Patents

Literature

471results about How to "Lifting speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jack of quick lift

The invention discloses a jack of quick lift, consisting of a driving device and a hoisting device. The jack is characterized in that: one end of a screw is provided with a quick lift device. When in use, the jack is put under an object to be jacked up; if the upper plane of the jack is comparatively far from the object to be jacked up, a flexible sleeve can be drawn quickly to drive the screw to be drawn out, and consequently, the top of the jack touches the object to be jacked up quickly; then a locating sleeve is rotated to lead an inner hole boss of a grip end to enter a circular tooth socket of the locating sleeve and be automatically locked and positioned; and subsequently a ratchet spanner is rotated to cause the screw to rotate to jack up the object. When in descending, reverse operation is conducted to cause load to be removed from the jack; and then the flexible sleeve is retracted in the grip to reset the jack. Proved by use, the jack-up operation of the jack is quick and saves time, the working efficiency is improved by more than 2 times, and the jack is safe, reliable, light in weight and convenient in use.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

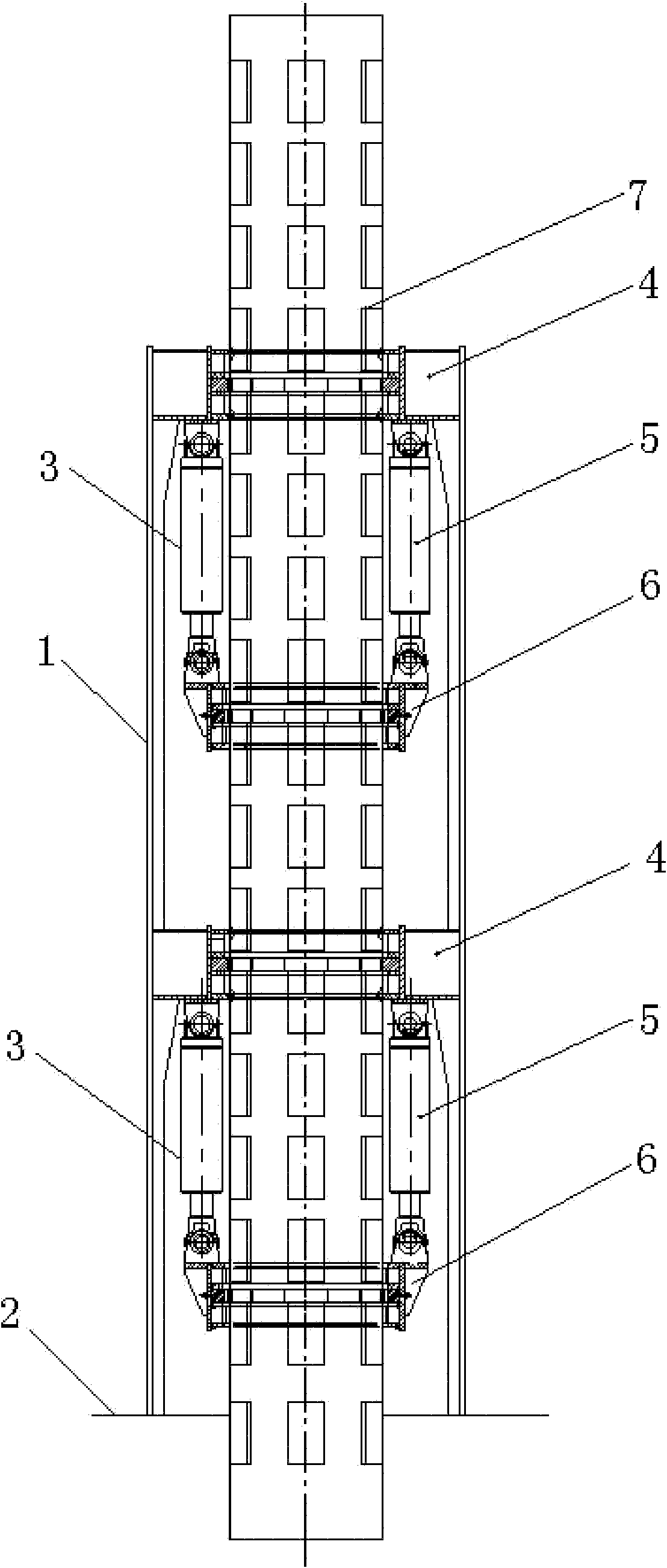

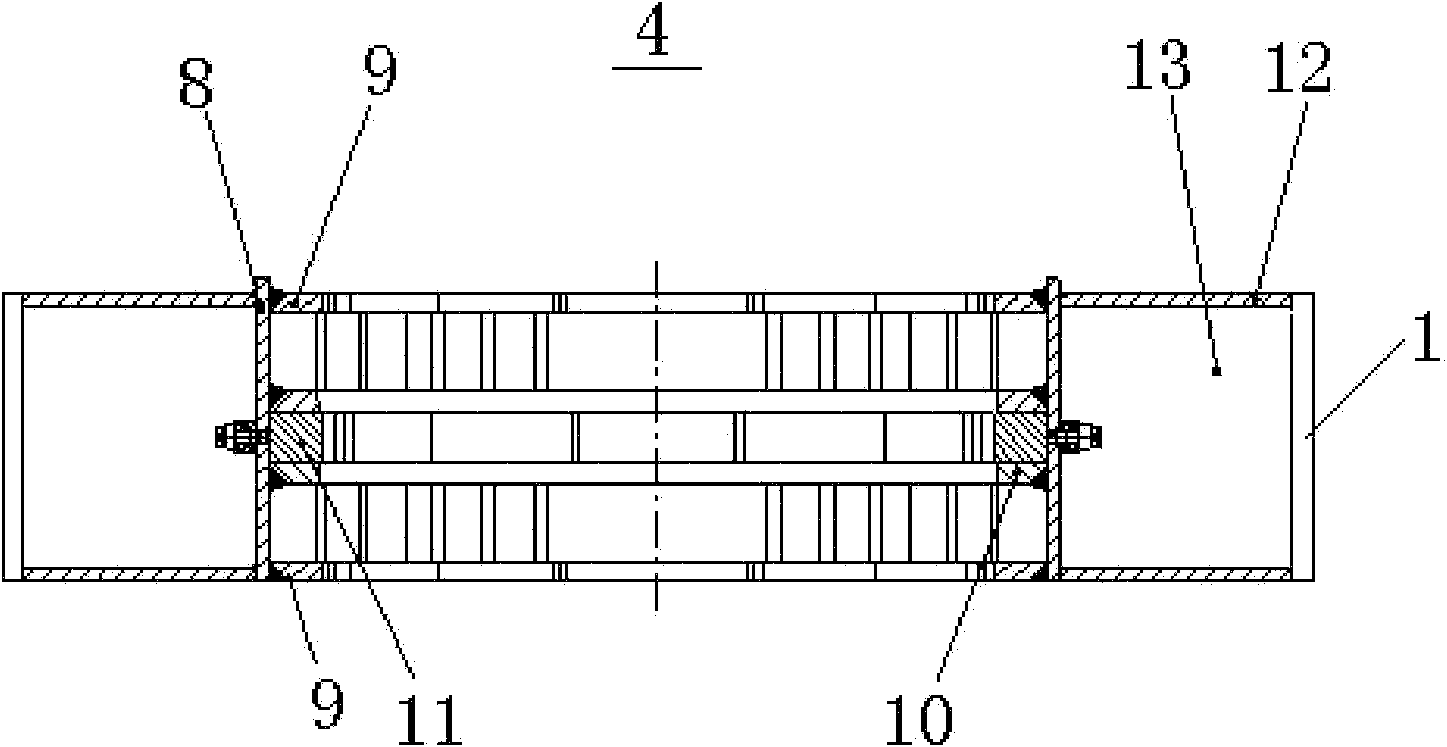

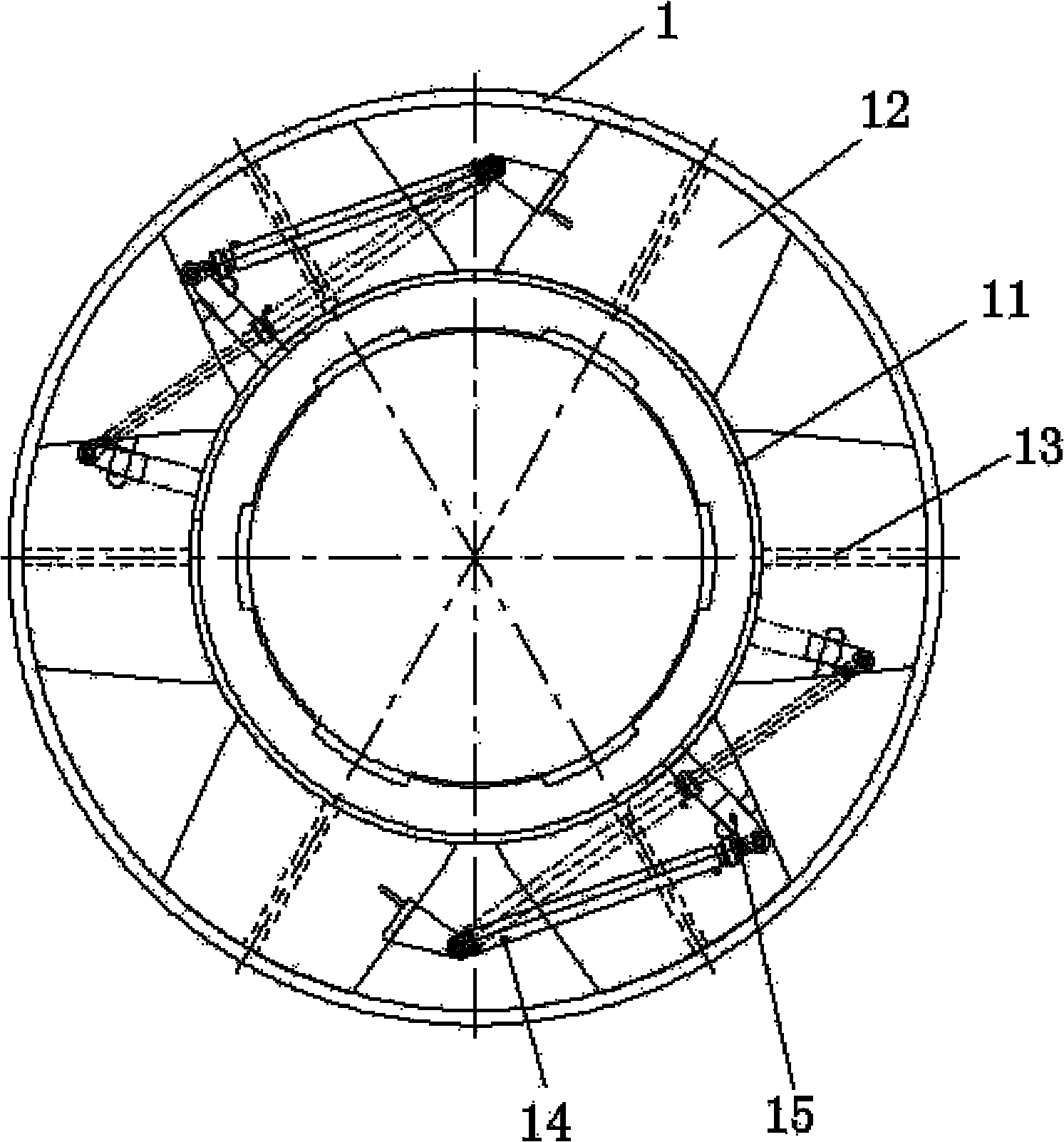

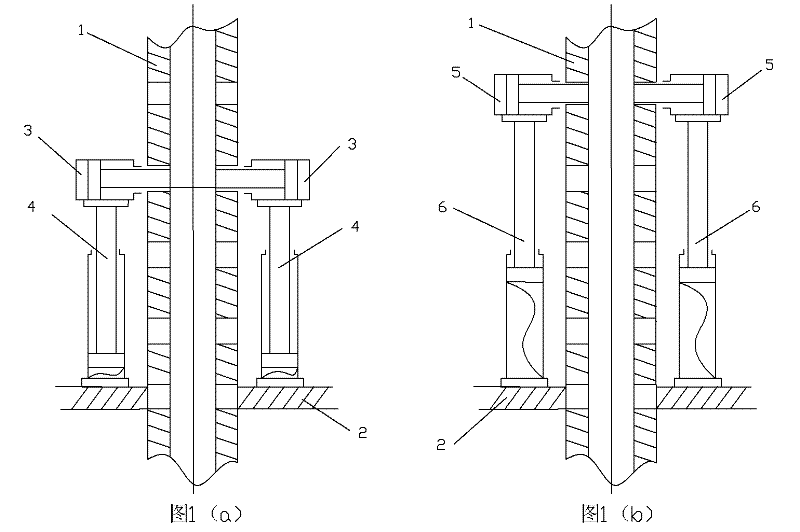

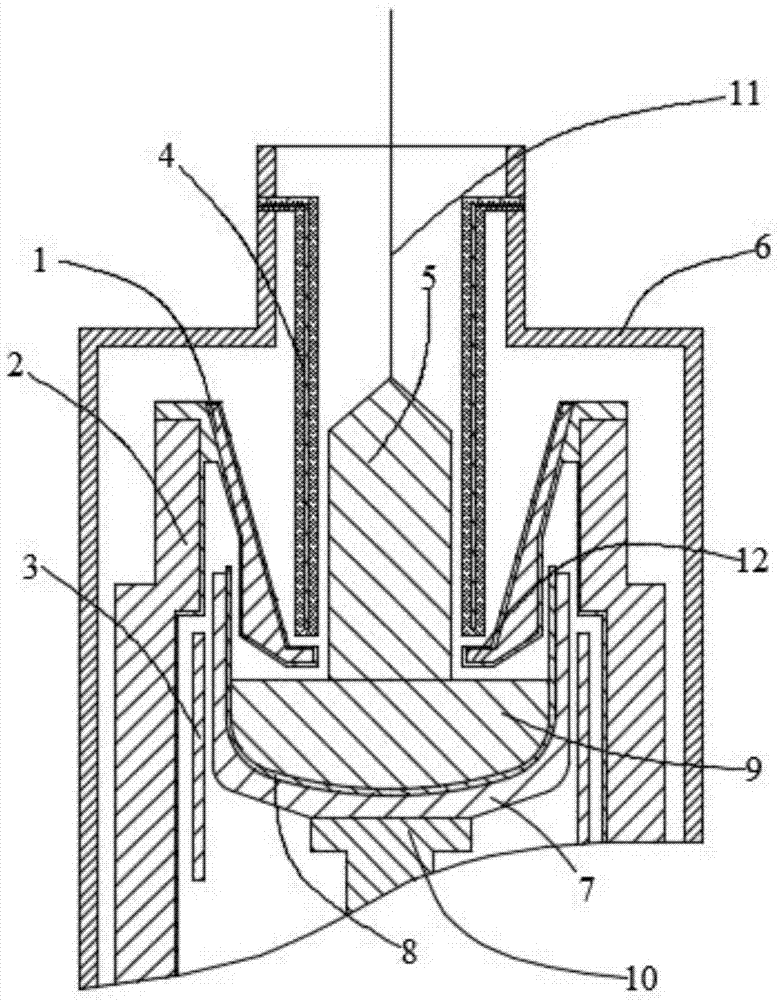

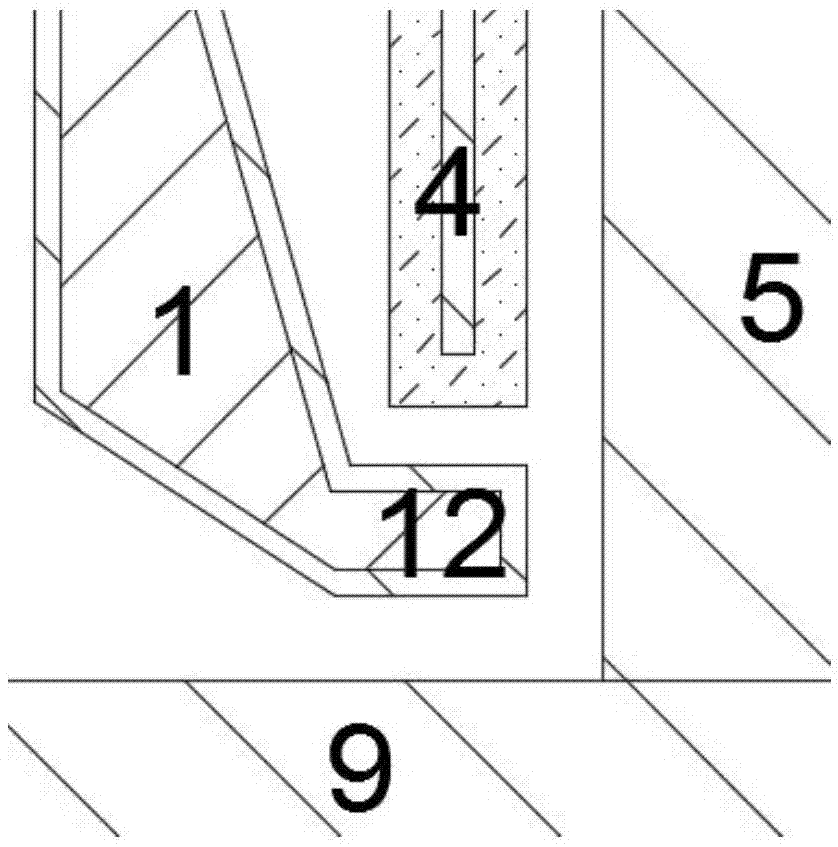

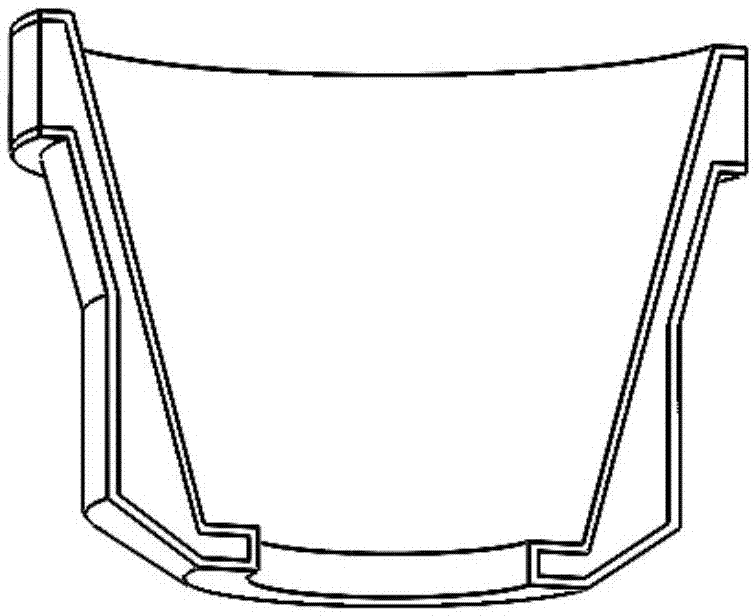

Continuous stepping hydraulic lifting device and method

ActiveCN102162233ARealize continuous step-by-step liftingShorten the timeArtificial islandsUnderwater structuresStructural engineering

The invention relates to a continuous stepping hydraulic lifting device and method. The continuous stepping hydraulic lifting device comprises a pile fixing cylinder integrated with a platform, wherein, the pile fixing cylinder is internally and symmetrically equipped with an upper lifting device and a lower lifting device; each lifting device comprises an upper pile clamping device for locking and loosening legs inserted into the pile fixing cylinder; the upper pile clamping device is welded on the inner wall of the pile fixing cylinder, and the bottom end of the upper pile clamping device is connected with a lifting oil cylinder; the bottom end of the lifting oil cylinder is connected with a lower pile clamping device for locking and loosening the legs; and the lifting oil cylinder is connected with a hydraulic system. The continuous stepping hydraulic lifting device has the advantages of simple and artful structure, capability of realizing continuous stepping lifting operation and fast lifting speed, and is convenient in operation, thus the device can be widely applied to an ocean self-elevating platform.

Owner:CHINA NAT OFFSHORE OIL CORP +1

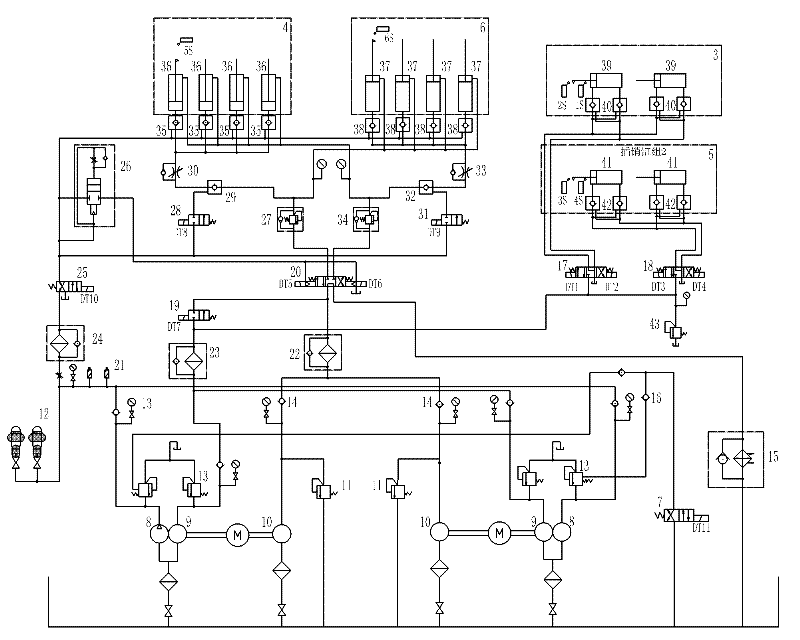

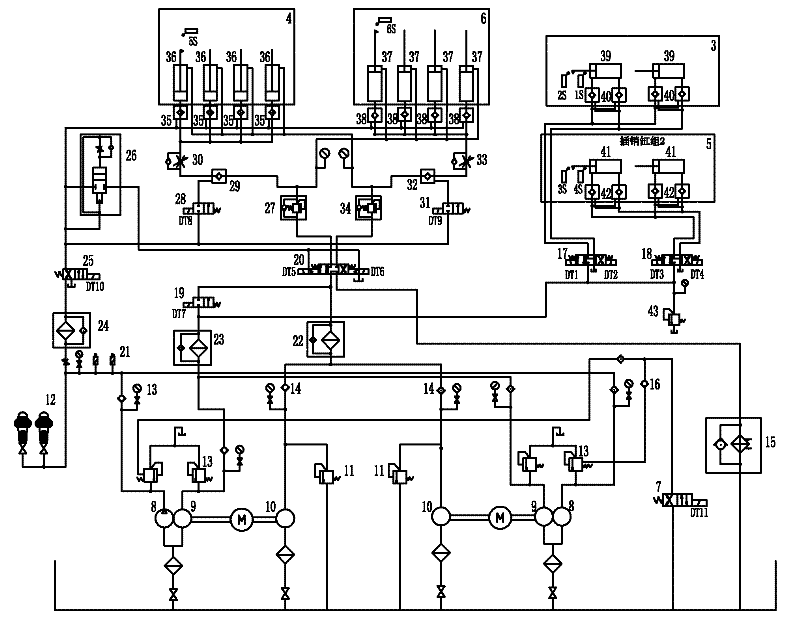

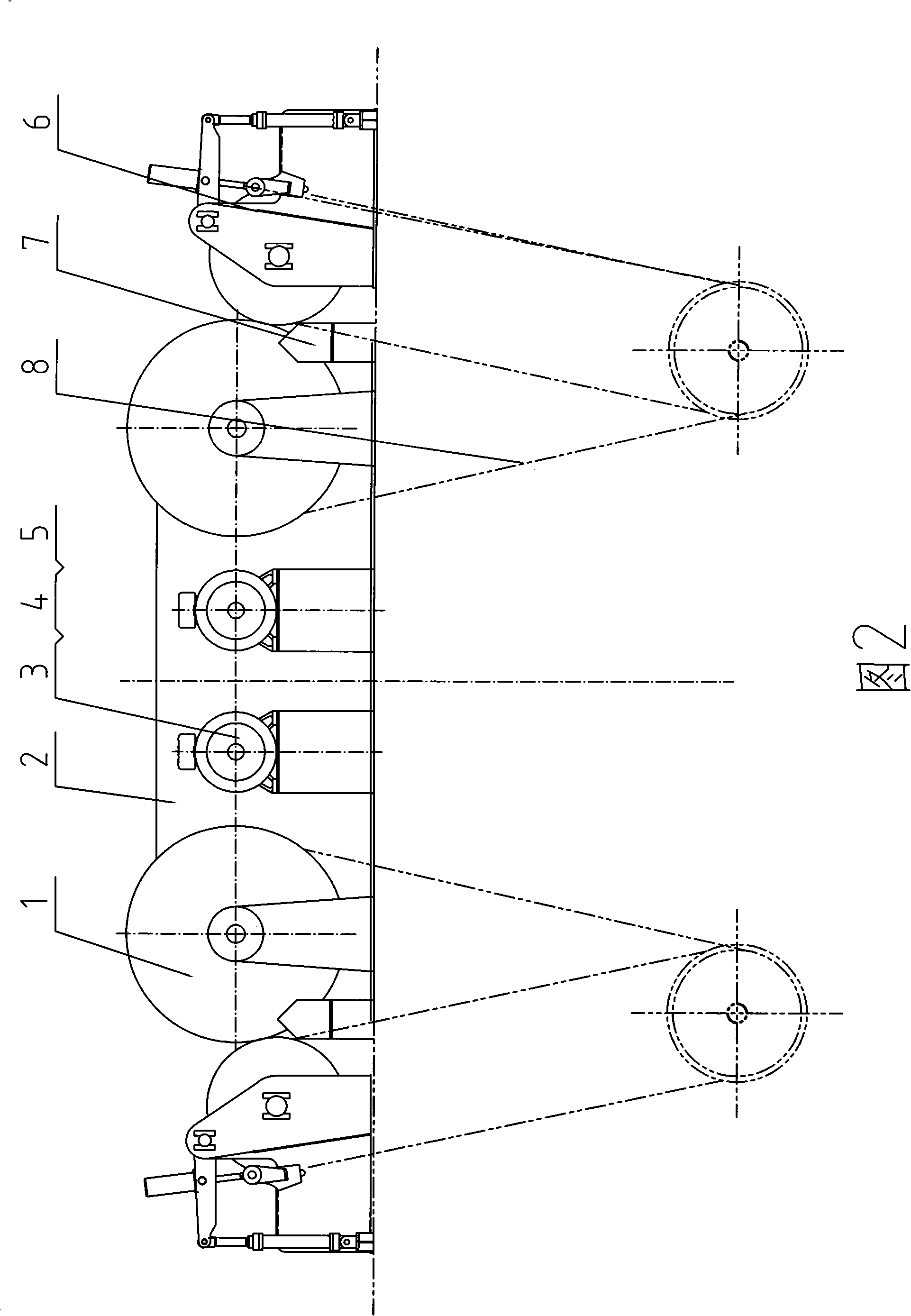

Hydraulic system applied to multi-spud leg lifting mechanism

InactiveCN102241371ALifting speed is fastHigh transmission efficiencyArtificial islandsUnderwater structuresElectro hydraulicEngineering

Owner:WUHAN UNIV OF TECH

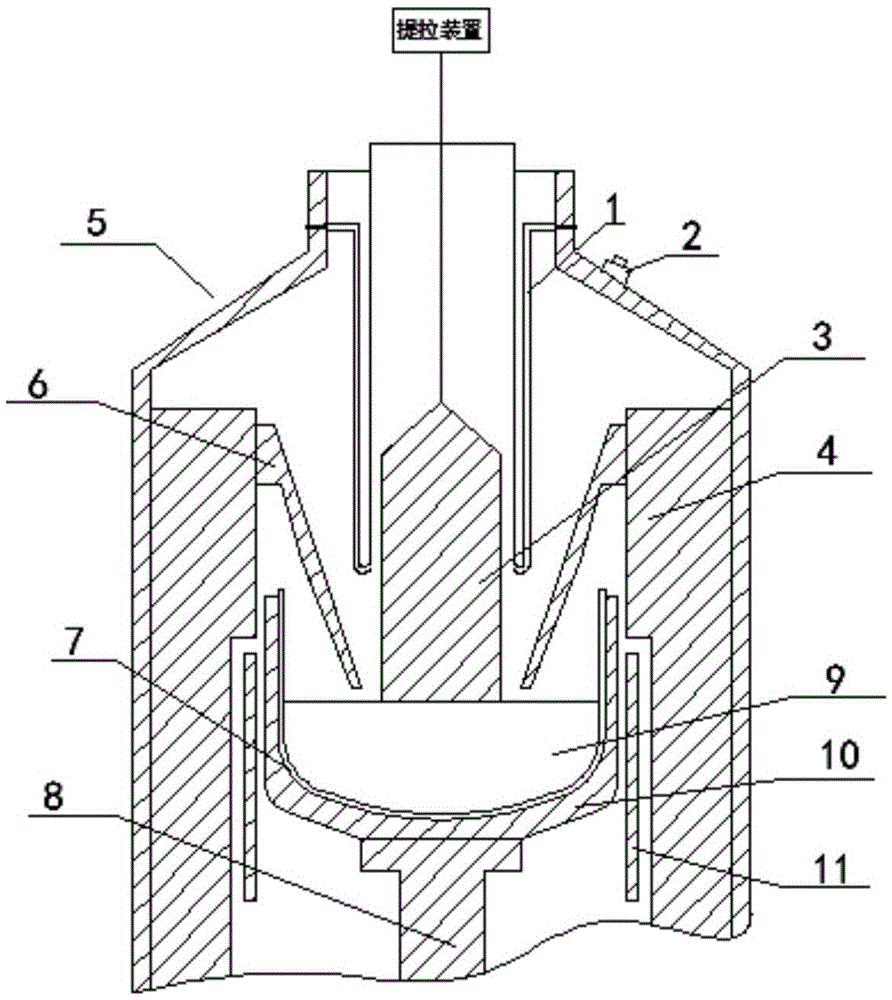

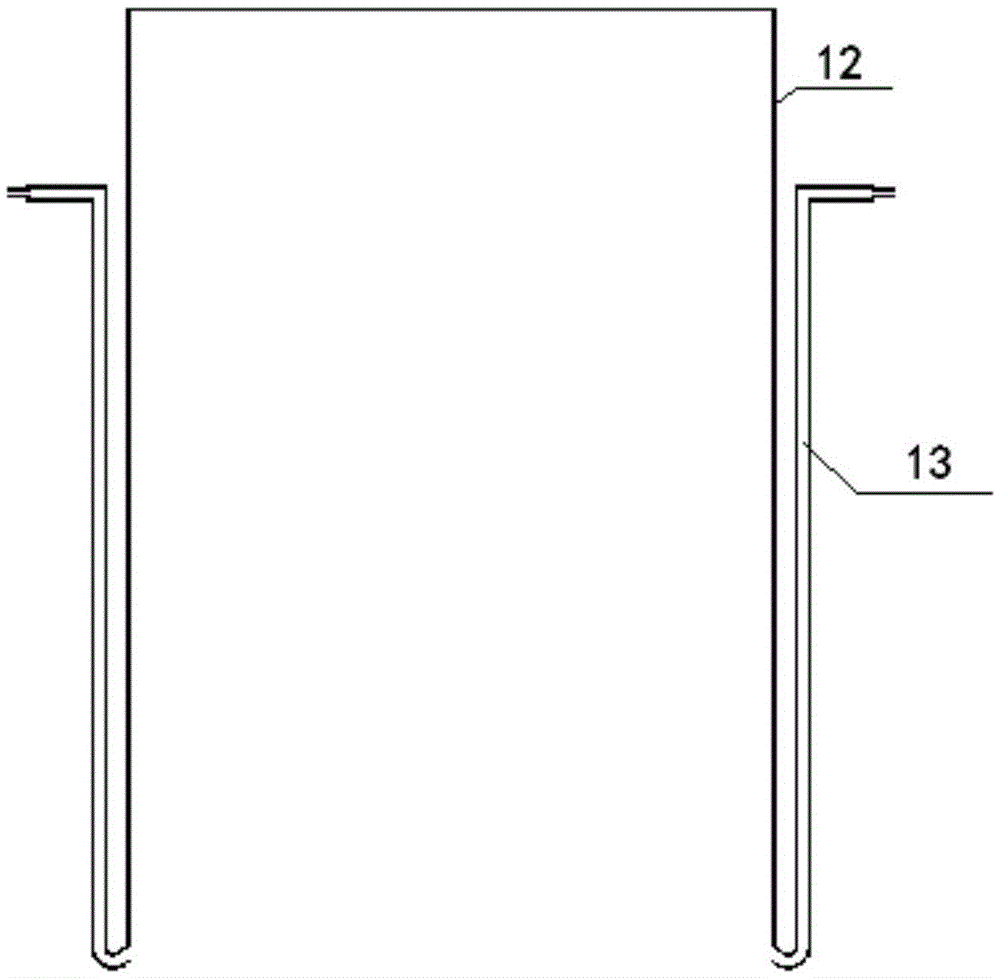

High-speed single crystal growth device

InactiveCN105442037AImprove cooling effectReduce heat dissipationPolycrystalline material growthBy pulling from meltHeat flowTriple point

The invention discloses a high-speed single crystal growth device which is characterized in that a guide cylinder is arranged above a crucible and the shape of the guide cylinder near a triple point is specially designed so as to control the direction of heat flow above a solidification interface; and a water jacket is arranged in the guide cylinder so as to reinforce the heat transfer of the crystal side. By designing the guide cylinder structure, the length of the water jacket extends to be near a solid-liquid interface. Compared with the conventional water jacket design, the heat dissipation capacity of the crystal side can be intensified greatly, and the crystal pulling speed is improved. The technical shortcoming that since the water jacket is too close to the solid-liquid interface, so that the concavity of the solid-liquid interface is increased is overcome, the flat solid-liquid interface shape can be achieved in the whole crystal pulling process, and the value of thermal stress in the crystal is controlled at a low level. Therefore, the high-speed single crystal growth device is favorable for quickly pulling high-quality single crystal.

