Automatic fetching device of injection molding machine

A technology for automatic reclaiming and injection molding machines, applied in the field of plastic machinery, can solve problems such as slow reciprocating speed, increased costs, and long strokes, and achieve the effects of reducing the height of the rack, improving work efficiency, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

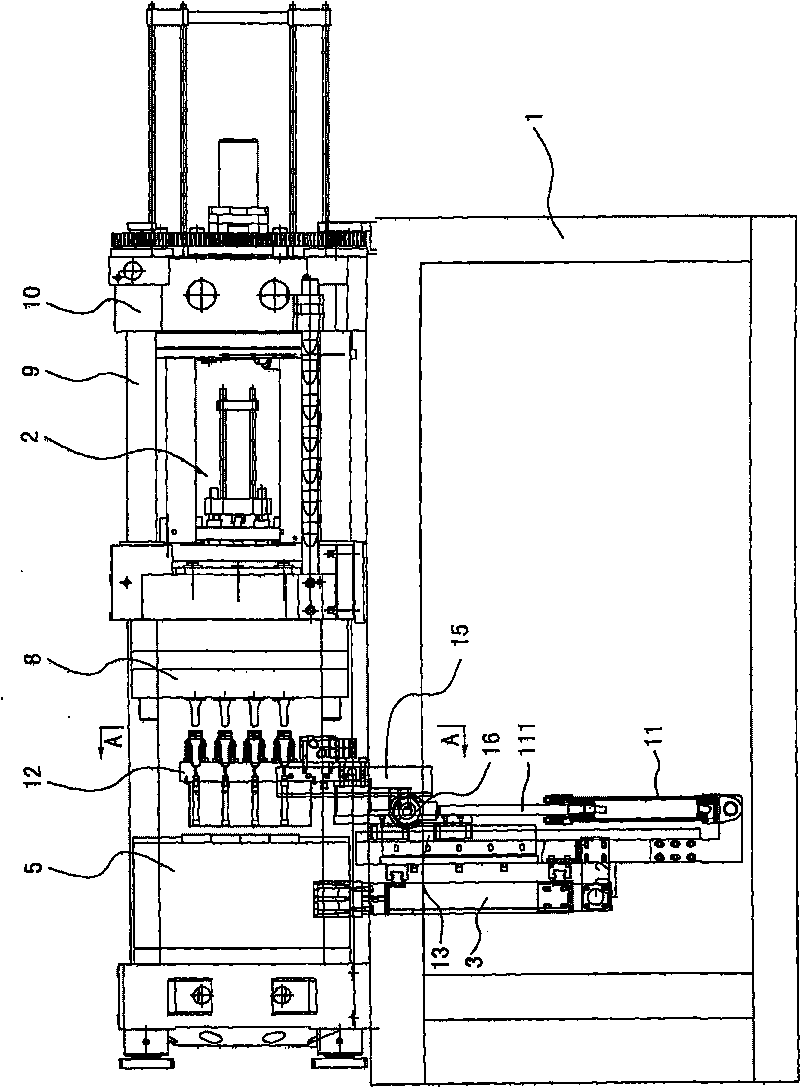

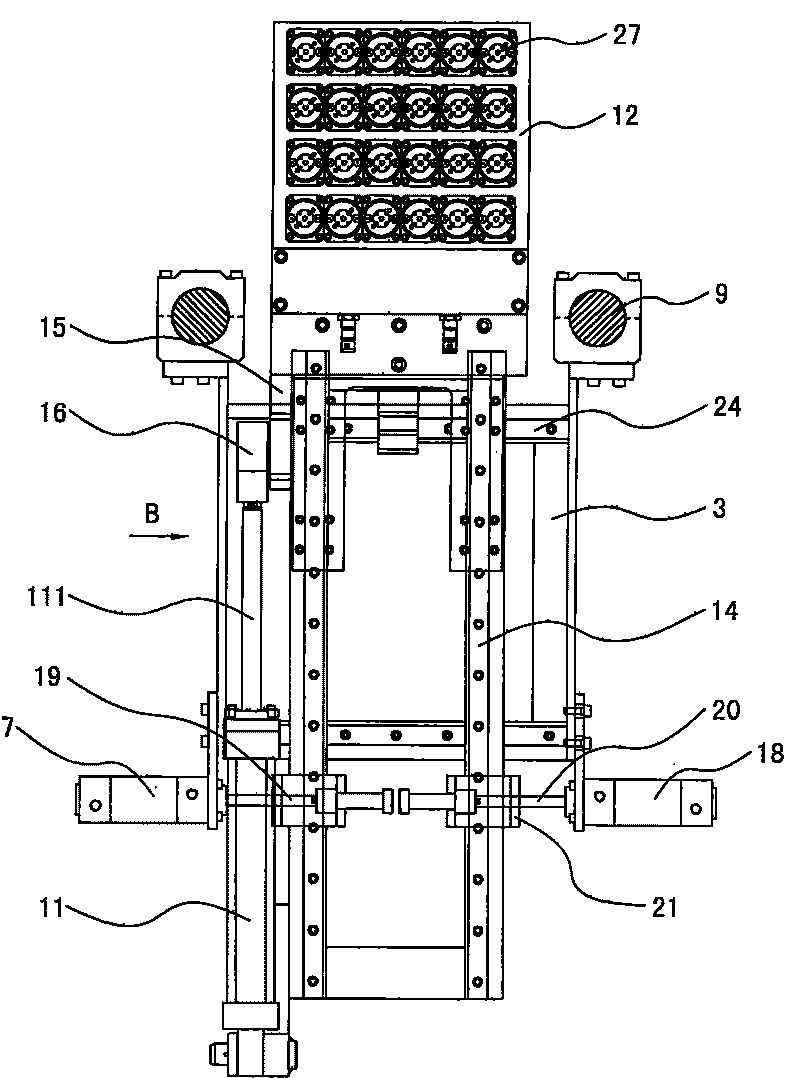

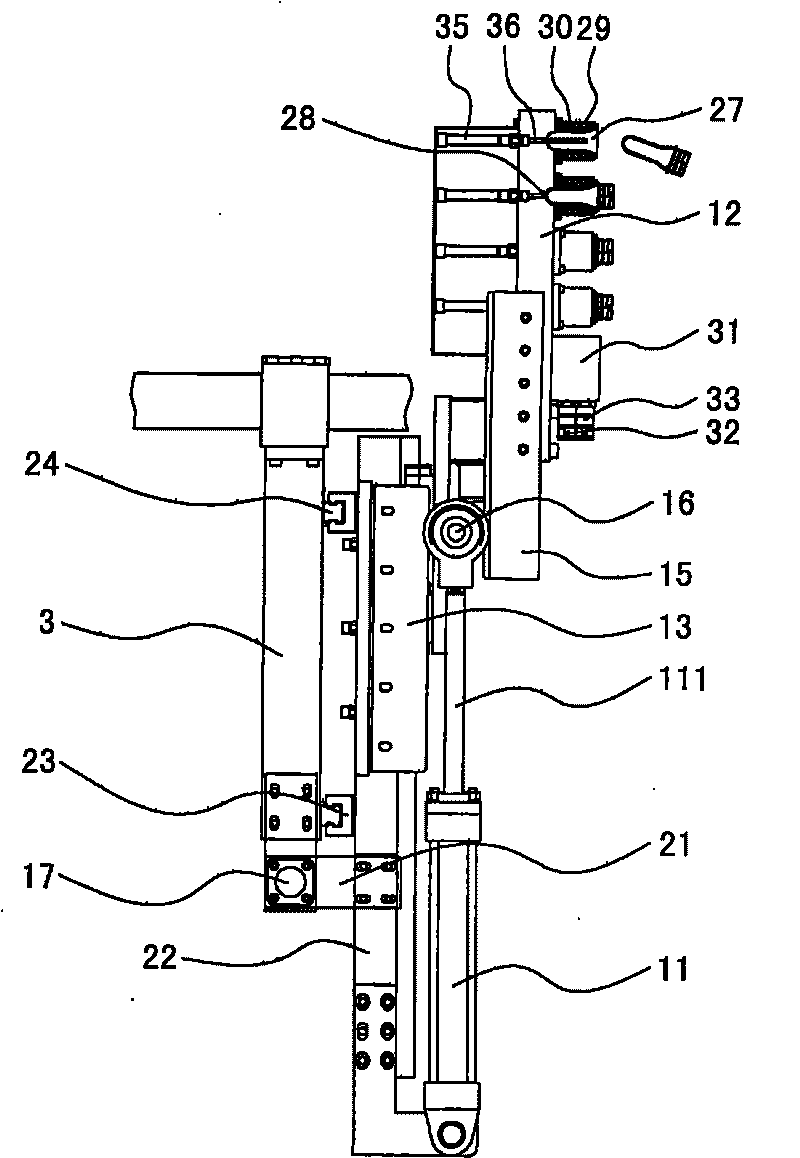

[0012] The invention relates to an automatic feeding device for an injection molding machine, such as Figure 1-Figure 5 As shown, it includes an injection molding machine frame 1, an injection device 2 is installed on the frame, a fixed template 5 on the frame is connected to a movable template 8 and a rear template 10 through a guide post 9, and an injection mold is respectively installed on the fixed template 5 and the movable template 8 , there is a cavity in the injection mold, there is a take-up plate 12 in the frame 1, a material suction device and an ejection device are installed in the take-up plate, the take-off plate 12 is driven by a lifting device, and the lifting device is installed on the fixed bracket 3 , it is characterized in that the lifting device includes a fixed rack 13 and a lifting guide rail 14 installed in the fixed bracket 3, the picking plate is connected to the lifting guide rail 14, a movable rack 15 is installed on one side of the picking plate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com