Patents

Literature

146results about How to "Huge economic benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

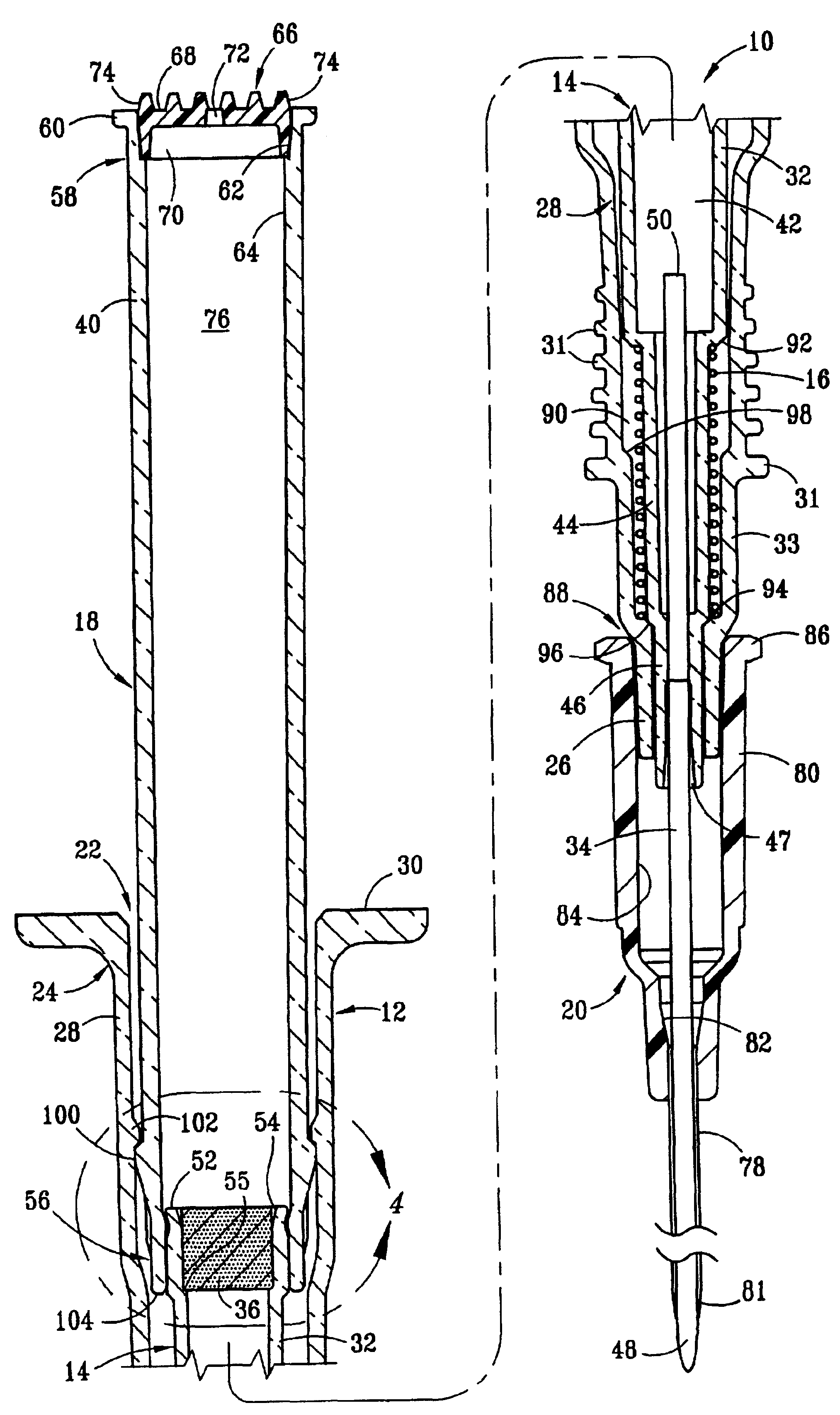

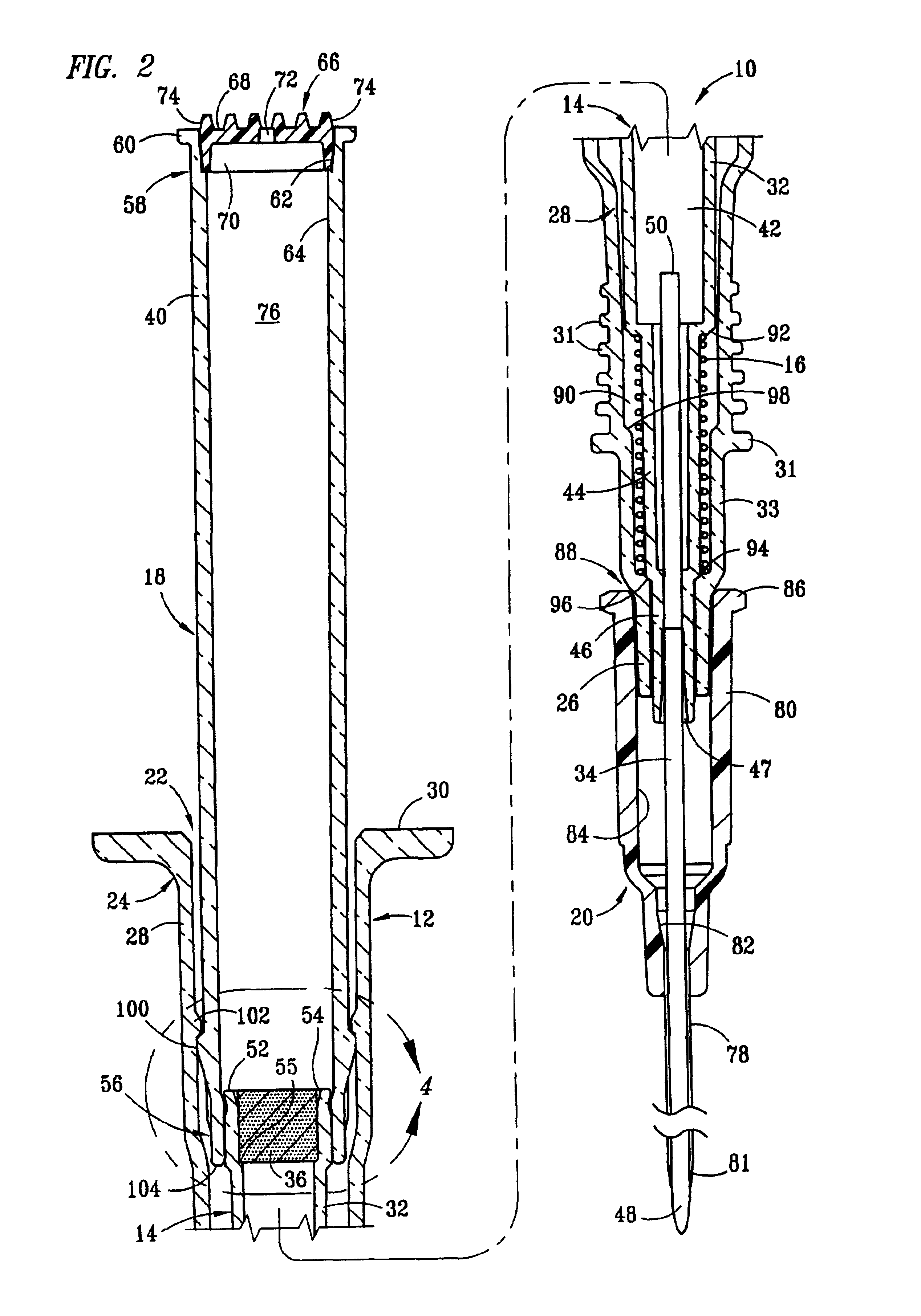

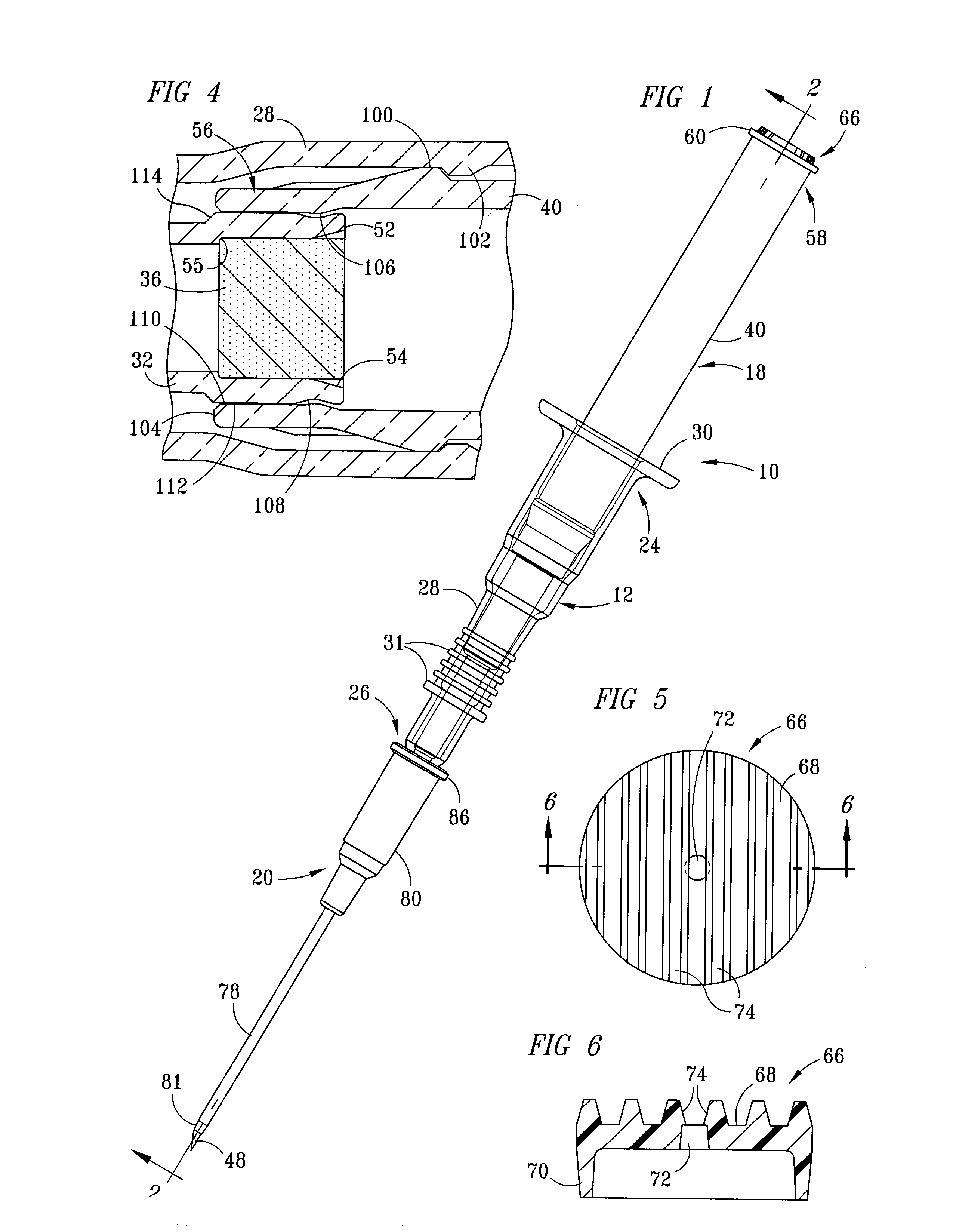

IV catheter introducer with retractable needle

InactiveUS6872193B2Reliable and reliableEasy to use with one handGuide needlesInfusion syringesDetentCatheter introducer

An IV catheter introducer having a retractable needle holder and a tubular plunger that are held by a detent structure in a preferred positional relationship prior to and during insertion of the catheter. Following insertion, the plunger is pushed past the detent structure, permitting a compressed spring to force the needle holder upwardly into the plunger. A vented end cap in the plunger permits rapid venting of air displaced during retraction of the needle holder. The needle holder includes a flash chamber that is easily viewable through a clear plastic housing. Wings are provided on the housing to facililate one-handed operation of the device. A method for assembling the subject catheter introducer is also disclosed.

Owner:RETRACTABLE TECH INC

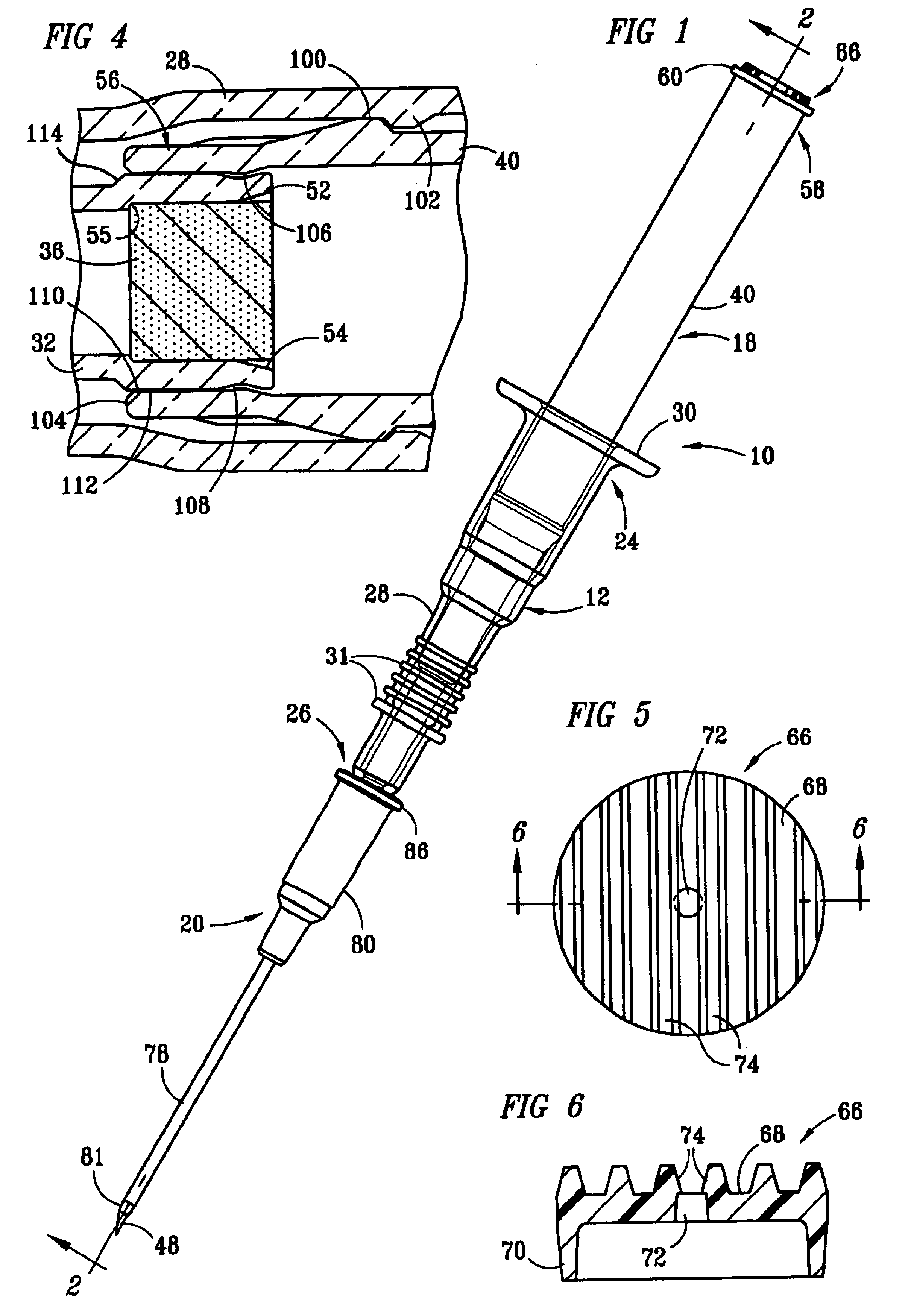

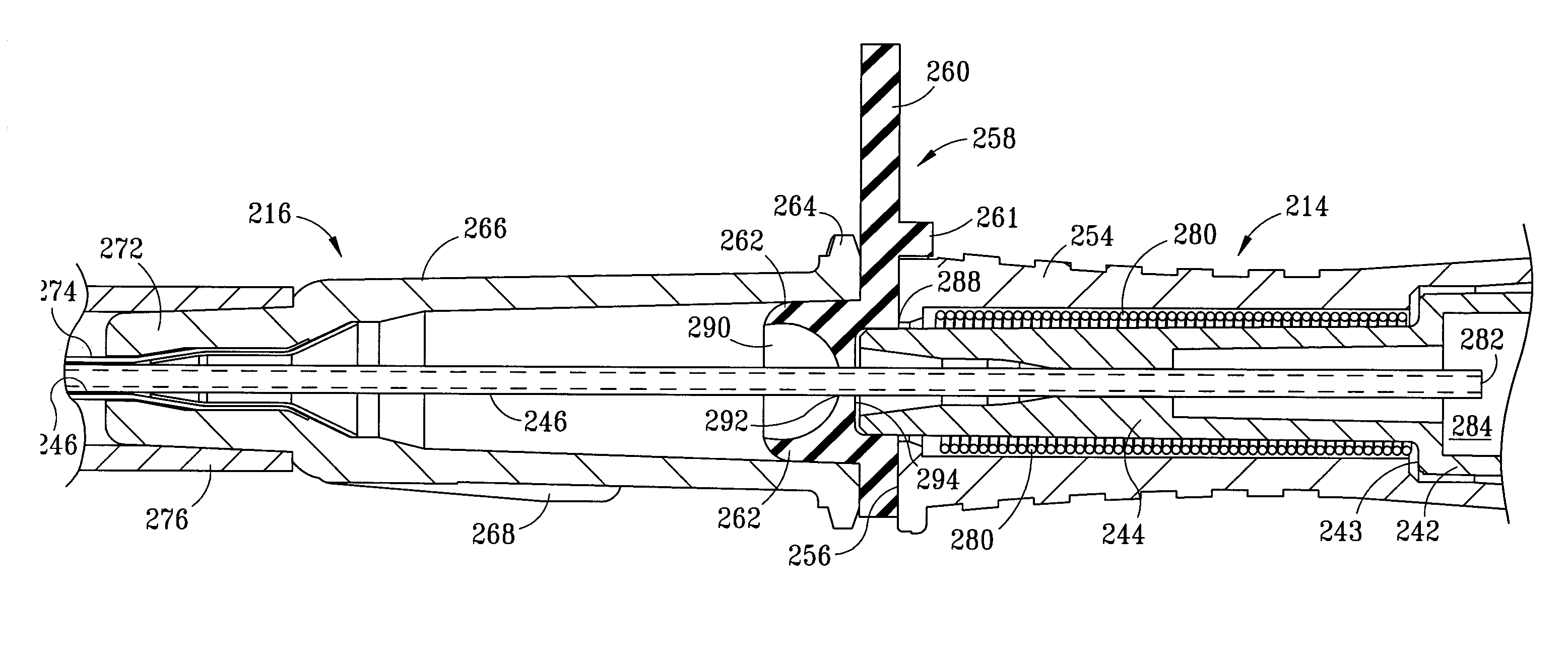

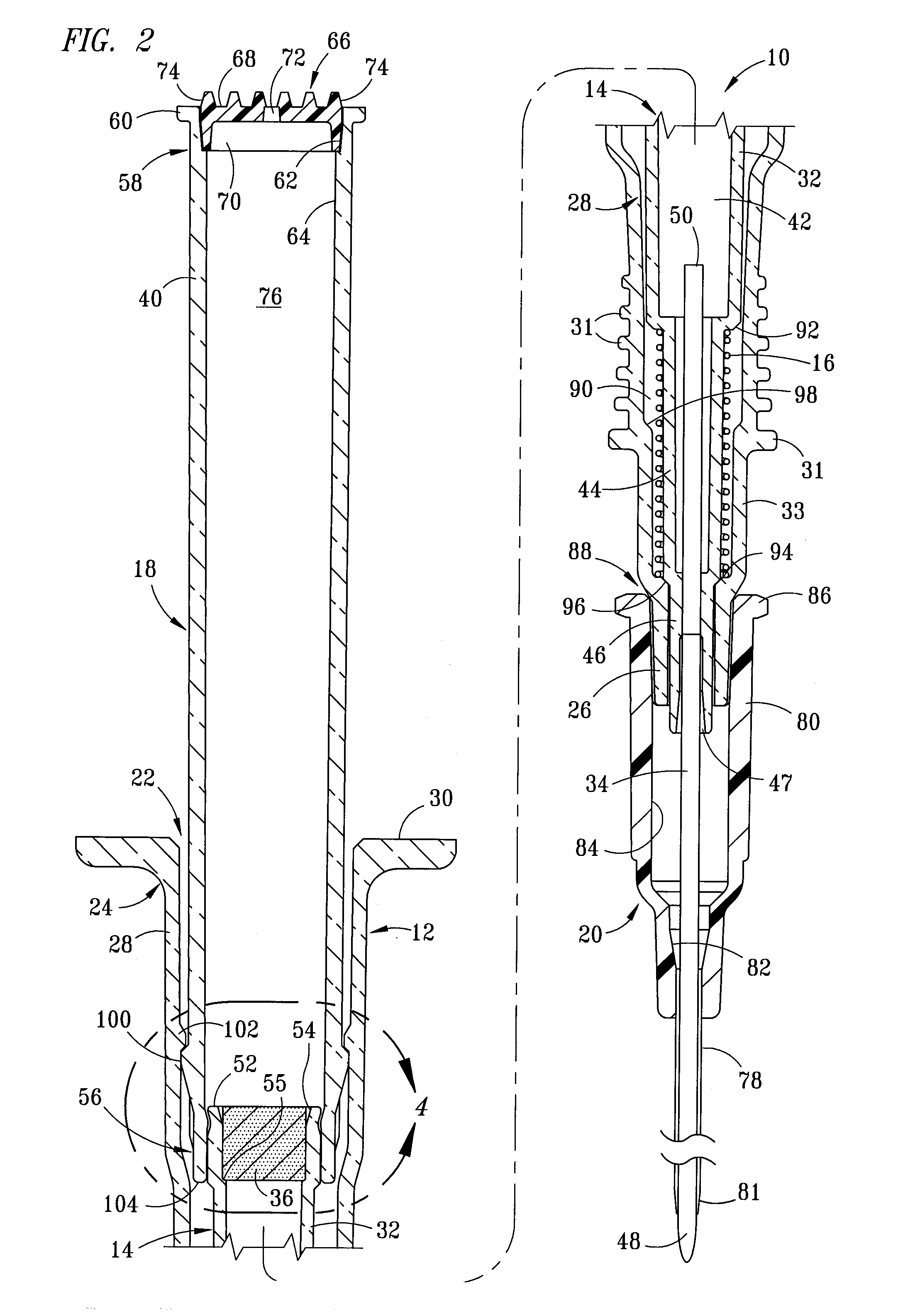

IV Catheter Introducer

ActiveUS20100168674A1Reduce the possibilityEasy to useInfusion syringesInfusion devicesCatheter hubCatheter introducer

An IV catheter introducer having an elastomeric grommet disposed between the housing and the IV catheter assembly that helps avoid unintentional separation of IV catheter assembly from the housing during shipping and handling prior to use, that acts as a needle guide, that helps align the housing and IV catheter assembly coaxially, that indicates that top side of the catheter introducer, that provides proper rotational alignment between the grommet and housing, that wipes blood off the needle during withdrawal of the needle from the catheter assembly and grommet, that impedes blood flow out of the catheter hub after needle withdrawal, and that assists the user in separating the housing from the IV catheter assembly following insertion of the catheter and withdrawal of the needle.

Owner:RETRACTABLE TECH INC

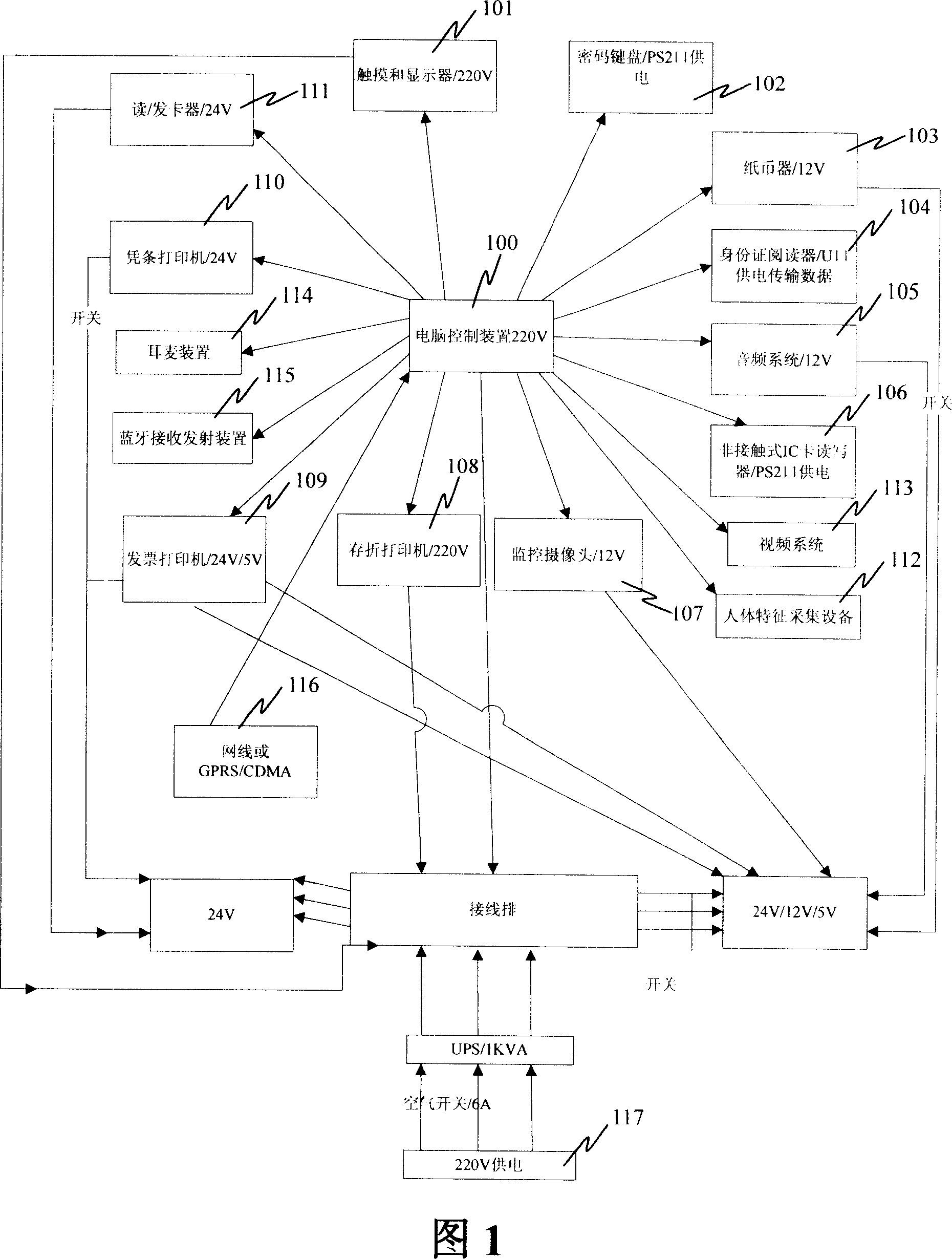

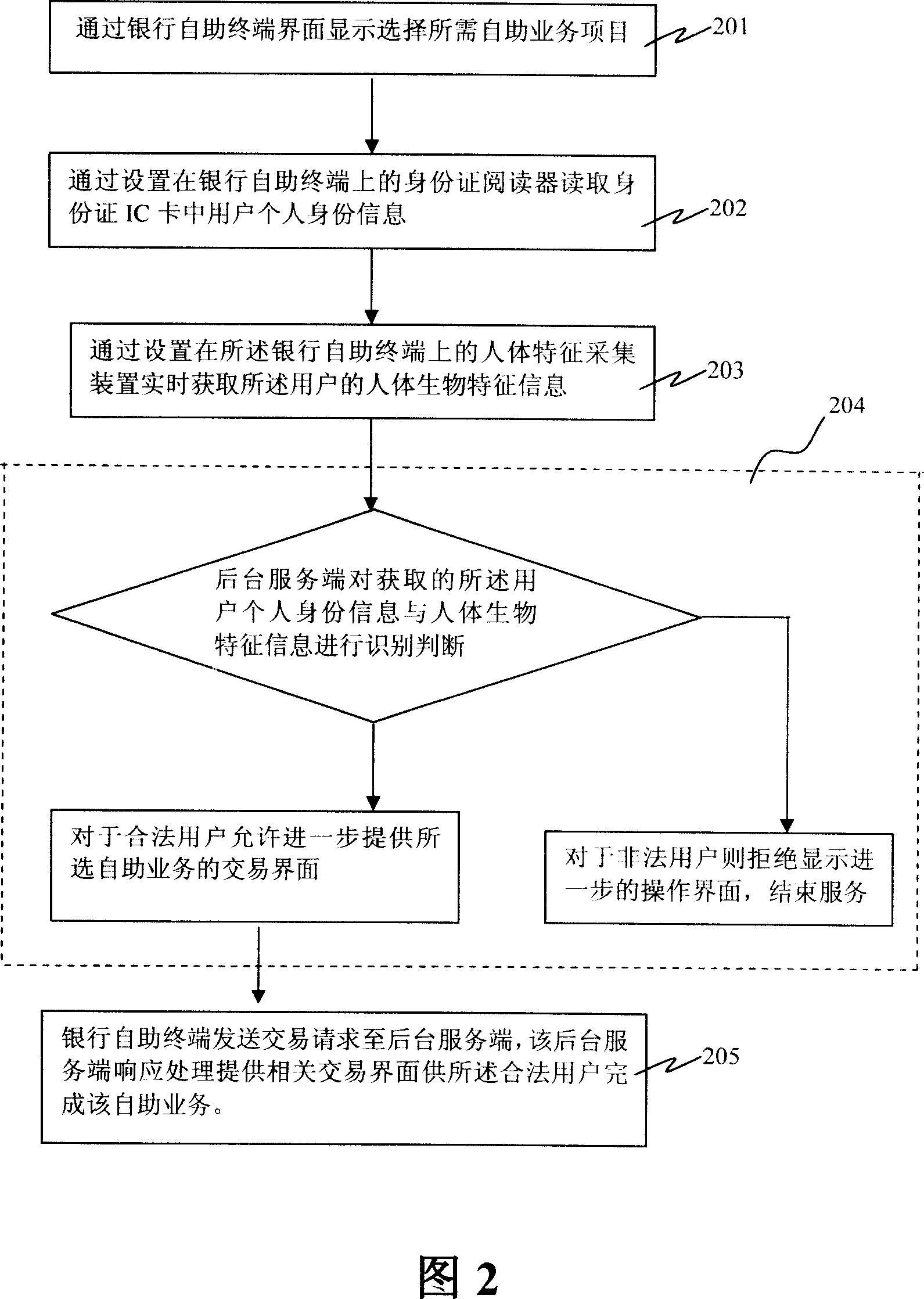

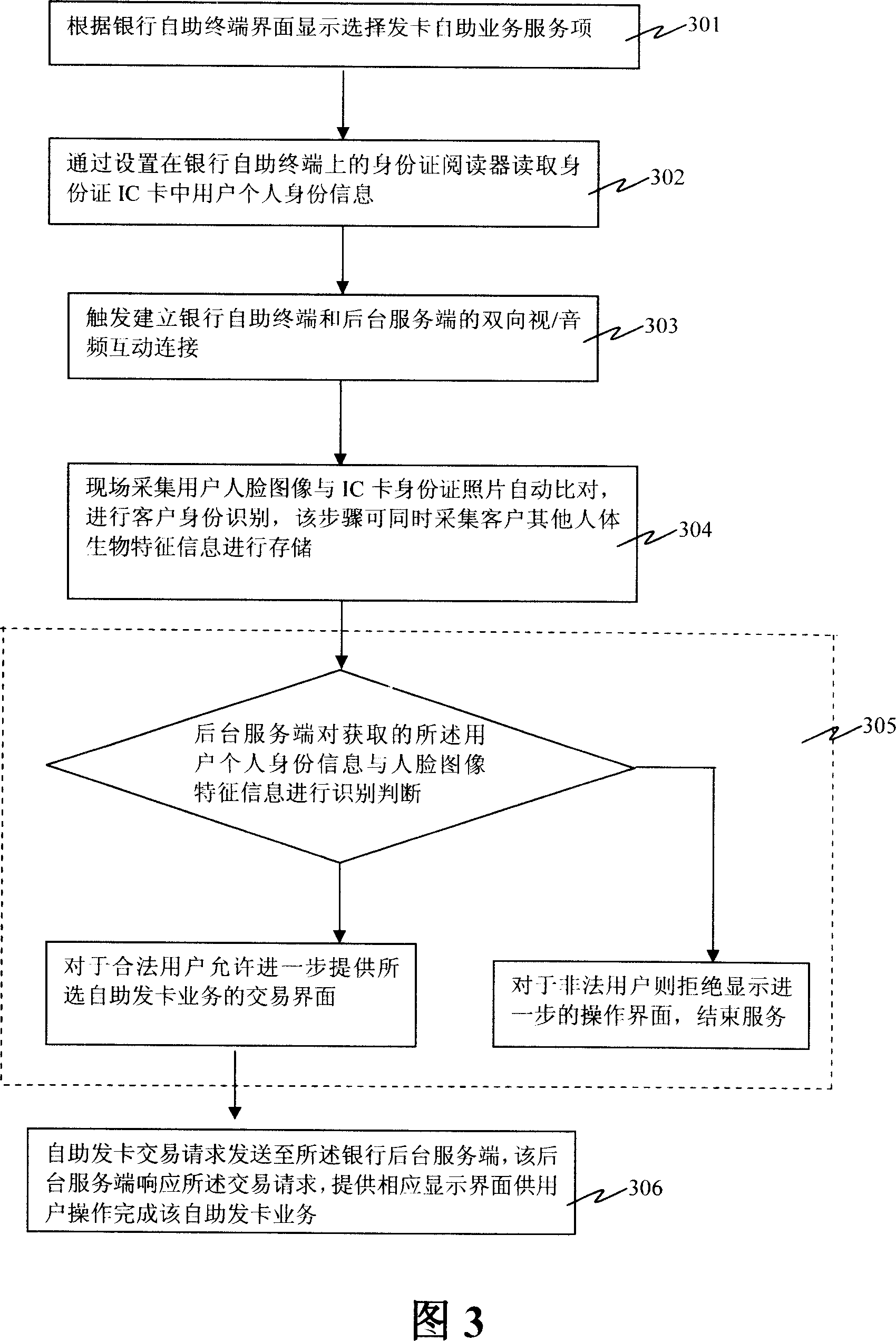

Self service system and method

InactiveCN101000702ARealize the function of cardless business applicationEasy to useComplete banking machinesCoded identity card or credit card actuationHuman bodyWeb service

A method for carrying out self-service includes selecting self-service item through bank self-service terminal boundary, fetching user personal status information in IC card by status reader on bank terminal, obtaining user human body biological character by human body character collection unit on bank terminal, carrying out identification and judgment on obtained status information and obtained character information by WEB server, allowing user to finish self-service business if it is judged to be a legal user or otherwise refusing any further self-service operation.

