A cab hydraulic lifting device

A lifting device and cab technology, applied to pump devices, parts of pumping devices for elastic fluids, transportation and packaging, etc., can solve the problems that the system cannot be turned over to provide hydraulic kinetic energy, and the electric pump loses its working function. To achieve the effect of compact structure, large lifting force and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

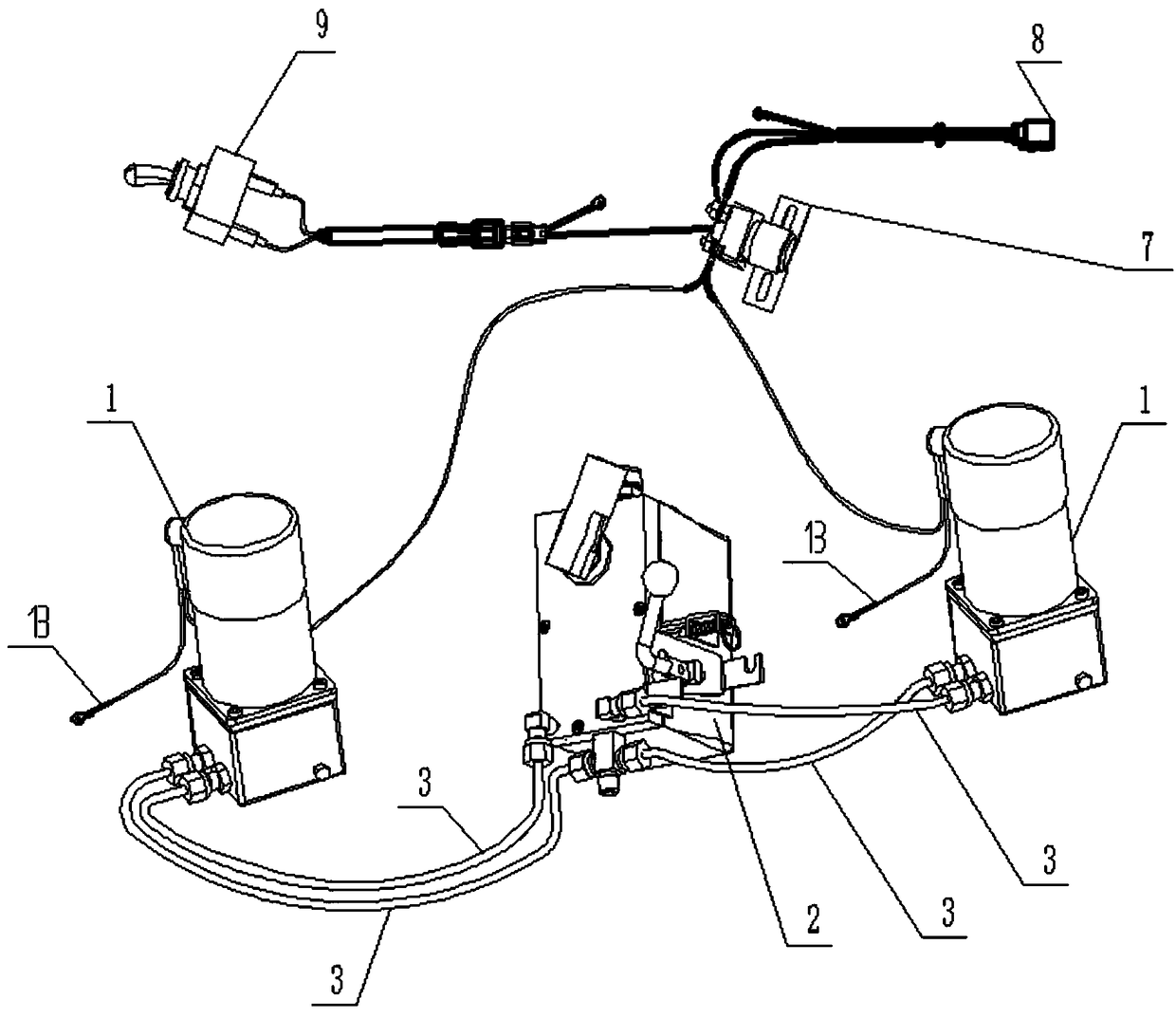

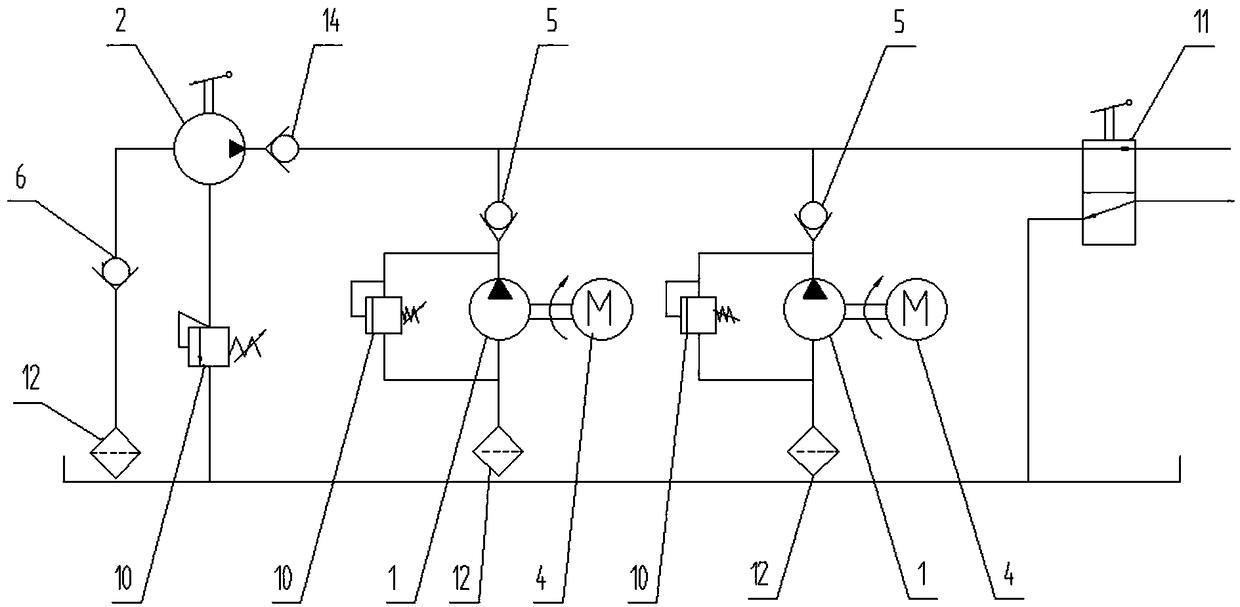

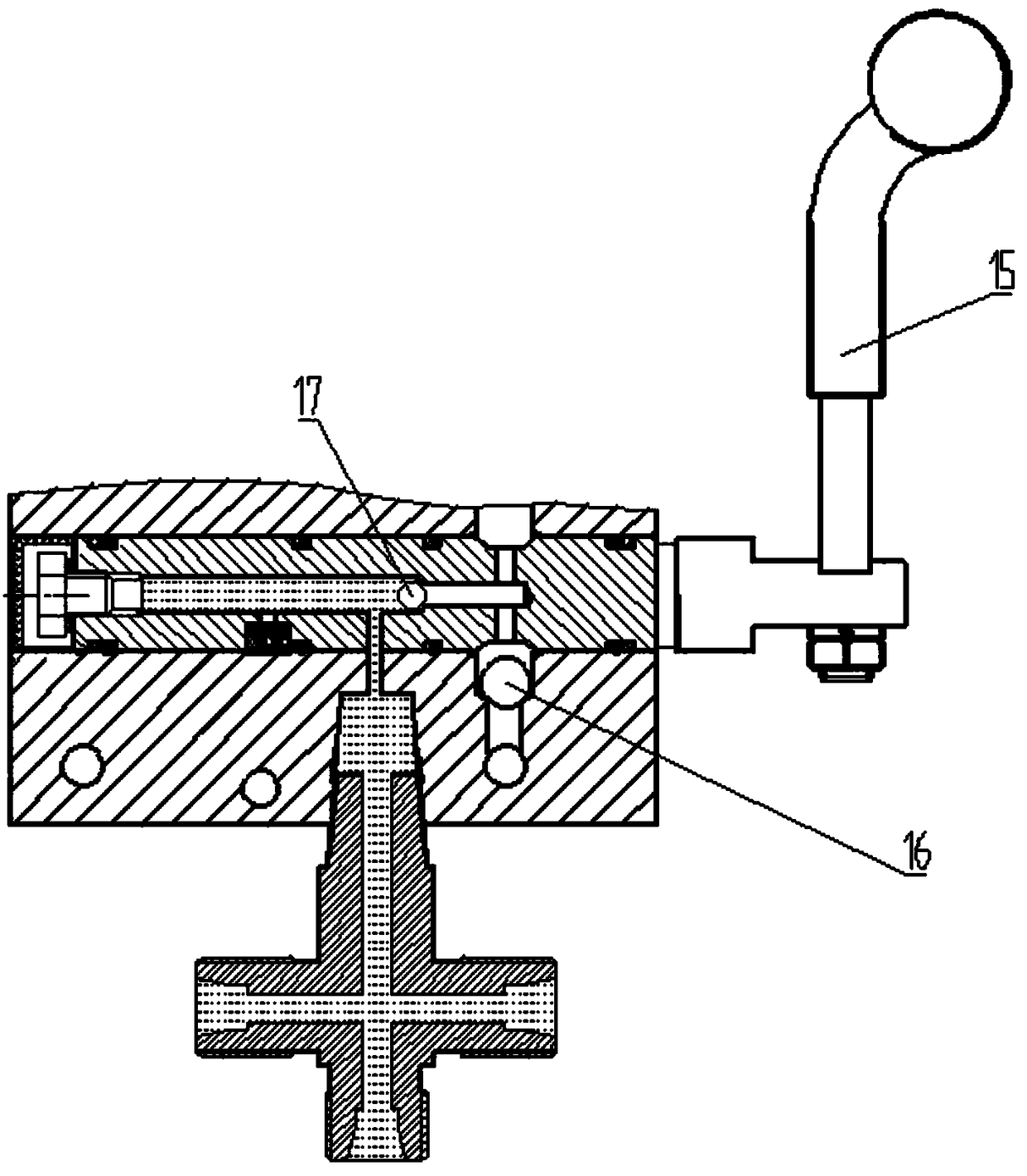

[0016] A cab hydraulic lifting device, such as figure 1 , figure 2 As shown, it includes two parallel electric pumps 1 and a manual pump 2 connected in series with each electric pump 1, which greatly reduces the hydraulic pulsation of the system, makes the actuator run more smoothly, and has a larger flow rate, thereby greatly shortening the turning time of the cab and saving energy. The time required for cab overturning maintenance is reduced, and the work efficiency is improved. The electric pump 1 and the manual pump 2 are connected by the oil pipe 3. The oil pipe 3 is made of stainless steel pipe, which is easy to form and is suitable for making pipelines of different shapes. Weather resistance Strong, strong rust resistance, high strength, high fatigue resistance, the electric pump 1 is equipped with a motor 4 connected to the electric pump 1, the motor adopts 24V voltage, permanent magnet DC motor, low noise, waterproof and dustproof, high speed belt Overheat protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com