Owner:XI AN JIAOTONG UNIV

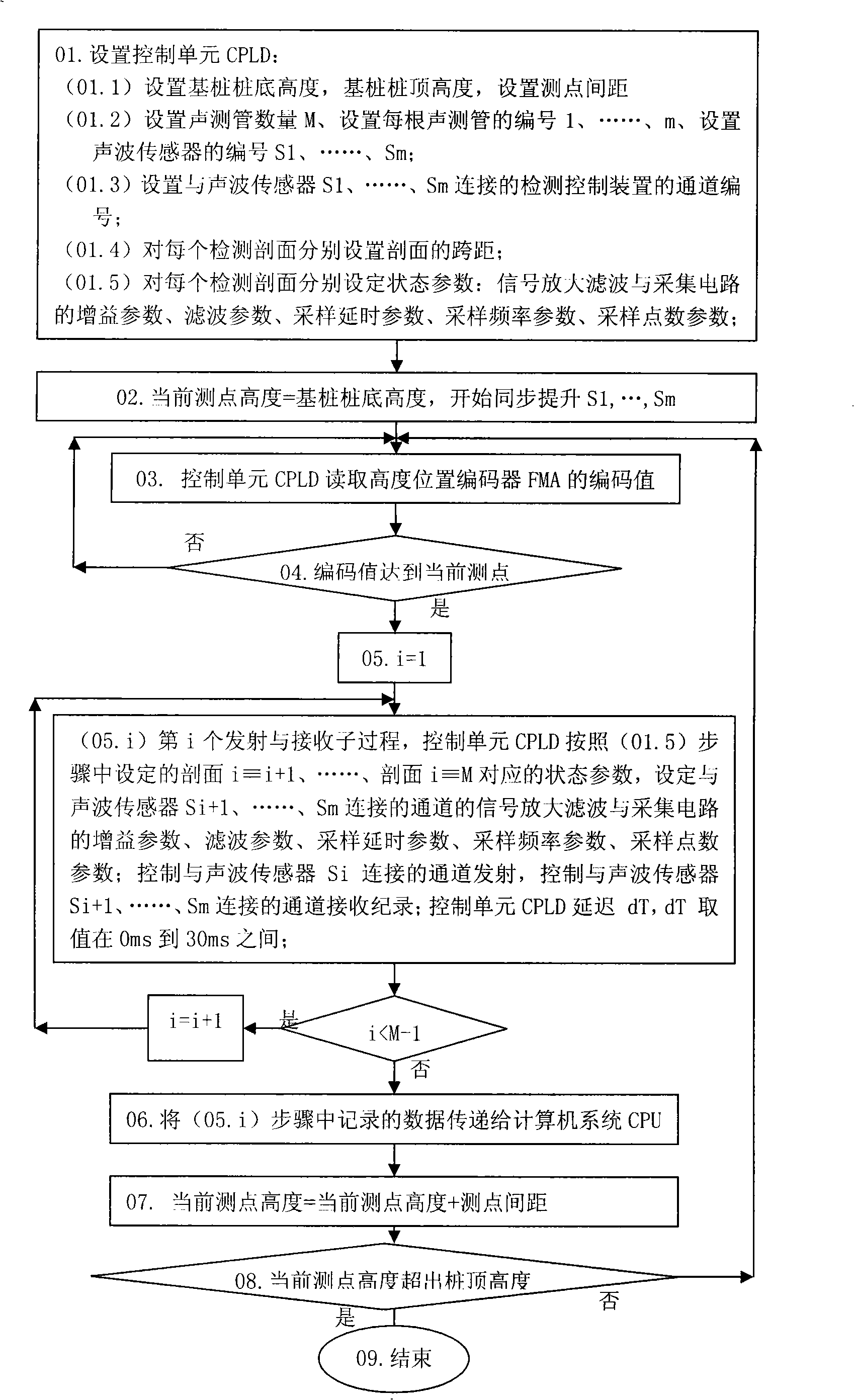

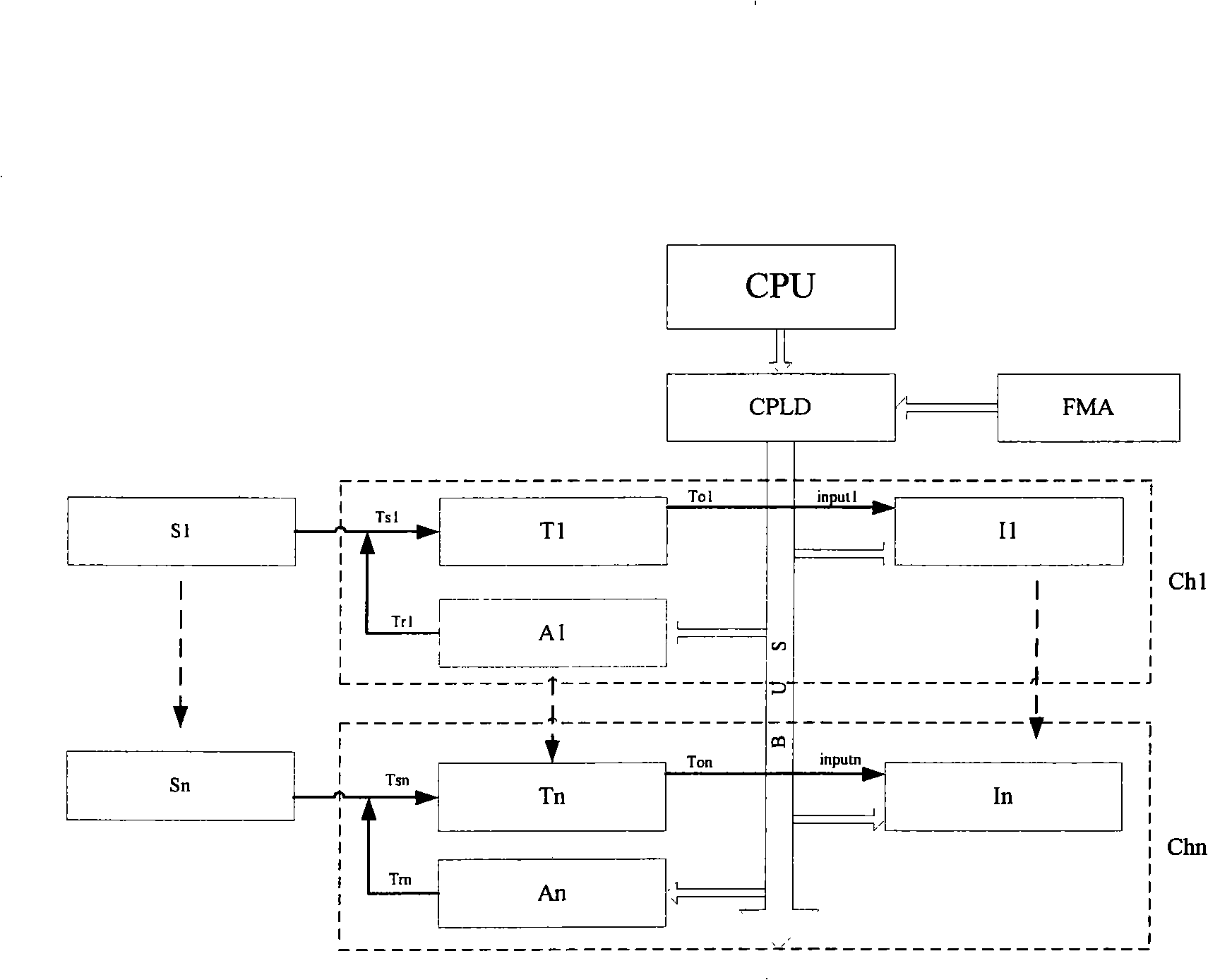

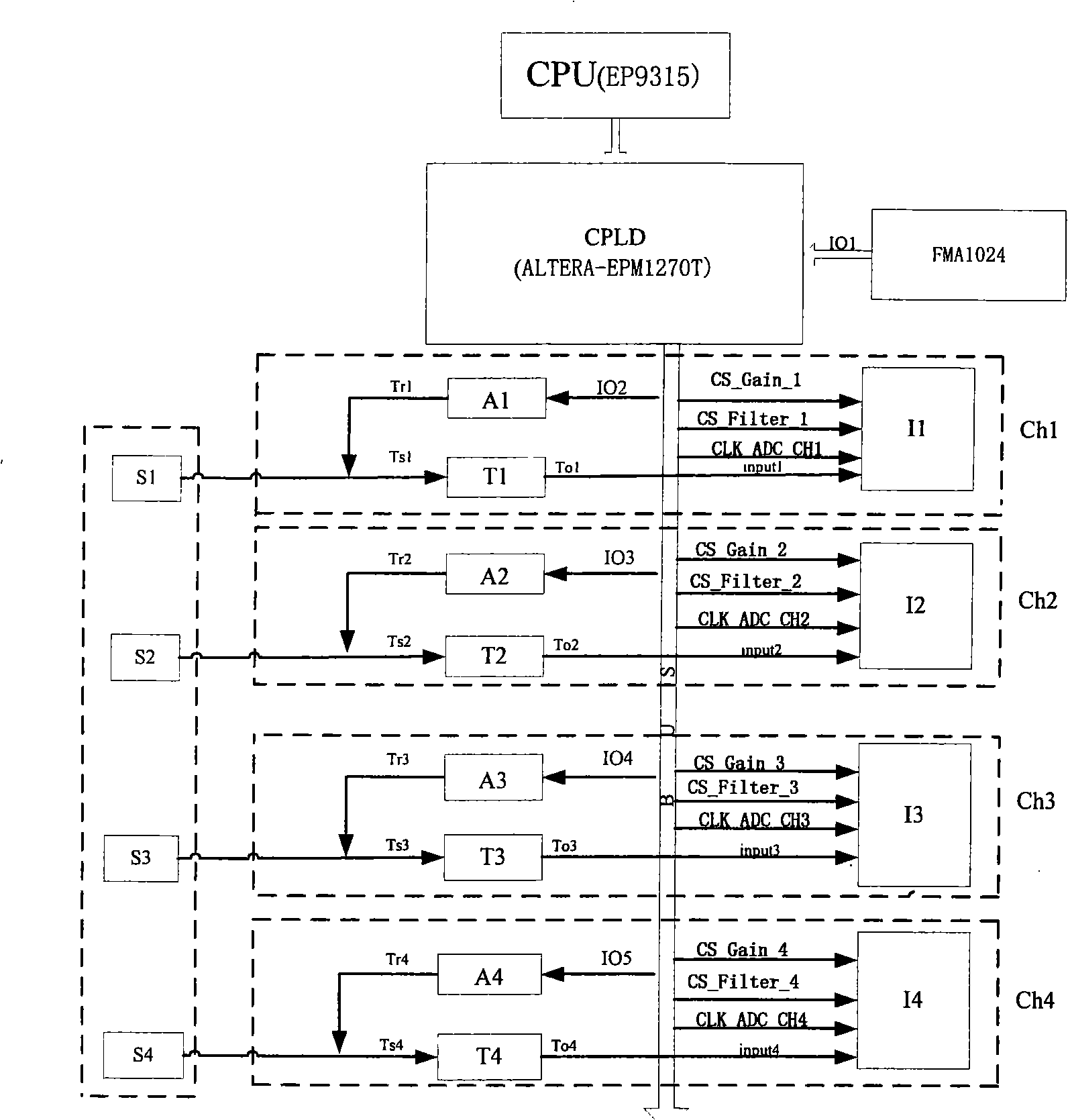

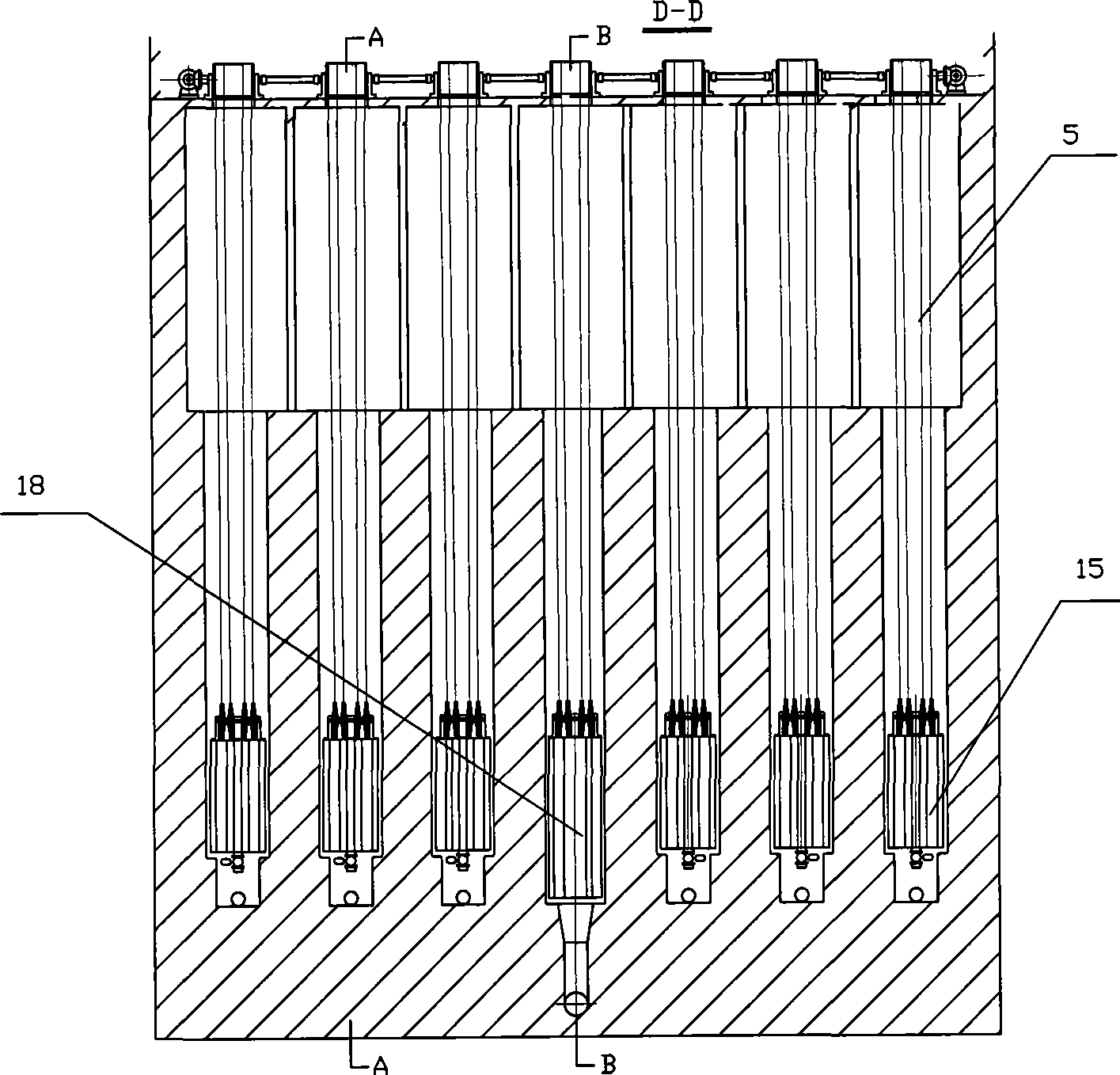

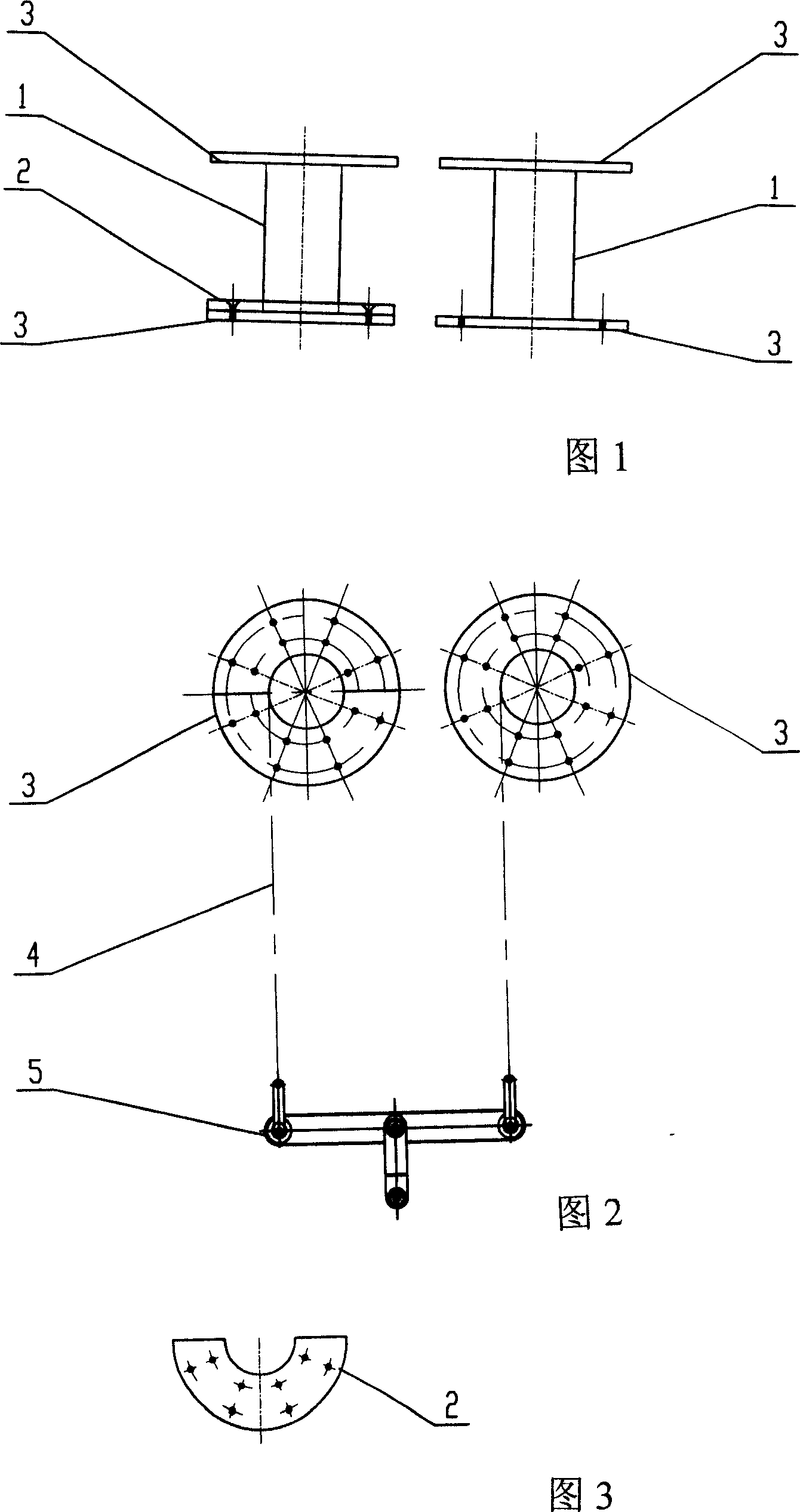

Sound wave detection control method and device

InactiveCN101270584AReduce in quantityImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesFoundation testingSection planeComputerized system

The invention discloses a sound wave detecting control method and device. The steps include: A, setting a control unit; B, setting a height of the current detecting point and beginning to synchronously lift wave sound sensors; C, reading the height positions of the wave sound sensors S1, Sm; D returning to the step C if the height position does not reach the height of the current detecting point; E, carrying out sub-processes of emitting and receiving with a number of M-1; F, transferring the data recorded into step E to a computer system; G, calculating a new height of the current detecting point; H, returning to step C if the height of the current detecting point is not higher than the height of the top of a foundation pile; finishing when the height of the current detecting point is higher than the height of the top of the foundation pile. The device consists of N receiving-emitting convertible wave sound sensors S1, Sn; N receiving-emitting convertible channels Ch1, Chn, a computer system CPU, a control unit CPLD and a height position coder FMA. The device can finish the detecting work of all the section planes formed by M sound detecting pipes in the pile foundation during a lifting detecting process and have a high detecting efficiency.

Owner:WUHAN RSM INTELLIGENC GEOTECHN

Hydropower floating quick vertical ship lift

ActiveCN101250865AHuge economic benefitsSave operating waterVertical ship-liftingMarine engineeringHydropower

The invention relates to a hydraulic floating type fast vertical ship lift, which belongs to the technical field of ship lift. The ship lift which is provided by the invention substantially comprises a balanced system, a hoisting system and a mechanical synchronous system. The working principle is that the total weight of a surge drum balances the total weight of a ship chamber, a lifting vertical shaft is filled with water or the water in the lifting vertical shaft is discharged through operating a feed valve or a drain valve, thereby achieving the purpose of changing the weight of the lifting surge drum, and overcoming the frictional resistance and impelling the ship chamber to lift. The hydraulic floating type fast vertical ship lift is capable of replacing locks flights or a wire rope hoisting ship lift to complete a lifting ship operation, thereby being capable of saving massive operation water. The lifting speed is rapid, massive time is capable of being saved when a ship crosses a dam, complex making and installment process of a miter gate and complex construction of a water-carriage system and a drainage system of a lock chamber are avoided, thereby saving massive project investment. The workload of repair and maintenance is small, and the cost is low.

