Patents

Literature

157results about How to "Improve automation control level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

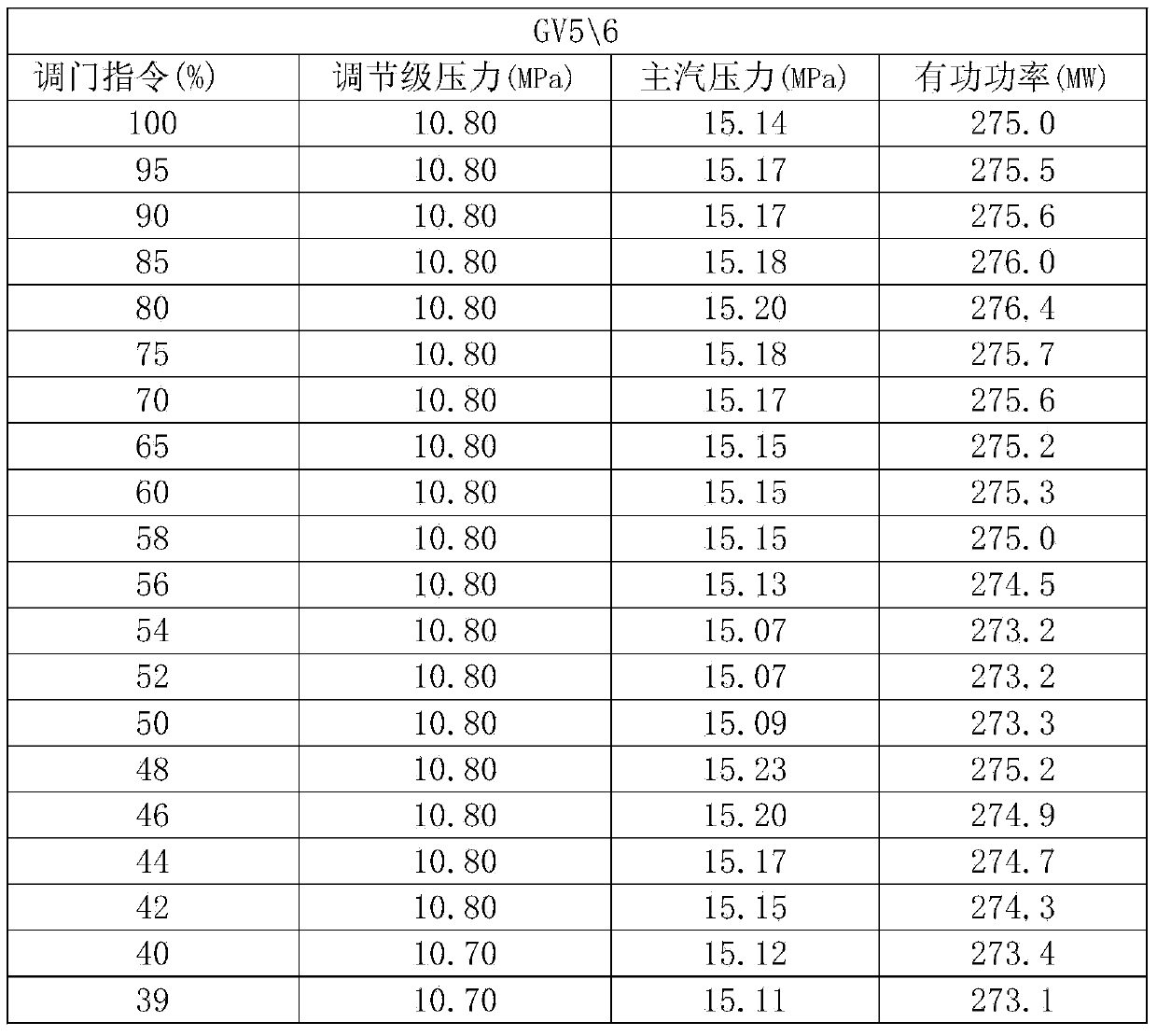

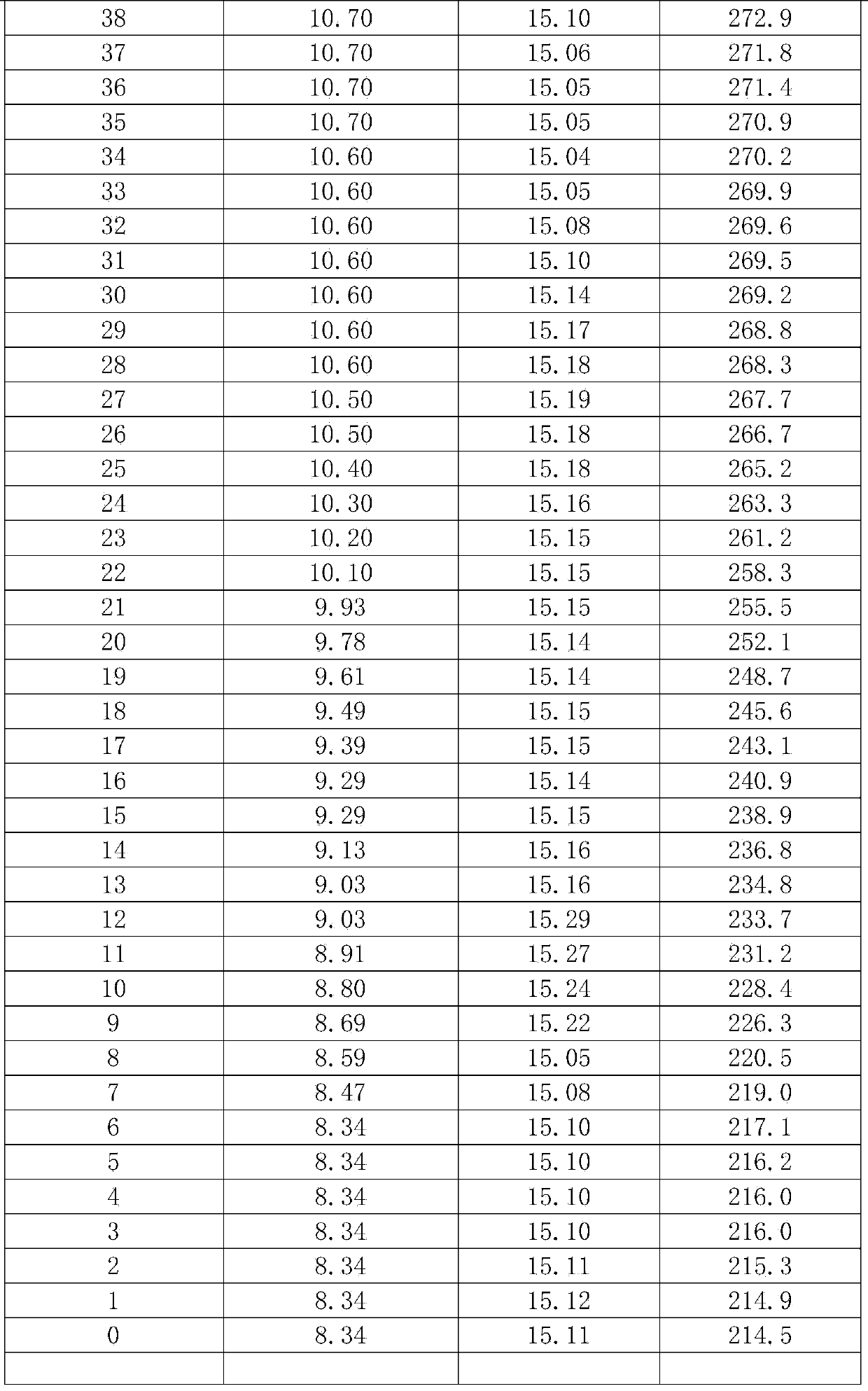

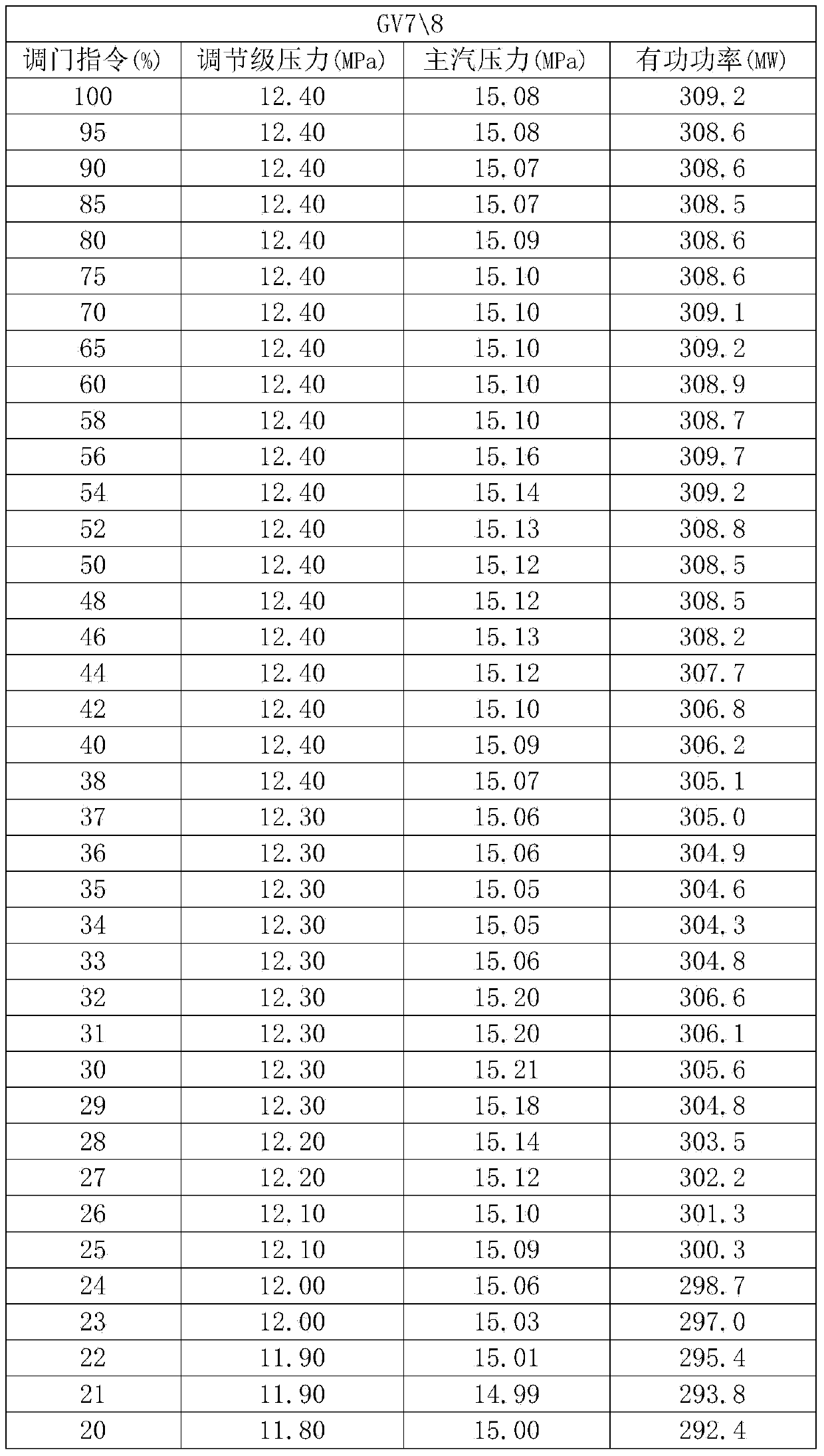

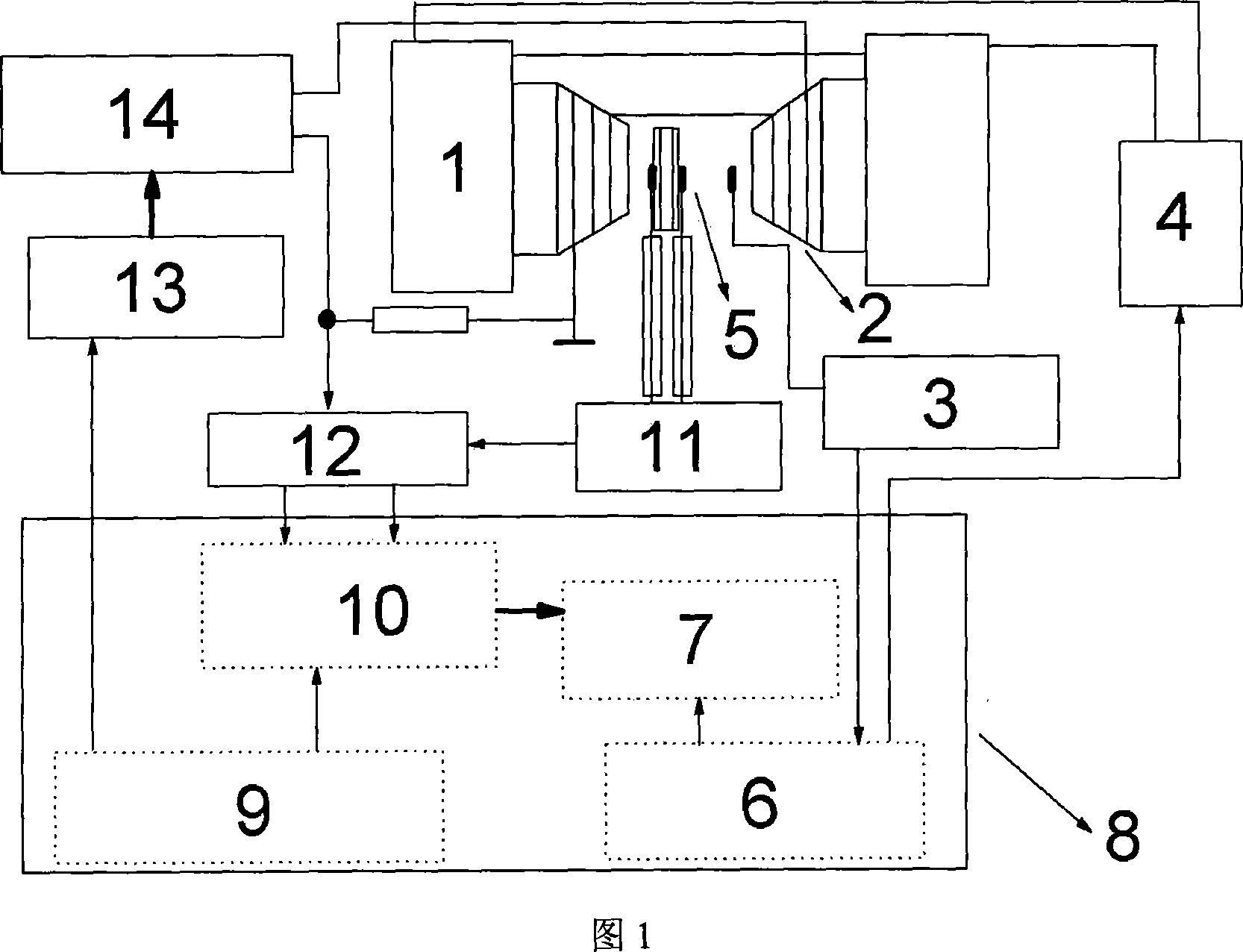

Turbine DEH system high-pressure regulating valve flow characteristic testing and setting method

ActiveCN103743560AImprove control qualityImprove efficiencyMachine part testingSteam pressurePerformance index

The invention discloses a turbine DEH system high-pressure regulating valve flow characteristic testing and setting method, which comprises the steps: relieving the AGC and the primary frequency modulation control method of a DEH system high-pressure adjusting valve, and recording the main steam pressure of a unit; relieving the coordination control method and the DEH remote control method of the DEH system high-pressure adjusting valve, and switching in a DEH valve control method and main steam pressure constant pressure automation; forcedly closing the high-pressure adjusting valve by an instruction according to a specified rule, and recording data; forcedly opening the high-pressure adjusting valve by an instruction according to a specified rule, and recording data; determining a flow characteristic correction curve of the high-pressure adjusting valve according to experimental result data. The testing and setting method has the beneficial effects that the unit efficiency and whole performance indexes are improved, the automation control level is improved, the operation efficiency of the unit is improved, and primary energy is saved.

Owner:STATE GRID CORP OF CHINA +1

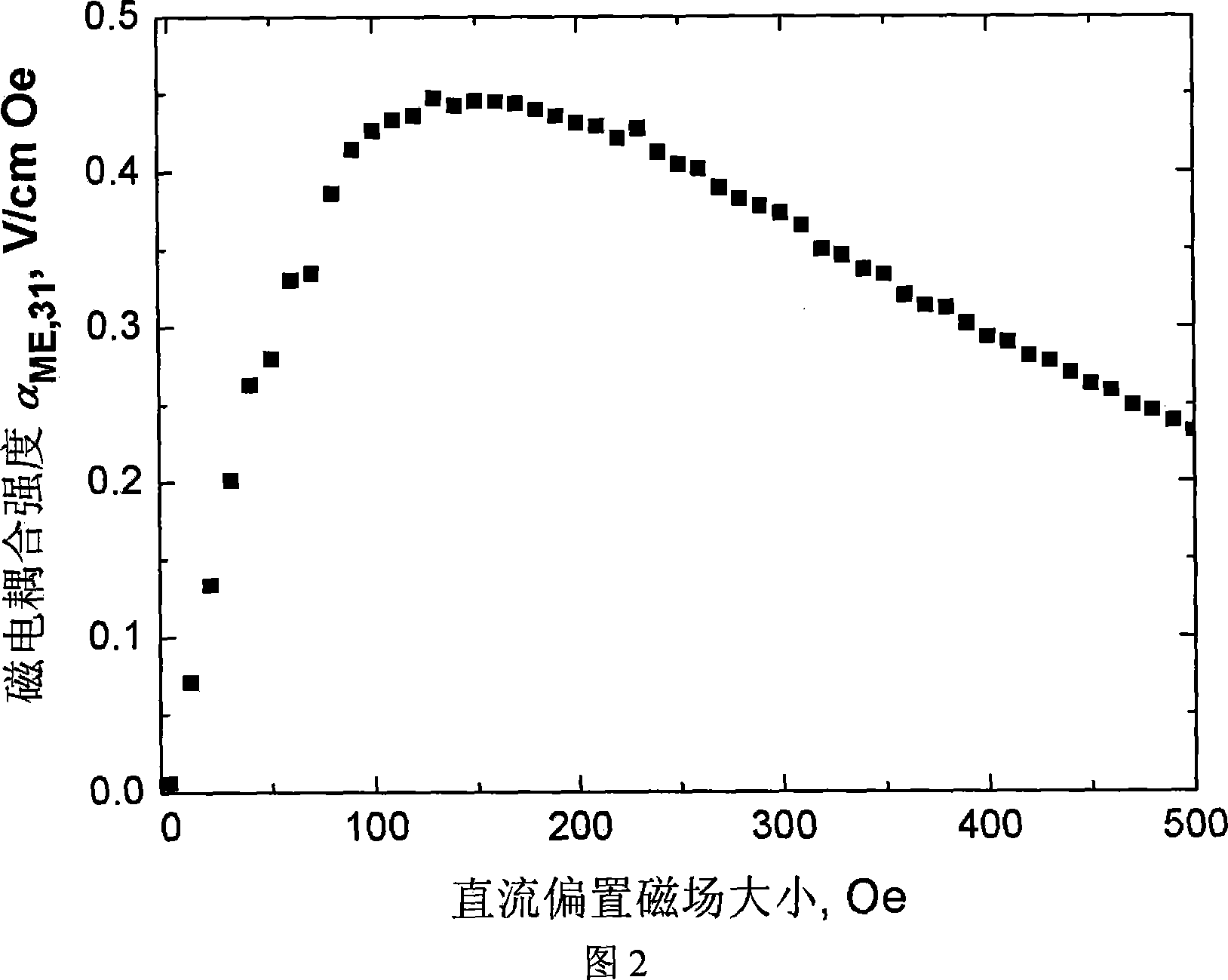

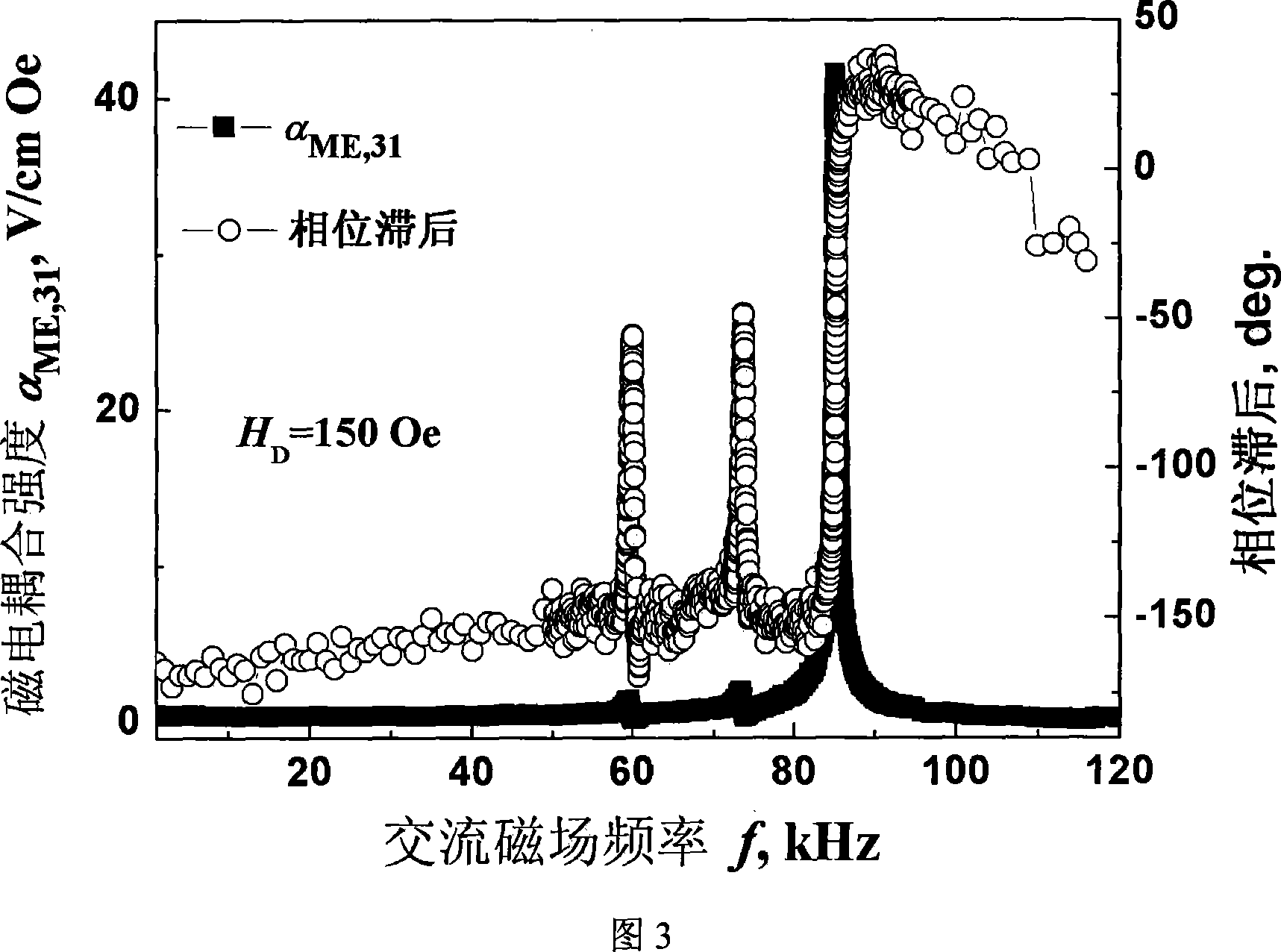

Full-automatic measurement device for magnetoelectric properties of magnetoelectric material and measuring method thereof

