Equipment for balancing outofstep sustained center of crane

A crane and balancing technology, which is applied in hoisting devices, transportation and packaging, and clockwork mechanisms, etc., can solve problems such as asynchronous lifting points, mutual winding of wire ropes, and accelerated lifting speed of lifting points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

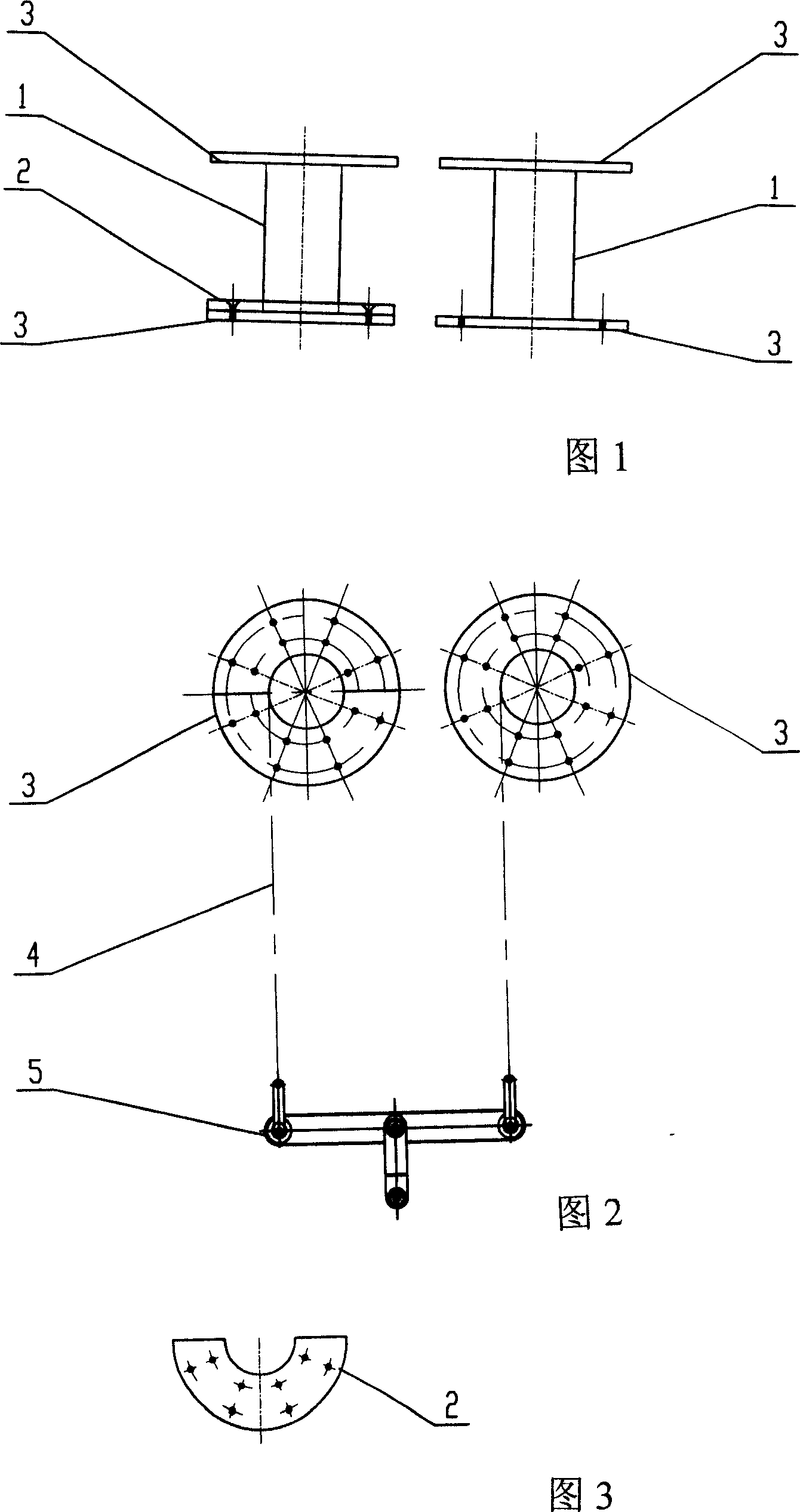

[0009] In order to solve the asynchronous phenomenon when the crane has multiple lifting points, it is first necessary to use a mechanical method or an electronic control method to make the multi-layer winding drum 1 with multiple lifting points rotate at the same speed. 3 Connect the reel adjustment flange 2 with bolts on the inner side, the length of the reel 1 becomes shorter, the shape of the reel adjustment flange 2 can be semicircular or other geometric shapes, the connection of the reel adjustment flange 2 Bolt connection can be used, and other connection methods can also be used. The thickness of the reel adjustment flange 2 just balances the asynchrony of the two suspension points. The reel adjustment flange 2 can be made of metal materials or other materials. Because the rotating speed of the reel 1 is the same, and the number of winding circles is equal, the reel flange 3 on the inner side of the lifting point with a slow lifting speed is bolted to the reel adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com