Owner:BEIJING ORIENT XINGHUA TECH DEV CO LTD

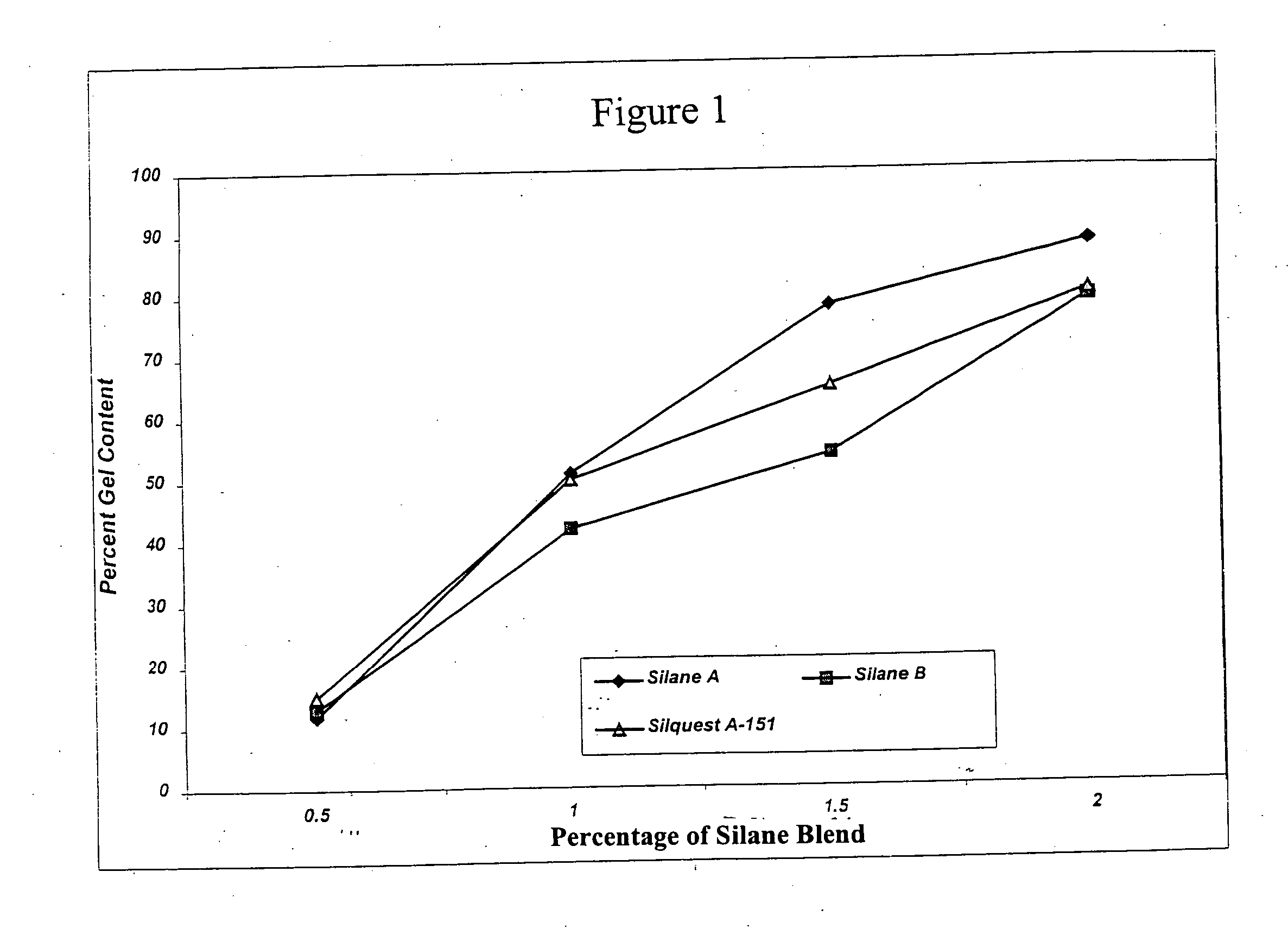

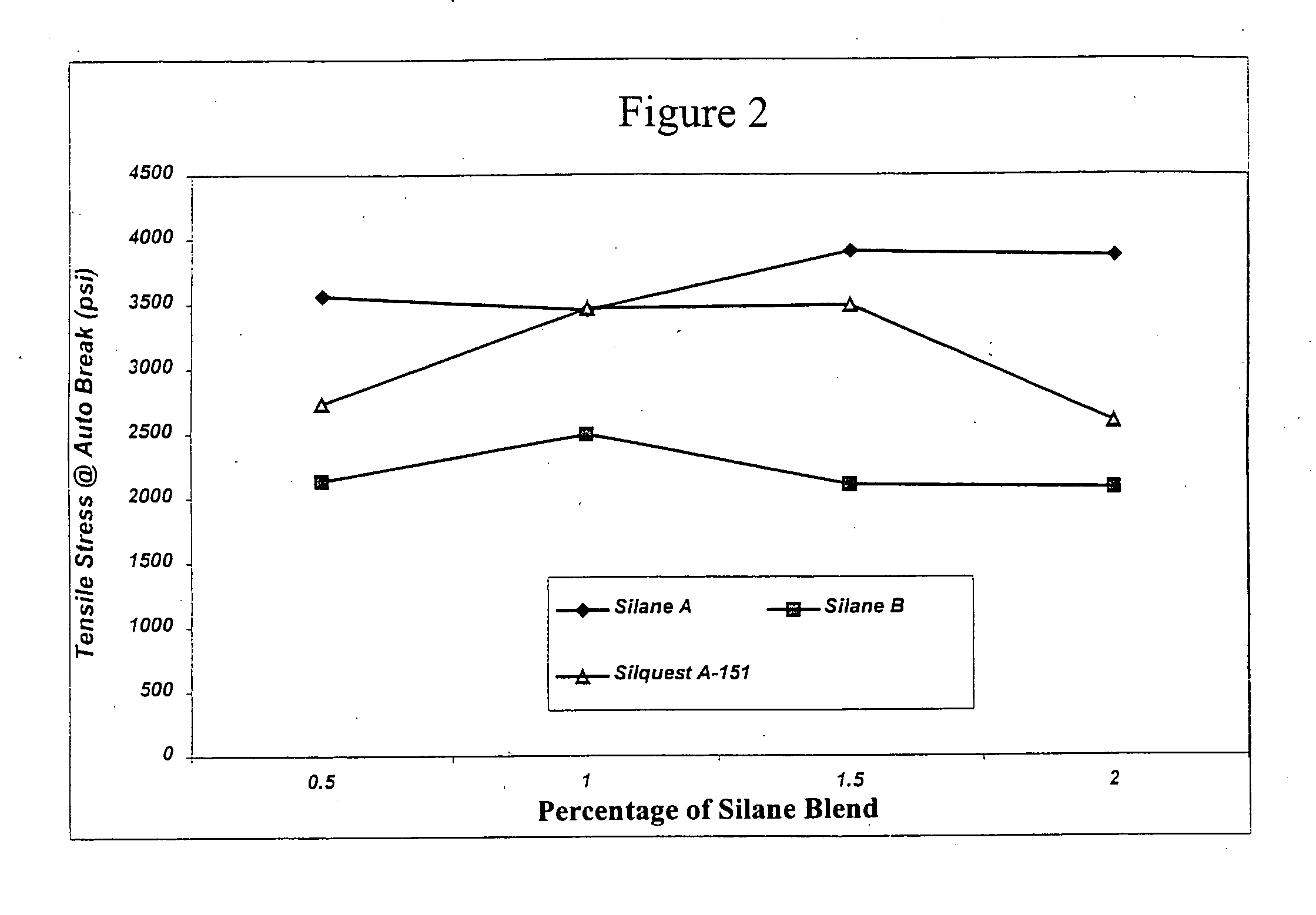

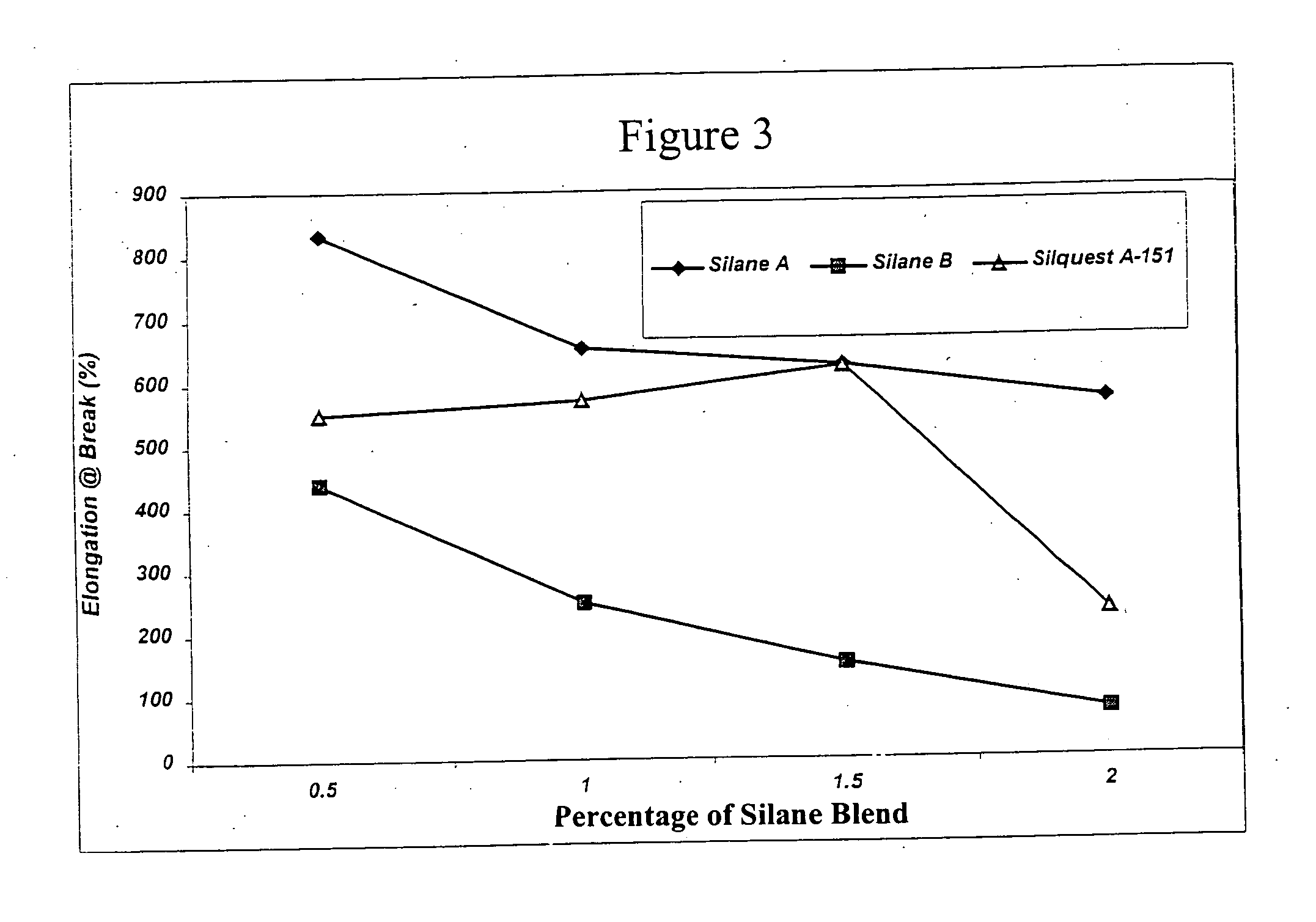

Process for the production of crosslinked polymer employing low VOC-producing silane crosslinker and resulting crosslinked polymer

A process for crosslinking polymers employs a silane crosslinker which, upon hydrolysis, produces a reduced quantity of volatile organic compound.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

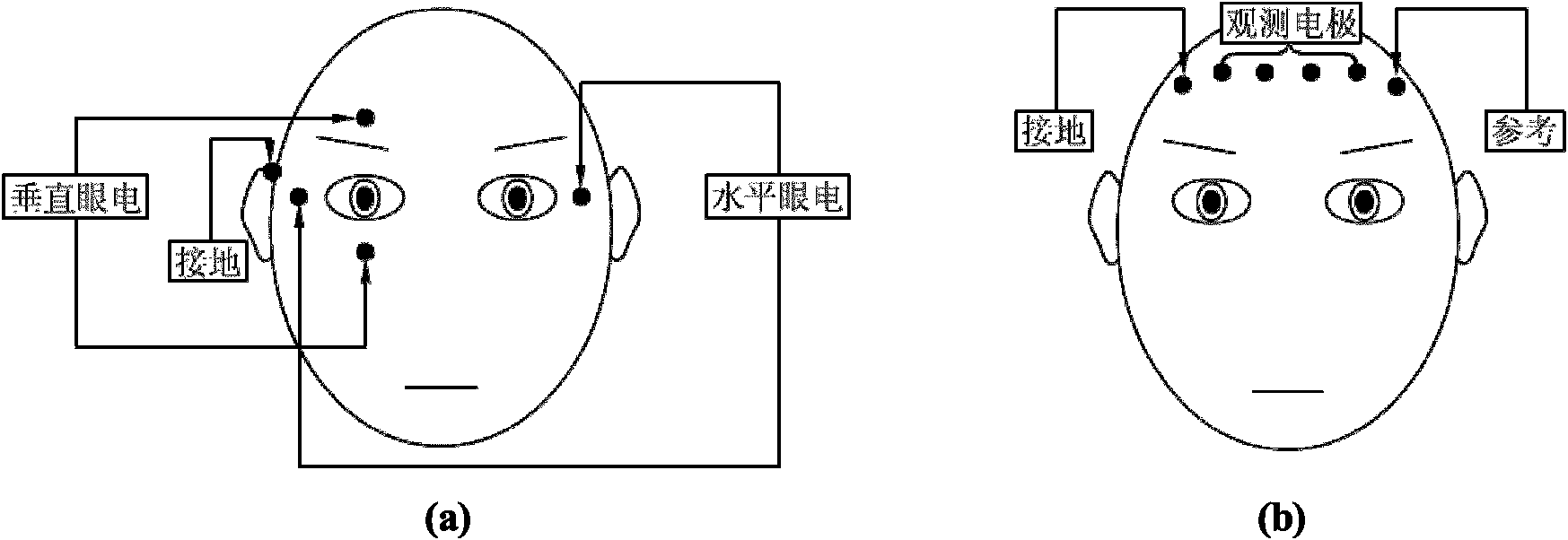

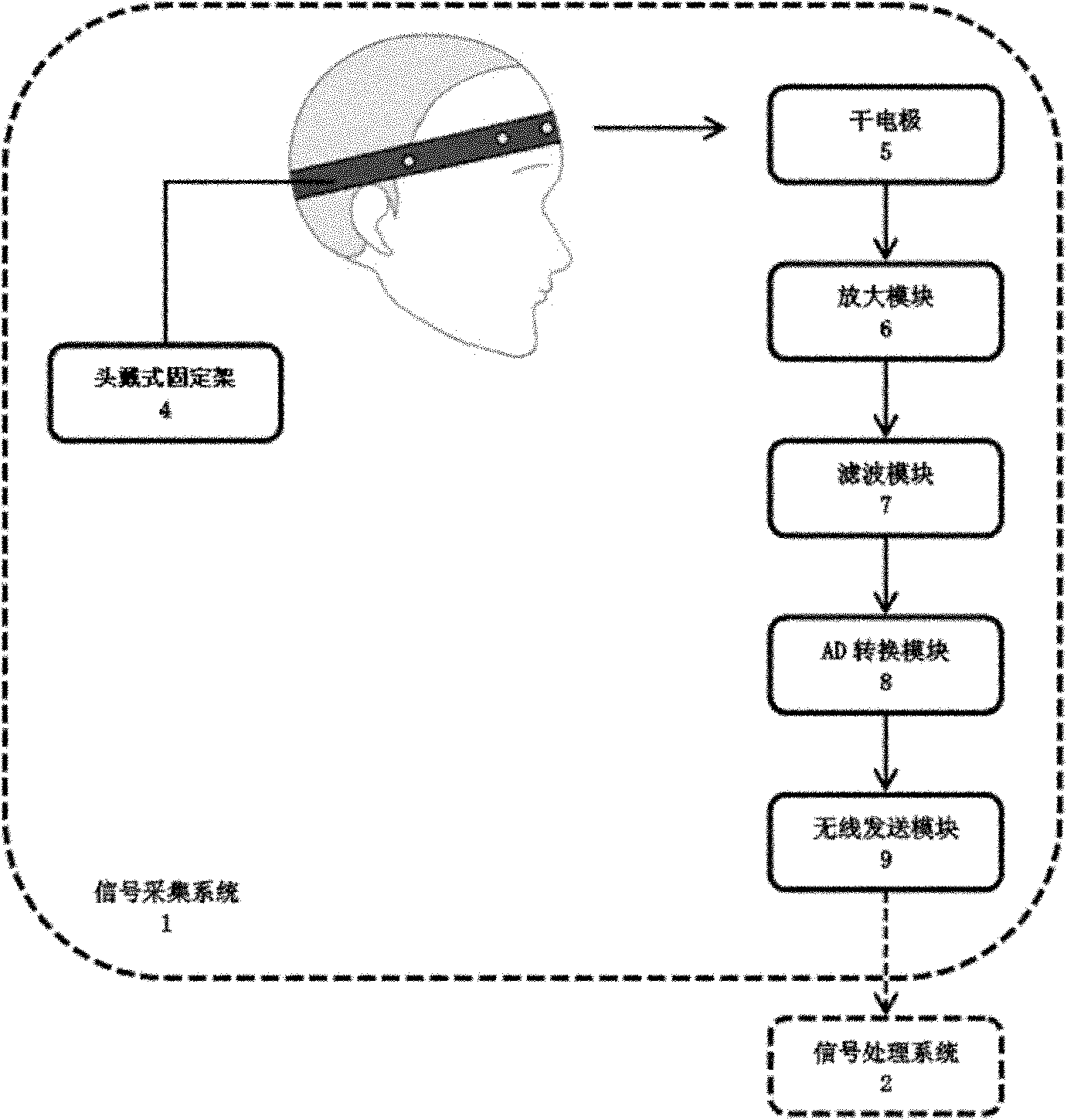

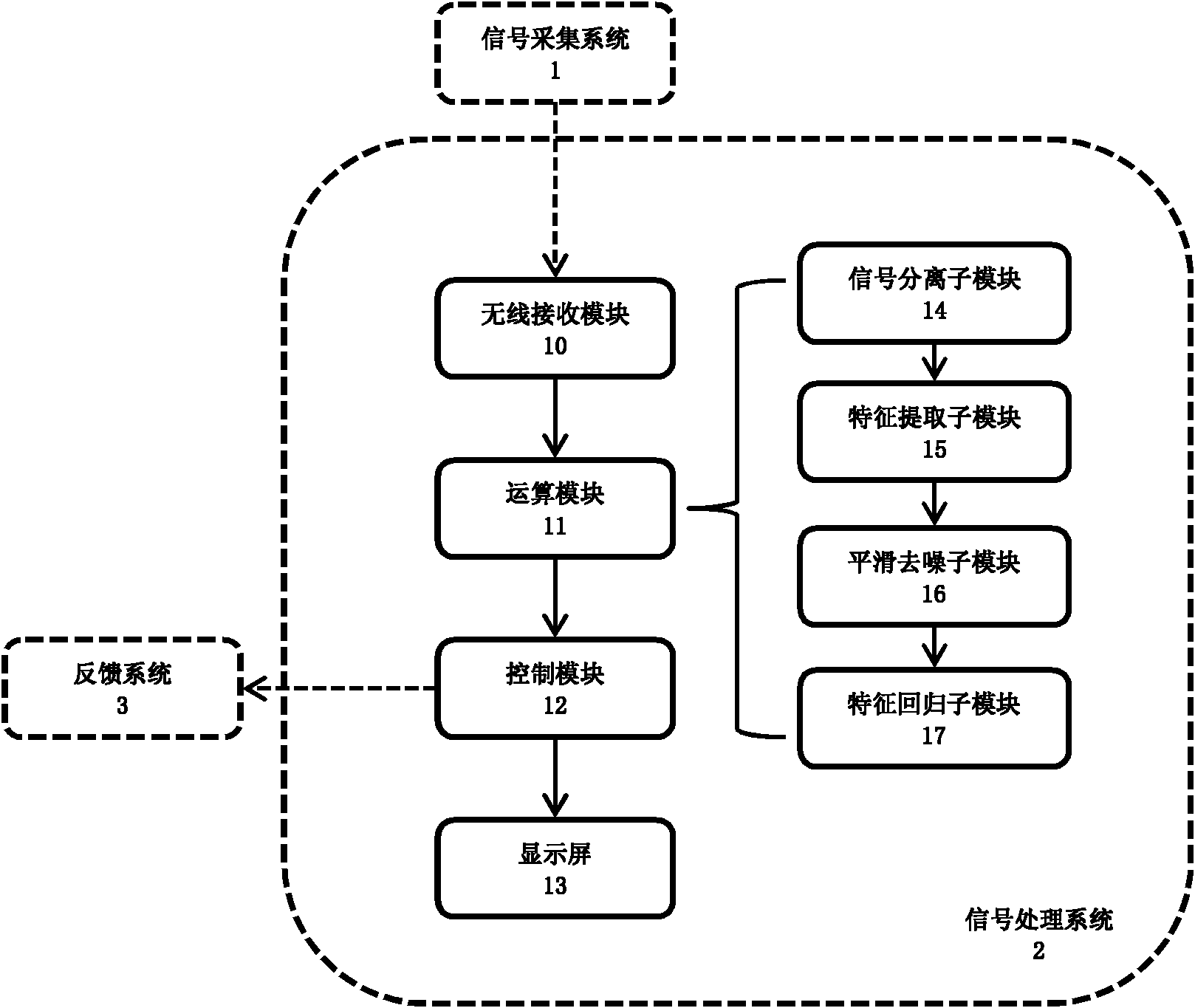

Alertness detection system based on electro-oculogram signal

InactiveCN102125429ALow costAvoid mistakesDiagnostic recording/measuringSensorsElectro oculogramFeature extraction

The invention discloses an alertness detection system based on an electro-oculogram signal in the technical field of signal processing. The system comprises a signal acquiring system, a signal processing system and a feedback system, wherein the signal acquiring system acquires an electro-oculogram analog signal and then outputs characteristic data to the signal processing system after performing amplification, filtration and digital-to-analogue conversion on the electro-oculogram analog signal; the signal processing system extracts characteristics from the input electro-oculogram signal, estimates an alertness state and then outputs the data to the feedback system; and the feedback system sends an alarm when an alarm condition is met. Through the alertness detection system based on the electro-oculogram signal, information more complete and accurate than an eye video can be provided; when the system is combined with the plurality of characteristics, such as low-speed eye movement, high-speed eye movement, blink and the like, which are extracted from an electro-oculogram (EOG) and a linear dynamic system supporting real-time property is adopted to de-noise, the fatigue state of a user can be timely and accurately reflected and an alarm is generated for the fatigue beyond a certain degree.