InactiveCN101034144AHigh measurement accuracyImprove automation control levelMagnetic field measurement using galvano-magnetic devicesMeasurement deviceApposition

This invention belongs to magnetic electricity material domain, which conretely relates to using fictitious multichannel phase-locking enlarging principle to implement test material magnetic electricity function method and device of computer control. This invention make phase-locking amplifier fictitious, which is that computer software implements function of phase-locking amplifier. It is very convenient to carry out phase-locking agnification process for random multipath signal by using fictitious phase-locking amplifier. Therefore, it not only precisely automatically survey dE and dH, improve magnetic electricity function measurement precision, but also work frequency limit is boosted a lot compared to hardware phase-locking amplifier, meanwhile decrease manufacture cost of magnetic electricity measuring device. This invention also combines control and measurement of apposition cocurrent offset magnetic field to boost automaticity of magnetic electricity measuring device, thereby improve precision and efficiency of magnetic electricity measurement.

Owner:UNIV OF SCI & TECH BEIJING

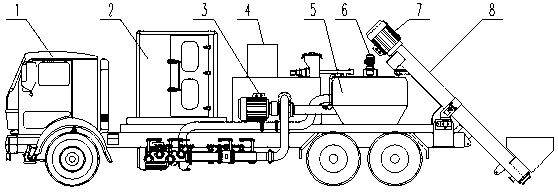

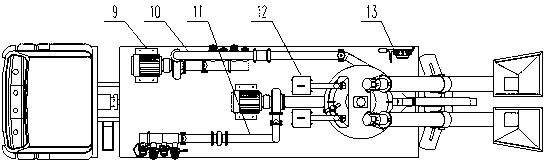

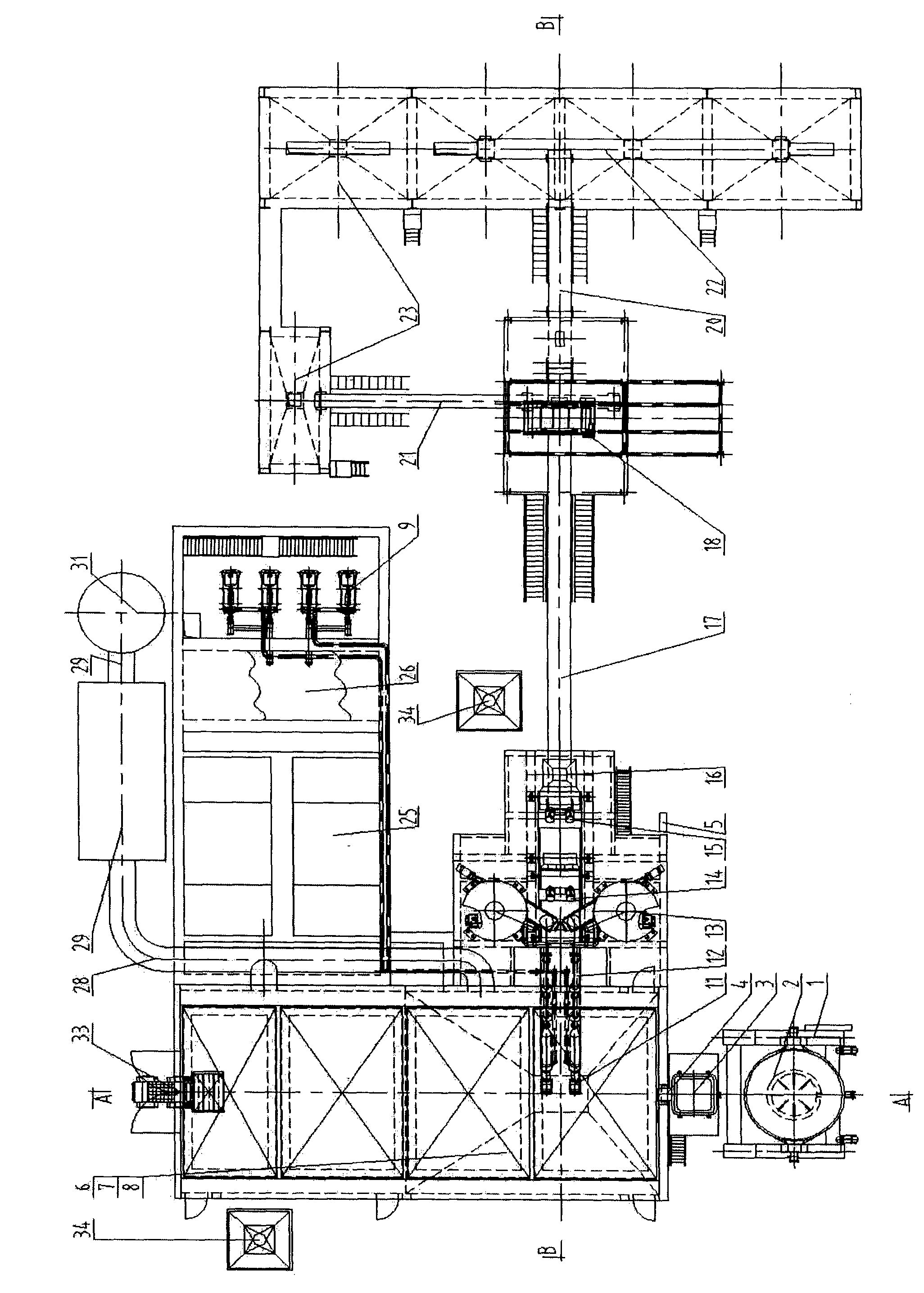

Electric drive sand mixing truck

InactiveCN103912259ASimple structureHigh localization rateFluid removalItem transportation vehiclesAutomatic controlElectric discharge

The invention belongs to the technical field of petroleum drilling and recovery and particularly relates to an electric drive sand mixing truck. The electric drive sand mixing truck comprises a truck chassis, a control room, a transformer, an electric discharge pump, an electric suction pump, a mixing tank stirring device, a sand conveying auger, a dry feeding system, a liquid feeding system, a suction manifold and a discharge manifold. The control room comprises a sand mixing truck automatic control system and a motor drive device. The electric drive sand mixing truck has the advantages that a motor is used as power source; compared with traditional sand mixing trucks using diesel engines and torque converters as main power output, the electric drive sand mixing truck is simple in structure, novel and reasonable in design, low in cost, low in noise, low in discharge, simple to control, high in sand-liquid matching precision, and convenient to popularize and use.

Owner:四机赛瓦石油钻采设备有限公司

Chemical cleaning method of hollow fiber membrane and device thereof

InactiveCN101829505AGuaranteed fluxImprove stabilitySemi-permeable membranesFiberHollow fibre membrane

The invention discloses a chemical cleaning method of a hollow fiber membrane, comprising the following steps of: (1) preparing a composite chemical cleaning agent with the active chlorine concentration of 10-13%; and (2) back washing the hollow fiber membrane on line by adopting the compounded composite chemical cleaning agent. The invention also discloses a chemical cleaning device of the hollow fiber membrane, which is provided with a composite chemical cleaning agent storage tank and a back washing system comprising a back washing pump; and the upper part of the storage tank is provided with a filling pipe, an electromagnetic valve and an air release valve. The invention can effectively keep the membrane flux of a membrane bioreactor and is matched with the running characteristic of a membrane bioreactor process. The invention solves the problems of large impact on microorganisms in a system, high labor intensity caused by needing to hang a membrane assembly out for cleaning and the like, and difficult running management, can integrate a membrane assembly cleaning system and the membrane bioreactor to improve the control level of automation. By adding a surfactant and regulating the pH value of the system to be greater than 13, the stability of a sodium hypochlorite solution can be improved.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

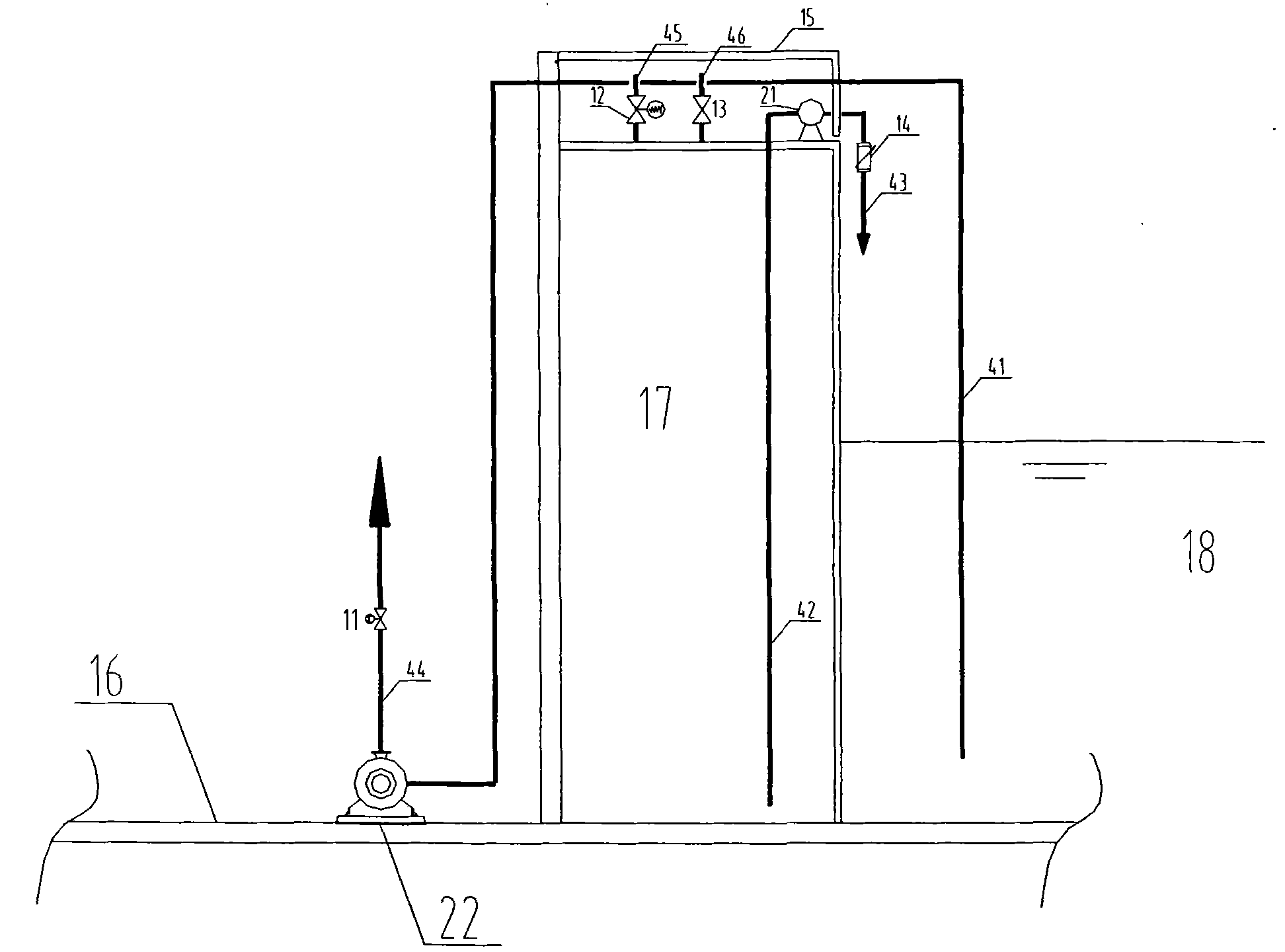

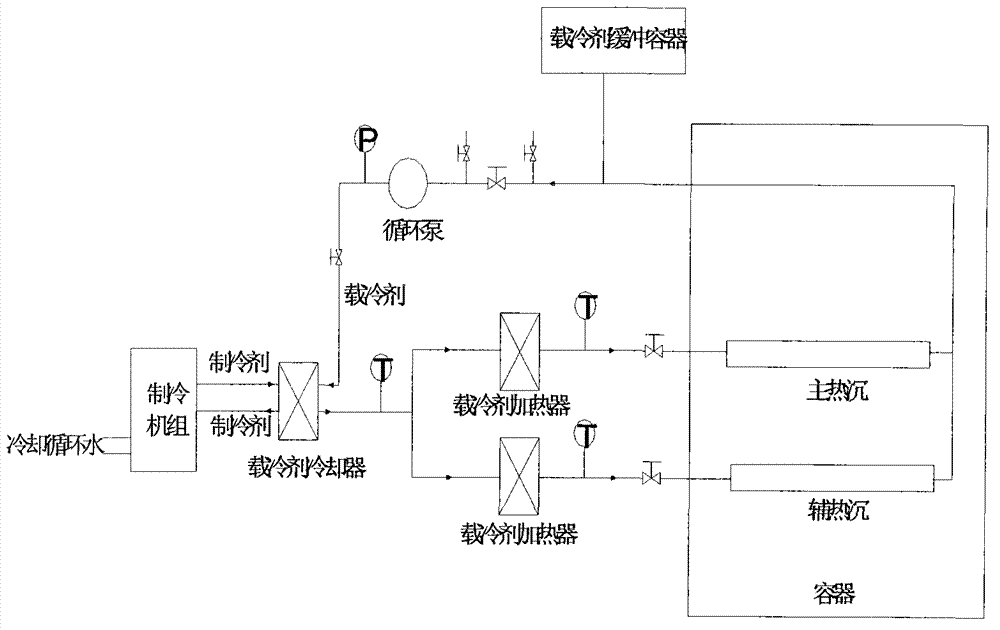

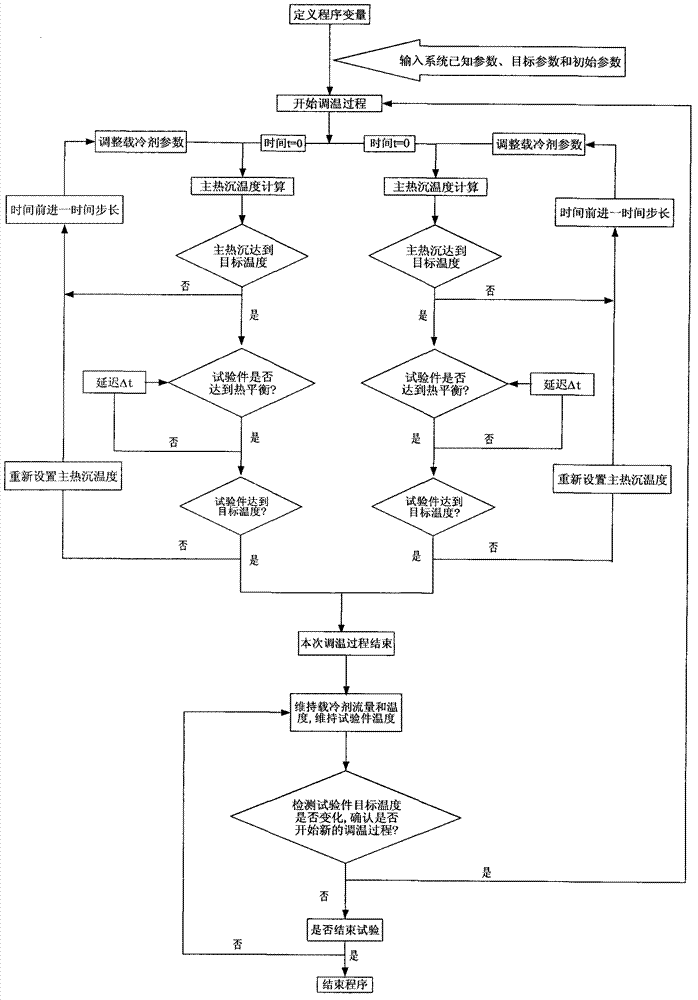

Heat sink temperature control system and method for thermal vacuum test

InactiveCN102768548AAdjustable heat sink temperatureHigh temperature control accuracyTemperature control using electric meansTemperature controlControl system

The invention discloses a heat sink temperature control system for a thermal vacuum test, comprising a refrigerating system, a secondary refrigerant cooler, a secondary refrigerant heating and temperature controlling system, a circulating pump, a secondary refrigerant buffer container and a heat sink system, wherein the secondary refrigerant heating and temperature controlling system comprises a secondary refrigerant heater for heating a main heat sink, a temperature controller for controlling temperature, a secondary refrigerant heater for heating an auxiliary heat sink and a temperature controller for controlling temperature, so that the temperature of a secondary refrigerant entering a heat sink is controlled by the secondary refrigerant heaters and the temperature controllers. The invention also discloses a temperature control method. Compared with the prior art, the heat sink temperature control system can be used for regulating the temperature of the heat sink in a fixed point, and the temperature of a test piece can be regulated and controlled without infrared electric heating equipment, so that the system is simplified, and the temperature control accuracy is improved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

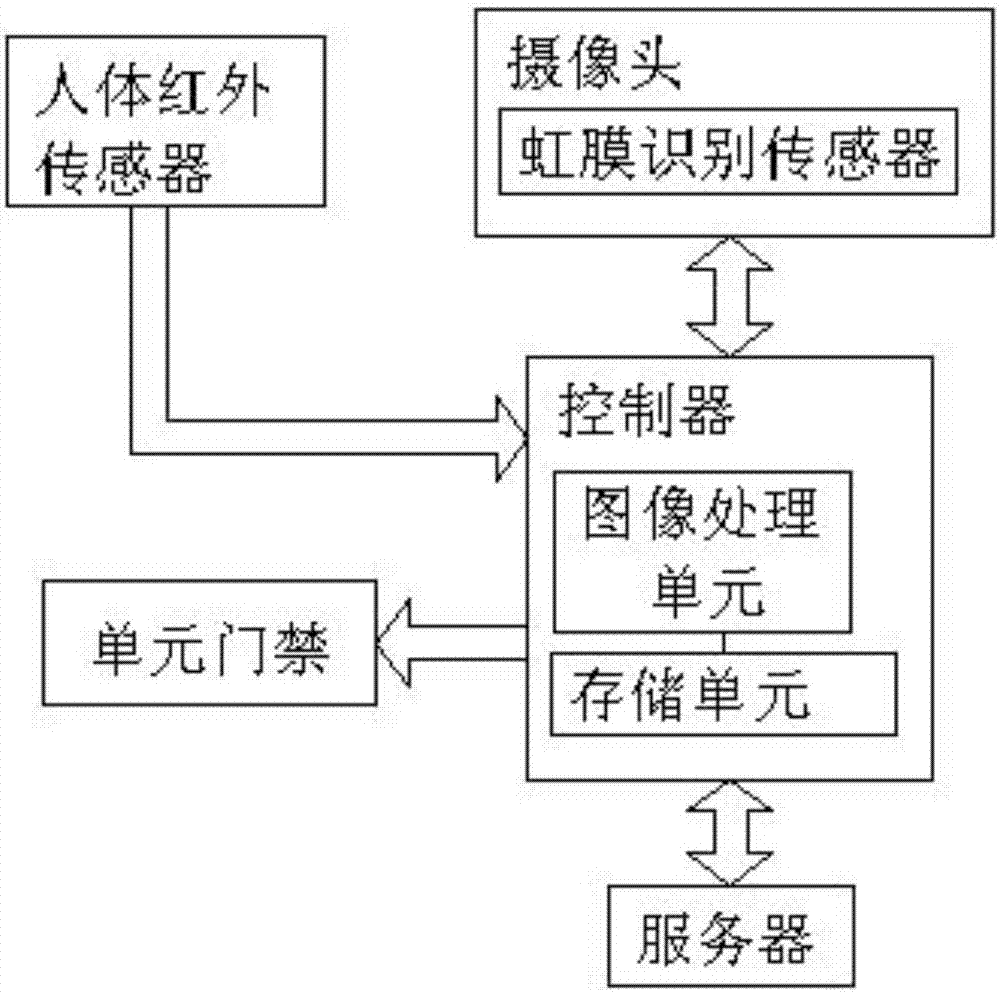

Intelligent control system for apartment door access based on human face recognition

InactiveCN107016761AImprove the efficiency of face recognition againExtended service lifeIndividual entry/exit registersHuman bodyAutomatic control

The invention discloses an intelligent control system for an apartment door access based on human face recognition. The intelligent control system comprises a human body infrared sensor, a controller, an apartment door access, a server and a camera, wherein the human body infrared sensor is used for acquiring a human body infrared signal and used for transmitting the human body infrared signal to the controller; the controller is used for powering on the camera and acquiring human face images after receiving the human body infrared signal, and furthermore the acquired human face images are transmitted back to the controller through the camera; the controller calls the human face data from the server and compares the received human face images, and the door access is kept in an opened or closed state according to comparison results. By adopting the intelligent control system, the intelligence and automatic control levels of the apartment door access are improved; as an iris recognition sensor is arranged inside the camera, the precision of the human face image acquisition precision and later human face recognition efficiency of the camera are improved; if the human body infrared sensor senses a visitor, the camera is powered on, so that the power can be saved, and the service life of the camera can be prolonged.

