Automatic control system of coal bed loads of thermal power generating unit

A thermal power unit and coal seam technology, which is applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problem of increased running time of single-layer coal seam sequential control switching coal seam, influence of system operation stability, and interference of fuel control, etc. problems, to achieve the effect of increasing the level of automation control, reducing human misoperation, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

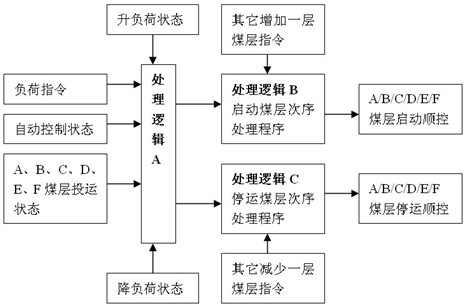

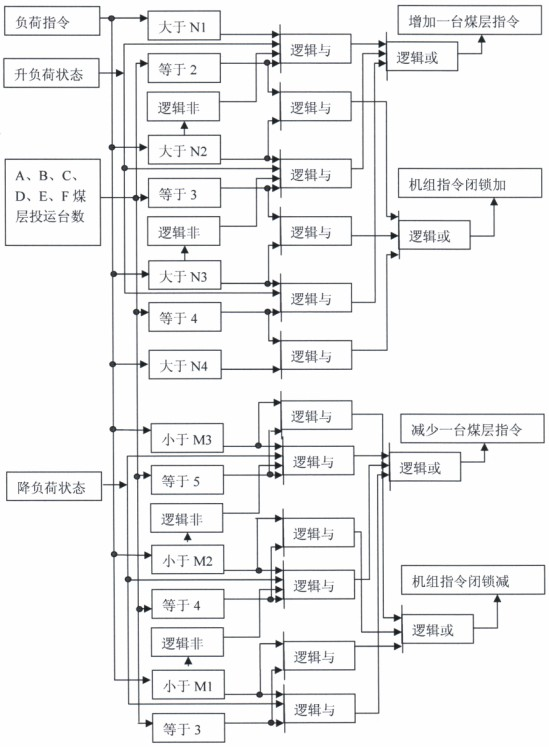

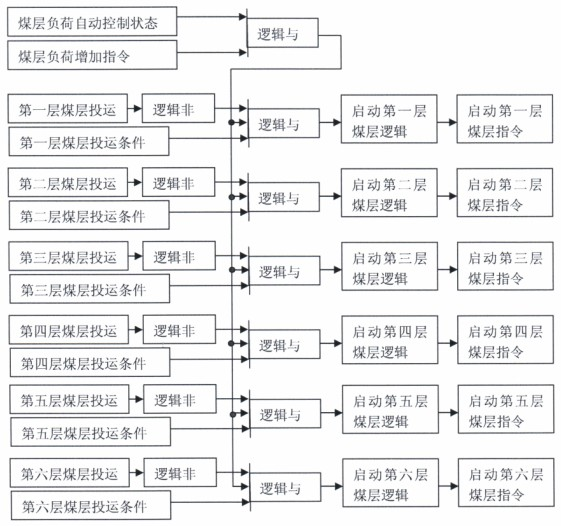

[0028] The invention provides an automatic coal seam load control system for a thermal power unit. The system has six coal seams (A / B / C / D / E / F), five coal seams need to be put into operation for full load operation, and one is reserved. Moreover, the sequential control of single-layer coal seam has perfect automatic operation and exit functions, and will not interfere with the coordinated control of DCS.

[0029] At present, there are two main ways to support coal seam combustion: fuel oil and plasma. For the former, according to the different start-up states of the boiler (cold state, warm state, hot state, and extremely hot state), the unit starts up through the following process: select fuel oil for operation, increase temperature and pressure, rush to run, put on initial load, and the boiler is ignited first. Seam coal seam, further increase the load, ignite the second coal seam, switch between the steam-driven feed water pump and the electric pump (commission the steam-dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com