Owner:SHANGHAI JIAO TONG UNIV

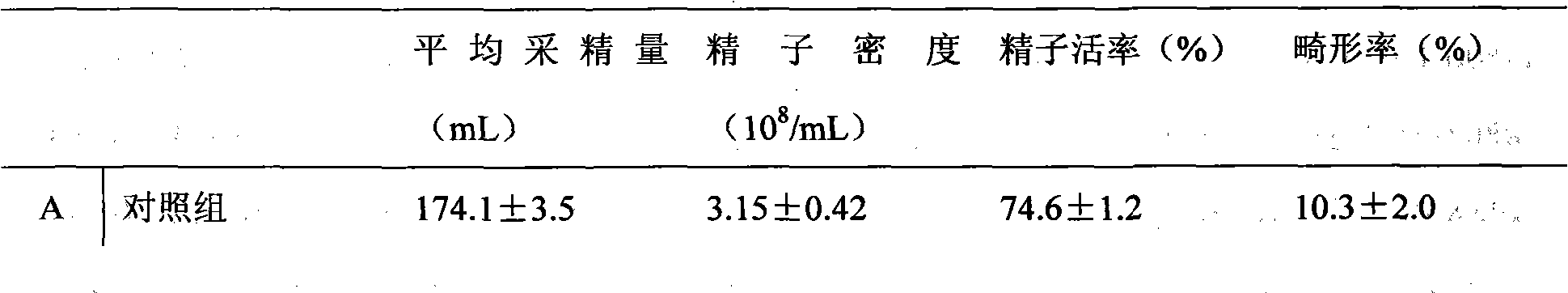

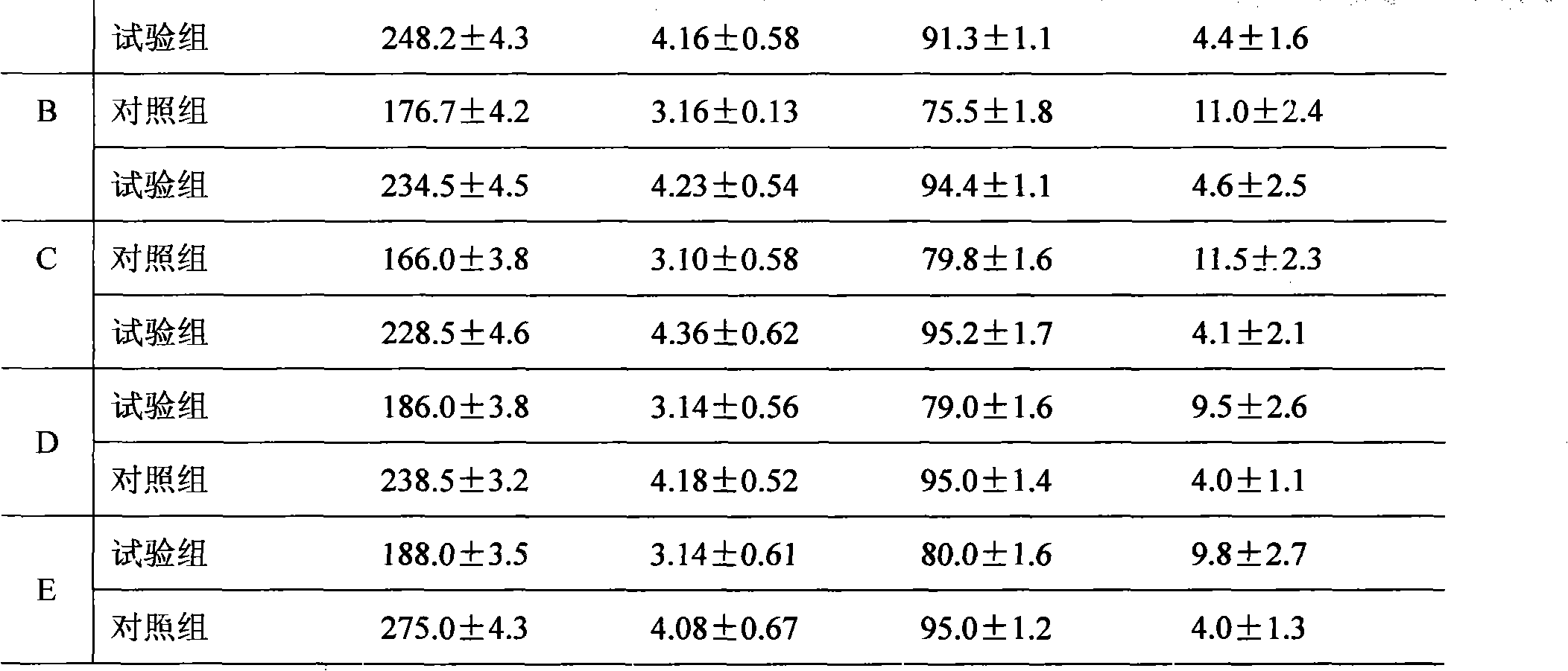

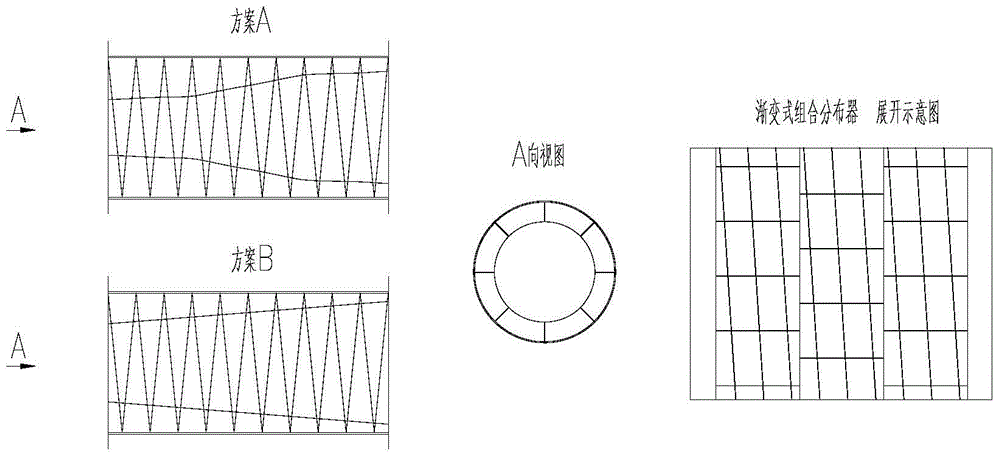

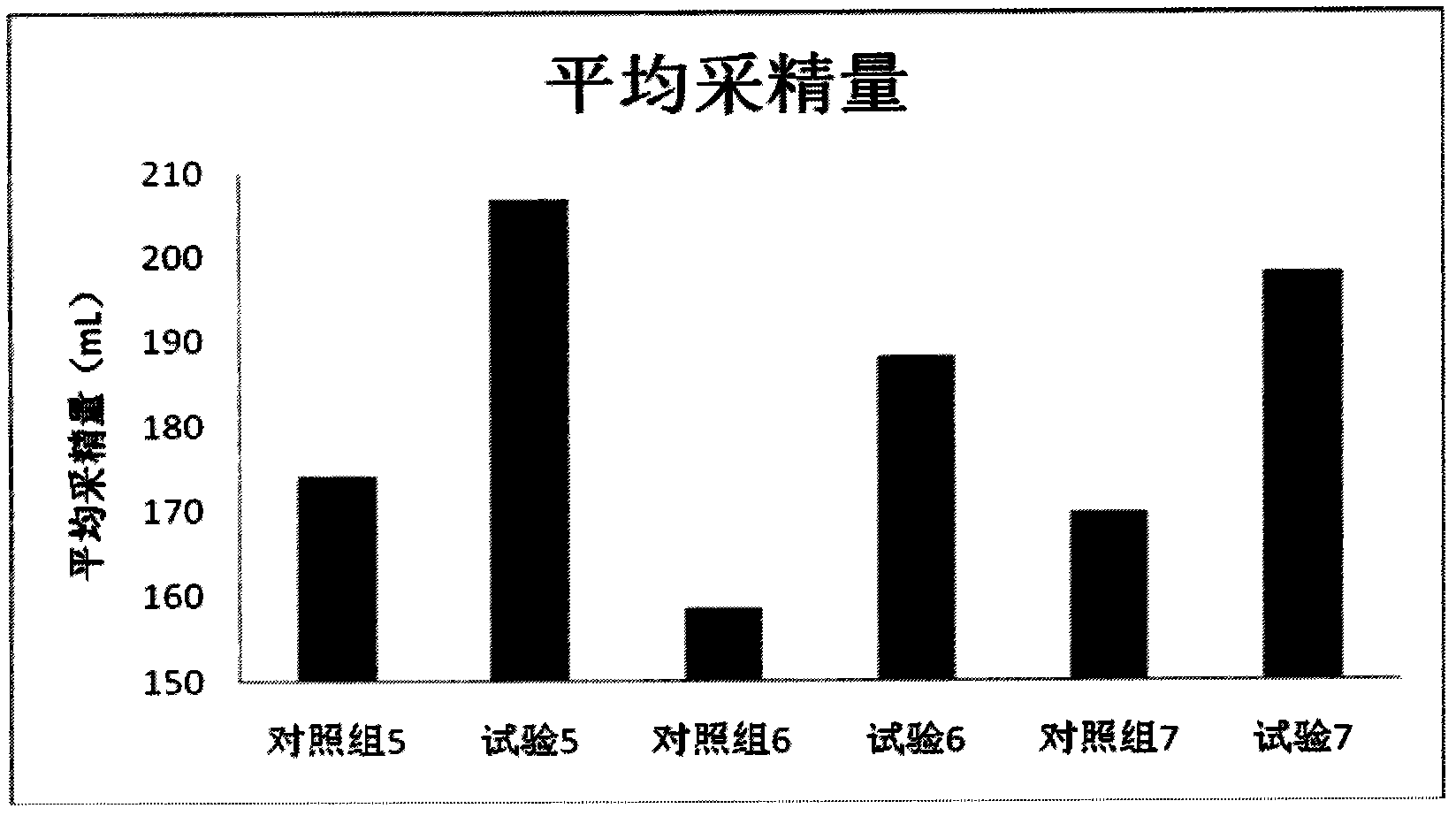

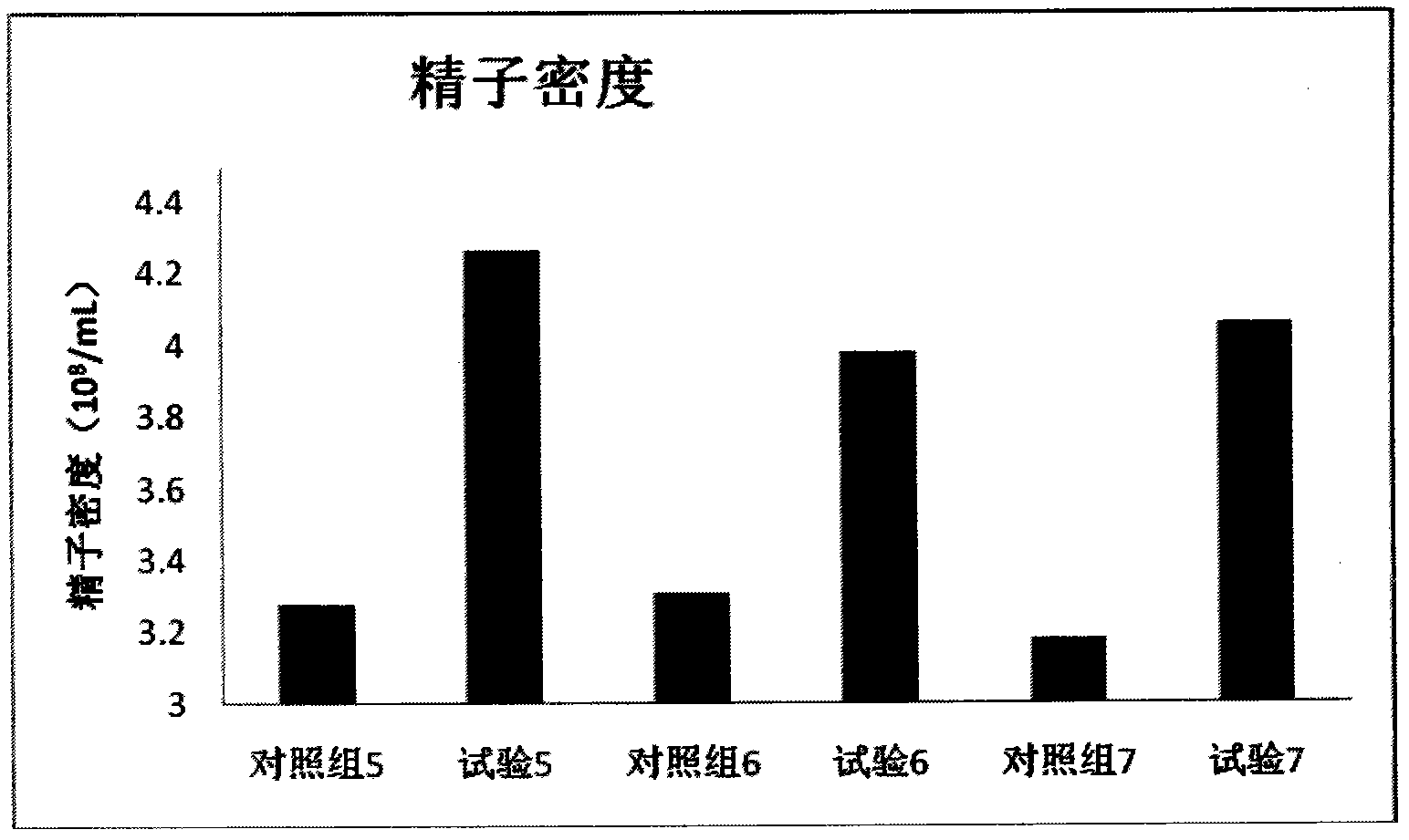

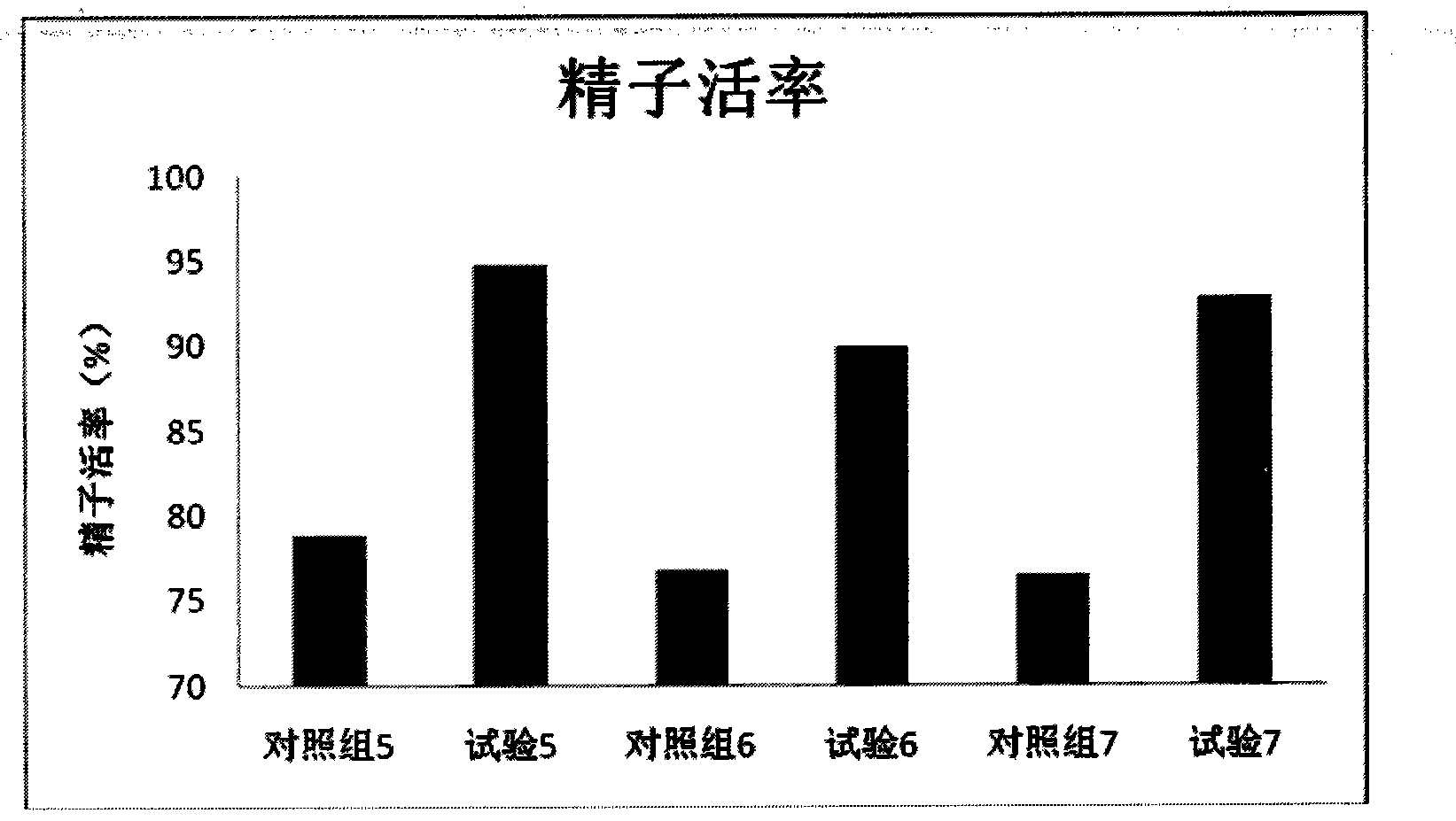

Complex additive for boars and preparation method and using method thereof

ActiveCN102106472AImprove reproductive performanceEasy to prepareAnimal feeding stuffAccessory food factorsCarbamylglutamic acidVitamin C

The invention relates to a complex additive for boars and a preparation method and a using method thereof. The additive is prepared from the following components in percentage by weight: 1.00 to 5.00 percent of N-carbamylglutamic acid, 1.00 to 5.00 percent of vitamin E, 0.10 to 0.30 percent of vitamin B2, 0.10 to 0.30 percent of vitamin C, 1.00 to 2.00 percent of organic zinc, 0.03 to 0.50 percent of organic chromium, 0.04 to 0.60 percent of organic selenium, 0.04 to 0.50 percent of carnitine 50, 0.001 to 80.00 percent of functional protein, 0.03 to 0.50 percent of antioxidant, 0.001 to 0.40 percent of anti-mildew agent and the balance of carrier. The preparation method comprises the following steps of: 1) weighing the N-carbamylglutamic acid, the vitamins, organic trace elements, the functional protein, the antioxidant, the anti-mildew agent and the carrier according to a proportion in percentage by weight respectively; and 2) fully mixing the raw materials weighed in the step 1) in a mixer uniformly to obtain the product. The using method comprises that the complex additive is added into daily ration of the boars, wherein the adding amount is 200 to 400 grams very day. The additive can promote the synthesis of source arginine in the bodies of animals and further enhance the synthesis of carbon monoxide (NO) and polyamine.

Owner:林州亚太兴牧科技有限公司

Adhesive formulations containing urea additives, methods of forming plywood therewith, and plywood products made thereby

InactiveUS20080292886A1Huge economic benefitsReduce or visibly eliminate stainingSynthetic resin layered productsOrganic non-macromolecular adhesiveUrea derivativesPolyamide

Compositions suitable for use as wood adhesives are described, which compositions comprise: (a) a polymeric component selected from the group consisting of lignins, proteins, and mixtures thereof, (b) an adhesion promoter comprising at least one component selected from the group consisting of (i) adducts of an epoxide and a resin selected from the group consisting of polyamine resins, polyamidoamine resins, polyamide resins, and combinations thereof, and (ii) combinations of a curing agent and a compound having at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group capable of reacting with at least one functional group of the polymeric component; and (c) an additive selected from the group consisting of urea, N-substituted ureas, N,N-disubstituted ureas, N,N′-disubstituted ureas, N,N,N′-trisubstituted ureas, N,N,N′,N′-tetrasubstituted ureas, urea derivatives, and mixtures thereof.

Owner:HERCULES INC

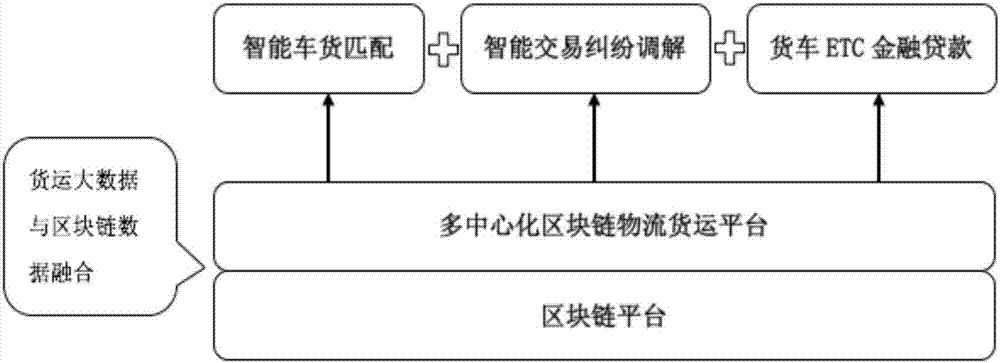

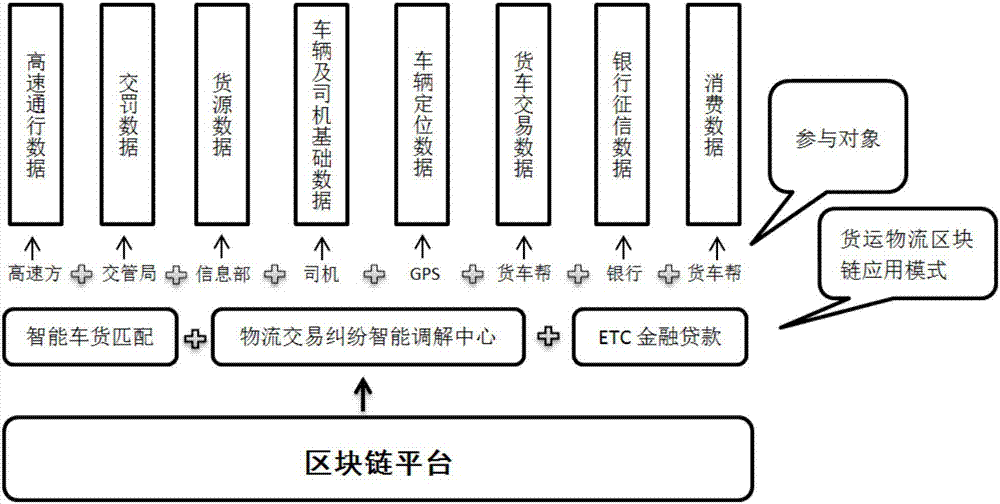

Freight logistics application method based on block chain

InactiveCN107122937ASolve the problem of mutual mistrustVerify authenticityFinanceLogisticsLogistics managementData sharing

The invention relates to the field of freight logistics application, specifically discloses a freight logistics application method based on a block chain and is to solve the problem of large data evidence collection difficulty in the later freight logistics link caused since all links in the freight logistics process are mutually independent, and data cannot be shared. The method is characterized by collecting freight logistics object data and establishing sub-block chains, and combining the sub-block chains to establish a block chain platform, thereby realizing trustworthy data sharing in the whole freight logistics process, enabling the data in the later freight logistics process to be scheduled, used and obtained for evidence as needed, and further promoting intelligent development of freight logistics application.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

