Full-automatic paving machine of ceramic colored code bricks

A color-coded brick, fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of sorting the front and back of color-coded bricks, and achieve fully automatic laying, saving production costs, and reducing labor effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

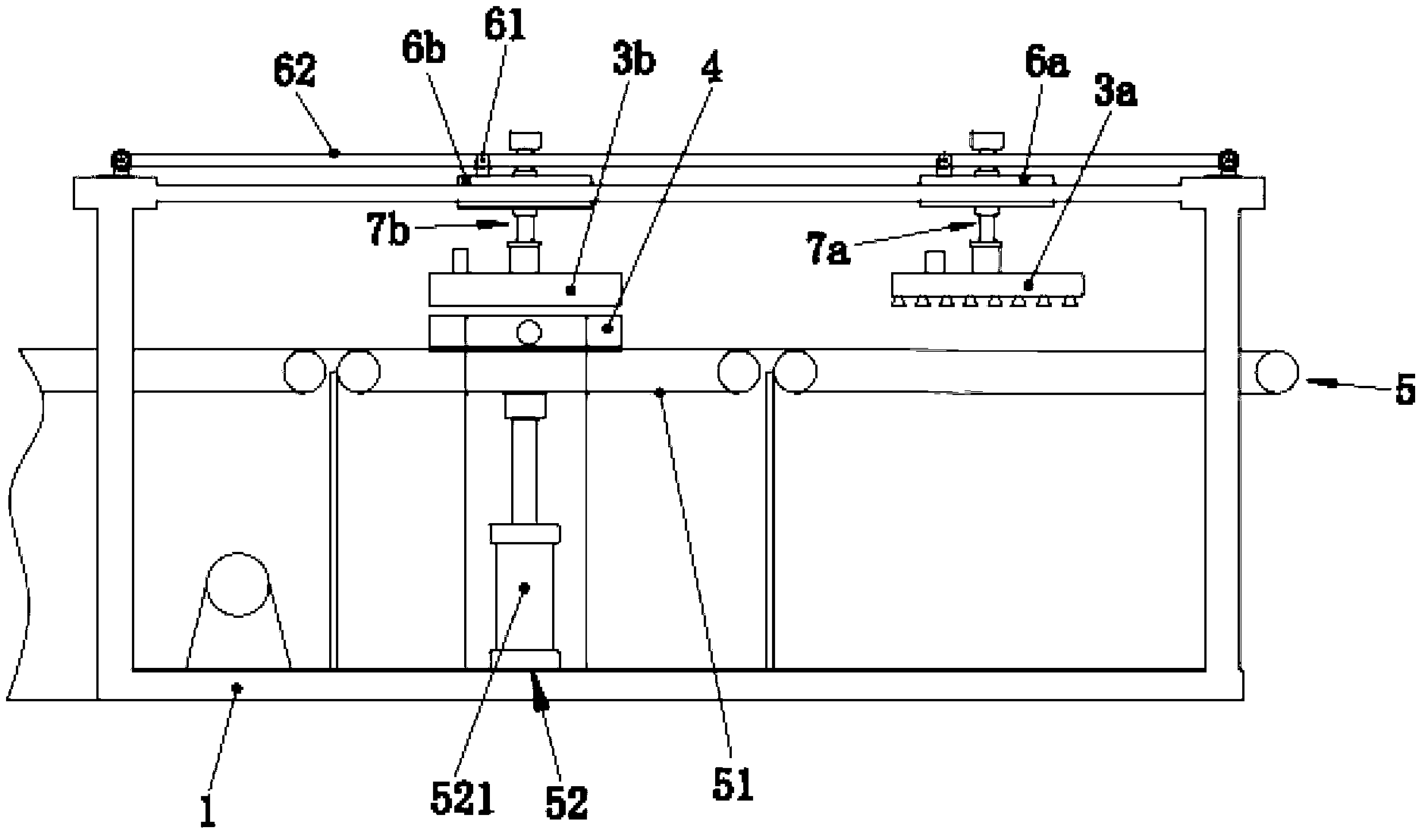

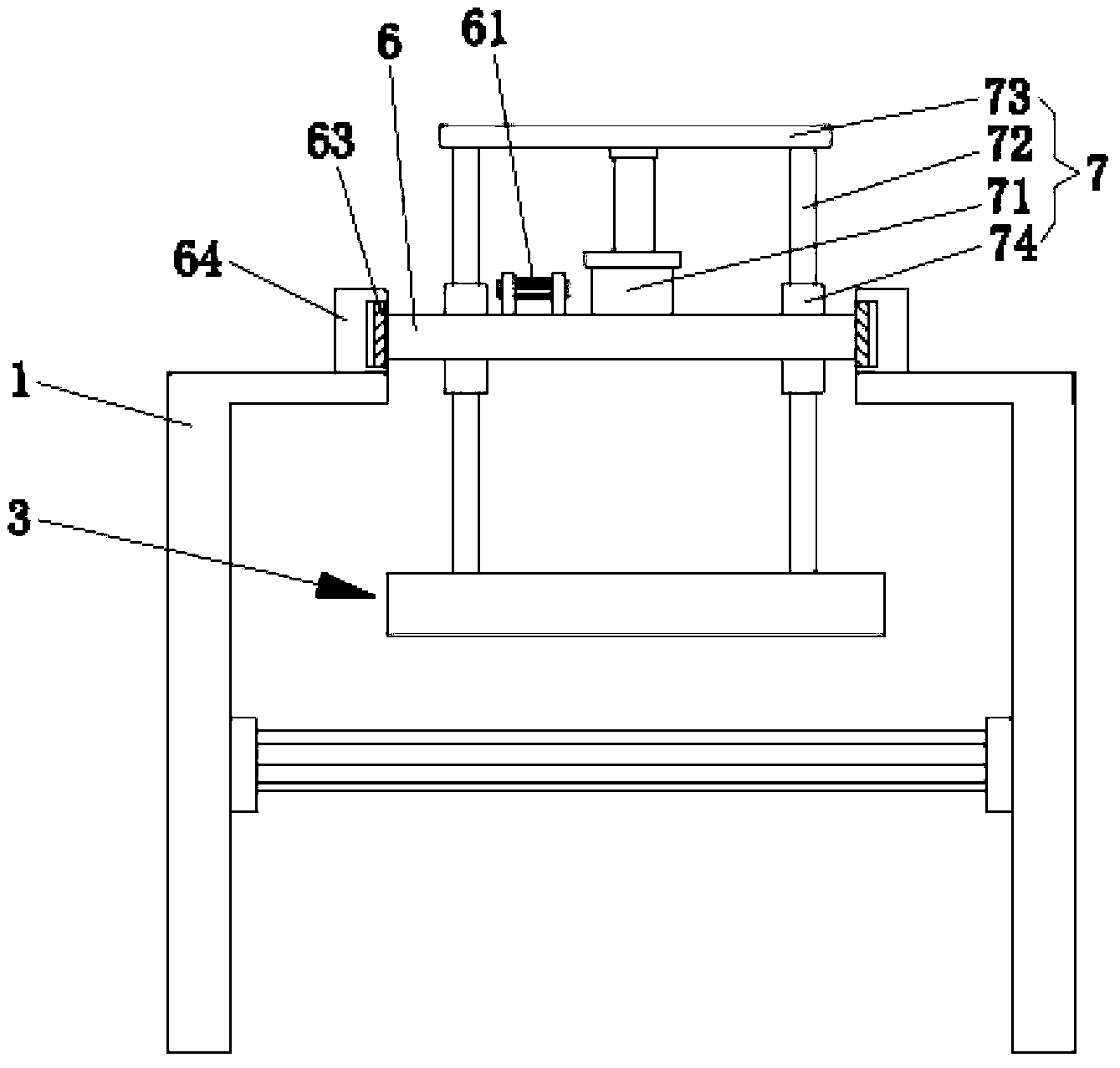

[0022] refer to figure 1 and figure 2 , ceramic color code tile automatic paving machine, including frame 1, vacuum pump (not shown), suction cup 3, negative pressure inversion box 4, conveyor belt 5 installed on frame 1 and removably mounted on the The mobile frame 6 on the frame 1, the mobile frame 6 is equipped with a suction cup lifting mechanism 7, the suction cup 3 is mounted on the suction cup lifting mechanism 7, and the negative pressure inversion box 4 is rotatably mounted on the on the frame 1; the suction port of the vacuum pump communicates with the suction cup 3 and the negative pressure inversion box 4 respectively through pipelines; the front and back sides of the negative pressure inversion box 4 are suction surfaces, so the After the pressure inversion box 4 is overturned, it can work continuously without waiting for the negative pressure inversion box to return to its original position, thereby improving efficiency. The conveyor belt 5 includes a lifting ...

Embodiment 2

[0027] This embodiment is basically the same as Embodiment 1, the difference is that the lifting mechanism of the conveyor belt adopts the rack and the gear to cooperate with lifting, that is, the frame is provided with a rack, and the lifting conveyor belt The side wall is equipped with a gear meshed with the rack, and a motor is connected to the gear. In addition, the conveyor belt lifting mechanism of the present invention can also be in other forms, such as adopting a worm gear transmission lifting mode, and its implementation is aimed at realizing the lifting of the lifting conveyor belt.

[0028] In the same way, the lifting mechanism of the suction cup can also adopt a rack and a gear to cooperate with the lifting mode, or a lifting mode such as a worm gear transmission and the like.

[0029] Work process of the present invention is as follows:

[0030] The conveyor belt transports the ceramic color code tiles to the bottom of the first suction cup 3a after sorting, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com