Floating track bed, jacking device and jacking method thereof

A technology of floating ballast bed and jacking device, which is applied in the field of rail transit, can solve the problems of poor adaptability, and achieve the effects of fast jacking speed, strong applicability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

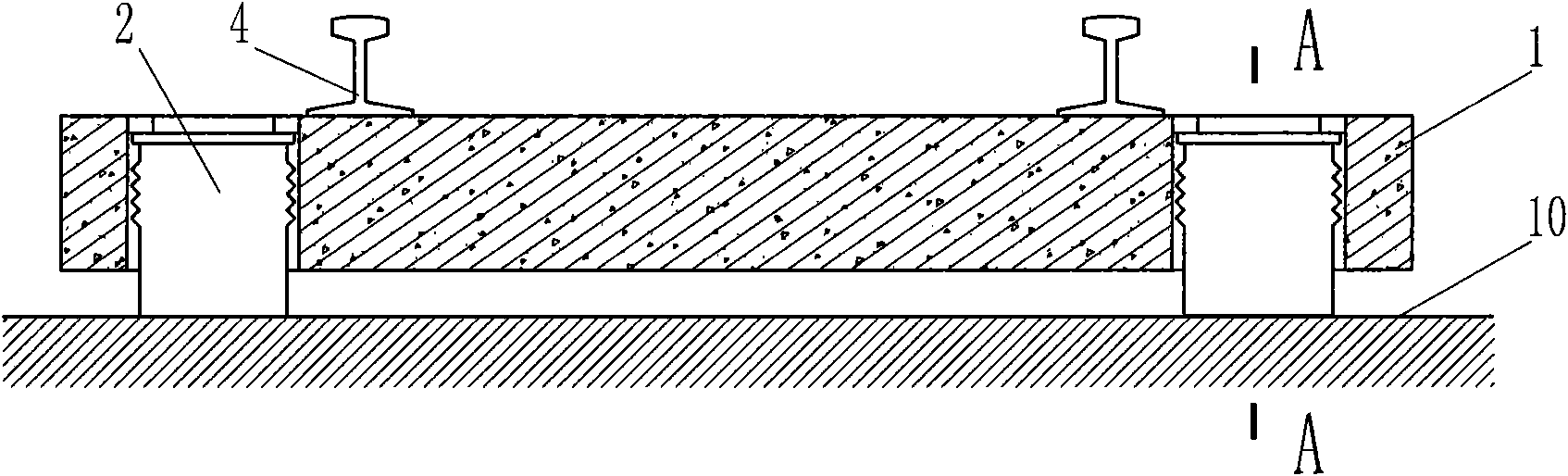

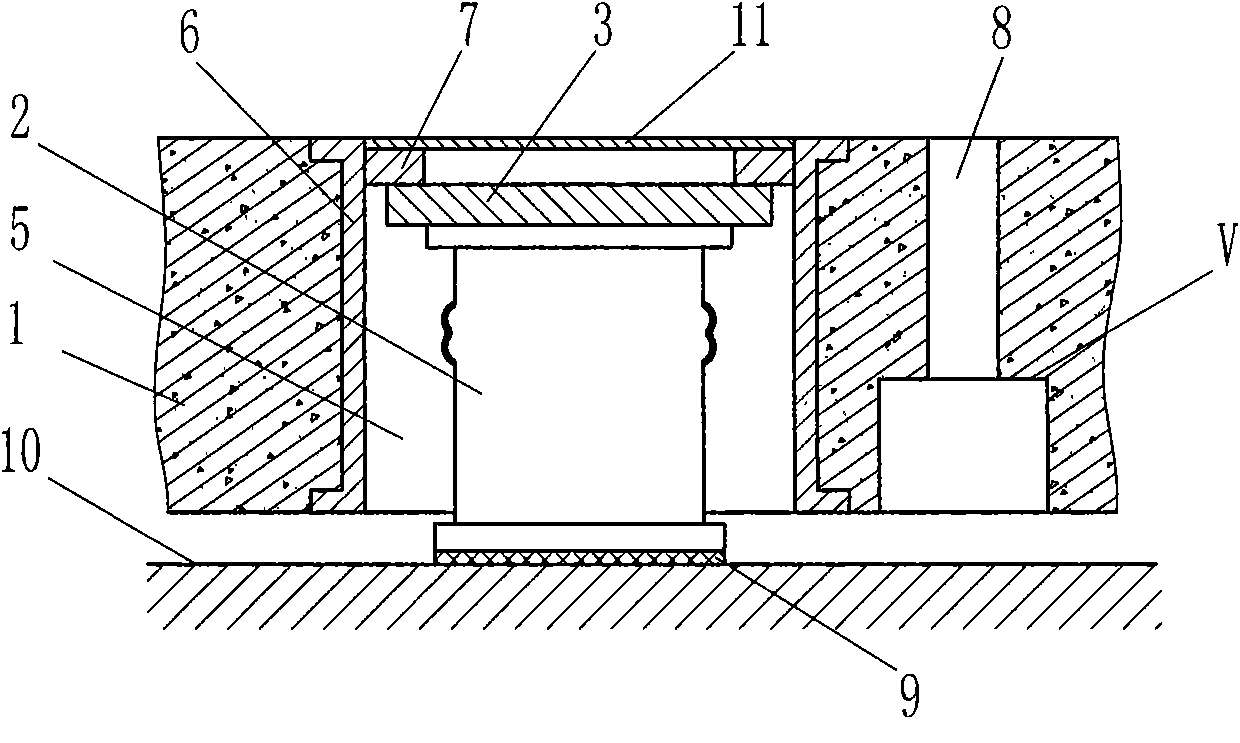

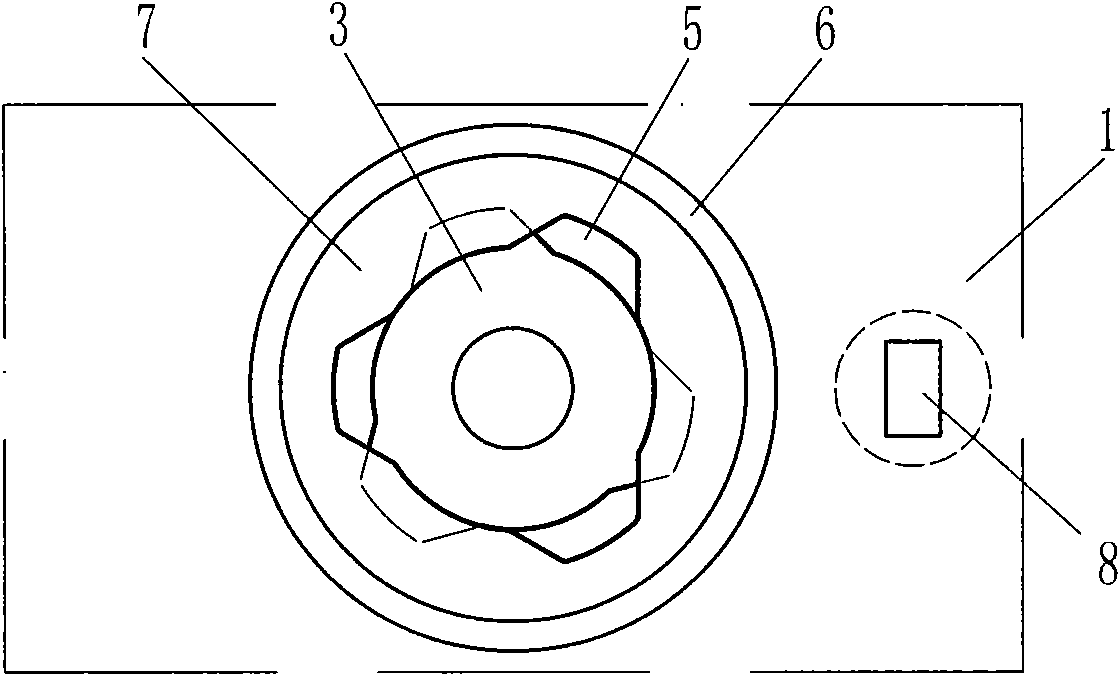

[0054] Such as figure 1 , figure 2 , image 3 The floating track bed of the present invention shown includes a floating plate 1, an elastic vibration isolator 2 and a gasket 3. The elastic vibration isolator 2 used in this example is a spiral steel spring vibration isolator with a silicone oil liquid damping material inside. . The elastic vibration isolator 2 and the spacer 3 are arranged in the reserved through hole 5 of the floating plate 1, and the connecting sleeve 6 is integrated with the floating plate in the reserved through hole 5, and the connecting sleeve 6 is only provided with a support Block 7, a through hole is left in the center of the support block 7, the elastic vibration isolator 2 and the spacer 3 are compatible with the size of the central through hole of the support block 7, and the spacer 3 and the support block 7 can realize misalignment The gasket 3 is partly supported on the support block, and the floating plate 1 is supported on the elastic vibrat...

Embodiment 2

[0062] Such as Figure 7 , Figure 8The difference between the floating ballast bed of the present invention and the first embodiment is that since there is no need to set a jacking block, the connecting sleeve is canceled and instead it is integrated with the floating plate 1 on the