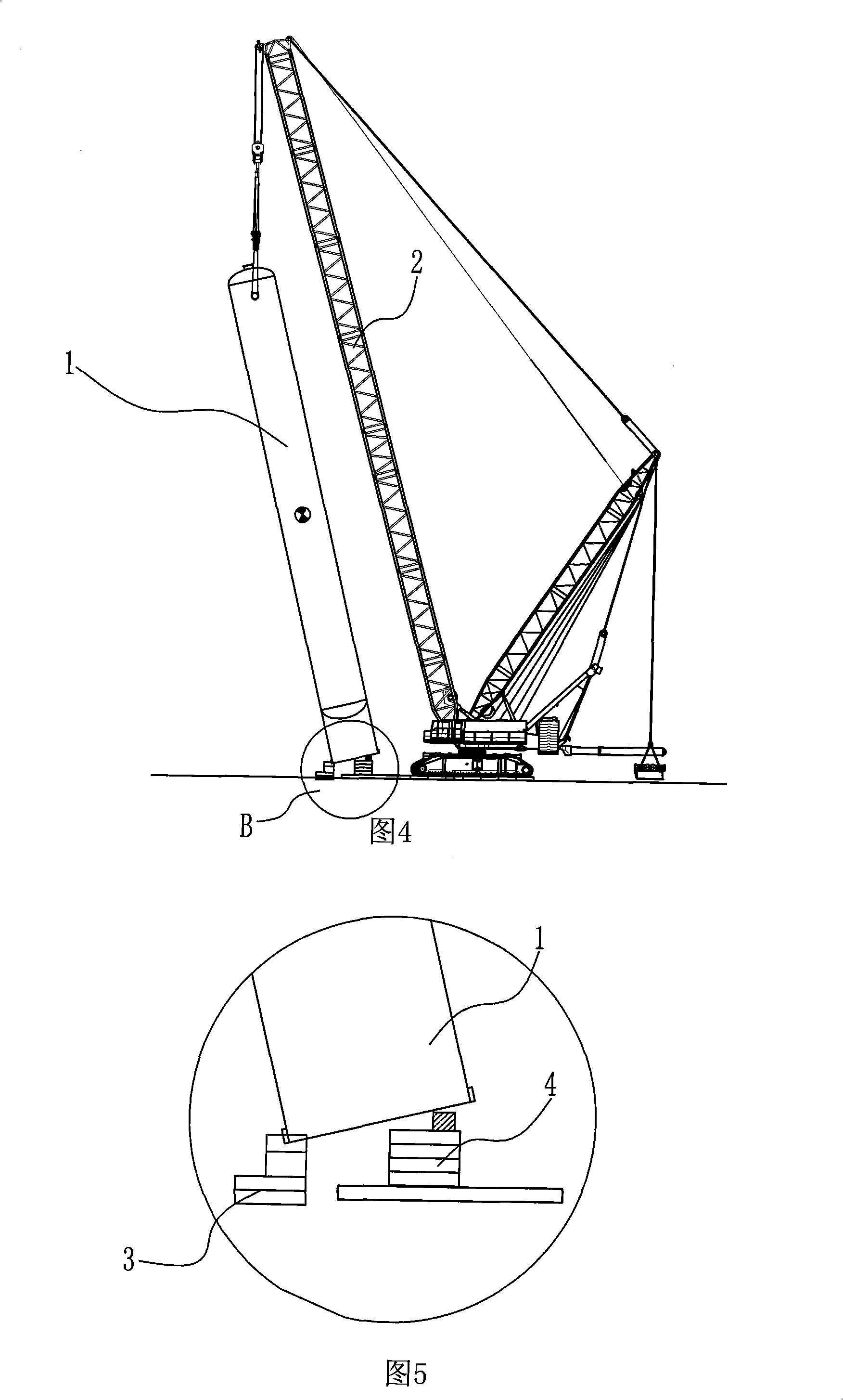

Turning hoisting method for vertical type apparatus

ActiveCN101513974AGood practical valueAvoid defectsLoad-engaging elementsCranesGravity centerIndustrial engineering

The invention relates to a turning hoisting method for the vertical type apparatus, characterized by comprising the following steps: a) the apparatus to be hoisted is unloaded according to the hoisting site condition and the hoisting machine station, and the tail of the apparatus faces to the hoisting machine; b) a rotating shaft system is arranged near to the tail of the apparatus, and a falling preventing device is arranged at the position where the apparatus arrive in the falling preventing angle; c) the lift hook of the hoisting machine is connected with the lifting point of the apparatus, which is located above the center gravity of apparatus; d) the hoisting machine lifts the lift hook and extends the arm rod of the hoisting machine to rotate the apparatus around the rotating shaft system and lift the apparatus step by step: e) the tail of the apparatus contacts with the falling preventing device when the apparatus arrive in the falling preventing angle position, the hoisting machine continuously lifts the lift hook and extends the arm rod of the hoisting machine to rotate the apparatus around the falling preventing device until the apparatus is completely vertical; f) the hoisting machine continuously lifts the lift hook to make the apparatus disengaged from the falling preventing device, the rotating shaft is removed; g) the operation radius of the hoisting machine is adjusted to be the positioning radius, then the apparatus is rotated to the base, the orientation is adjusted to position the apparatus. The hoisting method provided by the invention has no pulley set, no limitation to the lifting point orientation and simple operation.

Owner:SINOPEC NINGBO ENG

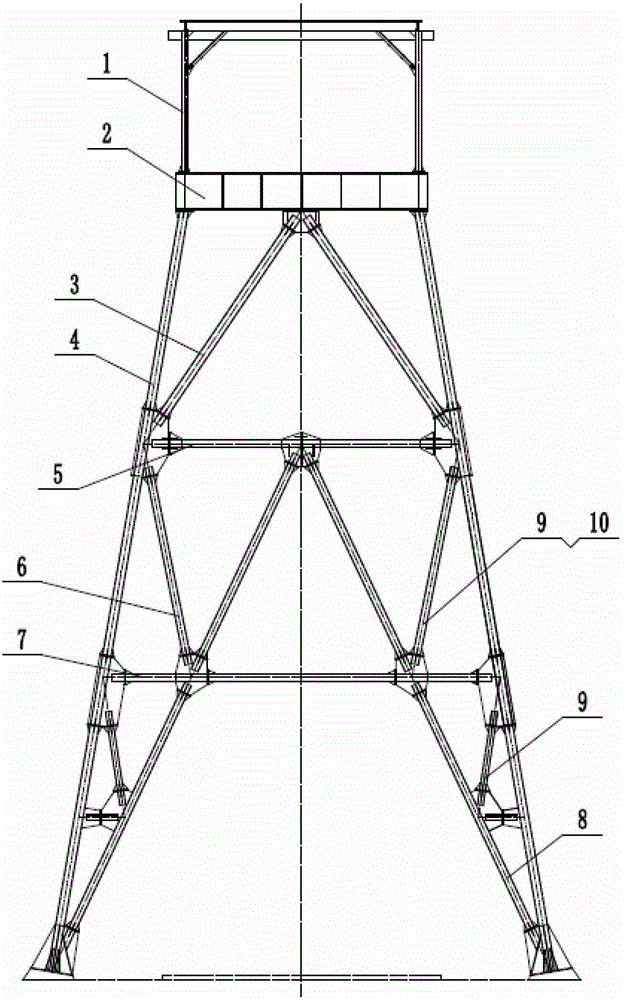

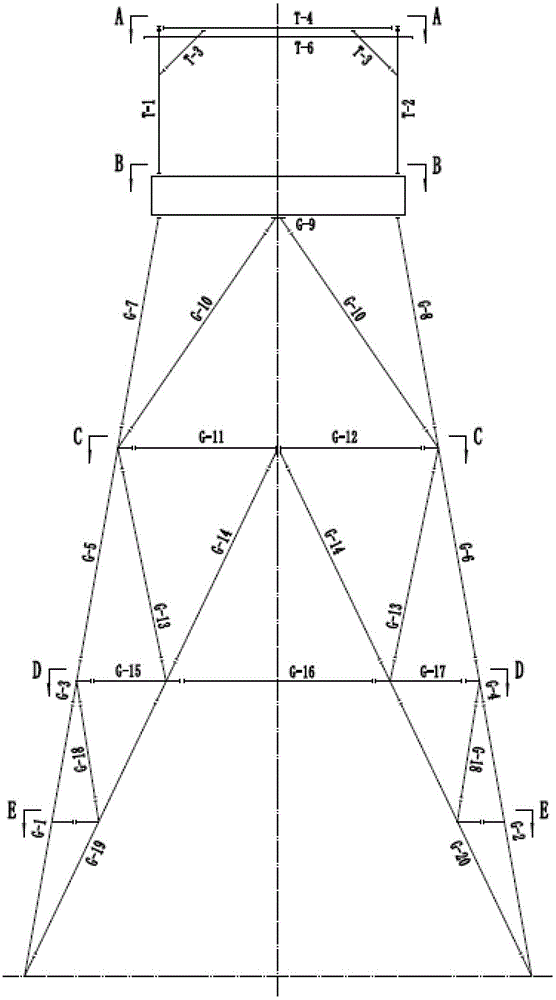

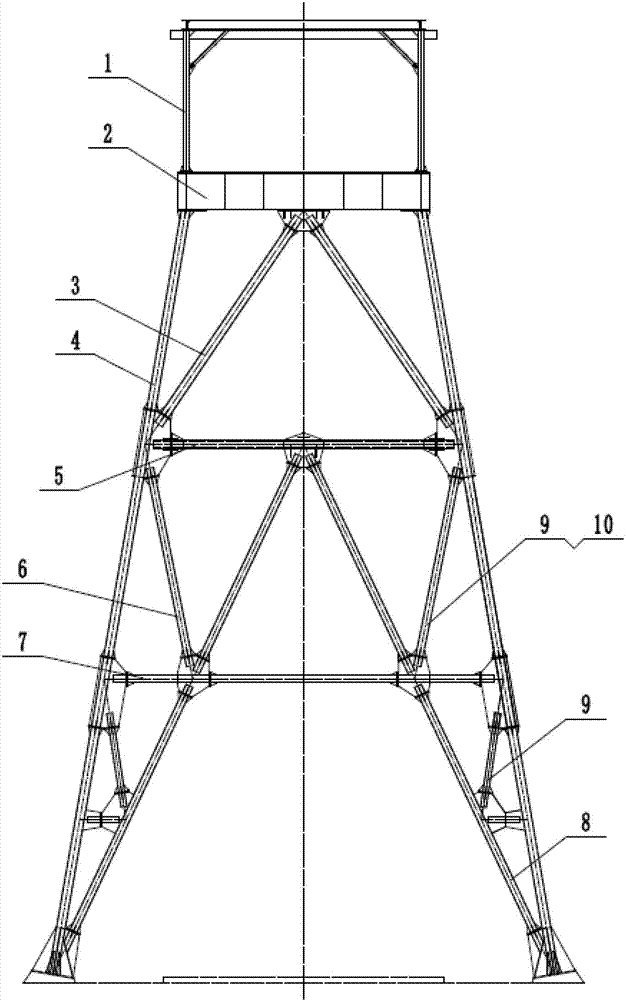

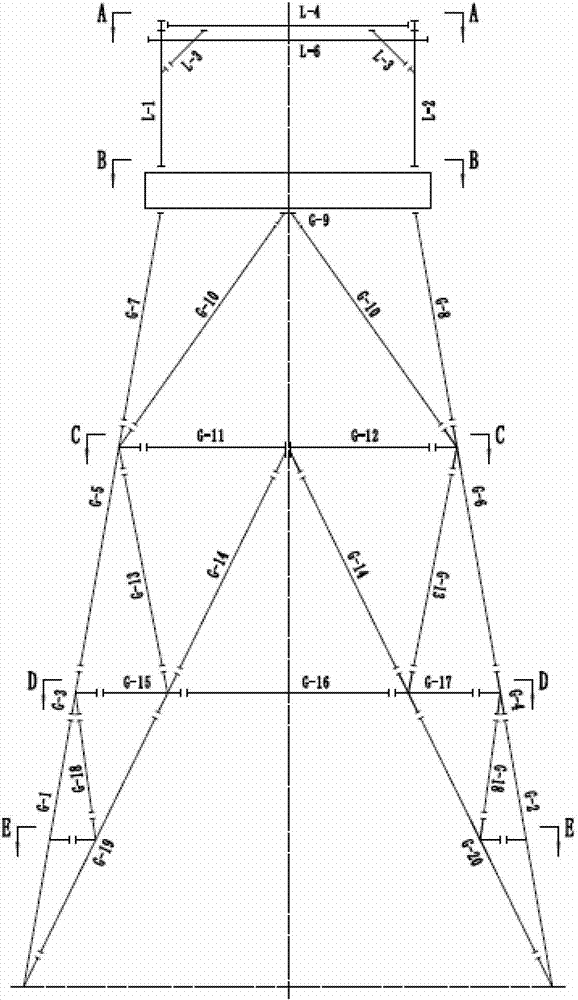

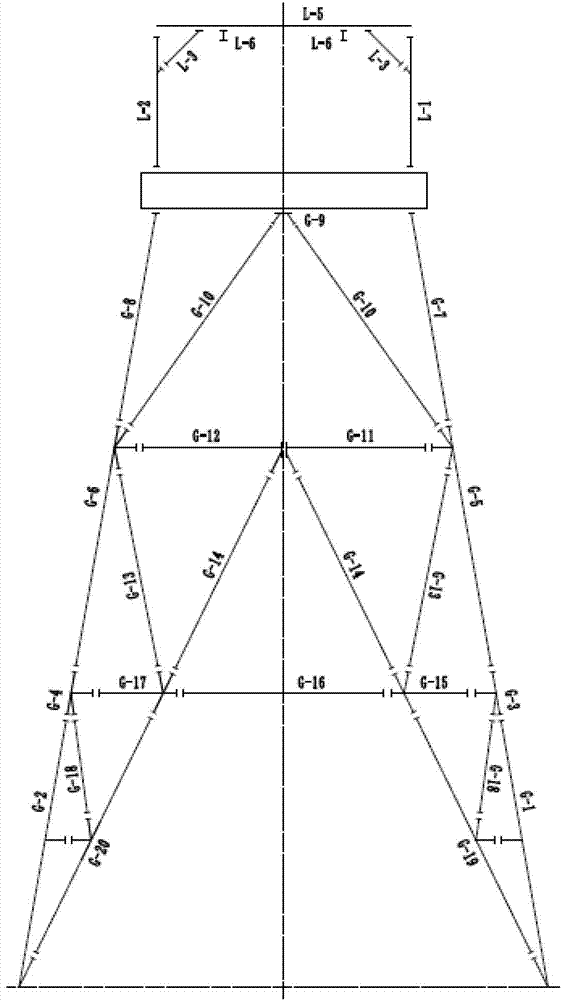

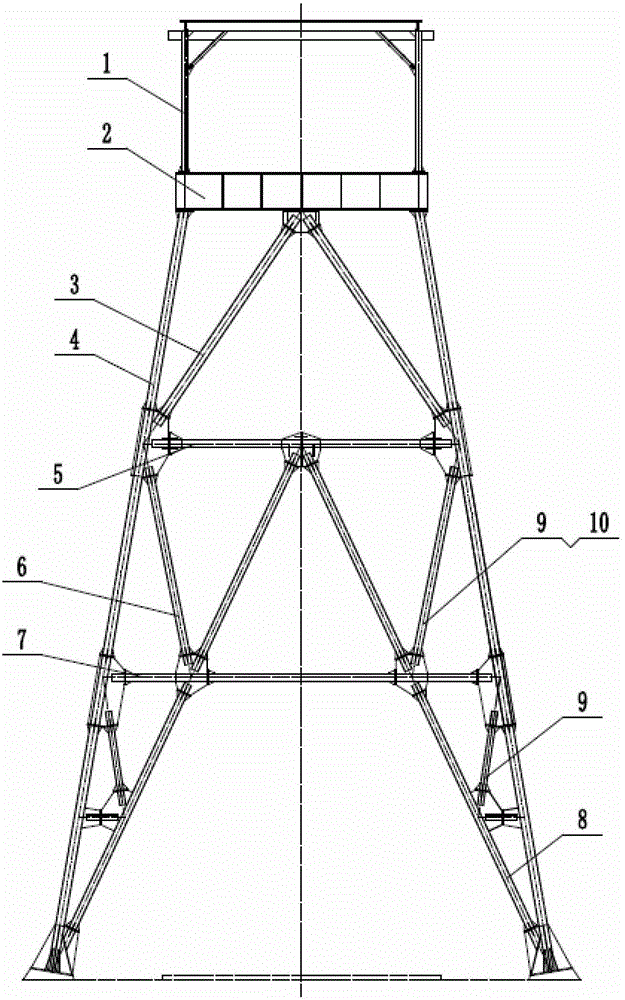

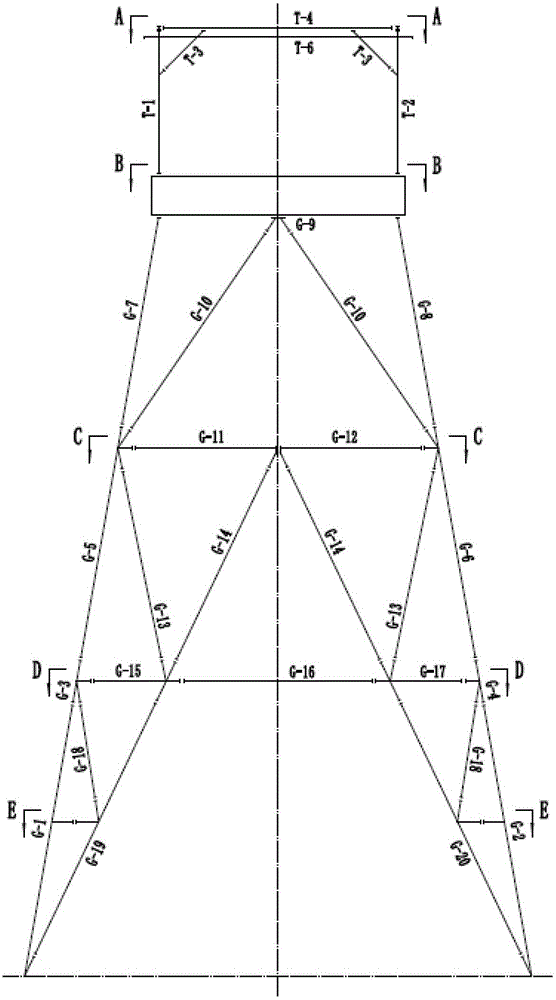

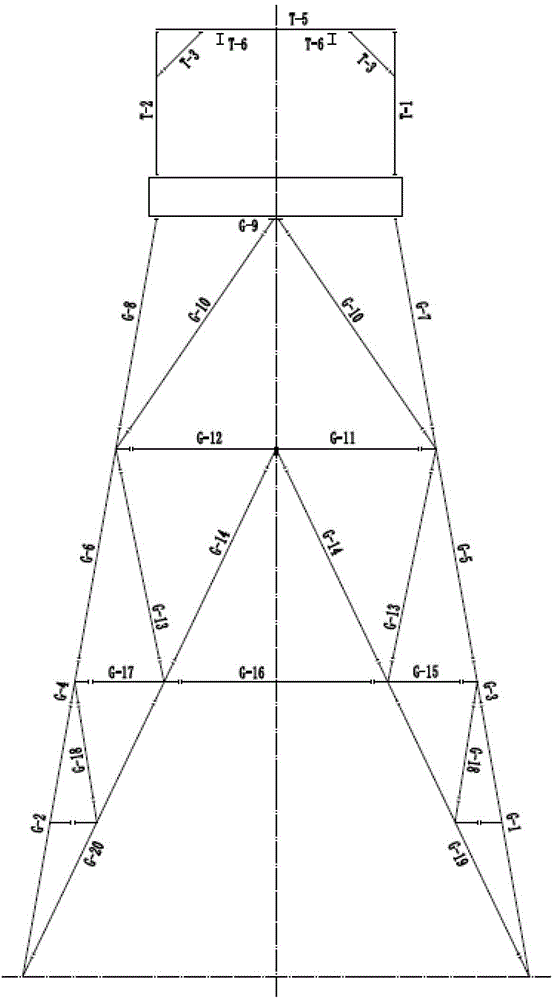

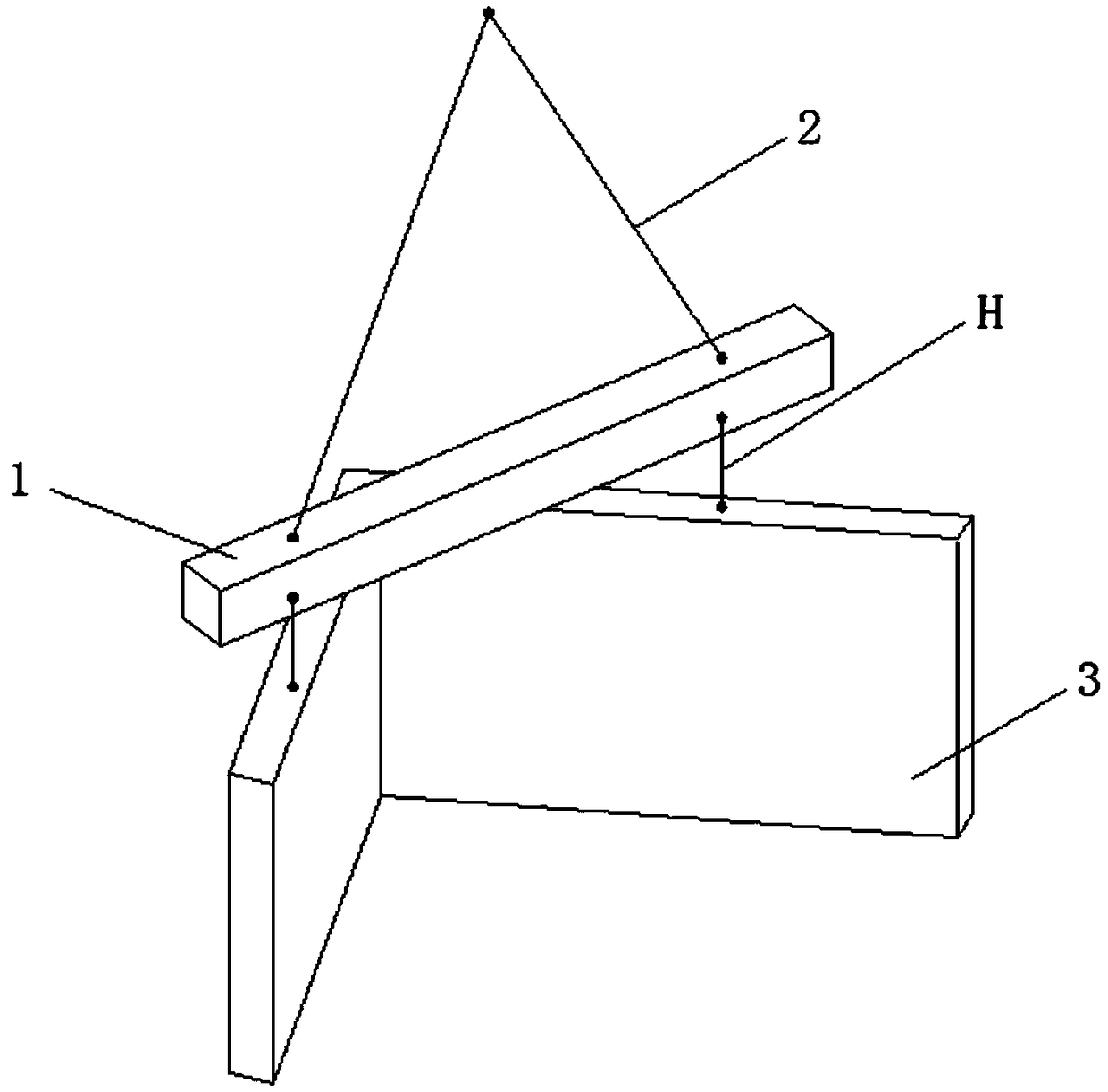

Sinking tubular steel derrick and mounting method of same

ActiveCN102913137AAdaptableEasy to processDerricks/mastsShaft sinkingChinese charactersArchitectural engineering