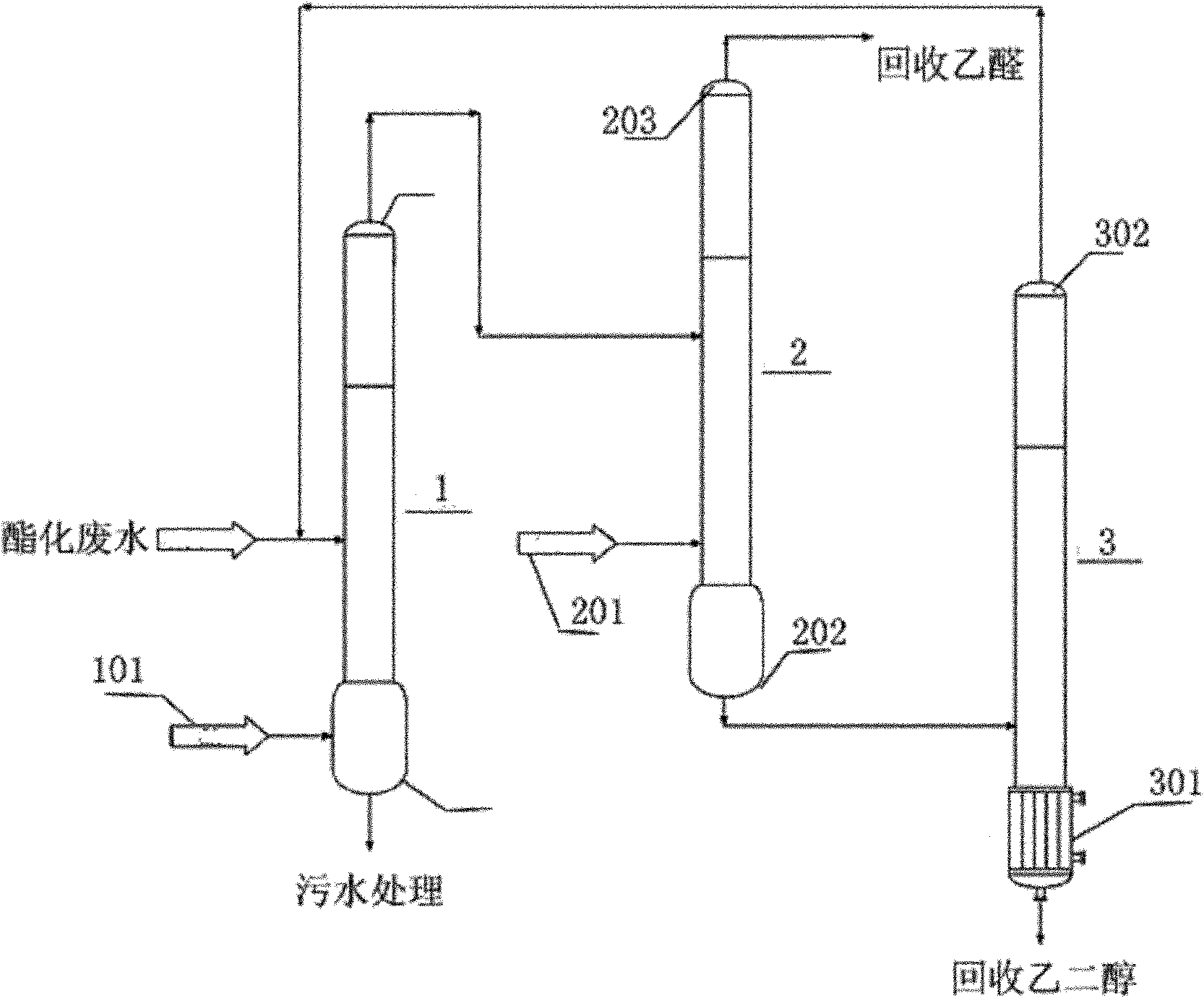

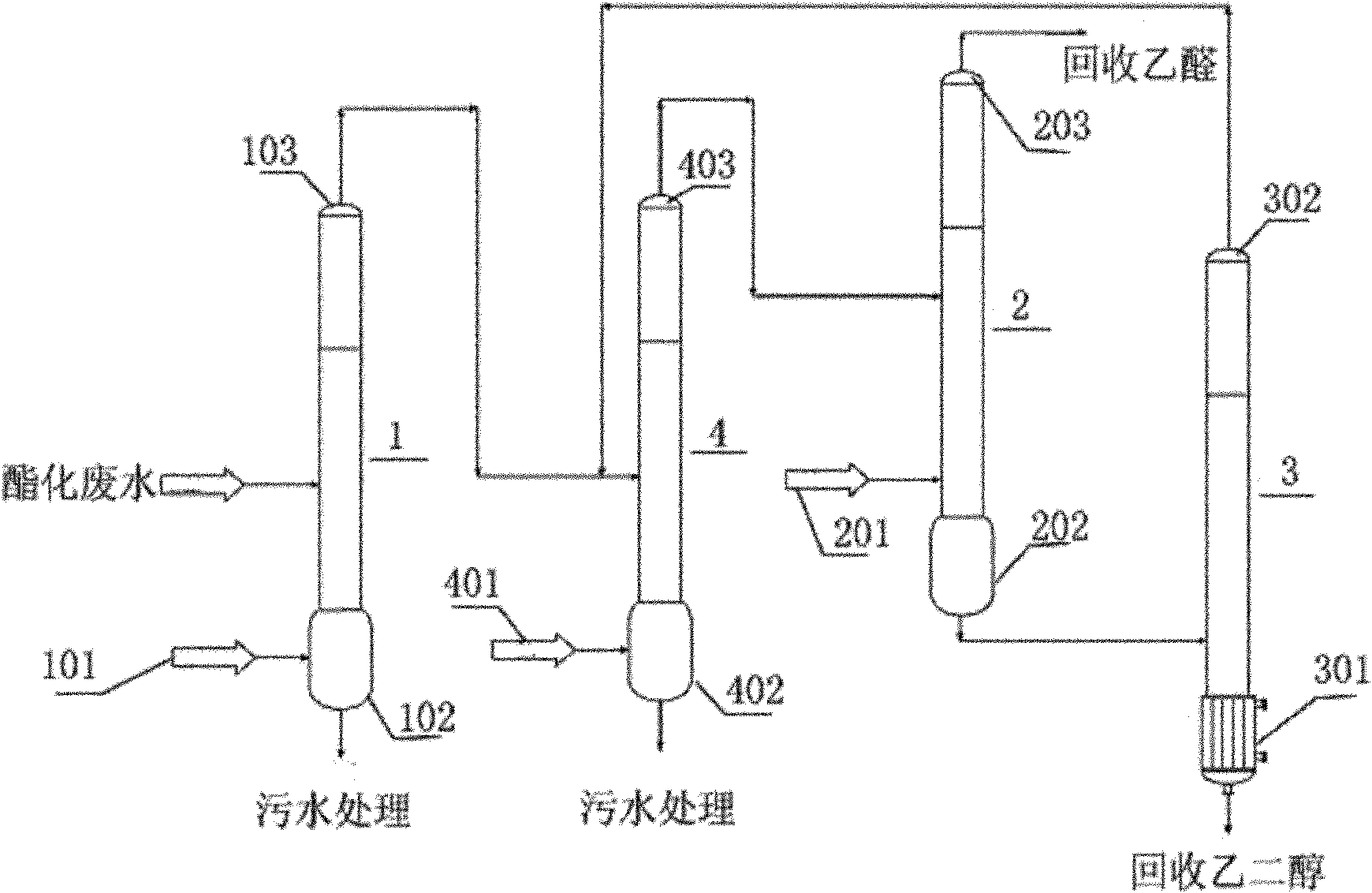

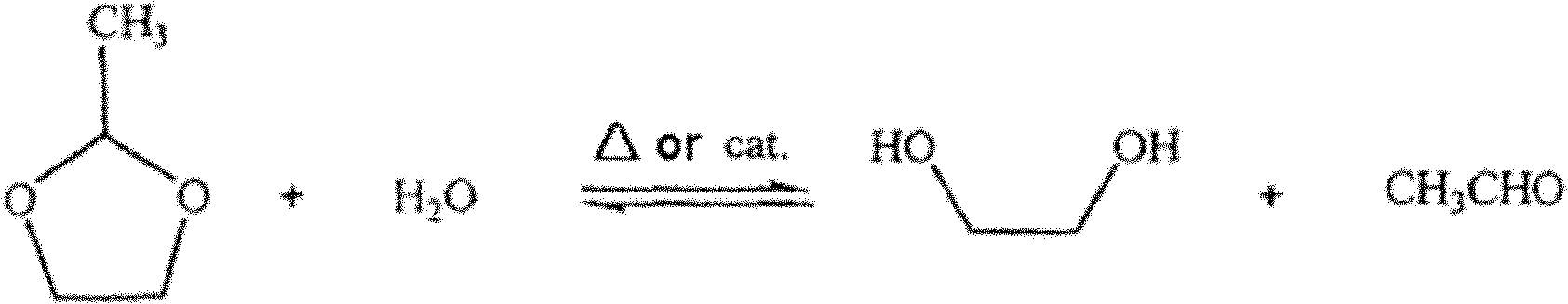

Method for recycling ethylene glycol and acetaldehyde from polyester waste water

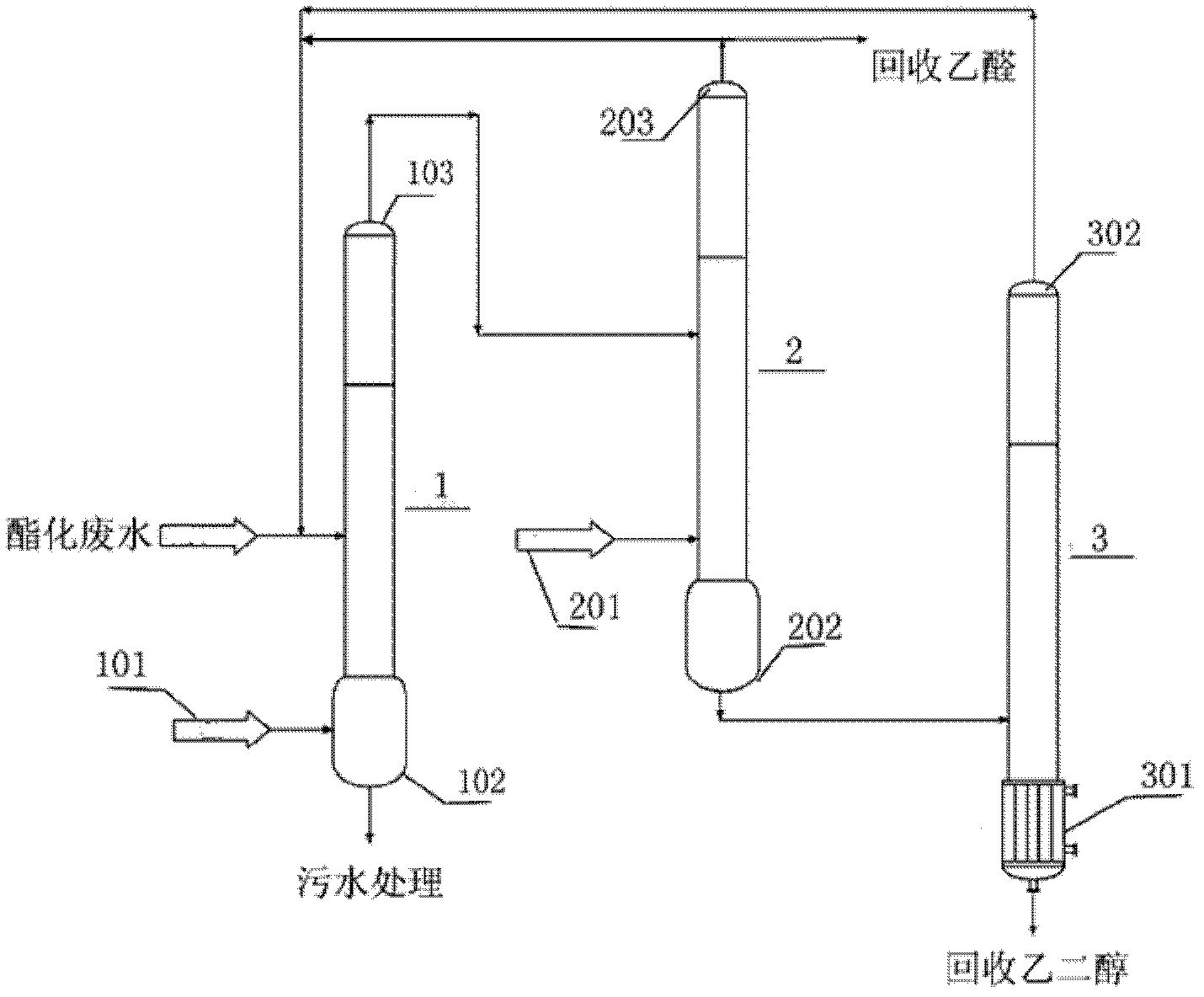

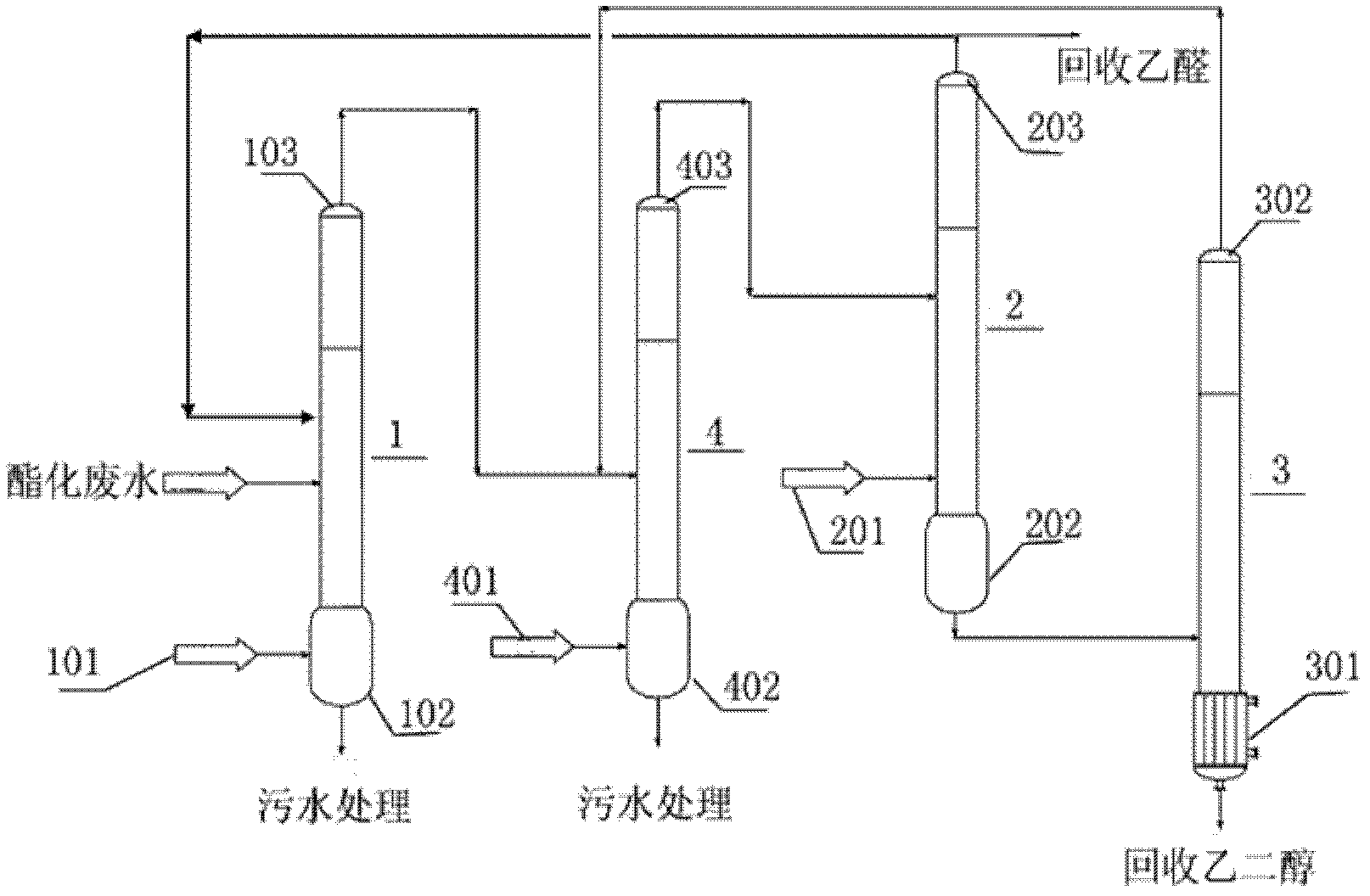

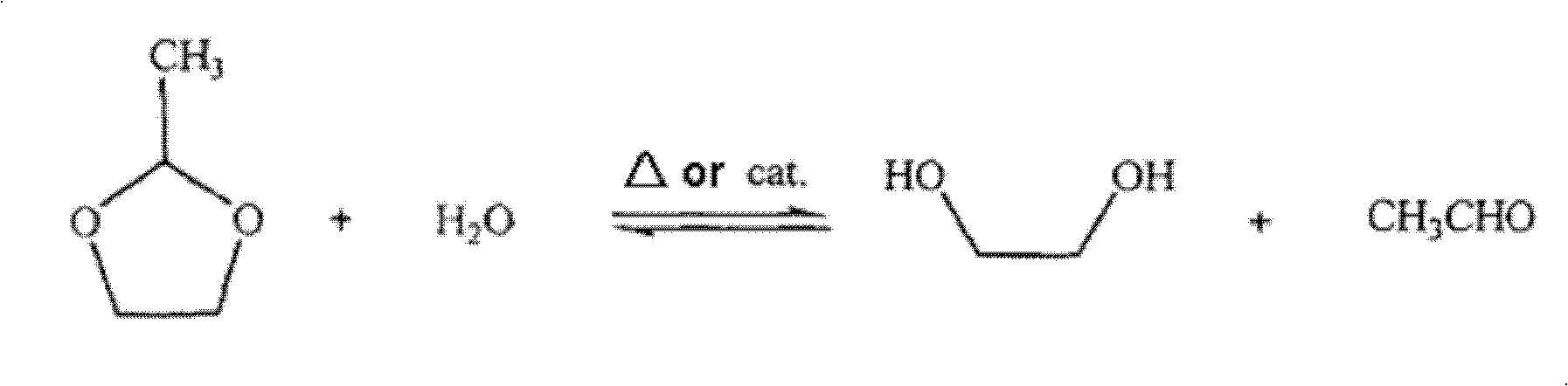

ActiveCN102126926AReduce COD valueFix security issuesMultistage water/sewage treatmentWater/sewage treatment by degassingPolyesterDistillation

The invention discloses a method for recycling ethylene glycol and acetaldehyde from polyester waste water. The method is implemented by the following steps of: (1) introducing esterification waste water into a stripping tower for treating and directly introducing organic matter gas and water vapor collected from a tower top into an acetaldehyde rectifying tower; (2) treating in the acetaldehyde rectifying tower, collecting high-purity acetaldehyde from the tower top and introducing waste water collected from a tower bottom into an ethylene glycol distillation tower; and (3) treating in the ethylene glycol distillation tower, collecting a high-purity ethylene glycol solution from the tower bottom and introducing waste gas and water vapor produced on the tower top into the stripping tower for cyclic treatment. In the method, acetaldehyde and ethylene glycol are continuously collected, so that hydrolysis of byproduct of 2-methyl-1,3-dioxolane in the esterification waste water is continuously performed positively and negatively, acetaldehyde with the concentration of over 95 percent and ethylene glycol with the concentration of over 70 percent are obtained at the end of treatment, and the 2-methyl-1,3-dioxolane is fully hydrolyzed.

Owner:SHANGHAI JUYOU CHEM ENG +1

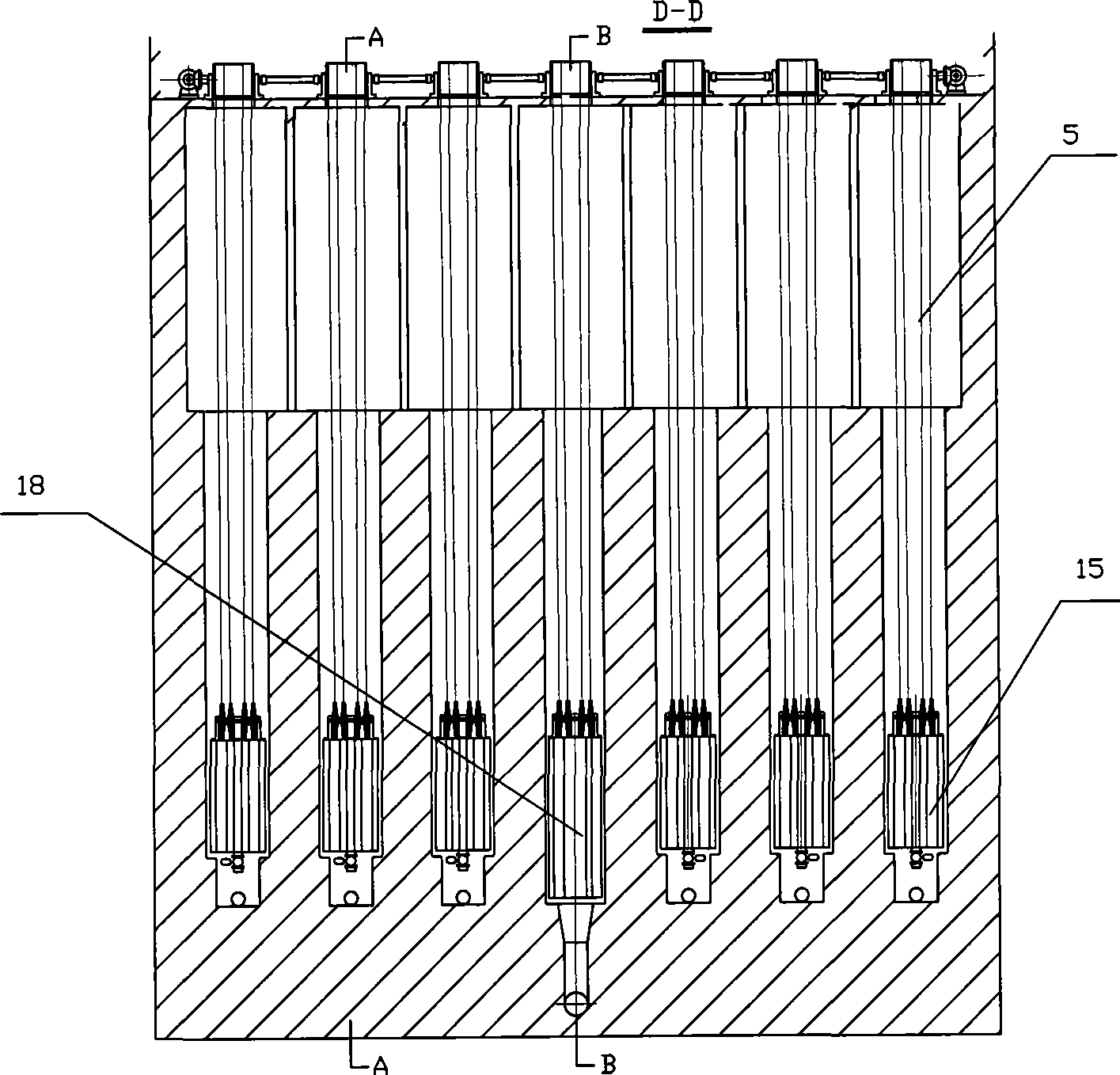

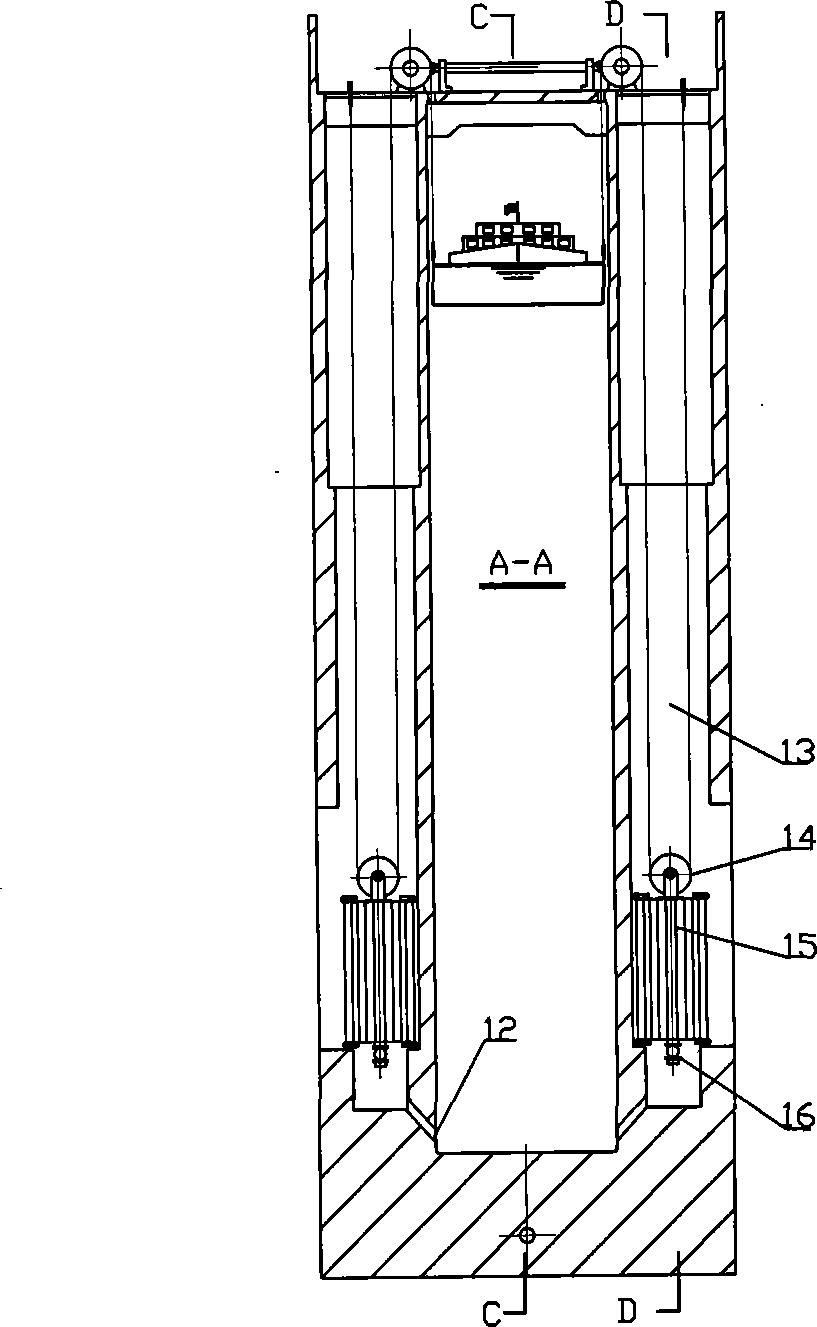

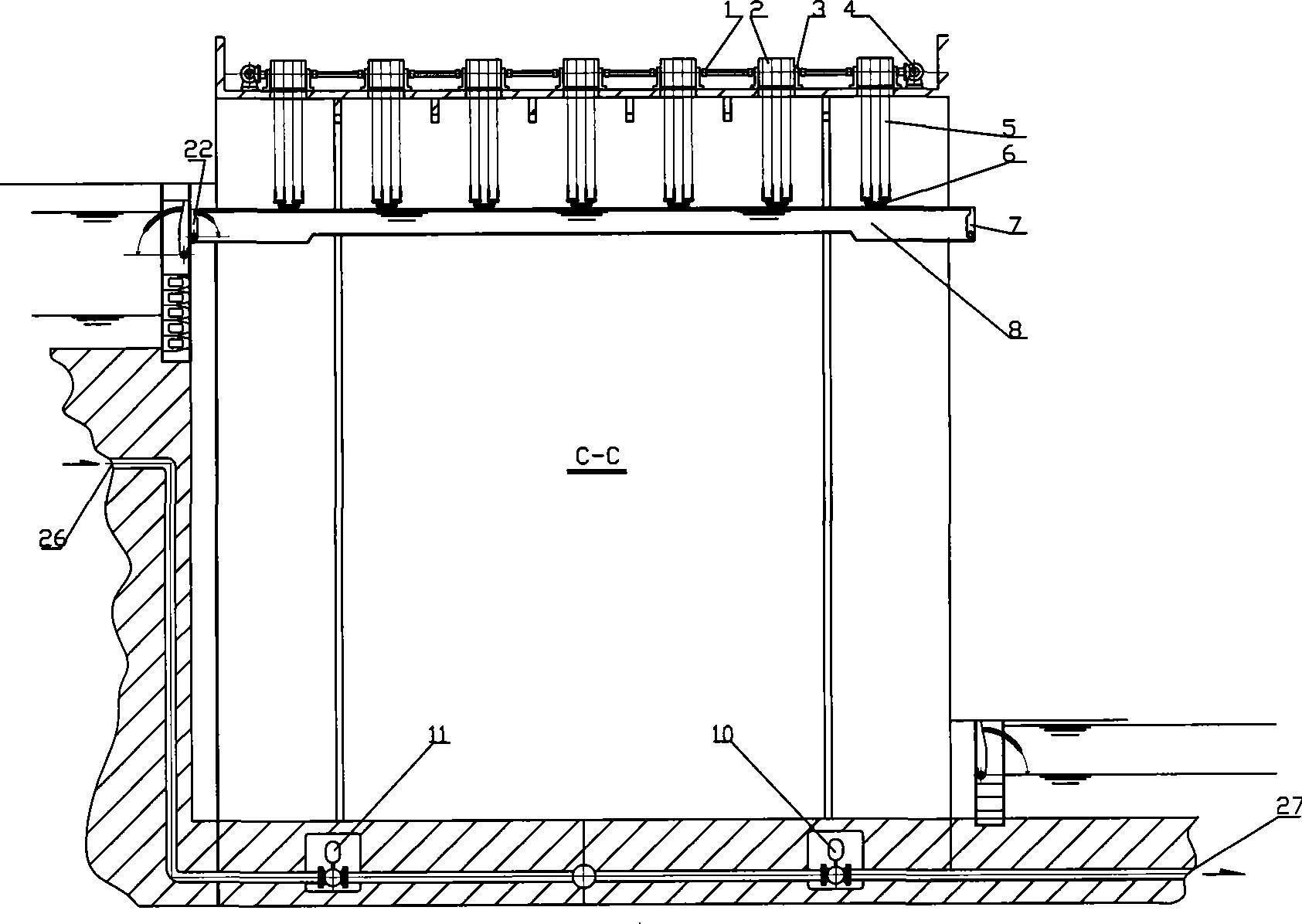

Hydropower floating quick vertical ship lift

ActiveCN101250865AHuge economic benefitsSave operating waterVertical ship-liftingMarine engineeringHydropower

The invention relates to a hydraulic floating type fast vertical ship lift, which belongs to the technical field of ship lift. The ship lift which is provided by the invention substantially comprises a balanced system, a hoisting system and a mechanical synchronous system. The working principle is that the total weight of a surge drum balances the total weight of a ship chamber, a lifting vertical shaft is filled with water or the water in the lifting vertical shaft is discharged through operating a feed valve or a drain valve, thereby achieving the purpose of changing the weight of the lifting surge drum, and overcoming the frictional resistance and impelling the ship chamber to lift. The hydraulic floating type fast vertical ship lift is capable of replacing locks flights or a wire rope hoisting ship lift to complete a lifting ship operation, thereby being capable of saving massive operation water. The lifting speed is rapid, massive time is capable of being saved when a ship crosses a dam, complex making and installment process of a miter gate and complex construction of a water-carriage system and a drainage system of a lock chamber are avoided, thereby saving massive project investment. The workload of repair and maintenance is small, and the cost is low.

Owner:中国长江三峡工程开发总公司

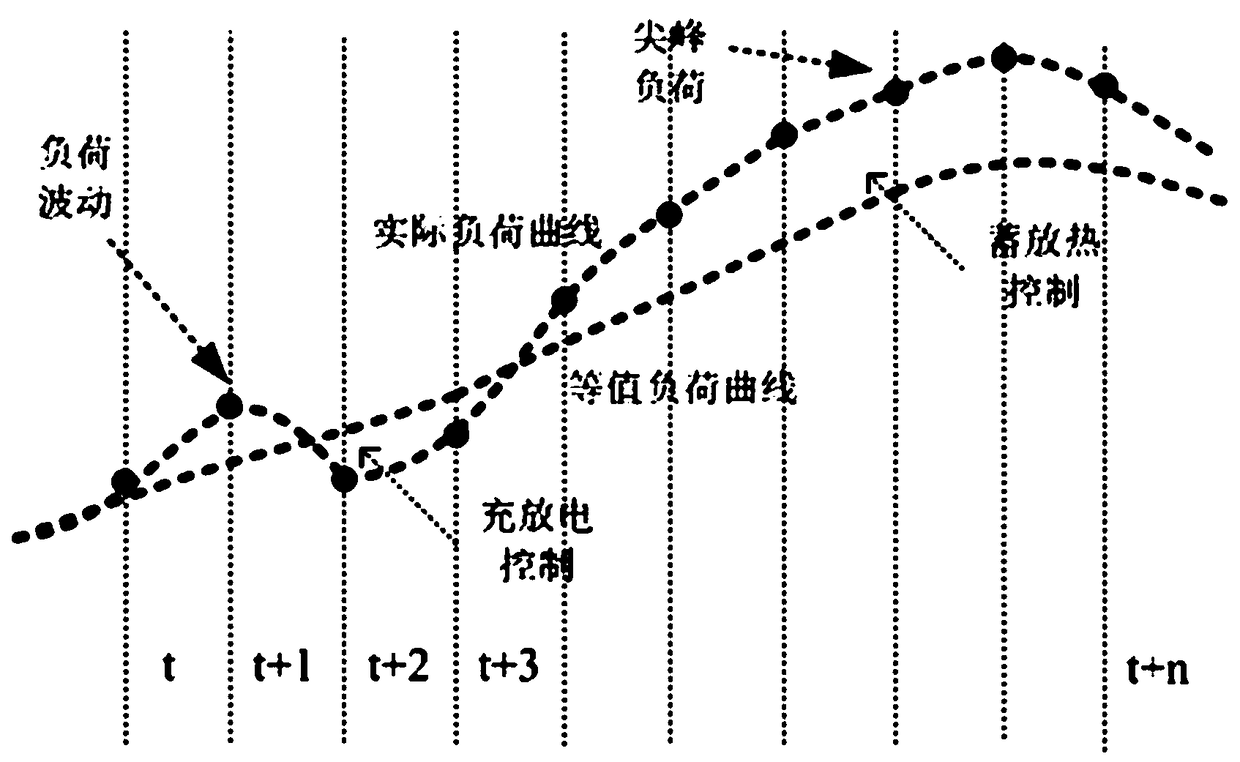

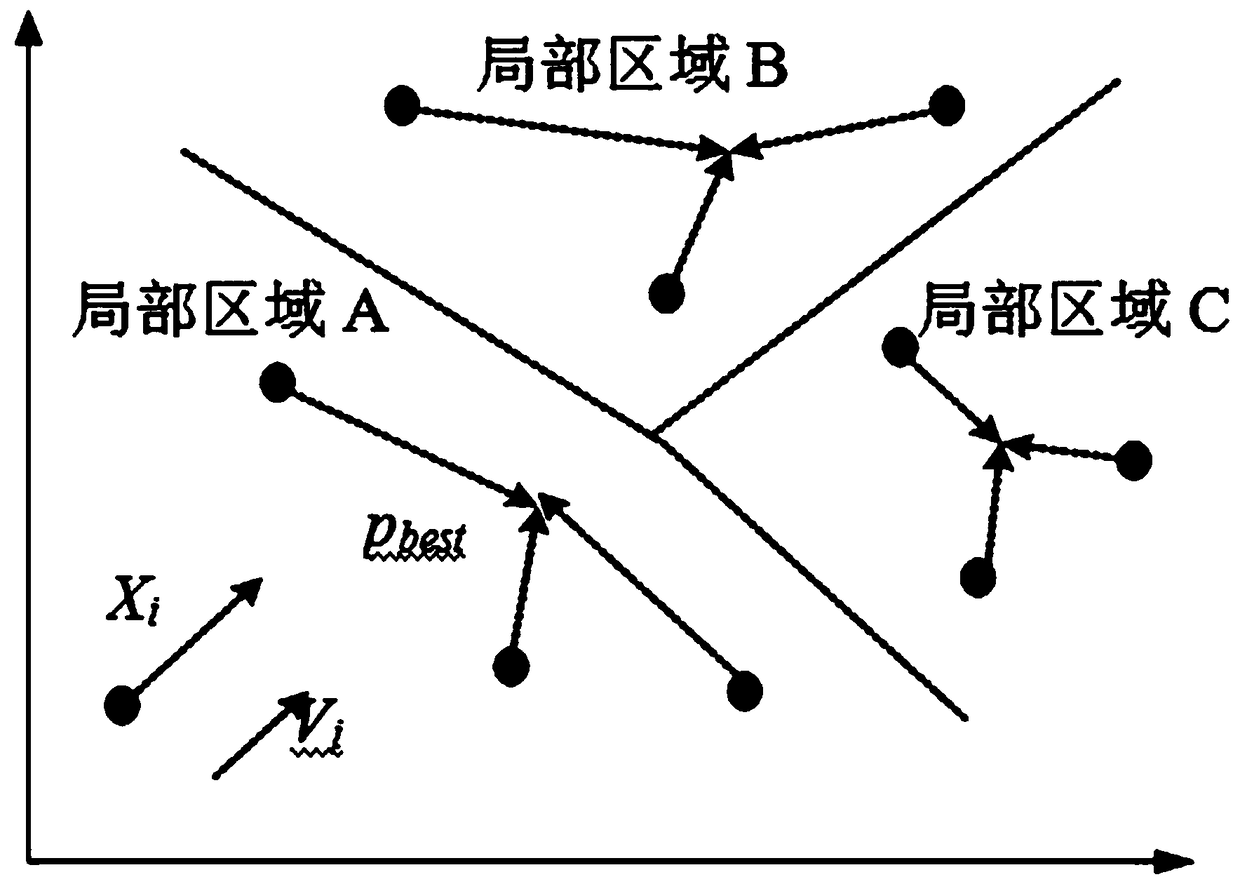

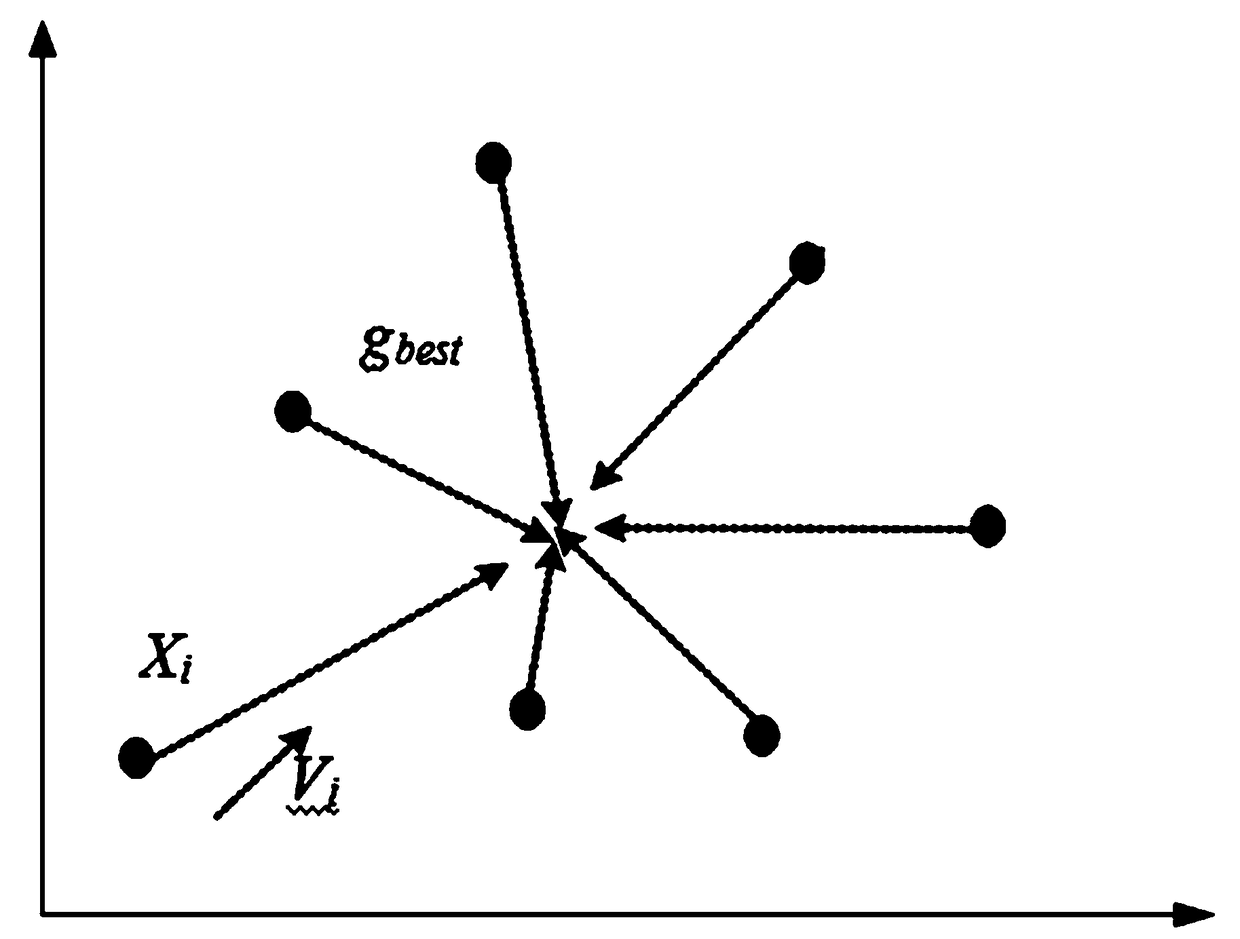

A cooperative load dispatching method for distribution network based on particle swarm optimization

ActiveCN109066800AIncrease elasticityImprove reliabilitySingle network parallel feeding arrangementsEnergy storageNew energyEconomic benefits

The invention relates to a distribution network flexible load cooperative dispatching method based on a particle swarm algorithm, belonging to the technical field of grid operation and control. The method comprises the following steps of: (1) considering stabilizing new energy access, peak clipping and valley filling and safe and economical operation of distribution network, establishing an optimization objective of flexible load cooperative dispatching model of distribution network; 2, synthetically considering the system balance constraint, the network constraint, the distribution power source and the adjustable load constraint, wherein each constraint condition can flexibly carry out parameter configuration and effective setting, and establishing the constraint of the optimization objective in the step 1; and 3, finally, solving the optimization objective of the load cooperative dispatch model satisfying the constraint condition by using the particle swarm optimization algorithm. This kind of cooperative control method provides space for alleviating the peak load regulation and realizing the large-scale consumption of new energy, and its economic benefits are enormous.