inner wall of the reserved through hole 5 The protrusion 17 of the concrete structure, the protrusion 17 forms a shoulder W, and the gasket 3 is partly supported on the shoulder W. A square opening is arranged in the center of the protrusion 17, and the corresponding gasket 3 is arranged in a square shape. The central opening of the shoulder is compatible with the size of the elastic vibration isolator 2 and the spacer 3 , and the shoulder W and the spacer 3 can form a dislocation overlap. The floating plate 1 is supported on the elastic vibration isolator 2 through the spacer 3 and maintains an elastic floating state with the foundation 10 . The elastic vibration isolator 2 used in this exampl...

Embodiment 3

[0069] Such as Figure 11 , Figure 12 , Figure 13 The difference between the floating track bed of the present invention and the first embodiment is that a circular gasket 3 with a flange 19 is used. In order to save materials and reduce costs, a through hole is still provided in the center of the gasket 3 . In addition, in order to obtain the shoulder structure, the reserved through hole 5 is set as a stepped through hole, and the shoulder W is formed at the junction of the upper and lower holes, wherein the upper hole of the reserved through hole 5 cooperates with the gasket 3 to have a corresponding gap The diameter of the upper hole at the shoulder W is smaller than that of the lower hole. The gasket 3 is partly supported on the shoulder W, and the floating plate 1 is supported on the elastic vibration isolator 2 through the gasket 3 . The central opening of the shoulder W should be compatible with the size of the elastic vibration isolator 2 and the spacer 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com