The invention relates to a sinking tubular steel derrick and a mounting method thereof. The sinking tubular steel derrick is of a flat top rectangular pyramid with a holohedral main body truss and comprises a main support rod piece, support rod pieces corresponding to three layers of platforms, namely a sheave wheel platform, an intermediate platform and a gangue turning platform, which are connected with the main support rod piece from top to bottom, and the like. Beams of the sheave wheel platform arranged in the shape of a Chinese character Ri; the support rod pieces of the sheave wheel platform are arranged in the shape of inverted V and connected with central nodes on the four sides of the sheave wheel platform and nodes at four corners of the intermediate platform; and the axial lines of the support rod pieces of the intermediate platform are in superposition with the extension lines of the axial lines of the support rod pieces of the gangue turning platform, and the support rod pieces of the intermediate platform are arranged in the shape of the inverted V and used for connecting the intersection points between the central nodes on the four sides of the intermediate platform, the main support rod piece and a derrick foundation. The derrick is suitable for vertical shafts with net diameter of 6.5m-9m, average depth of not more than 1400m and working load of the derrick of not more than 530t and second-stage engineering construction thereof, and can simplify processing, transportation, mounting and detachment, realize stronger applicability to terrain and provide reliable guarantee for realizing rapid construction and shortening construction period.

Owner:JCHX MINING MANAGEMENT

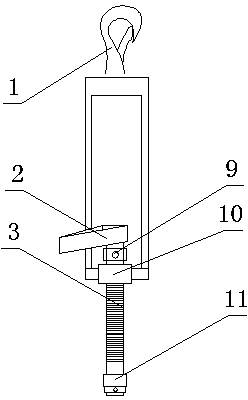

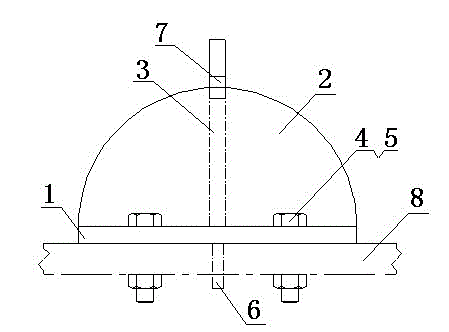

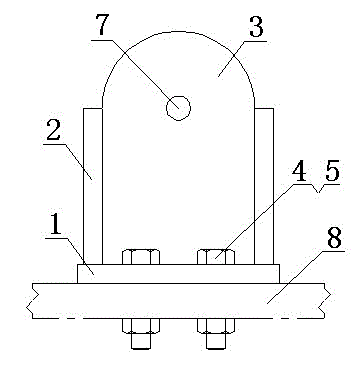

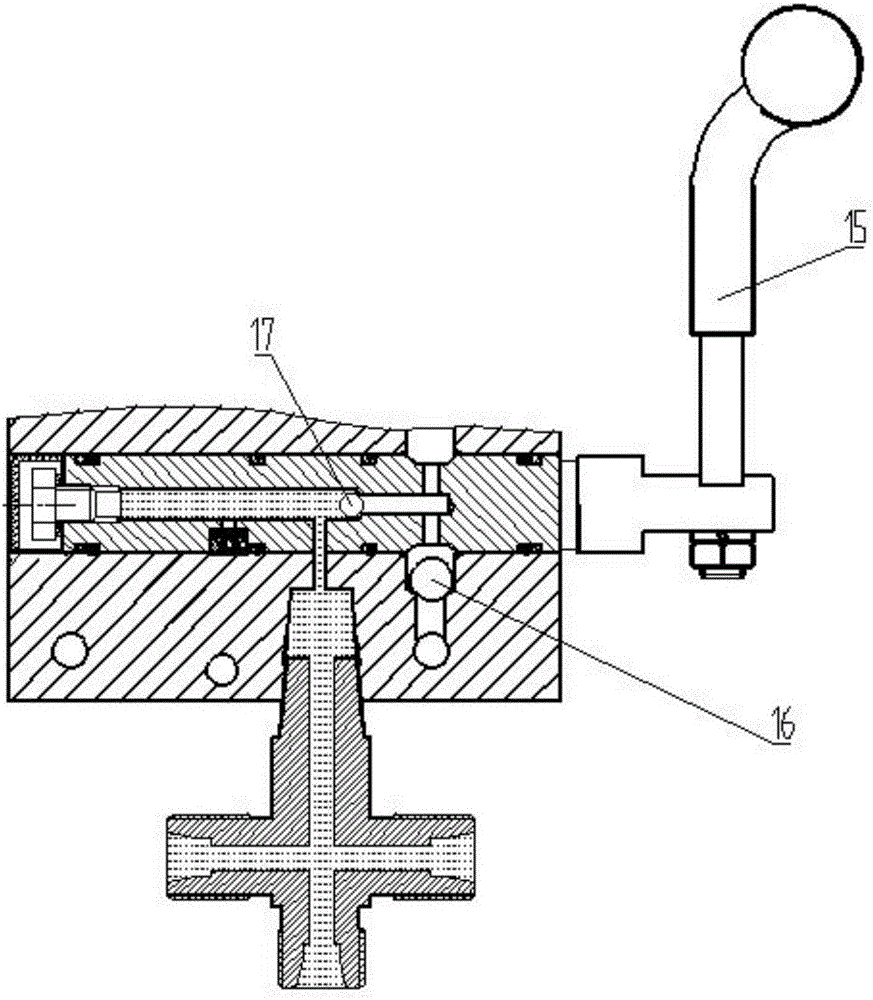

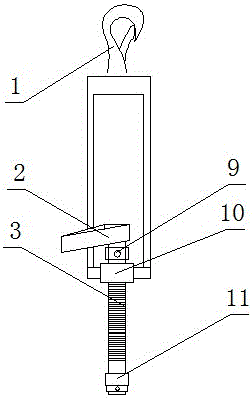

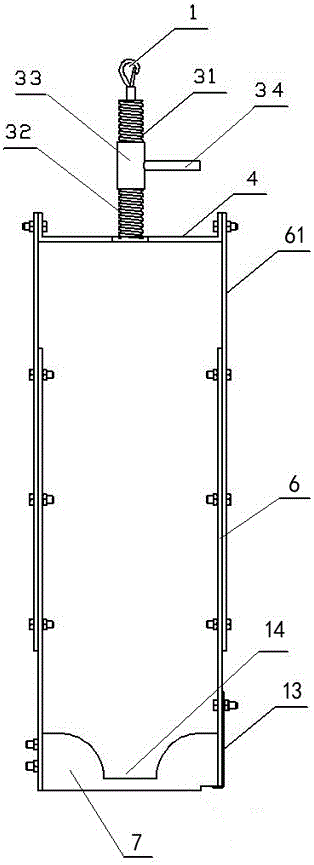

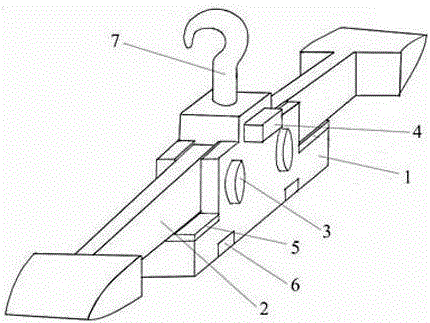

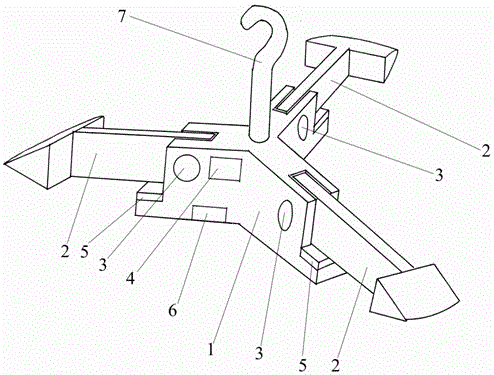

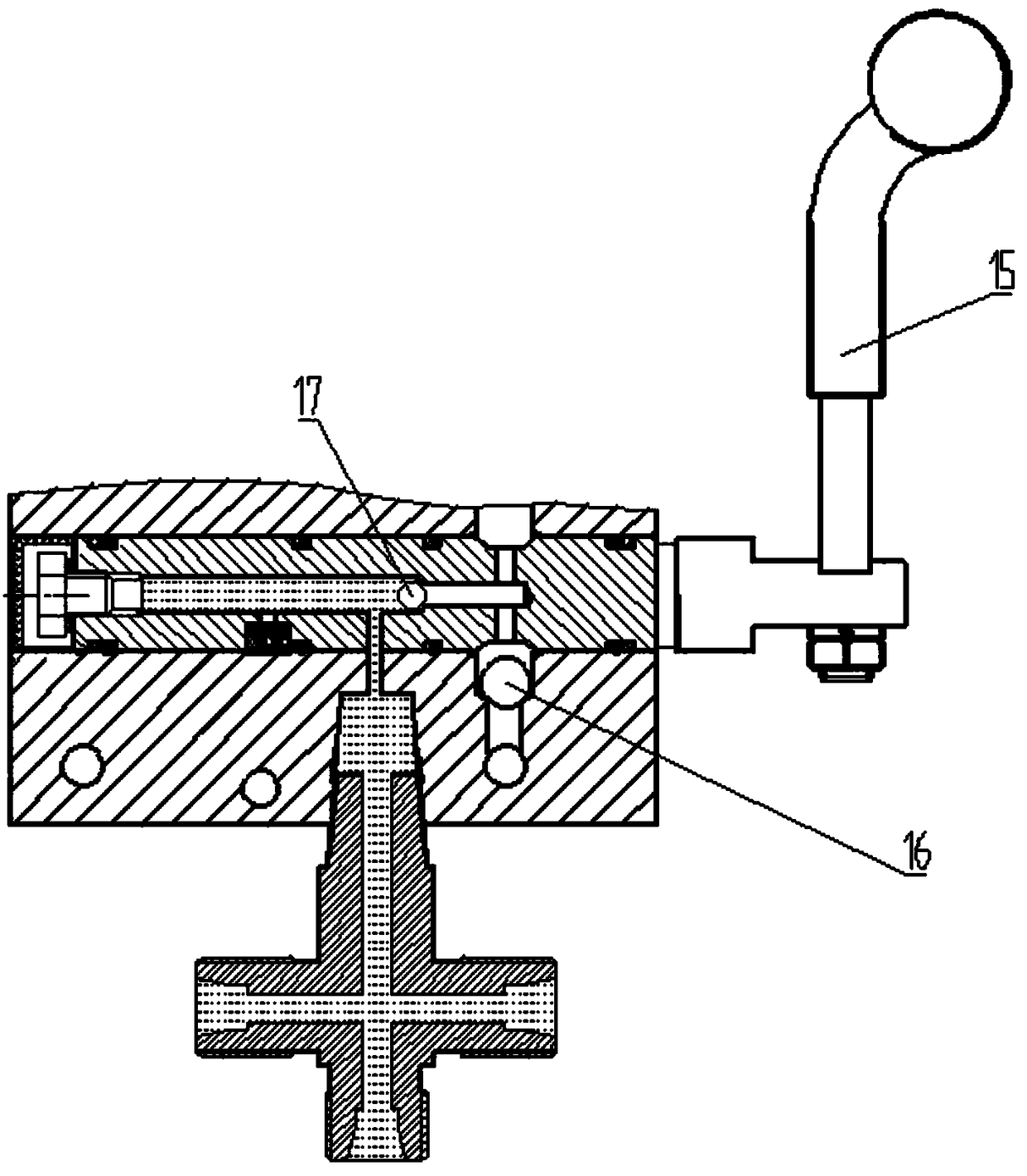

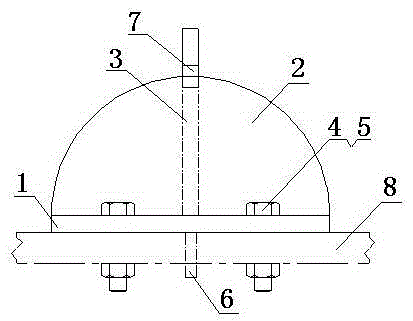

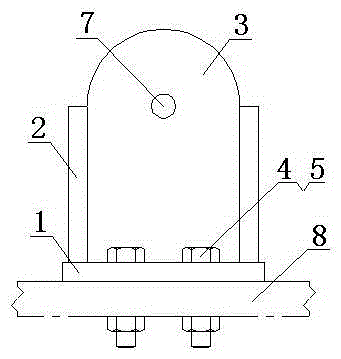

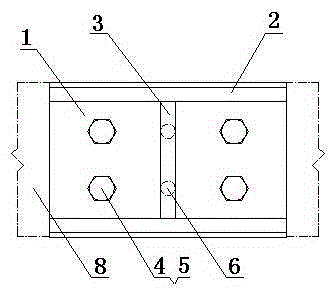

Tool for live-line replacement of suspension insulator and using working method thereof

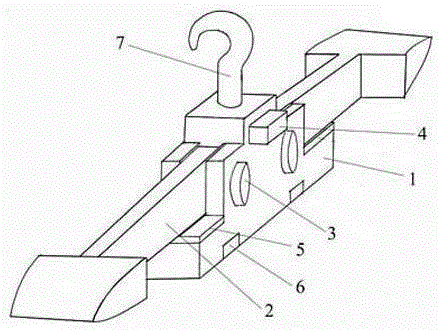

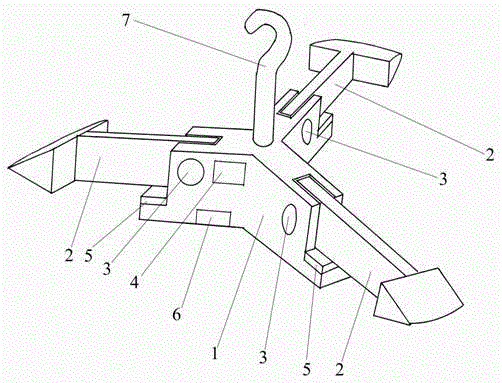

ActiveCN104167687AEasy to replaceImprove scalabilityApparatus for overhead lines/cablesEngineeringSelf locking

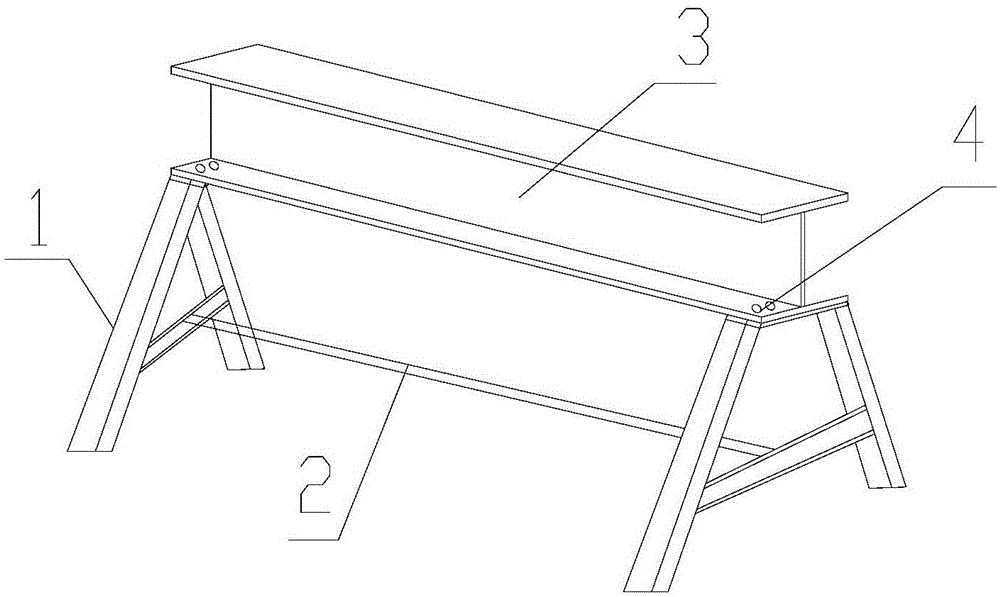

The invention discloses a tool for live-line replacement of a suspension insulator and a using working method thereof. The tool comprises a frame type bracket and a telescopic suspension mechanism arranged at the top of the frame type bracket. The telescopic suspension mechanism includes an adjusting lead screw and a self-locking hook arranged at the top of the adjusting lead screw. The frame type bracket includes a supporting plate at the bottom and a cross-brace unit at the top; the middle portion of the cross-brace unit is connected with the bottom of the adjusting lead screw; and the supporting plate and the cross-brace unit are connected by two insulating connecting elements with adjustable lengths. According to the invention, the frame type bracket with the telescopic suspension mechanism at the top is used for ground potential live-line suspension insulator replacement of the power transmission line; and the transmission line or weight is supported by the supporting plate, so that the tensile forces of the transmission line and the weight are transferred to the tool from the suspension insulator. Therefore, the cross arm worker can complete the replacement process of the suspension insulator by himself, thereby bringing the great convenience for suspension insulator replacement. Moreover, the tool has advantages of simple structure, high security, stability, and reliability, and high efficiency.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

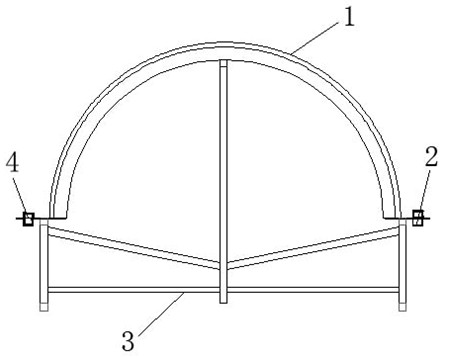

A laying method and auxiliary device for laying glass fiber cloth at the root of wind power blades

The invention provides a laying method and auxiliary device for laying glass fiber cloth at the root of wind power blades. Above, the two ends of the semi-circular steel plate are fixed grooves for glass fiber cloth, and the fixed grooves for glass fiber cloth are equipped with fixed square steel, and there are process holes on the semi-circular steel plate. Then lay glass fiber cloth on the device according to the order of leaf root laying, and fix it after laying a certain number of layers of glass fiber cloth. After all the glass fiber cloth is laid, directly lift the device and put it in the shell. The steel frame can still be used for the laying of the next set of glass fibers. The device is simple in use, convenient in process operation, good in laying quality of glass fiber cloth, and fast in hoisting time; simple in manufacture, convenient in assembly, low in cost, and long in service life.