Owner:SHENYANG INST OF ENG

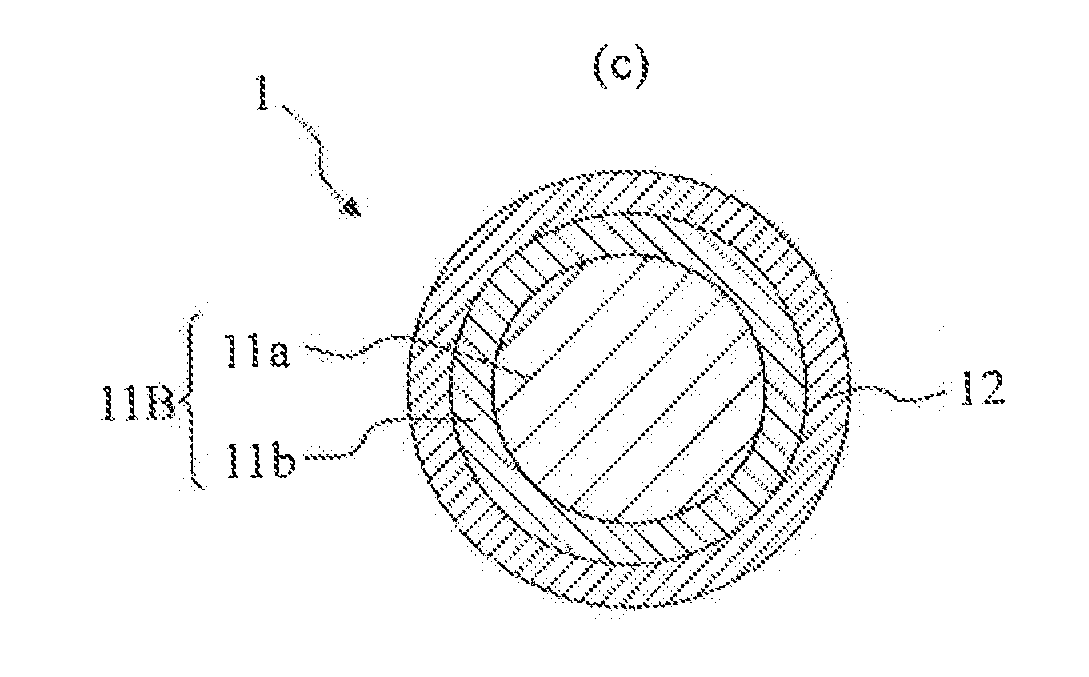

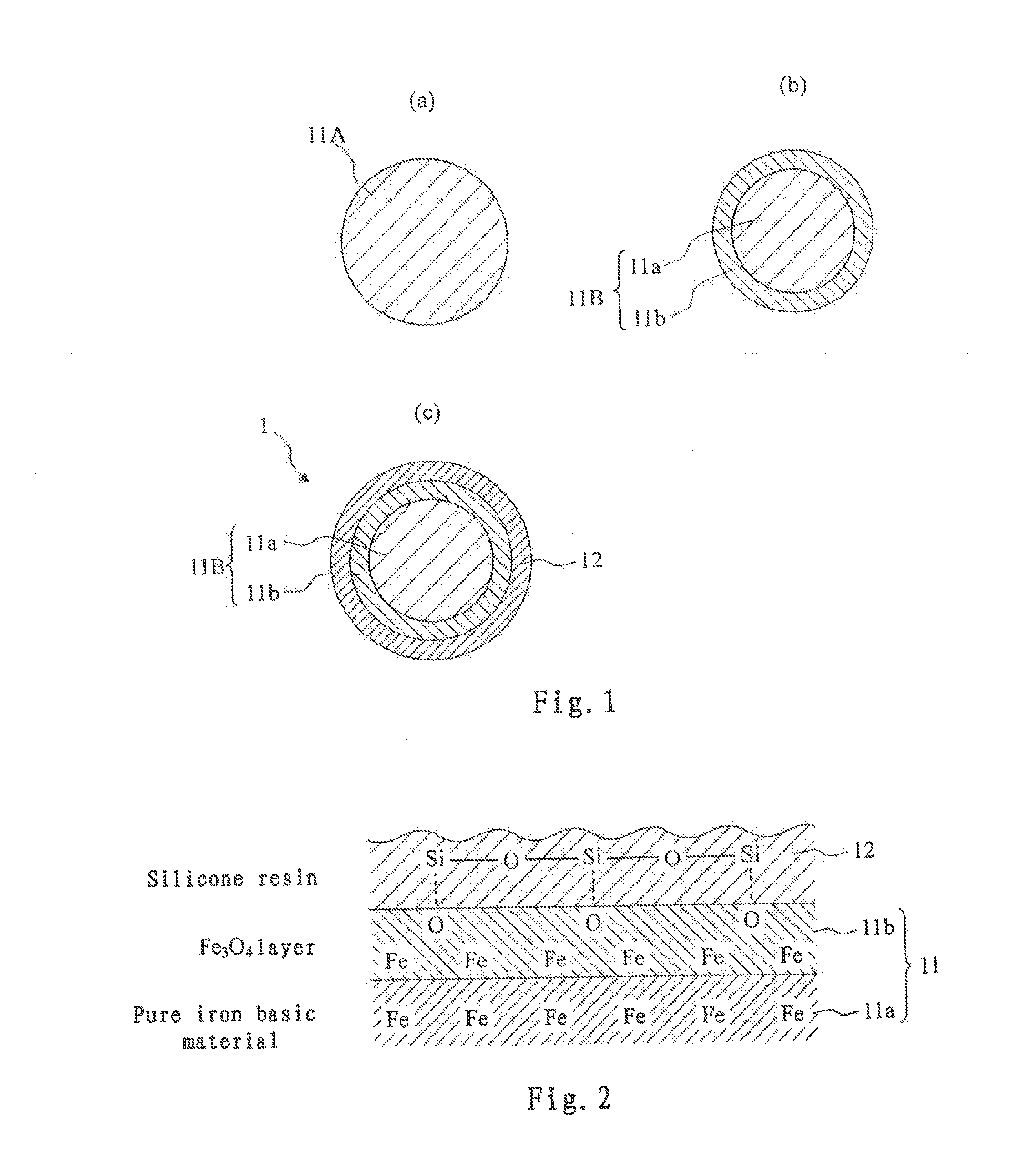

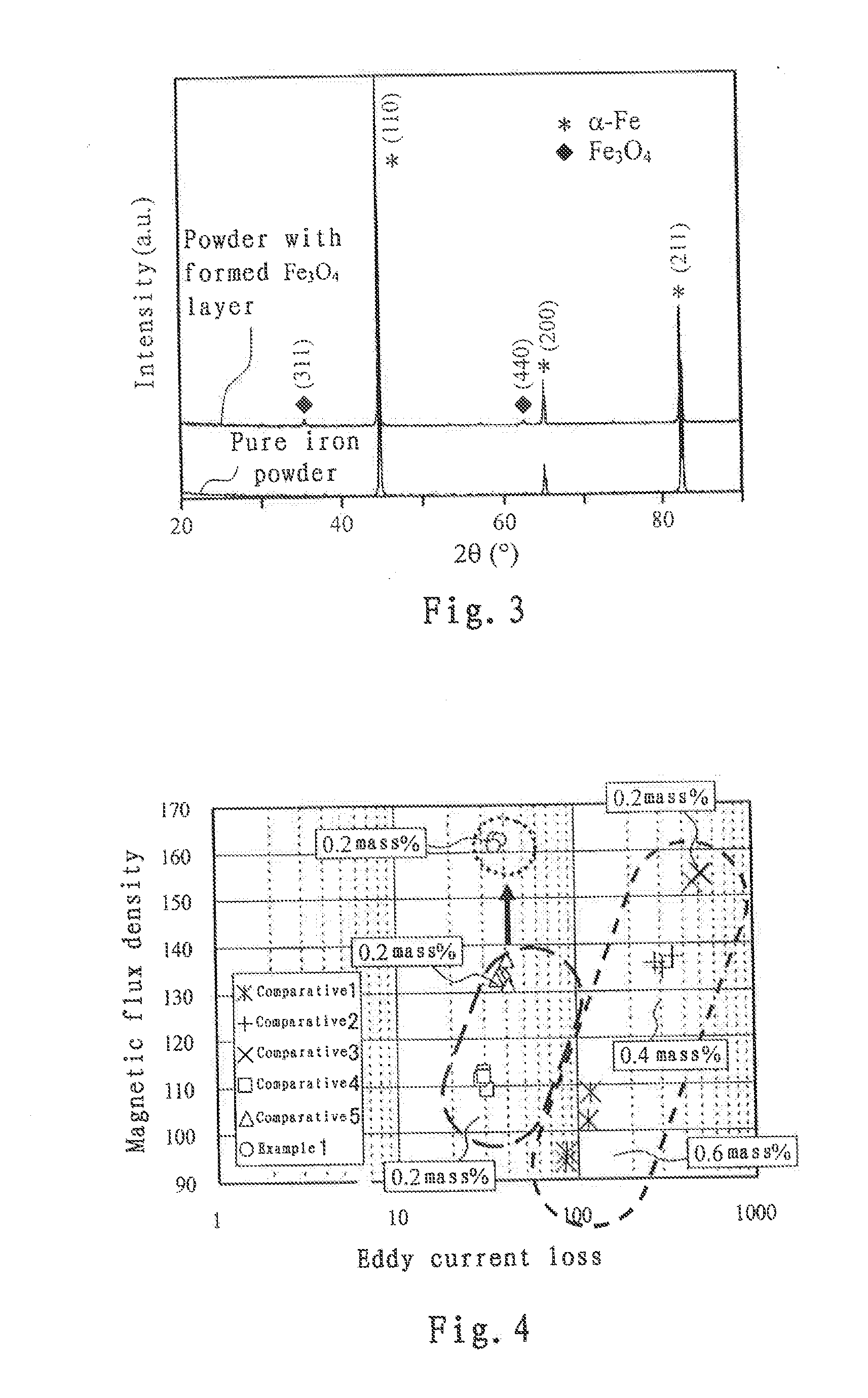

Composite soft magnetic powder, composite soft magnetic powder core, and preparation method therefor

InactiveUS20140104023A1Reduce lossHigh magnetic flux densitySynthetic resin layered productsMetal-working apparatusIron powderHigh density

The present invention discloses a composite soft magnetic powder core and a preparation method therefor, which belong to the technical fields of soft magnetic materials and preparation thereof. An Fe / Fe3O4 shell layer is generated in situ on surfaces of iron powder particles through a controlled oxidation process, to prepare Fe / Fe3O4 composite soft magnetic powder having a uniform structure. The Fe / Fe3O4 composite soft magnetic powder is mixed with suitable amount of silicone resin, and prepared into a high-performance Fe / Fe3O4 composite soft magnetic powder core by using a powder metallurgy compaction process. Such magnetic powder core has a high density, a high magnetic conductivity, a high magnetic flux density, a low loss, and a high breaking strength, and is useful in a large-power and low-loss application scenario. The present invention has the advantages of being rich in raw material resources, simple in process and environmentally friendly, and being suitable for industrial production.

Owner:TSINGHUA UNIV +1

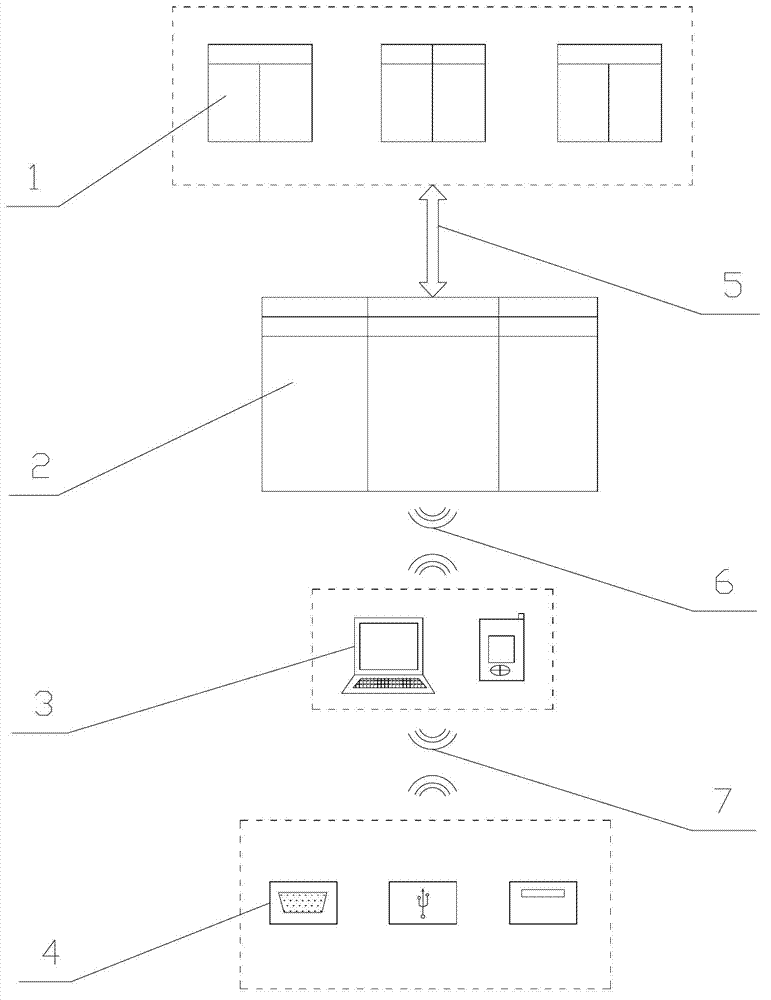

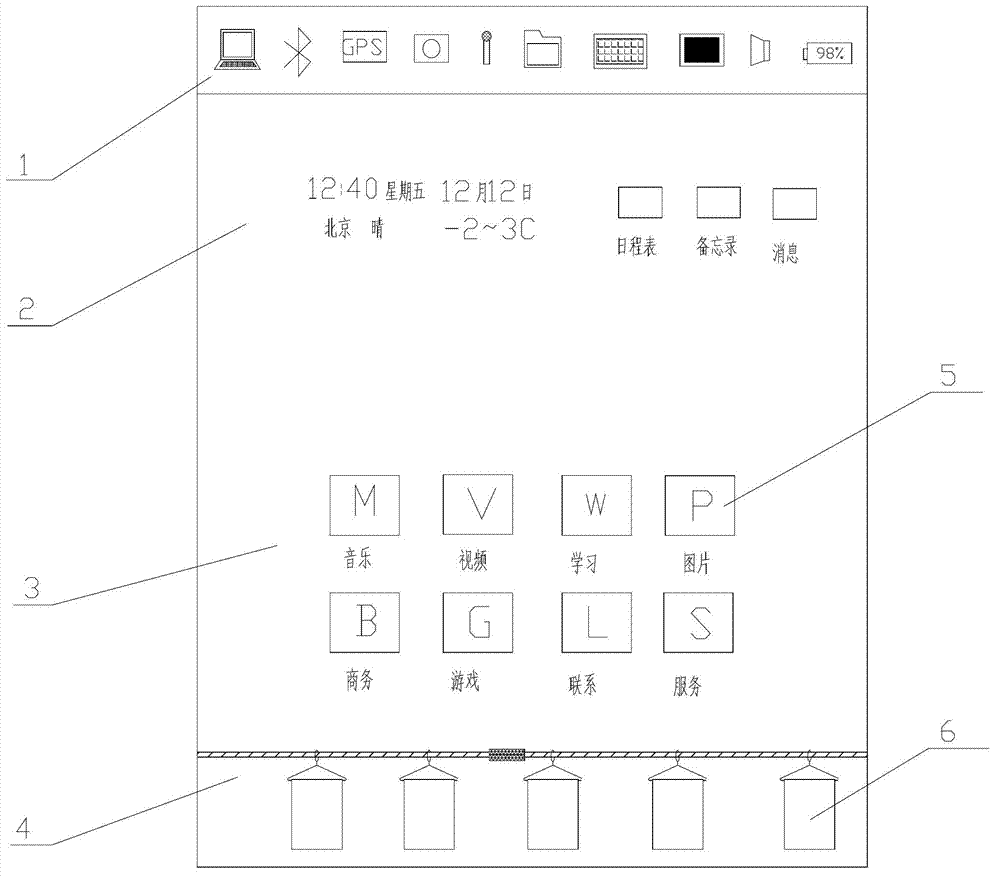

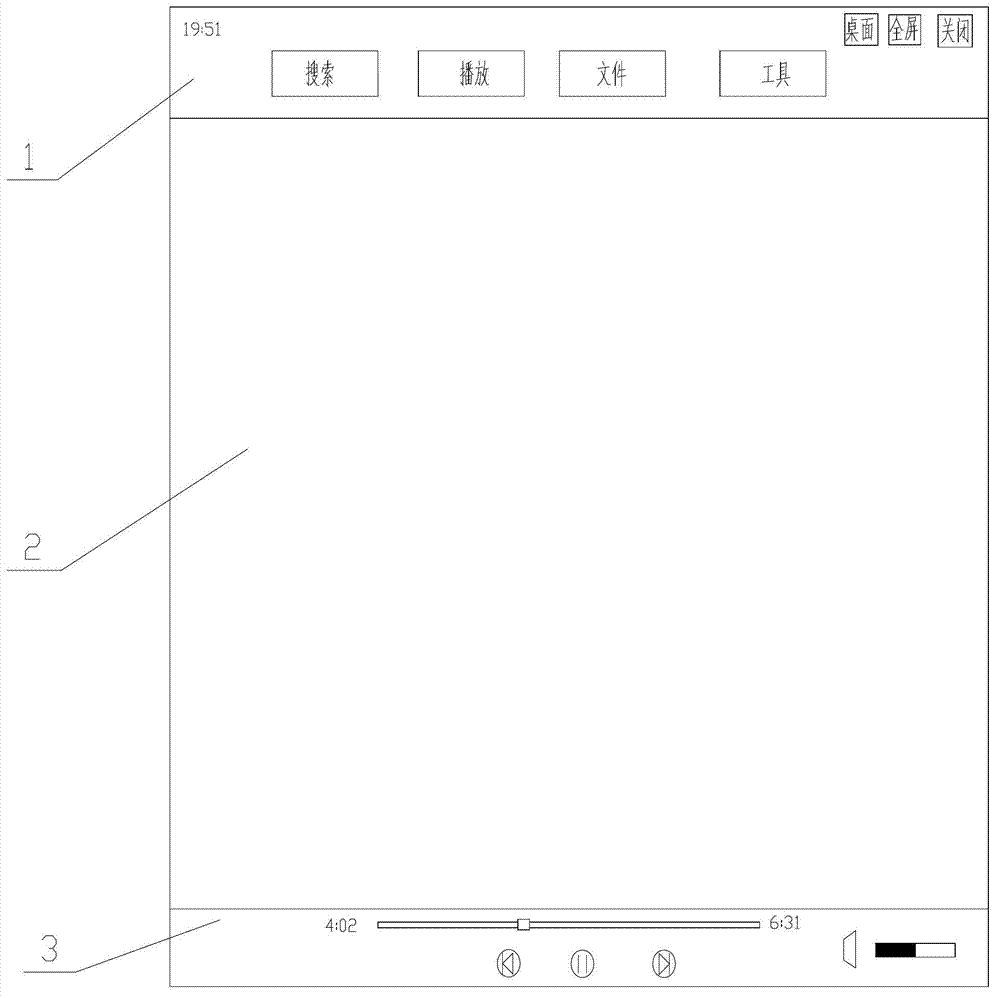

Personal information system based on cloud computing and formed by dependent special terminals

A personal information system based on the cloud computing and formed by dependent special terminals is mainly composed of a client device, a cloud end server and a corresponding connection network. The client device first needs to build connection with the cloud end server through the connection network to serve as a whole, and cannot visit other network serves alone or finish information processing and file storage tasks independently. Effect of the client device is similar to that of a browser in hardware level. The cloud end server finishes file storage and main information processing tasks of the whole system and can accept visit of client devices in different types of users as an information pivot. The whole system can respectively conduct software resource and hardware device expansion at the cloud end and the client. The system aims at resolving the problems of device performance, connection mode, file storage, information safety, manipulation experience, service provider profit, user using cost contradiction and the like in the field of personal information service.

Owner:马青川

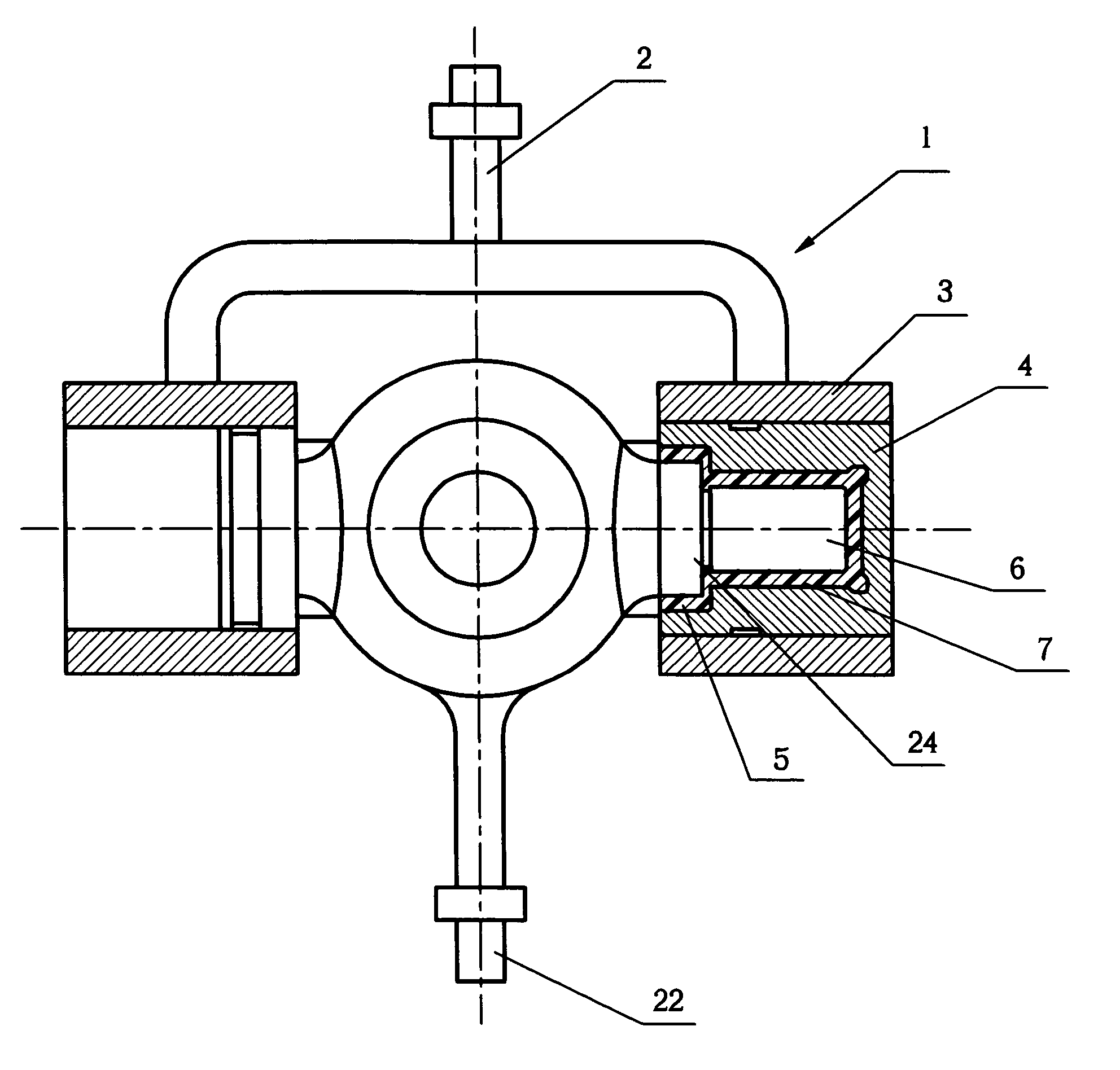

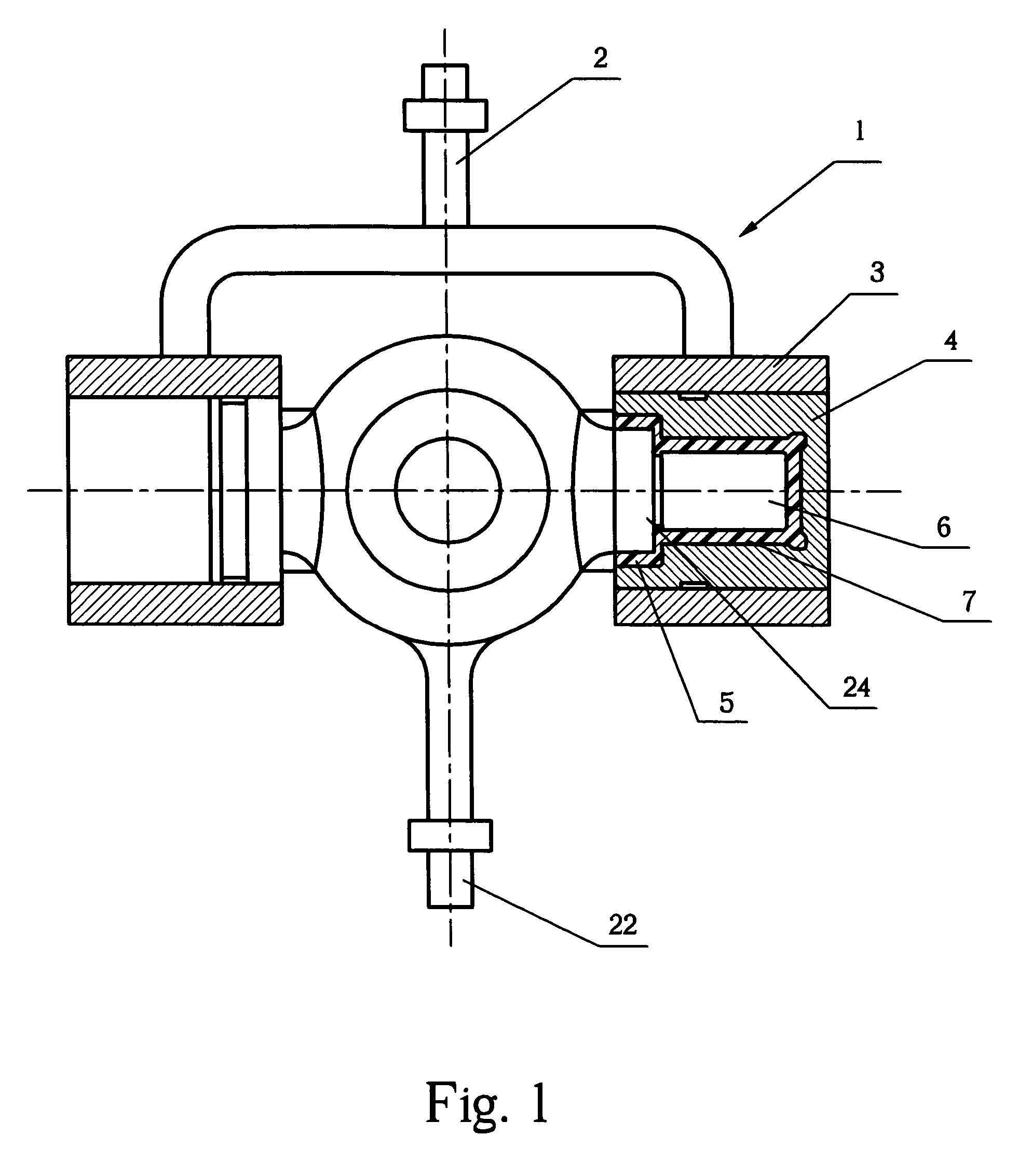

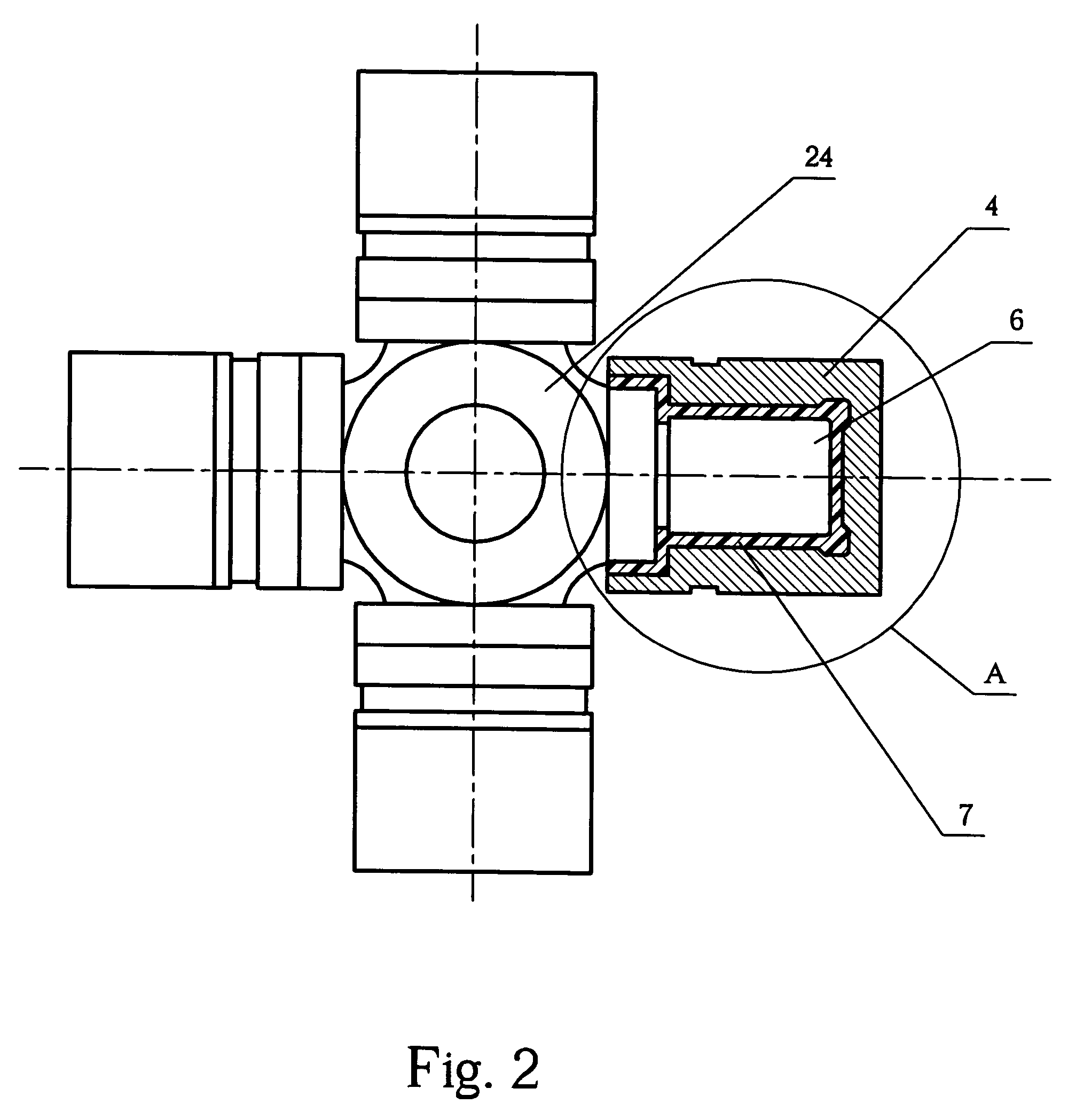

Yoke-trunnion universal joint without needle bearings

InactiveUS20060135269A1Increase production capacitySimple structureClutchesYielding couplingNeedle roller bearingUniversal joint

A yoke-trunnion universal joint has a plastic anti-wear coating disposed between the sleeve and trunnion for lubrication, anti wear and absorbing vibration. A combining means combines the plastic ant-wear coating with sleeve or trunnion tightly. The plastic anti-wear coating is made by nylon or polytetrafluoroethylene. The universal joint has a simple structure, long working life, low operating noise and cheap manufacture cost. The most advantage is that the universal joint needs not oil or grease for whole working life. It is an oil or grease free and maintenance free universal joint.