Owner:中国长江三峡工程开发总公司

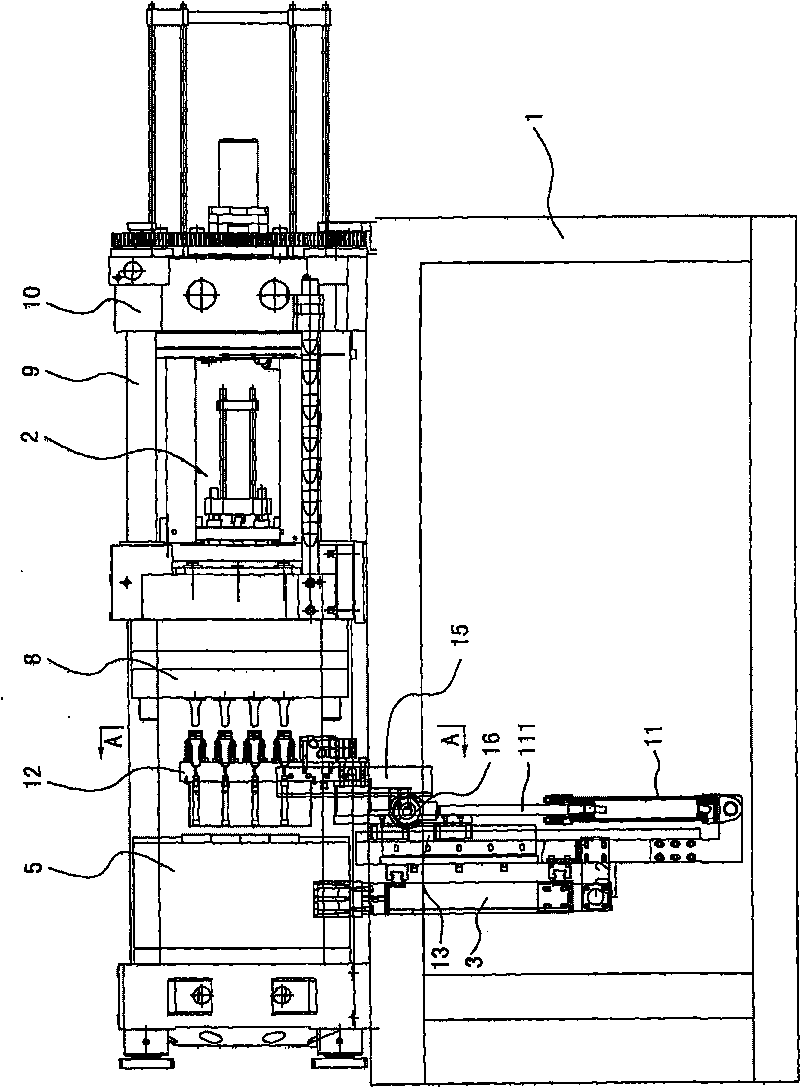

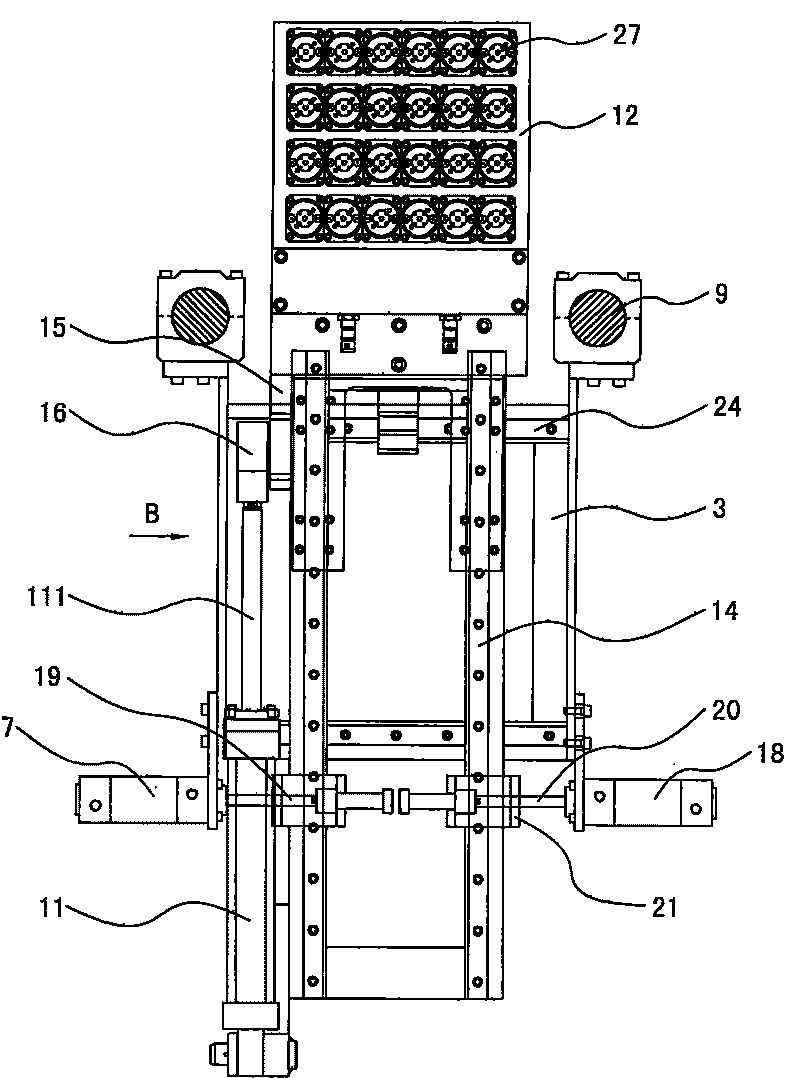

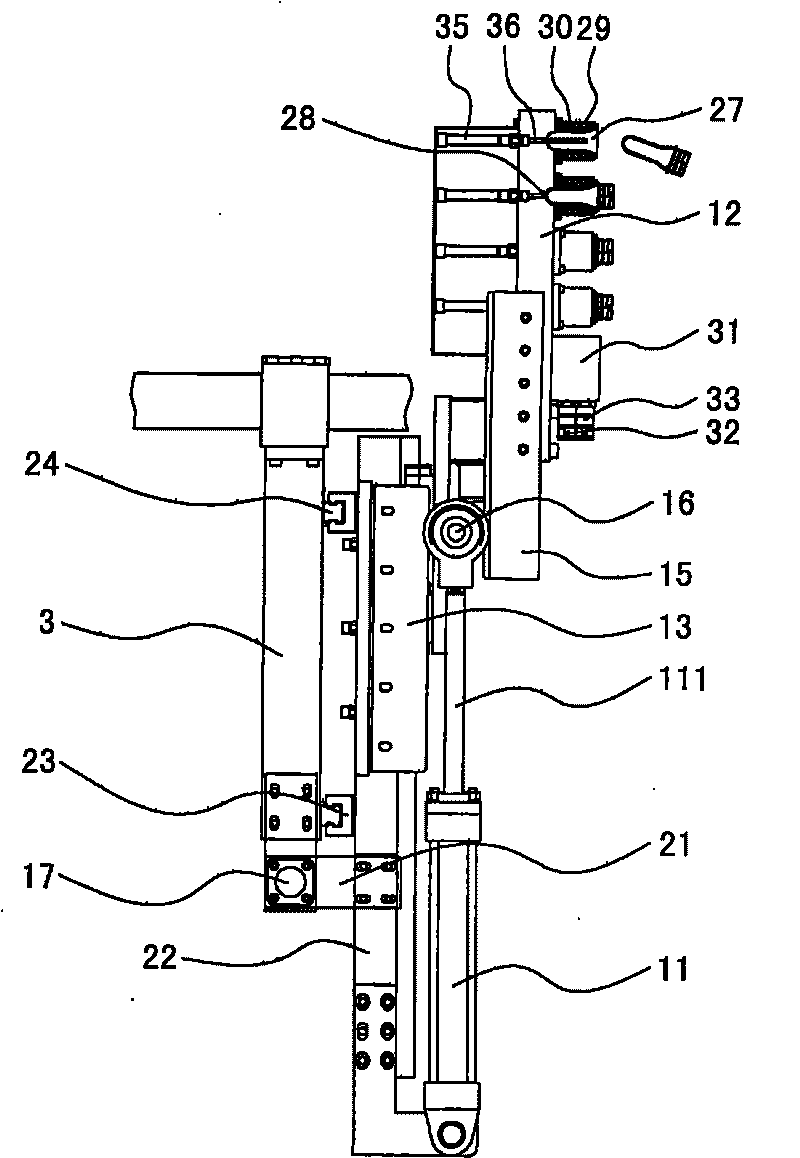

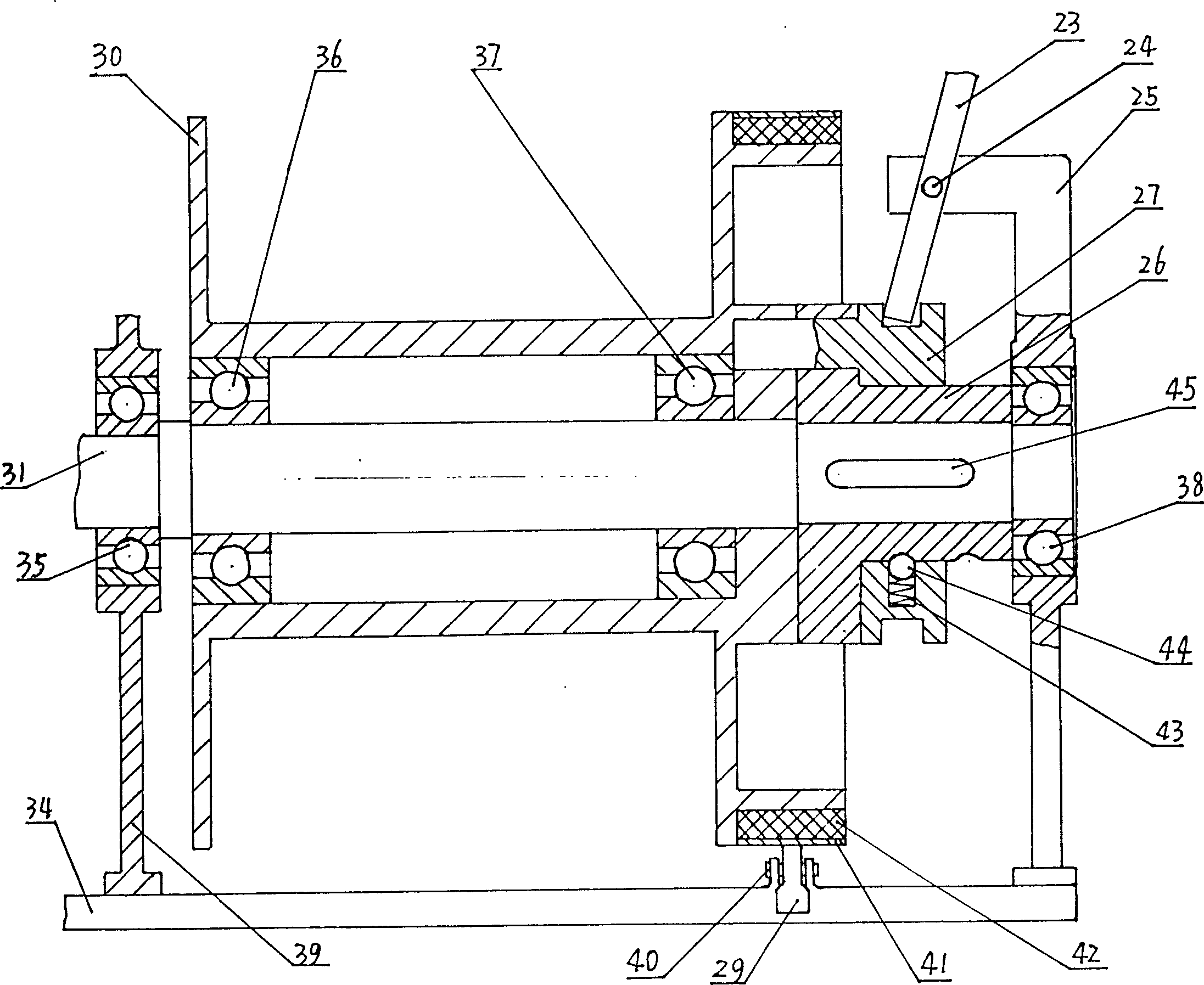

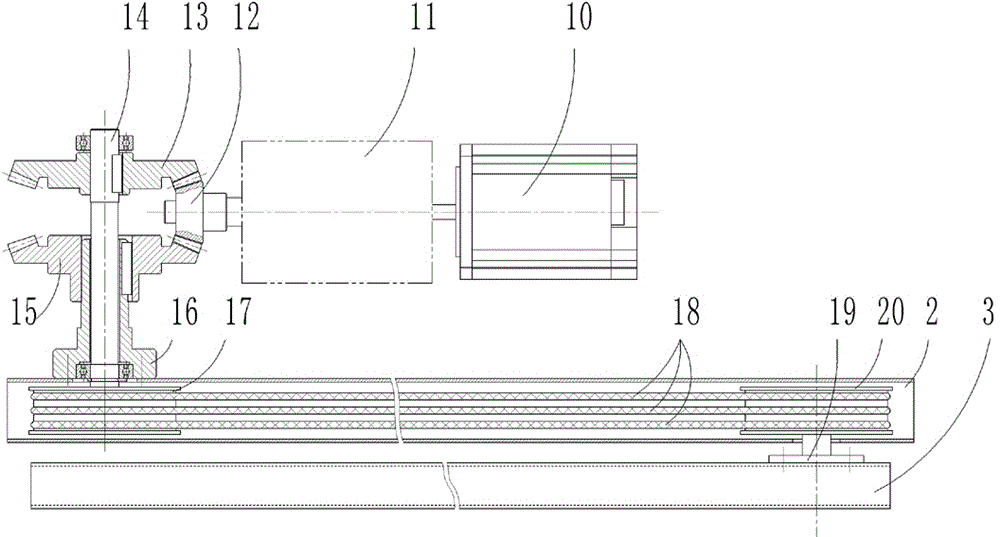

Automatic fetching device of injection molding machine

The invention relates to an automatic fetching device of an injection molding machine, which comprises an injection molding machine frame, wherein the machine frame is provided with an injection device; a fixed die plate on the machine frame is connected with a movable die plate and a back die plate through guide posts; the fixed die plate and the movable die plate are respectively provided with an injection die; a die cavity is arranged in the injection die; a fetching plate is arranged in the machine frame; a material absorption device and a push-out device are arranged in the fetching plate; the fetching plate is driven by an elevating gear; and the elevating gear is installed on a steady rest. The invention is characterized in that the elevating gear comprises a fixed rack arranged inthe fixed rack and an elevating guide rail, the fetching plate is connected with the elevating guide rail, one side of the fetching plate is provided with a movable rack, and the movable rack and thefixed rack mesh with the elevating gear driven by power. In the scheme of the invention, the elevation of the fetching plate is controlled by a multiple-path mechanism, which is formed by that the movable rack and the fixed rack mesh with the elevating gear, and the stroke of the fetching plate can be multiplied by twice or more than twice; and thus, the invention reduces the occupation space, decreases the height of the machine frame, has a high elevation speed, shortens the time and enhances the work efficiency.

Owner:蔡业

Overall assembling method for ultra-wide framing steel box girder

InactiveCN111926705AReduce weld volumeShorten the manufacturing cycleBridge erection/assemblyBridge materialsWeld seamButt joint

The invention discloses an overall assembling method for an ultra-wide framing steel box girder, and relates to the technical field of steel box girder assembling. The method comprises the steps performing plate unit manufacturing and plate assembly welding, beam section matching assembly welding and pre-assembling and pre-assembling inspection; carrying out beam section assembly welding accordingto the sequence of a bottom plate, a transverse partition plate, a middle top plate, a primary positioning inner web plate, an anchor web plate, other top plates, a secondary positioning anchor web plate, a middle cross beam and a cantilever arm block, and carrying out three-dimensional stepped propelling mode section-by-section assembly and welding; and during pre-assembling, with considerationof the influence of beam section compression amount caused by welding circular seam shrinkage amount and cable force on the length, correcting the accumulated total length and error of the previous pre-assembling in the next assembly. The method has the advantages that the butt joint weld joint amount of the steel box girder on the total assembly jig frame can be reduced, and the manufacturing period is shortened; a three-dimensional step-shaped propelling mode is adopted, pre-assembling is carried out after section-by-section assembly welding, and the boundary dimension is easy to control; the assembling precision of the steel box girder can be ensured, the assembling quality is controlled, high-altitude adjustment is avoided, and the erection period is shortened.

Owner:中铁山桥(南通)有限公司

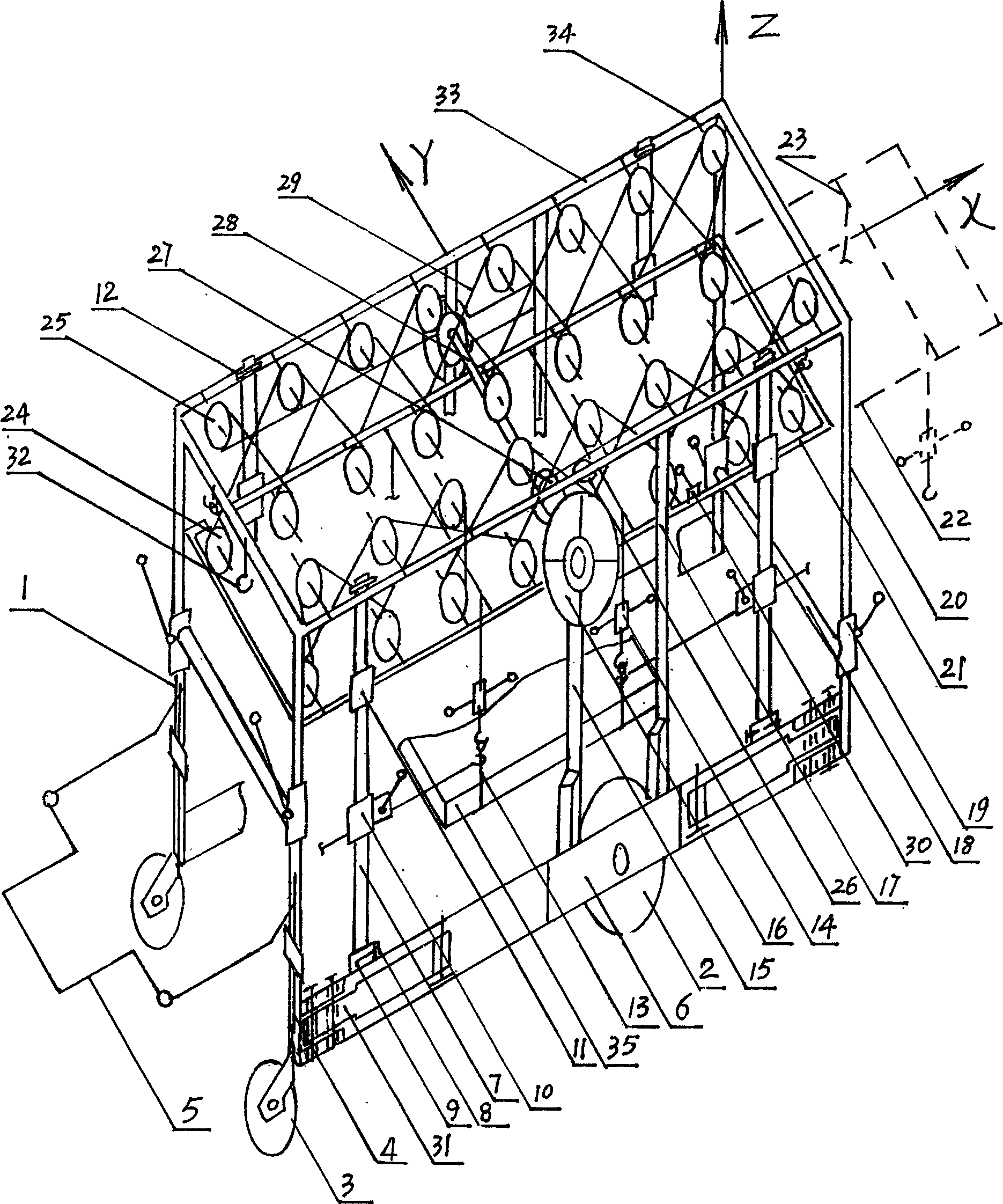

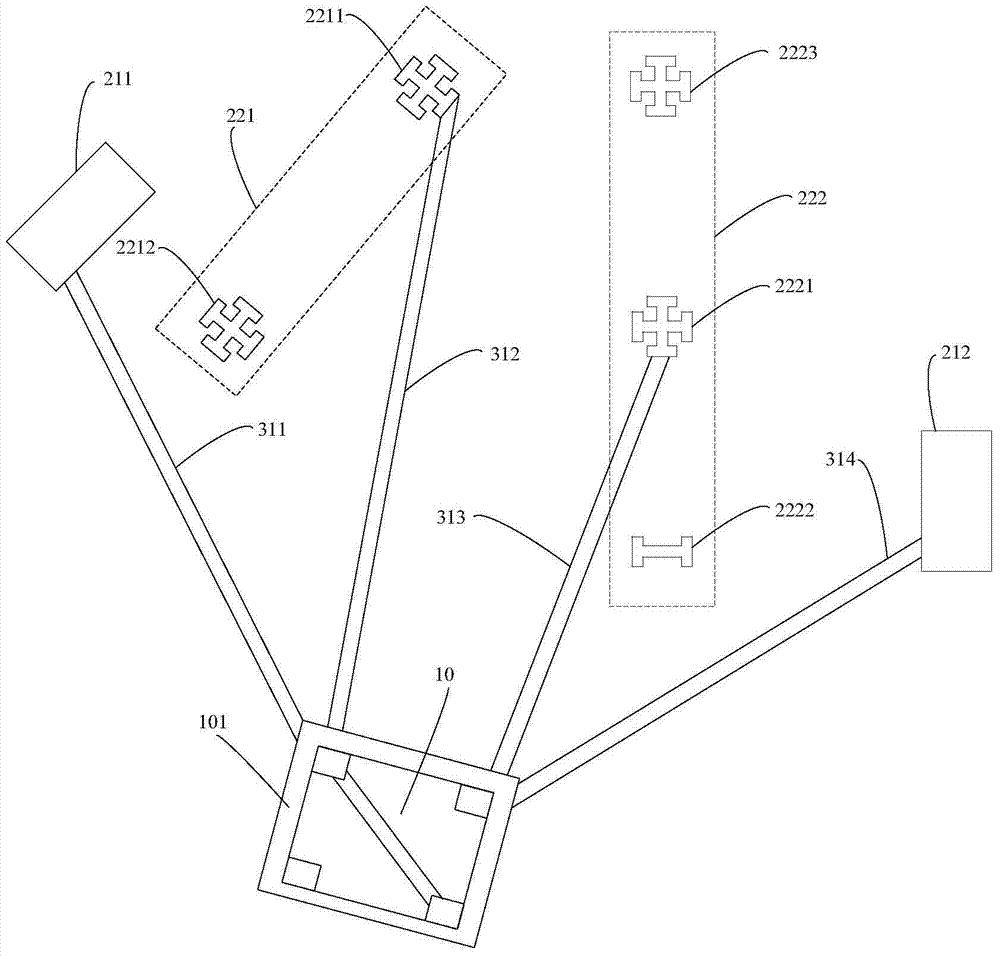

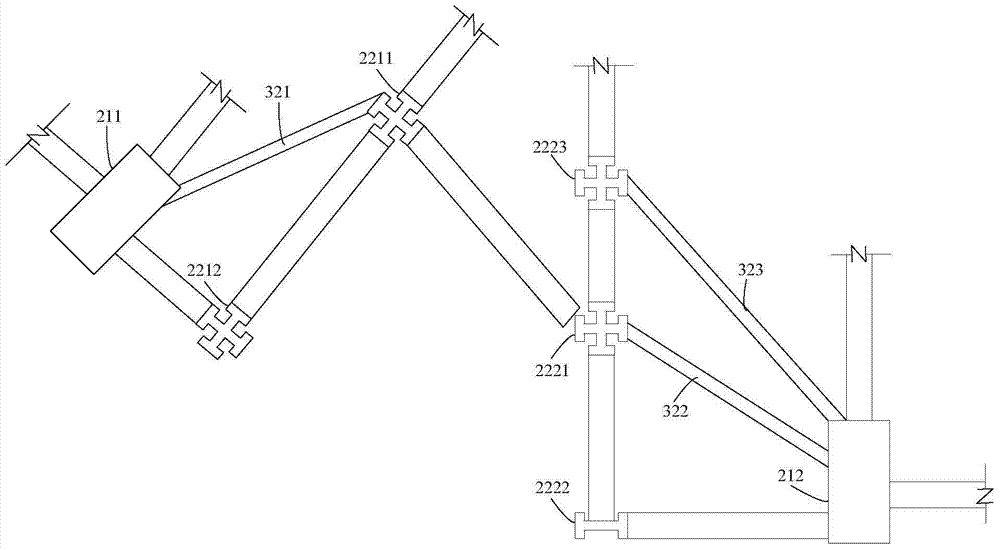

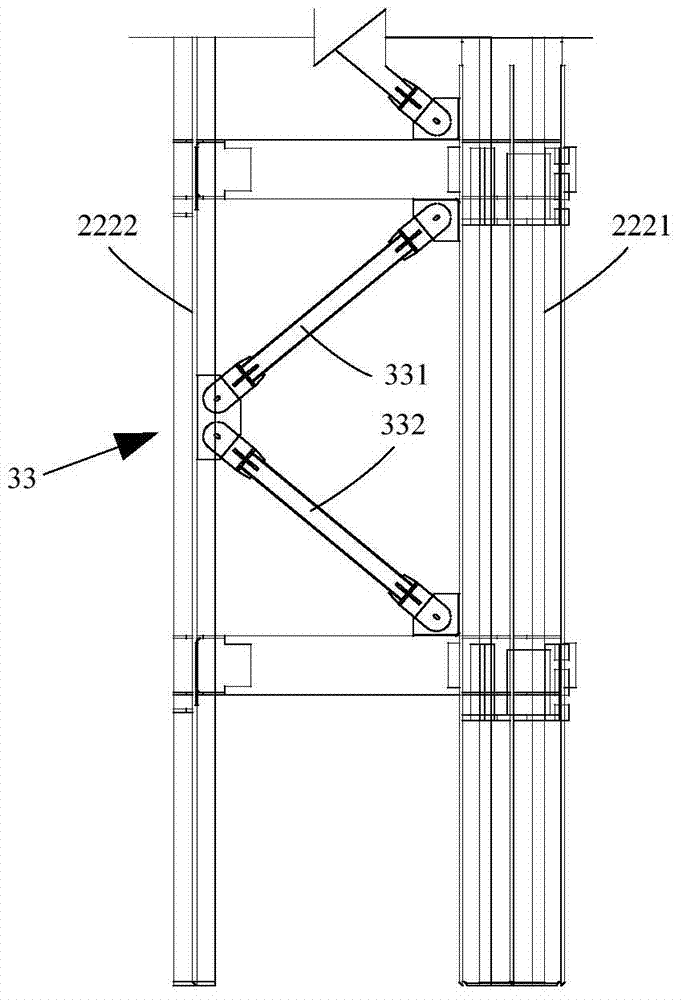

Multifunctional engineering installation vehicle

InactiveCN1544307AEasy to operateImprove installation qualityLifting devicesHydraulic cylinderPull force

The present invention discloses a multifunctional engineering installation vehicle used for engineering construction, which comprises a vehicular support frame, a walking and the like. In the vehicle as a gantry supporting frame structure, a extensible guide supporting frame for X axial movement is connected forwards with a Z axial direction tunable movable lift hook; at the C axial movement extensible guide supporting frame, there is an outside force acting at the Z axial direction, which can be a pull force of a armored rope or a cylinder rod clean and jerk force of the hydraulic cylinder and used for pushing the X axial movement extensible guide supporting frame for a vertical motion; a lifting platform is installed at the vehicle roof to execute pipe laying pipe laying, anti-corrosion, heat preservation, laying and maintenance of cable rope and crane span structure, and the like; the Z axial direction tunable movable lift hook inside the vehicle is used for lifting and loading articles of merchandise to realize installation of equipments; a labor saving and quick-releasing pipeline frame is allocated for carriage of pipelines; a ground tray is allocated, which is used for lifting, loading and transporting large and heavy workpieces. The multifunctional engineering vehicle is a powerful machinery for constructions, and the plurality of functions mentioned above greatly improves the installation quality, saves 2 times for the human energy and improves the work efficiency more than 10 times.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

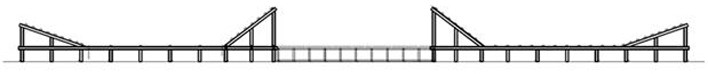

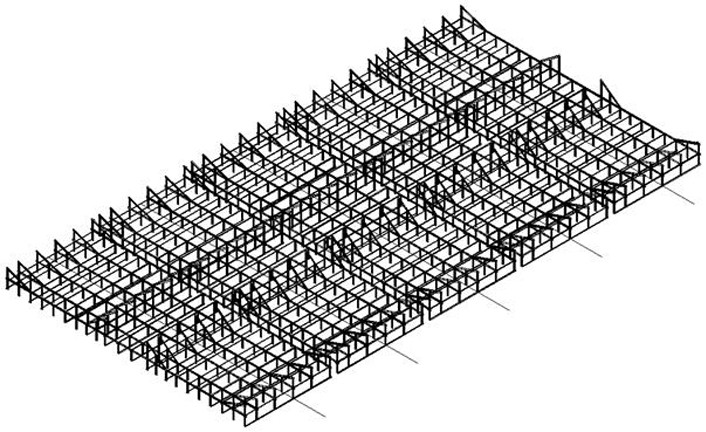

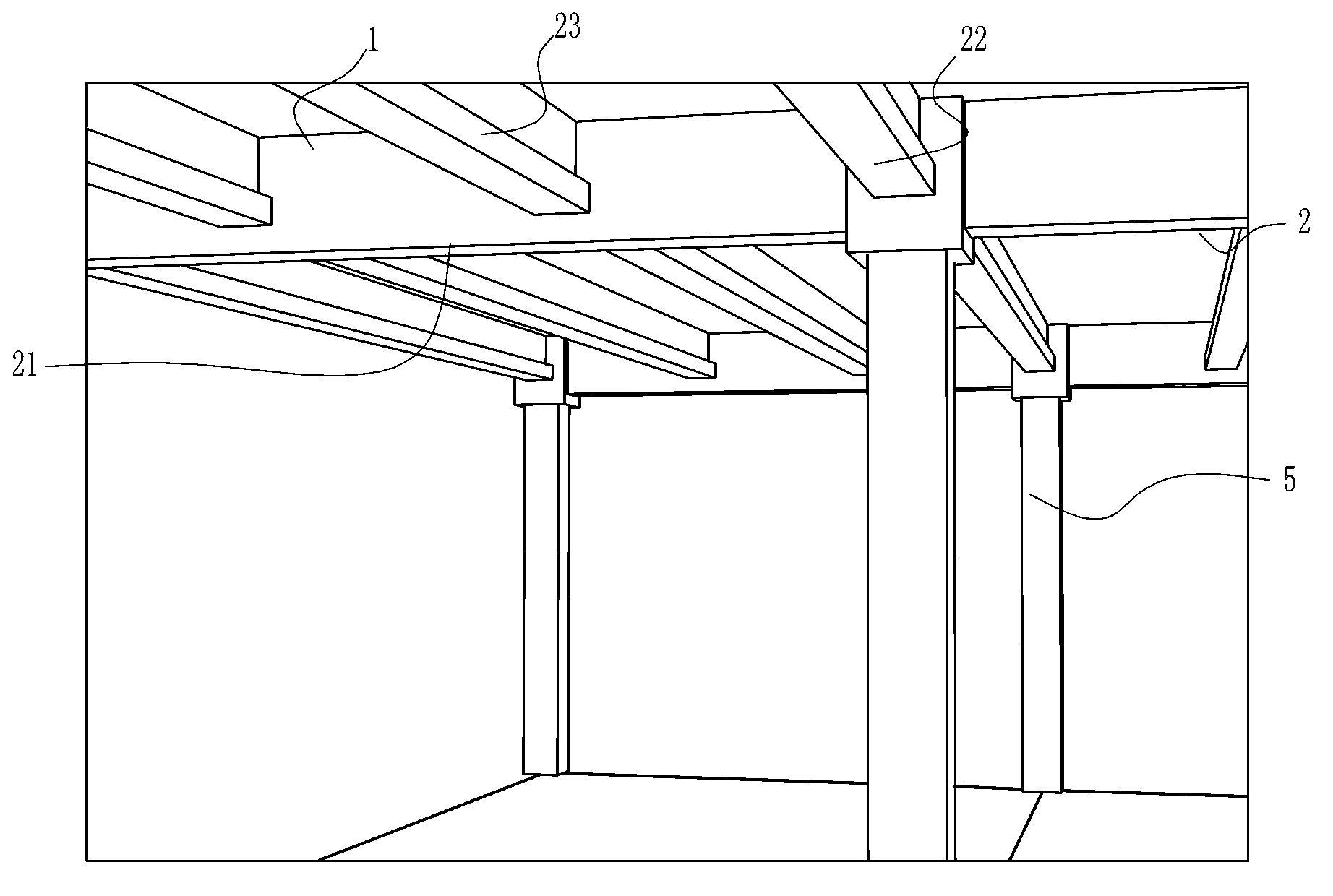

Large span prefabricated monolithic casting structure and construction method

ActiveCN103046645AImprove shear resistanceSmall floor spanBuilding material handlingShaped beamFloor slab

Disclosed is a large span prefabricated monolithic casting structure. The large span prefabricated monolithic casting structure comprises a floorslab, a superposed beam and a column, the superposed beam and the column are used for supporting the floorslab, the superposed beam is divided into a short frame main beam, a long frame beam and an auxiliary beam, the auxiliary beam is connected with the main beam, the superposed beam comprises a prestress prefabricated beam and a cast-in-situ portion, the prestress prefabricated beam comprises a beam body and a pre-stressed steel strand which is buried in the beam body and serves as a main rib, two ends of the short frame main beam and the long frame beam are connected with the column, cross sections of prefabricated beam portions of the long frame beam and the auxiliary beam are invertedly T-shaped, the superposed beam after monolithic casting is an I-shaped beam connected with the floorslab, and the auxiliary beam and the long frame beam utilize the inverted T-shaped prestress prefabricated beams with small intervals. The large span prefabricated monolithic casting structure has the advantages that the span, the thickness and the self weight of the floorslab are small, heights of the beams are reduced, reinforcing bars are reduced, and the short main beam which uses a superposed rectangular beam is good in shear resistance and convenient to connect with the auxiliary beam.