Owner:TIANJIN CRRC WIND POWER BLADE ENG CO LTD

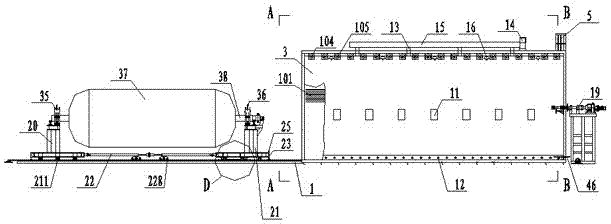

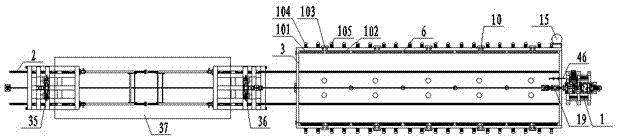

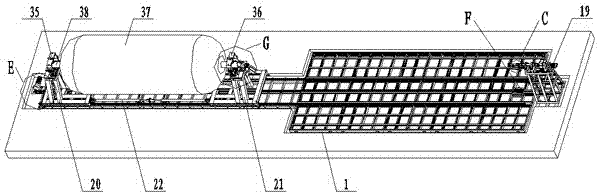

Extra-large drying oven structure provided with carbon fiber barrel

InactiveCN107192239ACompact structureGood drying effectDrying gas arrangementsDrying chambers/containersTuyereFiber

The invention discloses an extra-large drying oven structure provided with a carbon fiber barrel. The structure comprises a rack and sliding rails arranged in the rack. A drying oven is arranged at the upper end of the rack. A drying cavity is formed in the drying oven. A ladder is arranged on the drying oven. Heated air circulation side air ducts are symmetrically formed in the two sides of the interior of the drying oven. The upper ends of the two heated air circulation side air ducts communicate with each other through a heated air circulation upper air duct formed in the upper end of the drying oven. The lower ends of the heated air circulation side air ducts are provided with heated air circulation air outlets communicating with the drying cavity. A heated air circulation air return port communicating with the drying cavity is formed in the middle of the heated air circulation upper air duct. A plurality of heating units are uniformly arranged in the positions, at the upper ends of the heated air circulation side air ducts, of the drying oven correspondingly.

Owner:JIANGSU GUANGSHENGYUAN TECH DEV

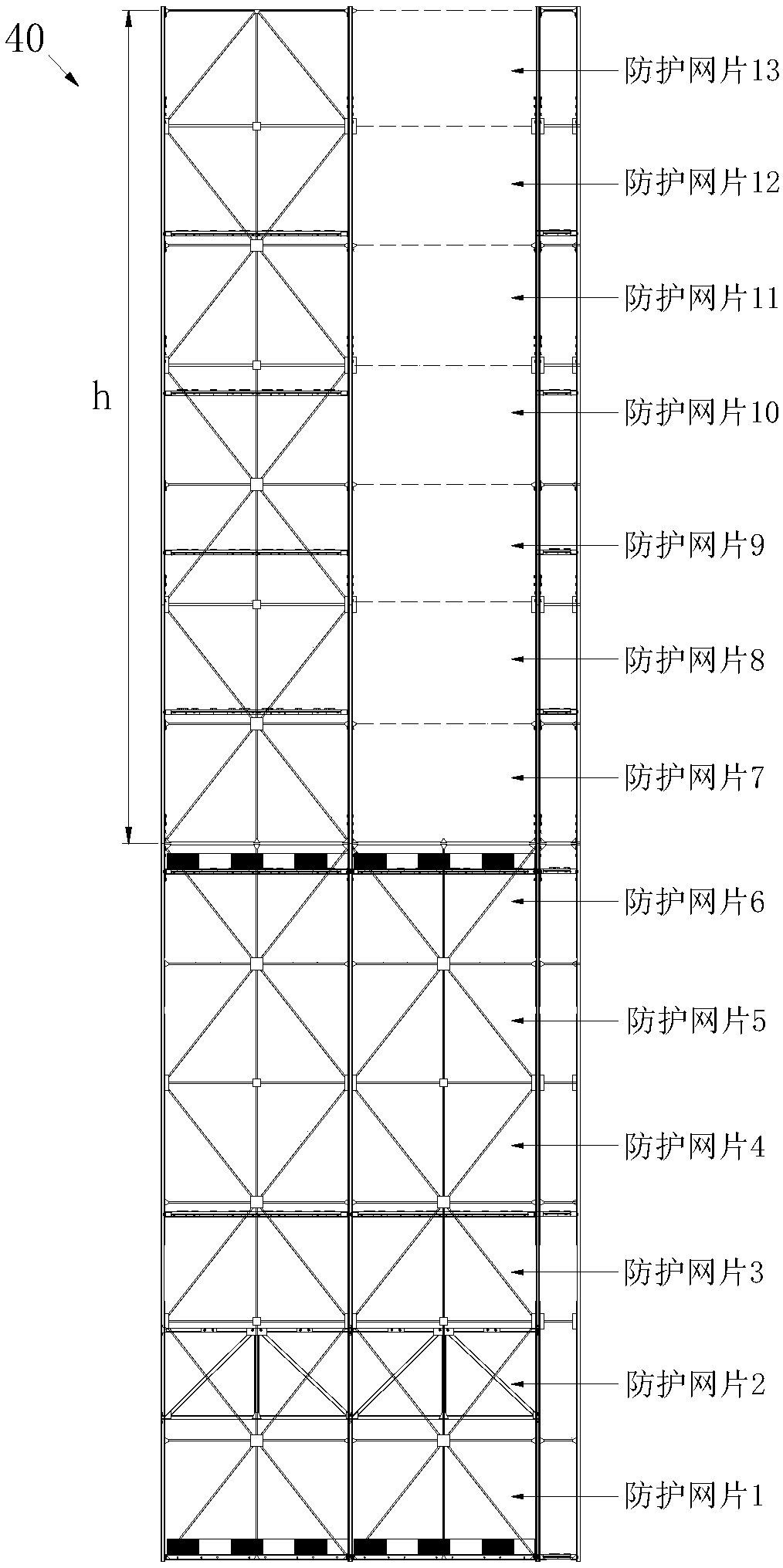

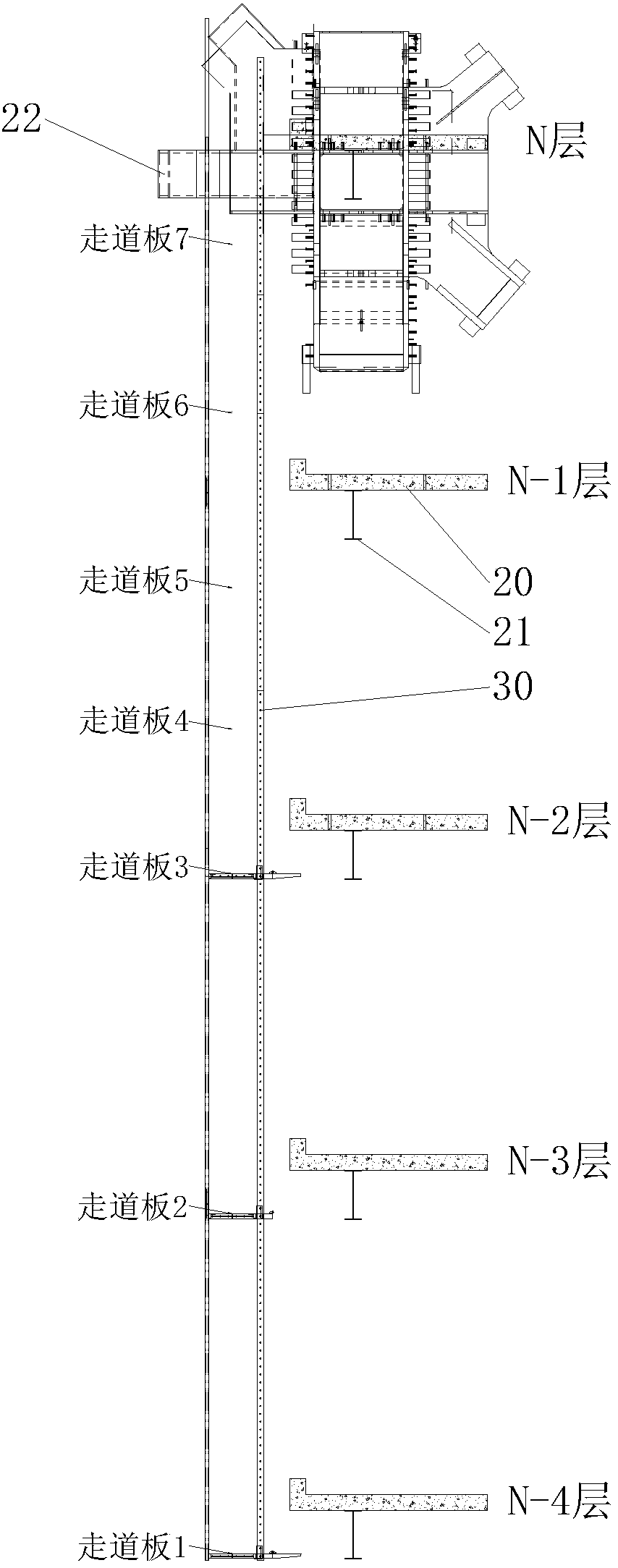

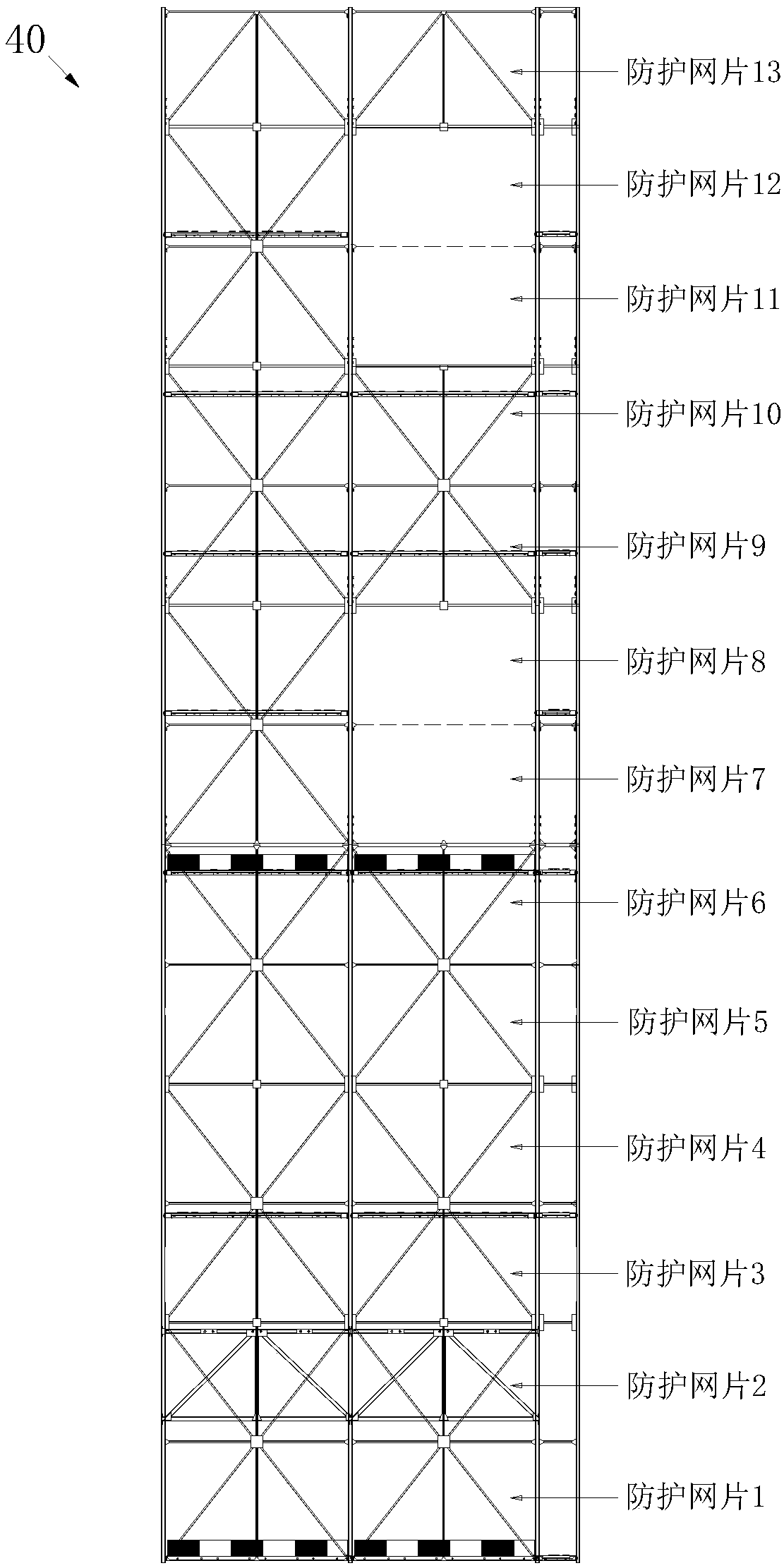

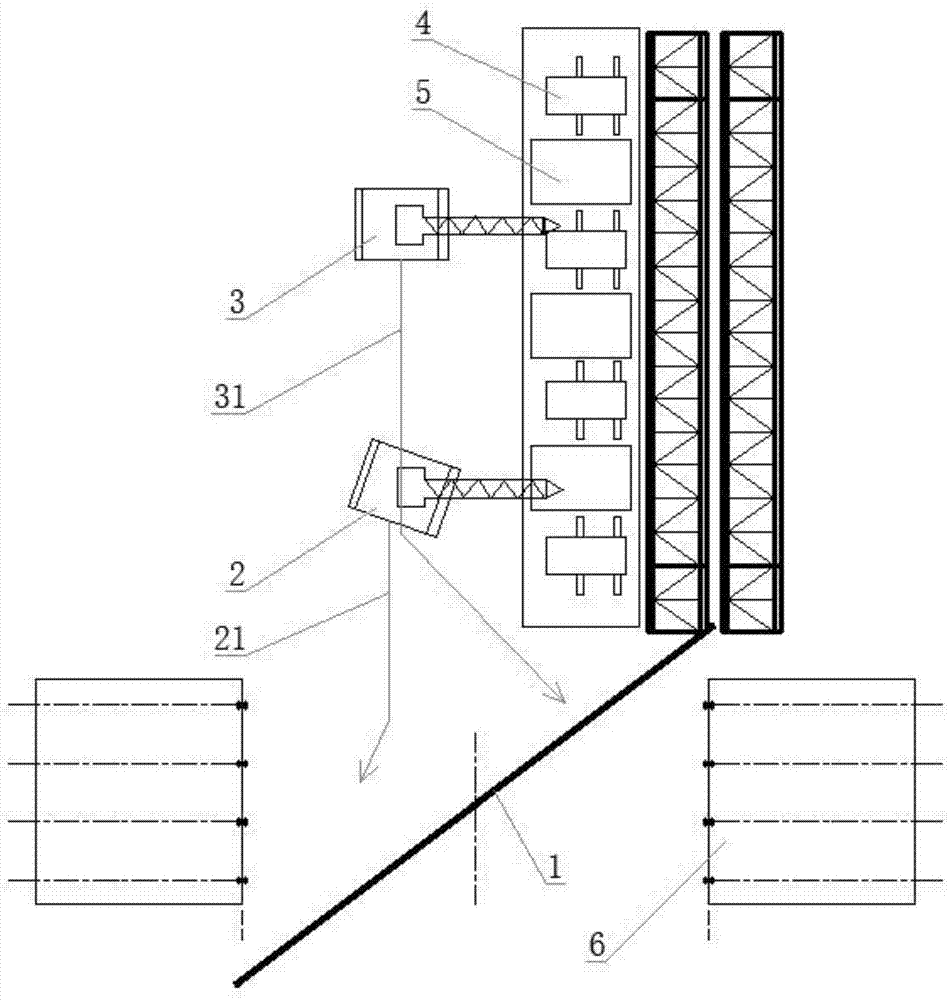

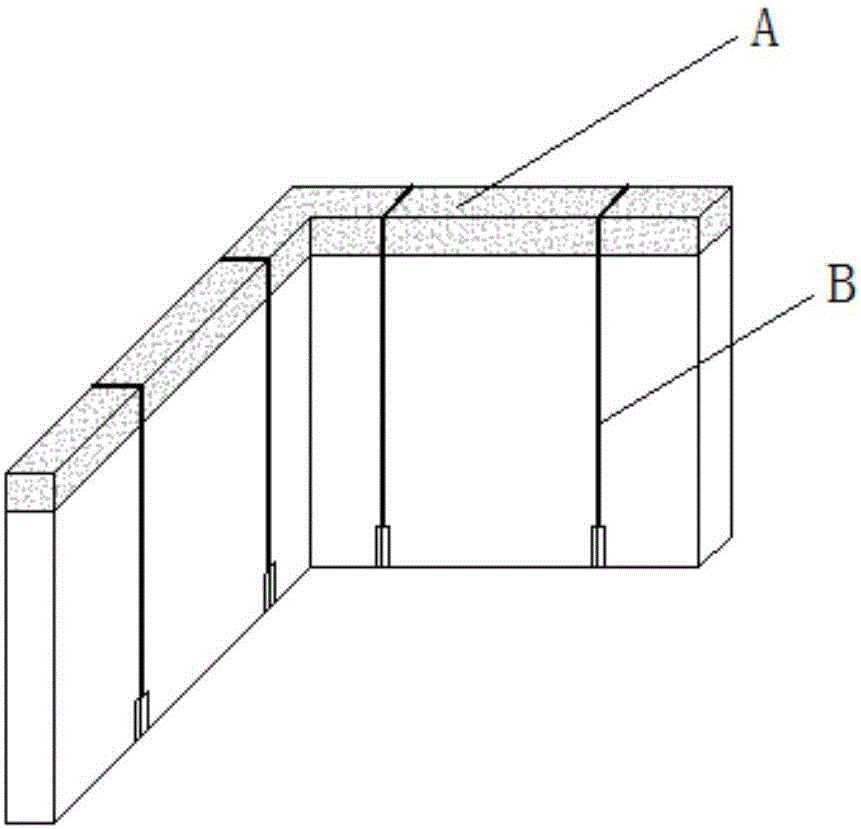

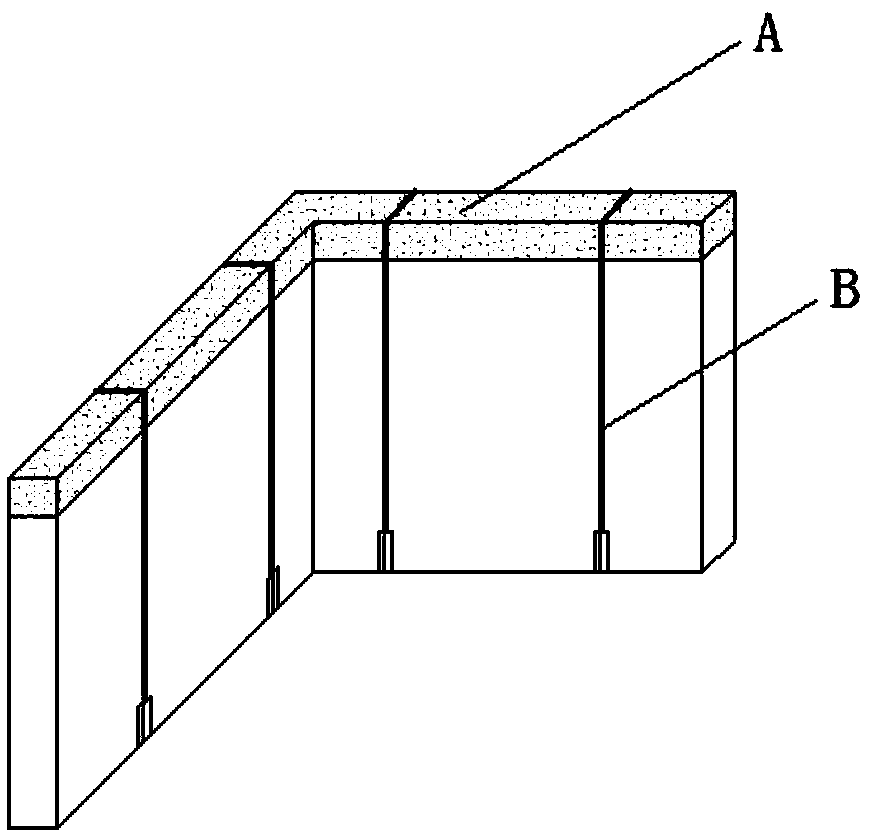

Construction method and device of ultrahigh connected group tower outer frame structure

PendingCN108412187AHigh turnover utilizationSimple structureScaffold accessoriesBuilding support scaffoldsFloor slabEngineering

The invention discloses a construction method and device of an ultrahigh connected group tower outer-frame structure, and relates to the technical field of building construction equipment. The construction method and device of the ultrahigh connected group tower outer-frame structure aim at solving the problem that in the prior art, a lifting scaffold cannot be integrally lifted according to normal processes because the lifting scaffold is in conflict with an overhung part. The construction device includes a frame main body, a guide frame, a wall-attached device and an outer protection net, wherein the frame main body surrounds the outer side of the outer-frame structure, the guide frame is vertically fixed to the inner side of the frame main body, and the two ends of the wall-attached device are detachably connected with a cast floor plate and the guide frame respectively. The construction method includes the steps that after the frame main body is lifted for the nth time, the construction device is located at the bottom of the overhung part; the components, in conflict with the overhung part, of the frame main body are removed in advance, and after being lifted to an appropriateposition, the frame main body is connected to the cast floor plate through the wall-attached device; the components, not in conflict with the overhung part, of the frame main body are restored, lifting is completed for the (n+1)th time, and the Nth layer of the outer-frame structure is constructed; in this way, operation is repeatedly conducted till the frame main body crosses the overhung part, and all structural layers where the overhung part is located are constructed layer by layer.

Owner:SHANGHAI NO 4 CONSTR

Installation method of large-span steel trusses

InactiveCN106869319AFast installationImprove securityBuilding material handlingLong spanSupport point

The invention discloses a large-span steel truss installation method, which belongs to the technical field of steel structure installation, and comprises the construction steps of preparation work→steel truss assembly→first long-span steel truss hoisting→subsequent steel truss installation. The large-span steel truss installation method of the present invention cannot meet the installation requirements for the assembly and hoisting site, especially for the large-span steel truss in a restricted space or cantilevered outside the support point, the installation progress is faster, the safety effect is better, and it is more economical The construction cost reduces safety risks, the ground assembly is convenient and fast, the installation progress and quality are effectively improved, the actual hoisting time is shorter, and the practicability is stronger.