Owner:合肥酷庆信息科技有限公司

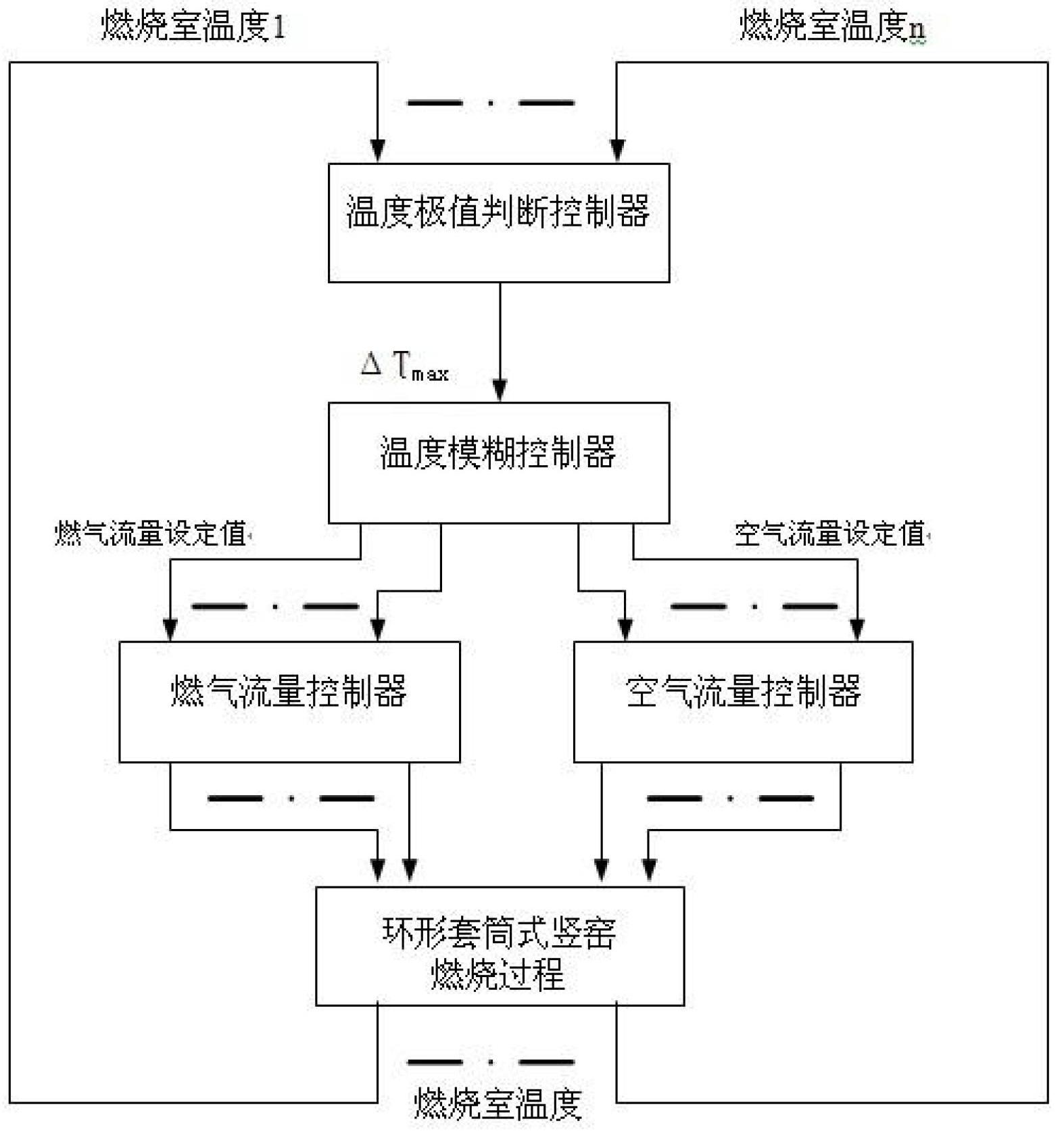

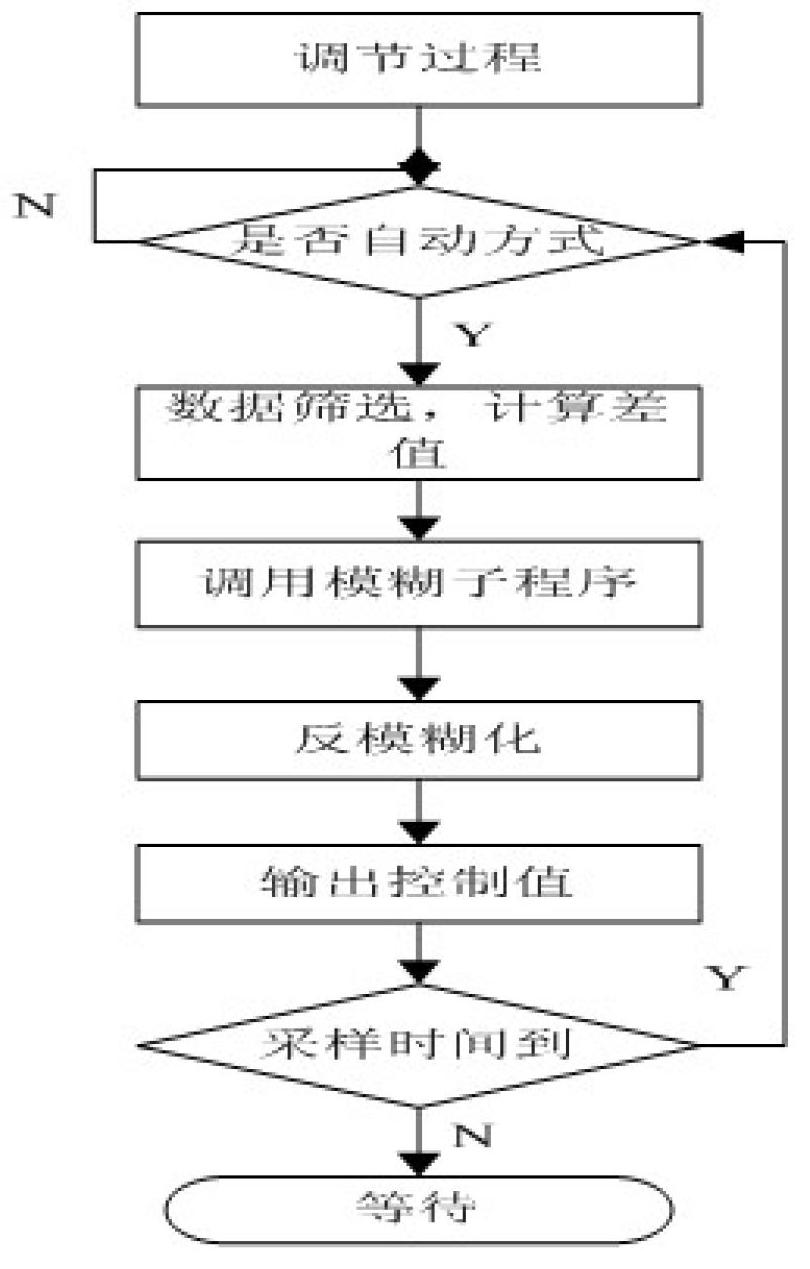

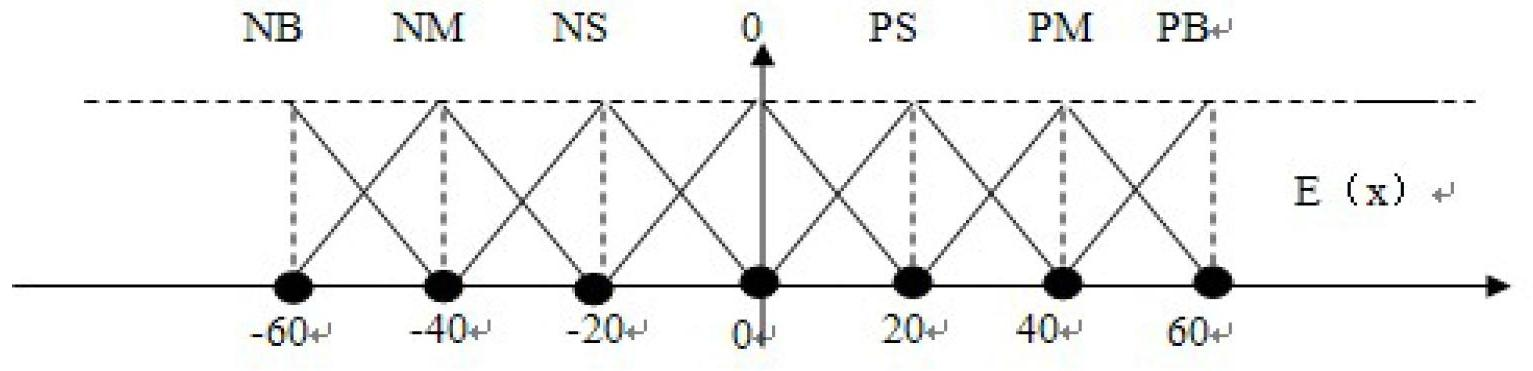

Automatic control method for improving uniformity of temperature of sleeve kiln

ActiveCN102692124AImprove uniformityStable and uniform qualityVertical furnacesCombustion chamberAutomatic control

The invention relates to an automatic control method for improving the uniformity of the temperature of a sleeve kiln and belongs to the technical field of industrial automation. According to the method, on the basis of a fuzzy control principle, the variation of the temperature of each combustion chamber of the ring-shaped sleeve vertical kiln is tracked by an industrial control computer so as to control the temperature of the ring-shaped sleeve vertical kiln. A temperature extreme value judgment controller, a temperature fuzzy controller, a gas flow regulation controller and a combustion air flow controller are arranged in a programmable logic controller (PLC) machine; and the temperature of the sleeve kiln is controlled and regulated by judging the variation of the temperature of each combustion chamber, automatically regulating a distribution coefficient of gas in each combustion chamber and regulating the gas flow and the combustion air flow of each combustion chamber according to the coefficient. According to the method provided by the invention, due to the adoption of the automatic control method, the uniformity of the temperatures of the combustion chambers can be improved, the product quality is improved and refractory materials inside the sleeve kiln are protected.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH +2

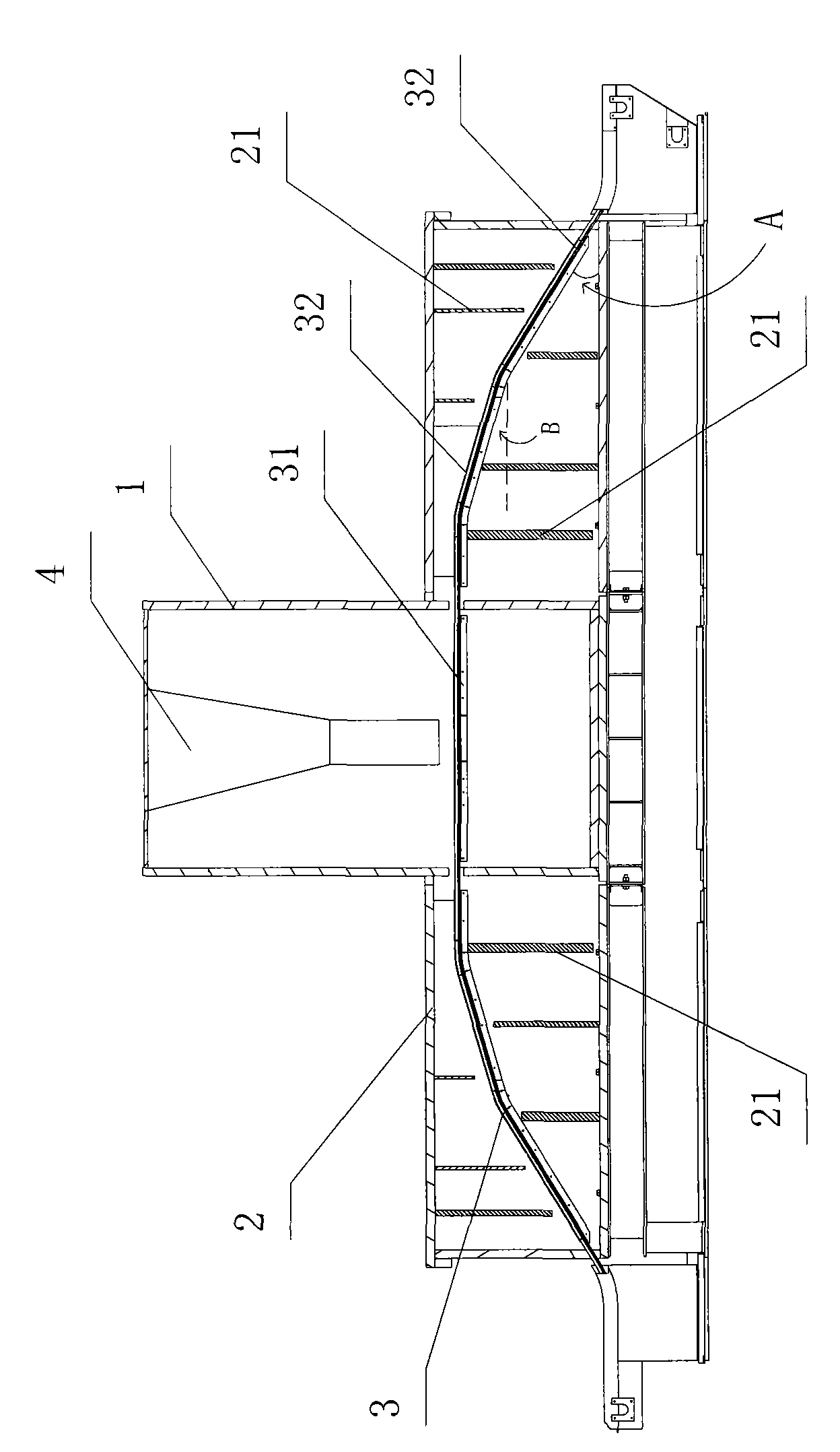

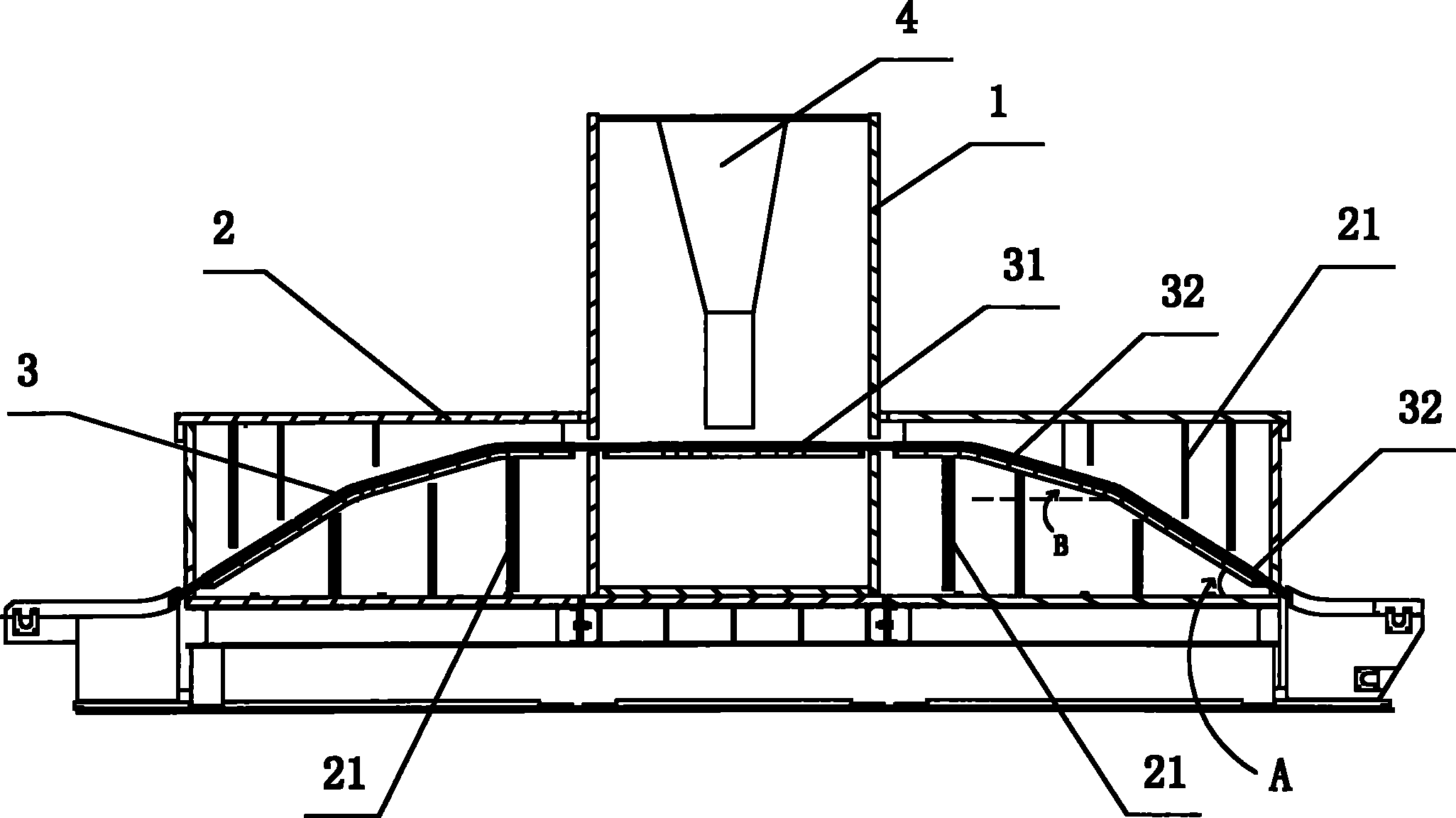

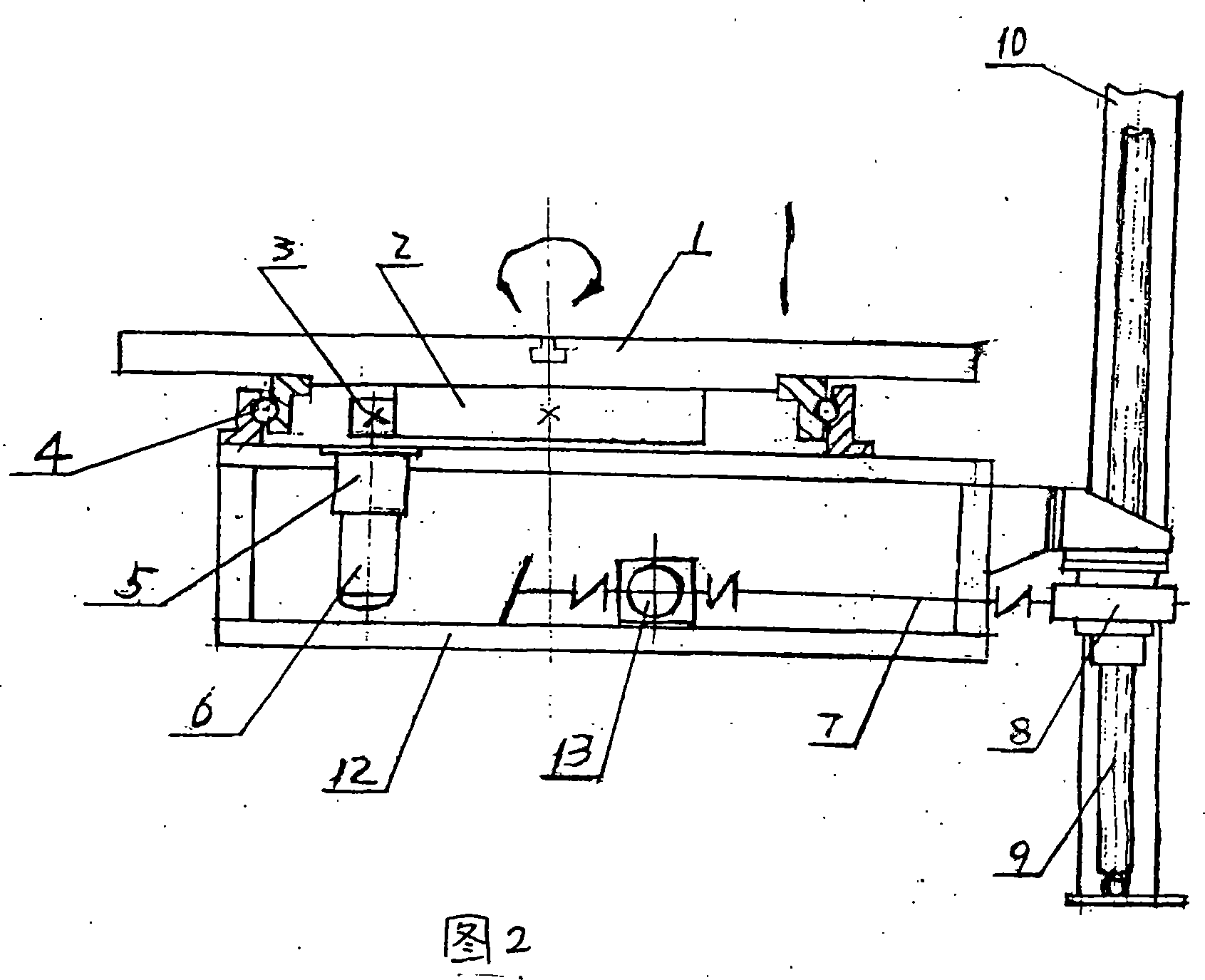

Tire rubber sheet electron radiation crosslinking pretreatment device and method

ActiveCN102092111AStrong penetrating powerIncrease the number of reflectionsTyresUltrasound attenuationPretreatment method

