Hydraulic bracket assembling machine

A technology of hydraulic support and installation machine, which is applied in the direction of mine roof supports, pillars/supports, mining equipment, etc., which can solve the problems of time-consuming and laborious, difficult adjustment of supports, and high labor intensity of workers, so as to reduce labor intensity and save installation time , The effect of improving the mechanization level of fully mechanized mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

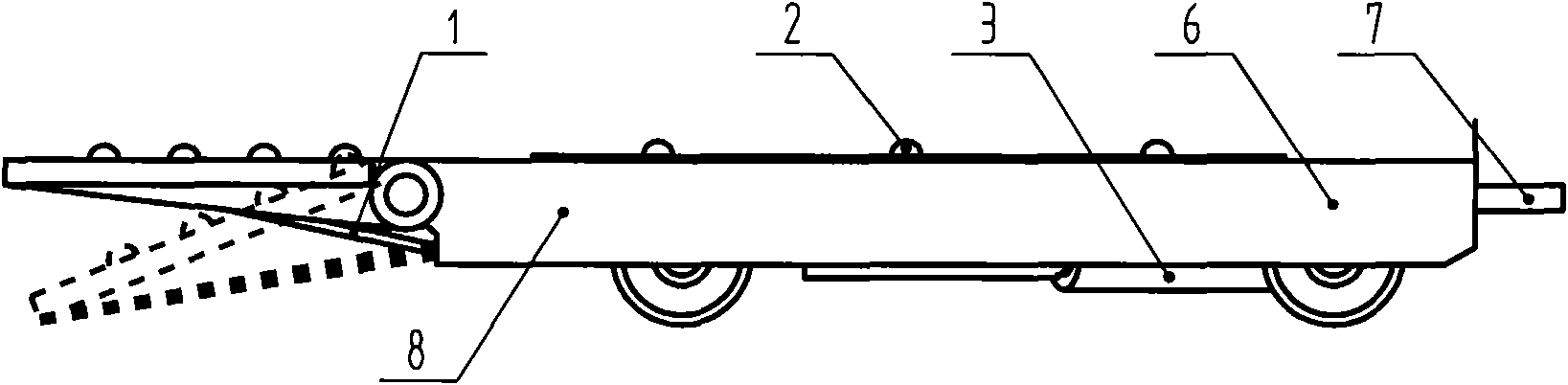

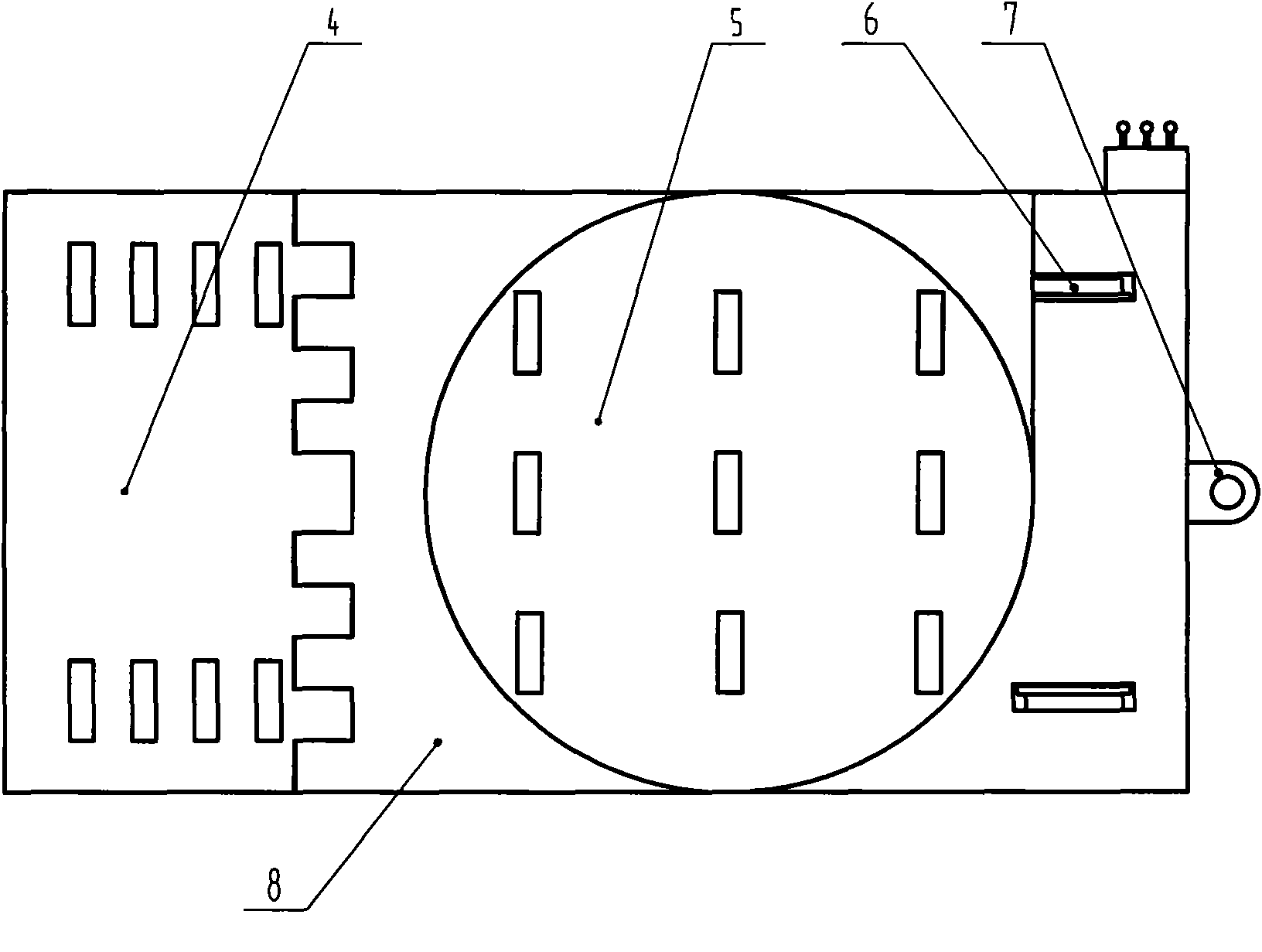

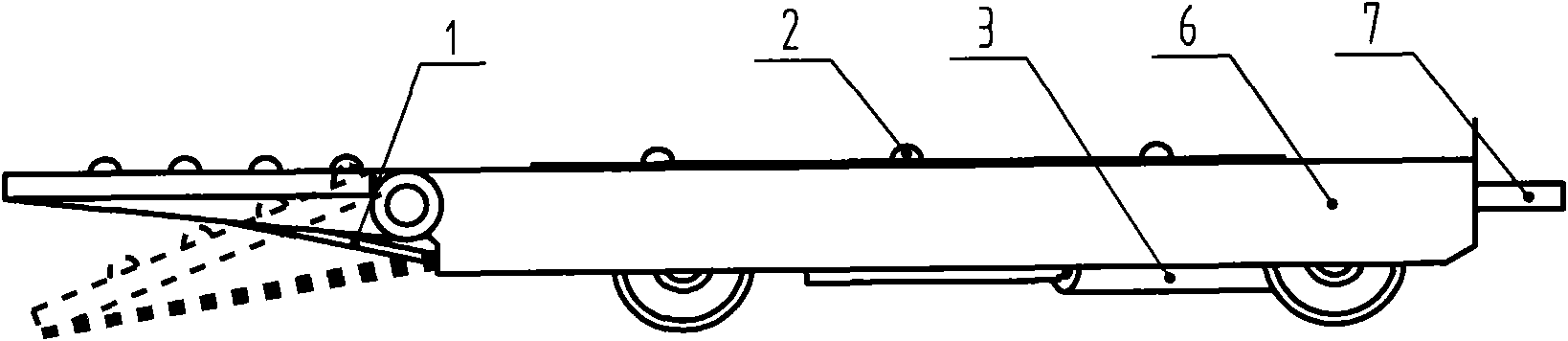

[0014] Such as figure 1 , figure 2 As shown, the structure of the hydraulic support installation machine is as follows: the pull ring 7 is fixed on one end of the car body 8; the other end of the car body 8 is hinged with a lifting plate 4; The cylinder block is installed on the car body 8 below the lifting plate 4, and the piston rod is connected to the bottom of the lifting plate 4;

[0015] Turntable 5 is positioned at car body 8 middle parts, and the cylinder block of rotary oil cylinder 3 is installed in car body 8 bottoms, and the piston rod end of rotary oil cylinder 3 connects the bottom of turntable 5 by crank; 4 pulleys 6 are installed in car body 8 bottoms. A plurality of rollers 2 are installed on the turntable 5 .

[0016] The car body 8 one ends of hydraulic support installation machine are provided with draw ring 7, and the bottom of car body 8 is provided with 4 pulleys 6, during use, winch pulls hydraulic support installer by draw ring 7 and moves on track....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com