Owner:CHINA MCC17 GRP

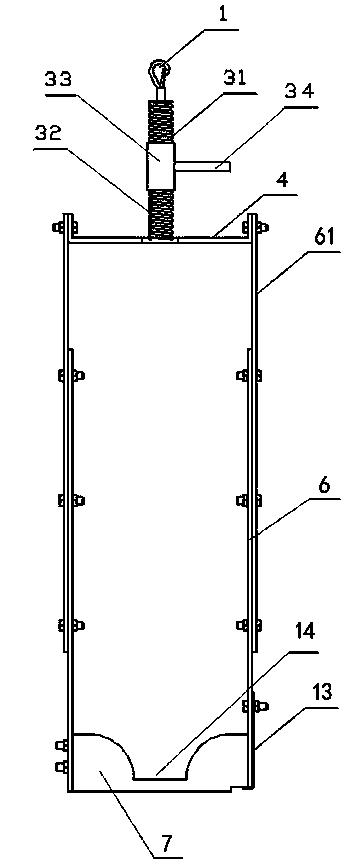

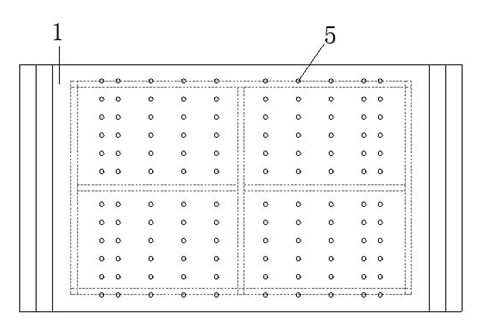

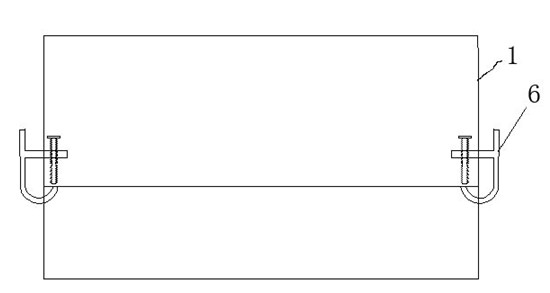

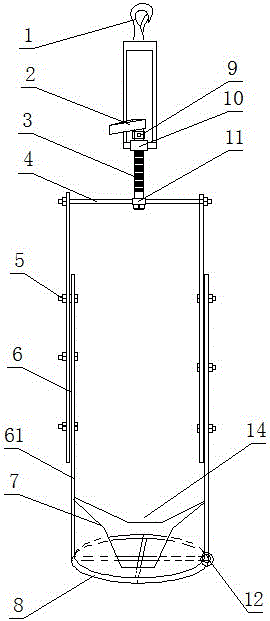

Binding system for concrete hollow building block wall piece in agglomeration building and binding method thereof

ActiveCN106592985AEasy to adjustReduce integrityBuilding material handlingLoad-engaging elementsConstruction industryBuilding construction

The invention provides a binding system for a concrete hollow building block wall piece in an agglomeration building and a binding method thereof and relates to a binding system and a binding method. According to the binding system for the concrete hollow building block wall piece in the agglomeration building and the binding method thereof, the problem that lifting of the hollow building block wall piece cannot be achieved by an existing two-lifting-point lifting method, and thus inconvenience is brought to site construction is solved. According to the binding system for the concrete hollow building block wall piece in the agglomeration building, a binding beam is bound on the wall piece through a plurality of binding parts, a balance beam is located above the binding beam, and the balance beam and the binding beam are connected through lifting ropes. One end of each lifting rope is connected to one side of the binding beam, the other end of each lifting rope is connected to the other side of the binding beam, and the joints of the lifting ropes and the binding beam are slidingly connected through sliding blocks. The binding method comprises the following steps that the binding beam is connected; the sliding blocks are slidingly arranged on the binding beam; the binding beam and the concrete hollow building block wall piece are bound together through the binding parts; the balance beam and the binding beam are connected; and the lifting ropes are installed, and lifting is conducted. The binding system for the concrete hollow building block wall piece in the agglomeration building and the binding method thereof are applied to the construction industry.

Owner:HARBIN DACHENG GREEN BUILDING TECH DEV

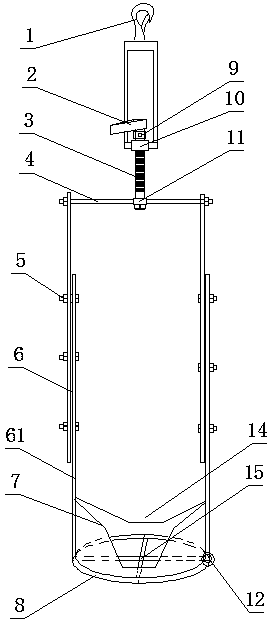

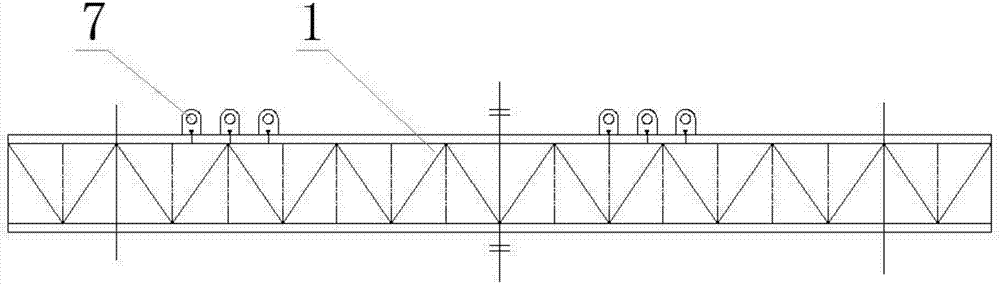

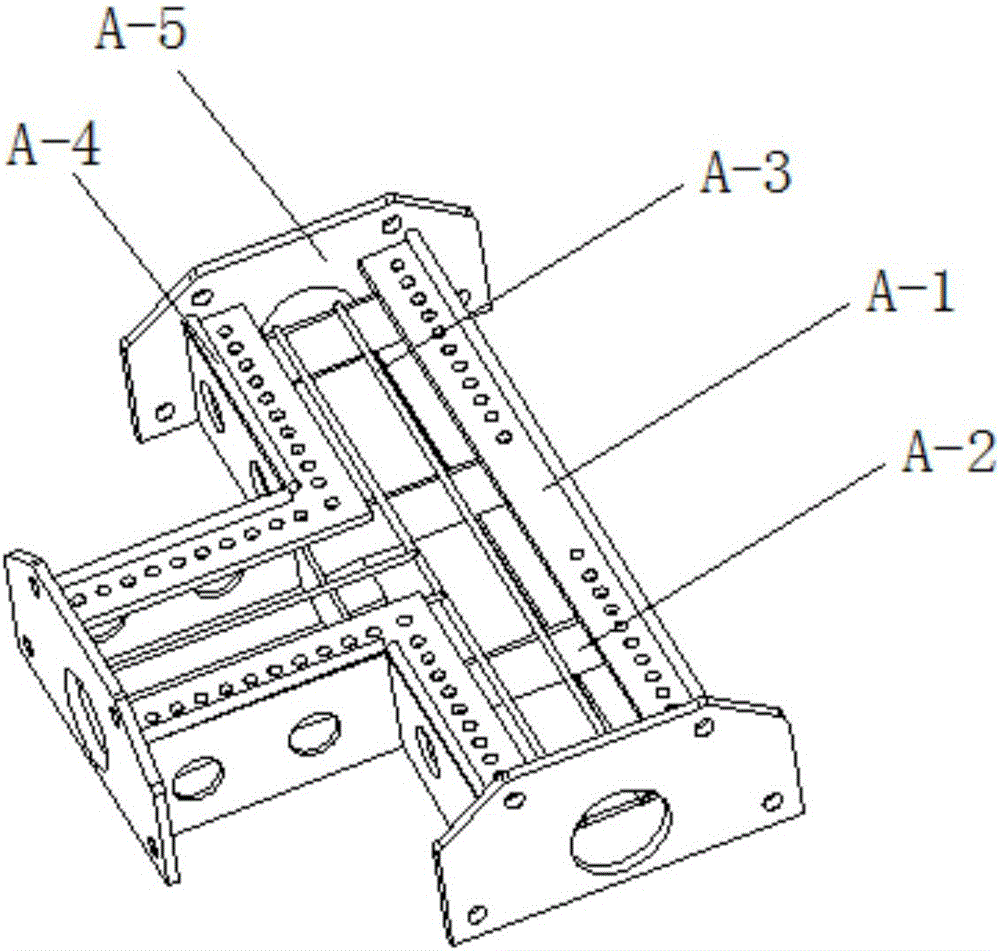

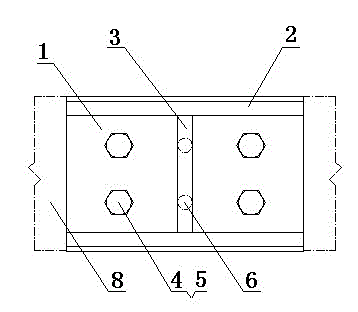

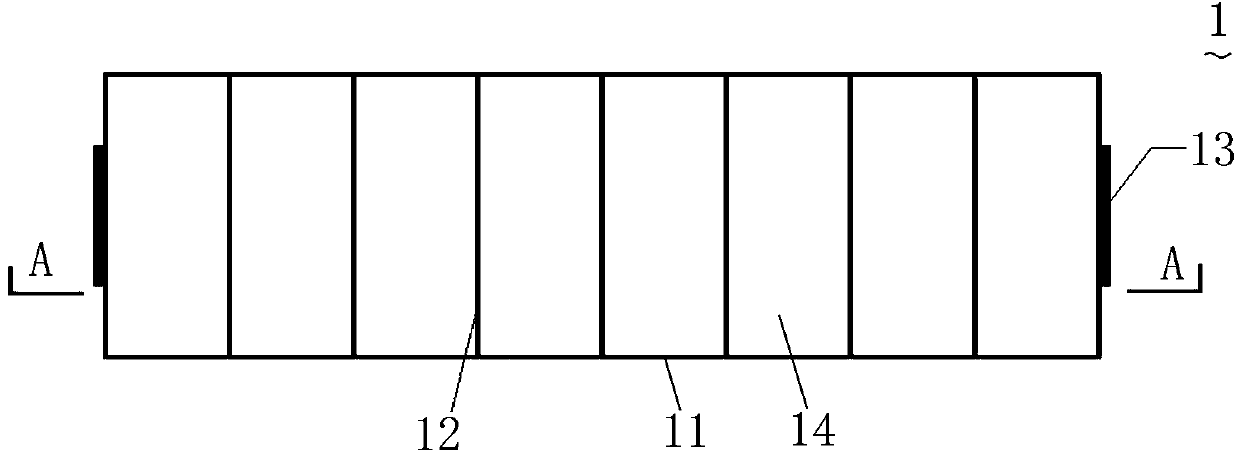

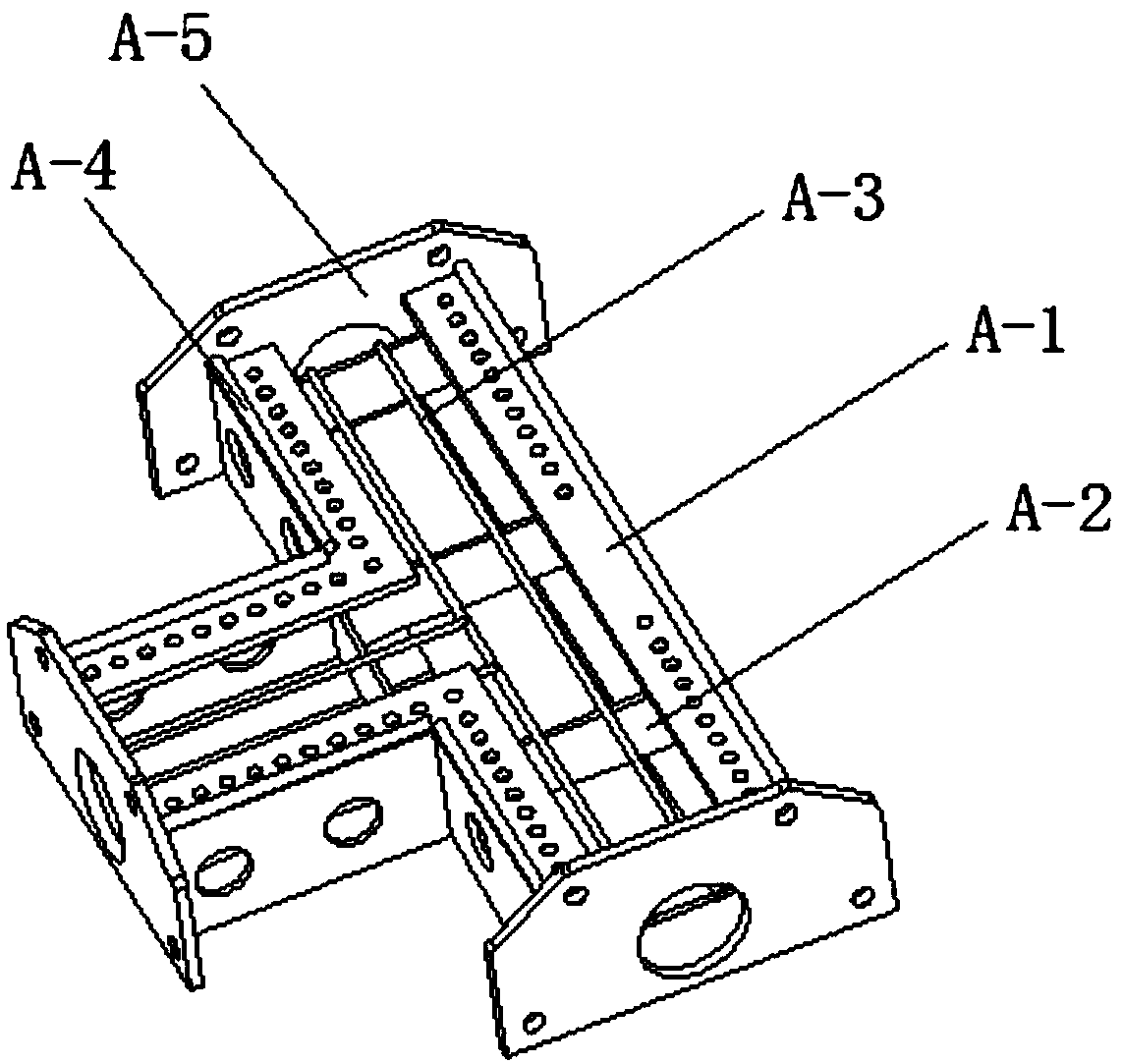

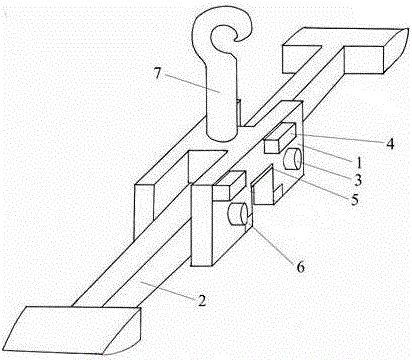

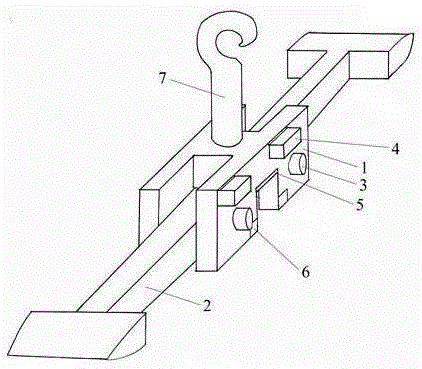

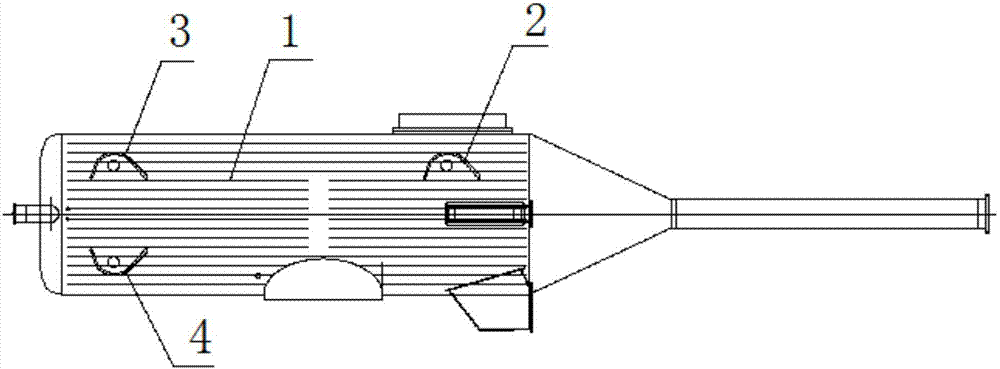

Lifting device special for rapidly lifting steel truss girder rod piece and using method

ActiveCN103556574ANo looseness or slippageShorter lift timeBridge erection/assemblyEngineeringBuilding construction

The invention discloses a lifting device special for rapidly lifting a steel truss girder rod piece and a using method. Side vertical plates are fixedly arranged on the two sides of a flat bottom plate respectively. A transverse clamping plate is fixedly arranged between the side vertical plates. Bolt holes are formed in the flat bottom plate. Positioning pins are fixedly arranged below the flat bottom plate. Intervals between the bolt holes and the positioning pins are completely consistent with those between bolt holes in the steel truss girder rod piece respectively. A lifting hole is formed in the upper part of the transverse clamping plate. When the lifting device is used, two special lifting devices are lifted to the two ends of the steel truss girder rod piece through a crane, fixing bolts are inserted into the bolt holes of the special lifting devices and the steel truss girder rod piece for fixation after the lifting devices are positioned respectively, the steel truss girder rod piece is lifted to a designed mounting position through the crane, and the fixing bolts are disassembled. According to the special lifting device, loosening and sliding in a lifting process can be avoided, secondary pollution to the rod piece can be avoided, the special lifting device is short in lifting time, high in reliability, easy to operate, high in construction speed, short in construction period and low in cost, and can be used for lifting steel truss girder rod pieces with different specifications, and a few matched operators are required.

