Quick lifting machine

A kind of lift, fast technology, applied in the direction of lifting frame, lifting device, buildings where cars are parked, etc., can solve the problems of long stroke of hydraulic cylinder, difficult installation and maintenance, complicated balance mechanism, etc., to achieve high speed, easy installation and The effect of simple maintenance and overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

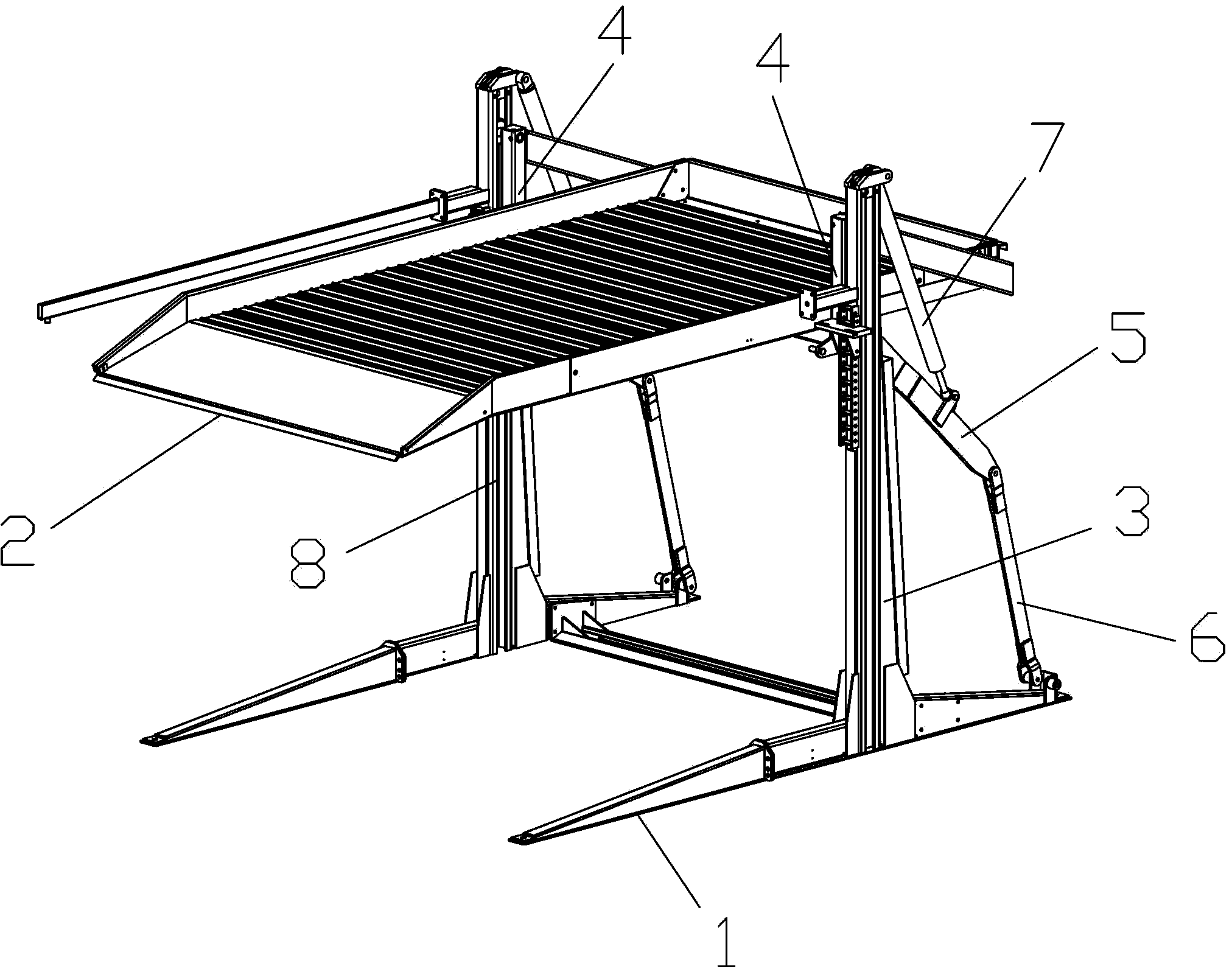

[0008] A kind of fast lifting lifting machine of the present invention, as figure 1 As shown, it includes a base 1 and a vehicle-carrying board 2. The base 1 is symmetrically provided with columns 3, and both sides of the vehicle-carrying board 2 are symmetrically provided with lift sliders 4. The vehicle-carrying board 2 is installed between the columns 3. Lifting slider 4 is all slidably installed in the chute 8 that corresponding column 3 is provided with, and connecting rod driving mechanism is all installed between lifting slider 4 and base 1, and described connecting rod driving machine includes main connecting rod 5, secondary connecting rod Rod 6 and hydraulic cylinder 7, the front end of the main connecting rod 5 is hinged on the lifting slider 4, the rear end of the main connecting rod 5 is hinged with the front end of the auxiliary connecting rod 6, the rear end of the auxiliary connecting rod 6 is hinged at the rear of the base 1, and the hydraulic cylinder 7 One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com