Owner:宁波优造建筑科技有限公司

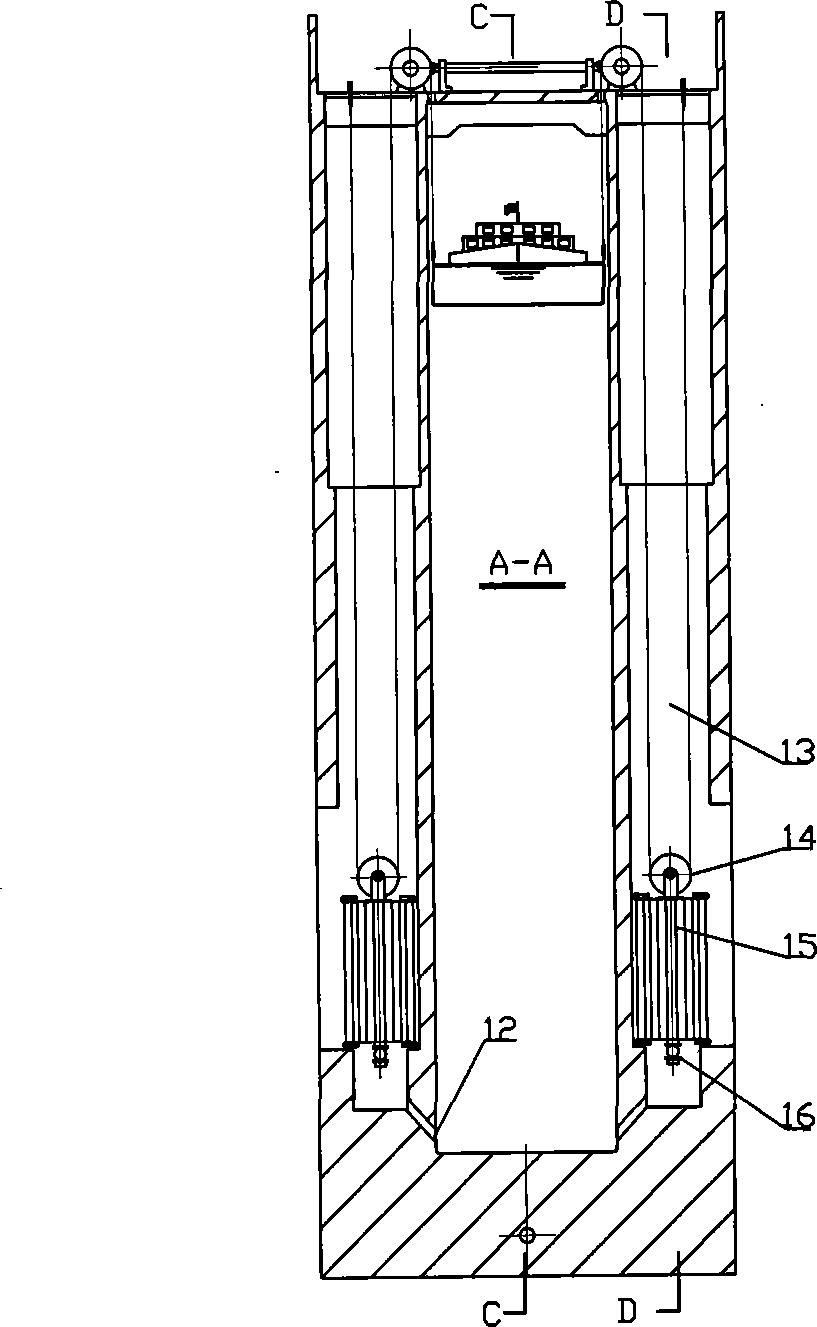

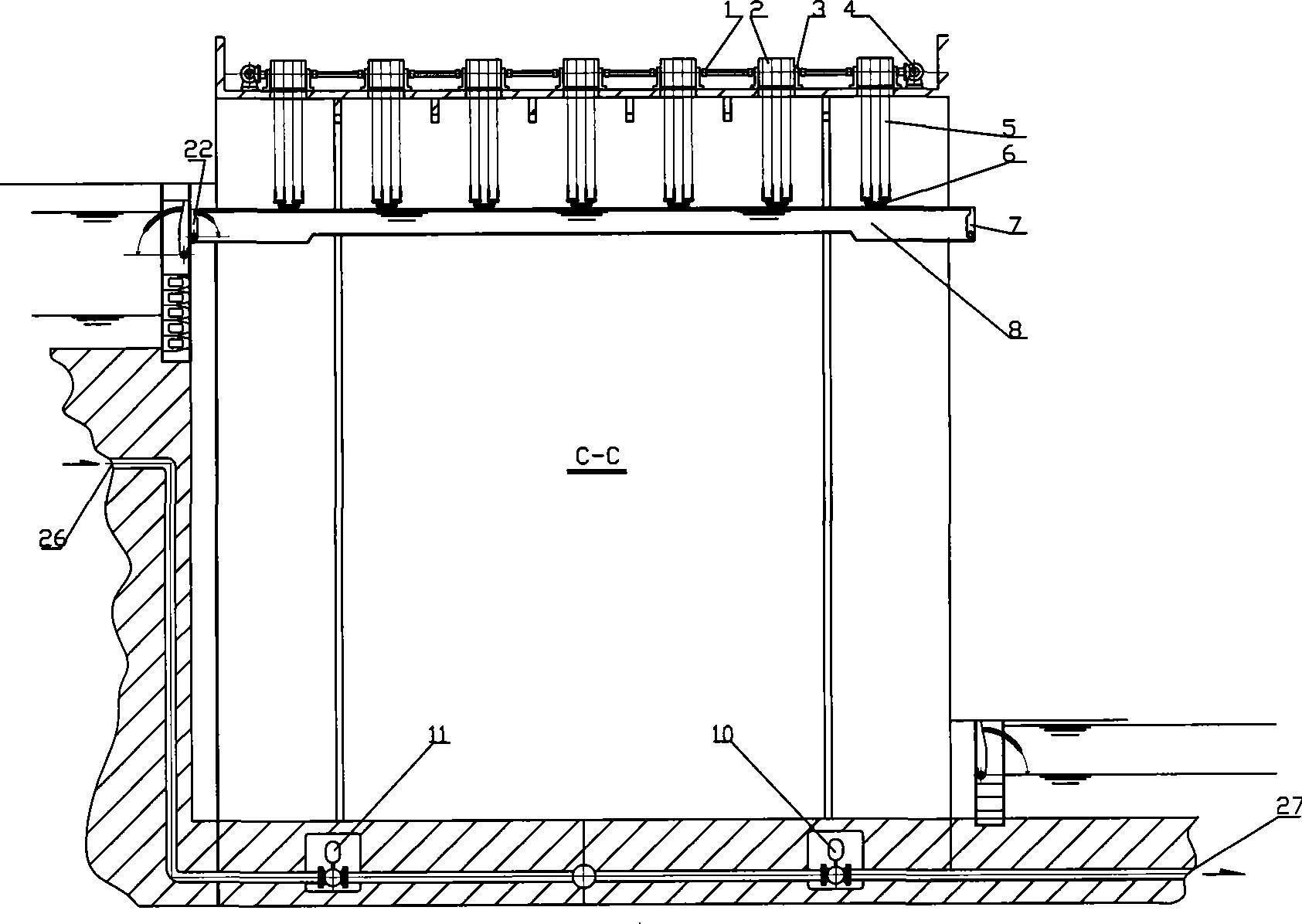

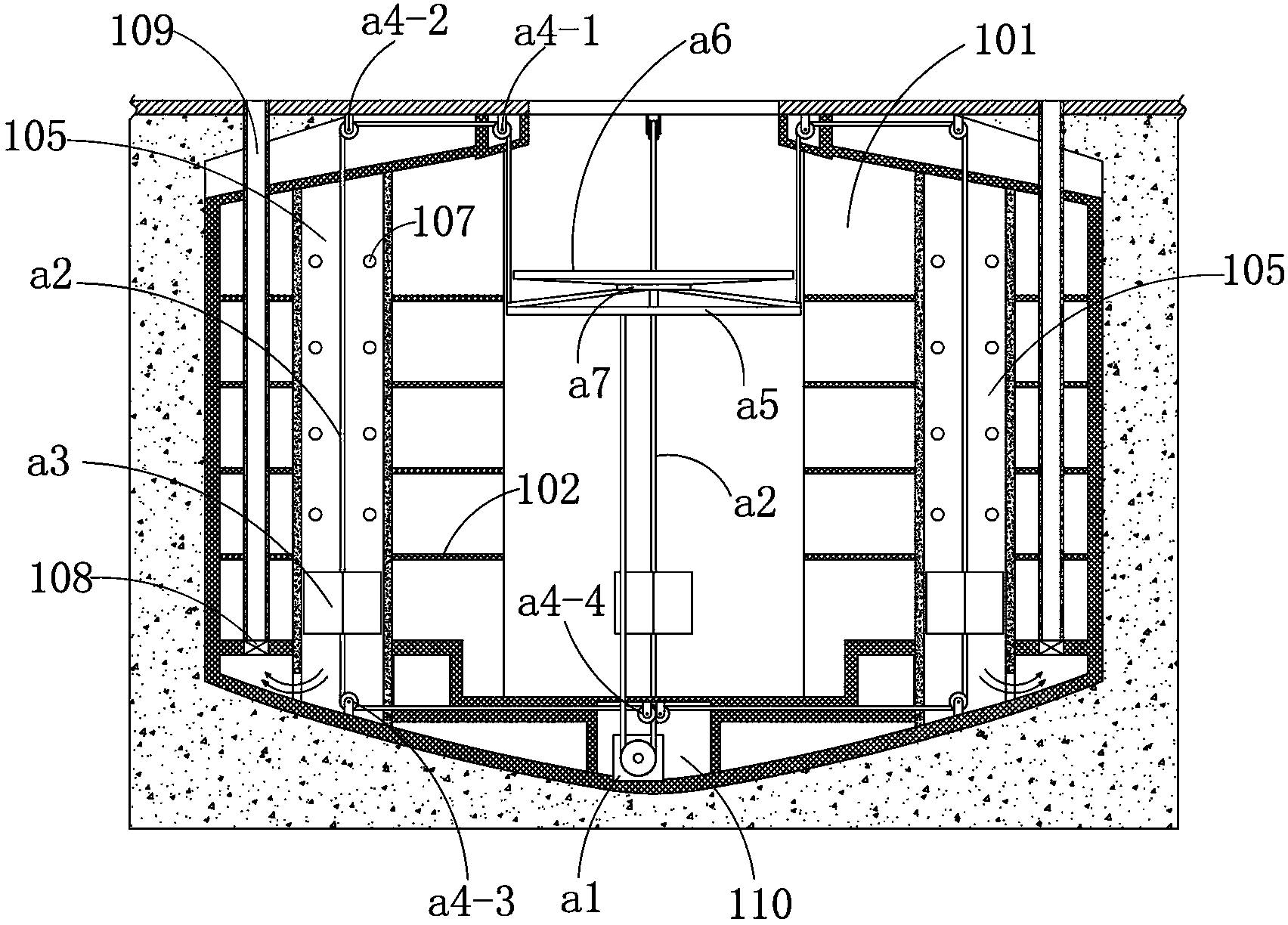

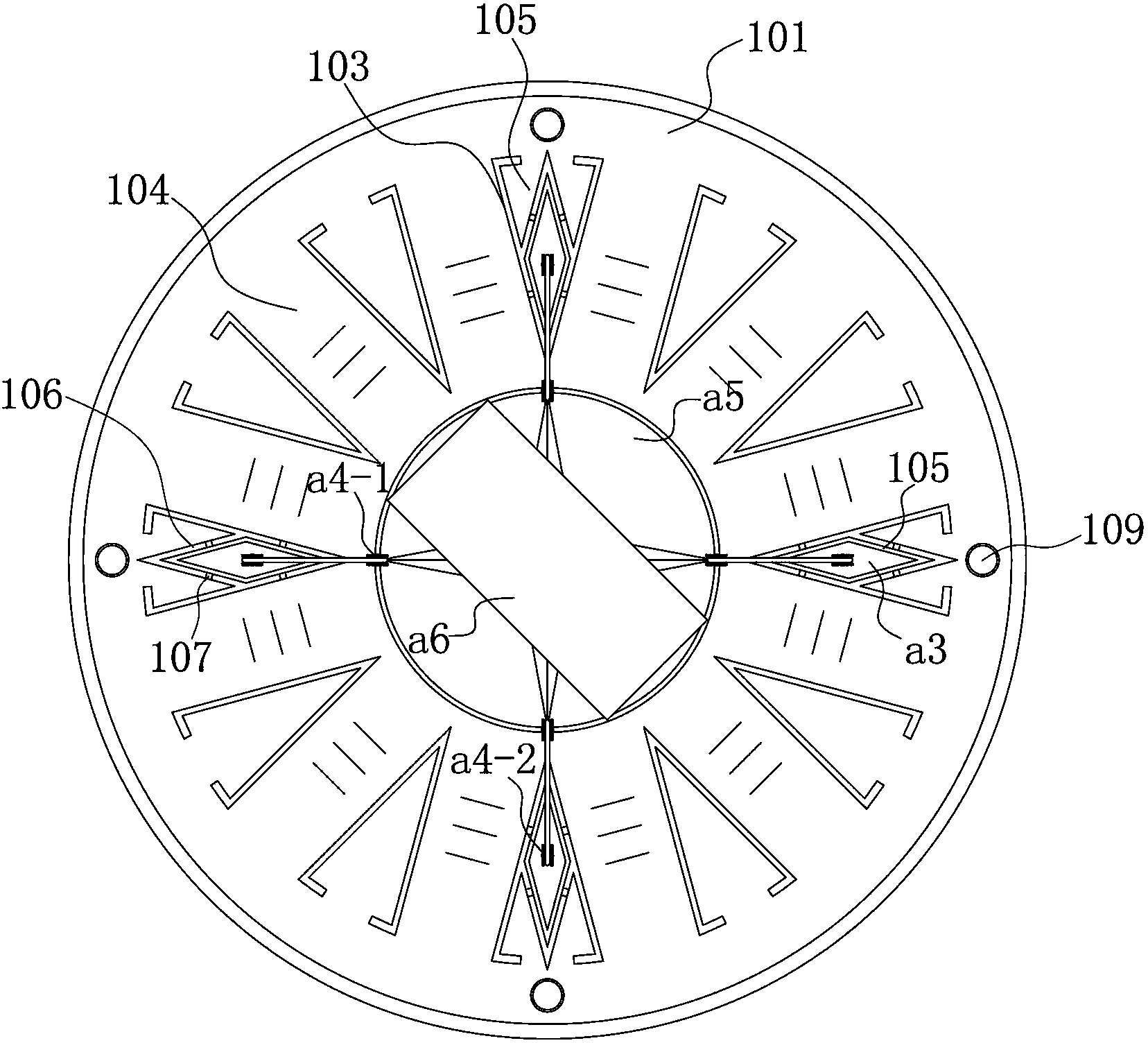

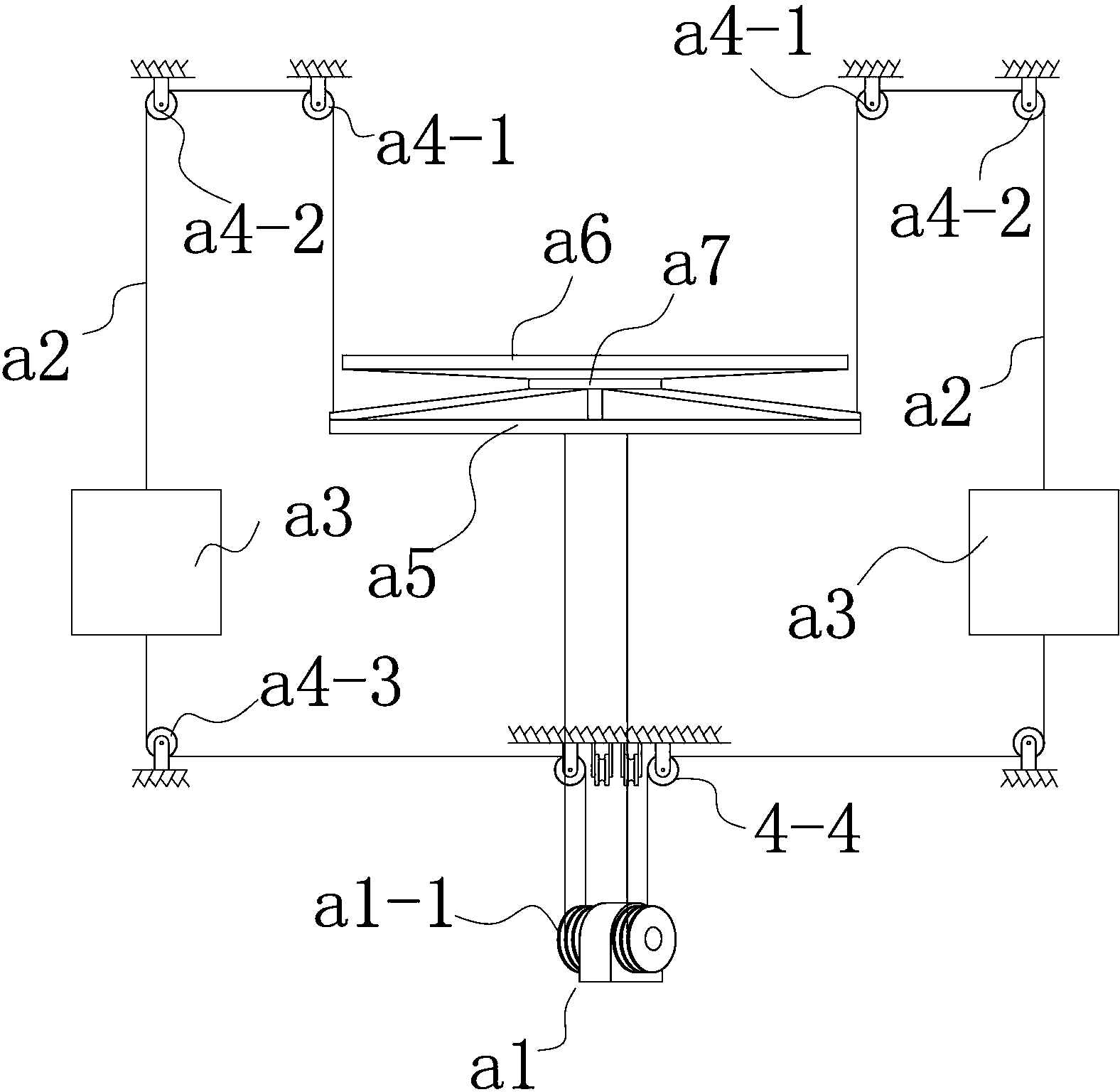

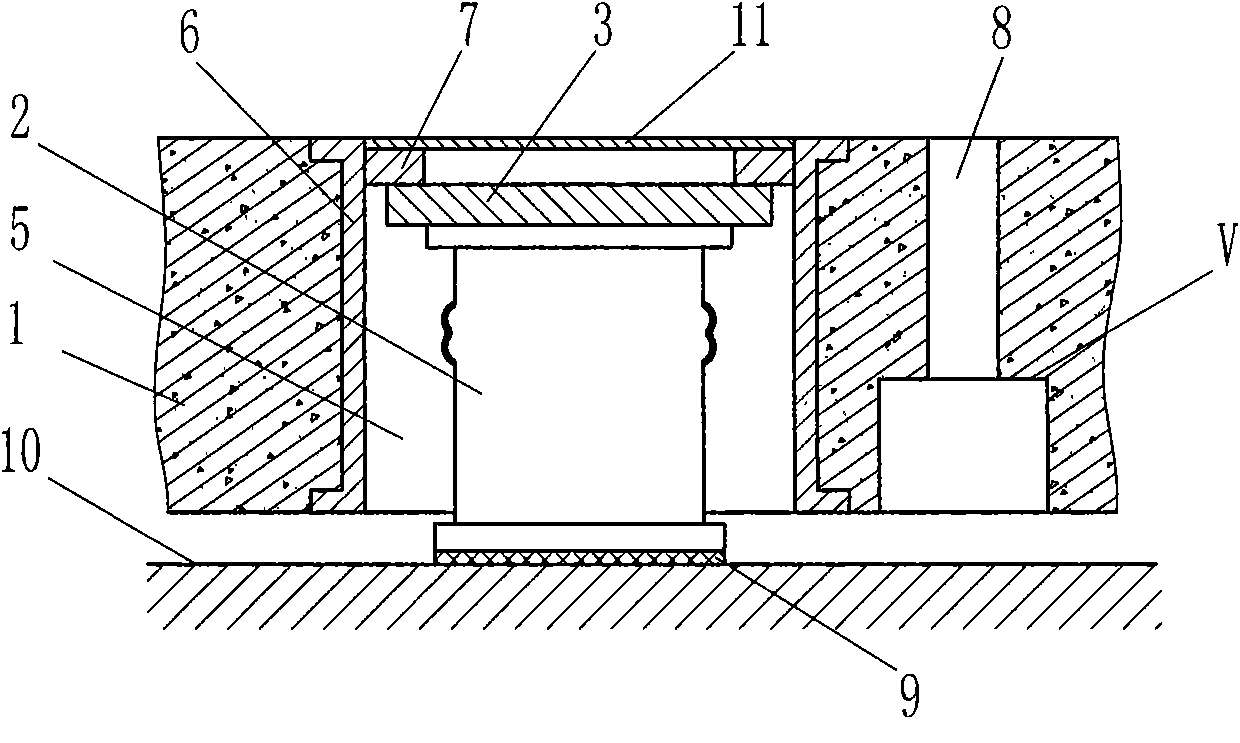

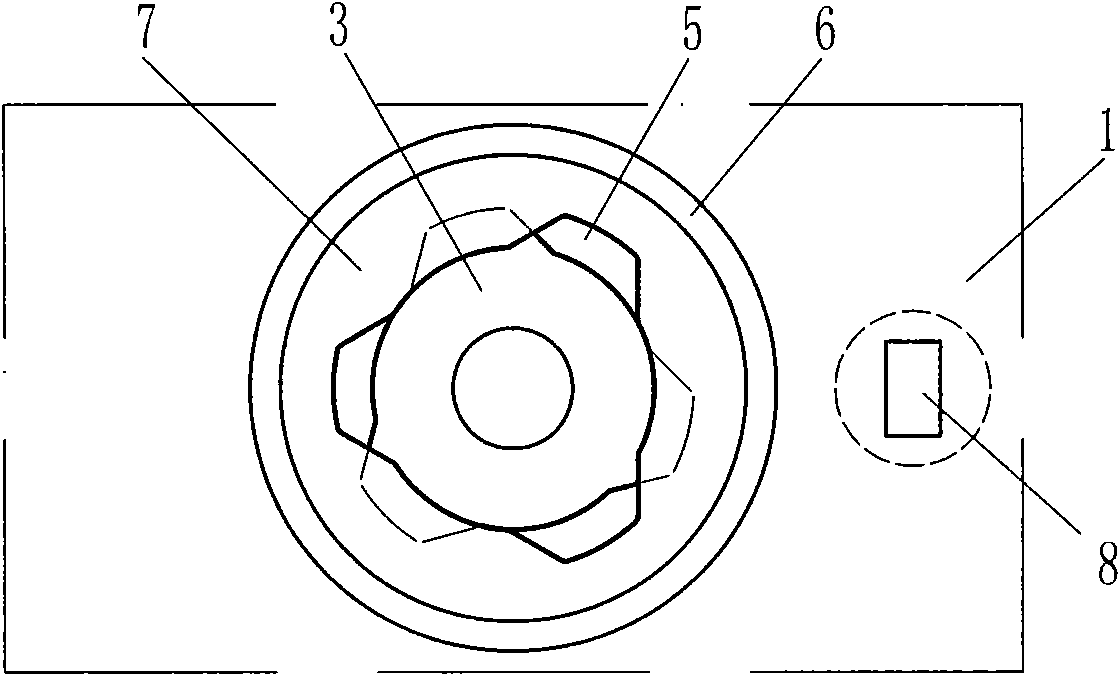

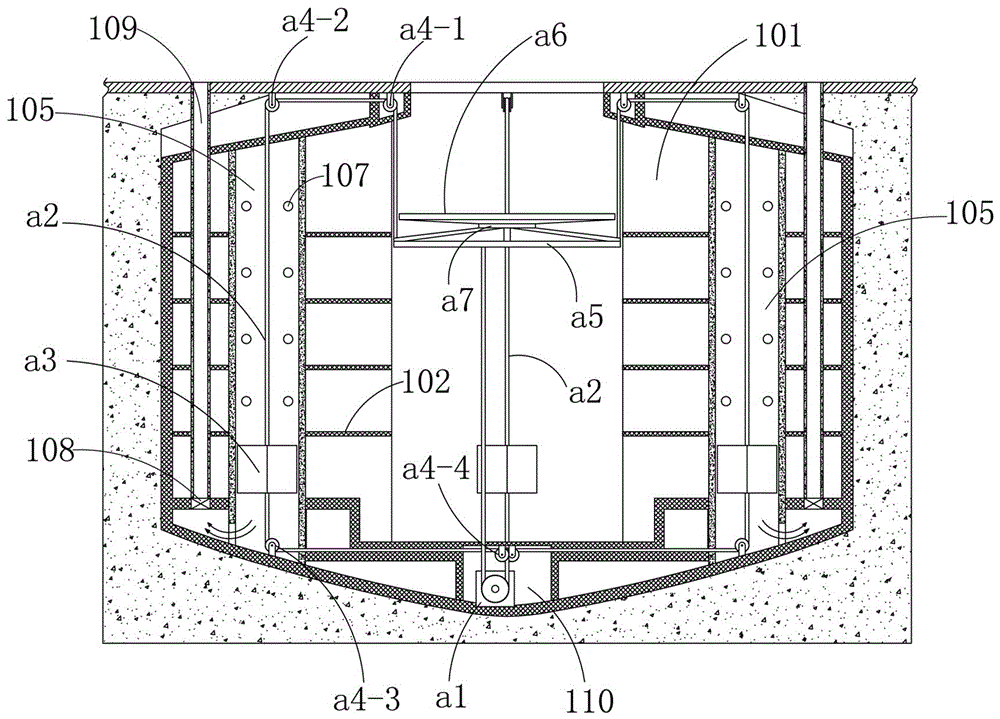

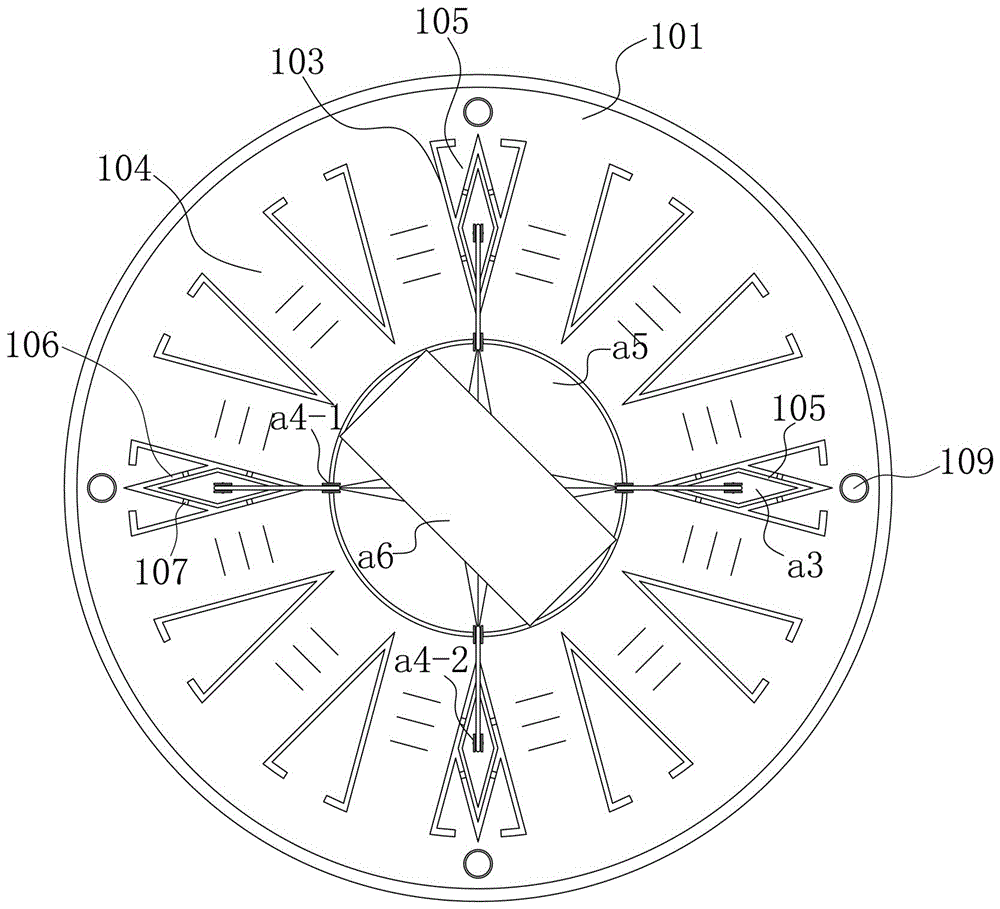

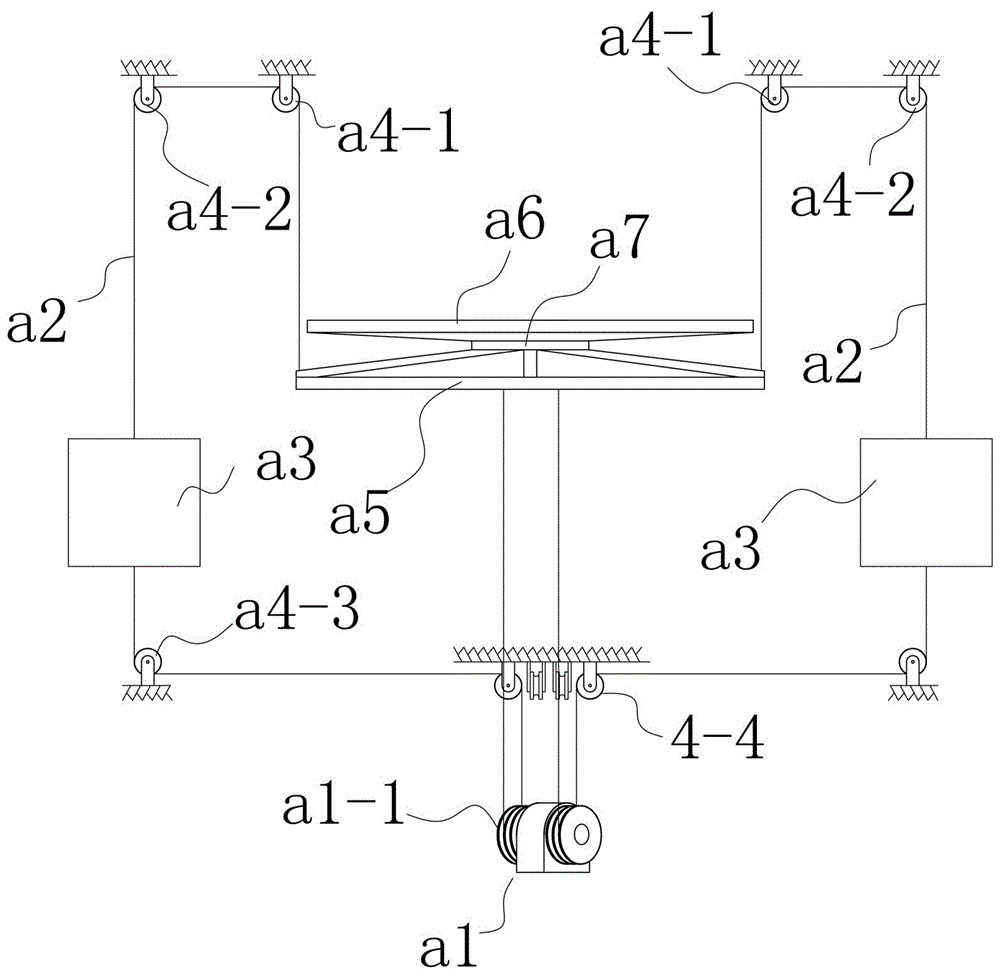

Cylinder-type stereo garage

The invention relates to the field of stereo garage devices, in particular to a cylinder-type stereo garage. The cylinder-type stereo garage comprises a cylindrical garage shaft, an entrance gate house system arranged on a shaft mouth of the top of the garage shaft, more than two layers of annular parking layers vertically distributed along the garage shaft, a lifting rotation platform arranged at the center of the garage shaft and used for fetching vehicles and a traction mechanism for driving the lifting rotation platform to vertically lift. The cylinder-type stereo garage is reasonable in structure, stable to operate, efficient and stable and is suitable for fetching vehicles.