The invention discloses a tire rubber sheet electron radiation crosslinking pretreatment device and a tire rubber sheet electron radiation crosslinking pretreatment method. A conveyor belt used for realizing an arc-shaped conveying track is arranged in a shielding room; based on the ray absorption by the interior wall of the shielding room, the ratio of attenuation generated by multiple times of refraction is increased by increasing the reflection times of rays, and thus, the rays can be absorbed to a maximum degree and the ray leakage can be reduced so as not to pollute the environment and hurt the body the operators. The device mainly comprises a radiation room, the shielding room and the conveyor belt for conveying rubber sheets, wherein an electron accelerator is arranged in the radiation room and above the conveyor belt, and the conveyor belt runs through the radiation room and the shielding room. Ray absorbing plates are adhered on all of the inner walls of the radiation room and the shielding room. The conveyor belt comprises a horizontal conveying part arranged in the radiation room and below the electron accelerator and an oblique conveying part arranged in the shielding room. The oblique conveying part has at least one group of left and right symmetric and vertically bent continuous conveying section.

Owner:MESNAC

Automatic control method for double slag operation of converter

InactiveCN101748237AImprove automation control levelEasy to controlManufacturing convertersSteelmakingAutomatic control

The invention relates to an automatic control method for the double slag operation of a converter, which belongs to the technical field of the converter steelmaking. The automatic control method comprises the step of based on a secondary automatic control system, when the content of Si in the molten iron feeding into the converter is higher than 0.60 percent, establishing an independent operation mode in the secondary automatic control system as follows: setting a target parameter of the prophase deslagging of the converter that when a calculating temperature reaches 1,300 to 1,350 DEG C, the operation of automatically lifting the blow gun to stop blowing is carried out; setting the control gun position in the whole process in the secondary automatic control system as low-high-low; setting the process oxygen flow between 300 and 310Nm3 / min; setting the increased oxygen flow in the final stage to between 340 and 350Nm3 / min so as to increase the stirring effect; and setting 30 to 40 percent of the total amount of the slagging materials which are put in the previous stage in a secondary model, wherein the residual slag materials are put when the secondary slagging starts. The invention has the advantages of making the endpoint control accurate, improving the automation control level of the converter and realizing the automation control that the converter utilizes the high Si molten iron to produce the low P molten steel.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

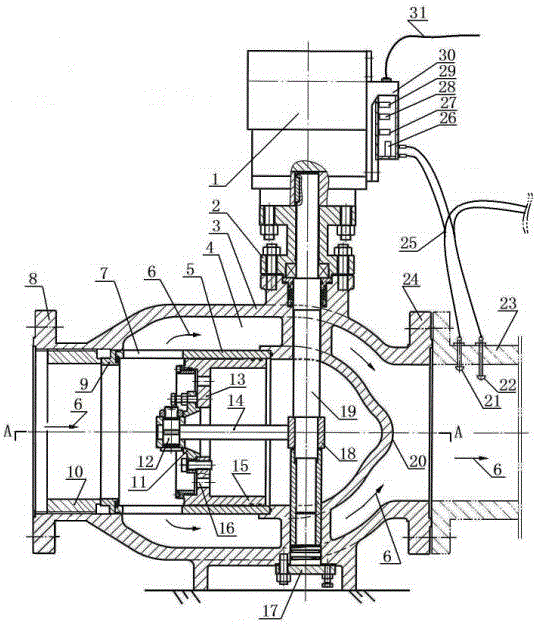

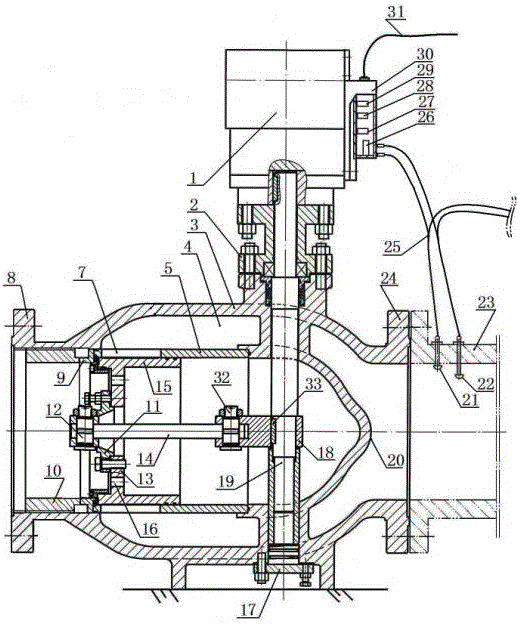

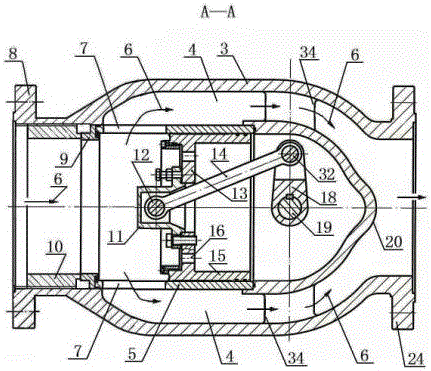

Axial-flow type adjusting valve

InactiveCN106321935ASimple structureEasy to useOperating means/releasing devices for valvesEqualizing valvesAutomatic controlEngineering

The invention discloses an axial-flow type adjusting valve which mainly comprises a valve body, an electric head, an adjusting controller, a connecting rod crank arm mechanism, a pressure sensor and a flow sensor, wherein the electric head is mounted in the valve body, the connecting rod crank arm mechanism is assembled in the valve body, and the pressure sensor and the flow sensor are mounted on an output tube. Output pressure and flow fluctuation signals are acquired on line by electronic integration technology and inputted to the adjusting controller for calculation, adjusting instructions are transmitted to the electric head, the electric head drives an adjusting rotation shaft to rotate, a valve spool is pushed by the connecting rod crank arm mechanism, opening of an adjusting valve port is changed to adjust output flow and pressure, and the output flow and the output pressure can be automatically adjusted and tend to be stable. The axial-flow type adjusting valve has the outstanding advantages of simple structure, convenience in mounting and using, high adjusting precision, high reaction speed, running safety and reliability, high automated control level and good conveying medium stability, and is particularly suitable for being mounted and used on a pipeline requiring high conveying medium dynamic stability.

Owner:SICHUAN ZHONGYOU LEYI ENERGY EQUIP MFG CO LTD

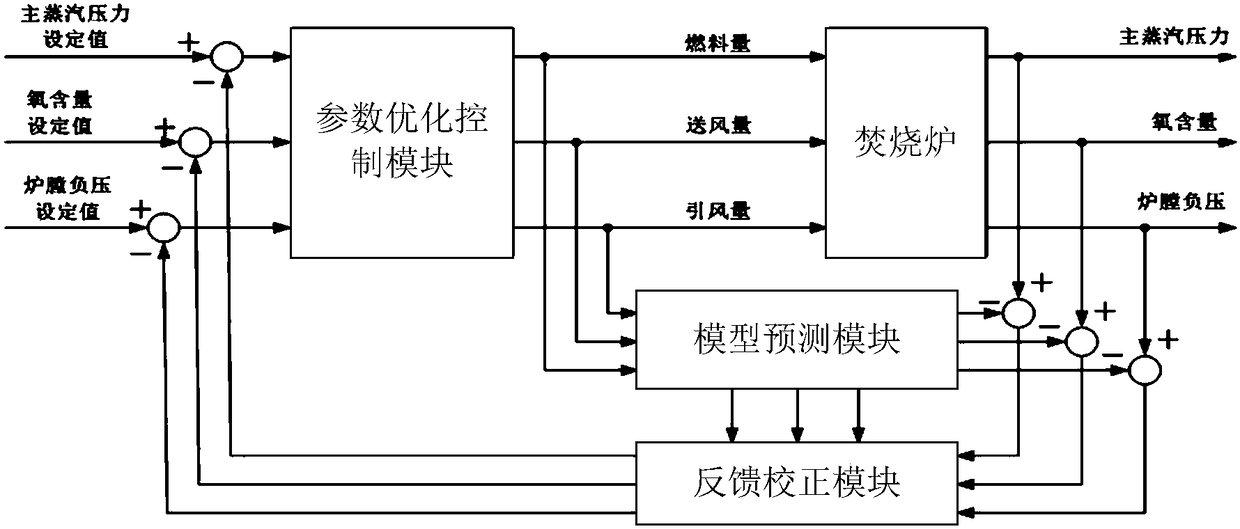

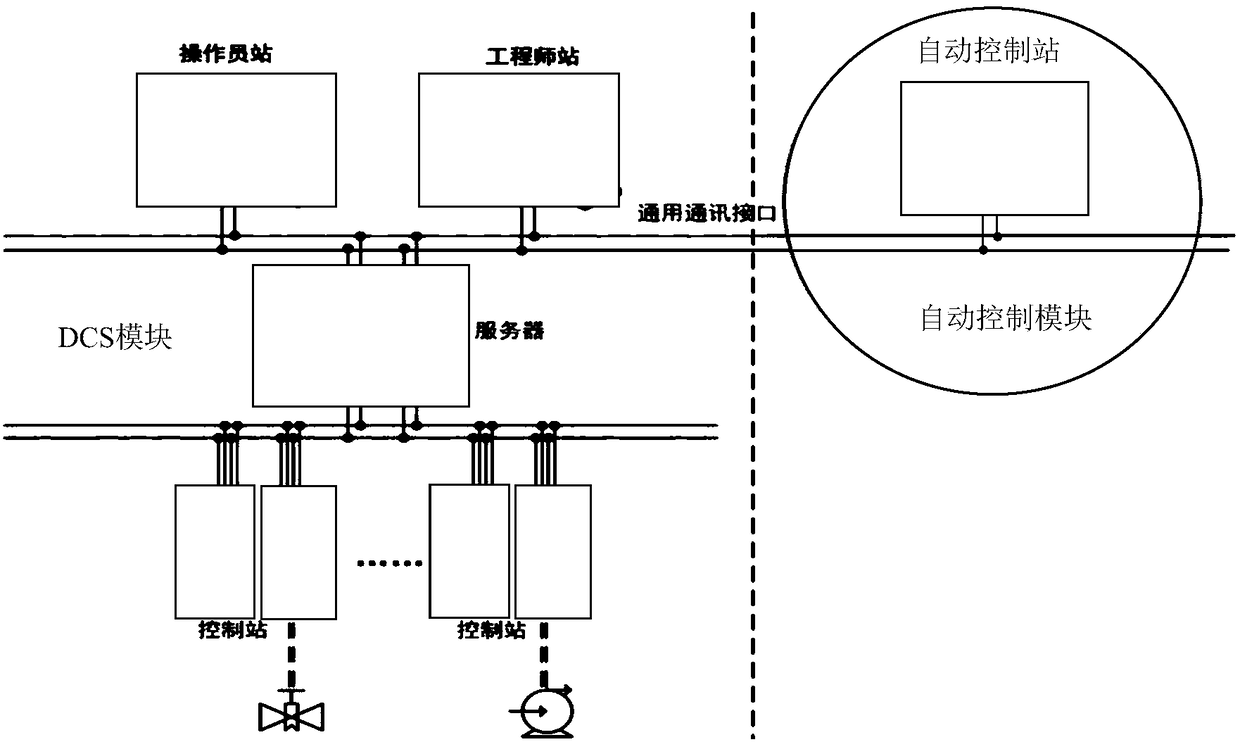

Garbage incinerator control system

InactiveCN108332213AImprove intelligenceImprove adaptabilityIncinerator apparatusAutomatic controlCombustion

The invention provides a garbage incinerator control system. The system comprises an incinerator and an automatic control module, wherein a data acquisition module is arranged on the incinerator and used for collecting combustion condition data related to control parameters of the incinerator, and the combustion condition data characterizes combustion conditions of the incinerator; the automatic control module performs collaborative optimization on at least two control parameters of the incinerator according to the combustion condition data to obtain optimized control parameters and automatically controls the incinerator according to the optimized control parameters. The garbage incinerator control system achieves the purposes of intelligence and adaptability of the incinerator and has theeffects of saving energy, increasing efficiency and improving operating economy.

Owner:光大环保能源(宁波)有限公司

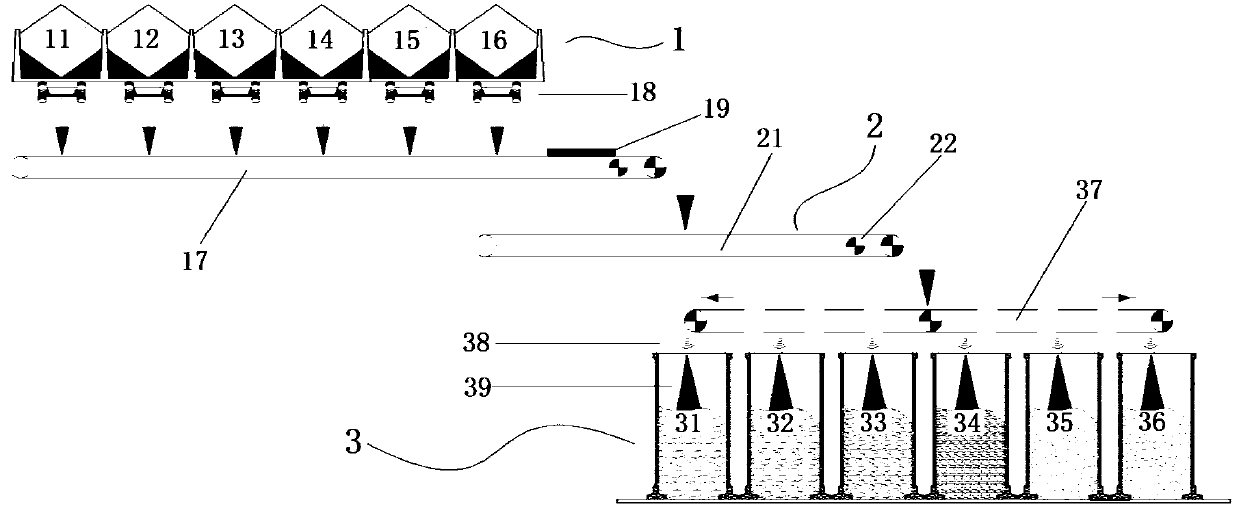

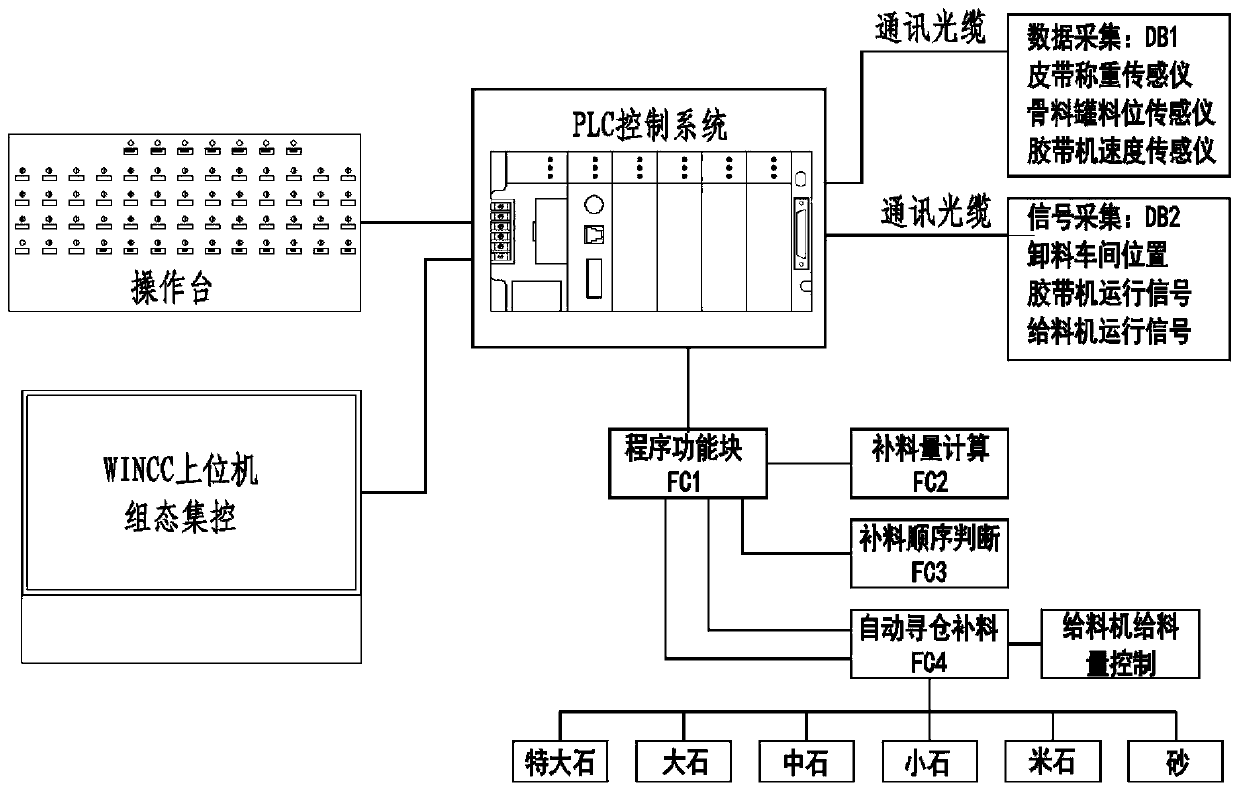

Concrete aggregate automatic bin-searching and feeding system

ActiveCN111331734AOptimal control methodImprove automation control levelMixing operation control apparatusIngredients storageControl systemTransit system

The invention discloses a concrete aggregate automatic bin-searching and feeding system. The concrete aggregate automatic bin-searching and feeding system comprises an aggregate raw material system, aconcrete production system, a belt conveyor transportation system and a control system; the aggregate raw material system comprises storage yards for each raw material with feeders and discharge conveyor belts distributed at the outlet ends; the belt conveyor transportation system comprises a discharge belt conveyor and a long-distance belt conveyor; and the concrete production system comprises aconcrete production device and a storage system, the storage system comprises raw material bins arranged according to the needs of concrete production, and movable material distribution trolleys arecorrespondingly arranged at the tops of the raw material bins. According to the concrete aggregate automatic bin-searching and feeding system, based on the combination of a sensing technology and a PLC control technology, the aggregate transportation amount, the aggregate bin material level, the automatic analyzing and controlling replenishment amount, the replenishment time and the replenishmentsequence are collected, the feeders automatically switch the feeding variety, the material distribution trolleys automatically search bins and replenish materials, the continuous transportation of multi-level aggregate from the aggregate yards to the aggregate storage bins is achieved, and purposes of optimizing the control of a replenishment system and improving the control level are achieved.

