Continuous stepping hydraulic lifting device and method

A hydraulic lifting device and lifting device technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of continuous lifting, low manufacturing precision requirements, slow lifting speed, etc., and achieve simple structure, convenient operation, The effect of fast lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

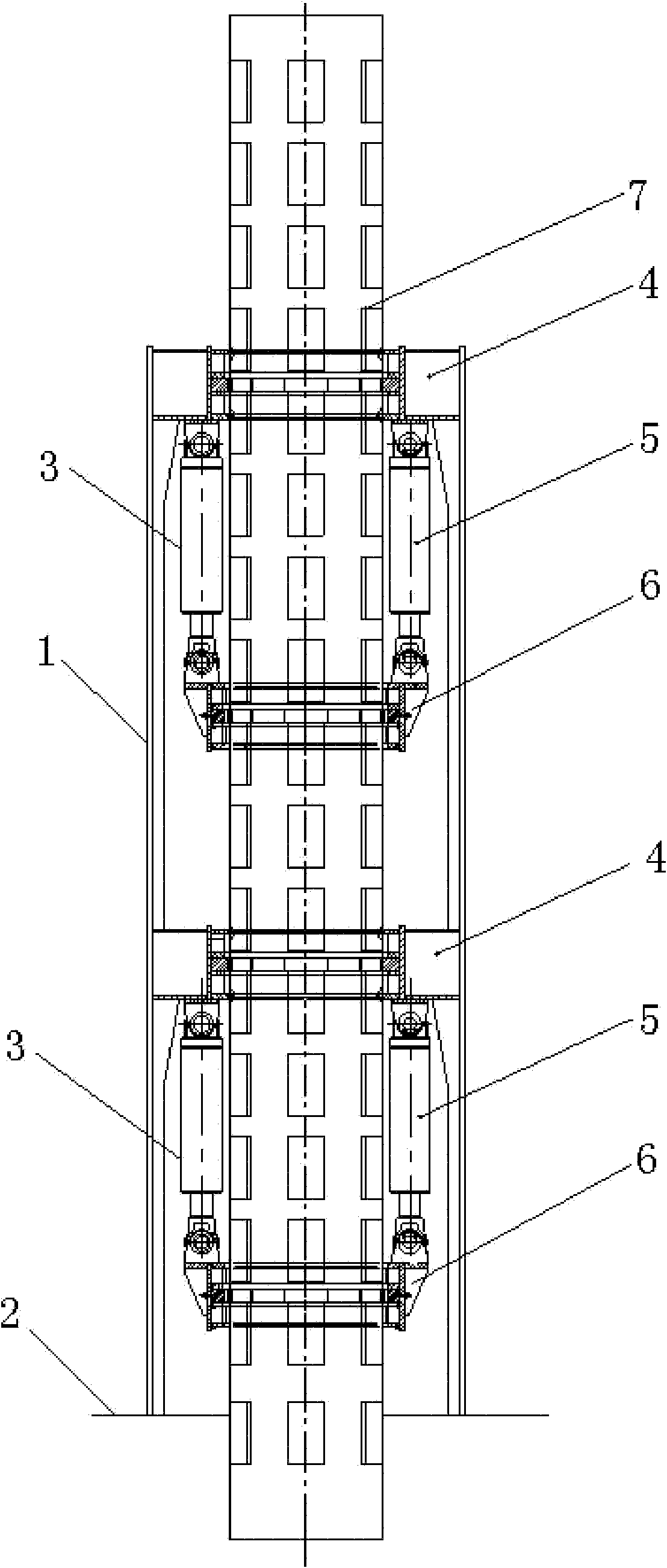

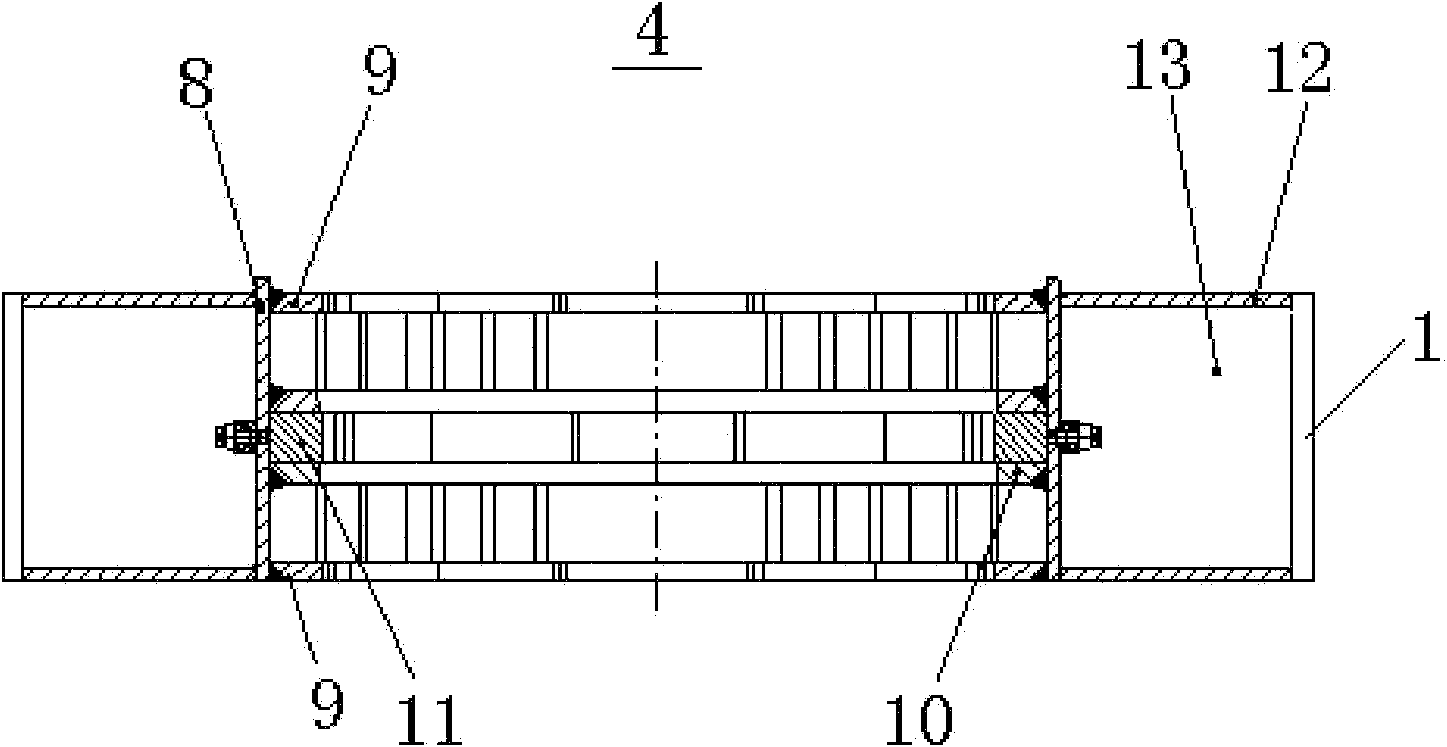