Owner:王景保

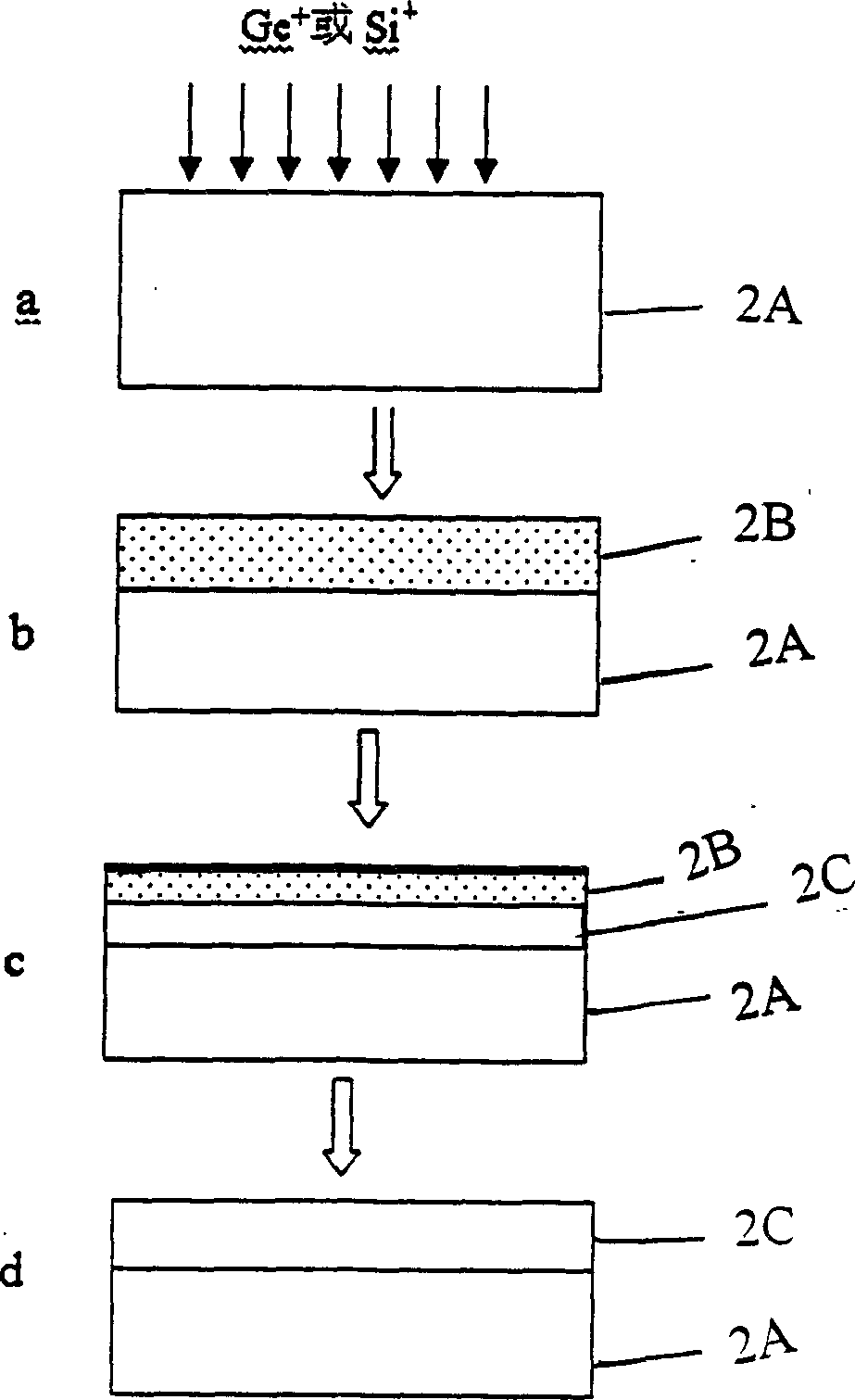

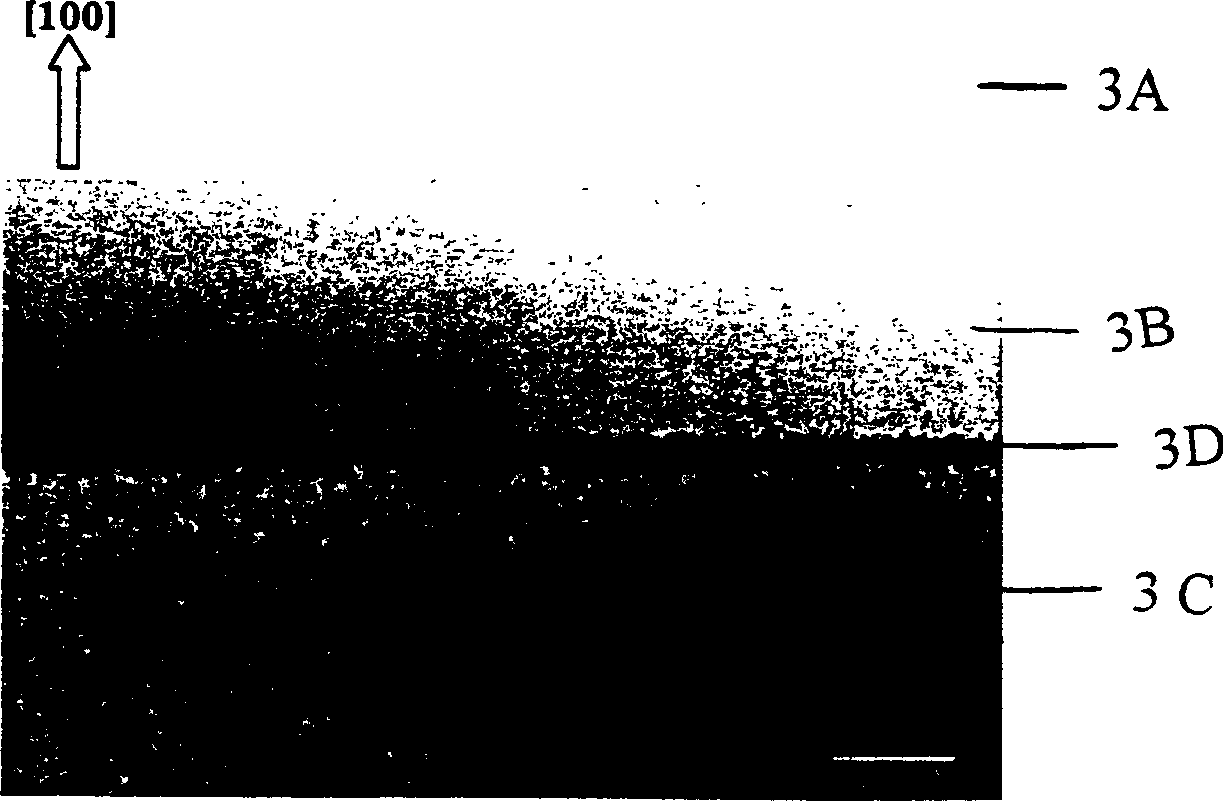

Method for eliminating primary pit defects of silicon monocrystal device making area

ActiveCN1632919AGood crystallization and high qualityIncrease growth rateSemiconductor/solid-state device manufacturingSurface layerRapid thermal annealing

This invention relates to a method to eliminate the silicon pad device process area original defection, which is used to eliminate the original defection of the silicon crystal surface. This method uses direct pull method to use silicon crystal pas as original silicon pad and injects the low dose ion of Ge#+[+] or Si#+[+] into the surface layer of the original silicon to make it non-crystal and then uses rapid heat annealing or oven annealing to make the silicon surface non-crystal layer.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

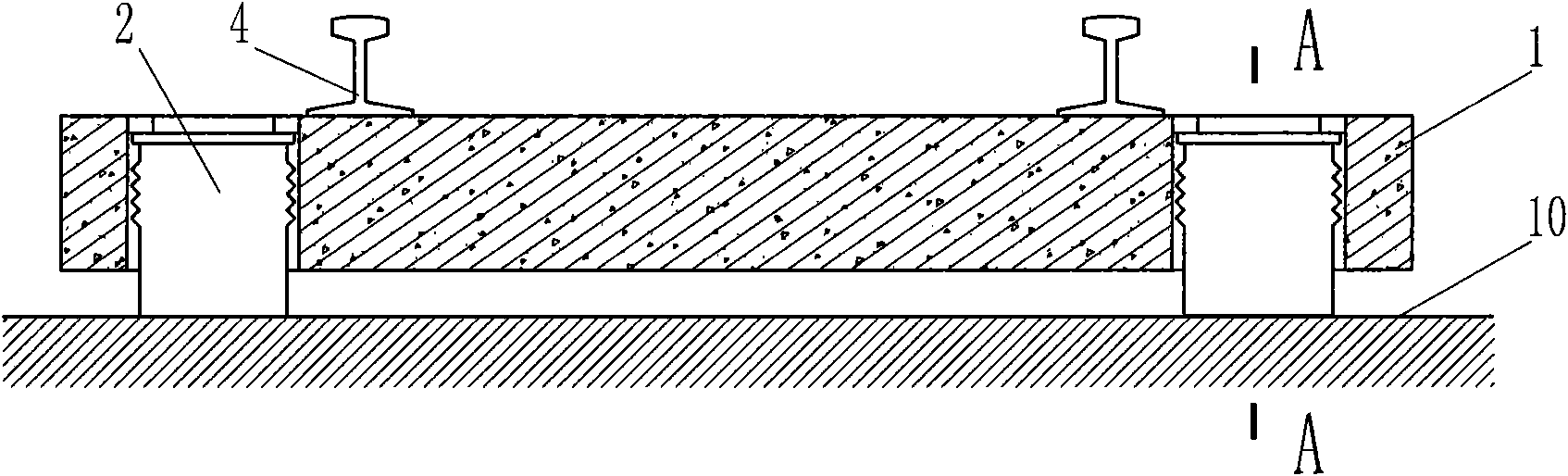

Floating track bed, jacking device and jacking method thereof

ActiveCN101845776AThe jacking method is simple and easyThe jacking method is safe and reliableRailway tracksLifting devicesMarine engineeringElastic vibration

The invention relates to the field of track traffic, in particular to a track bed and a jacking device used when the track bed is jacked. The floating track bed comprises a floating plate, a gasket and an elastic vibration isolator, wherein a pre-reserved through hole or a side groove for accommodating the elastic vibration isolator and the gasket is arranged on the floating plate, and the floating plate is supported on the elastic vibration isolator through the gasket; an articulating hole for jacking is arranged on the floating plate and is of a ladder hole, and the interface of the upper hole and the lower hole of the ladder hole forms a retaining shoulder; and the size of the upper aperture is smaller than the size of the lower aperture. The floating track bed has simpler structure, requires lower requirements for the thickness of the floating plate and the jacking space, and stronger practicality, is more favorable for reducing cost when not affecting the vibration isolating efficiency, prolongs service life, and has more higher performance-price ratio and very broad market application prospects.

Owner:尹学军

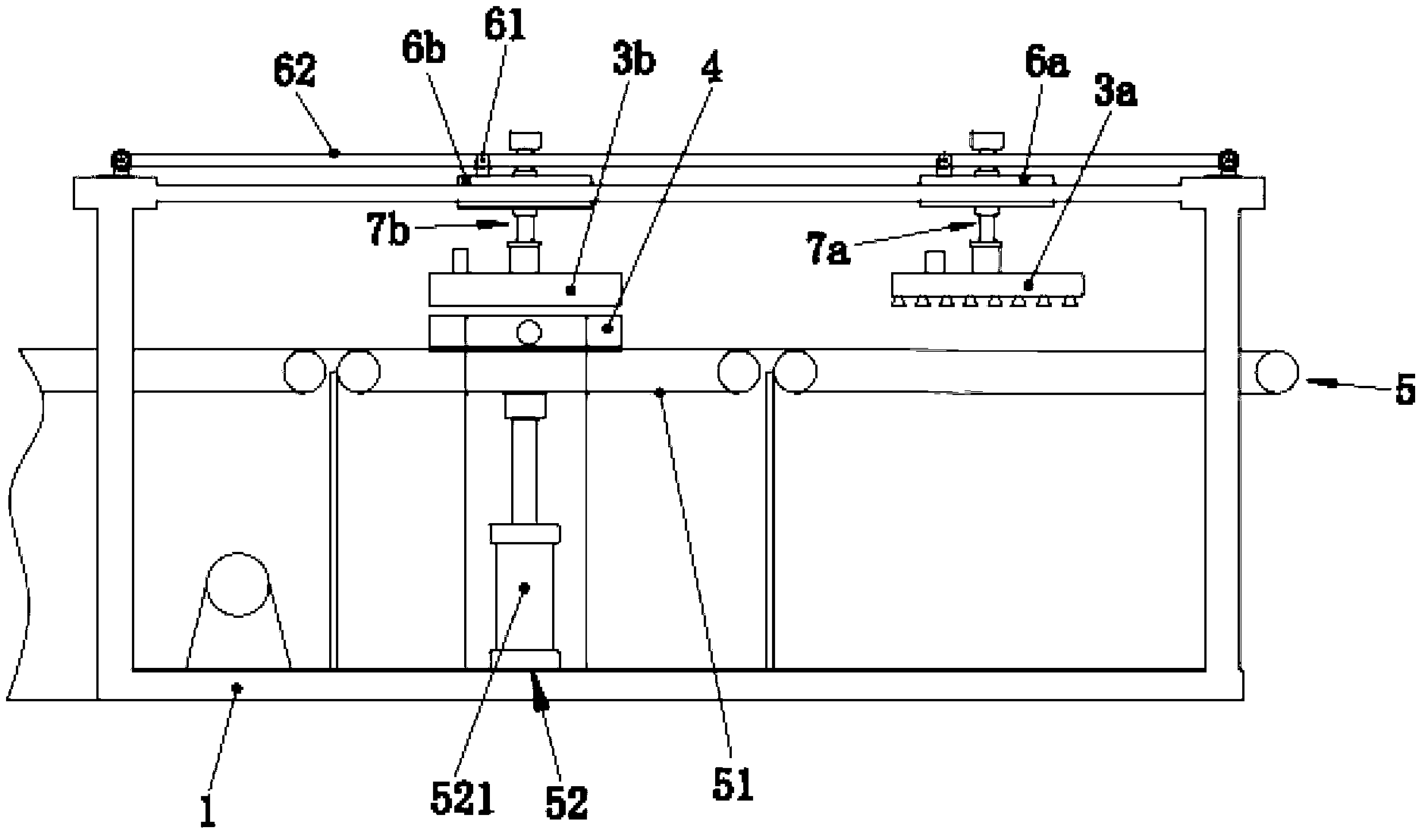

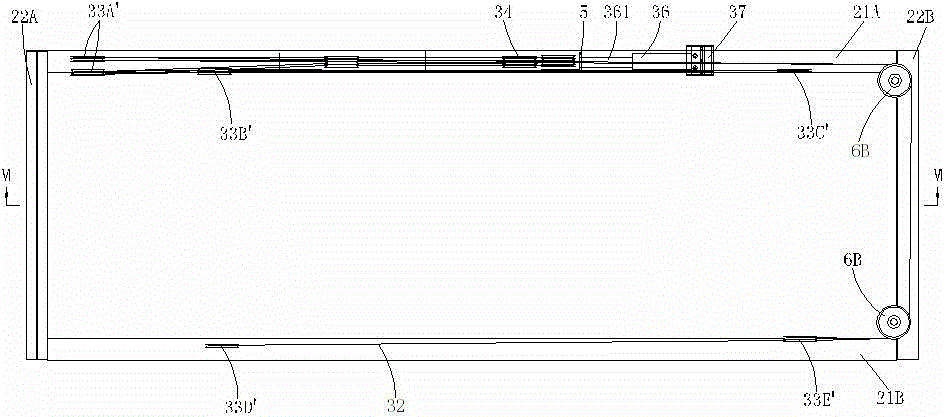

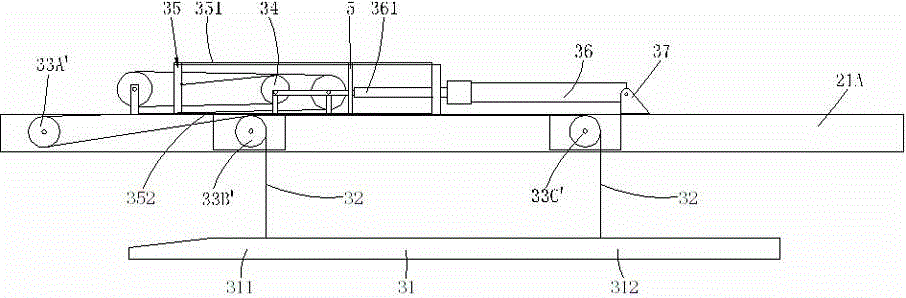

Full-automatic paving machine of ceramic colored code bricks

InactiveCN103171895ARealize automatic flipRealize fully automatic pavingConveyor partsBrickEngineering

The invention provides a full-automatic paving machine of ceramic colored code bricks. The full-automatic paving machine of the ceramic colored code bricks solves the problems that an existing paving machine cannot separate front faces and back faces of the colored code bricks and a mass of manual work is necessary to separate the front faces and the back faces of the colored code bricks and the like. The full-automatic paving machine of the ceramic colored code bricks comprises a rack, a vacuum pump, a sucking disc, a convey band and a shifting frame, wherein the convey band is installed on the rack, and the shifting frame is arranged on the rack in a movable mode. A sucking disc lifting mechanism is installed on the shifting frame. The sucking disc is installed on the sucking disc lifting mechanism. The full-automatic paving machine of the ceramic colored code bricks further comprises a negative pressure reversing box. The negative pressure reversing box is arranged on the rack in a rotatable mode. The sucking disc and the negative pressure reversing box are respectively communicated with an extraction opening of the vacuum pump through a pipeline. The convey belt comprises a lifting convey belt. The lifting conveying belt is connected with a convey belt lifting mechanism. The negative pressure reversing box is located over the lifting convey belt.

Owner:福建科颖工贸有限公司

Tower crane attached wall support structure and construction method thereof

ActiveCN103935911ALifting speed is fastImprove efficiencyBuilding material handlingCranesEconomic benefitsTower crane

The invention relates to a tower crane attached wall support structure and a construction method thereof. The support structure comprises an anchoring rod and a temporary beam, wherein the anchoring rod is in support connection with the tower crane and a core tube; the core tube comprises a box-type column and a steel rib column for forming a shear wall; the temporary beam is in support connection with the box-type column and the steel rib column. The tower crane attached wall support structure has remarkable economic benefit in fastening the construction progress, improving the use efficiency of the tower crane and lowering the construction cost.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

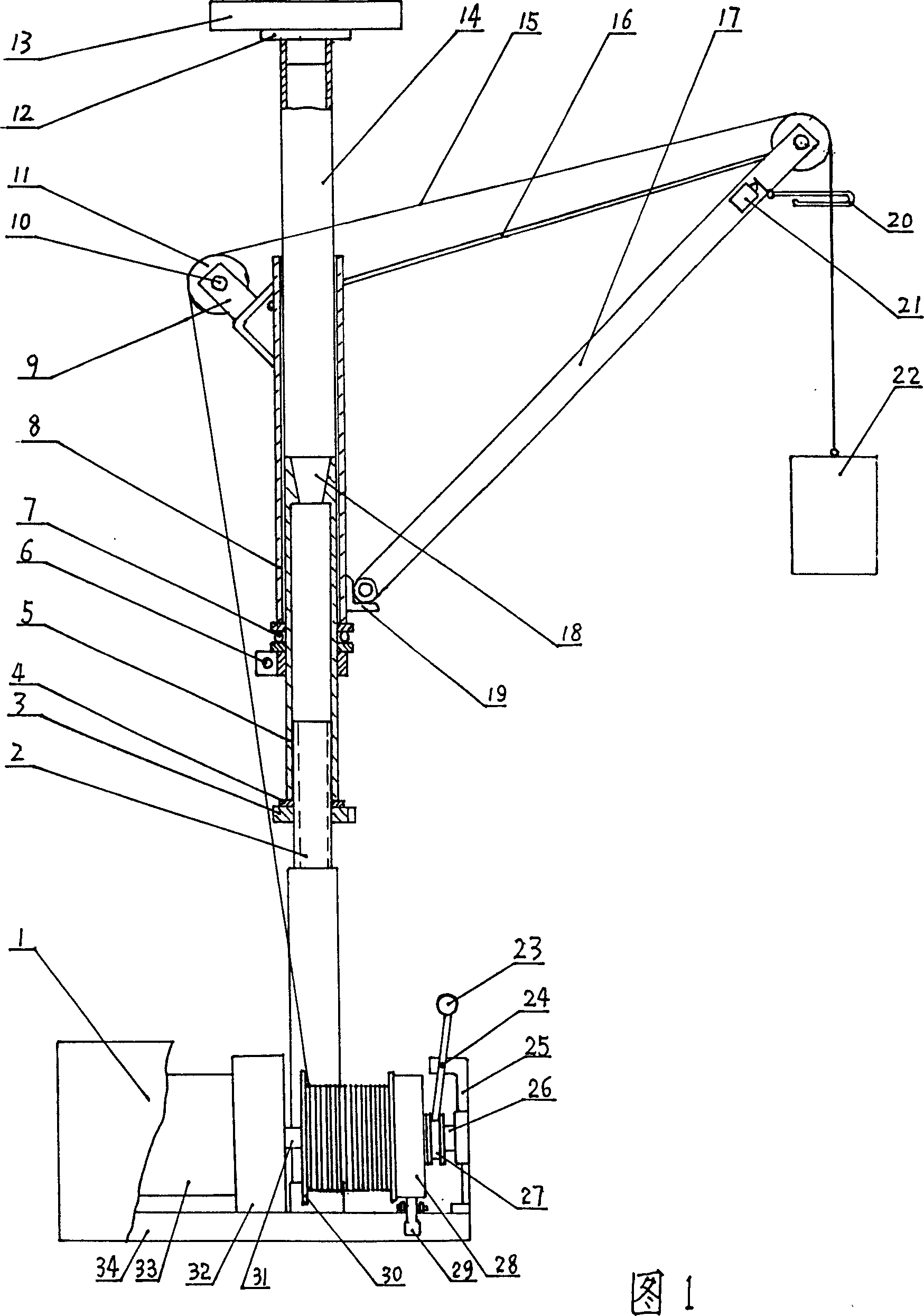

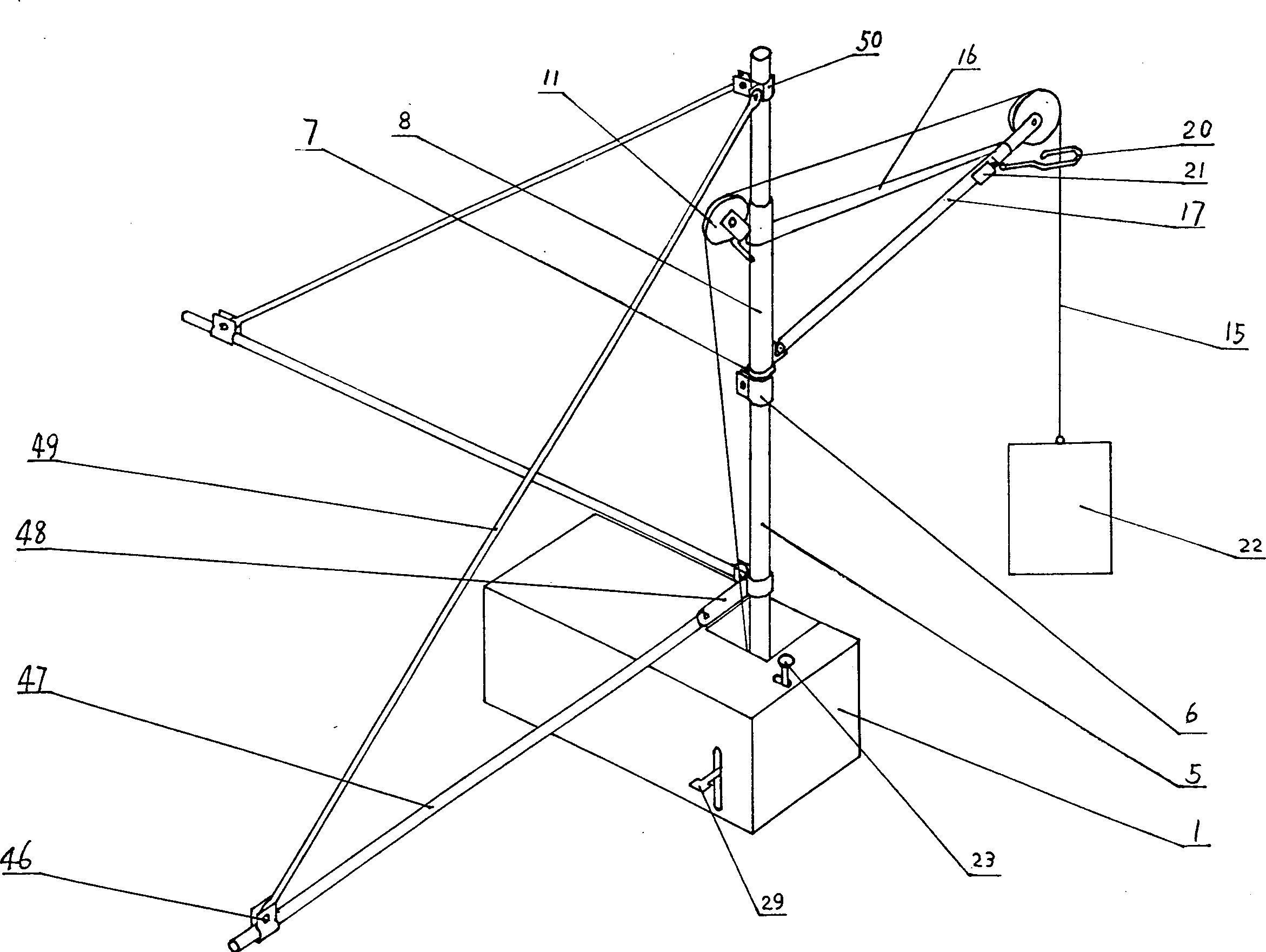

Portable lifting and carrying machine

A Portable trolley, relates to a feeding machinery using in building and decorate ornament. It is adapted for works of lifting or putting down weight in / out house. The purpose is high lifting efficiency, large scope of application, facilitating for carrying. The invention comprises: host machine, holdfast and rotor arm, the host machine comprises a electromotor, a decelerator, a chassis, a clutch coupling, a brake, a rope roll and armoured rope; the holdfast comprises a threaded rod, a vertical rod, a masthead cap, a gripper, a thrust bearing and a shelf; the rotor arm comprises a rotor sleeve, arm, a pulley yoke, a block, a pin axial, an arm dragline, a limit switch shelf and overtravel-limit switch; the motor connects with the driving part of the clutch coupling by the decelerator. The clutch coupling comprises a driving part, a connector, a knob, rope roll as the driven member of the clutch coupling connects with the driving part of the clutch coupling via the connector.

Owner:SHANGHAI CHUNSHAN IND

High-speed single crystal growth device and method

ActiveCN105603520ATimely releaseIntensive Cooling Crystal SurfacePolycrystalline material growthBy pulling from meltChemical reactionShielding gas

The invention discloses a high-speed single crystal growth device and method and mainly relates to a crystal cooling manner and a reaction cylinder for conveying reactants to perform chemical reactions. The reaction cylinder is made of high-temperature-resistant materials and comprises a gas inlet cylinder and a gas discharge cylinder. The gas inlet cylinder is provided with a passage for feeding the reactants and protecting gas. The reactants are sprayed to the surfaces of growing high-temperature crystals after passing the gas inlet cylinder to perform chemical reaction so as to absorb heat and fast remove the heat on the surfaces of the crystals. The gas discharge cylinder is used for discharging the reactants not completely reacted and reaction product gas out of a furnace. The gas inlet cylinder and the gas discharge cylinder are integrally connected and fixed on a furnace wall. The high-speed single crystal growth device and method has the advantages that the chemical heat-absorption reaction is applied to the intensified cooling in crystal growth for the first time, the heat on the surfaces of the crystals can be removed fast, the axial temperature gradient inside the crystals can be increased evidently, and accordingly the crystal growth speed is increased.