Owner:SINOHYDRO BUREAU 7 CO LTD

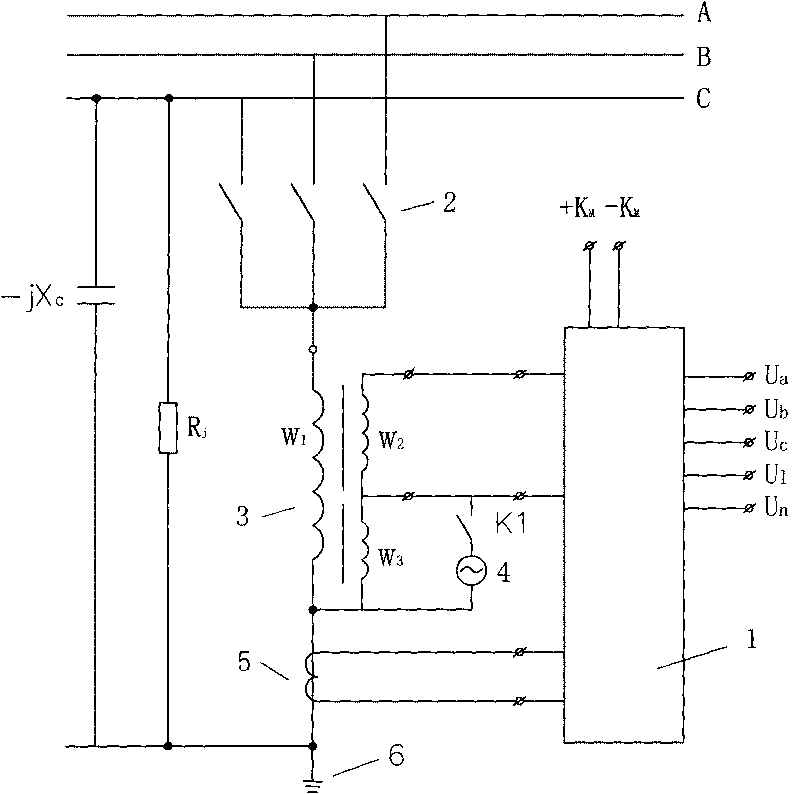

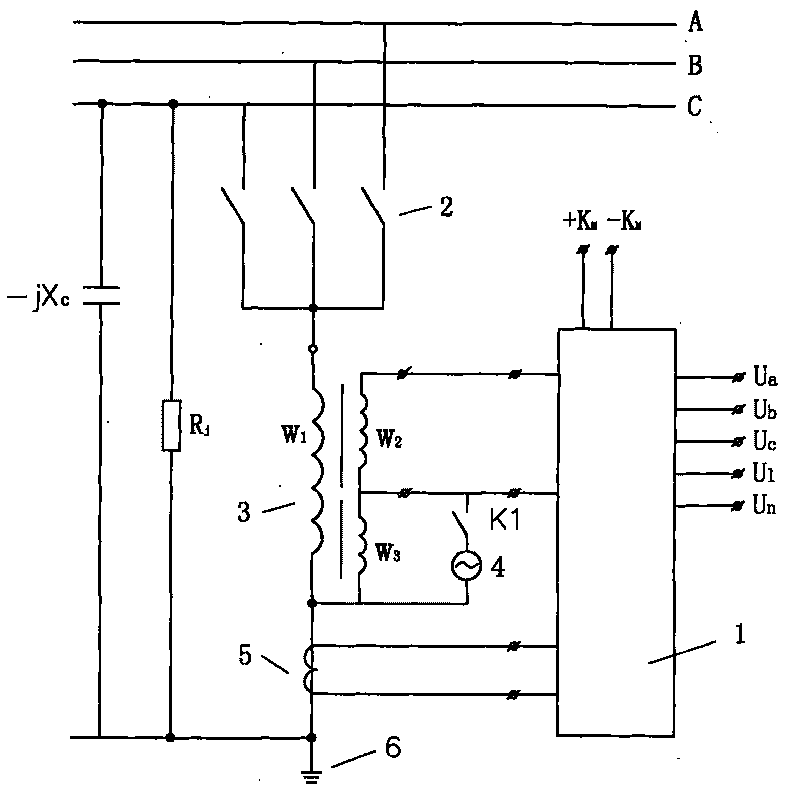

Method for automatically resetting grounding protection device of small-current system

ActiveCN101719660AAvoid the chance of phase-to-phase short circuitImprove power supply reliabilityEarth resistance measurementsEmergency protective arrangements for automatic disconnectionGrounding resistanceCurrent limiting reactor

The invention provides a method for automatically resetting the grounding protection device of a small-current system, which has the function of automatically resetting. The method comprises the following steps: an intelligent controller of a microcomputer judges whether the small-current system is grounded and further judges the grounding phase if the system is grounded; when the system is subjected to a grounding fault, a switching-on instruction is given to a fault-phase circuit breaker, and the fault-phase circuit breaker is rapidly switched on; the fault phase is connected with a grounding grid via a low-impedance current-limiting reactor provided with a secondary coil; then, a system grounding current flowing through the primary coil of the low-impedance current-limiting reactor is detected by a zero-sequence current transformer, and a high-frequency voltage signal generator connected with the secondary coil of the low-impedance current-limiting reactor is put into operation, so a high-frequency voltage and a high-frequency current are injected into the fault phase of the system; the high-frequency impedance of the fault phase of the system can be calculated by the intelligent controller of the microcomputer, so as to obtain the grounding resistance of the faulted return circuit; and the grounding resistance thereof is further compared with that in the normal system to judge whether the grounding fault disappears, if so, an automatic resetting instruction is given, so as to switch off the fault-phase circuit breaker, thereby automatically resetting the device.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY

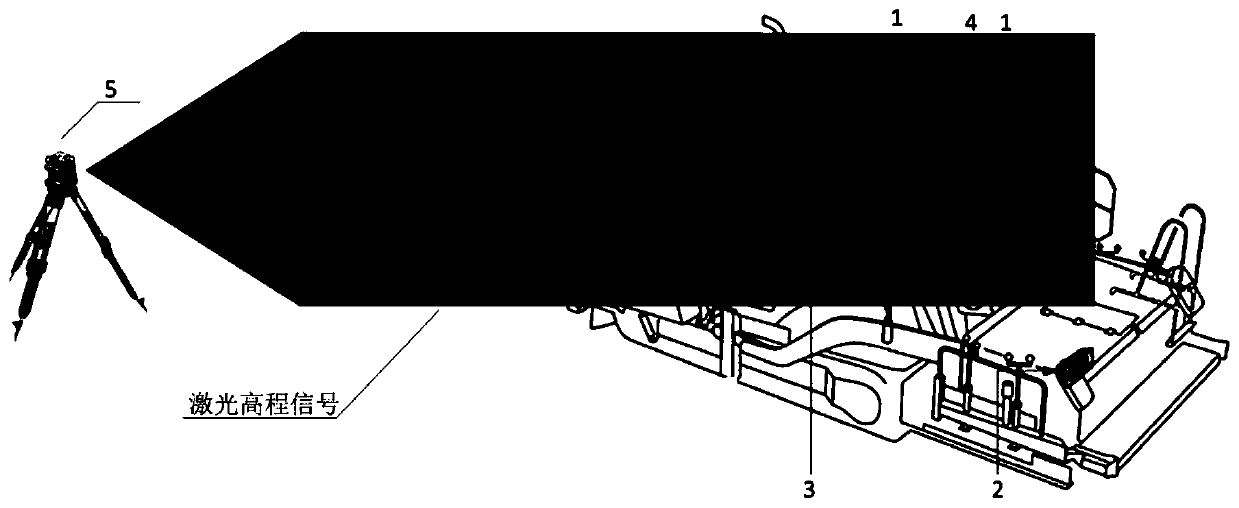

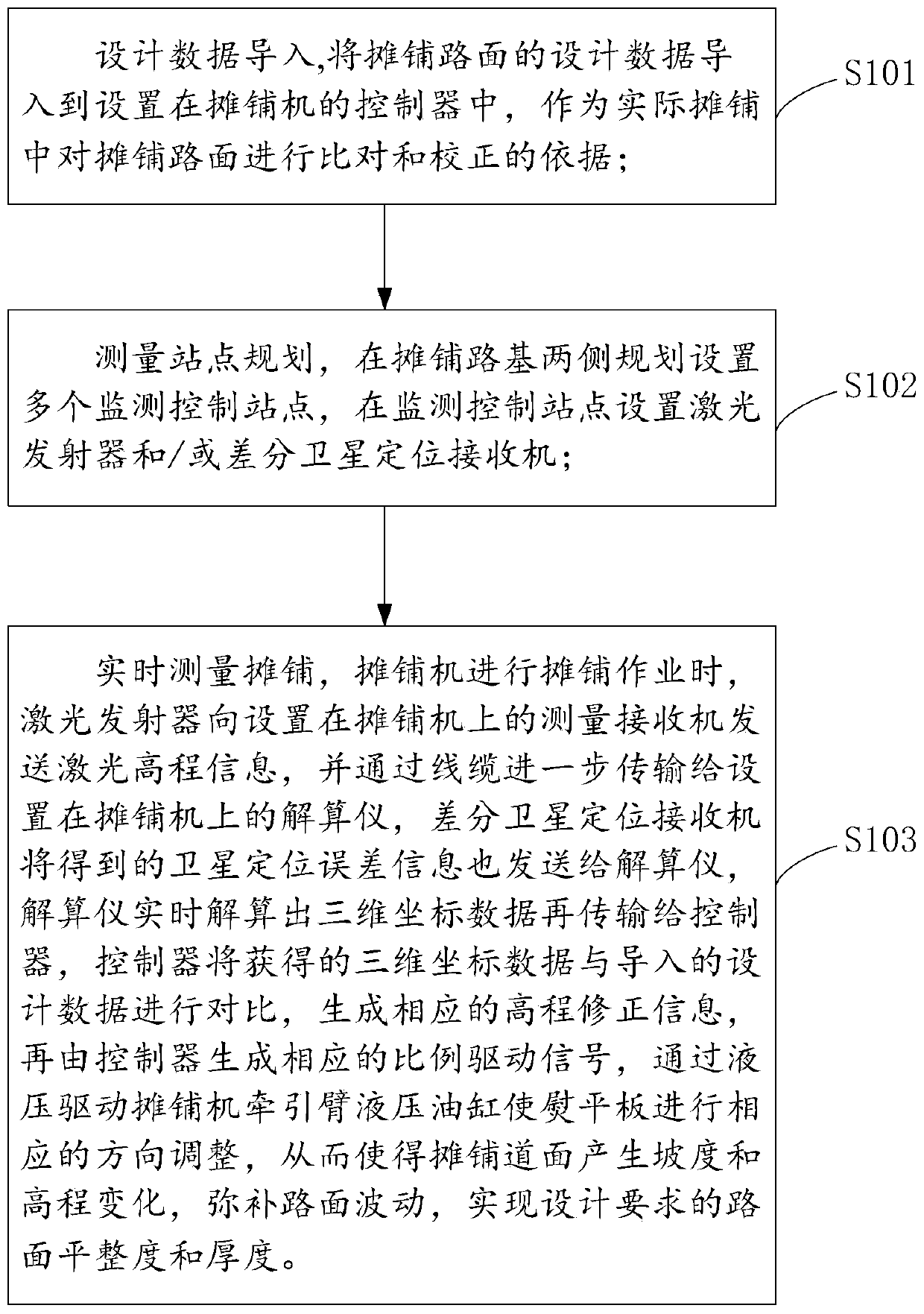

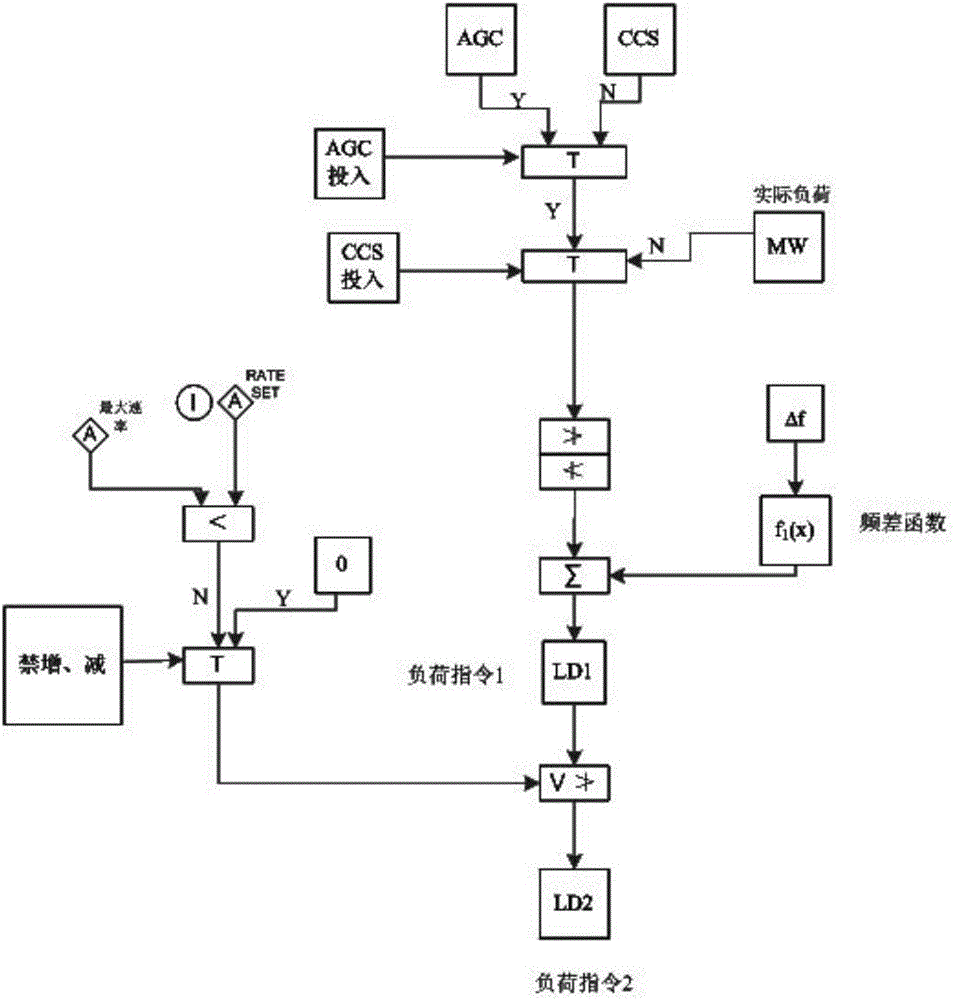

Automatic paving method based on laser scanning and satellite positioning

InactiveCN110983925AMake up for fluctuationsAchieve flatnessRoads maintainenceLaser transmitterAutomatic control

The invention discloses an automatic paving method based on laser scanning and satellite positioning. The method comprises the following steps: importing design data: importing the design data of a paving pavement into a controller of a paver, and taking the design data as a basis for the comparison and correction of the paving pavement in actual paving; planning measurement stations: planning a plurality of monitoring control stations at two sides of a paving roadbed, and arranging laser emitters and / or differential satellite positioning receivers at the monitoring control stations; and performing real-time measurement paving: when the paver is used for paving operation, sending information to a resolver by the laser emitters and the differential satellite positioning receivers, transmiting the information to the controller by the resolver, and adjusting the direction of a screed correspondingly by the controller, so that the paving pavement generates gradient and elevation changes, pavement fluctuation is made up, and the pavement flatness and thickness required by design are achieved. The automatic control level of pavement paving is improved, the control precision is high, andmulti-machine joint paving is realized.

Owner:HENAN HIGHWAY ENG GROUP

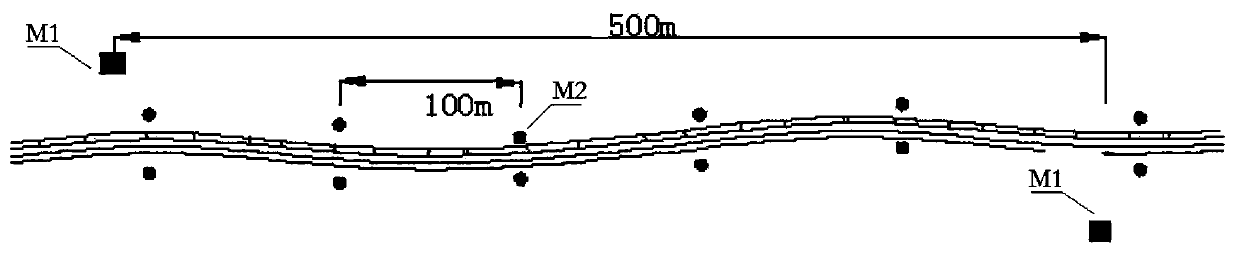

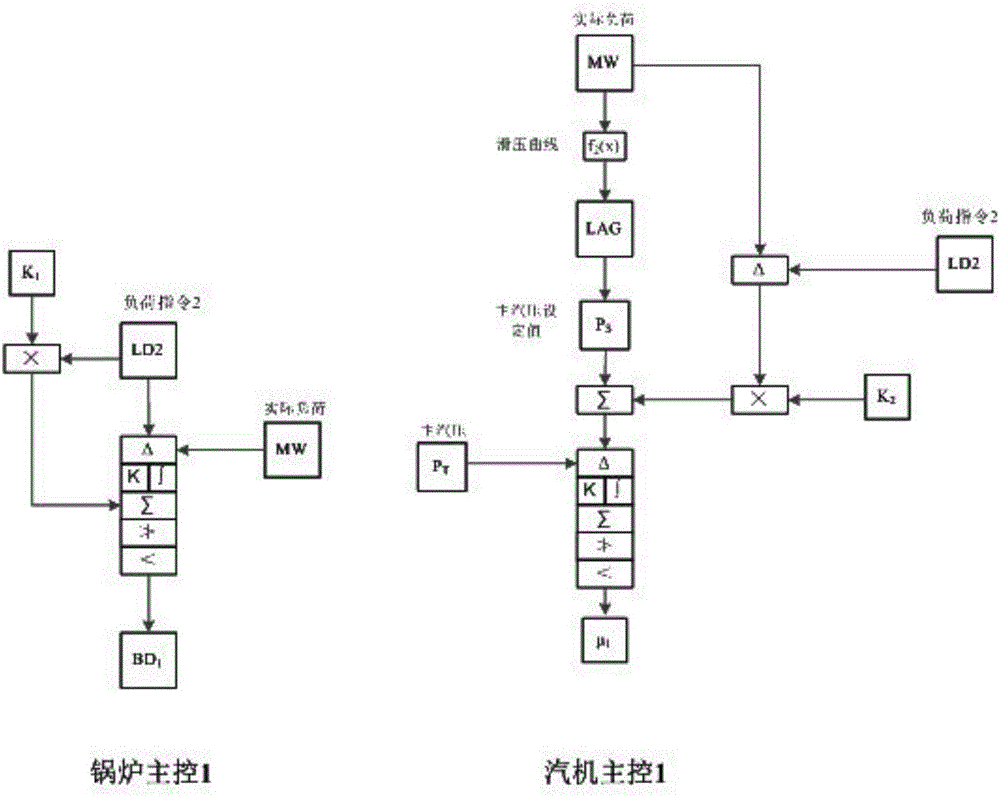

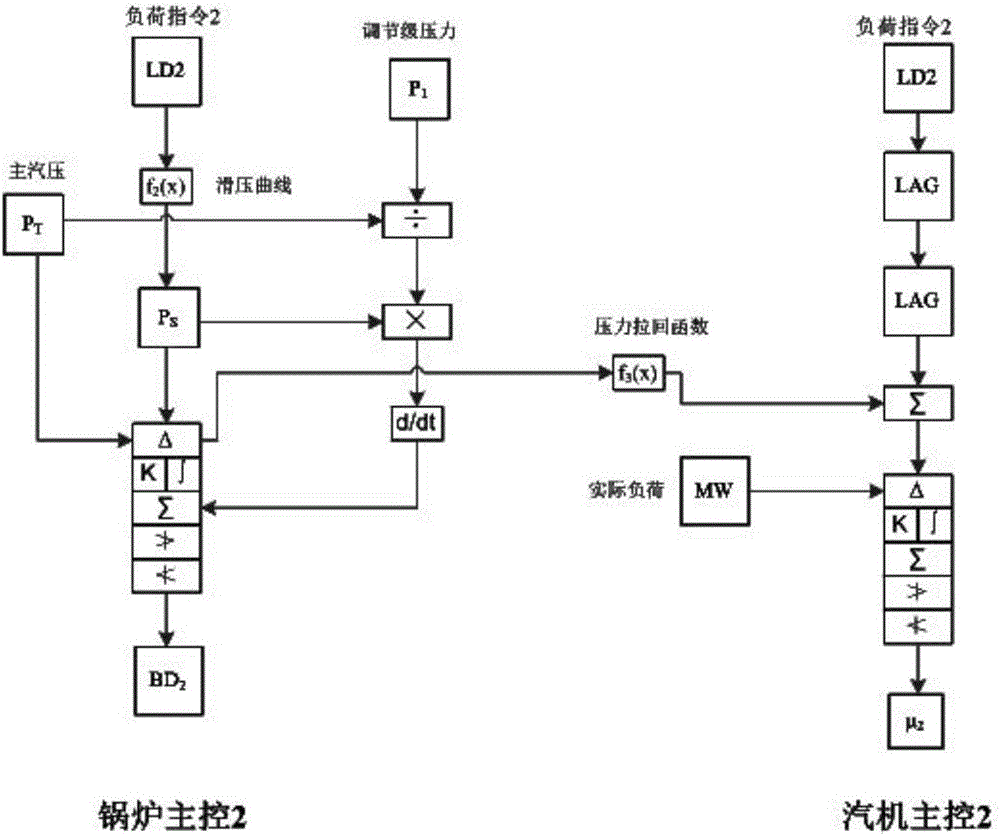

Whole-course load control method for supercritical direct current furnace

ActiveCN106224926AImprove automation control levelGuaranteed uptimeBoiler controlMachines/enginesLoad instructionEngineering