Owner:中铁二十一局集团路桥工程有限公司

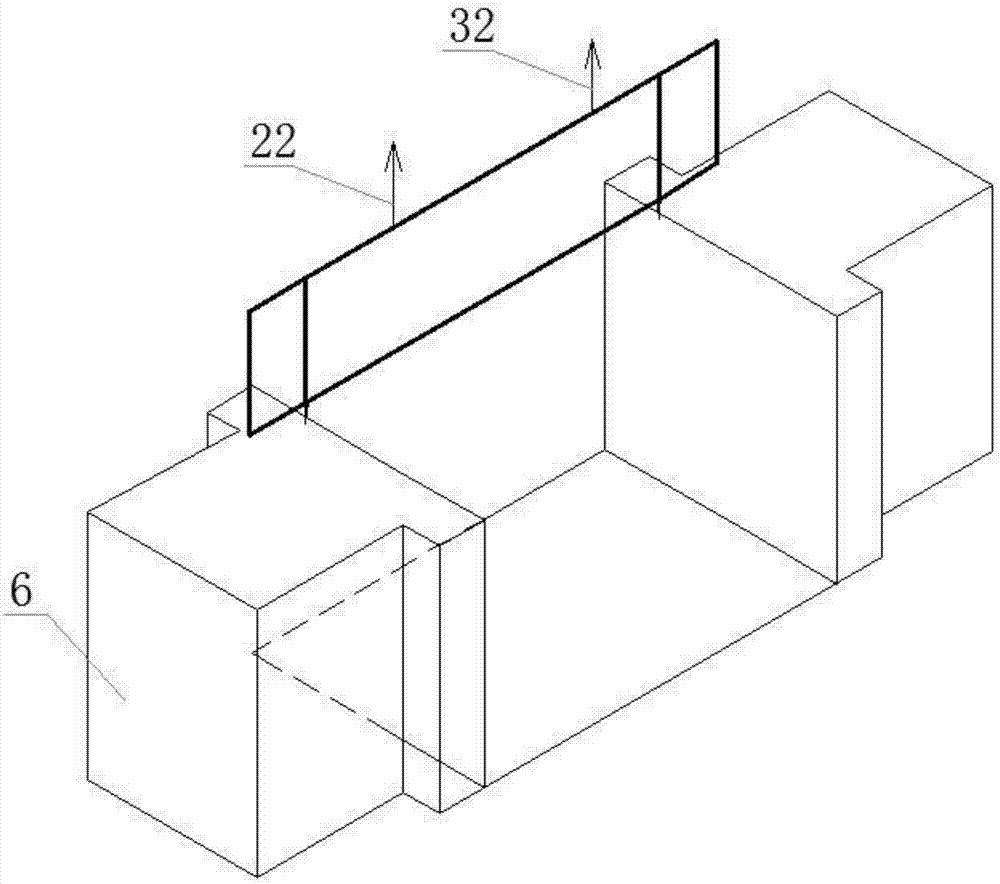

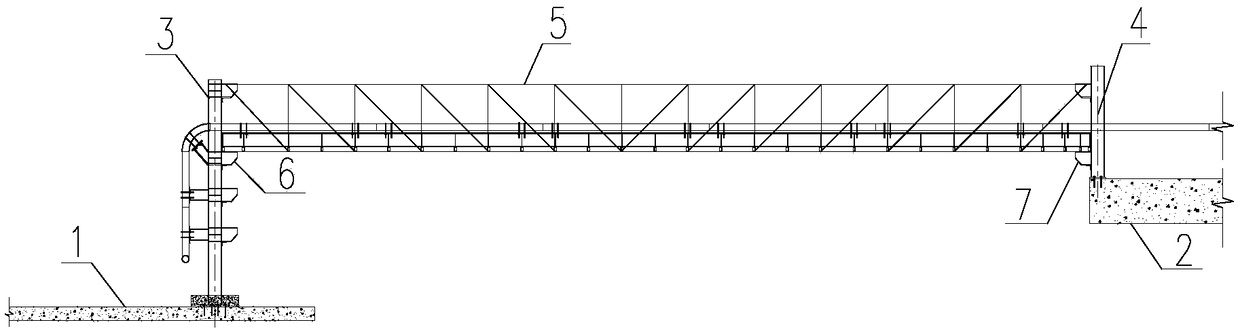

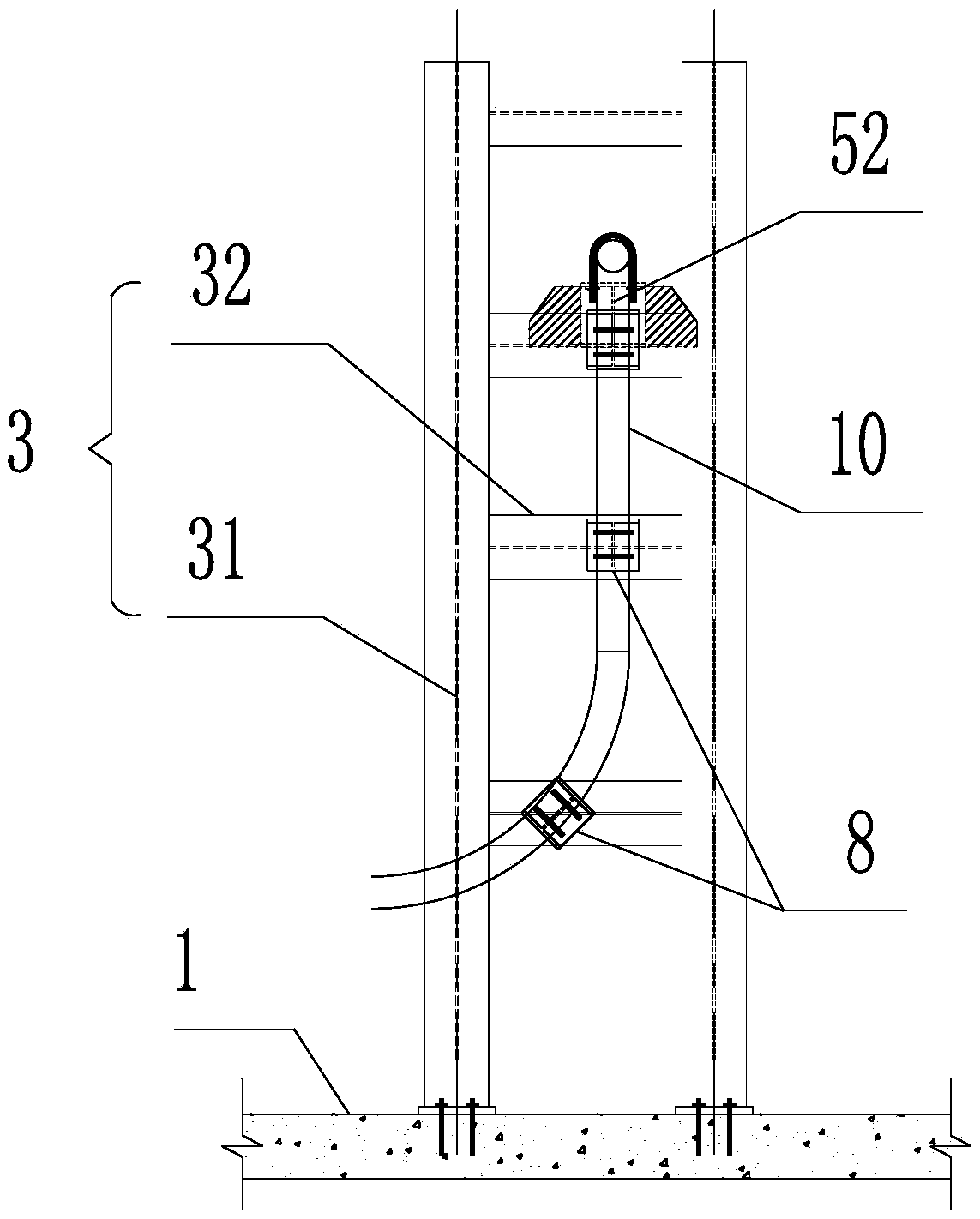

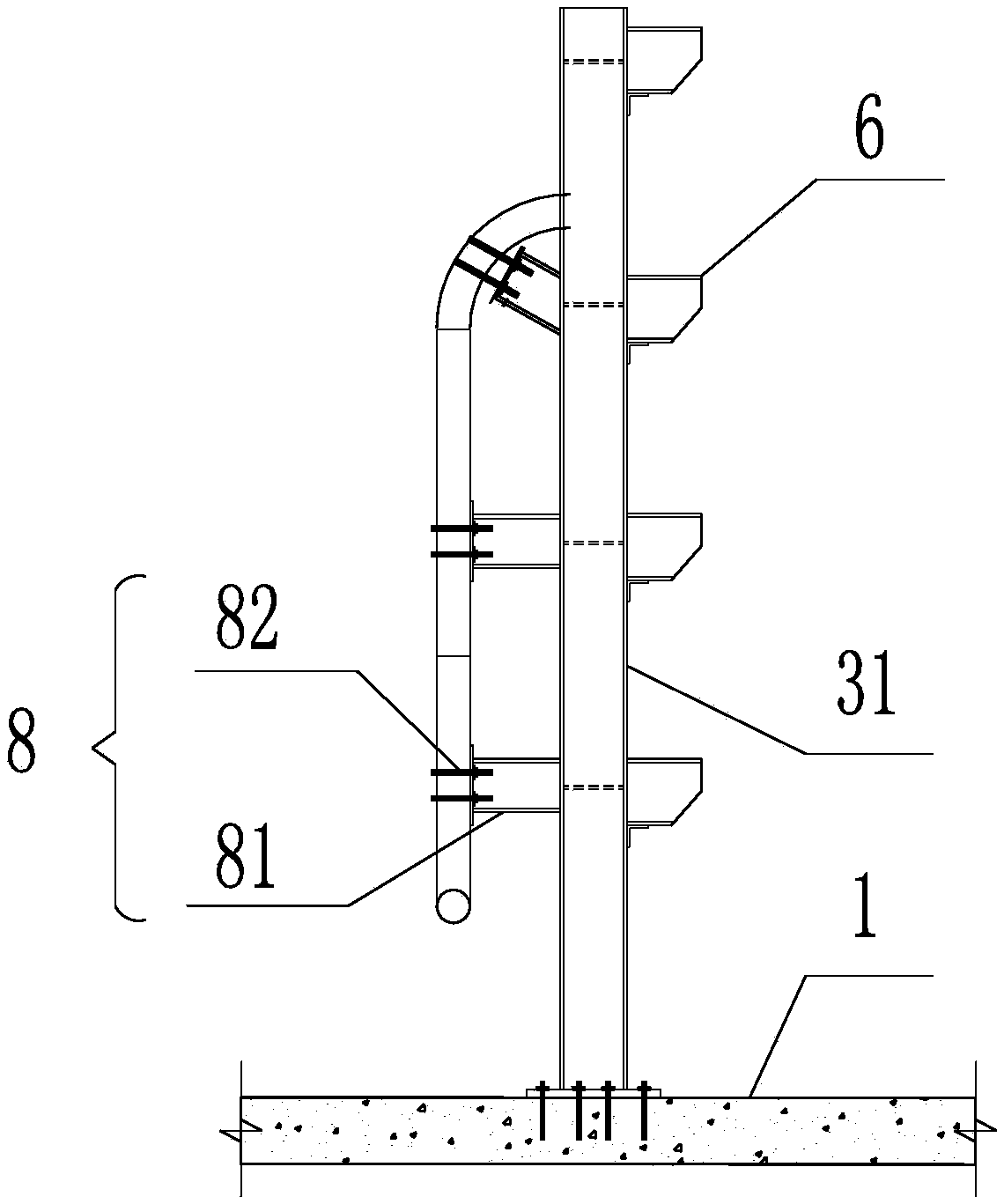

Super-high-level pump pipe gap bridge device and construction method thereof

PendingCN109138431ASolve bridge installationFix fixityBuilding material handlingEconomic benefitsSteel frame

The invention discloses a super-high-level pump pipe gap bridge device and a construction method thereof. The device comprises a fixed pump pipe vertical climbing frame arranged on a first concrete plate, a height-adjustable steel frame arranged on a second concrete plate and a horizontal pump pipe fixed truss. The first concrete plate is lower than the second concrete plate. The inner side of thefixed pump pipe vertical climbing frame is provided with several first brackets at intervals along a height direction. The height-adjustable steel frame is provided with a second bracket. The height-adjustable steel frame is used to adjust the height position of the second bracket so that the second bracket and one first bracket have the same height position. The two ends of the horizontal pump pipe fixed truss are arranged on the first bracket and the second bracket which are located at the same height. The adaptability of the device is high, the pump pipe gap bridge installation and fixingproblems of different projects and different conditions can be solved, the device can be reused and economic benefits are remarkable; and a construction mode that ground assembling is adopted, and hoisting is performed after assembling is completed is adopted, tower crane lifting time is short, and the occupied time of a tower crane is less.

Owner:SHANGHAI CONSTR NO 1 GRP

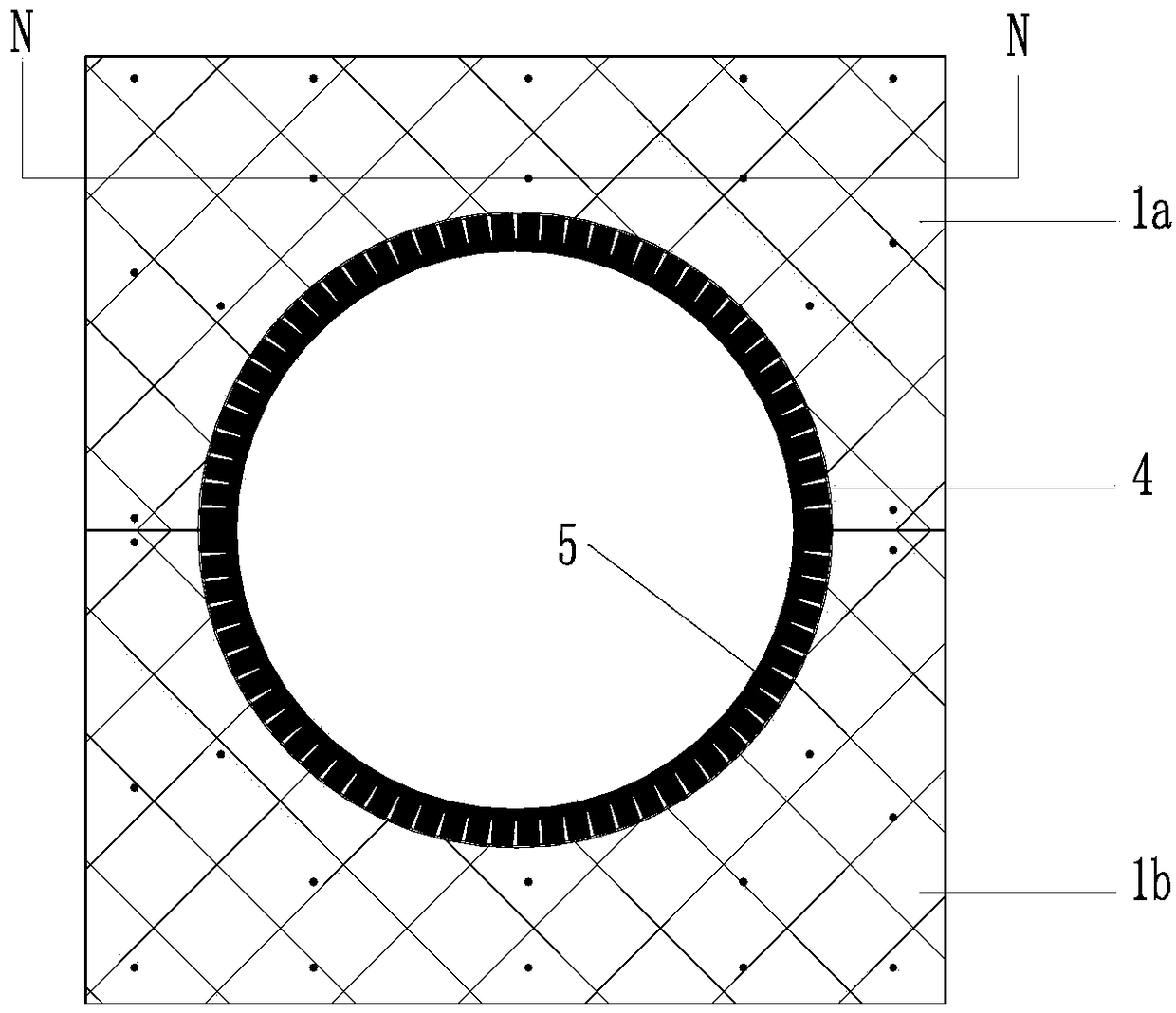

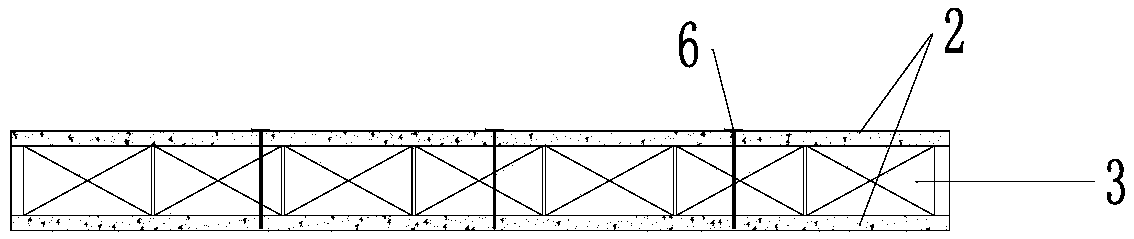

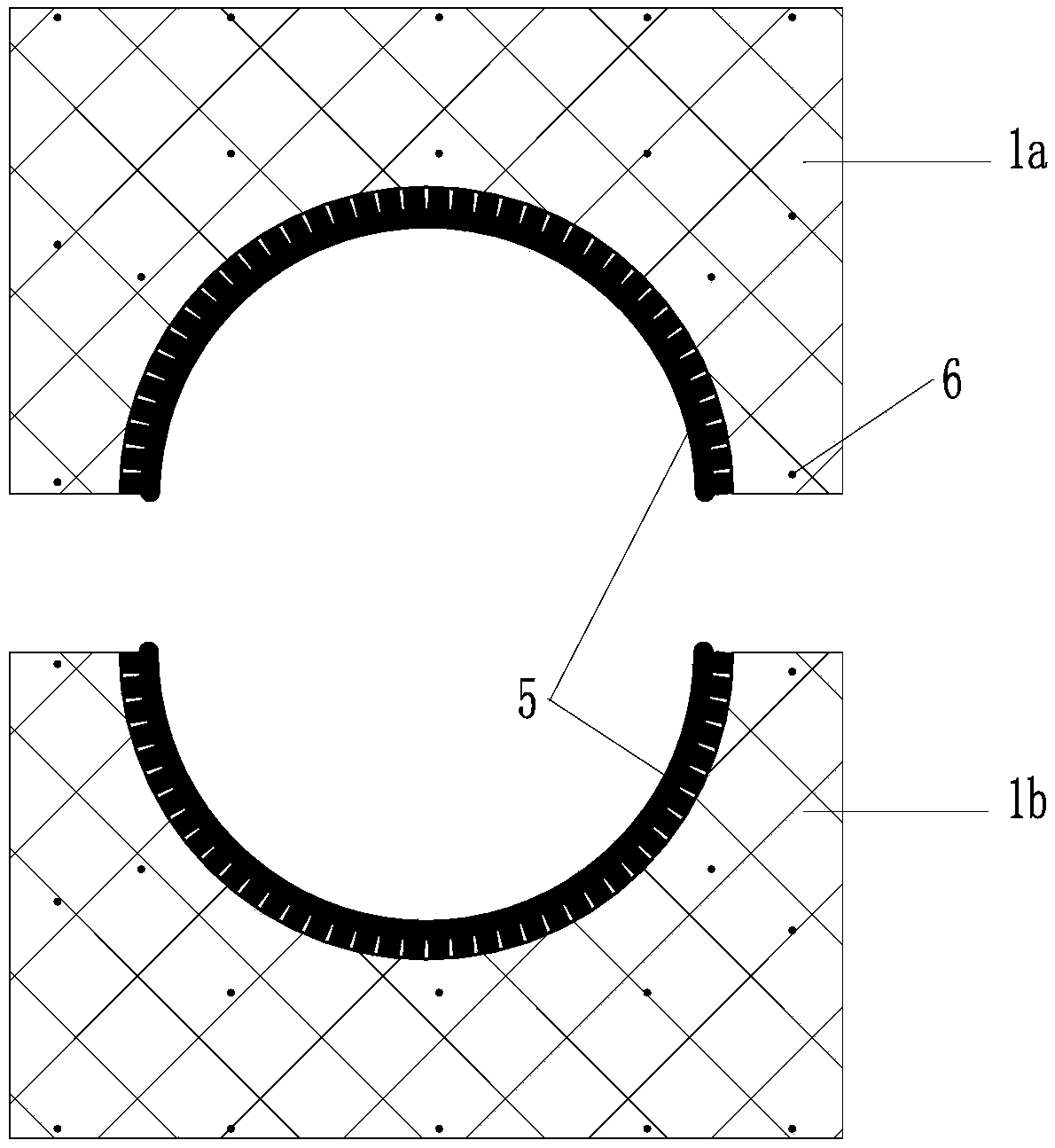

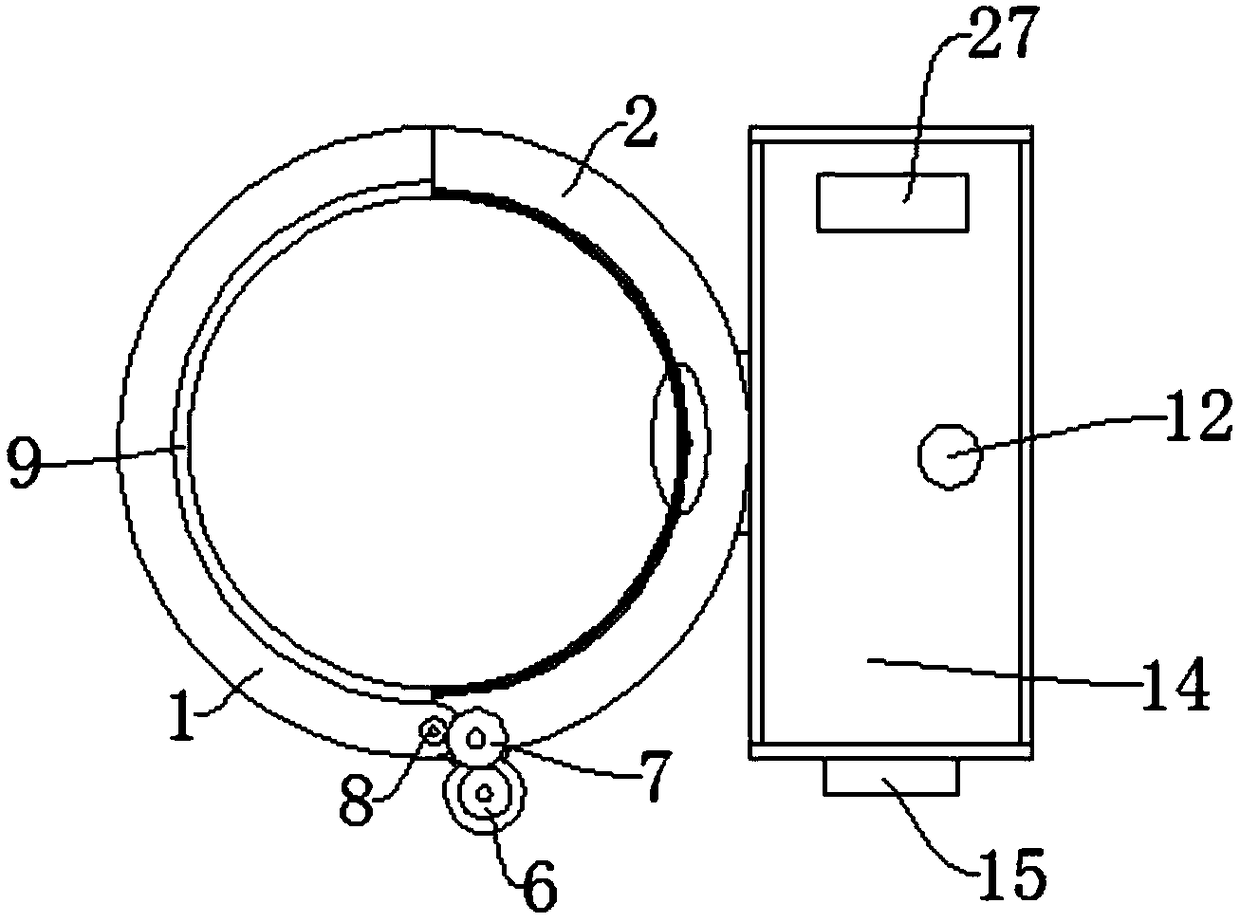

Mold for manufacturing reinforced concrete circular column and construction method thereof

InactiveCN109057324AHigh precisionImprove integrityForms/shuttering/falseworksReinforced concreteKeel

The invention provides a mold for manufacturing a reinforced concrete circular column. The mold comprises circular hoop film, wherein the innermost layer of the circular hoop film is in contact with circular column concrete, the circular hoop film is externally provided with a circular hoop keel composed of a plurality of wooden keels, two layers of composite nested plates are composed of A platesand B plates, and the inner sides of the A plates and B plates are provided with semicircular concave dies respectively; one part of the wooden keels forming the circular hoop keel is fixedly connected to the surface of the concave die at the A plate side, and the other part of the wooden keels is fixedly connected to the surface of the concave die at the B plate side. The invention further provides a construction method of the mold for manufacturing the reinforced concrete circular column. Two multi-layer laminated plates covered with film and a wood square layer sandwiched in the middle aremade into the composite nested plates; the composite nested plates are cut and divided into the A plates and the B plates from the middle, the A plate on the upper layer and the A plate on the lowerlayer are fixedly connected with the wooden keels, and the B plate on the upper layer and the B plate on the lower layer are fixedly connected with the wooden keels; the inner surface of the circularhoop keel is covered with the circular hoop film; and the circular hoop film is coated with a separant. The mold for manufacturing the reinforced concrete circular column and the construction method thereof have the advantages that the weight is smaller, the reshipment is convenient, turnover can be carried out many times, the cost is reduced, the integrality is good, the strength and rigidity aregood, the assembly and disassembly are simple, and the construction efficiency is improved.