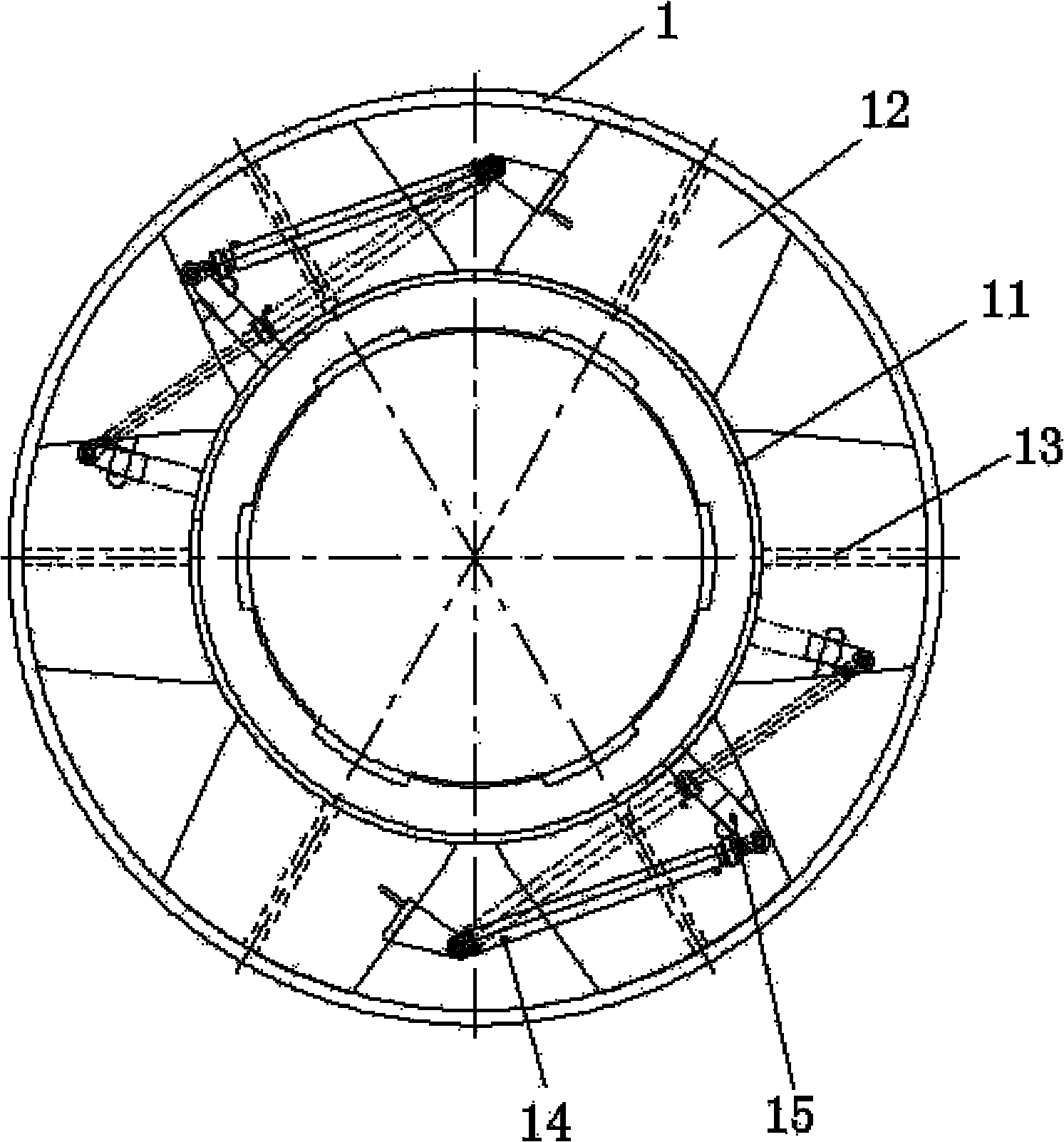

[0015] Such as figure 1 As shown, the present invention includes a pile-fixing tube 1, and the pile-fixing tube 1 is connected with the platform 2 as a whole. Two sets of lifting devices 3 are arranged symmetrically up and down in the pile-fixing barrel 1 . Each set of lifting device 3 all comprises a pile-holding device 4 welded on the inner wall of the pile-fixing tube 1, the bottom end of the last pile-holding device 4 connects the lifting cylinder 5, and the bottom end of the lifting cylinder 5 connects the following pile-holding device 6. The lifting cylinder 5 is connected to a hydraulic system (not shown in the figure). Both the upper pile gripper 4 and the lower pile gripper 6 are used for locking and loosening the pile leg 7 which is penetrated in the pile fixing barrel 1, and the pile leg 7 passes through the platform 2 and the bottom end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com