Owner:WANXIANGQIANCHAO CO LTD

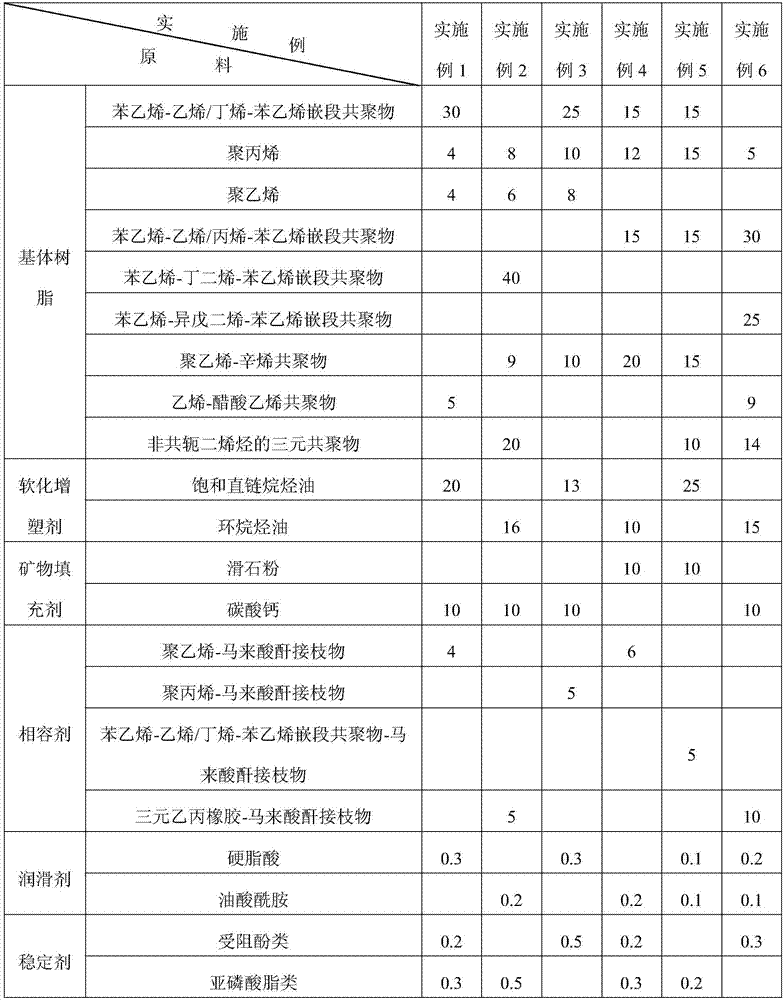

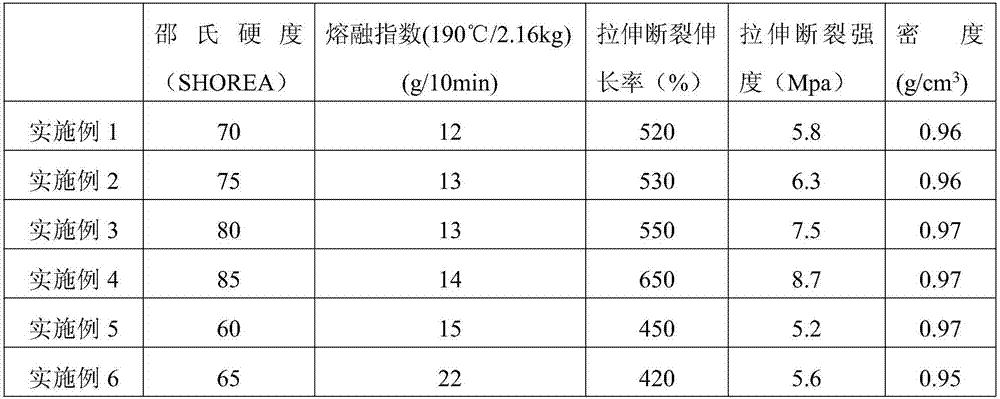

Thermoplastic elastomer, preparation method thereof and wood-plastic floor containing thermoplastic elastomer

The invention discloses a thermoplastic elastomer. The thermoplastic elastomer contains the following components in parts by weight: 40-90 parts of matrix resin, 5-30 parts of a softening plasticizer, 3-15 parts of a mineral filling agent, 3-15 parts of a compatilizer, 0.2-2 parts of a lubricating agent and 0.2-0.5 part of a stabilizer. The invention further discloses a preparation method of the thermoplastic elastomer. The preparation method comprises the following steps: sequentially adding the matrix resin, the softening plasticizer, the mineral filling agent, the compatilizer, the lubricating agent and the stabilizer into a high-speed mixer, and uniformly mixing, so as to obtain a mixture; and putting the mixture into a double-screw extruder, extruding at 170-195 DEG C, and sequentially carrying out bar drawing, water tank cooling and granulation, so as to obtain the thermoplastic elastomer. A wood-plastic floor is prepared from the thermoplastic elastomer disclosed by the invention. The thermoplastic elastomer provided by the invention has the advantages of strong coating cohesive force, soft texture, wear resistance, light specific gravity and the like; and furthermore, the prepared wood-plastic floor coated with the thermoplastic elastomer has the functions of shock absorption, skid prevention and noise reduction.

Owner:东莞市建泓新材料科技有限公司

Method for recovering organic matters in polyester wastewater

ActiveCN103012090AReduce COD valueFix security issuesWater/sewage treatment by heatingPreparation from heterocyclic compoundsPolyesterAfter treatment

The present invention discloses a method for recovering organic matters in polyester wastewater. The method comprises the following steps that: (1) polyester wastewater enters a gas stripping tower to be subjected to a treatment, and organic matter gas and steam collected from the top of the tower directly enter an acetaldehyde rectification tower; (2) after treatment by the acetaldehyde rectification tower, high purity acetaldehyde is obtained from the top of the tower, and is divided into two parts, one part is externally collected, and the other part is reused for the gas stripping tower in the step (1), such that the acetaldehyde reacts with a small amount of ethylene glycol in the wastewater to produce 2-methyl-1,3-dioxolane, concurrently 2-methyl-1,3-dioxolane hydrolysis during the process is reduced, and the wastewater on the bottom of the tower enters an ethylene glycol distillation tower; and (3) after treatment by the ethylene glycol distillation tower, a high purity ethylene glycol solution is collected from the bottom of the tower, and waste gas and steam produced from the top of the tower re-enter the gas stripping tower to be recycled. According to the present invention, continuous acetaldehyde and ethylene glycol collection is adopted, such that gas stripping efficiency is increased so as to further reduce a COD value of the sewage on the bottom of the tower, wherein the sewage is subjected to the gas stripping treatment.

Owner:SHANGHAI JUYOU CHEM ENG +1

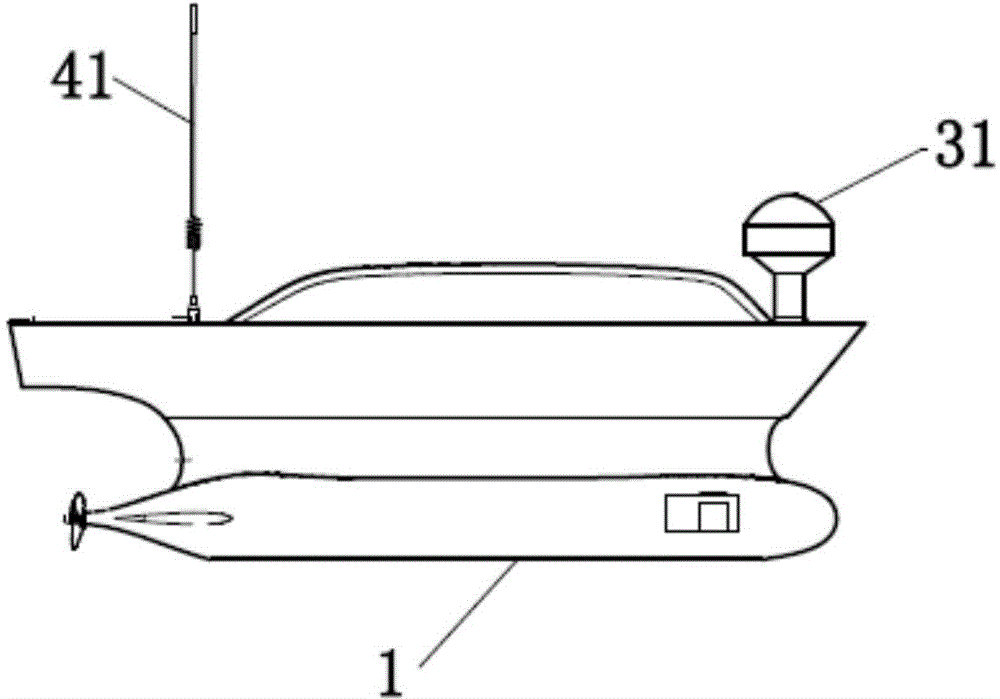

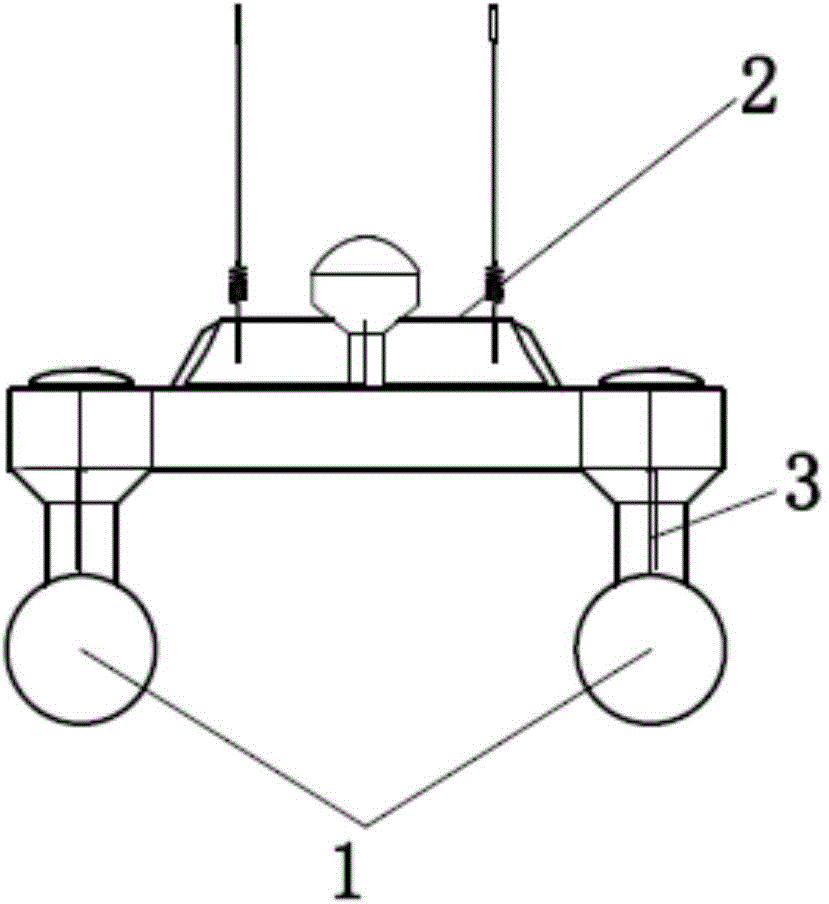

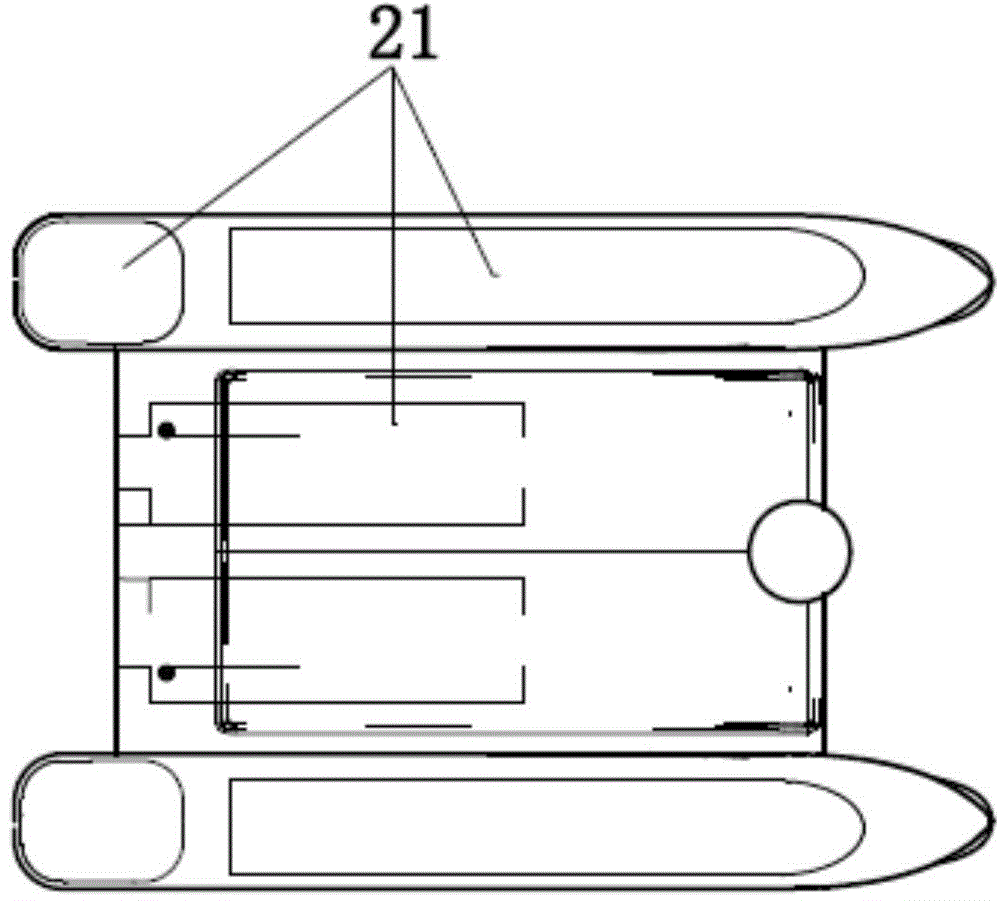

High-performance small-waterline-area twin-body intelligent measurement ship

InactiveCN104816796AReduce swayImprove efficiencyWatercraft hull designVessel safetyMeasurement deviceNew energy

The invention discloses a high-performance small-waterline-area twin-body intelligent measurement ship. A ship body of the ship comprises a submerging body and a case. A power unit and a direction control unit are arranged on the submerging body, a remote control unit and a measuring unit are arranged on the case, and a solar cell panel is arranged on the upper surface of the casing. The submerging body is formed by two parallel and symmetric torpedo submersible diving chambers. Each submersible diving chamber comprises three watertight battery compartments. Storage batteries are arranged in the three battery compartments and are connected through wires. The storage batteries are connected with the solar cell panel, the power unit, the remote control unit and the measuring unit through wires respectively. By means of the measurement ship, new energy is fully used during measurement ship navigation and stored, and accordingly, the endurance of the ship and the intelligent equipment normal operation are guaranteed, and the survey is efficient, energy saving and environmentally friendly.

Owner:ZHEJIANG OCEAN UNIV DONGHAI SCI & TECH COLLEGE

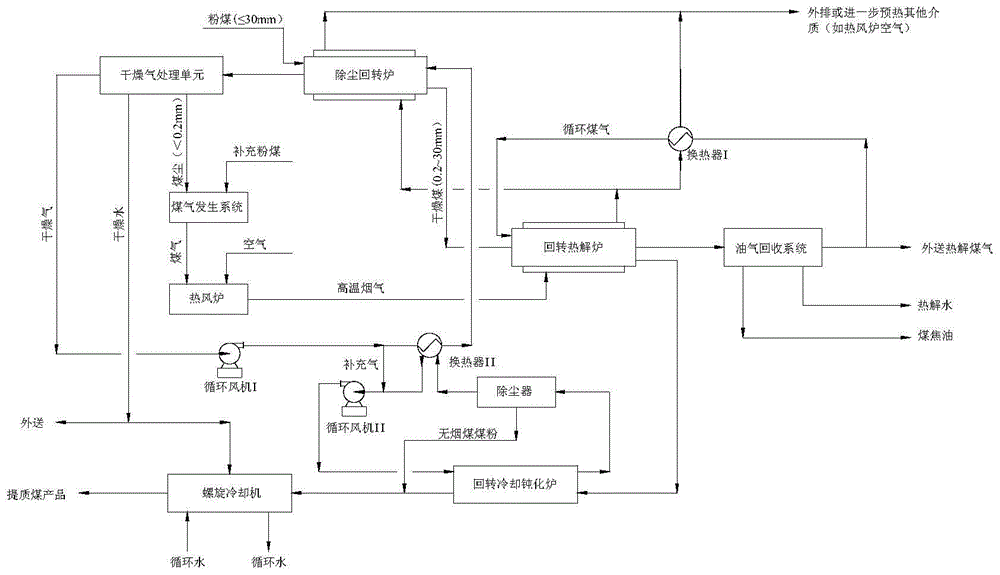

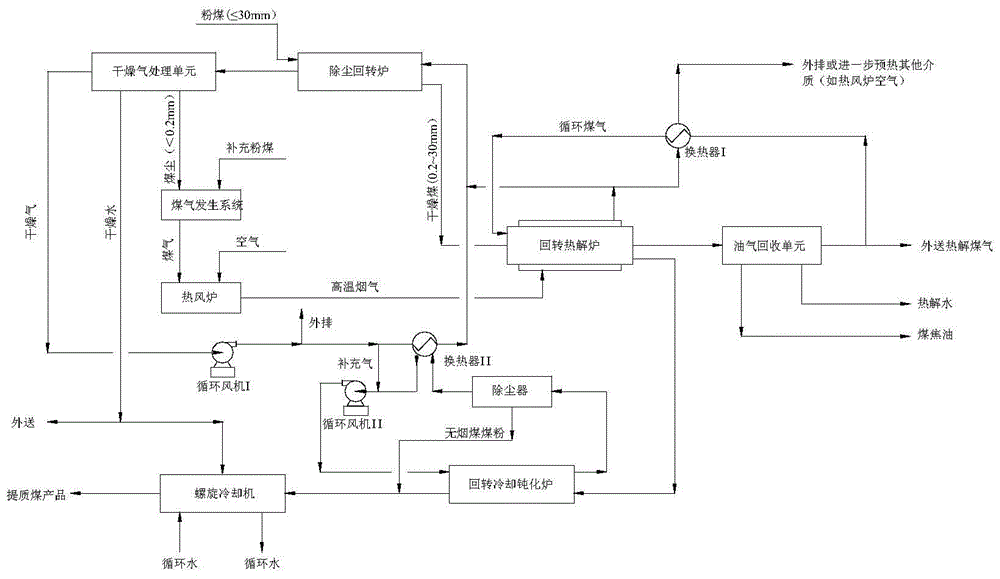

Gas-circulating method for pyrolysis production of anthracite in coal powder rotary furnace

ActiveCN104789244AHigh yieldReduce consumptionIndirect heating destructive distillationSpecial form destructive distillationCoal dustAnthracite

The invention provides a method for pyrolysis production of anthracite in a coal powder rotary furnace. The method relates to a coal powder dust removing rotary drying furnace system, an external-heating rotary furnace pyrolysis system with a coal gas circulation function, a rotary cooling passivation system with a heat recovery function, and an oil gas recovering system, wherein the coal powder dust removing rotary drying furnace system is used for heating coal powder to 110 to 280 DEG C and removing coal dust of which the particle size is smaller than 0.2 mm; drying water is recovered and fed to a downstream spiral cooling machine to be used for anthracite cooling and humidification; the coal dust obtained after separation is fed to a coal gas generating system to generate fuel, namely coal gas; after dust removing, coal is sent to a downstream rotary pyrolysis system for pyrolysis; high-temperature anthracite is generated, and cooled; the cooled anthracite is passivated at a middle-low temperature; the passivated anthracite is cooled in the spiral cooling machine; water is sprayed on the cooled passivated anthracite for humidification; the humidified anthracite is sent out; high-temperature oil gas produced in the process enters the oil gas recovering system to obtain coal tar, pyrolyzed water and coal gas. Part of the produced pyrolyzed coal gas returns to the pyrolysis furnace after preheating in a circulating manner, while the other part of the produced pyrolyzed coal gas is sent out.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

Edible packaging film prepared from carboxymethylated potato residues and preparation method thereof

InactiveCN102153783AHuge economic benefitsSimple production equipmentFlexible coversWrappersCarboxymethyl celluloseEconomic benefits

The invention relates to an edible packaging film prepared from carboxymethylated potato residues and a preparation method thereof, wherein the edible packaging film prepared from carboxymethylated potato residues comprises the following components in parts by weight: 20-40 parts of sodium carboxymethyl cellulose, 1000 parts of water, 6-20 parts of carrageenin, 3-10 parts of sodium alginate, 10-15 parts of glycerol, 10-15 parts of sorbitol, 1-3 parts of stearic acid and 1-3 parts of palmitin; and the edible packaging film prepared from carboxymethylated potato residues is prepared by the following steps of preparing a composite solution from the components and coating to form a film by using a casting method. The edible film prepared from the potato residues as the main raw material has the advantages of simple utilized production facilities, simple and convenient process, low production cost and high added value; in addition, a new way-out of potato residue utilization is found out for corporations, and remarkable economic benefits are also brought to the corporations at the same time.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Feed containing mixture of N-carbamylglutamic acid and sodium salt thereof for boars, preparation and application thereof

ActiveCN102106473APromote endogenous synthesisEasy to synthesizeAnimal feeding stuffAccessory food factorsCarbamylglutamic acidArginine

The invention relates to a feed containing N-carbamylglutamic acid and N-carbamylglutamic acid sodium salt for boars, preparation and application thereof. The feed is characterized by being prepared from the following components in percentage by weight: 0.10 to 0.25 percent of mixture of the N-carbamylglutamic acid and the N-carbamylglutamic acid sodium salt and auxiliary materials. The feed can promote the synthesis of source arginine in the bodies of boars, enhance the synthesis of carbon monoxide (NO) and polyamine, ensure that the boars exert the genetic potential more effectively, improve the utilization age limit and the health level of the boars and improve the economic benefit of raising the boars.

Owner:林州亚太兴牧科技有限公司

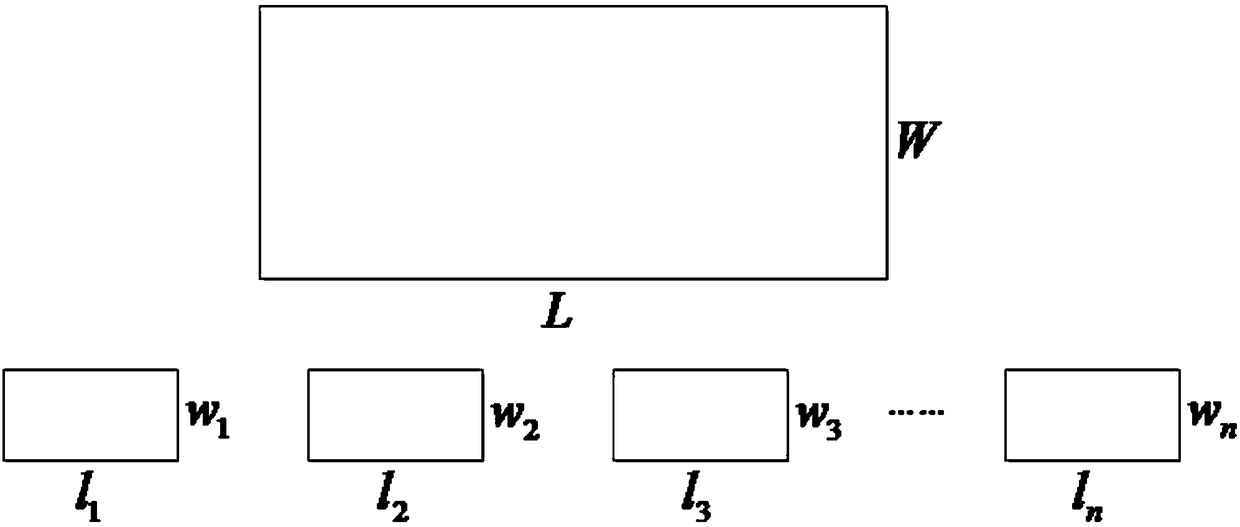

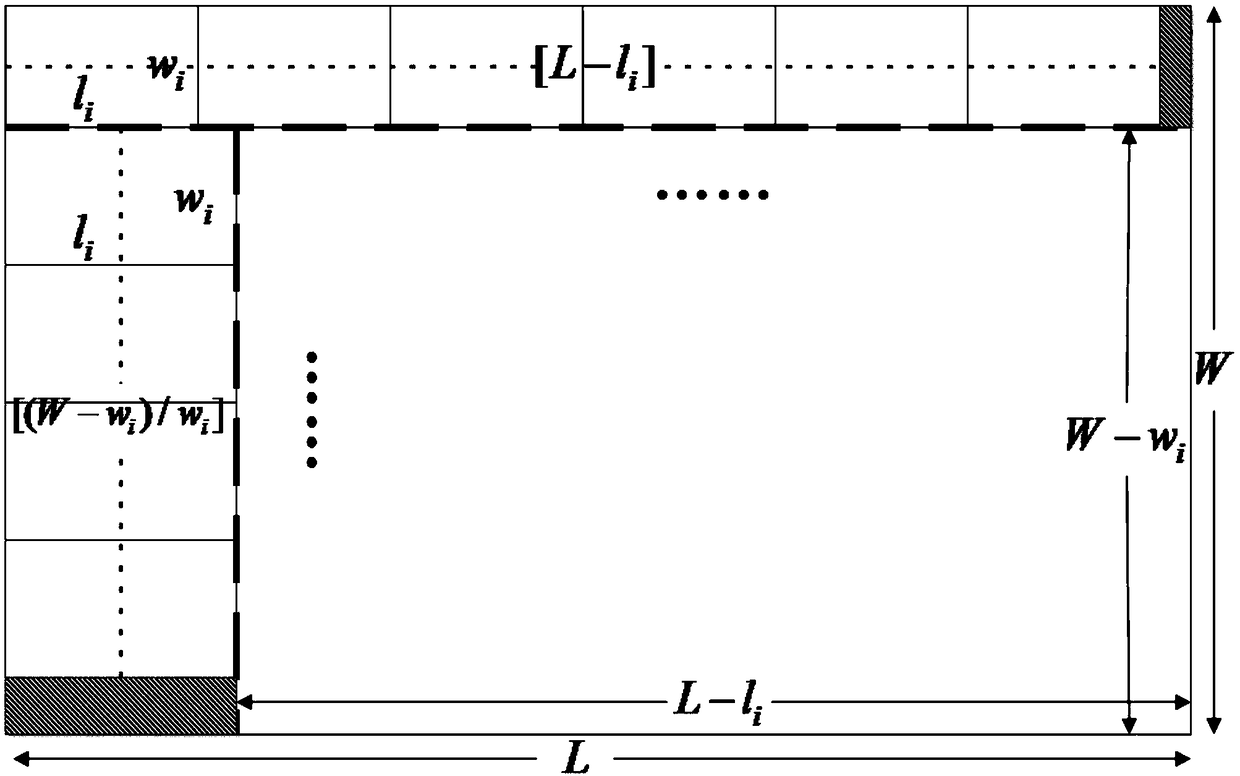

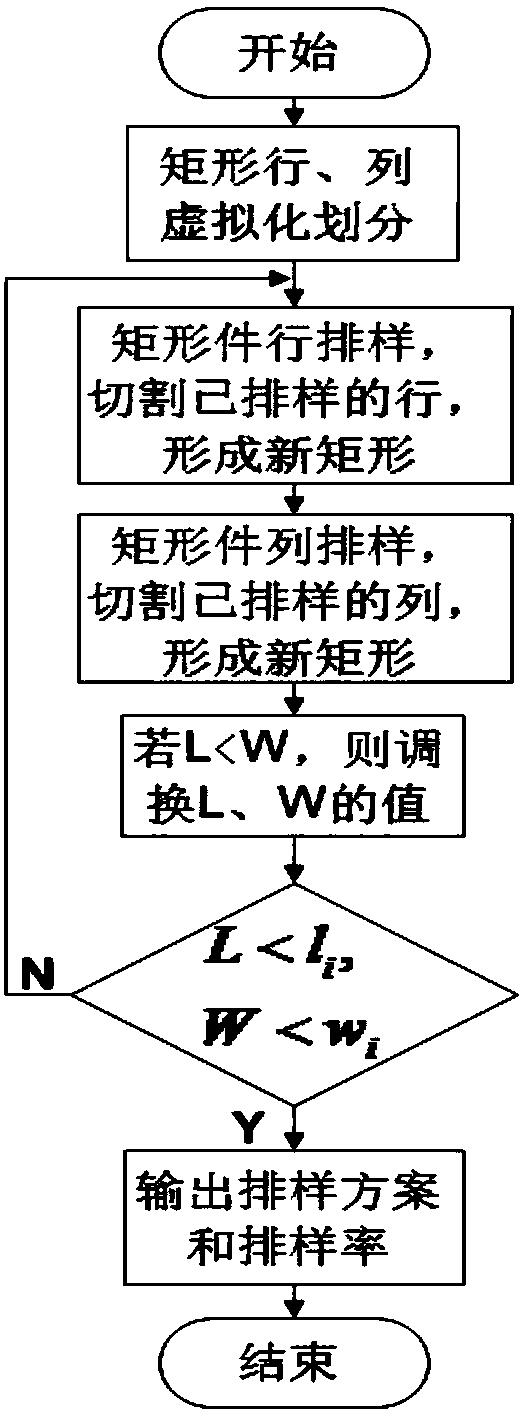

Cutting type filling method for optimal layout of rectangular parts

The invention discloses a cutting type filling method for optimal layout of rectangular parts. The method comprises the following steps of: 1, establishing a mathematical planning model: aiming at a layout problem of two-dimensional rectangular parts, firstly formalizing the two-dimensional rectangular part into a simple rectangular area and rectangular parts, establishing the mathematical planning model, setting the rectangular area to have a length of L and a width of L, and filling n rectangular parts respectively having lengths of l1, l2, ...ln and widths of w1, w2, ...wn into the rectangular area. Compared with existing layout algorithms, the method combines the characteristics that the algorithm is simple to realize and the layout efficiency is high, and can be widely applied to rawmaterial layout of rectangular parts in rolled steel blanking, newspaper and periodical typesetting and tailoring so as to provide theoretical guidance for realization of producing activities; and under the current fierce market economic competition pursuing resource utilization rate and production scale, the novel layout algorithm is simple and efficient, and is capable of bringing a novel thinking method and huge economic benefit for the field of two-dimensional raw material layout.