Owner:CHINA 22MCC GROUP CORP

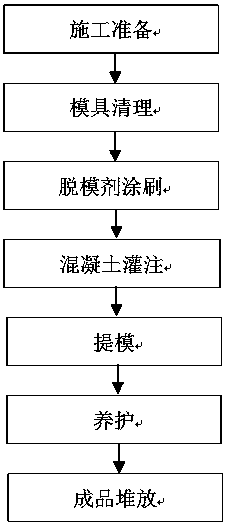

Manufacturing method for small concrete prefabricated blocks on construction site

InactiveCN110281347AImprove construction efficiencyImprove construction progressCeramic shaping apparatusAir temperatureMaterials science

The invention discloses a manufacturing method for small concrete prefabricated blocks on a construction site. The manufacturing method comprises the following steps: manufacturing a steel mould, selecting a site with a flat surface on the construction site as a bottom plate of the steel mould, clearing the mould and coasting a mould release agent on the side walls of the mould, pouring concrete in twice and compacting through a reamer, scraping off and trowelling concrete on the upper surface of the steel mould with a trowelling tool; and lifting the mould after set time according to conditions such as a temperature, and maintaining the concrete prefabricated blocks according to an air temperature and a site condition. The manufacturing method has the advantages of being low in requirements on an operation site, high in construction efficiency, low in cost, capable of being recycled, simple and convenient in operation, and high in finished product surface quality.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD +1

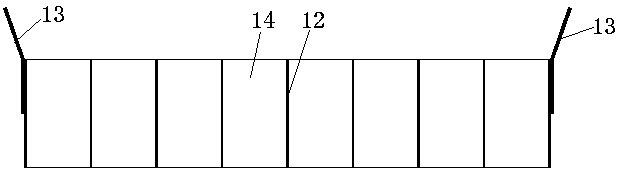

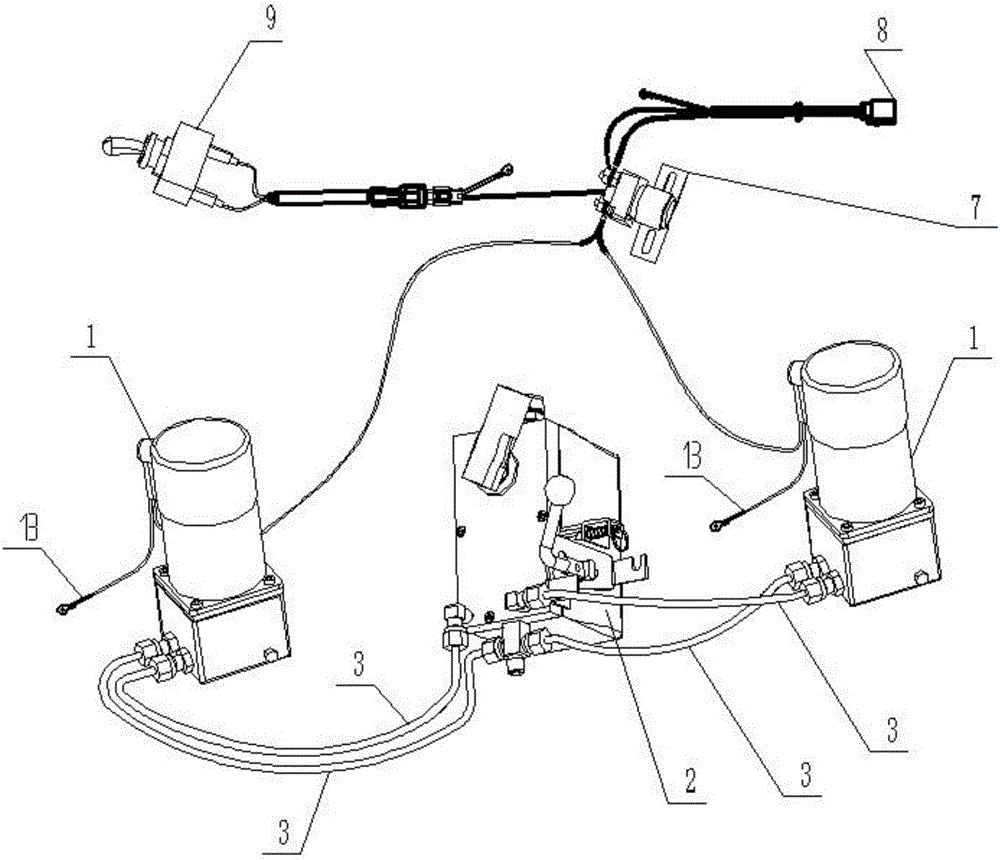

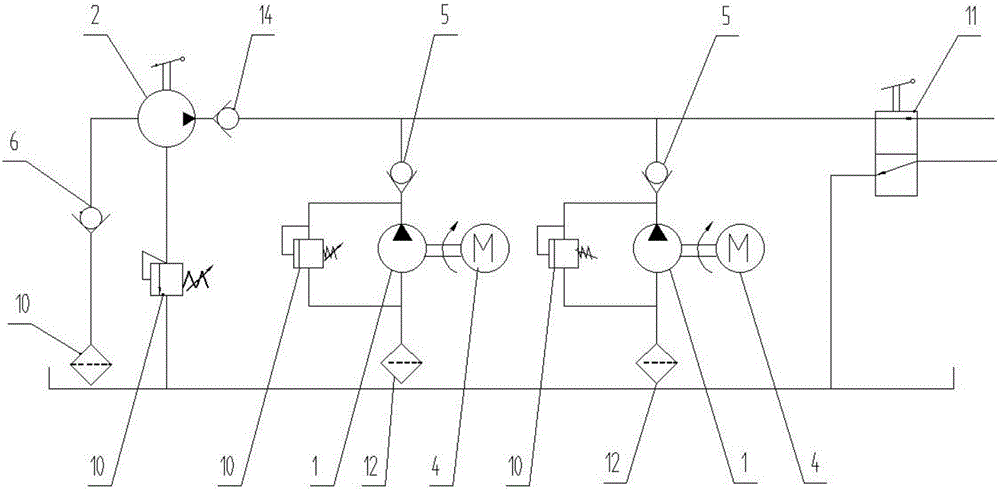

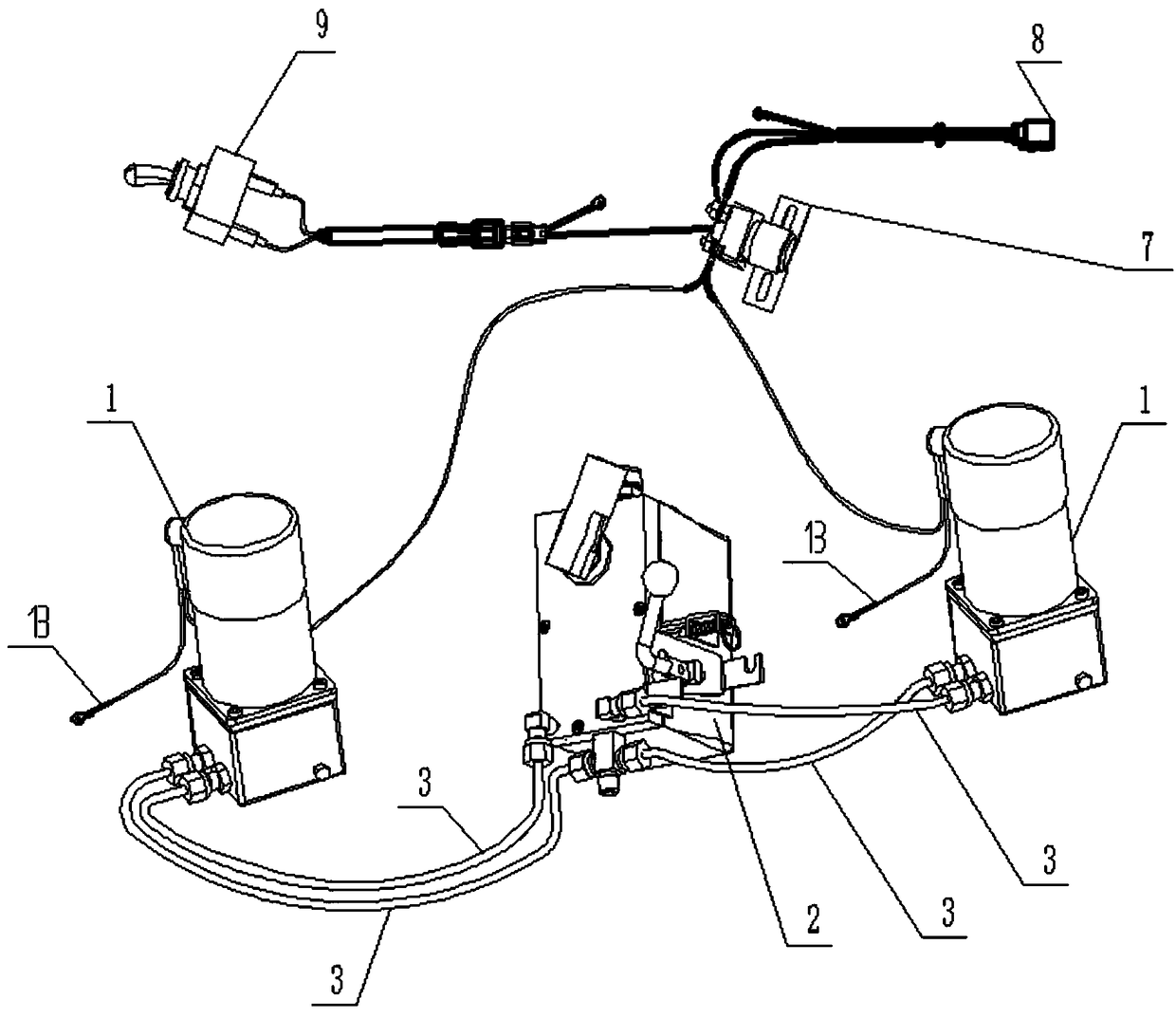

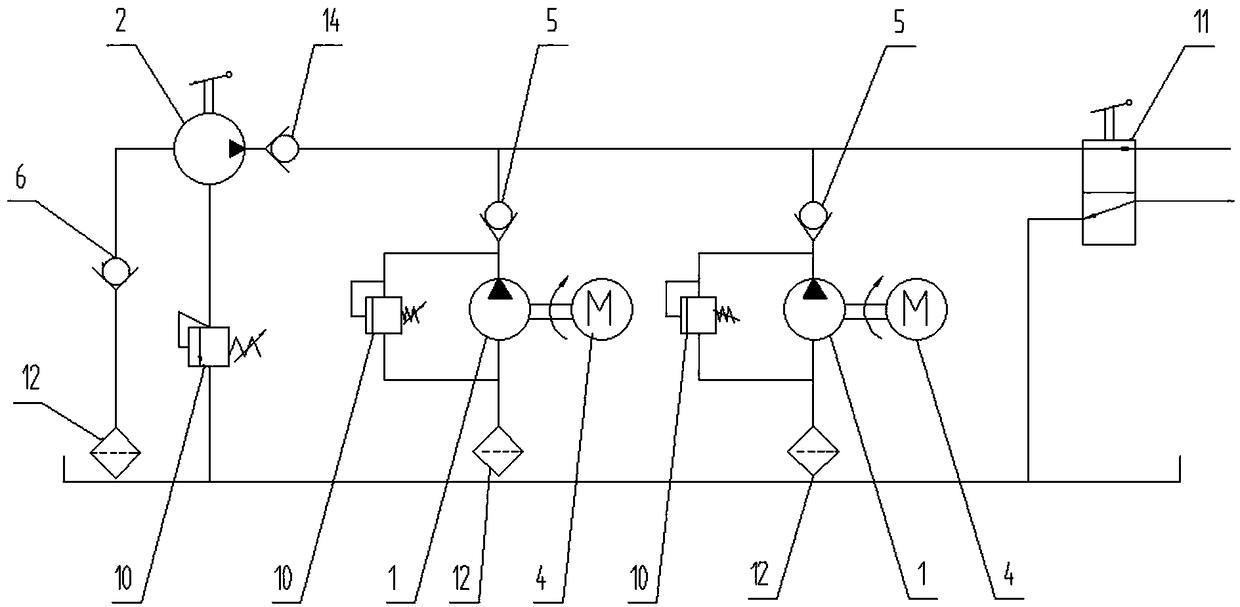

Cab hydraulic lifting device

ActiveCN106194641AShorten maintenance timeCompact structurePositive displacement pump componentsPump installationsToggle switchEngineering

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

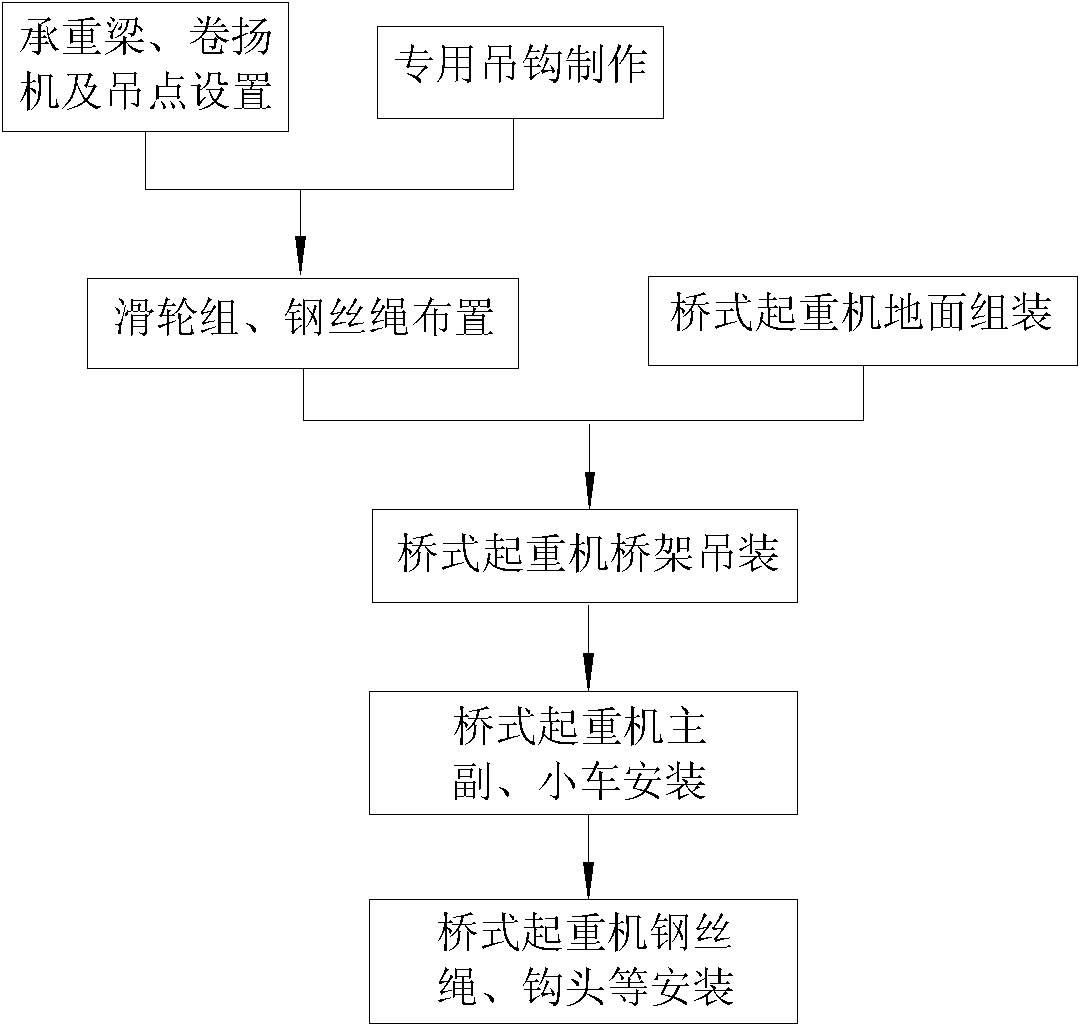

Method for installing bridge crane using load-supporting roof beam for hoisting and usage thereof

InactiveCN102267664BDoes not affect the installation progressReduce investmentTravelling cranesArchitectural engineeringBlock and tackle

The invention relates to a method for installing a bridge crane using load-supporting roof beams for hoisting and usage thereof. The invention is characterized in that: hoisting points are arranged on roof beams of a workshop, components of the bridge crane are assembled on the ground on site, and hoists and specified suspenders are used for hoisting the bridge crane; the method mainly comprises the steps of arranging of load-supporting beams for hoisting, hoists and hoisting points, fabrication of the specified suspenders, arranging of assembly pulleys and wire ropes, assembly of the bridge crane on the ground, hoisting of bridge stands of the bridge crane, hoisting of main and assistant trolleys of the bridge crane and installation of the wire ropes and the suspenders. According to the invention, site requirements are low, finished roofing of the workshop does not need to be dismounted, no giant crane is utilized, and facilities purchased and suspenders fabricated at a time can be used repeatedly, thereby saving cost; lifting and suspending with two cranes are avoided, thereby reducing safety risks; components are assembled in place on the ground and hoisted at a time, thereby improving working efficiency and abating risks in high altitude construction; time for actual hoisting is short and operationality is strong; the method is applicable to installation of large and medium-sized bridge cranes without being influenced by sites or hoisting height.

Owner:CHINA FIRST METALLURGICAL GROUP

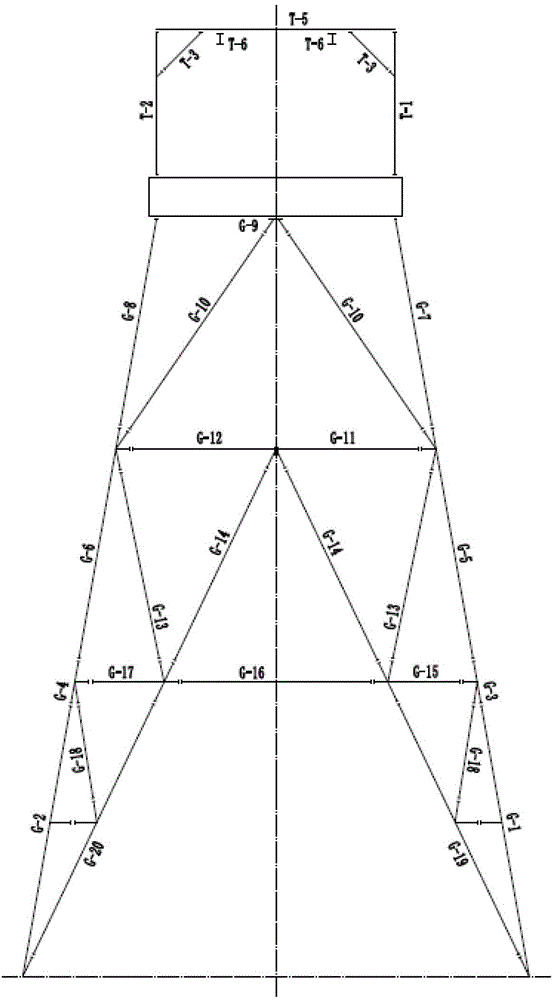

Shaft sinking tubular steel derrick

ActiveCN102900374AGuaranteed bearing capacityGuaranteed stabilityDerricks/mastsShaft sinkingWork periodChinese characters

The invention relates to a shaft sinking tubular steel derrick. The shaft sinking tubular steel derrick is of a flat-topping pyramid with a full-symmetric main body truss and comprises a main support rod, a sheave wheel platform, an intermediate platform, a strike turning platform, support rods and the like, wherein the sheave wheel platform, the intermediate platform and the strike turning platform are connected to the main support rod from top to bottom; the support rods correspond to three layers of platforms; the sheave wheel platform is arranged in a shape like a Chinese character 'ri'; the 'ri'-shaped middle is of a double-beam structure; the support rod of the sheave wheel platform is arranged in an inverted V-shaped shape and is connected with center nodes on four sides of the sheave wheel platform and nodes at four corners of the intermediate platform; and the axis of the support rod of the intermediate platform is superposed with an axial extension line of the support rod of the strike turning platform to form an inverted V-shaped arrangement for connecting center nodes on four sides of the intermediate platform with an intersection point of the main support rod and a derrick footing. The shaft sinking tubular steel derrick is suitable for a vertical shaft with the net diameter being 7-11m, the average depth being not more than 1800m and the work load of the derrick being not more than 620t as well as second-stage construction of projects; the processing, transporting, mounting and dismounting steps are simplified; and the shaft sinking tubular steel derrick is stronger in adaptability and provides reliable guarantee for quick construction and work period shortening.