Owner:徐州晶睿半导体装备科技有限公司

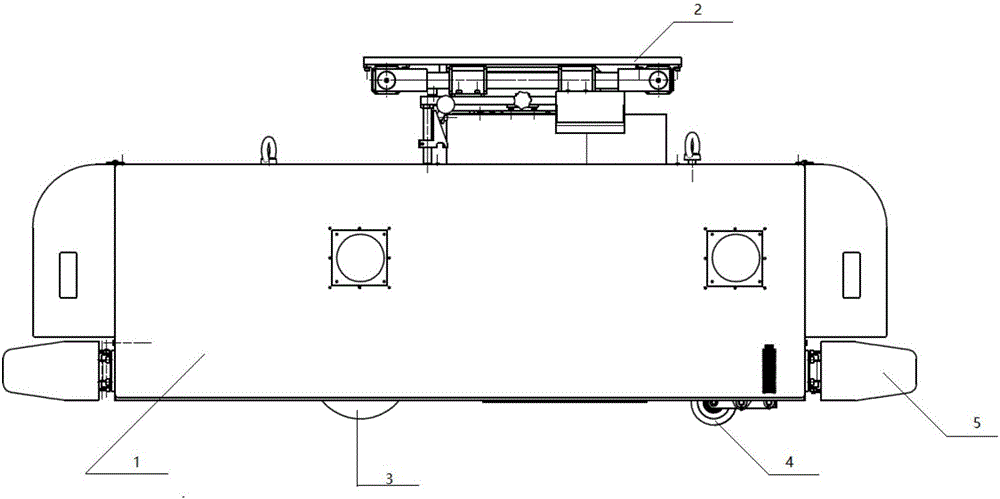

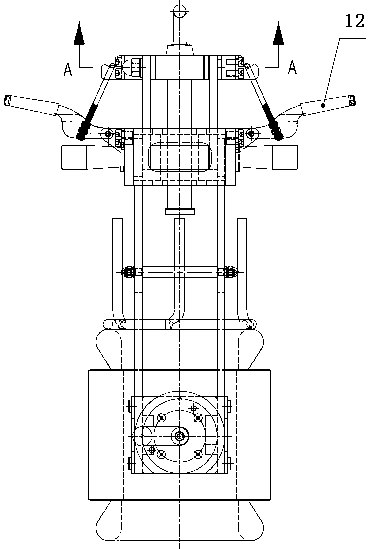

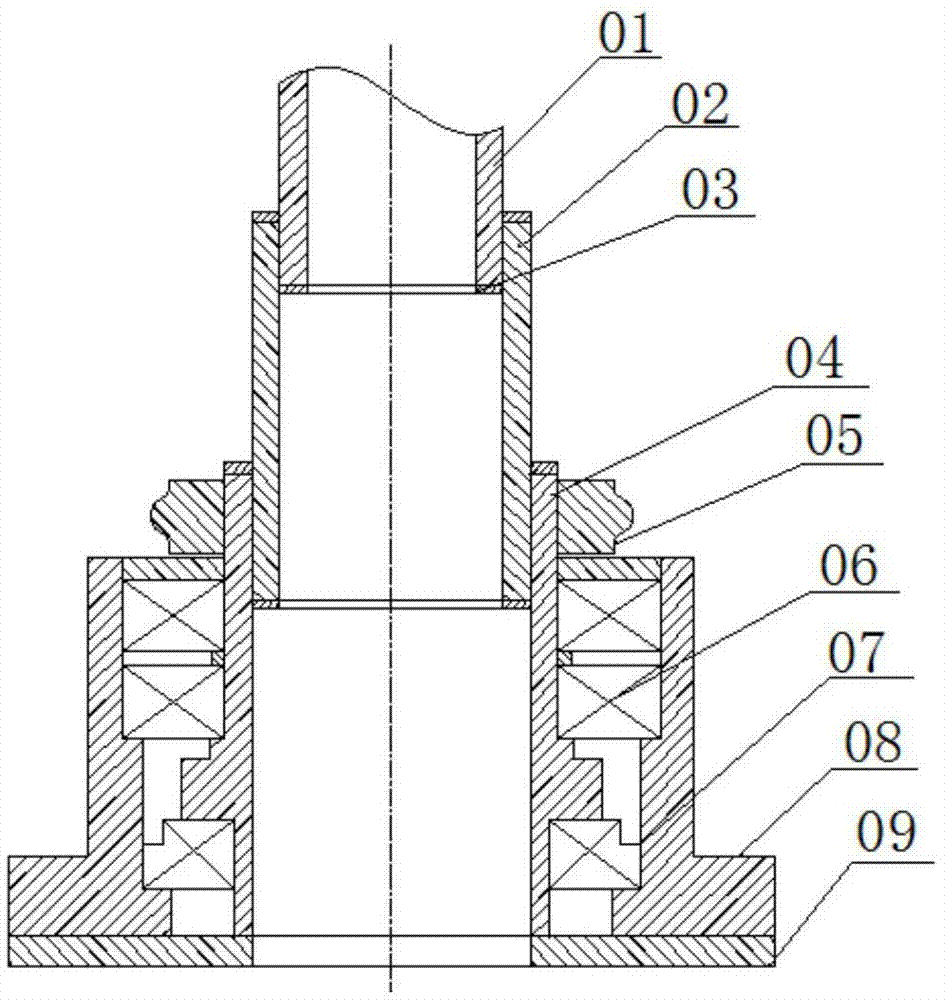

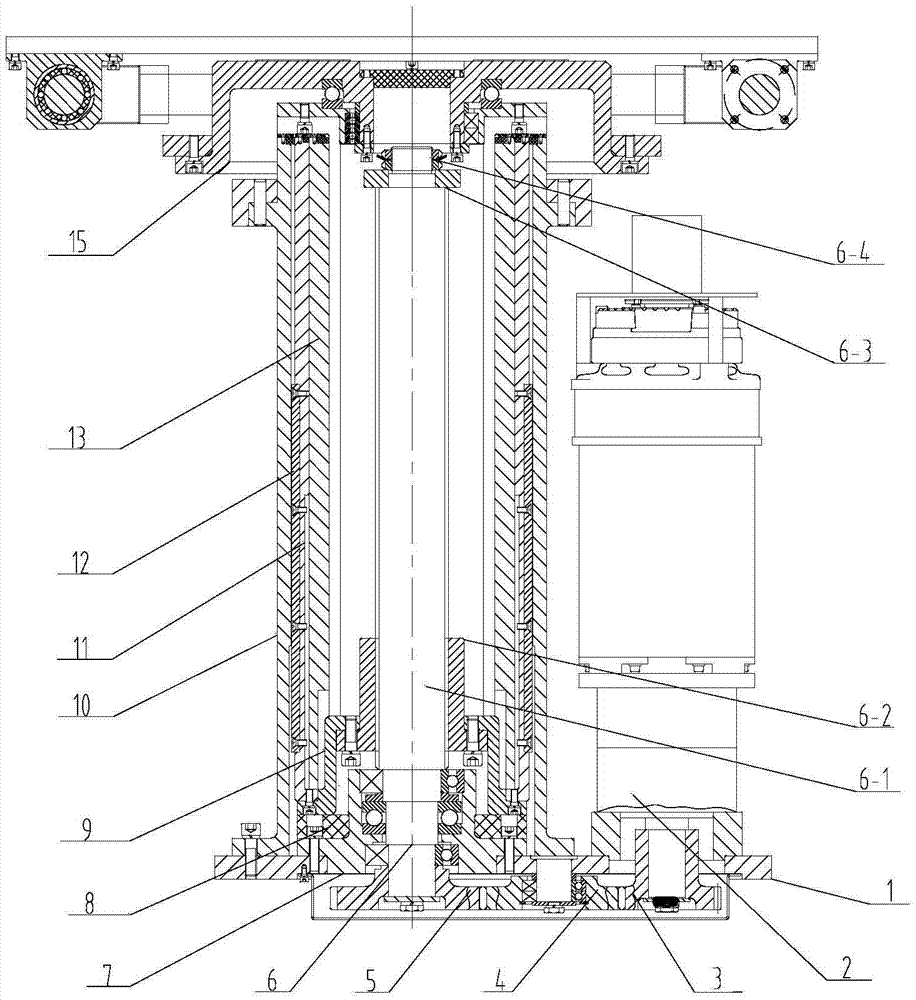

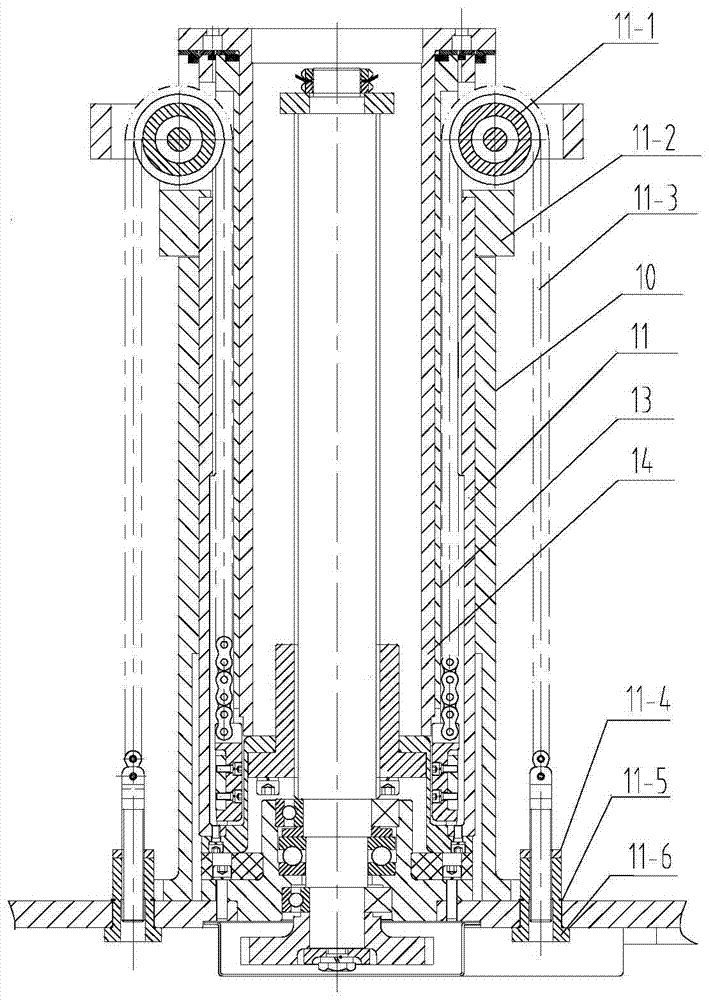

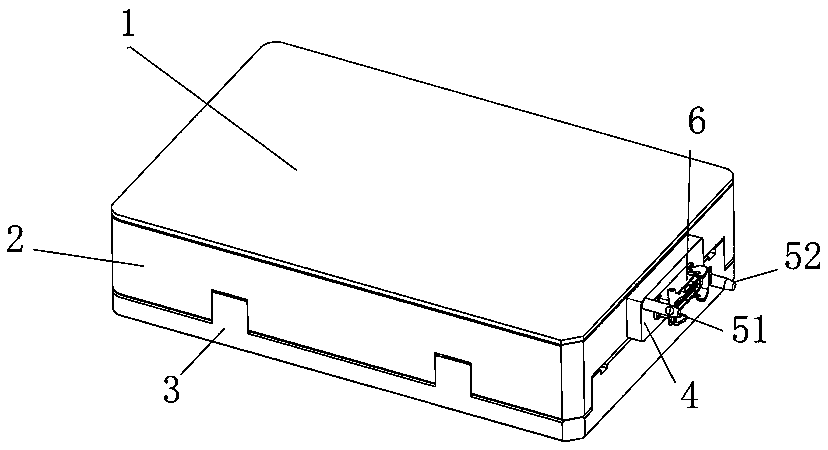

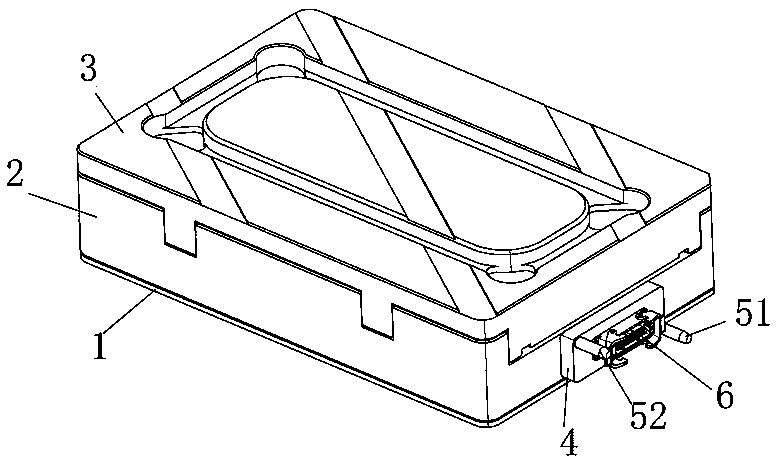

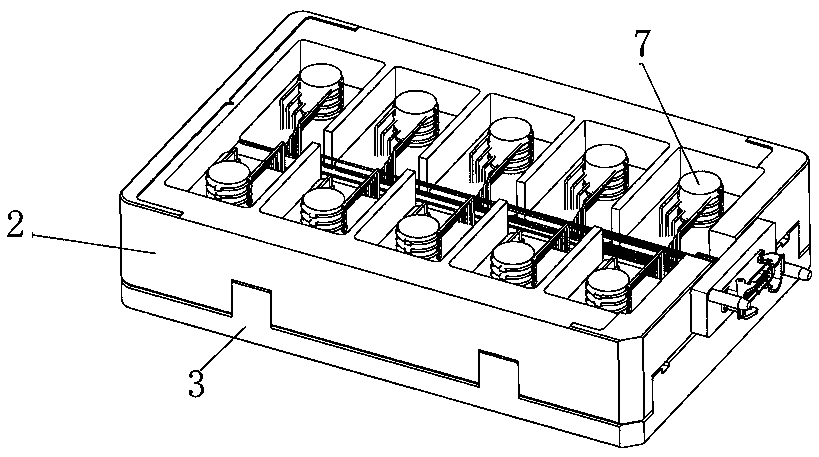

Automatic guiding vehicle with lifting mechanism

InactiveCN106672857ALifting speed is fastLifting framesResilient suspensionsDrive wheelMechanical lift

The invention discloses an automatic guiding vehicle with a lifting mechanism. The automatic guiding vehicle comprises driving wheels, driven wheels and a vehicle body, and the mechanical lifting mechanism is arranged on the vehicle body; the mechanical lifting mechanism comprises a driving mechanism, a fixing cylinder, a rotatable center screw rod, at least two layers of lifting cylinders and a cargo carrying platform, wherein the rotatable center screw rod is located on the central axis of the fixing cylinder, and the lifting cylinders are coaxially sleeved and overlaid between the center screw rod and the fixing cylinder; the driving mechanism can drive the center screw rod to rotate; at least one of the lifting cylinders are the main lifting cylinders, and the rest of the lifting cylinders are the driven lifting cylinders; the main lifting cylinders are in rigidity connection with screw rod nuts matched with the center screw rod; traction mechanisms are connected between the driven lifting cylinder and the main lifting cylinder as well as between the other adjacent driven lifting cylinders; and when the screw rod is driven by the driving mechanism to rotate, the main lifting cylinders move axial and lineal movement along with the center screw rod, and the driven lifting cylinders are driven by the traction mechanisms to move lineal movement in the same direction. The automatic guiding vehicle with the lifting mechanism has the characteristics that the lifting speed is quick, and the automatic guiding vehicle can be adaptable to many situations.

Owner:HUBEI HUACHANGDA INTELLIGENT EQUIP

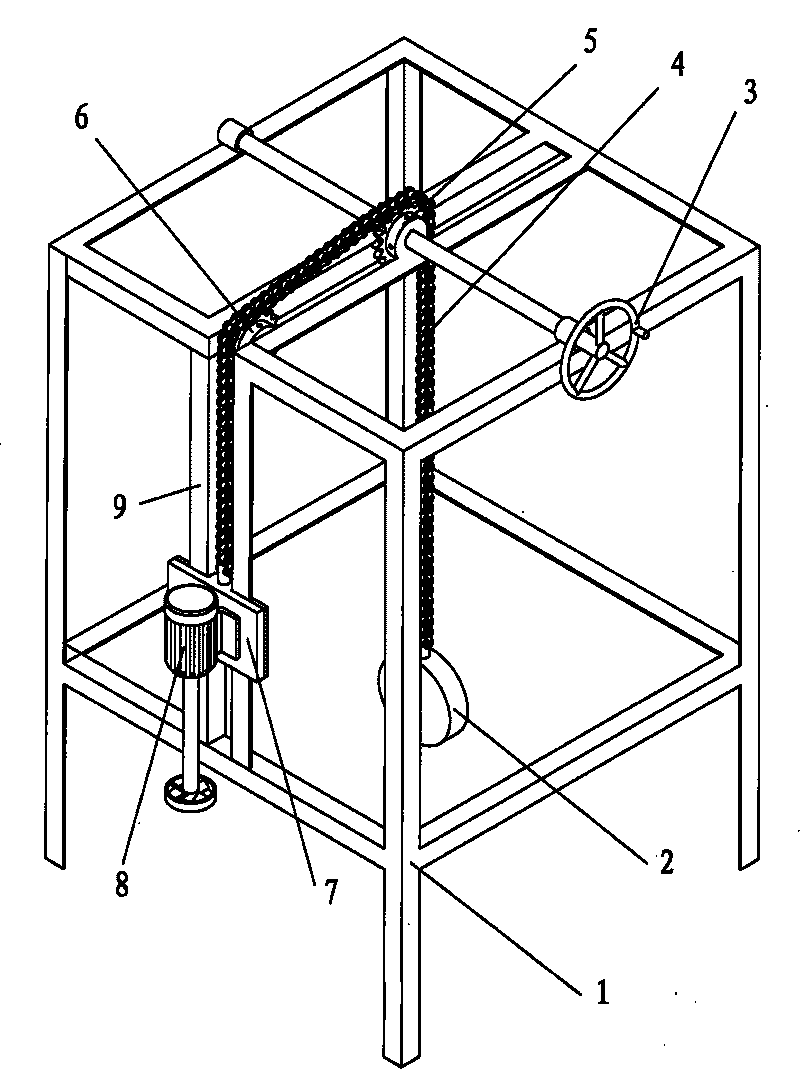

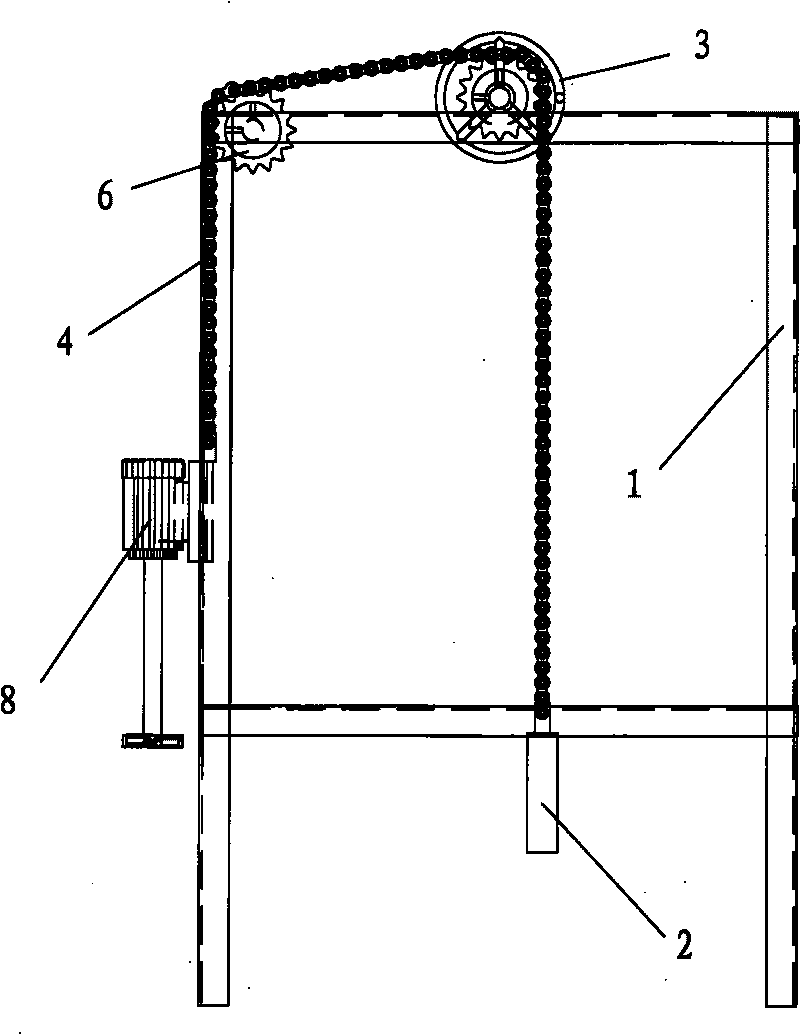

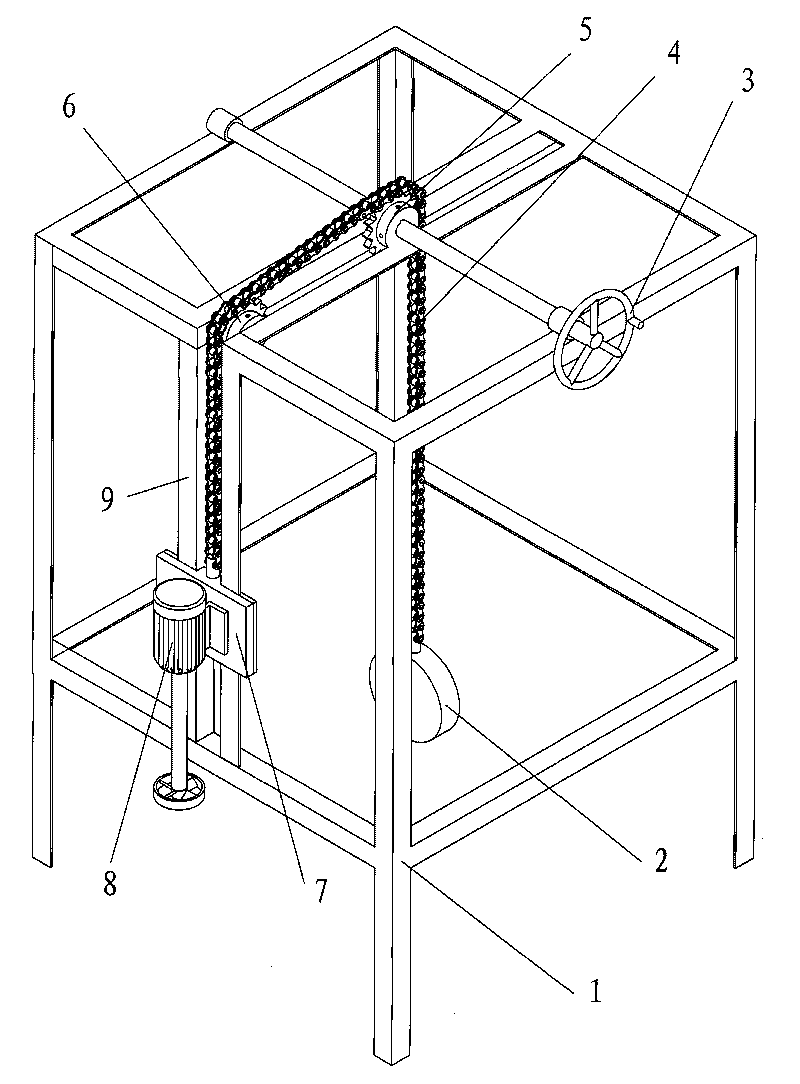

Color paste mixer

InactiveCN101757867ASimple structureLifting speed is fastRotary stirring mixersMixer accessoriesImpellerGear wheel

The invention discloses a color paste mixer, which comprises a rack, a stirring motor and a stirring impeller arranged on an output shaft of the stirring motor, a hand-wheel rotatably arranged on the rack, a second gear and a first gear coaxially connected with the hand-wheel; a chain winds the first gear and the second gear; two ends of the chain are respectively fixed with a counterweight block and a slide block; the stirring motor is fixed on the slide block; and the slide block is slidingly connected with a slide rail. The color paste mixer is simple in structure and quick in lifting speed.

Owner:WUJIANG YUJING EMBROIDERY

A barrel-type three-dimensional garage

The invention relates to the field of cylindrical three-dimensional garage equipment, in particular to a cylindrical three-dimensional garage, which includes a cylindrical garage shaft, an entrance door system arranged at the top of the garage shaft, and a ring with more than two floors vertically distributed along the garage shaft. parking floor, a lifting and rotating platform for accessing vehicles set in the center of the garage shaft, and a traction mechanism that drives the lifting and rotating platform to lift vertically; the invention has a reasonable structure and stable operation, and is more suitable for the storage of vehicles in the cylindrical three-dimensional garage. Use, efficient and stable.

Owner:王景保

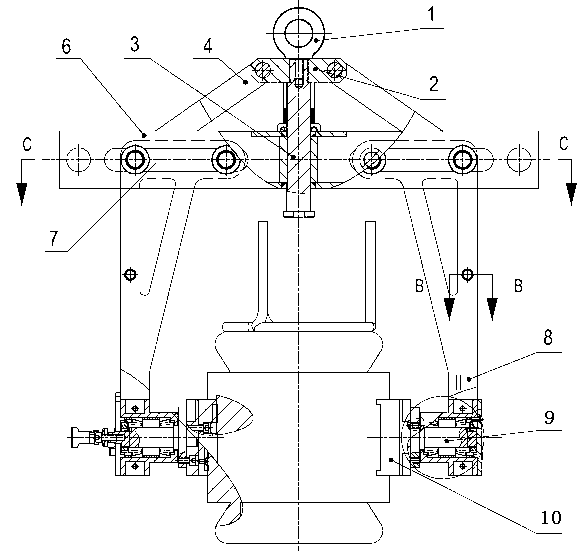

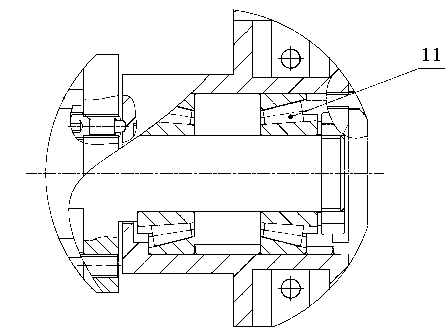

Coiling iron core overturning and hoisting apparatus

ActiveCN103224194ASmall footprintSave man hoursInductances/transformers/magnets manufactureLoad-engaging elementsStructural engineeringMechanical engineering

The invention relates to a turning device, specifically speaking, relates to a coiling iron core overturning and hoisting apparatus. The apparatus comprises the following components: a hanger, a connector, a suspension rod, a connecting rod, a connecting rod bolt component, a suspender main body, a chute, a L shaped support, a revolving axle, a clamping block, a bulb plunger, a rapid clamp, a support bolt component, a connection shaft, a handle, rotating arm and a positioning plunger; the hanger is connected to the connector, and the suspension rod traverses the connector, and the connector and four-piece connecting rods are connected by two revolving axles, and the connecting rod is divided into two groups, and the other end of each group of connecting rod is connected by the bolt component and two L shaped supports, and two L shaped supports form a group, and the bolt component is provided with two bearings, and the bearing is positioned in the suspender main body chute. The technical schemes of the invention have the following beneficial effects: the hoisting speed is fast without workpiece damage; the apparatus occupies a small area of place and saves working hours with high hoisting and overturning efficiencies.

Owner:DALIAN DEXIN M&E TECH ENG

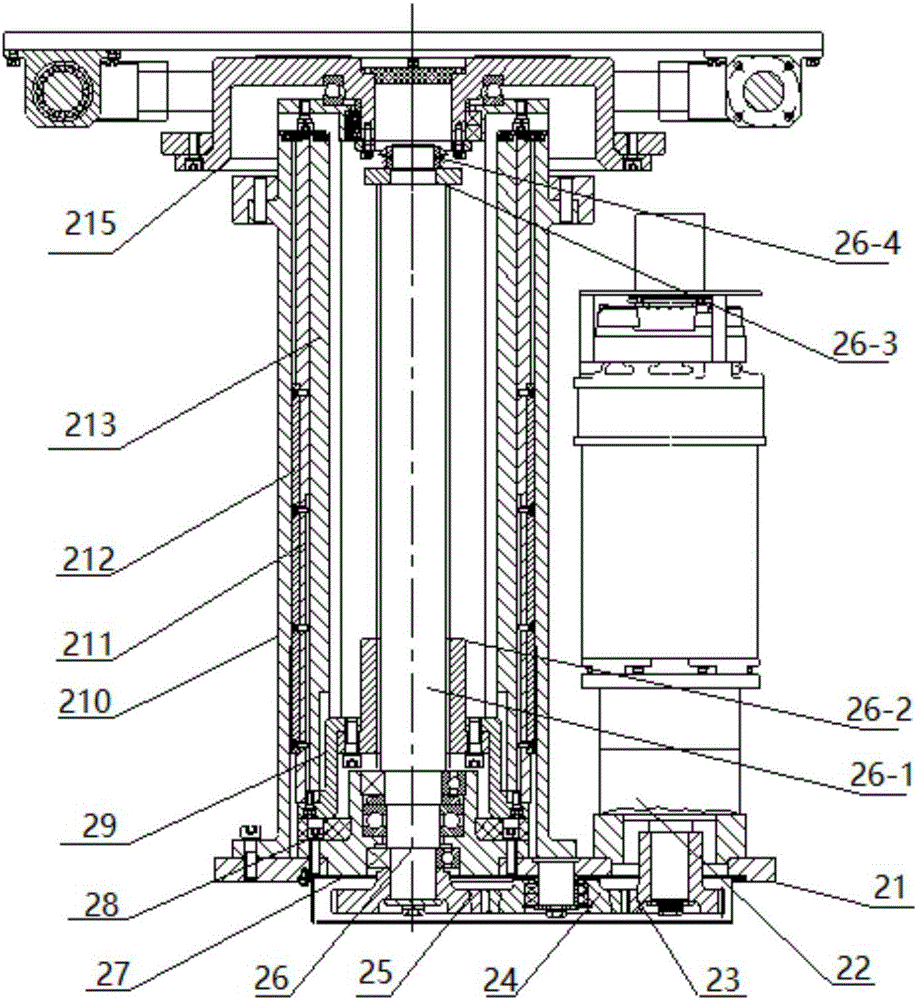

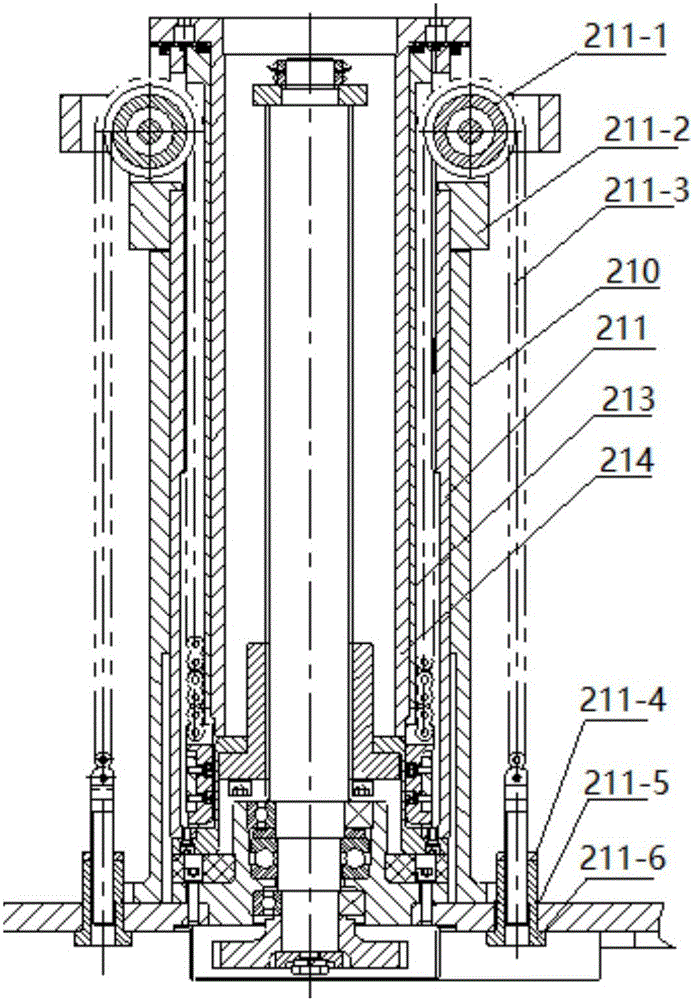

Mechanical lifting mechanism

The invention provides a mechanical lifting mechanism. The mechanical lifting mechanism comprises a driving mechanism, a fixing drum, a rotatable center screw rod, at least two layers of lifting drums and a cargo carrying platform, wherein the rotatable center screw rod is located at the central axis of the fixing drum, the two layers of lifting drums are arranged between the center screw rod and the fixing drum in a coaxially sleeved-folded mode, and the cargo carrying platform is located on the tops of the lifting drums in the innermost layer. The driving mechanism can drive the center screw rod to rotate. In the lifting drums, at least one lifting drum is a driving lifting drum, and the other lifting drums are driven lifting drums. The driving lifting drum is in rigid connection with a screw rod nut matched with the center screw rod. Traction mechanisms are connected between the driven lifting drums and the driving lifting drum as well as between the other adjacent driven lifting drums. When the center screw rod is driven to rotate by the driving mechanism, then the driving lifting drum does linear motion in the axis direction, and the driven lifting drums are driven to do linear motion in the same direction through the traction mechanisms. The mechanical lifting mechanism has the advantages of being compact in structure, long in lifting journey, high in lifting speed and the like.