The invention relates to a whole-course load control method for a supercritical direct current furnace. The method mainly includes the steps that a load processing center generates load instructions; a boiler main control instruction BD and a steam turbine main control instruction mu are generated according to boiler main control instructions BD1, BD2 and BD3 and steam turbine main control instructions mu1, mu2 and mu3 generated by the load at the three phases of 0%-30% Pe, 30%-60% Pe and 60%-100% Pe through instruction optimization selection; and then the BD is fed into a fuel main control device, the mu is fed into a DEH for regulation control, and whole-course load control of the supercritical direct current furnace is achieved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

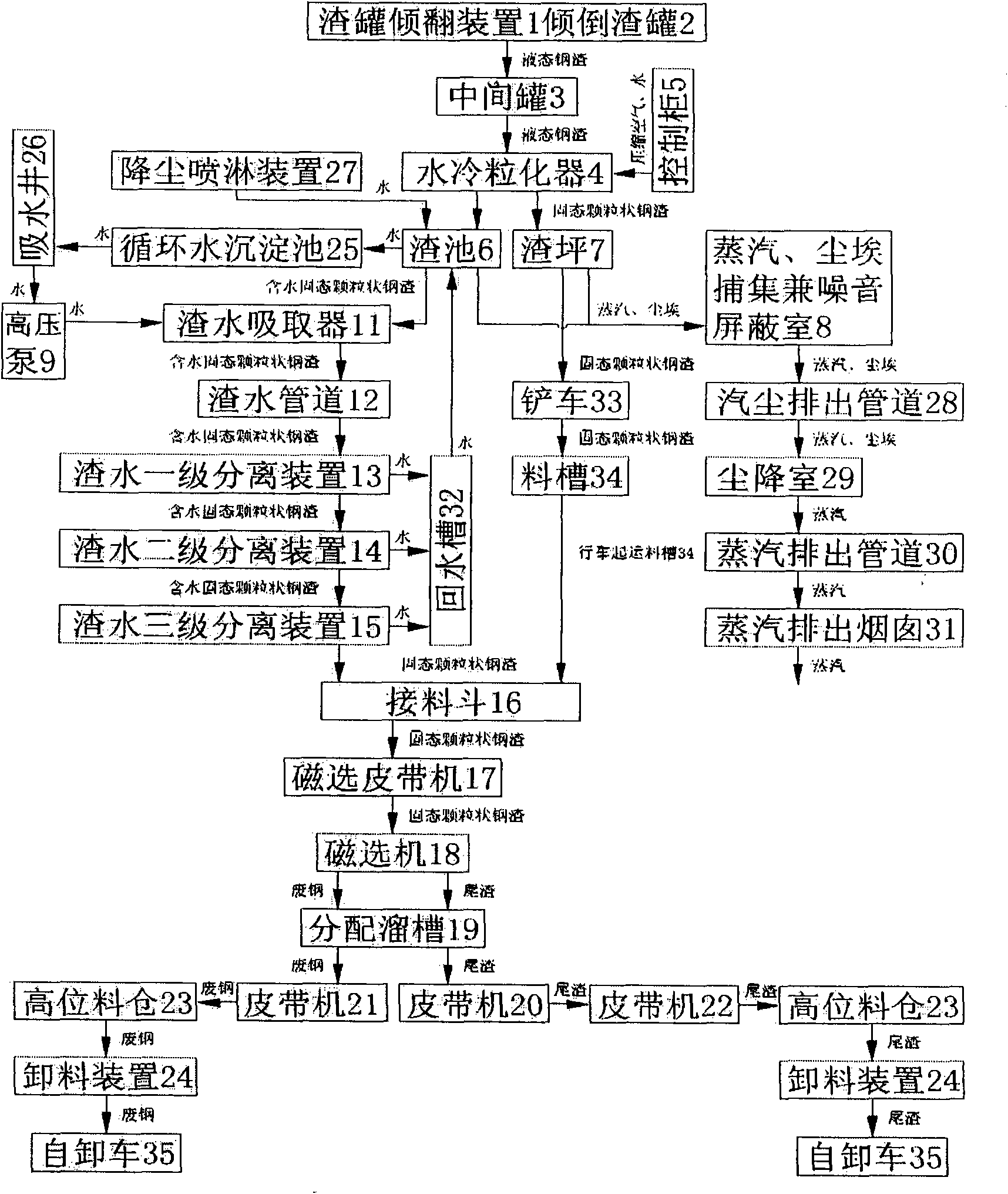

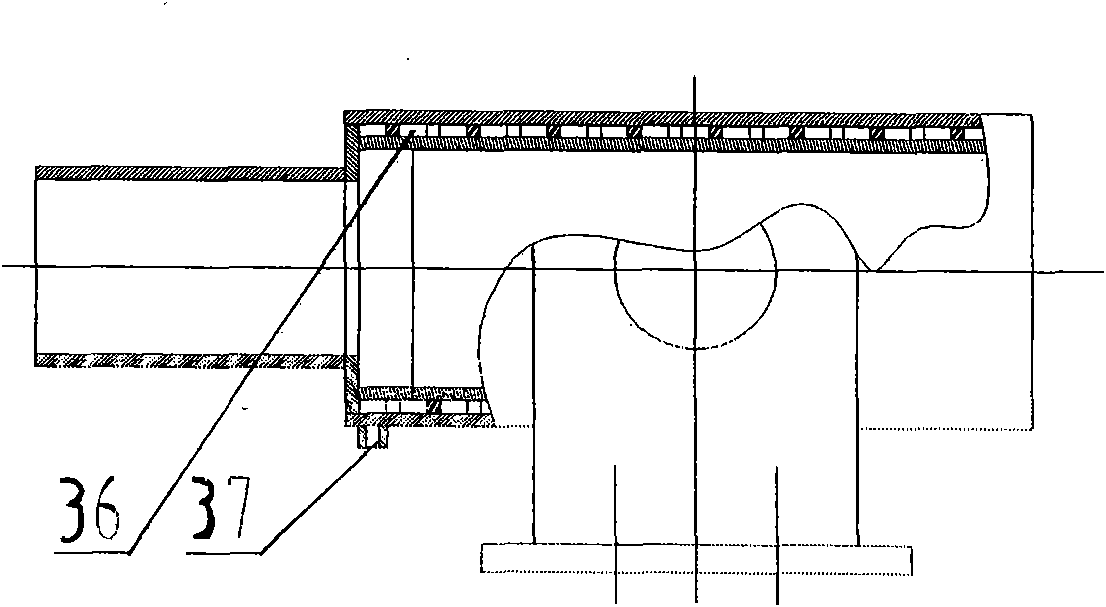

Steel slag wind-crushing system

InactiveCN101538622ATake advantage ofLow running costRecycling and recovery technologiesSlagWater cycling

The invention relates to a steel slag wind-crushing system which belongs to the steel slag treatment and is characterized in that a slag water sucking and separating device is arranged between a slag tank in a slag pretreating device and a magnetic separation belt in a slag separating device, wherein the slag water sucking and separating device mainly comprises a slag water sucker, a slag water pipeline, a slag water primary separating device, a slag water secondary separating device and a slag water third-stage separating device, a water return tank is arranged between the slag water primary separating device, the slag water secondary separating device and the slag water third-stage separating device and the slag tank; the outer side of a slag place is provided with a water circulating device, the water circulating device comprises a circulating water sedimentation tank, an absorbing well and a high-pressure pump which are sequentially connected, the high pressure pump is connected with the slag water sucker through a pipe, the periphery of a water-cooling granulator is additionally provided with a water-cooling sleeve and a water inlet pipe, a steam and dust collector of a dust-laying spraying device and a noise shielding chamber are arranged above the slag place of the slag tank, and the shielding chamber is externally provided with a steam and dust discharging pipe, a dust-laying chamber, a steam discharging pipeline and a steam discharging chimney which are sequentially connected. The invention treats the slag on-line so as to effectively utilize the resource, lowers the cost and reduces the consumption, saves the energy and reduces the emission, thereby meeting the environmental-friendly requirement.

Owner:马钢设计研究院有限责任公司

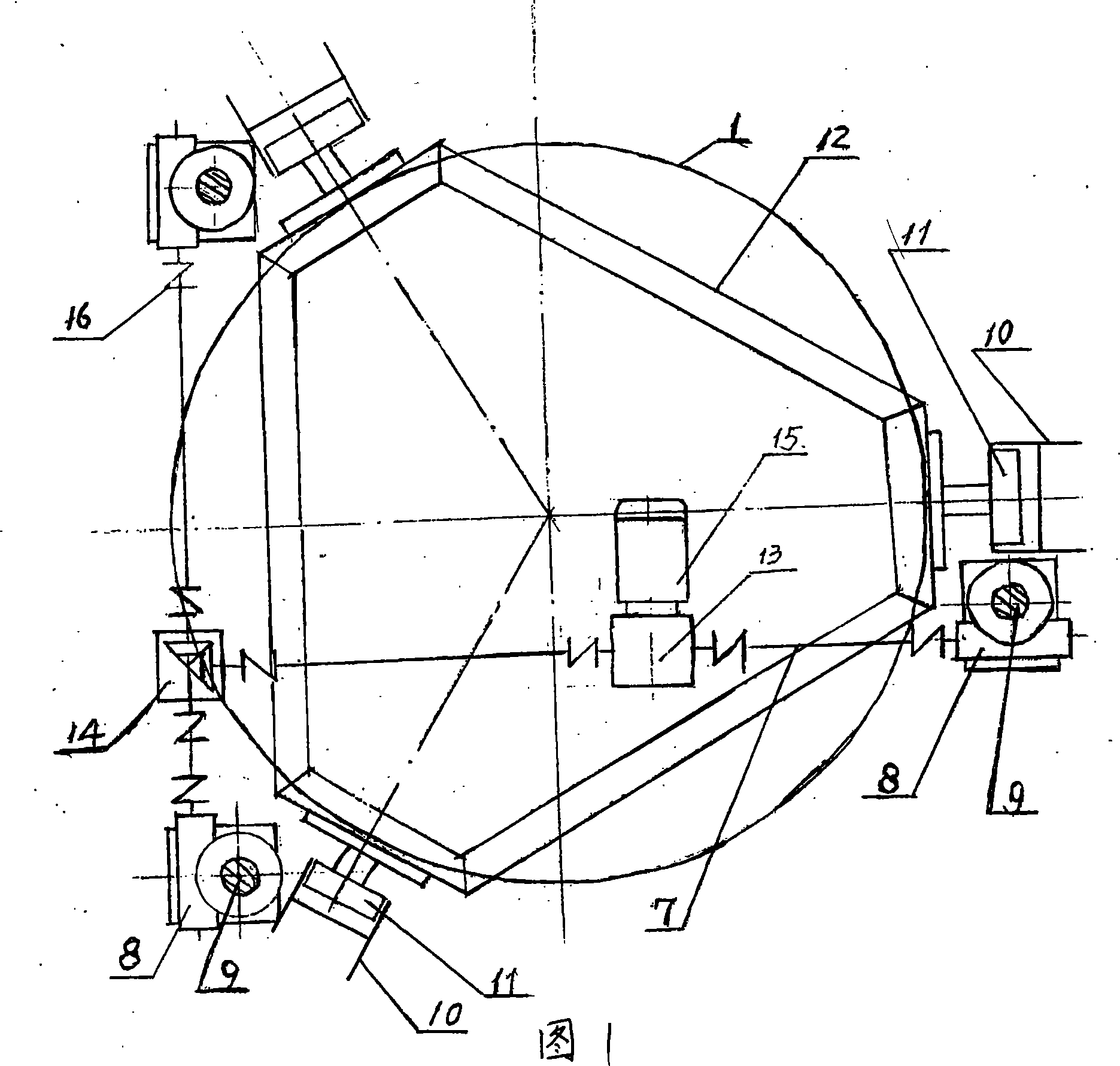

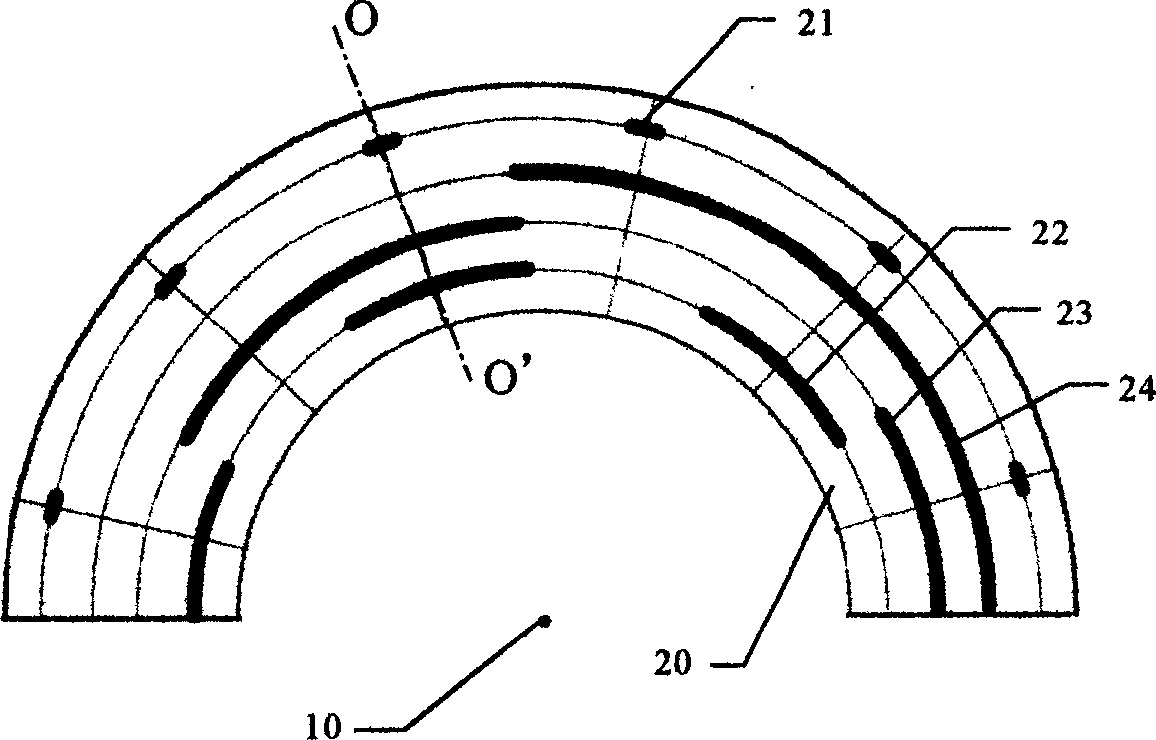

Dry transformer coil vertical coiling machine

ActiveCN101162647ASynchronized and smooth vertical liftGuaranteed rotation accuracySafety devices for lifting equipmentsMechanical energy handlingWinding machineTransformer

The invention relates to a big slewing ring bearing three guide post worm gear screw lifting vertical type coil winding machine, comprising a lifting system and a winding slewing system connected with the lifting system, wherein the lifting system comprises a lifting base, three or four worm gear screw lifters which are fixed on the lifting base and move on the lead screws, and a lifting driving device which drives the worm gear screw lifters to lift; the winding system comprises a slewing face plate connected with the lifting base by the big slewing ring bearing, a big gear fixed on the lower part of the slewing face plate, a small gear meshed with the big gear, a slewing reducer and a variable frequency main motor; the slewing reducer and the variable frequency main motor are directly connected with the small gear. The invention has the advantages of high efficiency, multifunction, stable running, high automatization control level, easy operation, fault-free, correct number of turns of the coiling and low manufacturing cost, etc.