Owner:JCHX MINING MANAGEMENT

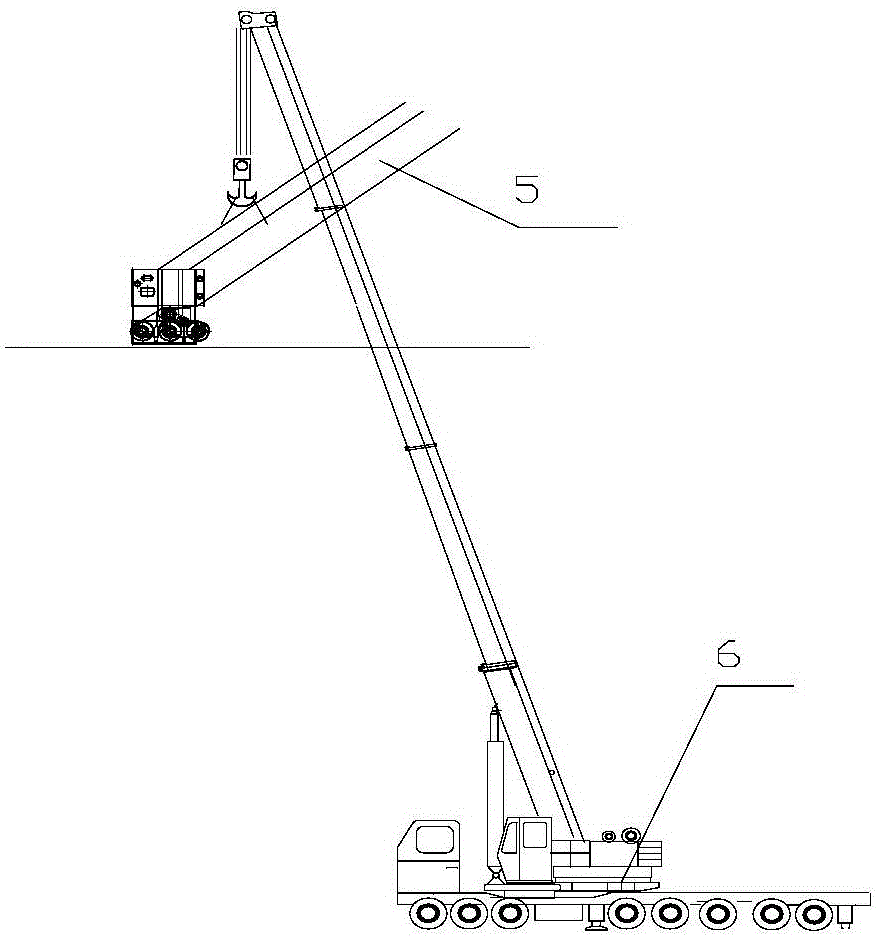

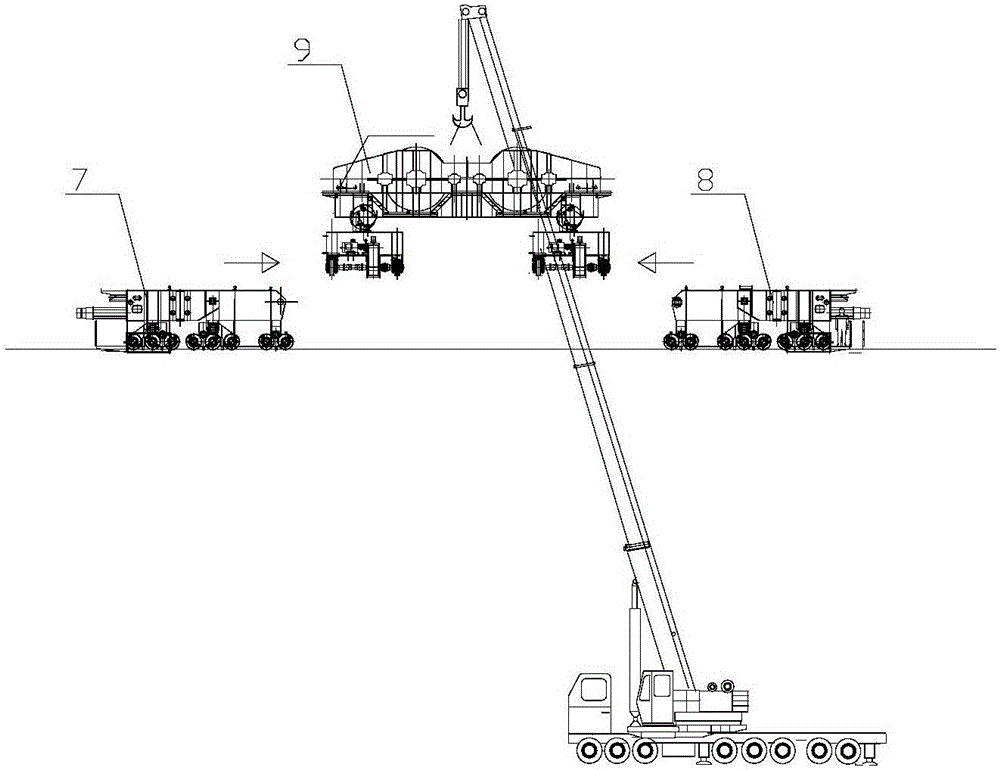

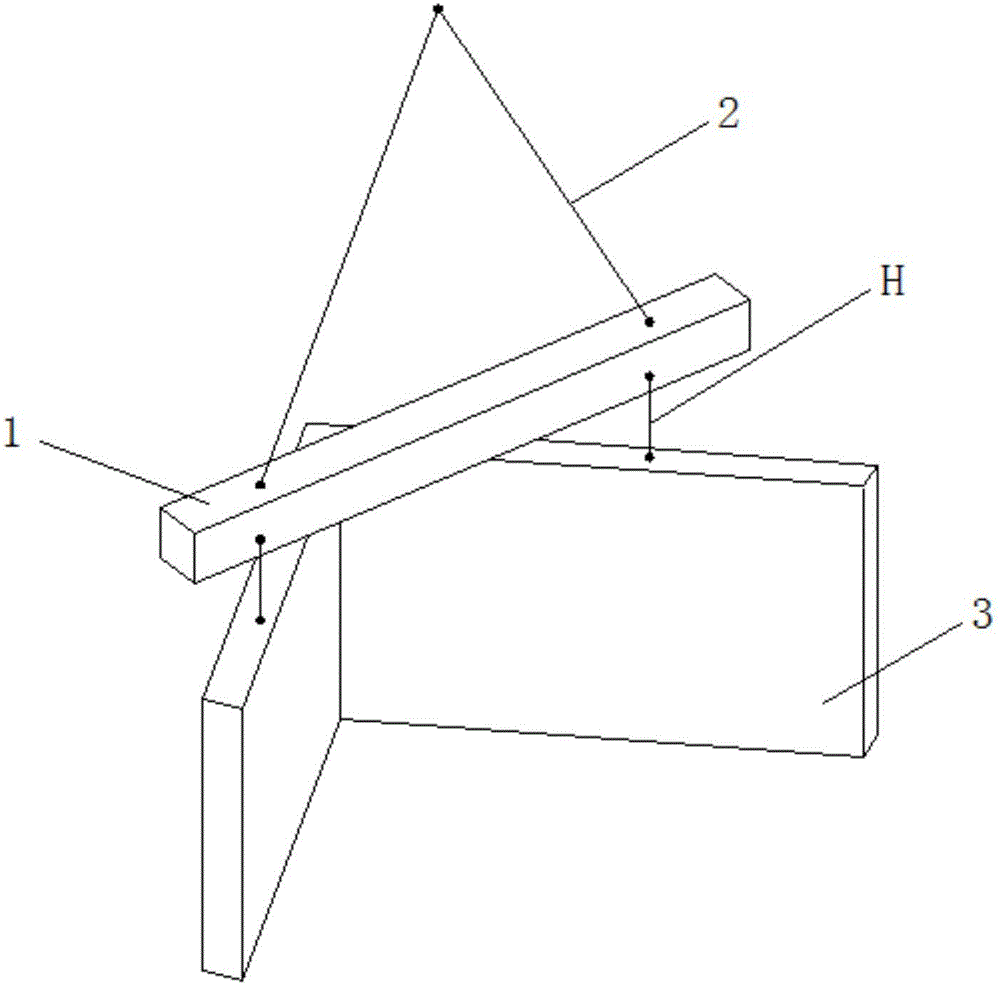

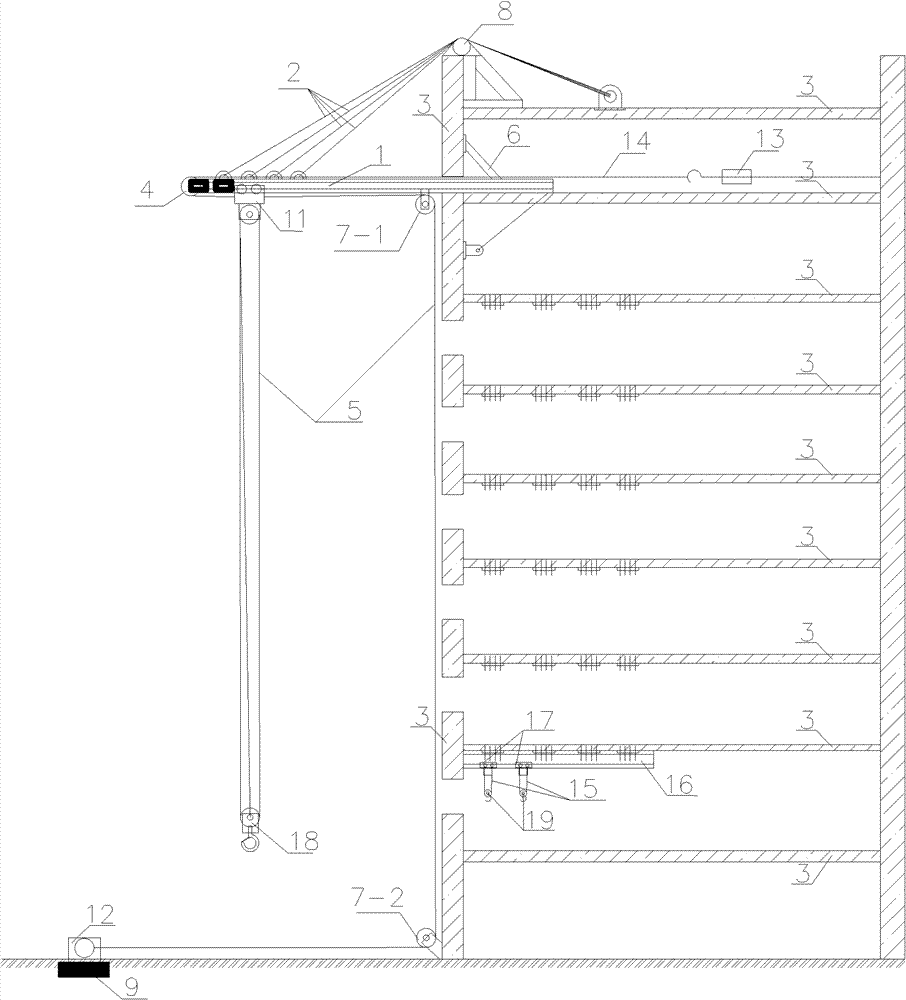

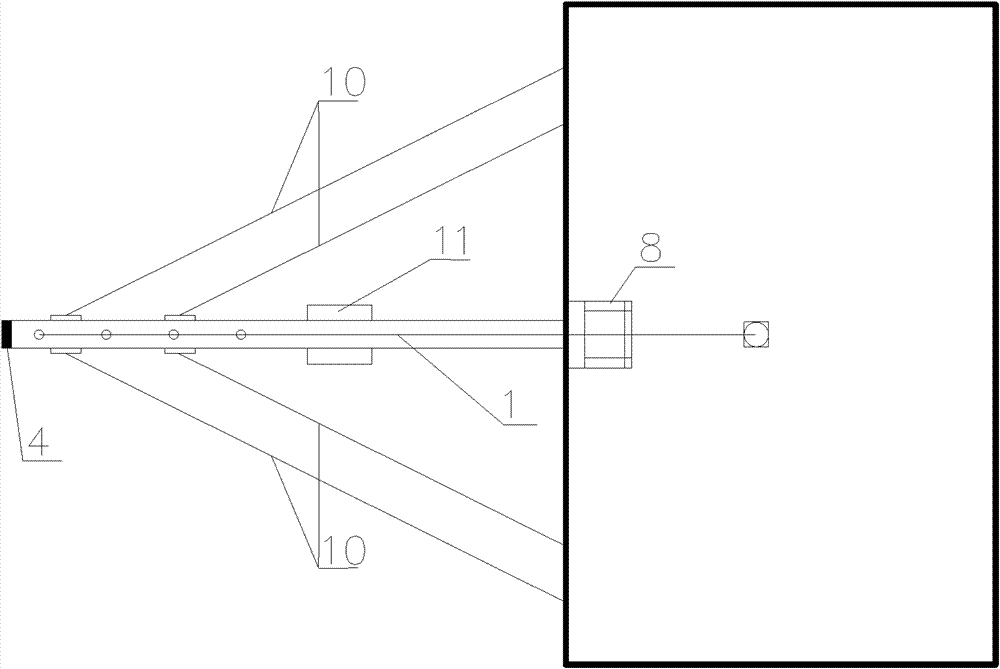

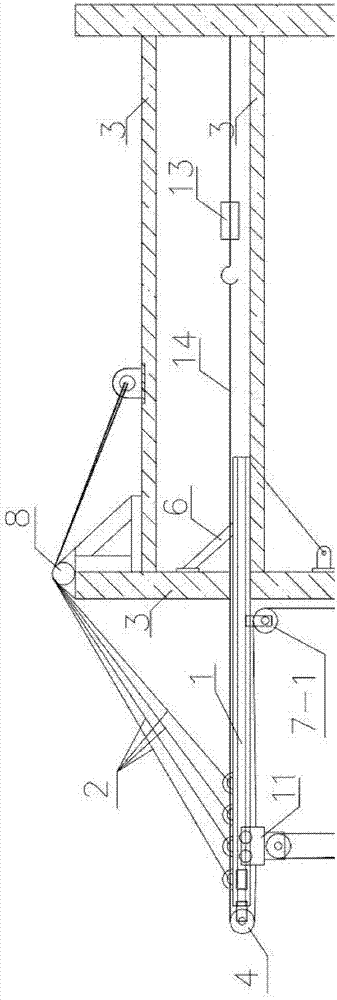

Hoisting in-place method for allowing large equipment to pass through ultrahigh hole

The invention discloses a hoisting in-place method for allowing large equipment to pass through an ultrahigh hole. Hoisting equipment of a high-altitude monorail combined cantilever crane is adopted in the method, and the high-altitude monorail combined cantilever crane comprises a main crane positioned at the outer side of a building structure and a secondary crane positioned at the inner side of the building structure. The method adopting the hoisting equipment of the high-altitude monorail combined cantilever crane comprises the following steps of: (1) hoisting the equipment to a reserved hole by using the main crane, and effectively butting the equipment and the edge of the reserved hole: 1) positively starting a winch, hoisting the equipment above the reserved hole, and braking the winch; 2) loosening a balance chain block, lowering the equipment at the same time of horizontal movement, and gradually moving the equipment to the reserved hole; 3) repeating the steps 1) and 2), starting and stopping the winch and loosening and tightening the position of balance chain block adjusting equipment till the equipment body is effectively butted with the edge of the reserved hole; and (2) drawing the equipment to the interior of the building structure by using the secondary crane, loosening a hook of the main crane, and hoisting the equipment in place by using the secondary crane. The method is convenient for operation and short in hoisting time.

Owner:中建六局第一建设有限公司

Sinking tubular steel derrick and mounting method of same

InactiveCN102913137BAdaptableEasy to processDerricks/mastsShaft sinkingChinese charactersArchitectural engineering

The invention relates to a sinking tubular steel derrick and a mounting method thereof. The sinking tubular steel derrick is of a flat top rectangular pyramid with a holohedral main body truss and comprises a main support rod piece, support rod pieces corresponding to three layers of platforms, namely a sheave wheel platform, an intermediate platform and a gangue turning platform, which are connected with the main support rod piece from top to bottom, and the like. Beams of the sheave wheel platform arranged in the shape of a Chinese character Ri; the support rod pieces of the sheave wheel platform are arranged in the shape of inverted V and connected with central nodes on the four sides of the sheave wheel platform and nodes at four corners of the intermediate platform; and the axial lines of the support rod pieces of the intermediate platform are in superposition with the extension lines of the axial lines of the support rod pieces of the gangue turning platform, and the support rod pieces of the intermediate platform are arranged in the shape of the inverted V and used for connecting the intersection points between the central nodes on the four sides of the intermediate platform, the main support rod piece and a derrick foundation. The derrick is suitable for vertical shafts with net diameter of 6.5m-9m, average depth of not more than 1400m and working load of the derrick of not more than 530t and second-stage engineering construction thereof, and can simplify processing, transportation, mounting and detachment, realize stronger applicability to terrain and provide reliable guarantee for realizing rapid construction and shortening construction period.

Owner:JCHX MINING MANAGEMENT

A kind of binding system and binding method of concrete hollow block wall piece of aggregate building

ActiveCN106592985BEasy to adjustReduce integrityBuilding material handlingLoad-engaging elementsConstruction industryBuilding industry

Owner:HARBIN DACHENG GREEN BUILDING TECH DEV

A tool for live replacement of a suspension insulator and its operating method

ActiveCN104167687BEasy to replaceImprove scalabilityApparatus for overhead lines/cablesSelf lockingElectric wire

The invention discloses a tool for live-line replacement of a suspension insulator and a using working method thereof. The tool comprises a frame type bracket and a telescopic suspension mechanism arranged at the top of the frame type bracket. The telescopic suspension mechanism includes an adjusting lead screw and a self-locking hook arranged at the top of the adjusting lead screw. The frame type bracket includes a supporting plate at the bottom and a cross-brace unit at the top; the middle portion of the cross-brace unit is connected with the bottom of the adjusting lead screw; and the supporting plate and the cross-brace unit are connected by two insulating connecting elements with adjustable lengths. According to the invention, the frame type bracket with the telescopic suspension mechanism at the top is used for ground potential live-line suspension insulator replacement of the power transmission line; and the transmission line or weight is supported by the supporting plate, so that the tensile forces of the transmission line and the weight are transferred to the tool from the suspension insulator. Therefore, the cross arm worker can complete the replacement process of the suspension insulator by himself, thereby bringing the great convenience for suspension insulator replacement. Moreover, the tool has advantages of simple structure, high security, stability, and reliability, and high efficiency.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

