Slide lifter

A technology of lifts and skids, which is applied in the direction of lifting frames and lifting devices, which can solve the problems of difficult assembly of lifting frame guiding mechanisms and counterweight frame guiding mechanisms, and achieve the effect of easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

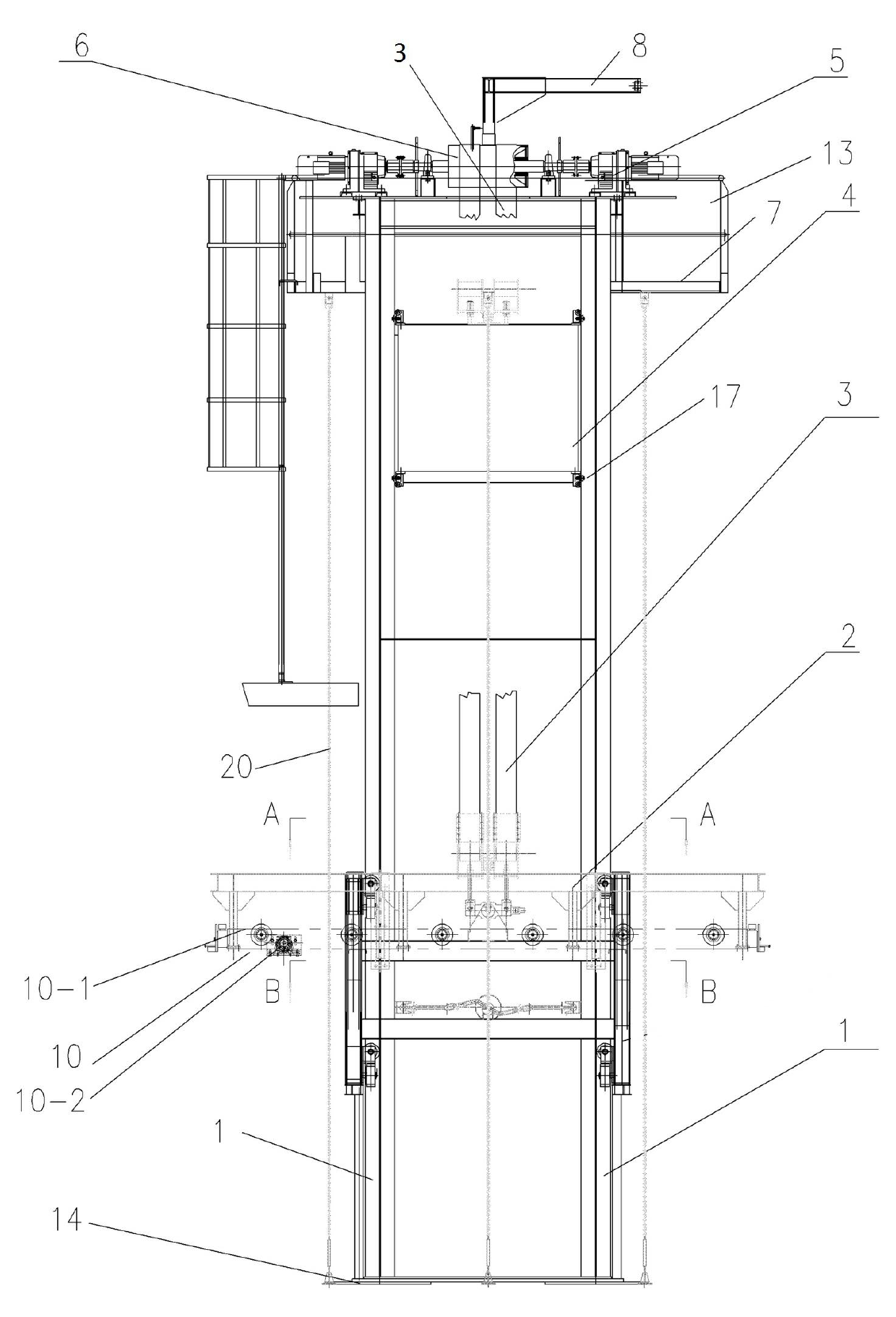

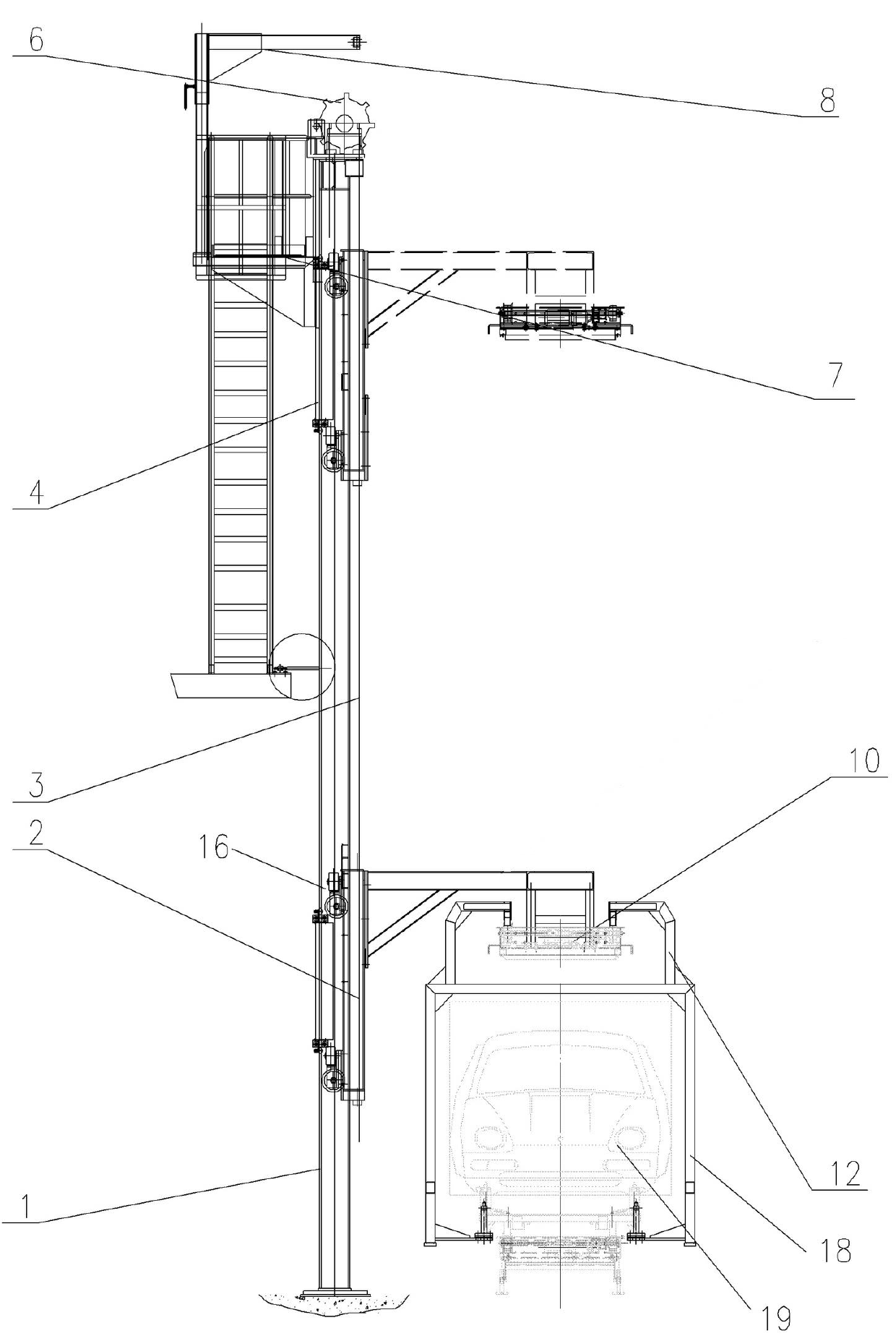

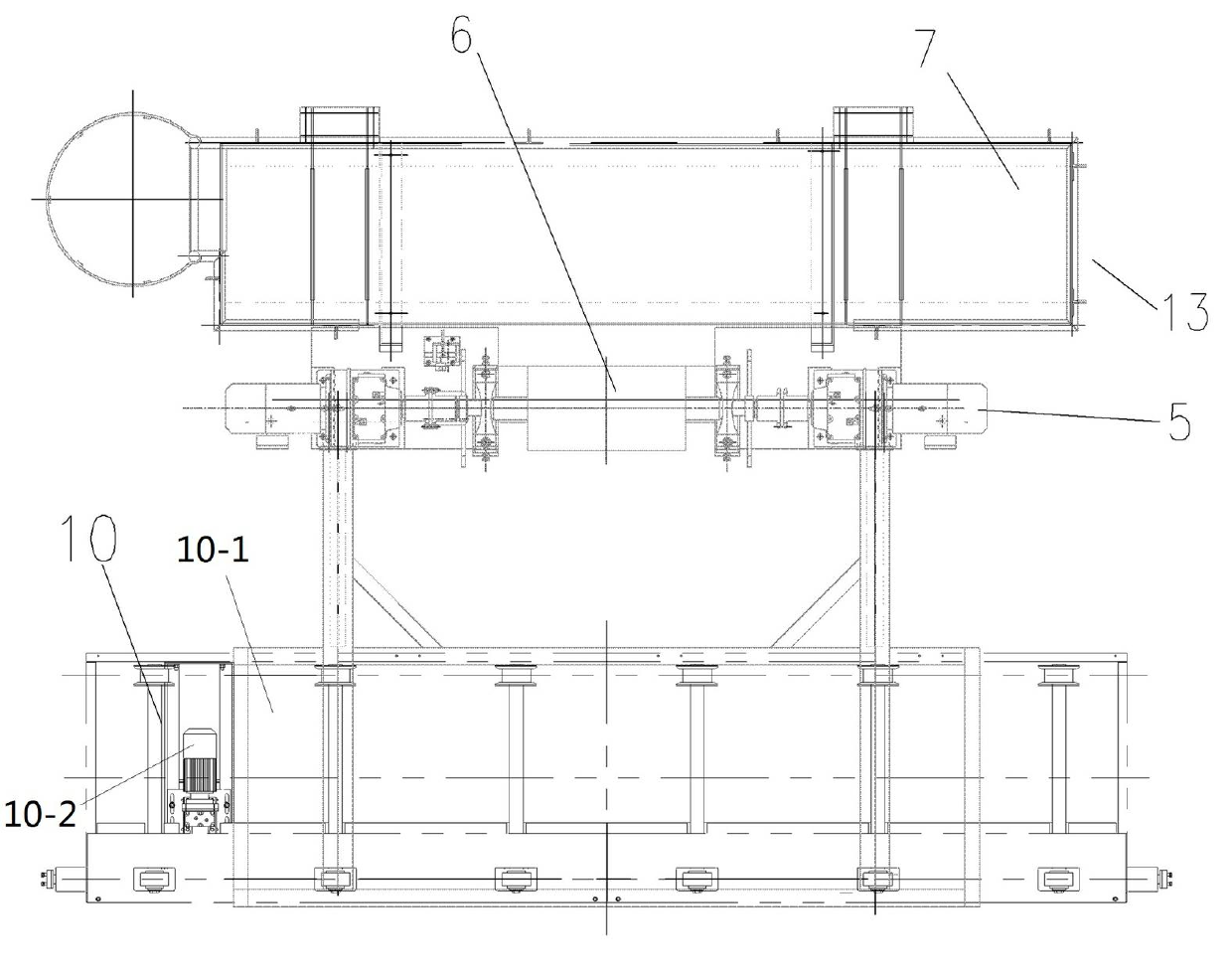

[0020] Embodiment 1 of a kind of skid lift Figure 1~5 As shown: it includes a base 14 and two H-shaped steel structure columns 1 arranged on the base 14 at intervals along the left and right directions and extending in the up and down direction. The H-shaped steel structure column 1 includes webs 1-1 and respectively fixed The front flange 1-2 and the rear flange 1-3 on the front and rear end faces of the web 1-1. The top of the two columns 1 is provided with a mounting frame 13, on which a drum reduction motor 5 is installed, and the output end of the drum reduction motor 5 is connected to a drum 6, and the drum 6 is wound with a front end wound to the two columns 1 The front side and the rear end are wound around to the middle of the rear sides of the two columns 1 and the belt 3 with the steel wire rope is passed through. The front and rear sides of the two upright columns 1 are equipped with a lifting frame 2 and a counterweight frame 4 respectively through the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com