Owner:SHANDONG JULI ELECTRO MACHINERY

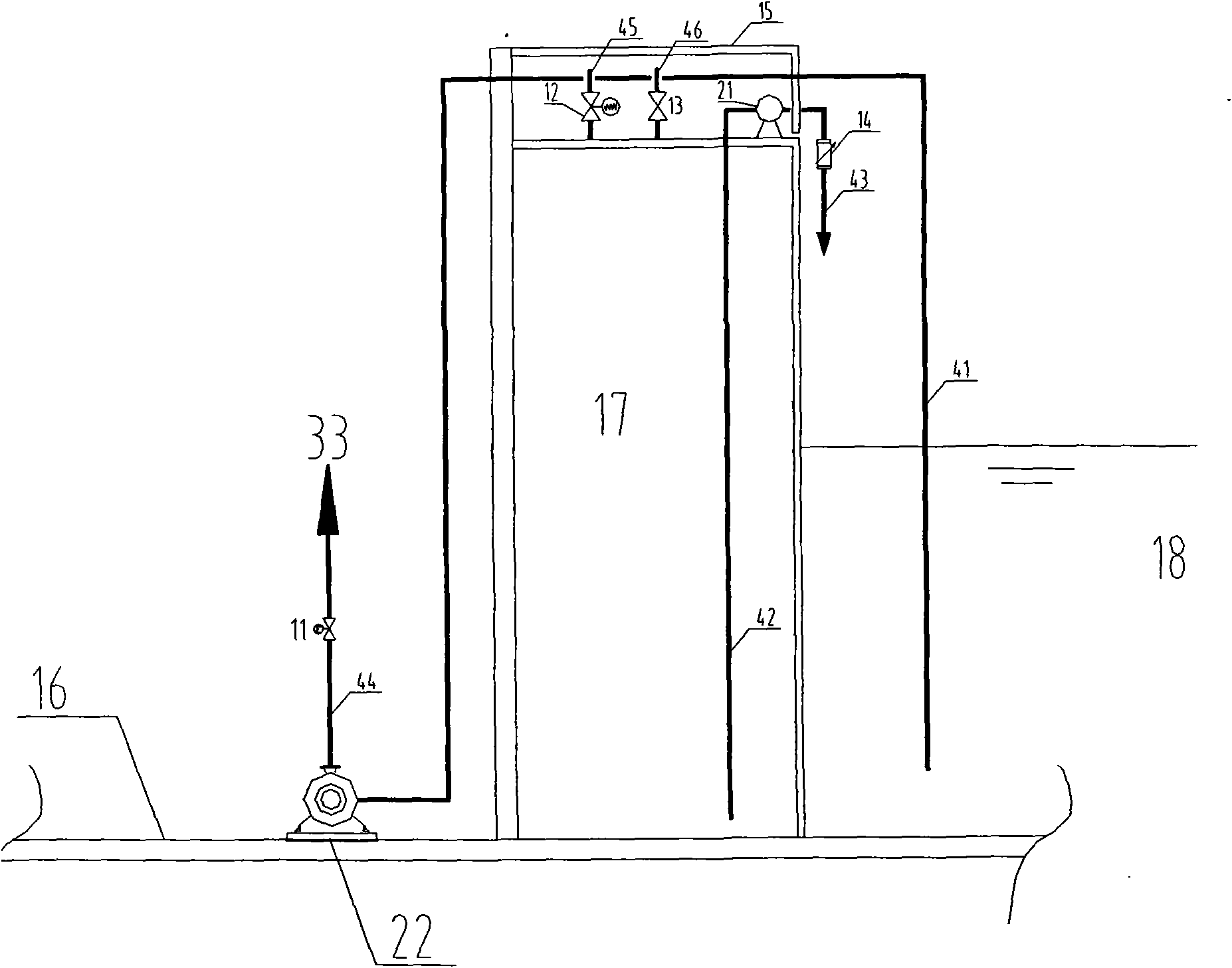

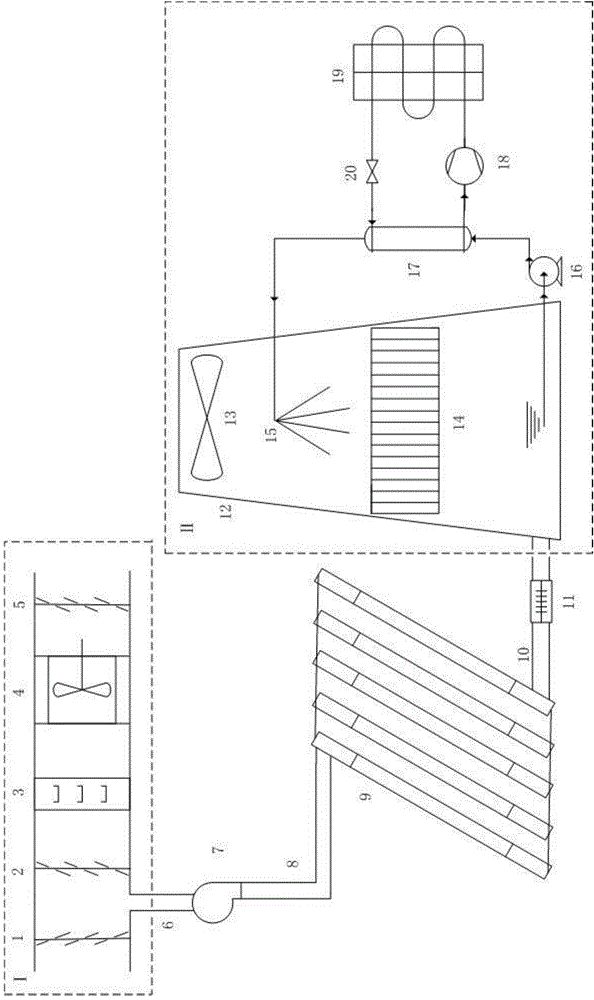

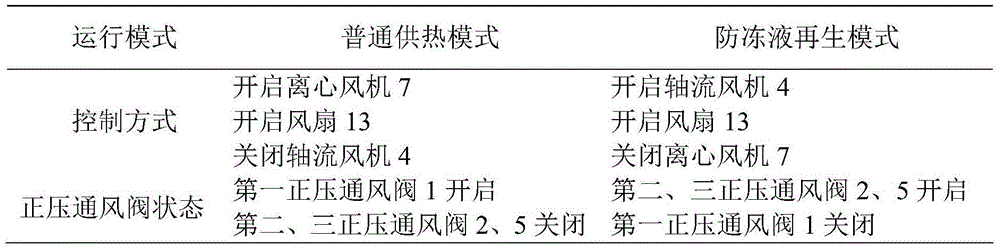

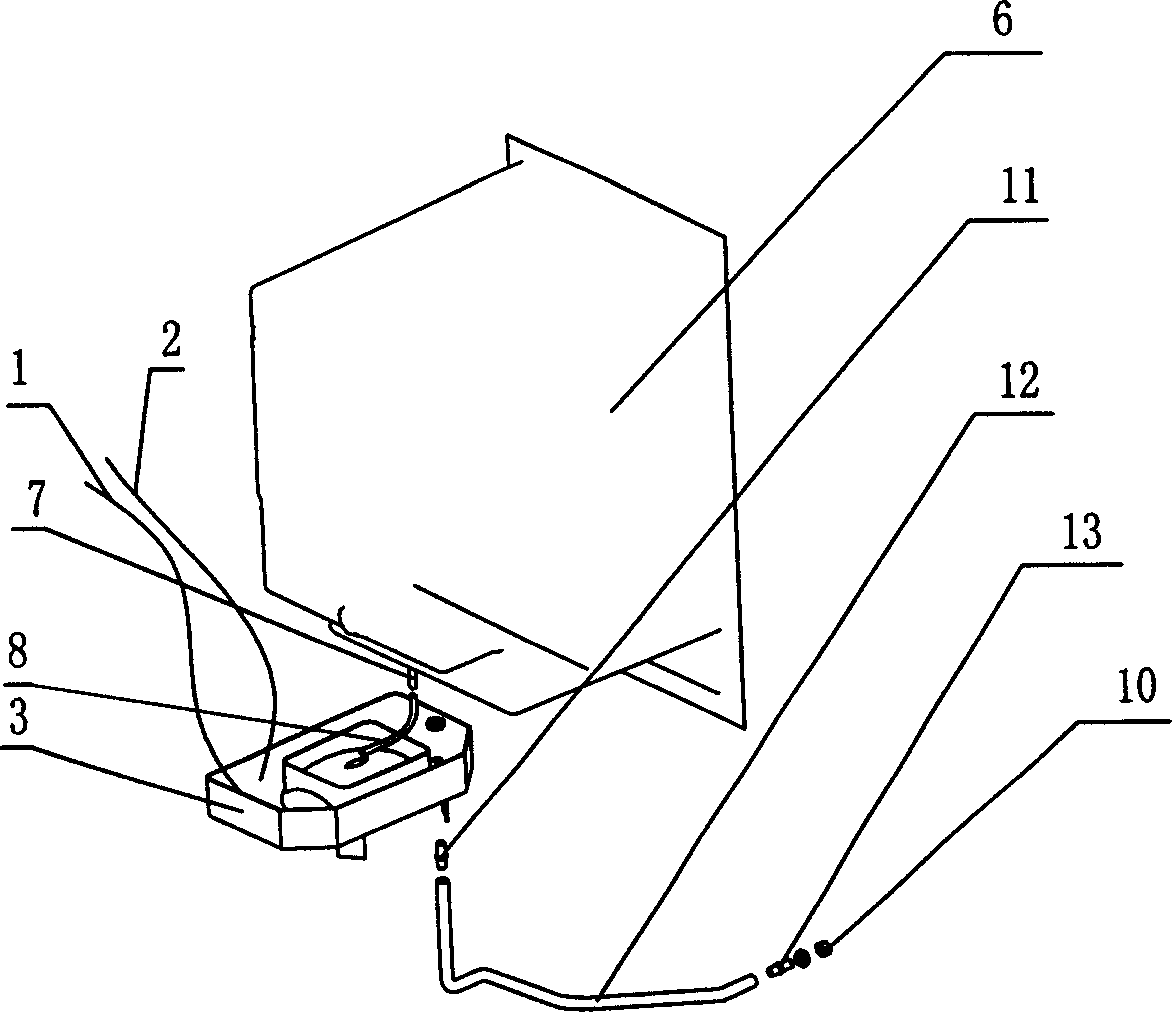

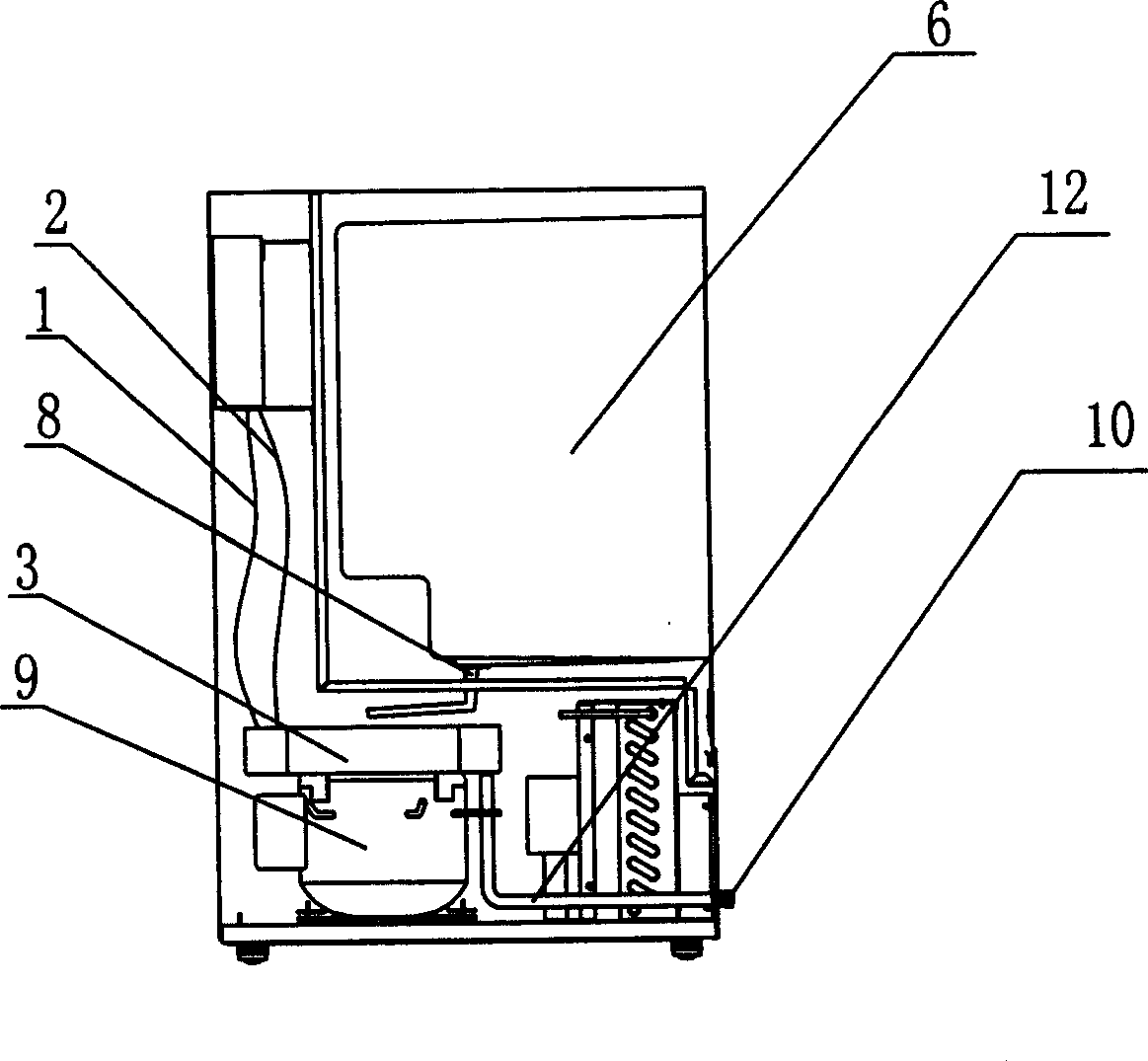

Solar-assisted real-time regeneration system for anti-freezing solution of open heat-source tower

ActiveCN104864736ASolving the practical problem of freezing point riseAchieve instant regenerationHeat recovery systemsSolar heat devicesEngineeringHeat pump

The invention discloses a solar-assisted real-time regeneration system for an anti-freezing solution of an open heat-source tower. The system comprises an air inlet pipe I, a centrifugal fan, a solar air heat collector and an open heat-source tower heat pump system II. The air inlet manner is controlled, the anti-freezing solution in the open heat-source tower can be regenerated, and problems that the concentration of the anti-freezing solution gradually decreases and the freezing point rises during operation of a heat pump of the open heat-source tower are solved; real-time regeneration of the anti-freezing solution is realized, the heat pump is not required to be shut down, and the continuity of heat supply of the heat pump of the open heat-source tower in winter is kept. The solar air heat collector is added in the system, so that sensible heat exchange between air and the anti-freezing solution can be improved. An air type solution regeneration manner is adopted, the requirement of regeneration of the anti-freezing solution for high-grade energy sources is met, and complex equipment is avoided. The solar-assisted real-time regeneration system for the anti-freezing solution is integrated on the basis of the open heat-source tower, renewable energy sources are fully utilized, and large-scale application of solar and heat-source tower heat pump technologies is promoted.

Owner:TIANJIN UNIV

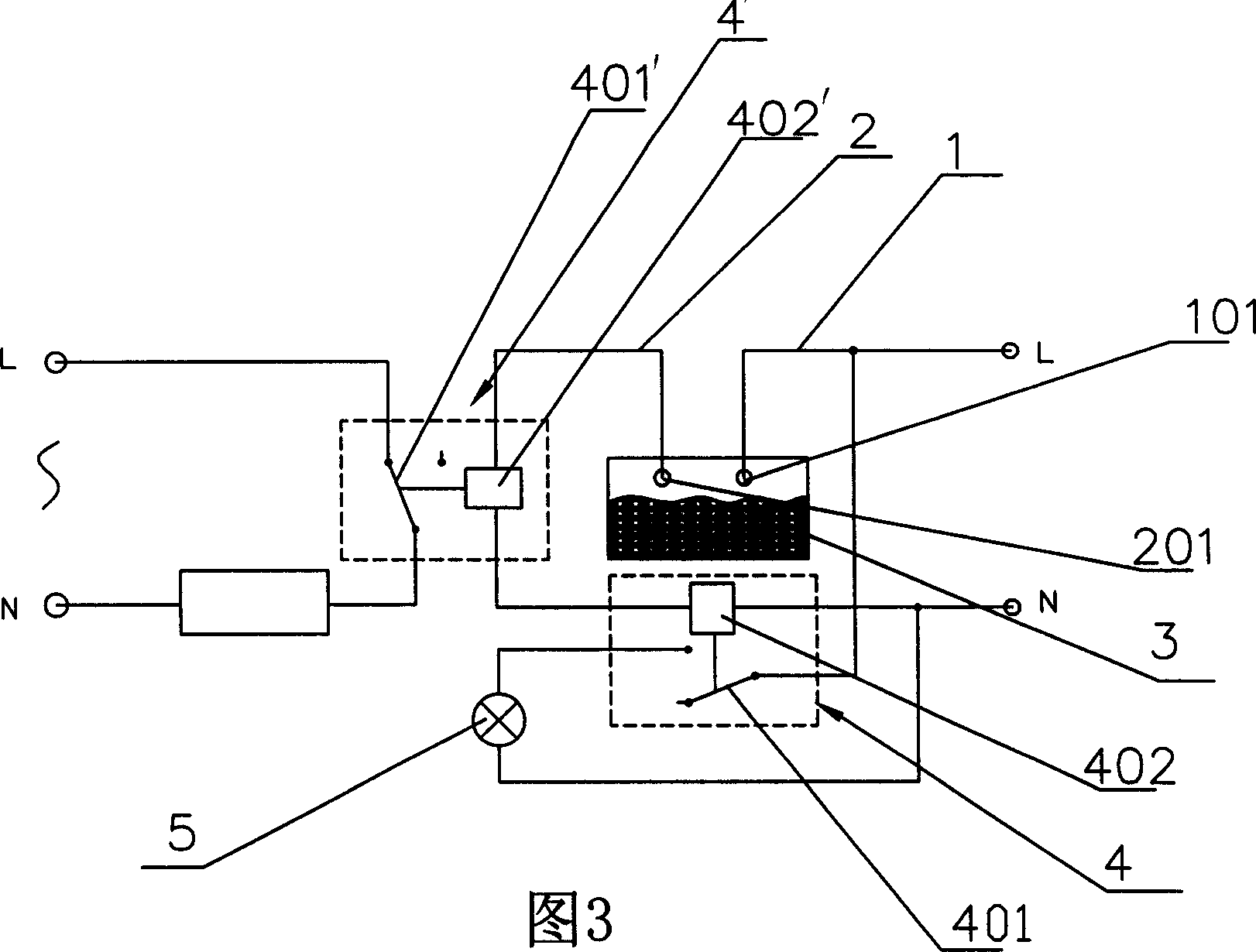

Water-receiving tray with alarm function

InactiveCN1677032AImprove automation control levelEasy to integrateLighting and heating apparatusAlarmsWater levelControl circuit

The invention discloses a defrosting tray acquiring alarming function. Above tray is set with limit water level survey warning circuit which comprises constant-current power source, water level survey and control circuit and warning circuit with warning components. The water level survey and control circuit switches the circuit of alarming lines meanwhile controls the open and shut of the main set working circuit. It has the function that when the defrosting is full, the circuit auto shut off the main set till the water is discharged then recovers the system automatically.

Owner:青岛澳润商用设备有限公司

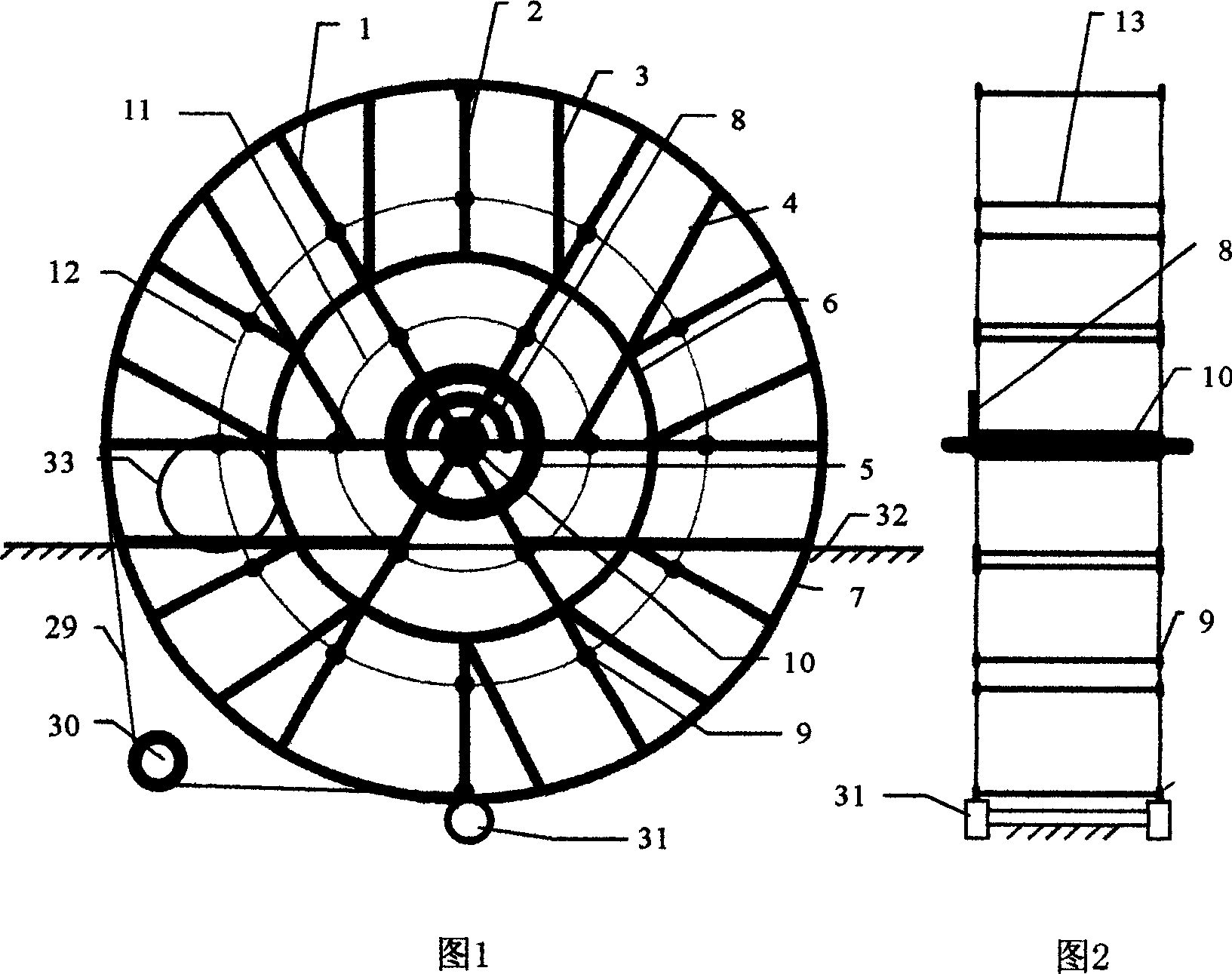

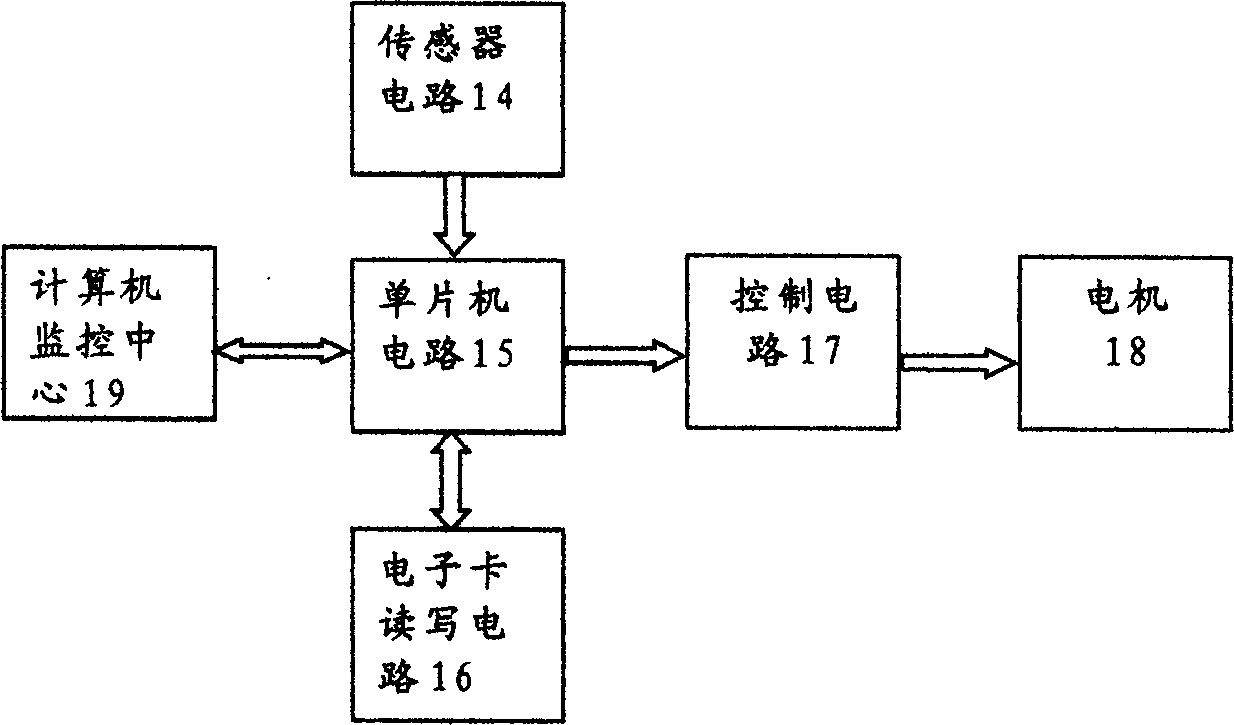

Vertical rotating-disk stereo garage and control system

InactiveCN1676828ASimple structureEven by forceComputer controlParkingsAutomatic controlControl system

A kind of turnplate type 3-D garage and its' control system, this is its' character: it comprises a upground and underground disc which is upright; there is the fix structure of the central axletree, the disc use the structure supported by steel framework. The parking point was hung on the bracket of the disc, so the parking point displaying symmetrically. There is coding disc go with the main disc in-phase, and just around the coding disc is the sensor which can feedback the circumrotative angle. The sensor couplings with the coding disc, and sends the digital signal to the SCM, enables kinetic system automatically control the turnplate, and a reasonable layout, and secure function.