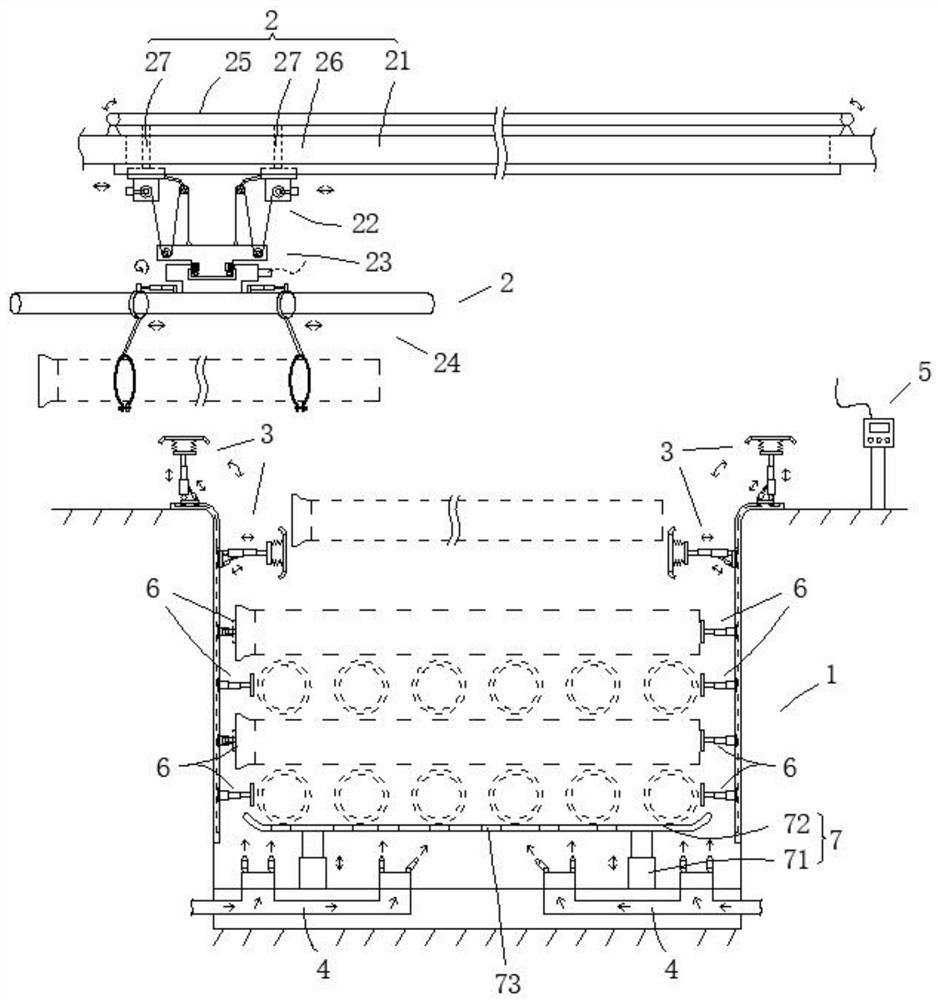

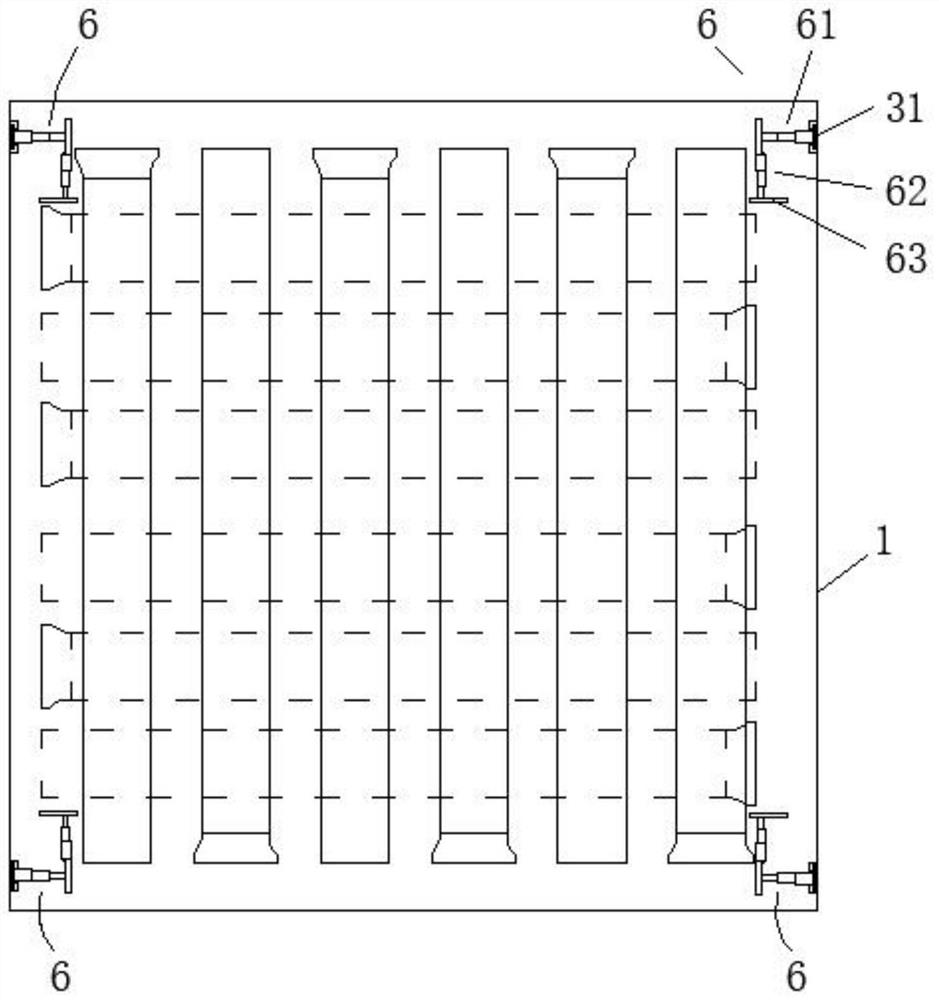

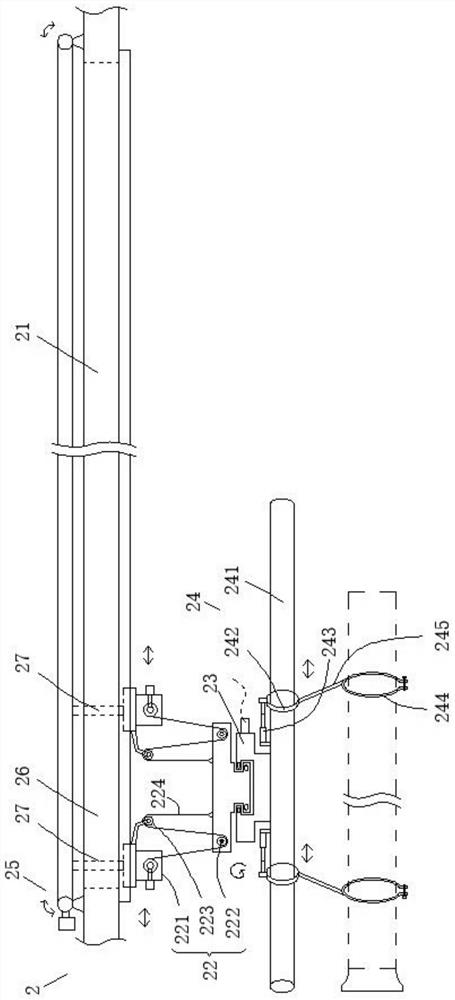

Nodular cast iron pipe curing pool system

The invention provides a nodular cast iron pipe curing pool system, and belongs to the technical field of cast pipe curing. The system comprises a curing pool, a hoisting mechanism, an anti-shaking mechanism and a steam mechanism, wherein the hoisting mechanism is arranged above the curing pool, to-be-cured nodular cast pipes can be hoisted into the curing pool, the hoisting mechanism can ascend, descend and rotate, the plurality of nodular cast pipes are stacked in the curing pool in a cross mode, the anti-shaking mechanism is arranged on the side wall of the curing pool, when the nodular cast pipes are hoisted into the curing pool, the anti-shaking mechanism is used for abutting against the nodular cast pipes and preventing shaking, the nodular cast pipes are lowered and are placed in the curing pool by means of the hoisting mechanism after being static, steam is enabled to fill the curing pool by means of the steam mechanism, and the curing pool can be used for curing the nodular cast pipes. The nodular cast iron pipe curing pool system has the technical effects that hoisting time of the nodular cast pipes is short, the nodular cast pipes are not prone to shaking when stacked in the curing pool, and the curing effect is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

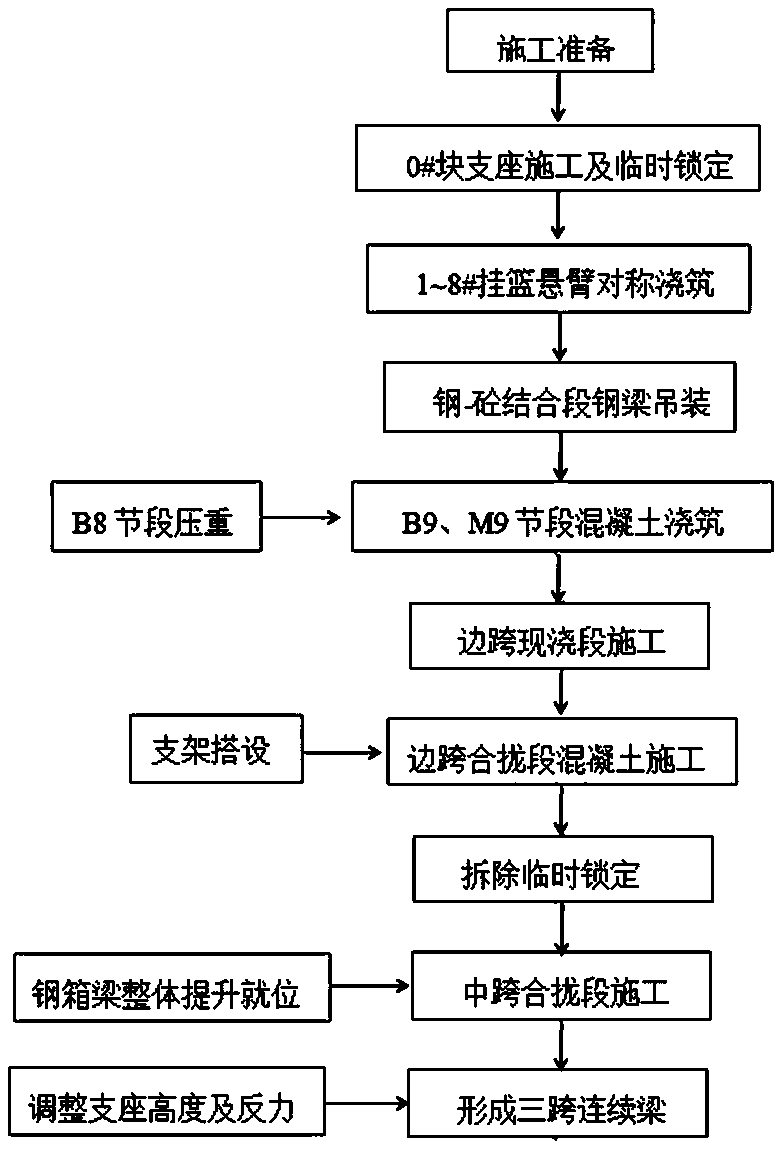

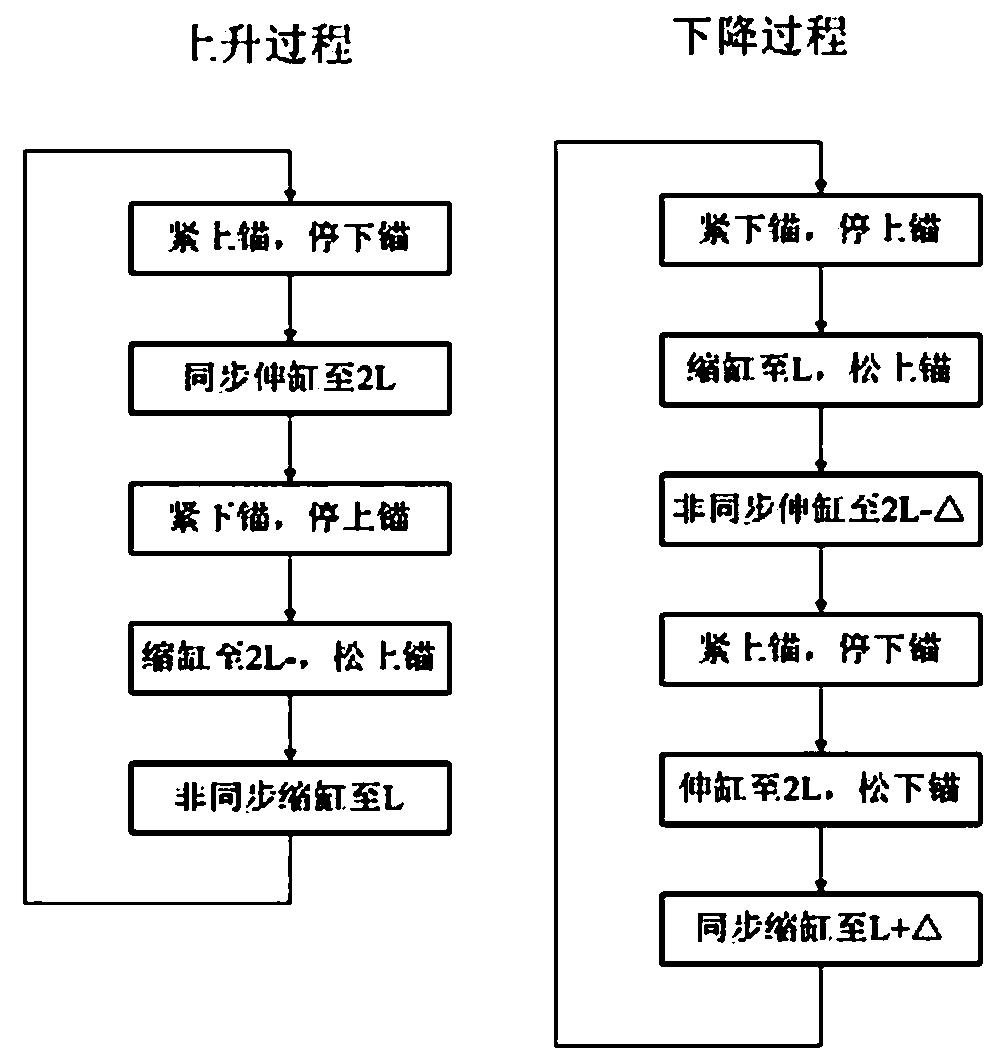

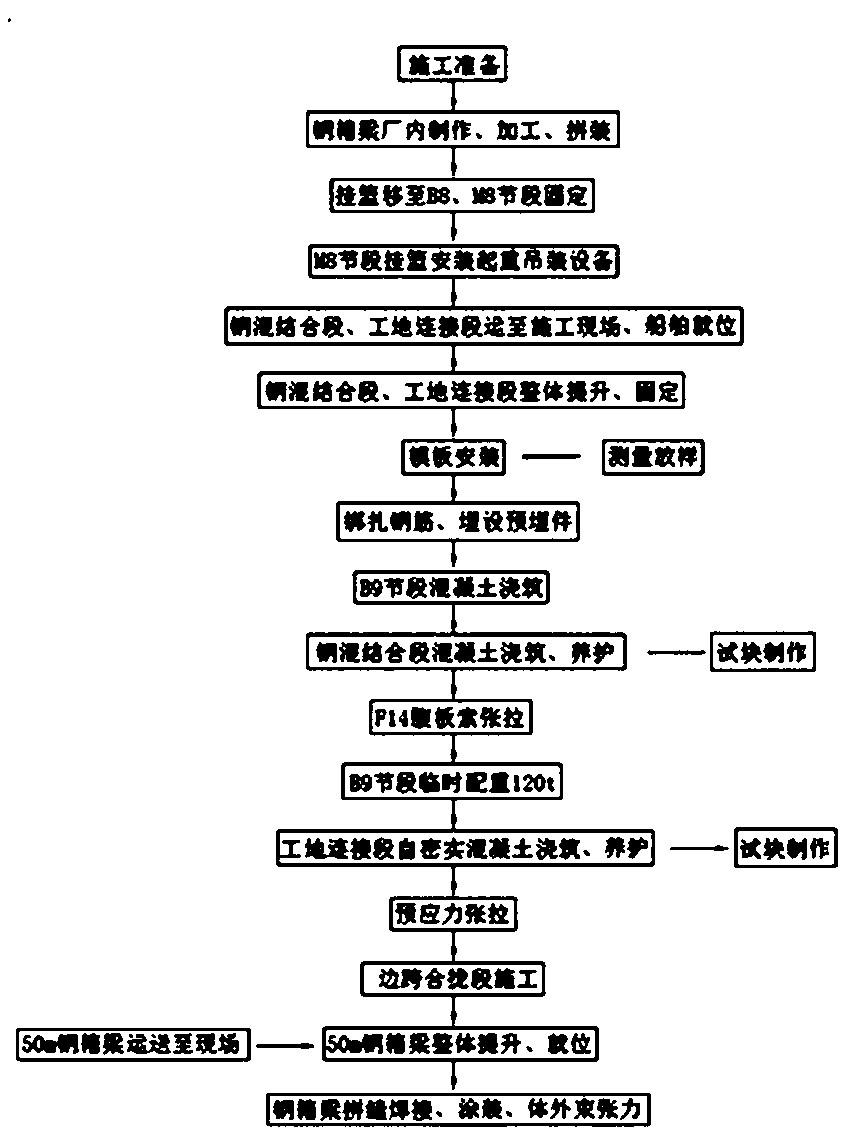

Three-span variable-height steel-concrete mixed continuous beam construction method

PendingCN111501558AShort lifting timeReduce temporary occupancy timeBridge erection/assemblyContinuous beamRebar

The invention relates to the technical field of bridge construction, in particular to a three-span variable-height steel-concrete mixed continuous beam construction method which comprises the following steps: firstly, constructing a NO. 0 block of a steel-concrete mixed continuous beam; after completion, symmetrically pouring first to eighth hanging basket cantilevers; after completion, hoisting asteel-concrete combined section; during hoisting, arranging a rhombus hanging basket at the position of an eighth poured beam body section, arranging a hoisting platform on the rhombus hanging basket, wherein the hoisting platform is provided with four hydraulic lifters, and the four hydraulic lifters are used for hoisting the steel box girder of the steel-concrete combined section to a mountingposition of the steel box girder from a river middle girder transporting ship; after the steel box girder is hoisted in place, creating a steel-concrete combined section reinforced concrete structureof the girder section, so that a steel-concrete combined section is formed; removing the temporary lock of the NO. 0 block; constructing a mid-span closure section and forming the three-span variable-height steel-concrete mixed continuous beam. The invention has the advantages that hoisting time is short, the traffic can be opened after the vehicle is in place, the temporary occupation time of roads and navigation channels is shortened, and the adverse effect on social traffic is reduced.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

Engineering pile foundation static load detection resistance anchor hoe

An engineering pile foundation static load detection resistance anchor hoe is characterized by comprising a supporting seat, a resistance rod plate, a shaft falling-off device and a hanging ring. A supporting shaft is arranged on the supporting seat, and the resistance rod plate is connected with the supporting seat through the supporting shaft and can do circumferential rotation along the supporting shaft; the shaft falling-off device is arranged on the upper portion of the supporting seat and is connected with the supporting seat, and the hanging ring is arranged in the middle position of the top of the supporting seat; and a recycling device is arranged at the bottom of the supporting seat. The engineering pile foundation static load detection resistance anchor hoe has the beneficial effects that the hoe is reasonable in structural design, easy and convenient to operate and low in equipment manufacturing, maintaining and implementing cost; the detection site is easy to assemble and disassemble; and after the test is finished, recycling is convenient, and the working efficiency and the safety of an engineering pile foundation static load detection test can be obviously improved.

Owner:陆剑

A cab hydraulic lifting device

ActiveCN106194641BShorten maintenance timeCompact structurePositive displacement pump componentsPump installationsToggle switchCheck valve

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

Continuous lifting suspension type ladder

InactiveCN108358127AShort lifting timeImprove practicalityLifting devicesCuttersEngineeringControl switch

The invention discloses a continuous lifting suspension type ladder. The continuous lifting suspension type ladder comprises at least three clamps arranged from top to bottom in a lined shape. The side face of each clamp is provided with a machine base. An electric cylinder is arranged on the upper surface of each machine base. A seat plate is mounted on the upper portion of the electric cylinderlocated at the uppermost end. A control switch, a battery box and a PLC are mounted on the seat plate. The continuous lifting suspension type ladder has the beneficial effects that the continuous lifting suspension type ladder can conduct continuous lifting without stopping in the lifting process; thus, the consumed lifting time is short, the continuous lifting suspension type ladder can continueto rise and drop under blocking of forked branches in the lifting process, and the practicality is good.

Owner:张立升

How to use the fast hoisting steel truss member

ActiveCN103556574BNo looseness or slippageShorter lift timeBridge erection/assemblyEngineeringBuilding construction

The invention discloses a lifting device special for rapidly lifting a steel truss girder rod piece and a using method. Side vertical plates are fixedly arranged on the two sides of a flat bottom plate respectively. A transverse clamping plate is fixedly arranged between the side vertical plates. Bolt holes are formed in the flat bottom plate. Positioning pins are fixedly arranged below the flat bottom plate. Intervals between the bolt holes and the positioning pins are completely consistent with those between bolt holes in the steel truss girder rod piece respectively. A lifting hole is formed in the upper part of the transverse clamping plate. When the lifting device is used, two special lifting devices are lifted to the two ends of the steel truss girder rod piece through a crane, fixing bolts are inserted into the bolt holes of the special lifting devices and the steel truss girder rod piece for fixation after the lifting devices are positioned respectively, the steel truss girder rod piece is lifted to a designed mounting position through the crane, and the fixing bolts are disassembled. According to the special lifting device, loosening and sliding in a lifting process can be avoided, secondary pollution to the rod piece can be avoided, the special lifting device is short in lifting time, high in reliability, easy to operate, high in construction speed, short in construction period and low in cost, and can be used for lifting steel truss girder rod pieces with different specifications, and a few matched operators are required.

Owner:中铁二十一局集团路桥工程有限公司

Engineering pile foundation static load detection resistance anchor hoe

ActiveCN105350587ASolve the limited numberAddress insecurityFoundation testingArchitectural engineeringResistance force

An engineering pile foundation static load detection resistance anchor hoe is characterized by comprising a supporting seat, a resistance rod plate, a shaft falling-off device and a hanging ring. A supporting shaft is arranged on the supporting seat, and the resistance rod plate is connected with the supporting seat through the supporting shaft and can do circumferential rotation along the supporting shaft; the shaft falling-off device is arranged on the upper portion of the supporting seat and is connected with the supporting seat, and the hanging ring is arranged in the middle position of the top of the supporting seat; and a recycling device is arranged at the bottom of the supporting seat. The engineering pile foundation static load detection resistance anchor hoe has the beneficial effects that the hoe is reasonable in structural design, easy and convenient to operate and low in equipment manufacturing, maintaining and implementing cost; the detection site is easy to assemble and disassemble; and after the test is finished, recycling is convenient, and the working efficiency and the safety of an engineering pile foundation static load detection test can be obviously improved.

Owner:陆剑

Method and system for intelligent hoisting of prefabricated buildings based on machine vision

ActiveCN106966298BImprove hoisting efficiencyImprove accuracyImage enhancementImage analysisImaging processingMachine vision

The present invention discloses the machine vision -based prefabricated building intelligent hanging method and system. This system includes image acquisition modules, image processing and decision -making modules, and device control modules, image processing and decision -making modules and image acquisition modules, device control modules and imagesProcessing and decision -making module communication.The present invention uses machine vision to replace the dependence on human vision during the prefabricated building lifting process.Use machine vision to identify obstacles in complex assembly scenarios through convolutional neural network+two -type fuzzy neural network deep learning model.EssenceThe present invention uses the camera to replace people's eyes from complex scenes to obtain the best solution, which can better plan the path of prefabricated pieces, greatly improve the hanging efficiency and accuracy of the prefabricated buildings, realize the intelligentization of assembly building hanging, intelligentization, Improve the disadvantages of artificial lifting.

Owner:日照安泰科技发展有限公司

A method of relay hoisting gas cooler

The invention discloses a relay hoisting method for a gas cooler. The method comprises the following steps: S1, preparation for construction; S2, settings of a hoisting point, a winch and a pulley block; S3, hoisting of a gas cooler; and S4, recovery of a steel-constructed platform. According to the technical scheme, requirements on the structure of original factory buildings are low; large area of the steel structure is not demolished; and mechanical use is less. Requirements on machinery, cooperation, steel structure welding and the like are high. For an integral hoisting, efficiency is relatively high; investment is saved; actual hoisting time is short; and practicality is strong.

Owner:CHINA MCC17 GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com