Large wall thickness foundation sinking method by combining diversion and negative pressure technology

A combined and basic technology, applied in the field of foundation sinking with large wall thickness, can solve the problems of large resistance and the inability to effectively sink the structure in place, so as to increase the installation speed, avoid the interference of environmental conditions, and simplify the sinking process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

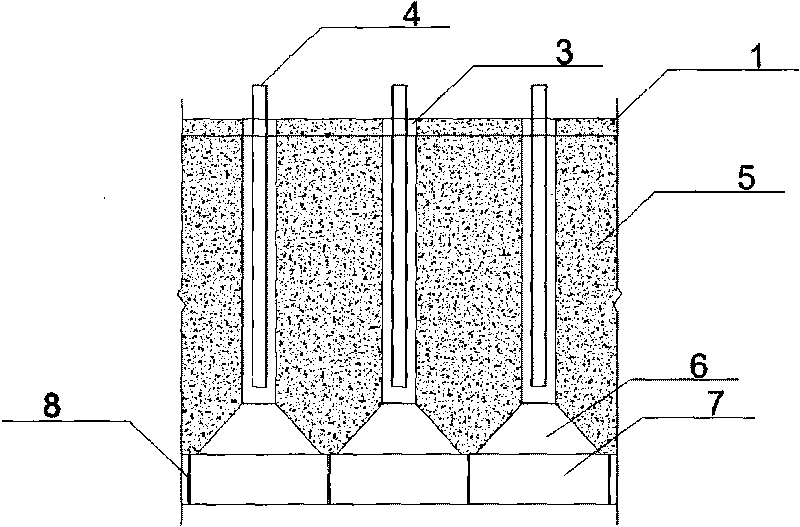

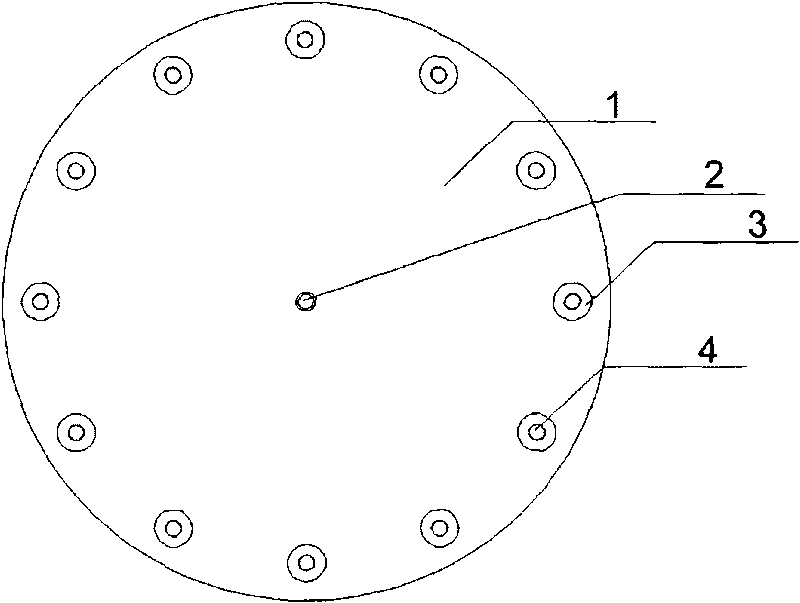

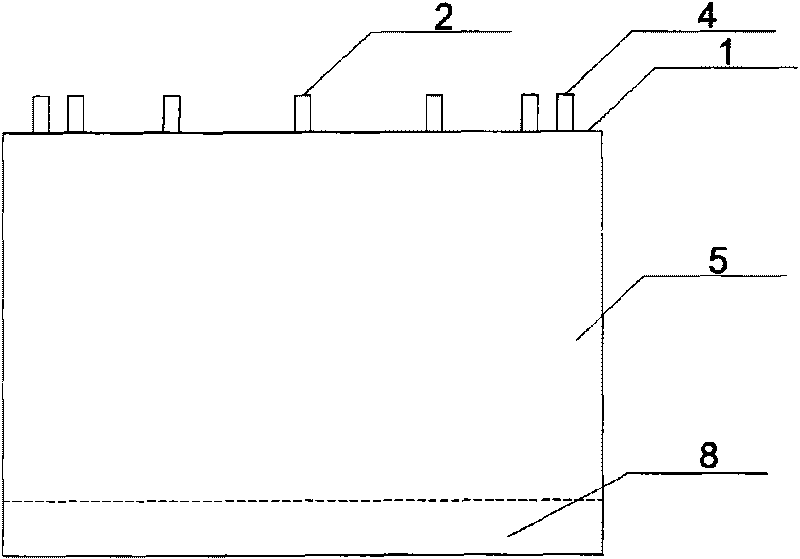

[0015] An embodiment of the present invention is as follows: a concrete cylindrical foundation with a diameter of 35m and a height of 15m, the thickness of the foundation wall 5 is 0.5m, and 12 vertical holes with a diameter of 0.3m are arranged at equal intervals along the perimeter on the foundation wall 5, that is, suction The mud pipe 3 and the air supply pipe and / or water supply pipe 4 (also known as the diversion pipe) with a diameter of 5 cm are placed in the middle of the mud suction pipe 3, and the hole of the mud suction pipe 3 is tapered to expand to a height at the bottom of the foundation wall 5 It is a cone cavity 6 of 0.5m, and a loose soil cavity 7 with a height of 0.5m formed by a partition plate 8 is connected below the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com