Installation method of large-span steel trusses

An installation method and technology of steel trusses, which are applied in construction, building structure, and construction material processing, etc., can solve the problems of insufficient steel truss assembly progress, accuracy, safety, etc. on the site, so as to save the cost of mechanical shifts and the installation progress Fast, quality controllable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

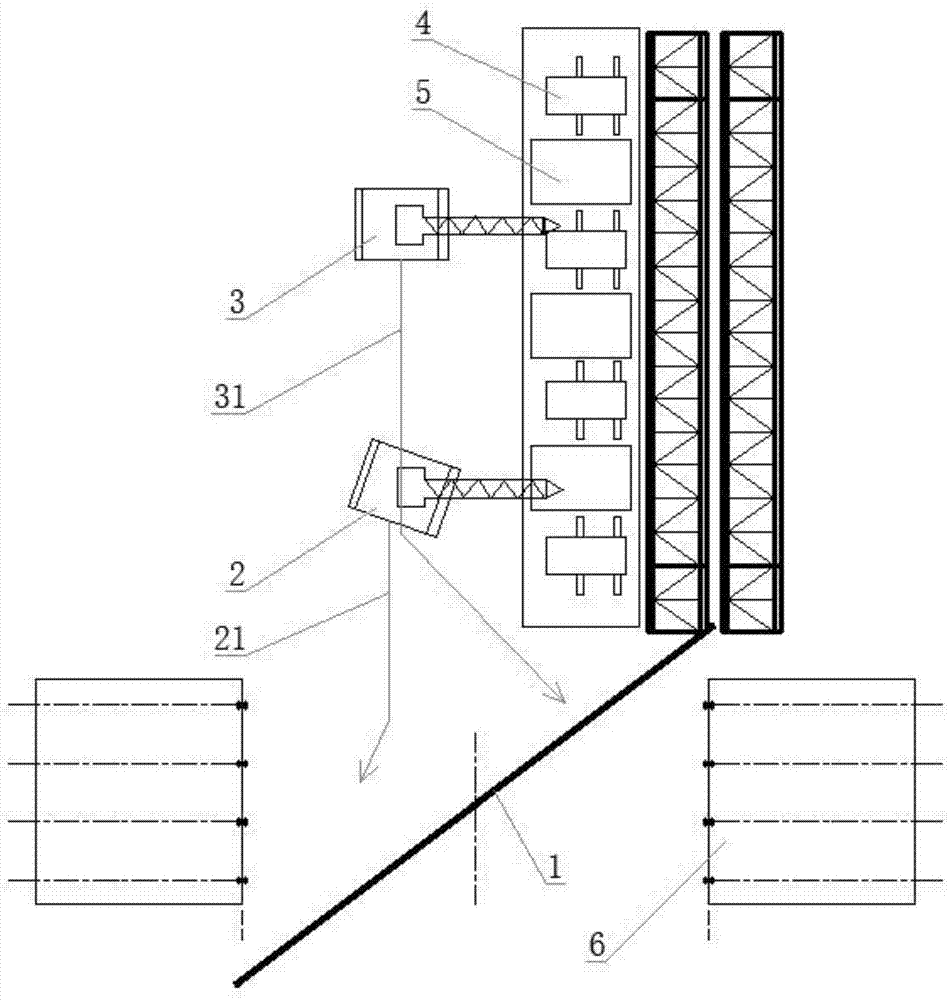

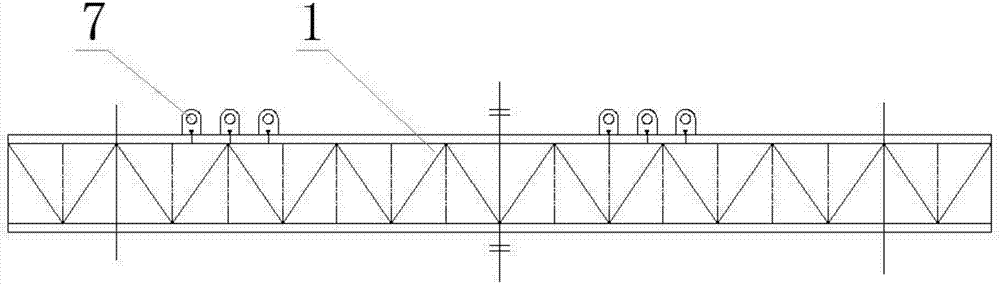

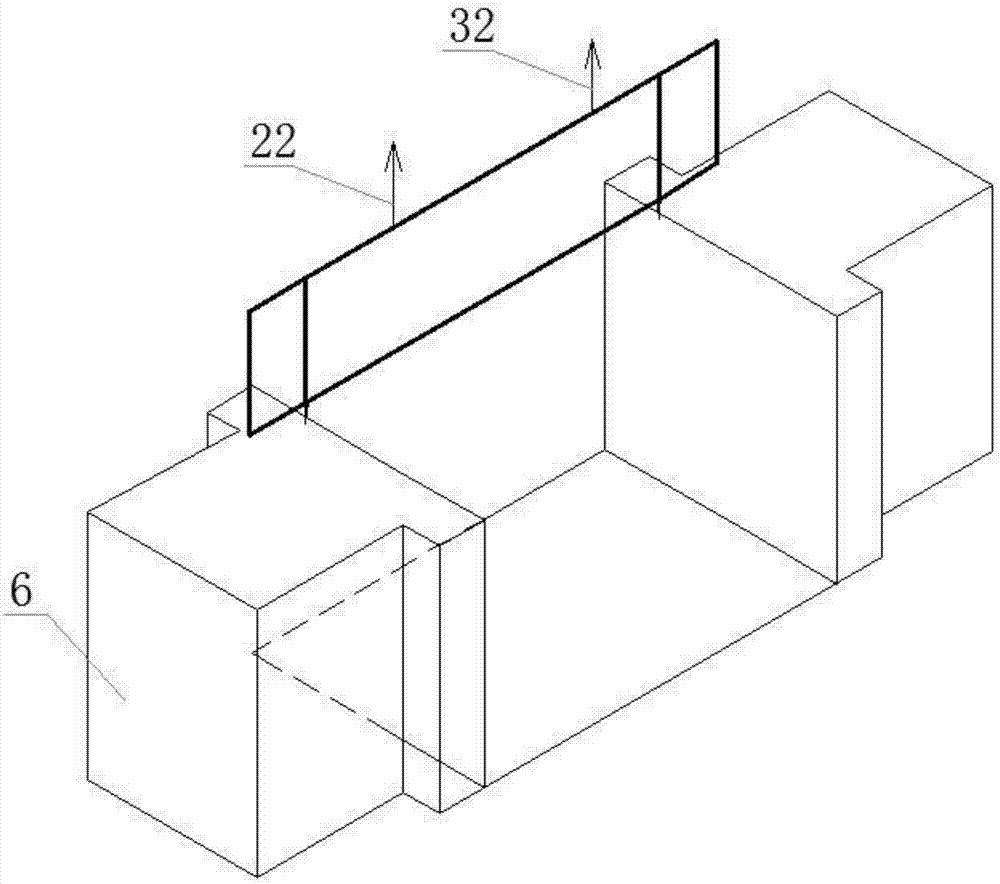

[0059] like Figure 1 to Figure 3 As shown, the crane station area 4 and the component stacking area 5 are located on the same side of the building 6, and the two cranes are respectively the first crane 2 and the second crane 3, and the first crane travel route 21 and the second crane travel route 32 are shown in the figure shown. The installation method of long-span steel truss 1 includes the following steps:

[0060]Step 1: Preparations

[0061] A1. Retest the elevation and center line of the steel column at the supporting point twice, and fine-tune until it meets the installation requirements of the large-span steel truss 1;

[0062] A2. The assembly site is cleaned, leveled, and compacted. The horse stool is finished, placed in place, and the level and elevation of the top of the horse stool are adjusted;

[0063] A3. The hoisting ground site is cleaned up, the crane walkway is backfilled in layers, compacted and accepted;

[0064] A4. The steel truss 1 has been manufa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com