Owner:HUBEI HUACHANGDA INTELLIGENT EQUIP

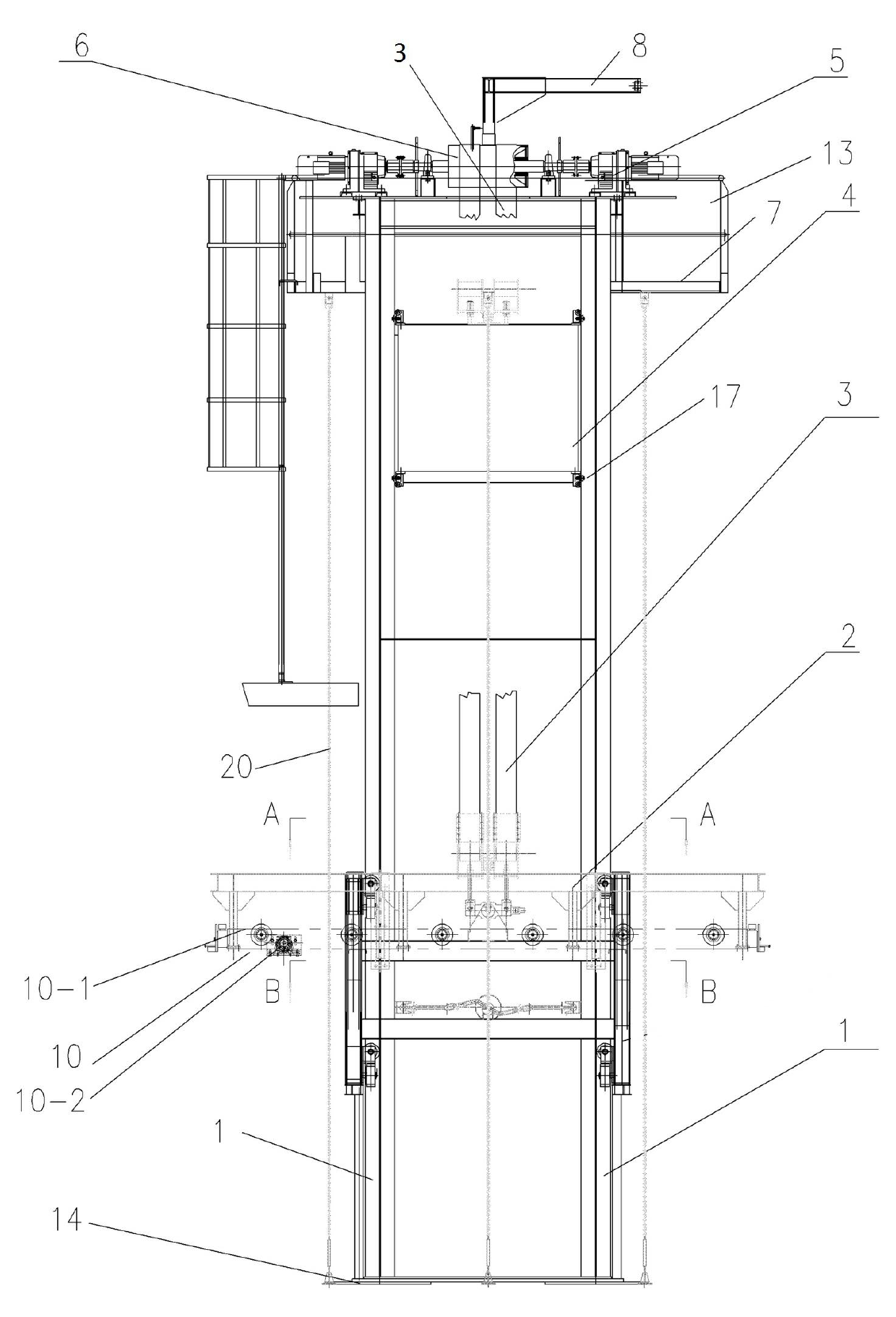

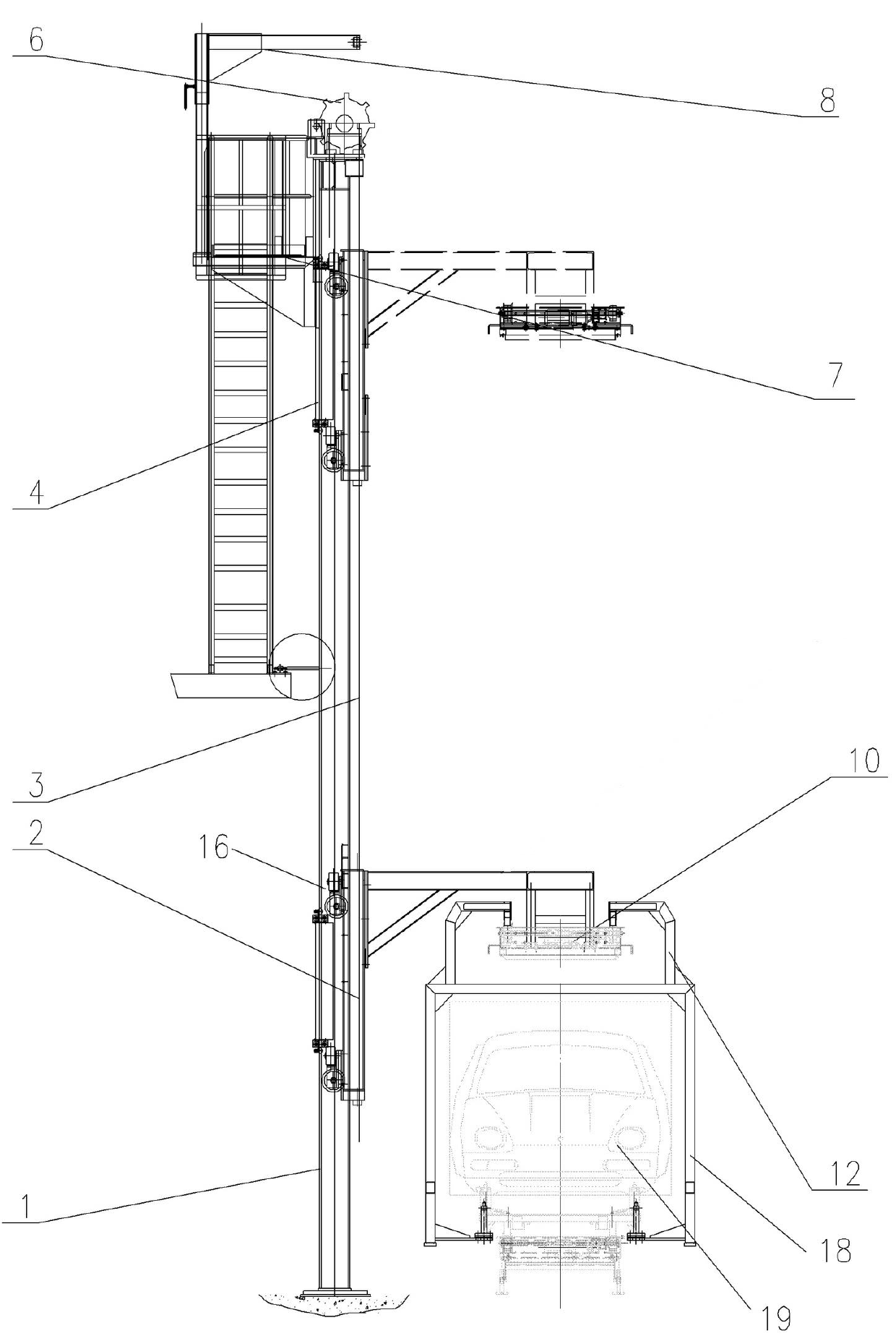

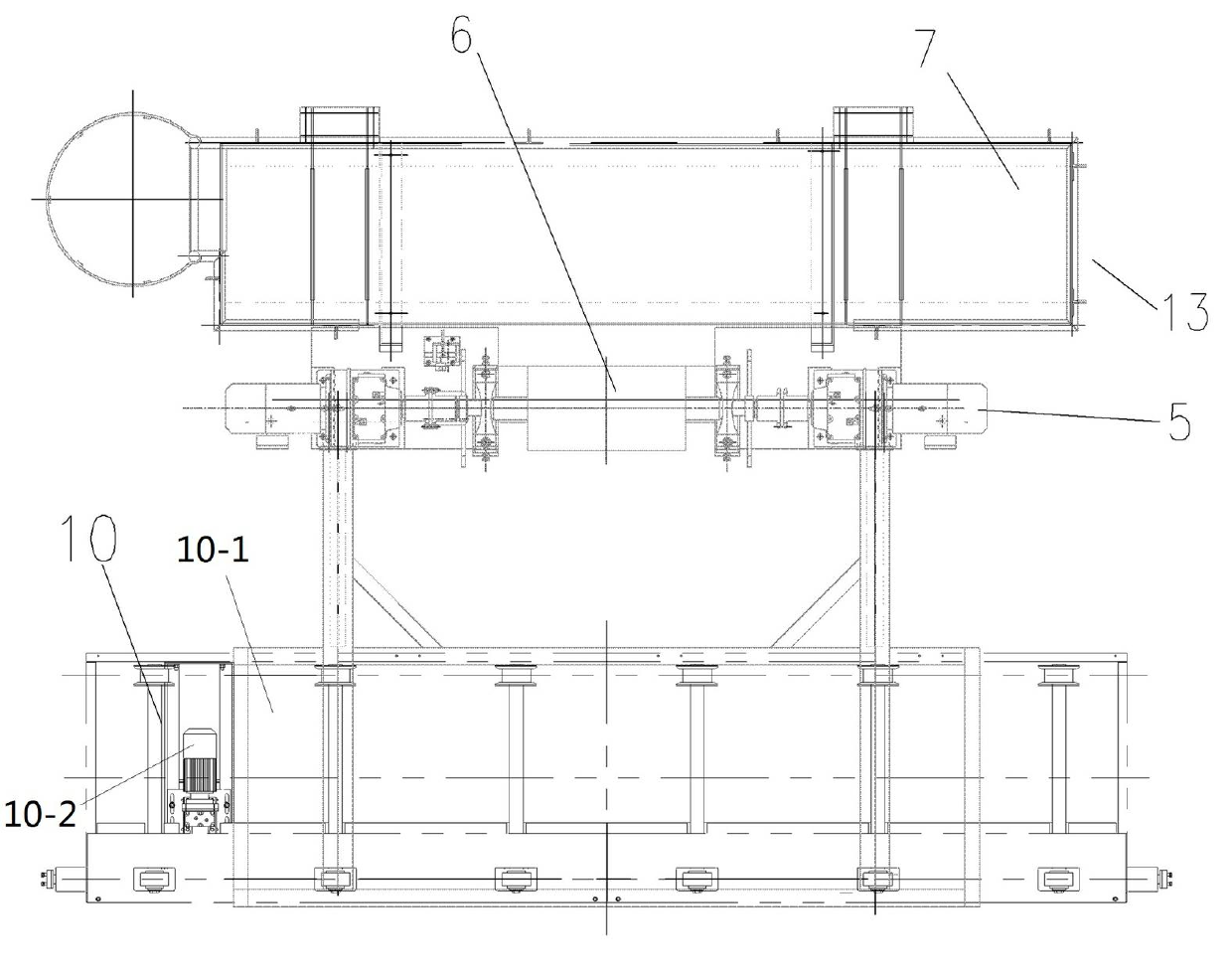

Slide lifter

The invention relates to a slide lifter which comprises two H-shaped upright columns, a lifting frame and a counterweight frame, wherein each H-shaped upright column is provided with a web plate, a front flange and a rear flange; and the lifting frame and the counterweight frame are respectively assembled at the front sides and the rear sides of the upright columns through the guide of a lifting frame guide mechanism and a counterweight frame guide mechanism. The lifting frame guide mechanism comprises upper and lower lifting frame guide wheel sets; the upper and lower lifting frame guide wheel sets respectively comprise upper and lower lifting frame guide rollers matched with the corresponding web plates in a limiting manner and also respectively comprise upper and lower lifting frame supporting rollers matched with supports on the rear end surfaces of the corresponding front flanges or on the front end surfaces of the corresponding rear flanges in a limiting manner; the counterweight frame guide mechanism comprises upper and lower counterweight frame guide wheel sets; and the upper and lower counterweight frame guide wheel sets respectively comprise counterweight frame left and right guide rollers matched with the corresponding rear flanges in a guiding and limiting manner and counterweight frame front and rear guide roller sets. With the adoption of the slide lifter, the problem that the lifting frame guide mechanism and the counterweight frame guide mechanism are not easily assembled on the upright columns is solved.

Owner:ZHONGQI CHANGXING LUOYANG ELECTROMECHANICAL EQUIP ENG +1

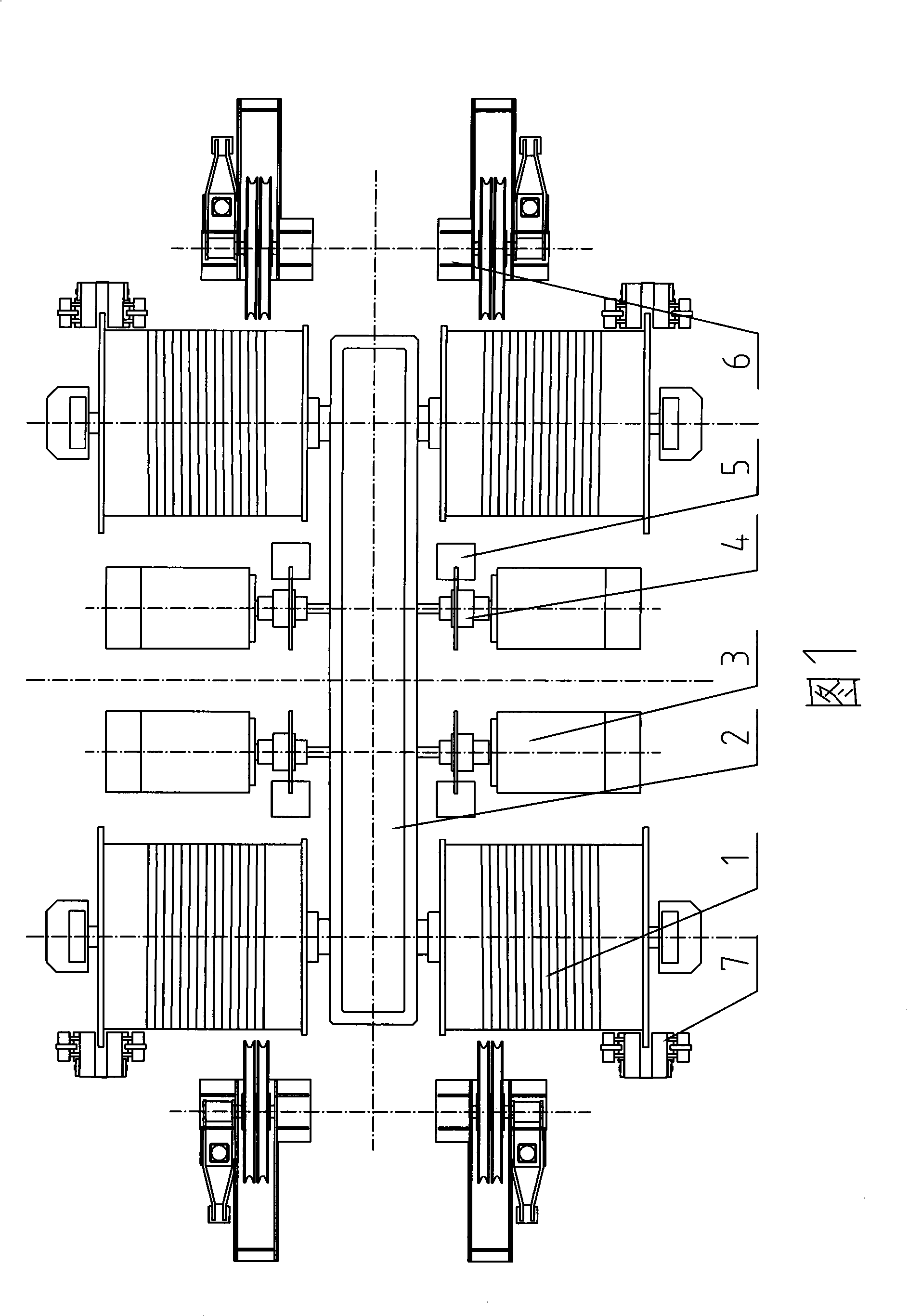

Hoisting mechanism of crane for coke pot

InactiveCN101343024AImprove reliabilityImprove securityCoke quenchingWinding mechanismsCouplingDistributed structure

The invention provides a lifting mechanism of a coke tank carrying crane, which relates to the lifting transportation and coking machinery; the lifting mechanism is composed of a winding drum group, a planetary reducer, a motor, couplings, brakes, a crown block group and a safety brake; the planetary reducer mounted on the pulley frame is provided with four input shaft ends and four output shaft ends which are symmetrically distributed. The four input shafts are arranged on the middle part of the planetary reducer and connected with the motor respectively through the couplings; the brakes are respectively mounted on the couplings; the four output shafts are arranged on both sides of the end part of the planetary reducer and connected with the single linkage winding drum group respectively; the safety brake directly acts on the winding drum edge of the single linkage winding drum group; the crown block group is mounted on the opposite side of the single linkage winding drum group. The lifting mechanism of the coke tank carrying crane has the advantages of novel structure, safety, reliability, great bearing capacity, symmetrically-distributed structure, even stress and being the lifting mechanism device of the novel coke tank carrying crane with economical and practical properties.

Owner:DALIAN HUARUI CO LTD

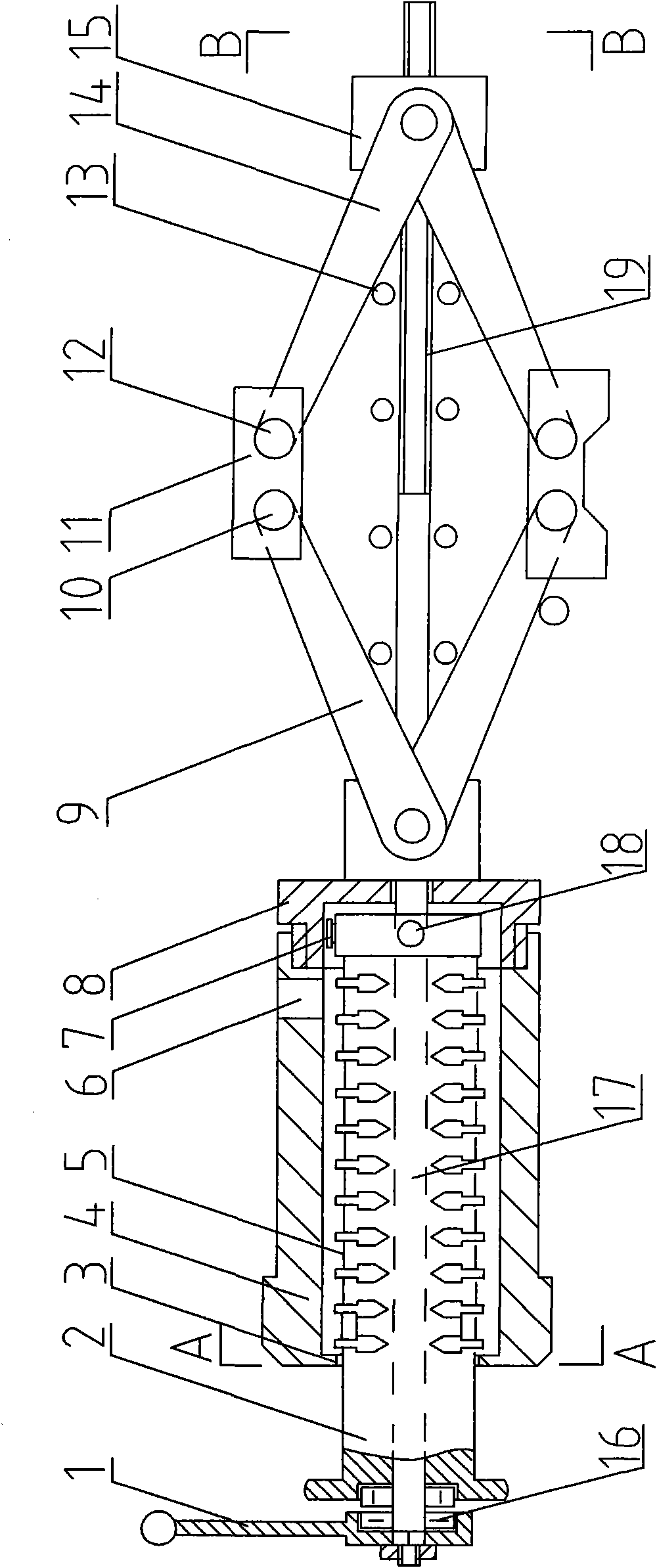

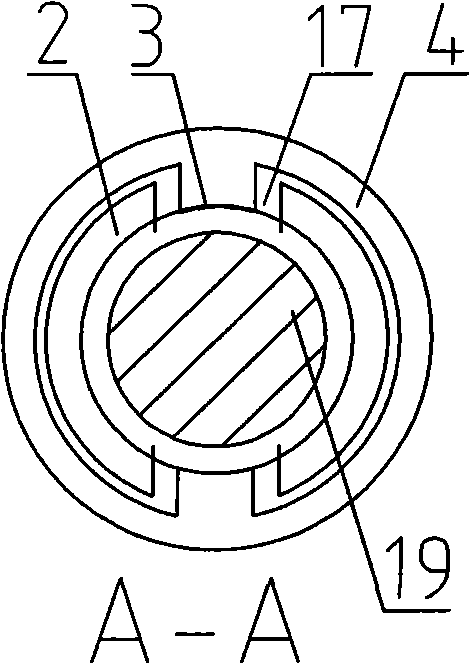

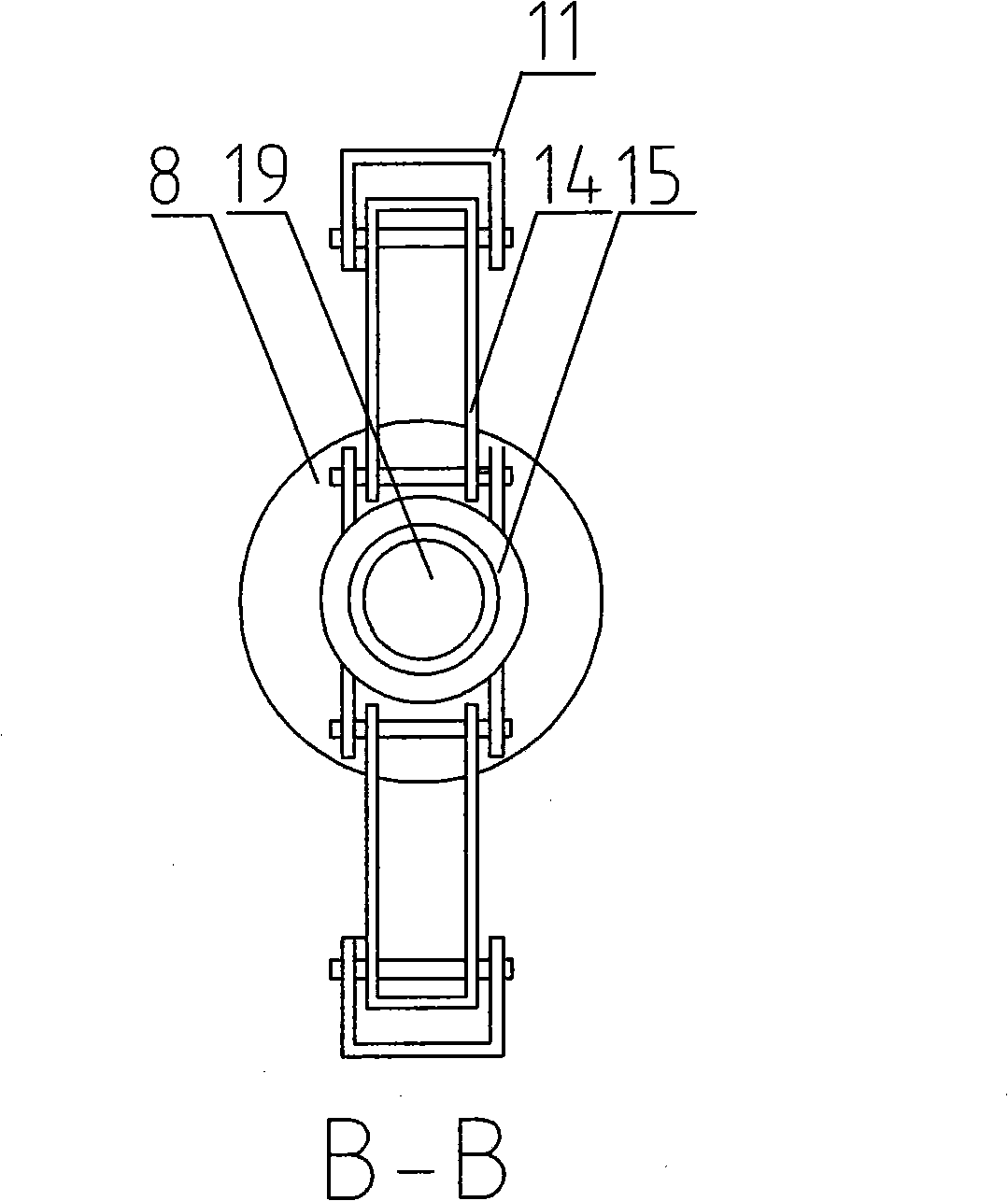

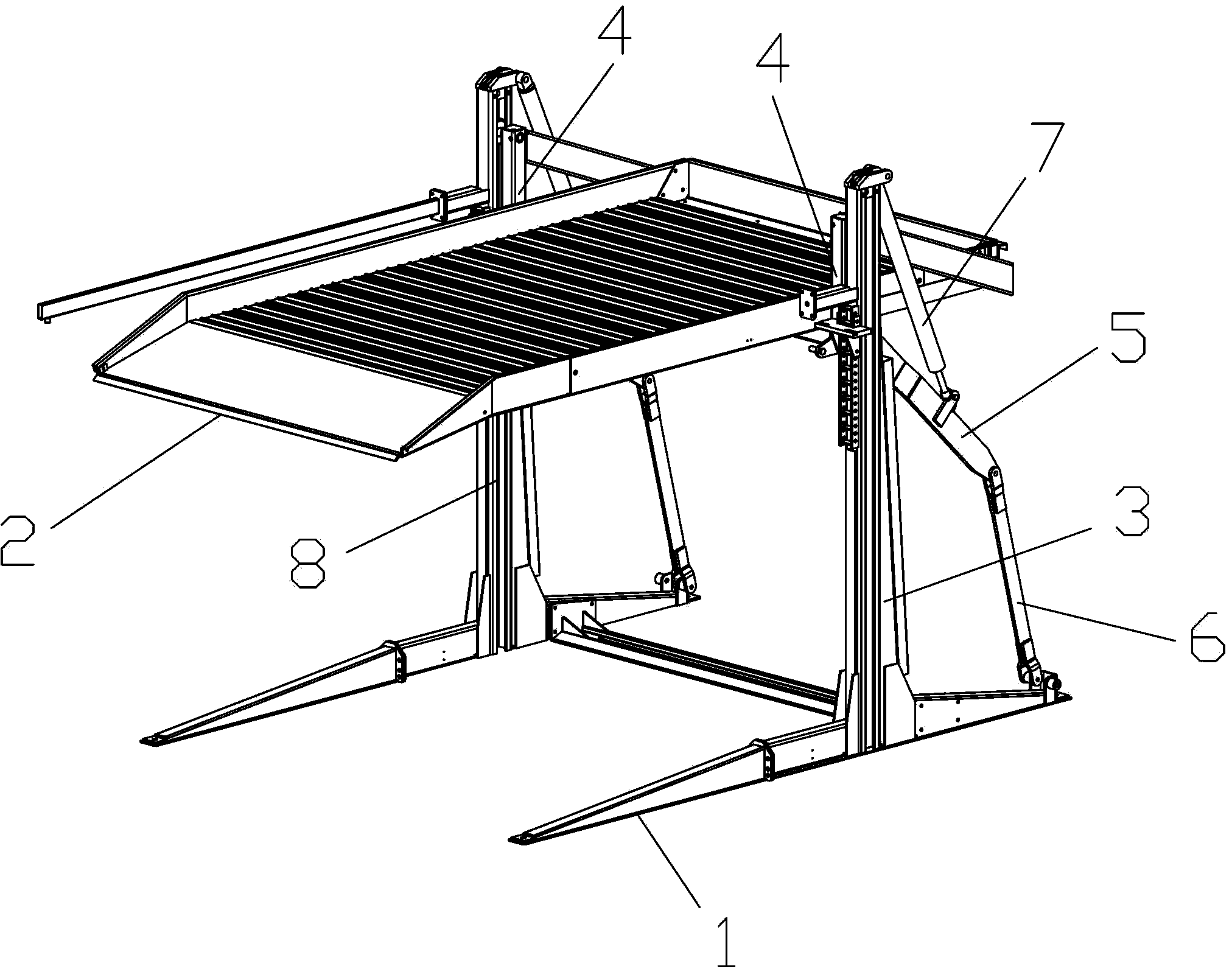

Quick lifting machine

InactiveCN104343261AIncrease the speed of liftingEasy to installLifting framesParkingsHydraulic cylinderEngineering

A quick lifting machine comprises a base and a car carrying plate. Columns are arranged on the base symmetrically, lifting sliding blocks are arranged on two sides of the car carrying plate symmetrically, the car carrying plate is arranged between the columns, the lifting sliding blocks of the car carrying plate are installed in sliding grooves formed corresponding to the columns in a sliding mode, and a connection rod driving mechanism is installed between the lifting sliding blocks and the base. The connection rod driving mechanism comprises a main connection rod, an auxiliary connection rod and a hydraulic cylinder. The front end of the main connection rod is hinged to the lifting sliding blocks, the rear end of the main connection rod is hinged to the front end of the auxiliary connection rod, the rear end of the auxiliary connection rod is hinged to the rear portion of the base, one end of the hydraulic cylinder is hinged to the top of the columns, and the other end of the hydraulic cylinder is hinged to the middle of the main connection rod. The hydraulic cylinder of the quick lifting machine lifts the car carrying plate through the connection mechanism to enable a labor-costing lever structure to be formed by the main connection rod and the hydraulic cylinder, the stroke of the hydraulic rod of the lifting machine is reduced, and the lifting speed of the car carrying plate is increased. The mechanical balancing structure is adopted, the whole structure is simple, and the lifting machine is easy to install and maintain.