Owner:GUANGDONG UNIV OF TECH

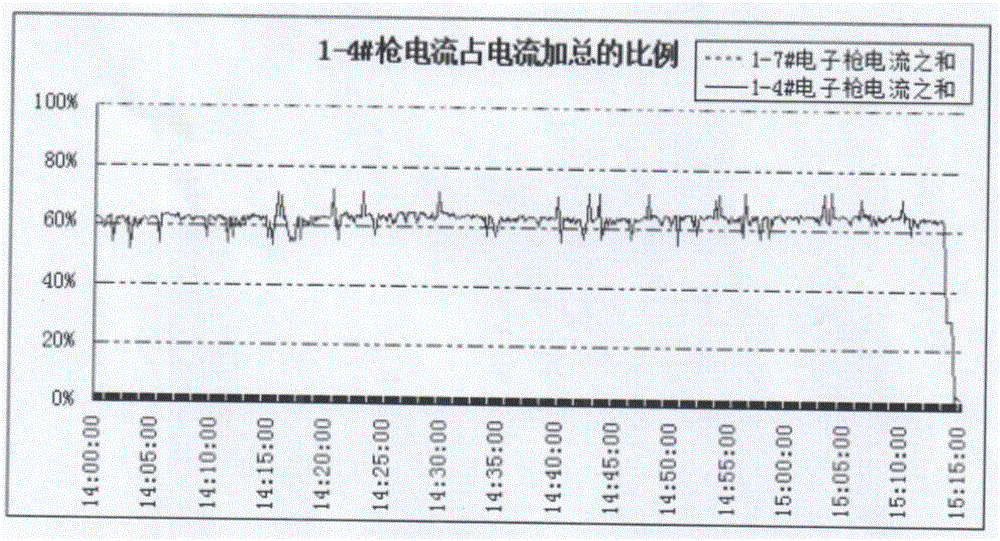

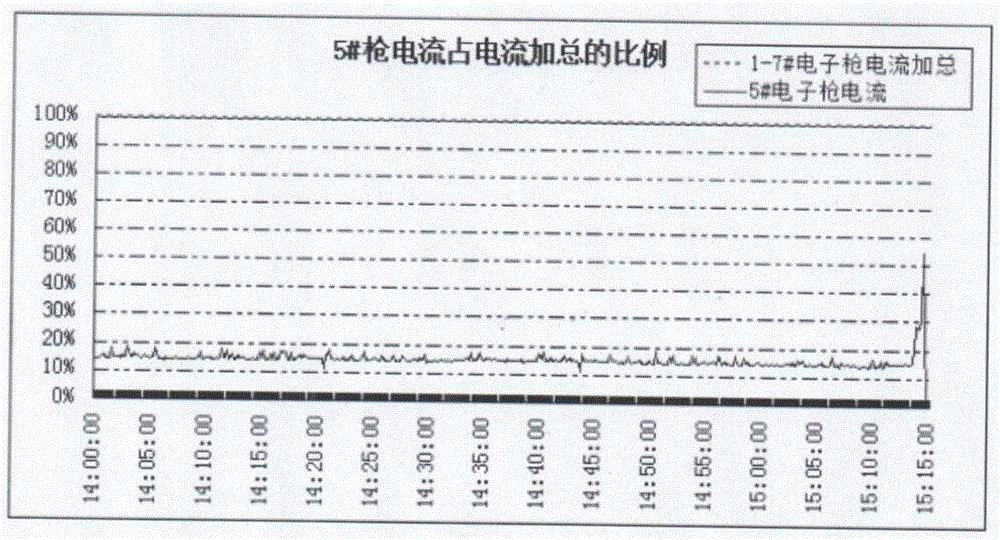

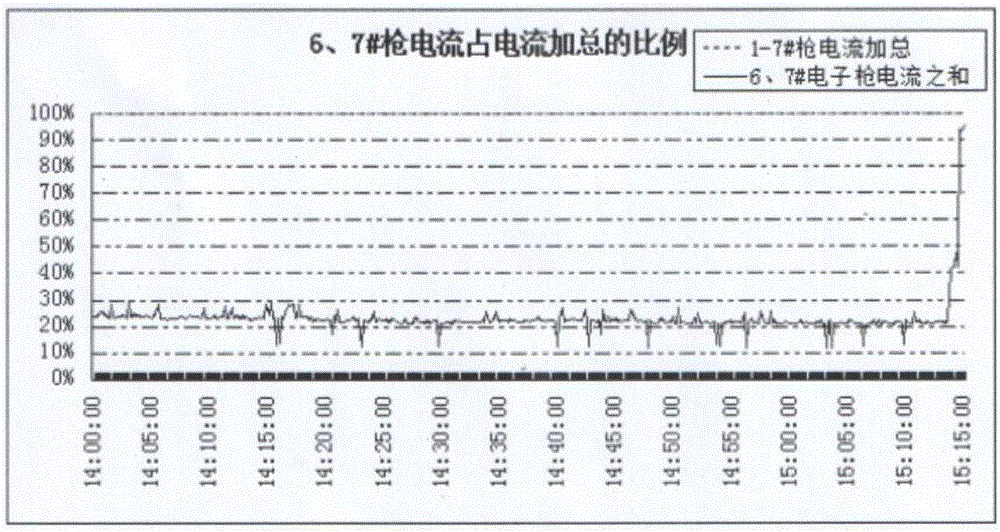

Electron beam cold hearth single melted TC4 titanium alloy cast ingot head feeding process

The invention discloses a single-time smelting TC4 titanium alloy ingot head feeding process on an electron beam cooling bed, which belongs to the technical field of titanium alloy ingot feeding technology and comprises the following steps: determining the ingot head to be fed; Once the metal liquid flows into the crystallizer, keep the current of 6-7# at 5.5A for 5 minutes; the current of 6-7# decreases from 5.0A to 0.5A in steps of 0.5A, and lasts for 5 minutes for each step down; Start with a current of 3.0A, narrow the scanning range of 6-7#; enlarge 6-7# to the edge until the molten pool disappears, and complete the feeding; after the feeding is completed, cool down. The invention has the advantages of simple process, convenient operation and good use effect, can effectively solve the defects in the head of the ingot, greatly improves the primary yield of the ingot, and can obtain obvious economic benefits.

Owner:QINGHAI JUNENG TITANIUM IND CO LTD

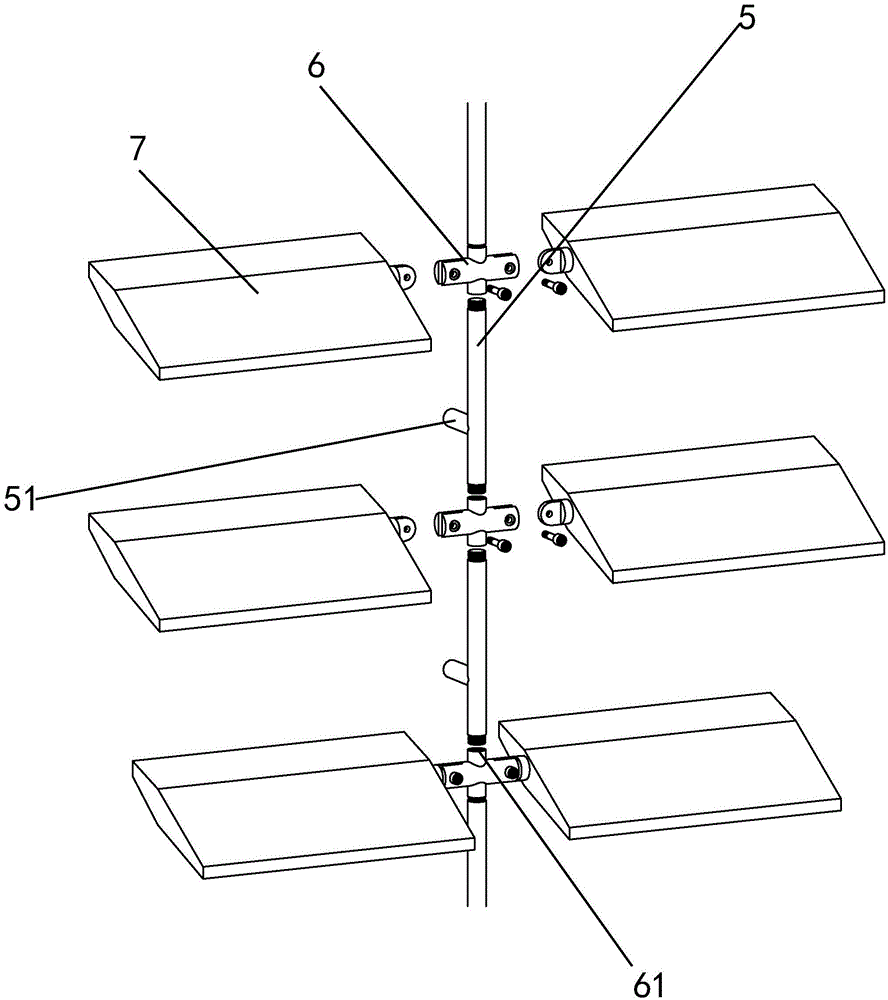

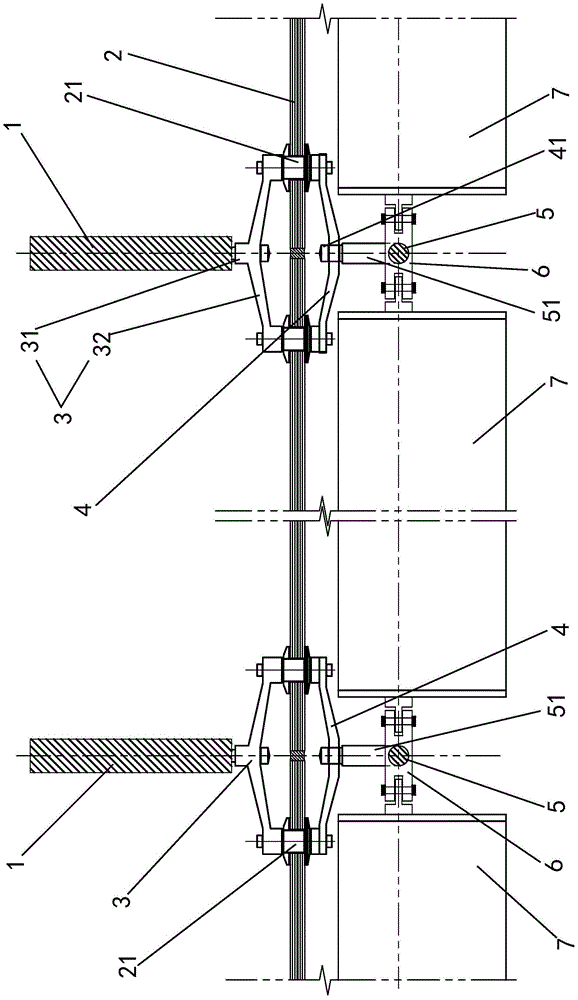

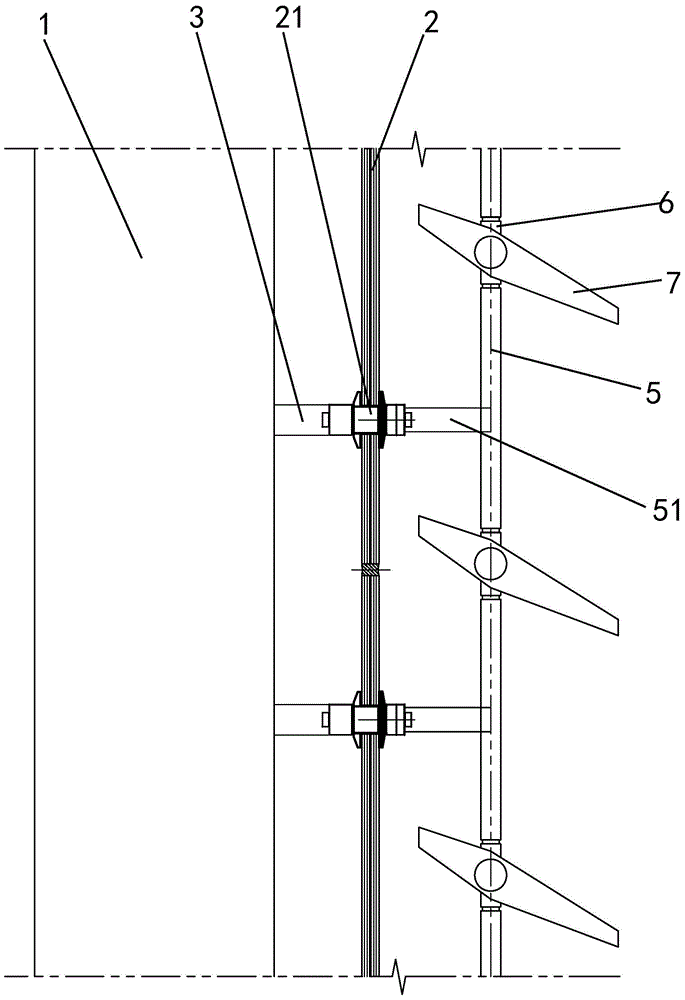

Outer sunshade device of point-supported-type glass curtain wall and installation method thereof

The invention relates to an outer sunshade device of a point-supported-type glass curtain wall and an installation method thereof. The outer sunshade device of the point-supported-type glass curtain wall comprises indoor supporting structures and glass panels, wherein sleeves are arranged at junctions of adjacent glass panels in a penetrating manner, and the indoor ends of the sleeves are fixedly connected with the corresponding indoor supporting structures through connecting pieces; the outdoor ends of adjacent sleeves are respectively and fixedly connected with the two ends of outdoor connecting pieces; the outer sides of the middle portions of the outdoor connecting pieces are provided with a plurality of pull rods which are vertically connected in tandem, the upper and lower ends of the pull rods are provided with external threads, and the side surfaces of the pull rods are provided with threaded sleeves perpendicularly connected with the pull rods; the tail ends of the threaded sleeves are fixedly connected with the middle portions of the outdoor connecting pieces through connecting bolts; adjacent pull rods are connected through adapting pieces, and the upper and lower ends of the adapting pieces are provided with threaded holes corresponding to the tail ends of the pull rods; louvers are fixedly arranged between adjacent adapting pieces. The outer sunshade device of the point-supported-type glass curtain wall has the advantages that the structure is stable and reliable, the sunshade effect is good, the energy-saving and environmental-friendly effect can be achieved, the installation and adjustment are facilitated, the construction period is shortened and good economic benefits are obtained.

Owner:GUANGZHOU JANGHO CURTAIN WALL SYST ENG

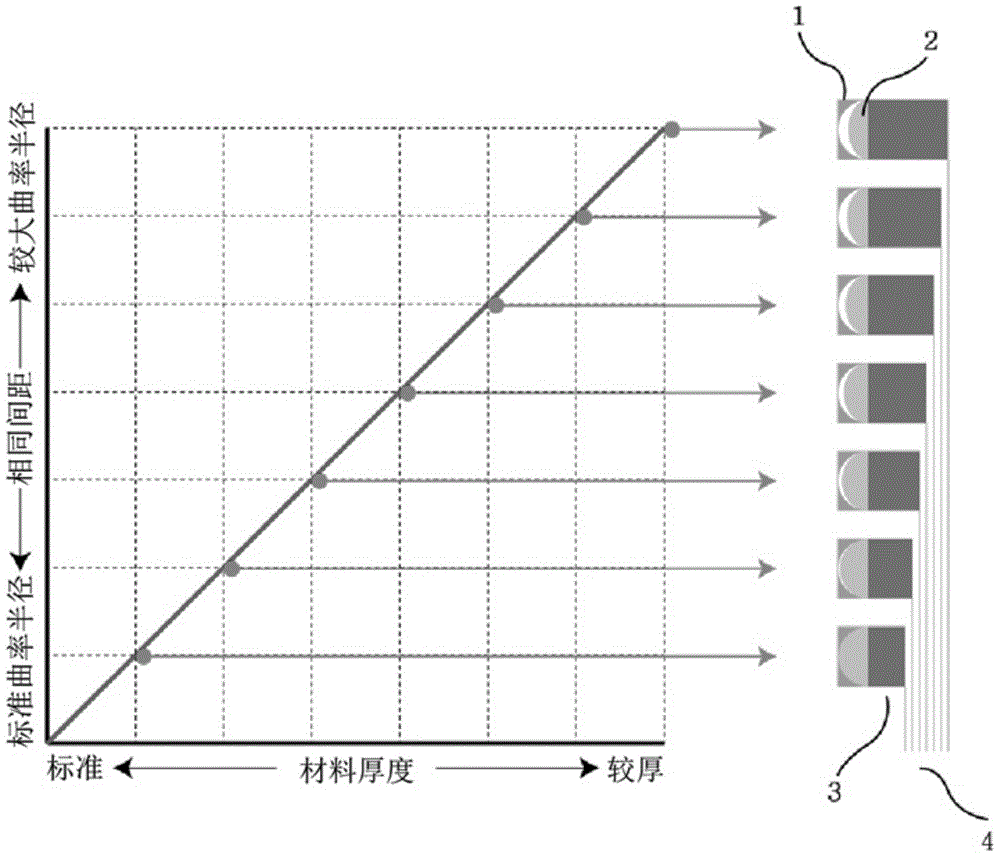

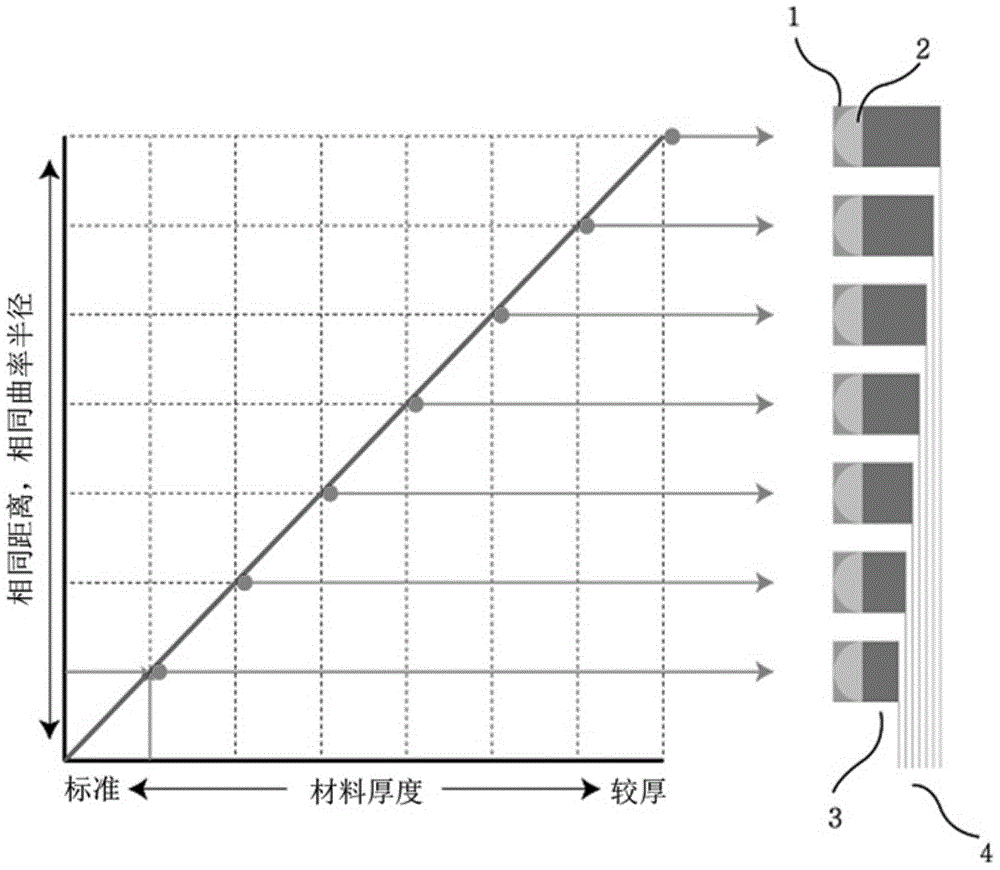

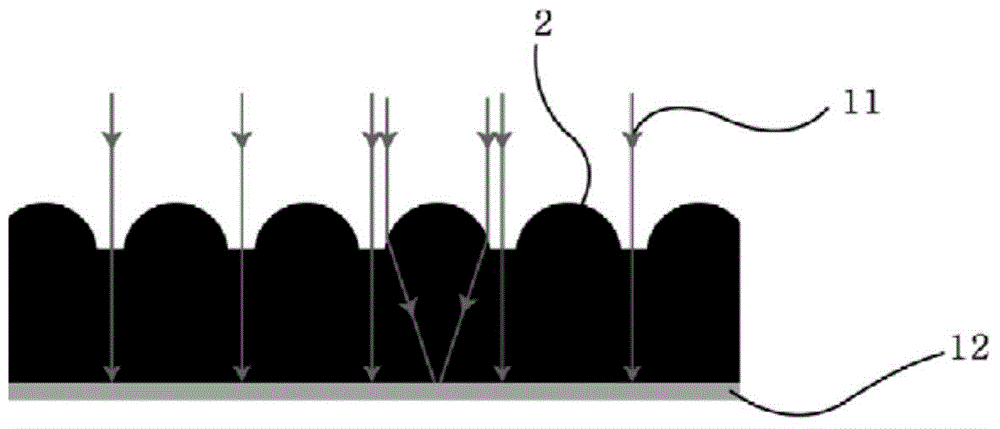

Stereoscopic lens manufacturing method

The invention discloses a stereoscopic lens manufacturing method, in which a stereoscopic lens material with adjustable curvature radius and focal distance under the condition of a fixed spacing is produced through combination of a mould head and a pair of moulds. The stereoscopic lens manufacturing method comprises a device preparing step and a stereoscopic lens material producing step, wherein the device preparing step comprises the following substeps: preparing the mould head for extruding molten plastic, manufacturing aspheric stereoscopic lens moulds for extruding and moulding a lens, and manufacturing a polishing roller for polishing the other surface of the lens material; the stereoscopic lens material producing step comprises the following substeps: adjusting the fitting degree of the moulds and the molten plastic, adjusting the extruding amount, the depositing amount and the producing speed of the mould head, extruding one surface of the plastic by using the aspheric stereoscopic lens moulds so as to form the front surface of the stereoscopic lens material, and polishing the other surface of the plastic by using the polishing roller so as to form the back surface of the stereoscopic lens material, by the stereoscopic lens manufacturing method, the stereoscopic lens material which has the same lens spacing, but has different curvature radiuses and corresponding focal distances.

Owner:SHANGHAI CAICHENG NEW MATERIAL TECH CO LTD

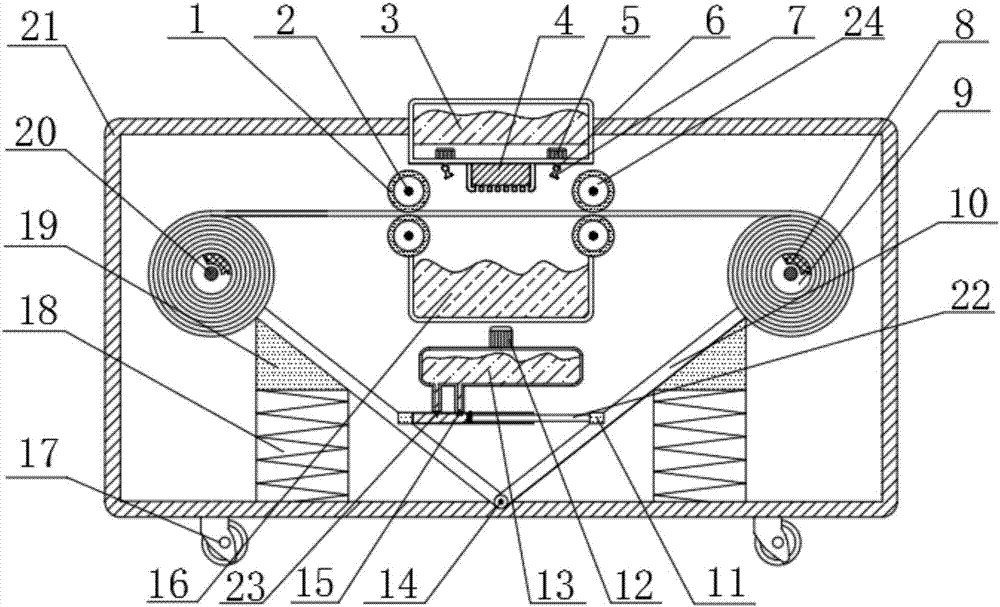

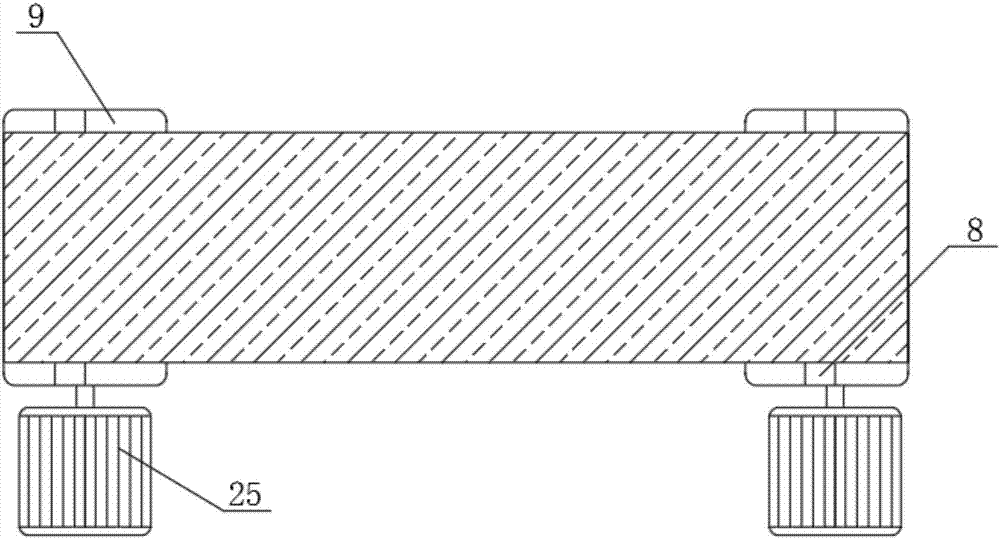

Novel textile fabric ironing device

InactiveCN106894189AIncrease the effect of straightening clothAvoid damageTextile shapingRotational axisWater storage tank

The invention discloses a novel textile fabric ironing device which comprises an electric heating wire, a first rotating shaft, a water storage tank, a steam spray nozzle, a water spray machine, a universal hinge, a water spray nozzle, a clamping block, a roller, a connecting rod, a rubber support rib, a hydraulic pump, a hydraulic box, a hinge, a hydraulic cylinder, a waste water tank, a roller wheel, a spring, a cushion rubber, a second rotating shaft, a housing, a piston rod, a check valve, a pressing wheel and a motor. The novel textile fabric ironing device provided by the invention is simple in structure, novel in design, easy to be realized, and the hydraulic device is added to play a role of straightening fabric during ironing, so as to improve the ironing quality; the water storage tank and water spray devices are also added to avoid damaging the fabric due to excessive temperature during ironing; the motor is added to solve a problem of low efficiency of manual ironing and improve the operating efficiency; the roller wheel are added to facilitate movement and transportation; the novel textile fabric ironing device has great economic benefits and wide market prospect, and is worth to be popularized and applied.

