Thermoplastic elastomer, preparation method thereof and wood-plastic floor containing thermoplastic elastomer

A thermoplastic elastomer, matrix resin technology, applied in the directions of architecture, building structure, floor, etc., can solve the problem of poor elongation at break of plastic wood-plastic composite materials, and achieve great promotion and application potential, large elongation, low elongation The effect of a fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

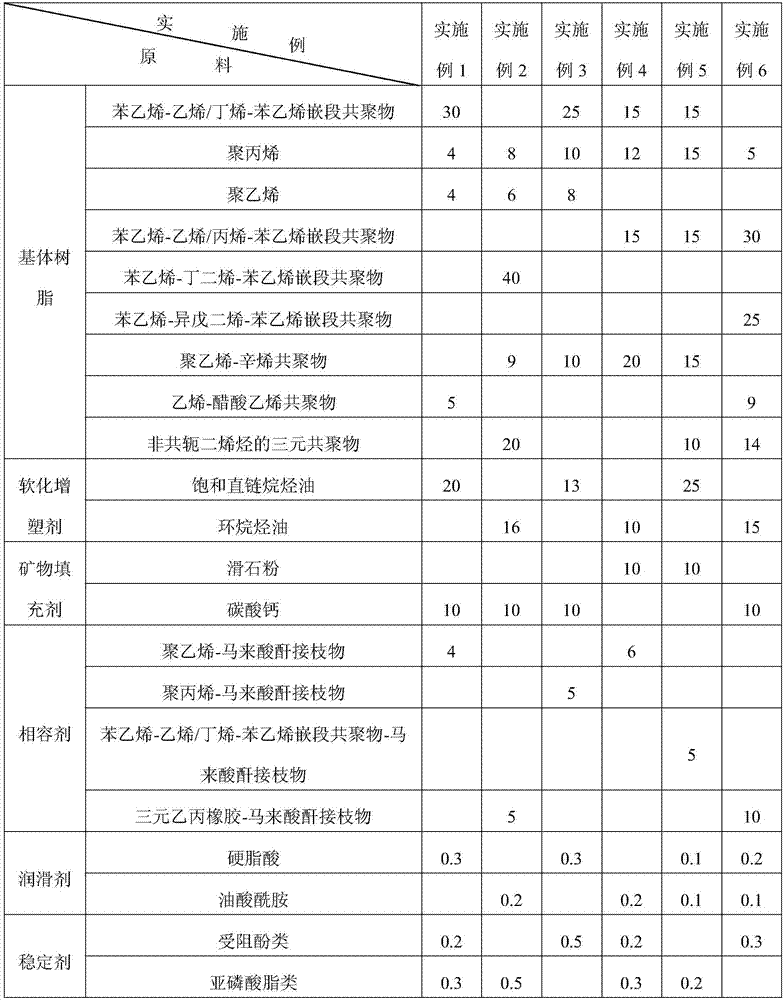

[0031] According to the raw material that table 1 provides, prepare thermoplastic elastomer in the following way:

[0032] Step 1. In parts by weight, 40 to 90 parts of matrix resin, 5 to 30 parts of softening plasticizer, 3 to 15 parts of mineral filler, 3 to 15 parts of compatibilizer, 0.2 to 2 parts of lubricant and 0.2 ~0.5 parts of stabilizer are added to the high-speed mixer in turn and mixed evenly, without heating during the mixing process;

[0033] Step 2. Put the homogeneously mixed raw materials in step 1 into a twin-screw extruder, extrude at a temperature of 170° C. to 195° C., and perform stranding, water tank cooling, and granulation in sequence to obtain a thermoplastic elastomer.

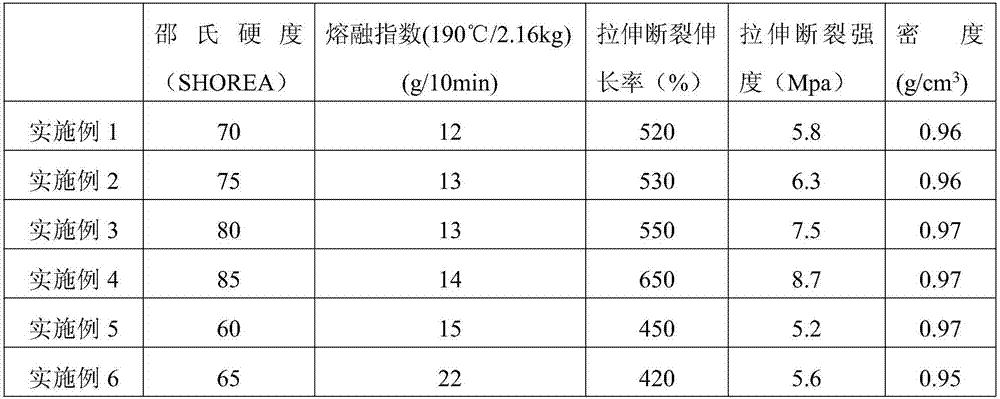

[0034] The raw material of the thermoplastic elastomer of table 1 embodiment 1~6

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com