Owner:QINGDAO DESIREE AUTOMOBILE INSPECTION DEVICE

Equipment for balancing outofstep sustained center of crane

InactiveCN101003347ALifting speed is fastShorten the lengthWinding mechanismsLoad-engaging elementsConductor CoilMultiple layer

An apparatus for equalizing between asynchronous lifting points of lifter is composed of steel cable, spool for winding said steel cable by multiple layers, spool flanges, equalizing beam, and a spool regulating flange at the internal side of spool flange for changing the active length of spool to equalize between asynchronous lifting points.

Owner:WEIHUA GROUP

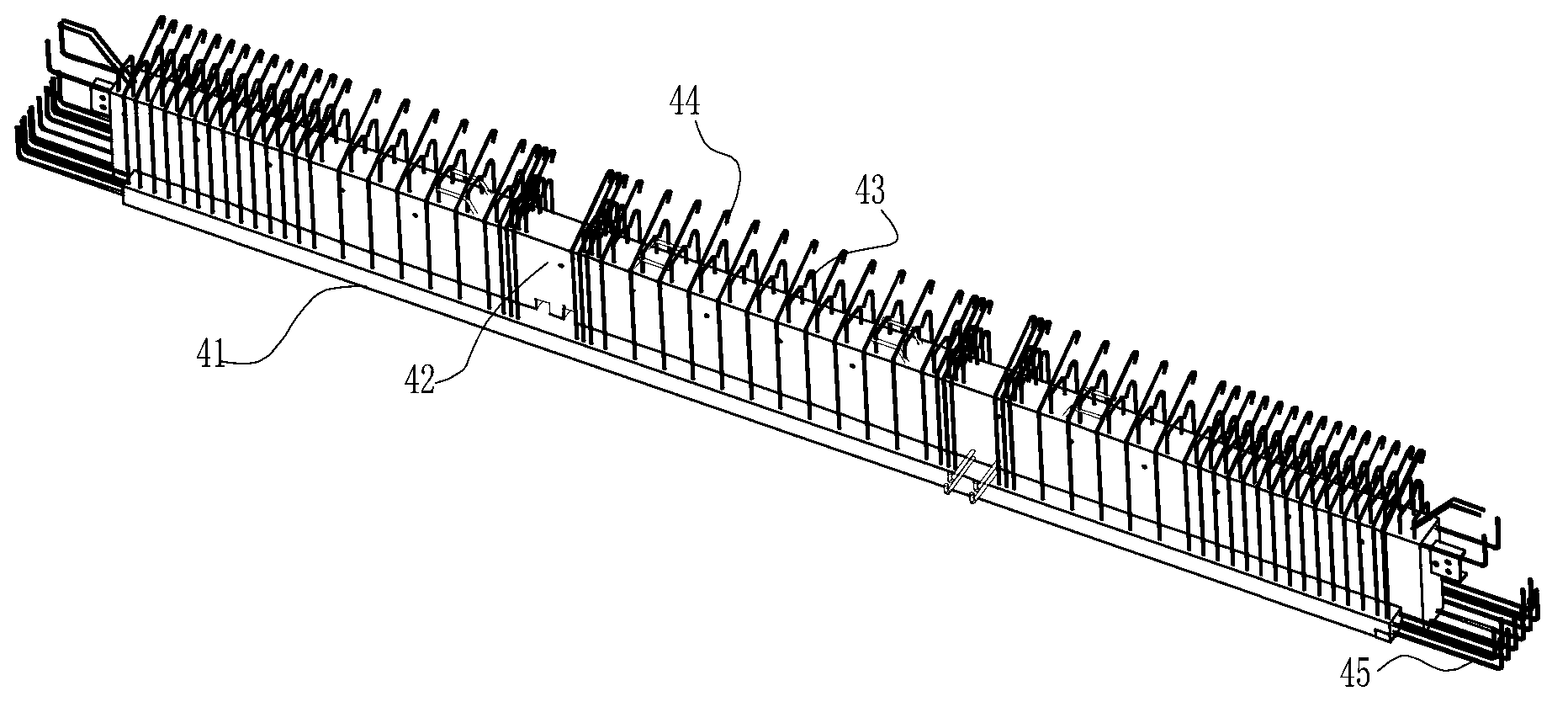

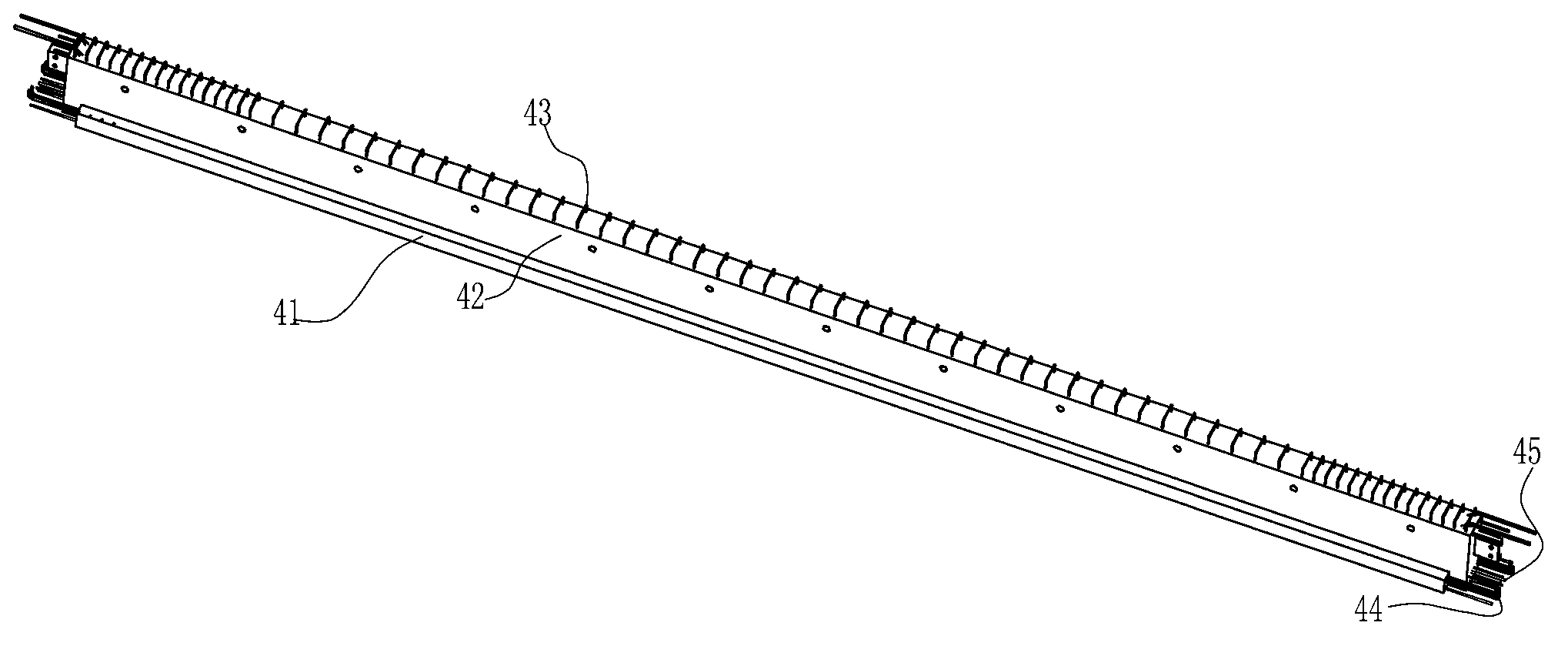

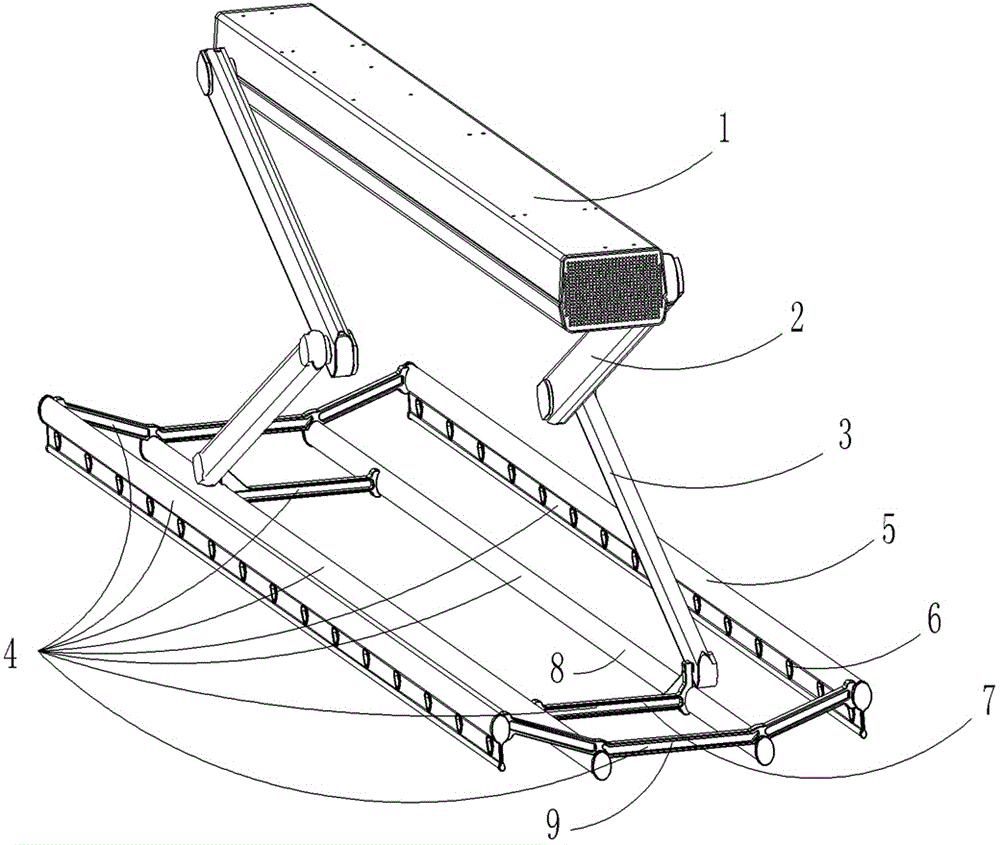

Auto-lift airing machine with double power crank arms

ActiveCN104562594AWon't shakeReasonable driving and lifting structure relationshipOther drying apparatusTextiles and paperGear driveCrank

The invention belongs to the field of living articles and relates to an auto-lift airing machine with double power crank arms. The auto-lift airing machine comprises a main part (1), a crank arm A (2), a crank arm B (3) and an airing bar unit (4). A motor, a reducer and a gear drive device are mounted within a shell of the main part (1). A wire pulley drive device is mounted in the crank arm A (2). The main part (1) is connected to the crank arm A (2), the crank arm B (3) and the airing units (4) through hinges. Under driving of the a power drive device of the main part, the crank arm A (2) and the crank arm B (3) rotate oppositely in the same time to lift the airing bar unit (4). The auto-lift airing machine has the advantages that the drive lifting structural relation is more reasonable, overall appearance is attractive, lifting speed is high, noise is lower, and power consumption is low.

Owner:王方白

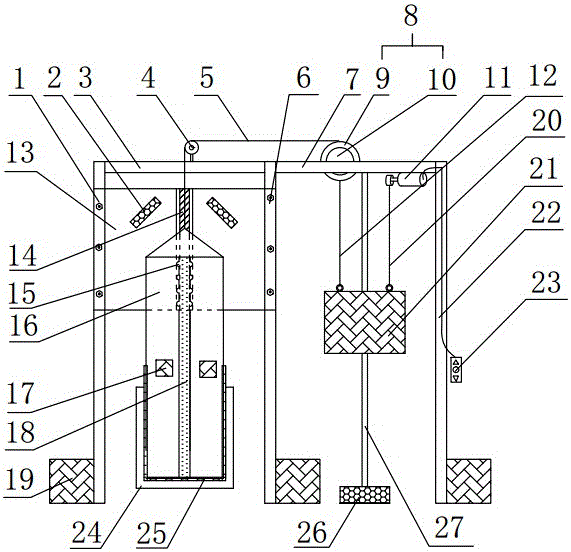

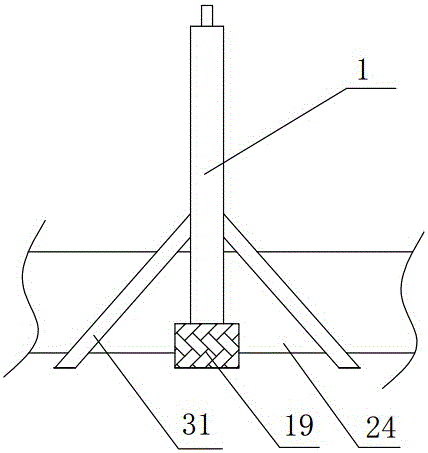

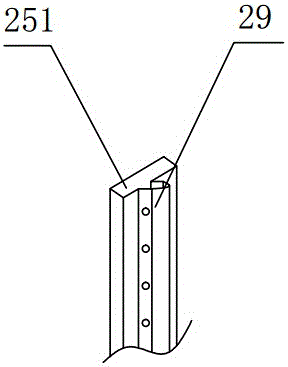

Automatic gantry type gate used for simulating instantaneous dam break

ActiveCN106087852AOpen fastLifting speed is fastBarrages/weirsHydraulic modelsElectric machineryEngineering

The invention belongs to the field of hydraulics experimental models and particularly relates to an automatic gantry type gate used for simulating the instantaneous dam break. The automatic gantry type gate comprises a gantry type support, a gate plate located below the gantry type support and a gate plate lifting control device. The gate plate lifting control device comprises a first weight block matched with a vertical guide rail fixedly connected to the gantry type support, and a lifting motor controlling the first weight block to ascend and descend. The gate plate is connected with the first weight block after being connected to a pulley block arranged on the gantry type support in a winding manner through a steel cable set. The gantry type support is fixedly provided with a fixing plate provided with a guide groove. The guide groove slides vertically in cooperation with a vertical guide bar arranged on the gate plate. Sealing buffering bars are arranged on the edges of the two sides of the gate plate and at the bottom end of the gate plate correspondingly. The first weight block is controlled to ascend and descend through a lifting motor controller, and therefore the gate plate is controlled to ascend and descend. The automatic gantry type gate can be automatically started and reset and is suitable for various sizes of water tanks, time and labor are saved, and errors can be effectively reduced.

Owner:ZHEJIANG UNIV

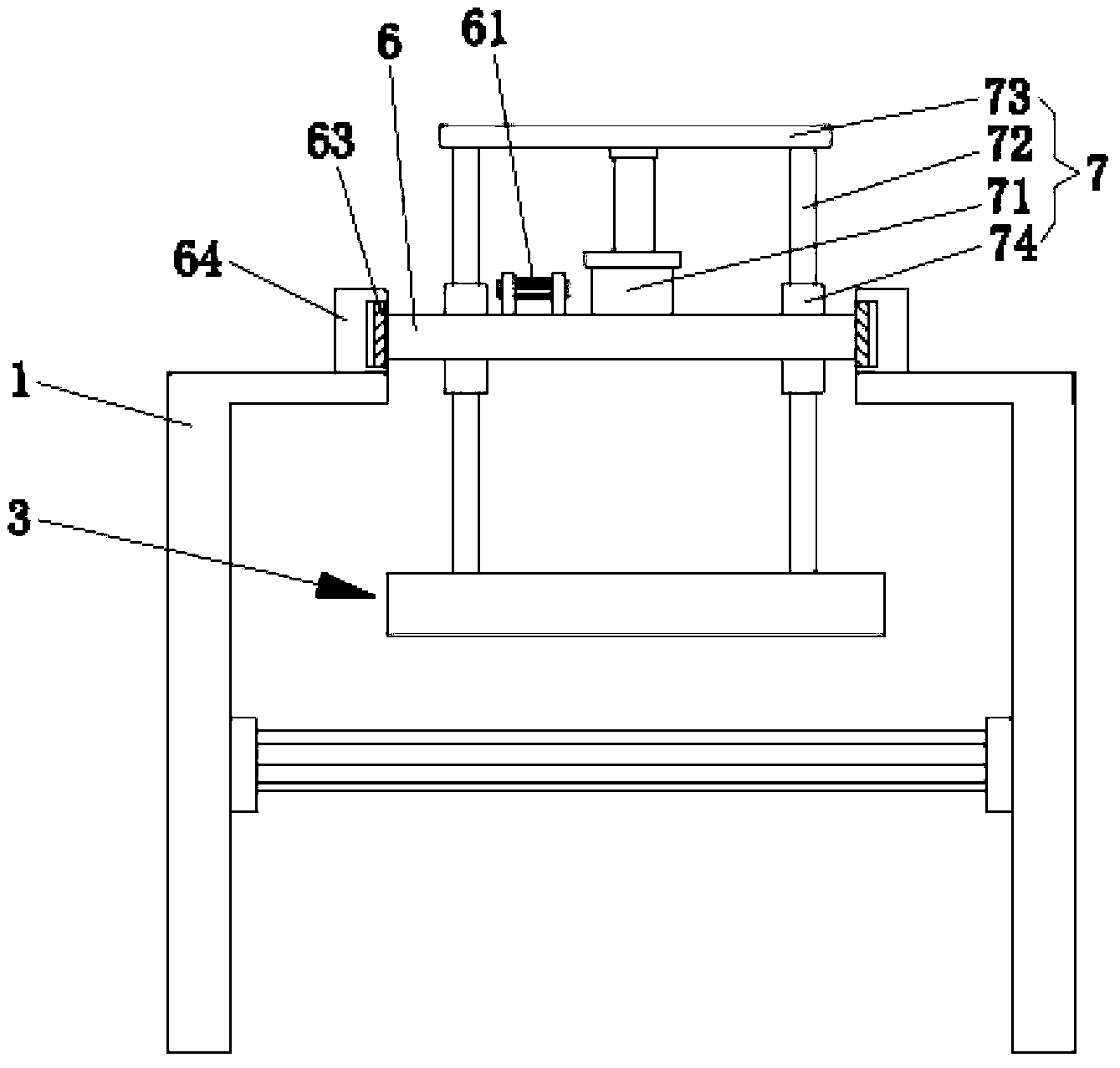

Intelligent temperature control mold for hot bending of 3C member, and control method thereof

PendingCN109970326AEasy to controlUniform temperatureGlass reforming apparatusGlass productionTemperature controlHysteresis

The invention discloses an in intelligent temperature control mold for hot bending of a 3C member, and a control method thereof. The mold comprises an upper mold and a lower mold, the upper mold is stitched on the lower mold, an accommodating cavity is formed between the upper mold and the lower mold, the upper mold and the lower mold are respectively connected with a primary heating device, a secondary heating device is arranged in the lower mold, a heat conducting seal plat is mounted at the bottom surface of the lower mold, and the mold is heated by the control of the primary heating deviceand the secondary heating device in order to effectively control the temperature. The mold and the control method have the advantages of high temperature rising rate, small hysteresis effect, and easiness in realization of temperature regulation.

Owner:GUANGDONG HUST IND TECH RES INST

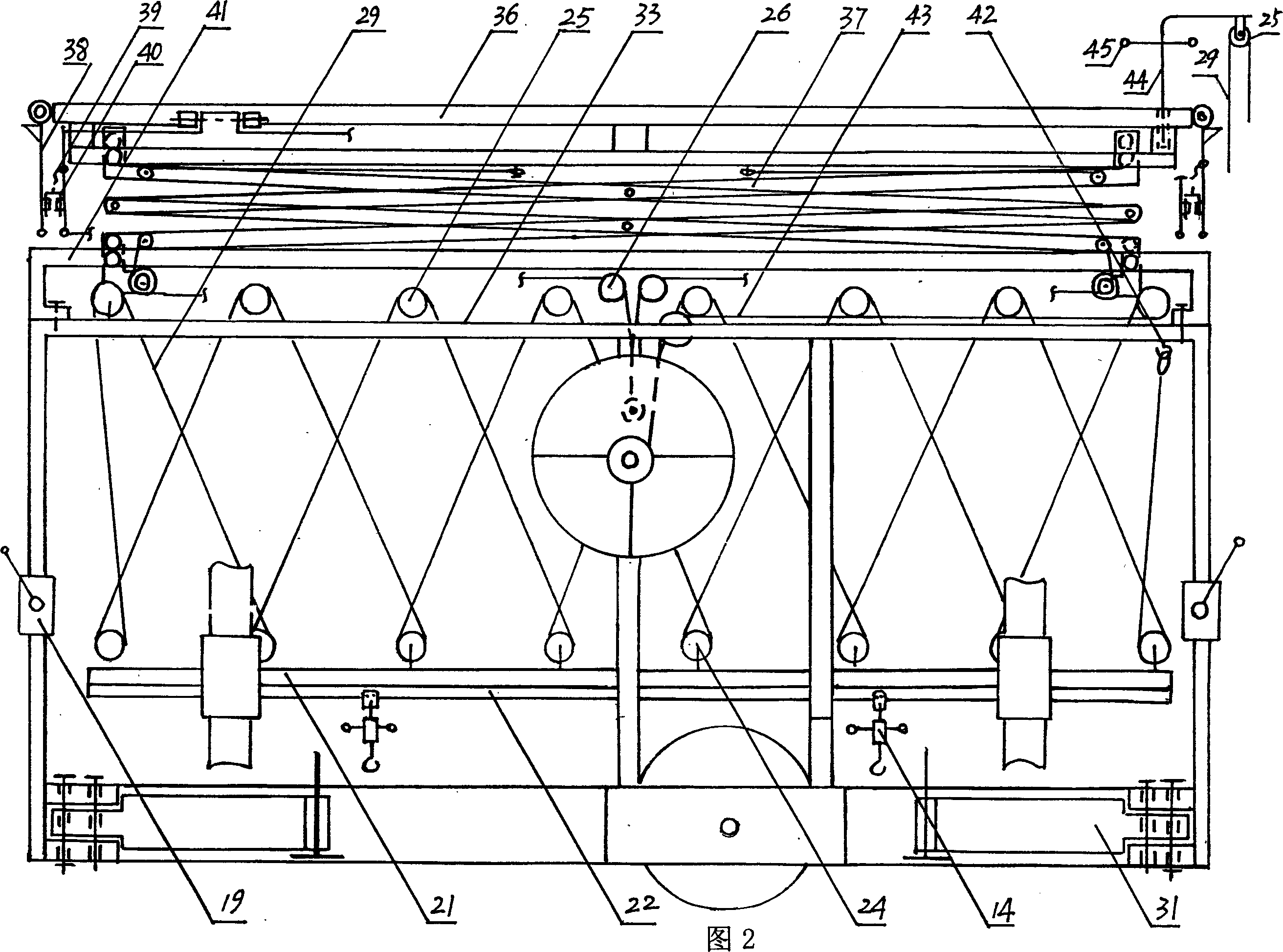

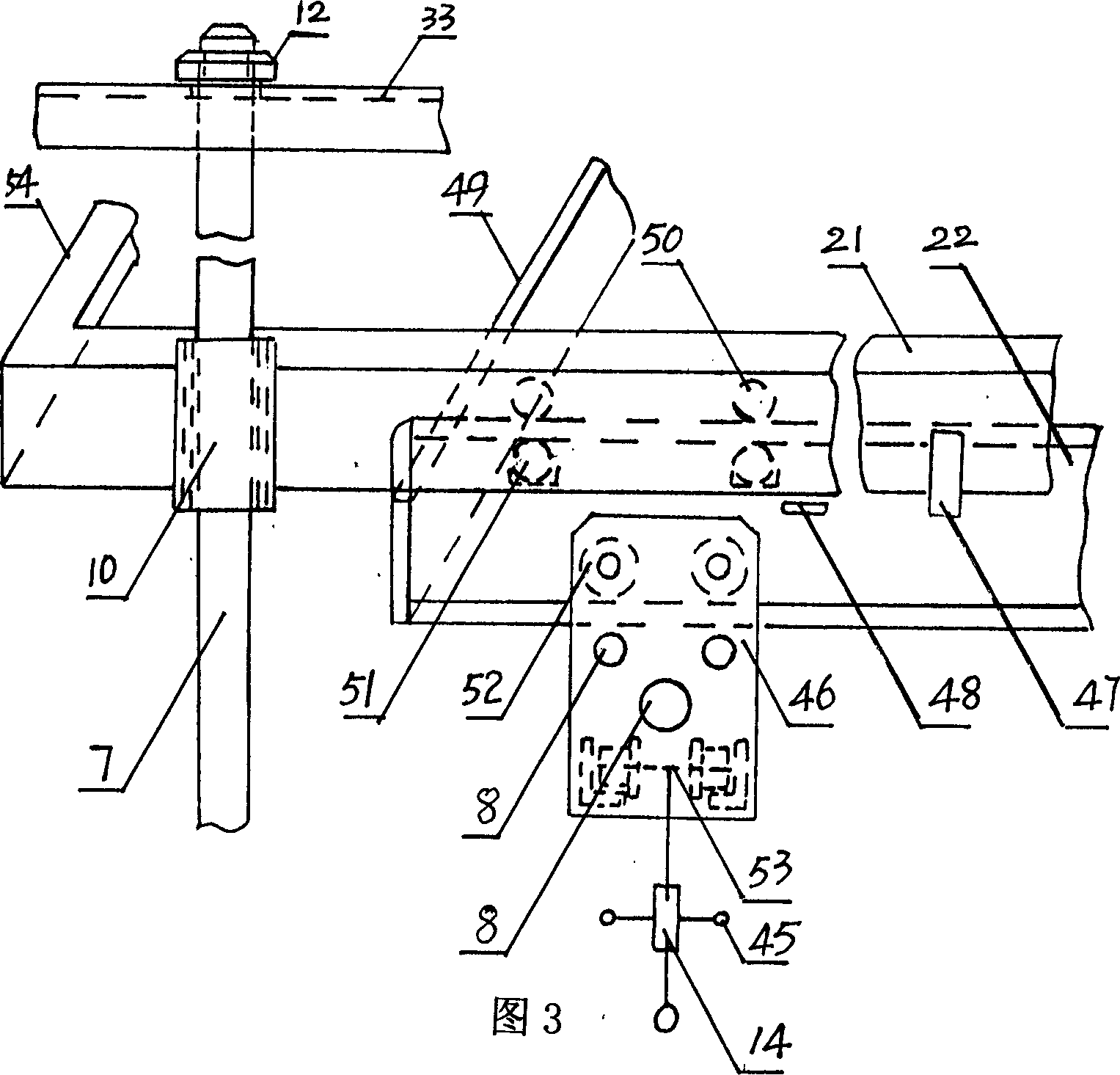

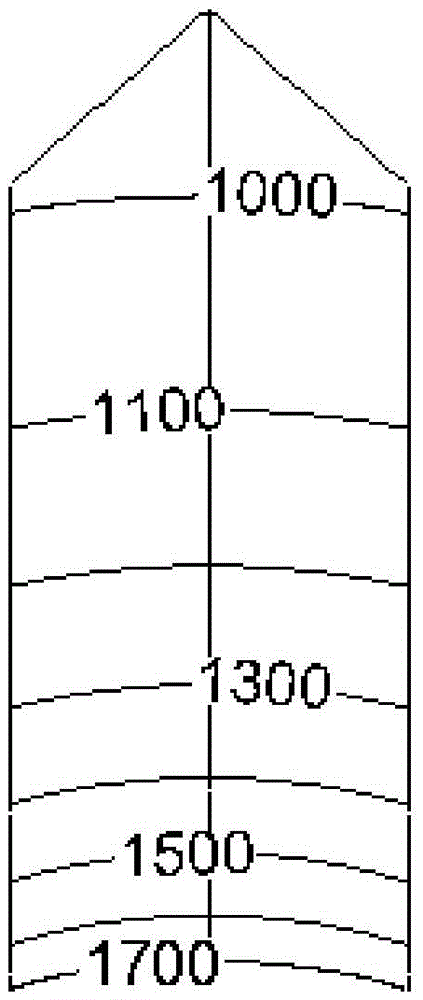

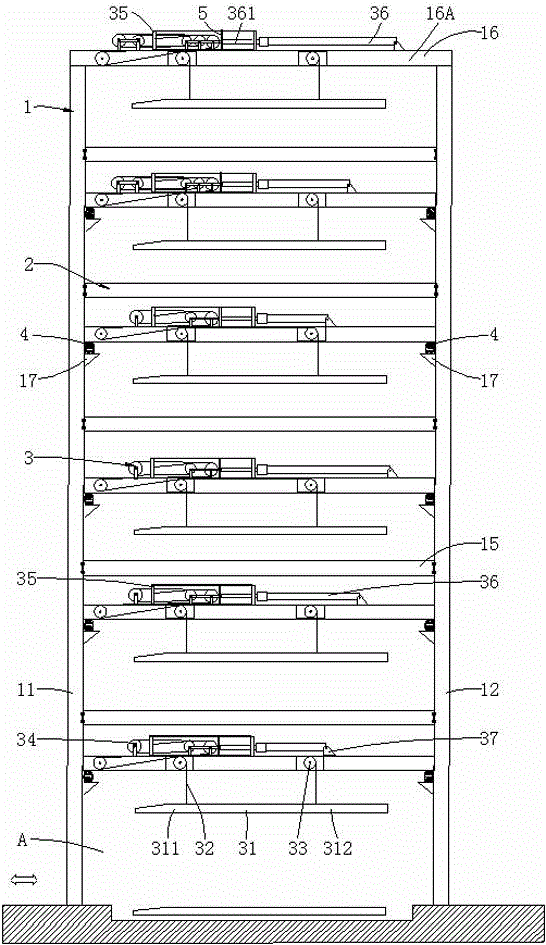

High-speed hoisting system for steel wire ropes on electric push rods

The invention relates to a high-speed hoisting system for steel wire ropes on electric push rods, which comprises multiple layers of three-dimensional garages and car-loading lifting devices, wherein each three-dimensional garage is composed of an outer frame structure and an inner frame structure, each layer of the garage is provided with a car-loading lifting device, and the upper and lower adjacent garages are separated by the inner frame structure. Each car-loading lifting device comprises a car-loading plate, four steel wire ropes, a plurality of guide pulleys, a four-fluted pulley block and a holder thereof, an electric push rod and a mounting rack, wherein the four steel wire ropes are used for lifting the car-loading plate, the electric push rod and the four-fluted pulley block are arranged at the top of each layer of the garage, one ends of the steel wire ropes are fixed on the car-loading plate, the other ends of the steel wire ropes are fixed on the mounting rack after passing across the guide pulleys and the four-fluted pulley block, and the electric push rod can drive the four-fluted pulley block to move in the holder. The high-speed hoisting system disclosed by the invention takes the electric push rod as a power driving source, and the actual lifting speed of the car-loading plate is 4 times and 6 time as larger as the actual pushing speed of the electric push rod in case that the four-fluted pulley block carries out winding in a rate of 1:4 and a rate of 1:6. According to the invention, the lifting speed is high and can reach 8-12 m / min; and the high-speed hoisting system is simple in structure and convenient to maintain.

Owner:HANGZHOU DAZHONG BOAO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com