Owner:扬州市嘉鑫织造实业有限公司

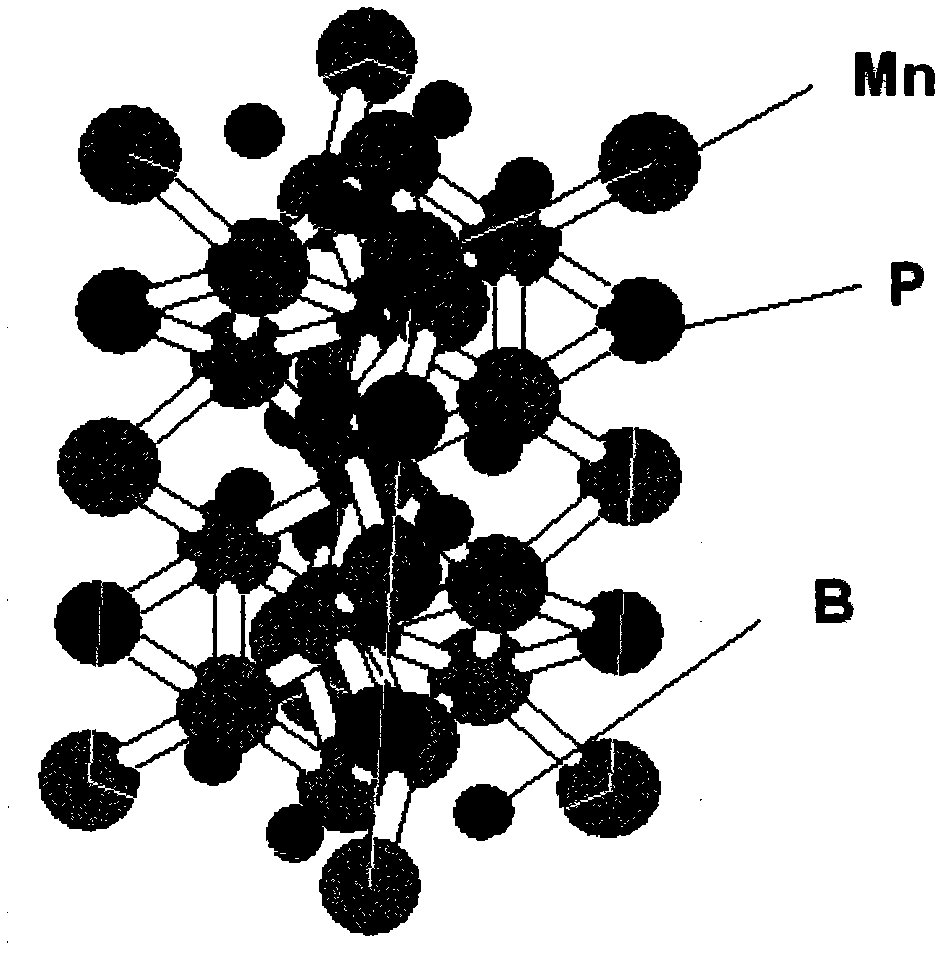

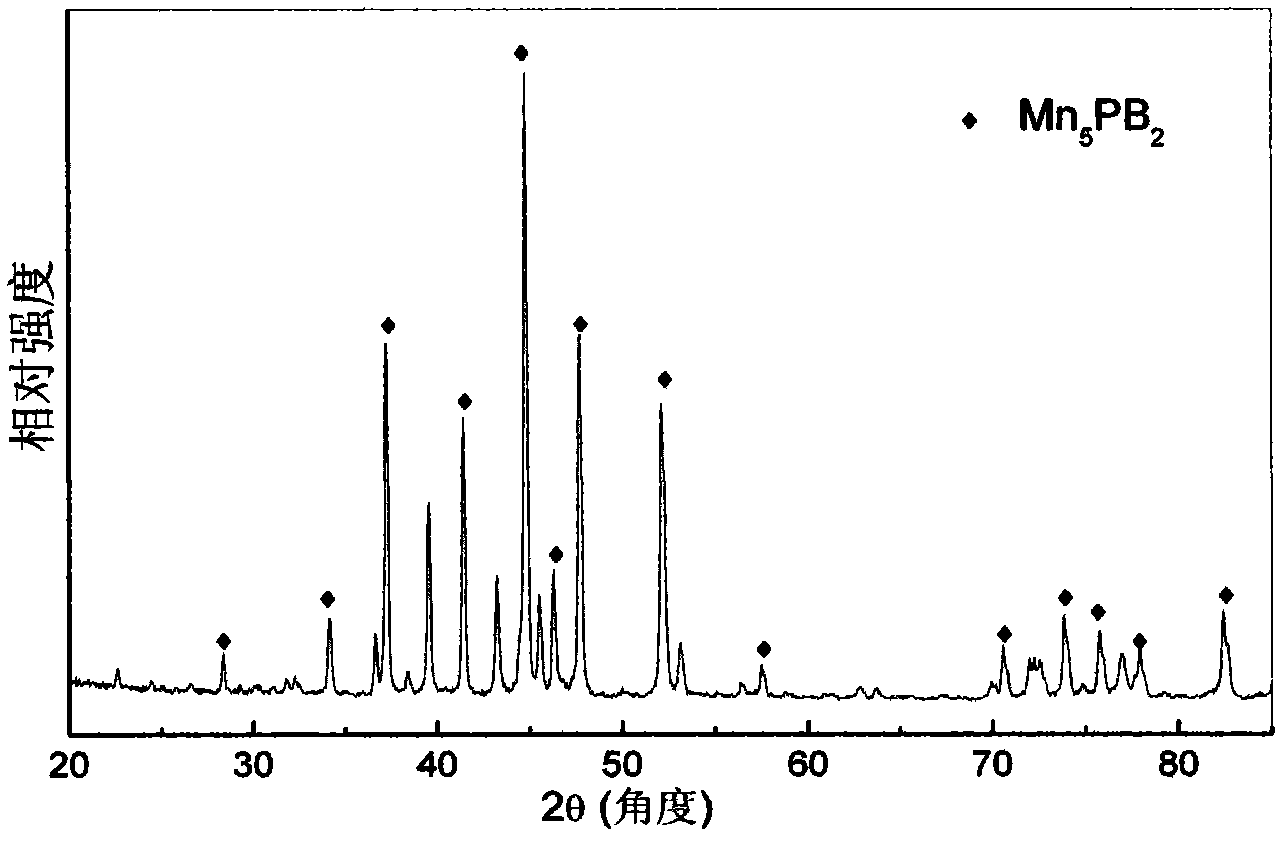

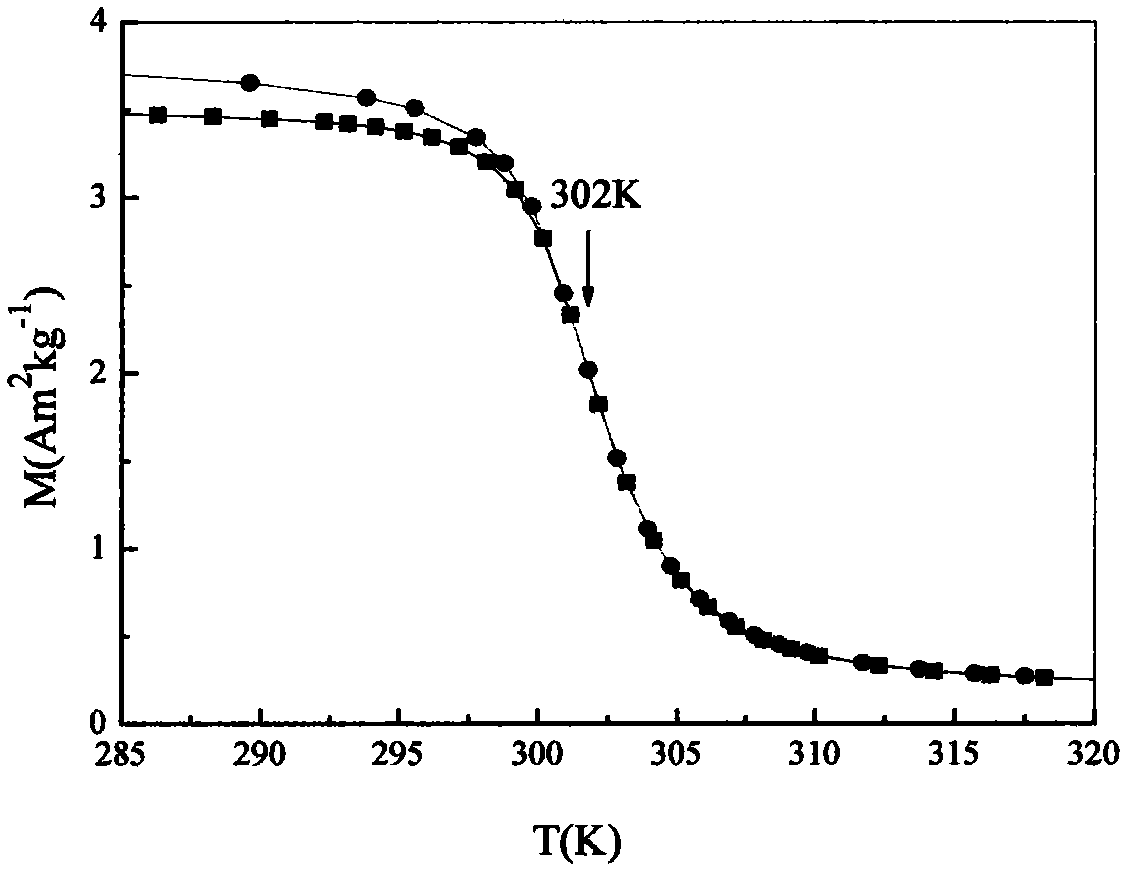

Room temperature magnetic cooling material

The invention provides a room temperature magnetic cooling material, which is characterized by containing Mn, P and B elements simultaneously, with Mn5PB2 as the main phase, a space group of I4 / mcm and a quadrangle structure. Specifically, the main phase Mn5PB2 accounts for 60-100 wt% of the magnetic cooling material. The material of the invention has the advantages of small thermal hysteresis, small magnetic hysteresis, no rare earth, and proper Curie point. In a 3000 Oe magnetic field, the magnetic intensity of Mn5PB2 can be 80% of a saturation value, so that Mn5PB2 can be applied in a 3000 Oe magnetic field established by a relatively low permanent magnet NdFeB, thus making the volume of a magnetic cooling machine small.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

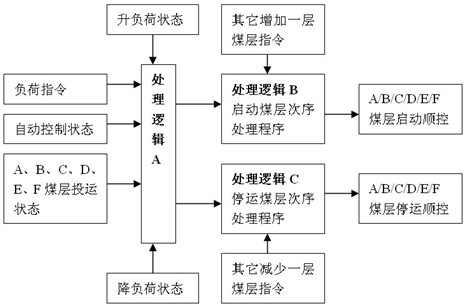

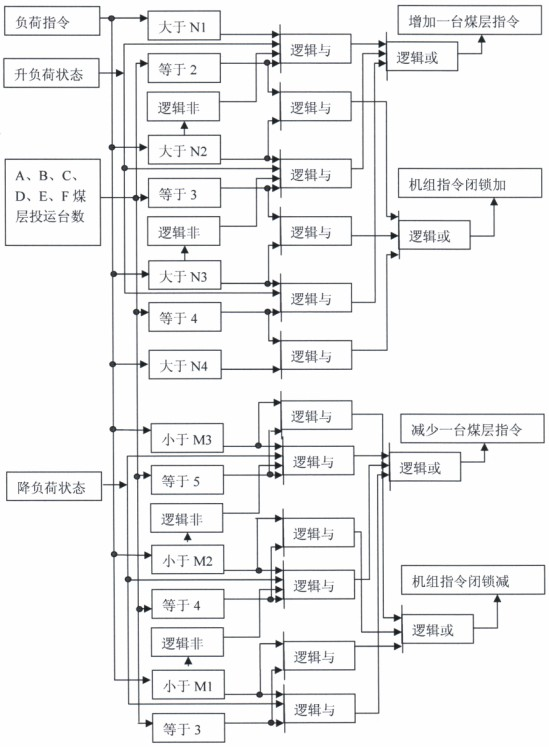

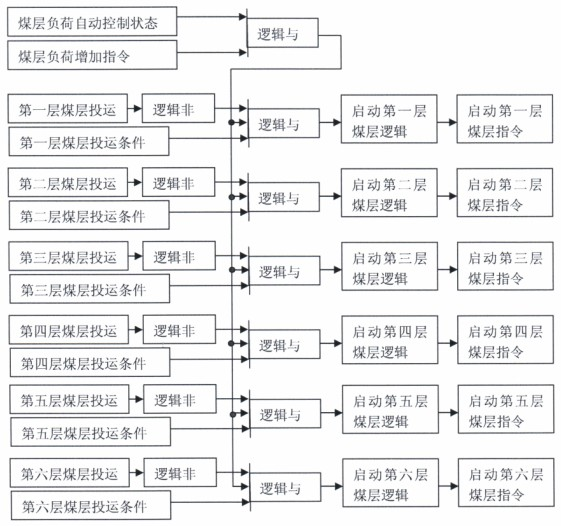

Automatic control system of coal bed loads of thermal power generating unit

ActiveCN102323798AImprove automation control levelAccelerateTotal factory controlProgramme total factory controlAutomatic controlAutomatic train control

The invention provides an automatic control system of coal bed loads of a thermal power generating unit. The automatic control system comprises six layers of coal beds, a processing module, a coal bed commissioning sequence module and a coal bed decommissioning sequence module and is characterized in that: in a loading-up process, the processing module is used for commissioning the coal beds in sequence according to five load sections; and in a loading-down process, the processing module is used for decommissioning the coal beds in sequence through three load sections. According to the automatic control system, the automation control level of coordination control can be greatly increased, the loading-up speed and the loading-down speed are accelerated, human misoperation is reduced, the safety is improved, and a foundation is laid for unit-level automatic control.

Owner:SHANGHAI POWER EQUIP RES INST

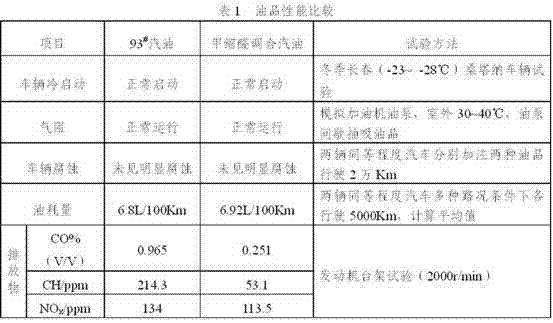

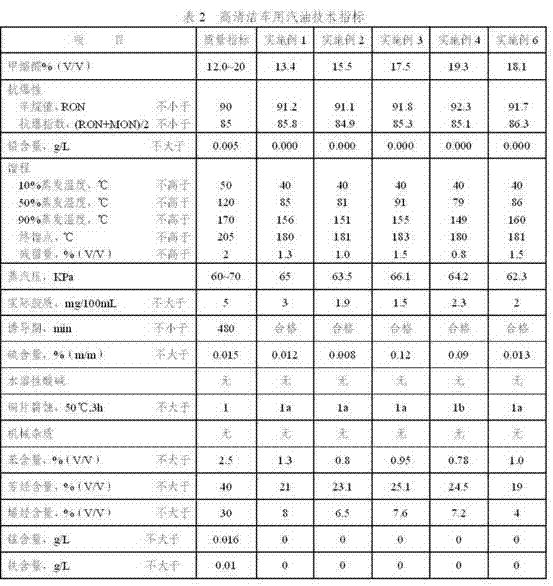

Gasoline for high cleaning vehicle

ActiveCN102226116AEfficient emissionsIncrease energy densityLiquid carbonaceous fuelsNaphthaGasoline

The invention relates to a gasoline for a high cleaning vehicle, which is prepared from the following raw materials in percentage by volume: 15-20% of methylal, 40-50% of naphtha, 12-18% of aromatic oil, 1-5% of methyl tert-butyl ether, 12-18% of solvent oil or gasoline and 0.5-1% of additive. The saturated vapor pressure of the gasoline for a high cleaning vehicle meets the requirement in Chinese Standard; and the gasoline for a high cleaning vehicle has a small corrosion action on rubber parts, can not easily stratify when meeting water, and solves the technical problems existing in the low-proportion methanol gasoline at present, so that the oil product is suitable for blending, storage and transportation, and also suitable for the consumption of the vehicle in a better way.

Owner:CRPC INNOVATION ENERGY

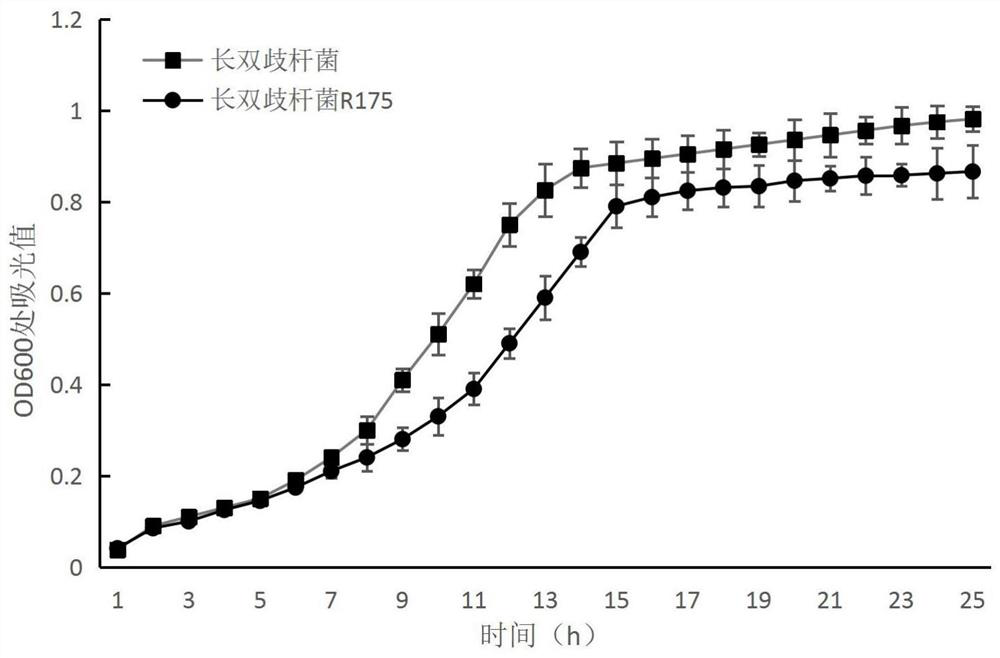

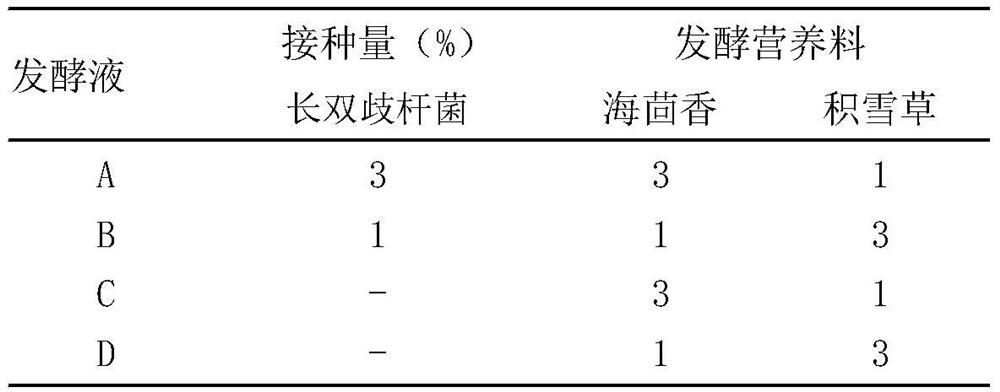

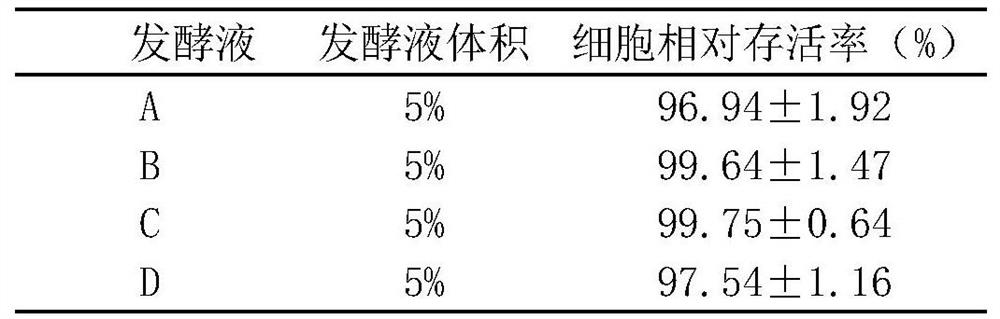

Bifidobacterium longum as well as application and product thereof

ActiveCN113073070AIncrease growth densityFast growth rateCosmetic preparationsBacteriaBiotechnologyBifidobacterium

The invention discloses a bifidobacterium longum as well as application and a product thereof. The bifidobacterium longum is classified and named as Bifidobacterium longum 5b5d1 and is preserved in the China Center for Type Culture Collection (CCTCC) on April 16, 2021, and the preservation number of the bifidobacterium longum is CCTCC M 2021390. The bifidobacterium longum 5b5d1 with high growth rate and high growth density is obtained through open high-throughput strain screening, the fermentation time can be shortened, the production cycle can be shortened, meanwhile, the yield of a fermentation product can be increased, and the economic benefit is huge. The fermentation product is proved to have an epithelial tissue repairing effect, and can be applied to preparation of medicines, foods and cosmetics including skin repairing preparations.

Owner:君维安(武汉)生命科技有限公司

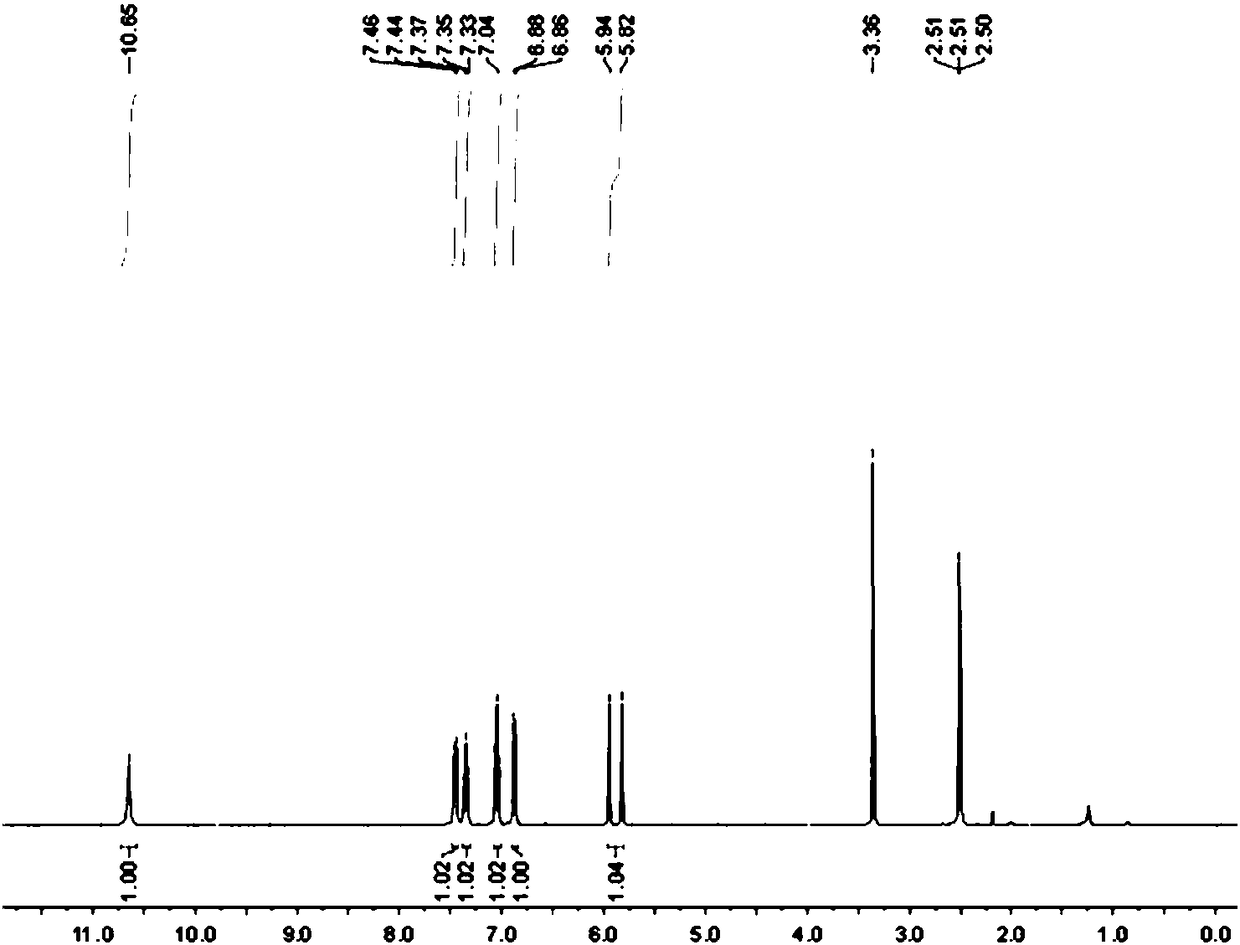

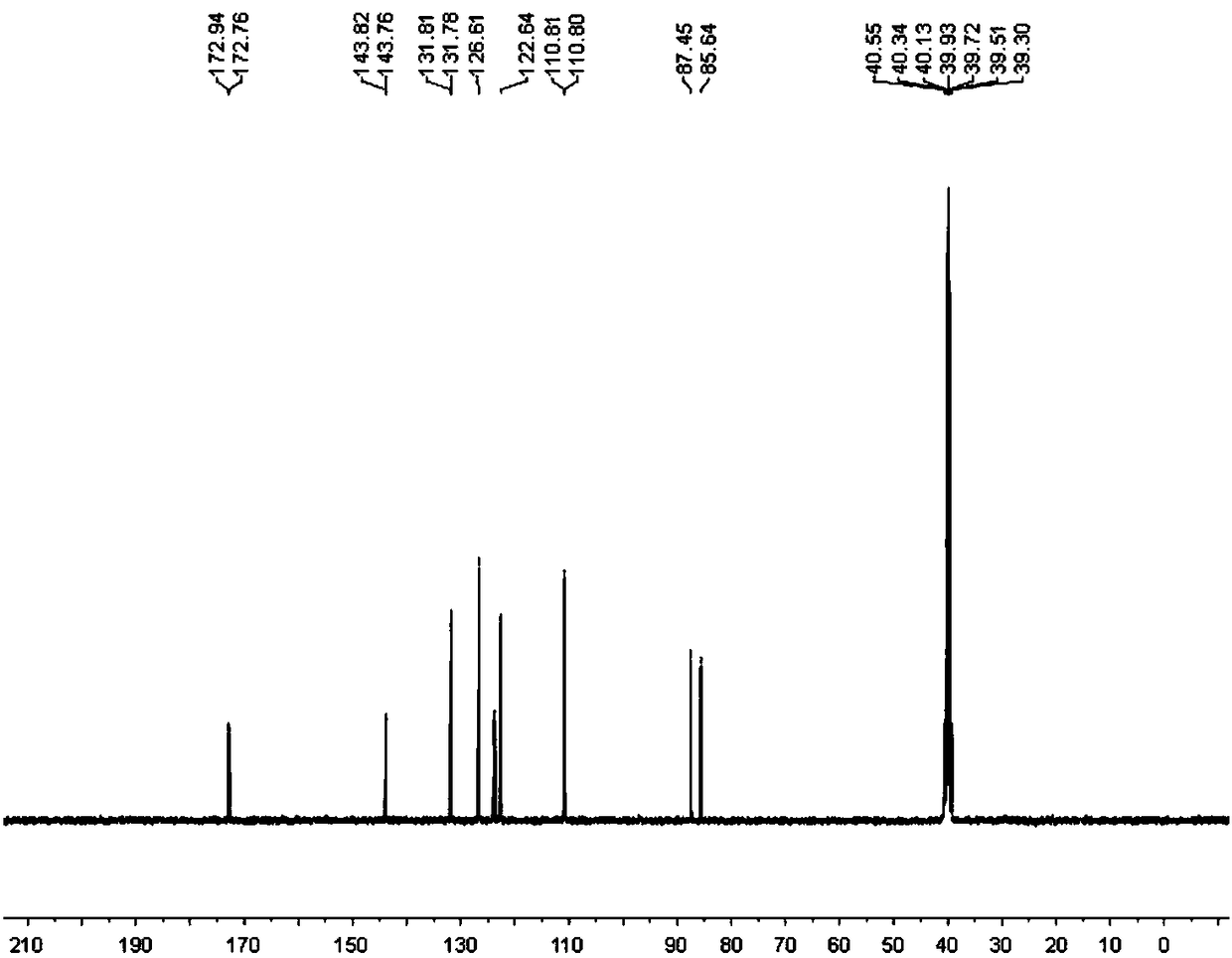

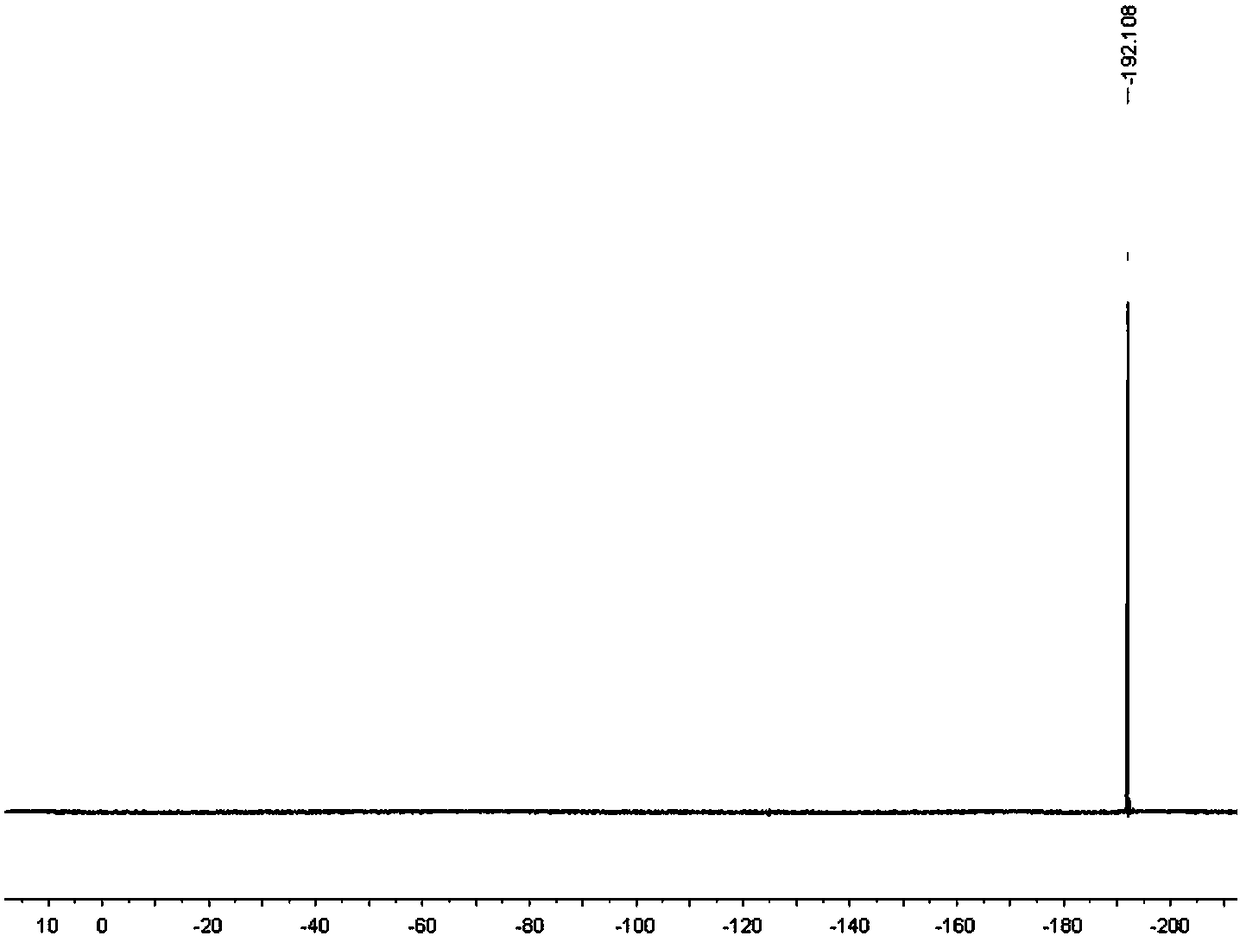

Selective fluorination method for isatin hydrazones compounds

InactiveCN108299137AMild process conditionsShort processOrganic halogenationHydrazoneTetrafluoroborate

The invention discloses a selective fluorination method for an isatin hydrazones compound. The method comprises the steps that one pot reaction is carried out on isatin hydrazone, 1-chloromethyl-4-fluorine-1,4-diazabicyclo [2.2.2] octane bis (tetrafluoroborate) salt and alkali compounds, corresponding 3,3-difluoro indolone and fluorooxindole fluorination products are selectively synthesized; the method fills up technical gaps in the prior art that isatin hydrazones compound is selectively synthesized by using a three-position single fluorination or double fluorination technology starting fromisatin, the operation is simple, the process is short, the product yield is high, and industrial production requirements are met.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com