Owner:LUOYANG NORMAL UNIV

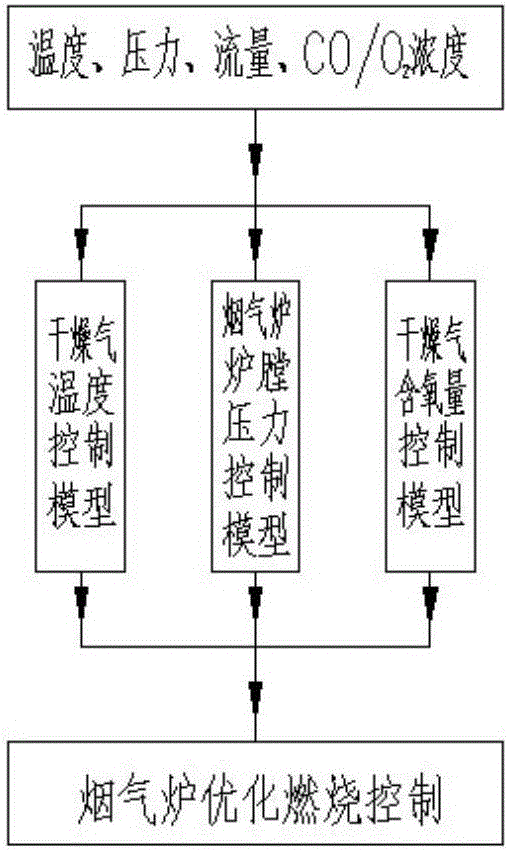

Method for controlling full-automatic optimization burning furnace of blast furnace coal injection system flue gas furnace

ActiveCN106839746AIndicators fluctuate greatlyReduce labor intensityDrying gas arrangementsBlast furnace detailsAutomatic controlAir temperature

The invention relates to a method for controlling a full-automatic optimization burning furnace of a blast furnace coal injection system flue gas furnace. The method comprises a step S1 of establishing a model: respectively establishing a dry air temperature control model, a flue gas furnace hearth pressure control model and a dry air oxygen content control model; a step S2 of performing parameter adjustment: adjusting medium temperature, pressure, flow, CO concentration and O2 concentration through the three models in the step S1, and respectively controlling dry air temperature, flue gas furnace hearth pressure and dry air oxygen content. The method has the advantages that the flue gas furnace runs under an optimum working condition through full-automatic burning furnace optimization and precise control over the flue gas furnace, index fluctuation in the flue gas furnace burning and control system is high, it is guaranteed that a system performs production stably, and a negative impact caused by manual operation is eliminated; in addition, the method not only can improve automatic control level, but also can greatly reduce operators' labor intensity and improve production efficiency.

Owner:CISDI ENG CO LTD

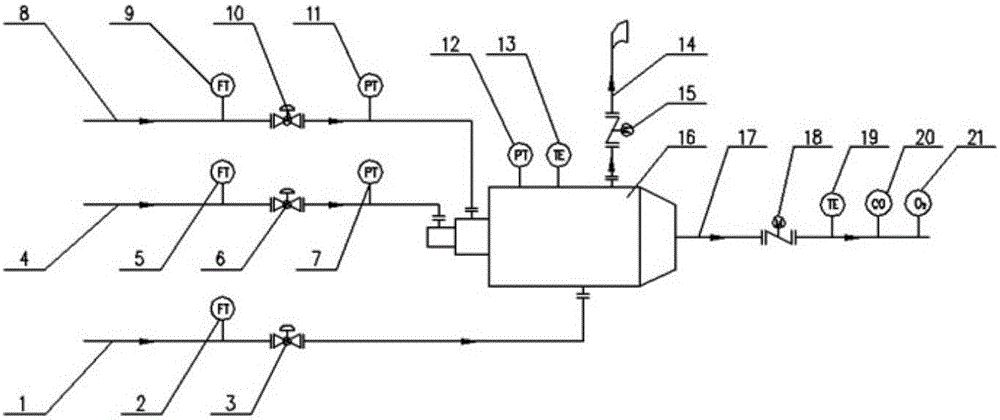

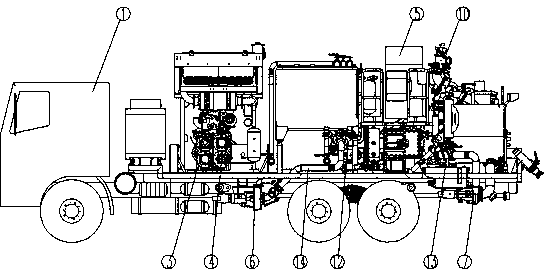

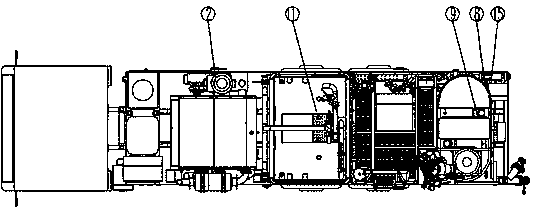

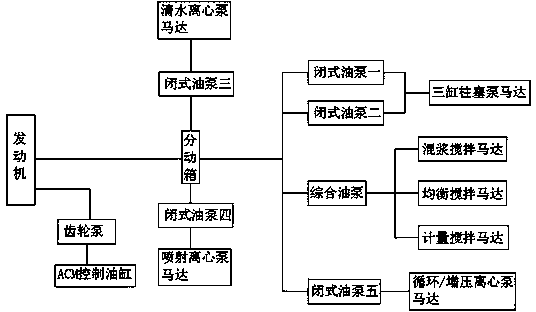

All-hydraulic well cementing truck

InactiveCN104005730AReduce volumeIncrease output powerItem transportation vehiclesSealing/packingHydraulic motorWell cementing

The invention belongs to the technical field of petroleum drill and exploitation, relates to a key device for well cementation operation, and in particular relates to an all-hydraulic well cementing truck. The all-hydraulic well cementing truck is characterized in that a ride engine is taken as a power source and a hydraulic system is used for driving a hydraulic motor so as to drive devices such as a high-pressure plunger pump to act. Compared with a traditional well cementing truck utilizing the ride engine and a torque converter as main power outputs, the all-hydraulic well cementing truck is simple in structure, more flexible in overall layout, novel and reasonable in design, low in cost and simple to control, and the all-hydraulic well cementing truck is wider in output flow range because the high-pressure plunger pump is capable of realizing stepless speed change; the all-hydraulic well cementing truck is capable of meeting the requirements of various different operations.

Owner:四机赛瓦石油钻采设备有限公司

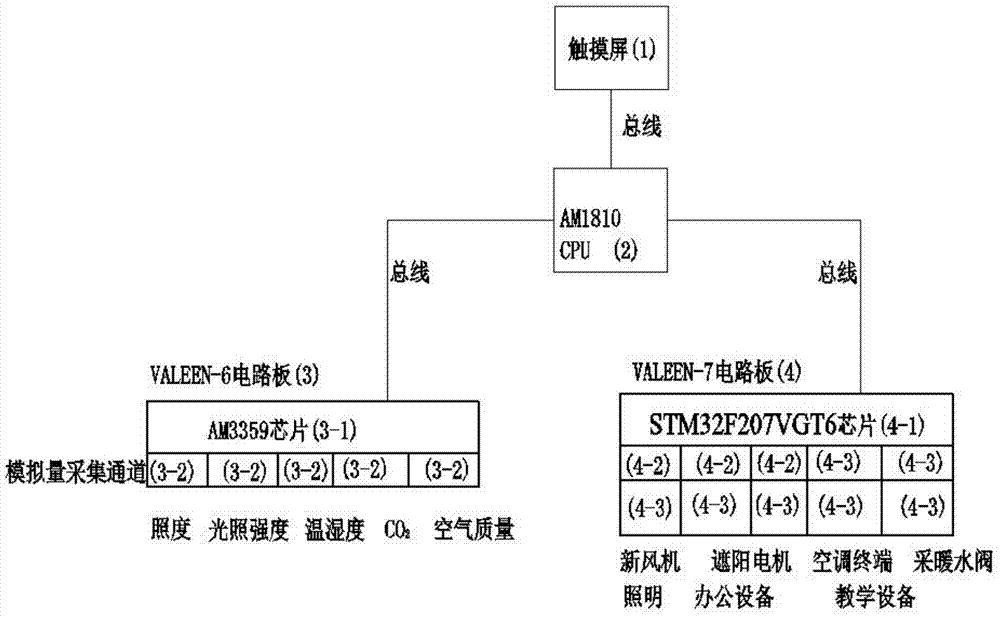

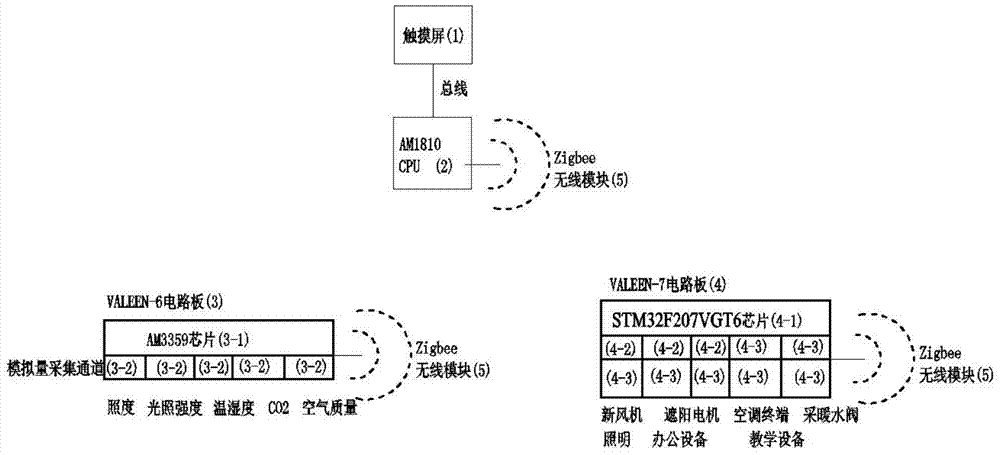

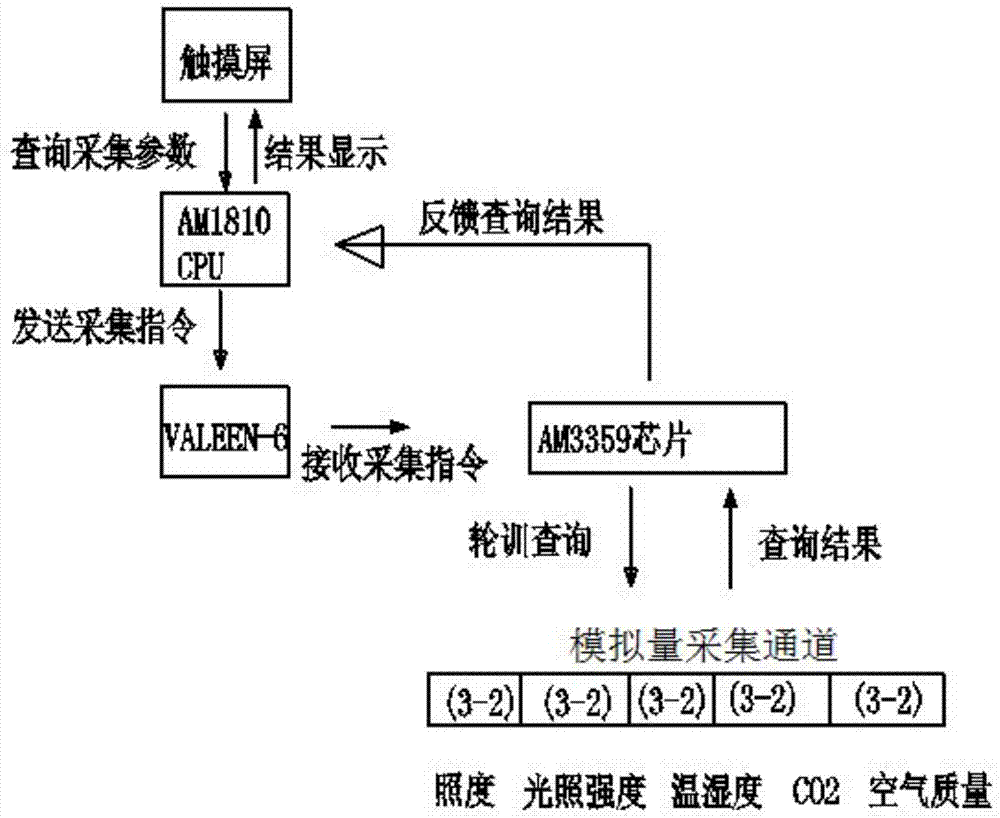

Teaching office environment comprehensive energy-saving control device based on dynamic thermal comfort

InactiveCN103941656AImprove automation control levelReduce communication control conversion processProgramme total factory controlClose rangeDevice parameters

The invention relates to a teaching office environment comprehensive energy-saving control device based on dynamic thermal comfort and belongs to the technical field of green intelligent buildings. Through acquisition of parameters such as air temperature and humidity, carbon dioxide concentration, illuminance and irradiance and the like in classrooms and offices, an indoor environment state is displayed through a man-machine interactive touch screen panel and an AM1810CPU model calculates a thermal comfort optimal effect so that air-conditioning, fresh-air, illuminating, heating and sunshading device parameters are adjusted and office devices are controlled so that while indoor air quality and environment quality are ensured, device power consumption is reduced at the same time; and at the same time, the teaching office environment comprehensive energy-saving control device is high integration degree and a plurality of kinds of sensors and actuators form three parts of intelligent control, environment monitoring and adjusting execution and a communication transportation method which combines bus and close-range wireless transmission is adopted so that construction wiring difficulties are reduced and effects on decoration are reduced and the device is suitable for being popularized in an existing building reconstruction project.

Owner:BEIJING VALEEN LEADING GREEN BUILDING TECH

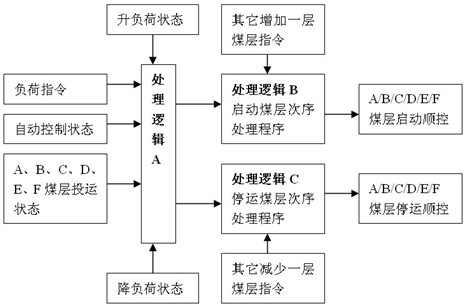

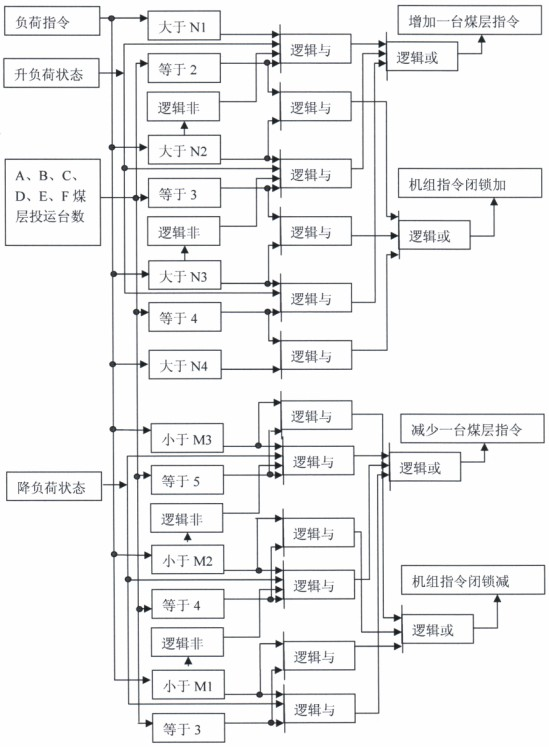

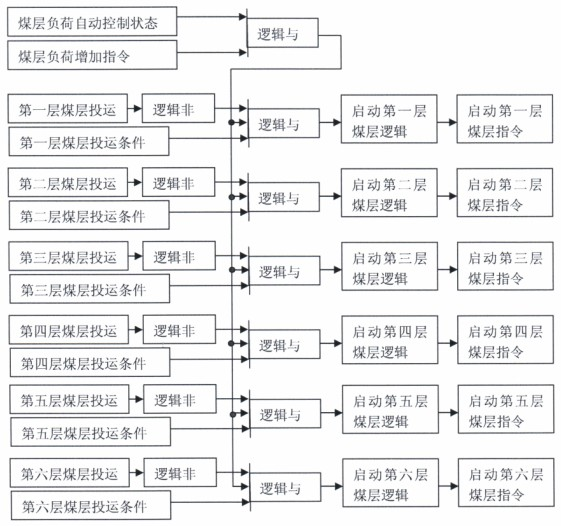

Automatic control system of coal bed loads of thermal power generating unit

ActiveCN102323798AImprove automation control levelAccelerateTotal factory controlProgramme total factory controlAutomatic controlAutomatic train control

The invention provides an automatic control system of coal bed loads of a thermal power generating unit. The automatic control system comprises six layers of coal beds, a processing module, a coal bed commissioning sequence module and a coal bed decommissioning sequence module and is characterized in that: in a loading-up process, the processing module is used for commissioning the coal beds in sequence according to five load sections; and in a loading-down process, the processing module is used for decommissioning the coal beds in sequence through three load sections. According to the automatic control system, the automation control level of coordination control can be greatly increased, the loading-up speed and the loading-down speed are accelerated, human misoperation is reduced, the safety is improved, and a foundation is laid for unit-level automatic control.

Owner:SHANGHAI POWER EQUIP RES INST

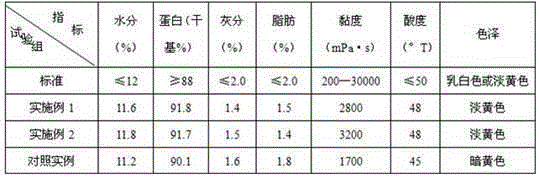

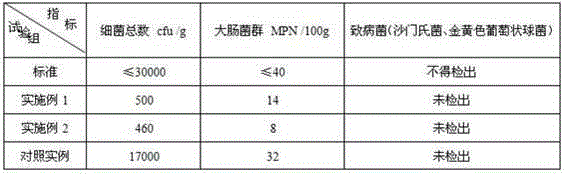

Method for producing casein through dry sterilization

InactiveCN105315358AEfficient killingLess investmentPeptide preparation methodsAnimals/human peptidesMilk SerumSodium metabisulfite

The invention discloses a method for producing casein through dry sterilization. The method comprises the following steps: putting Qula into a dissolving vat, adding an auxiliary material, dissolving while the pH value is kept to be 9.5-10.0, filtering, performing centrifugal degreasing, regulating the feed liquid temperature to be 40 DEG C after degreasing, adding sodium hydrosulfite, sodium sulfite and sodium pyrosulfite, performing precipitation on casein through the diluted hydrochloric acid with the Baume density of 4.5, regulating the feed liquid pH to be 4.4-4.6 to enable the casein to be fully precipitated, and removing milk serum to obtain a precipitate; washing the precipitate with lukewarm water, dehydrating through plate frame pressure filtration and extrusion, performing material pelletization through a screen mesh, drying, pulverizing the pelletized and dried material, conveying the pulverized material to a material mixing bin, and fully sterilizing the material in the material mixing bin through ozone. According to the method, sterilization is realized by introducing ozone during the packaging link of casein production, so that microbes can be effectively killed; the operation is run in a dry environment and equipment is simple, so that equipment investment can be reduced, the product quality is stabilized, the automatic control level is improved, water and electricity consumption is reduced, and human resources are saved.

Owner:GANSU PULUO BIOTECH

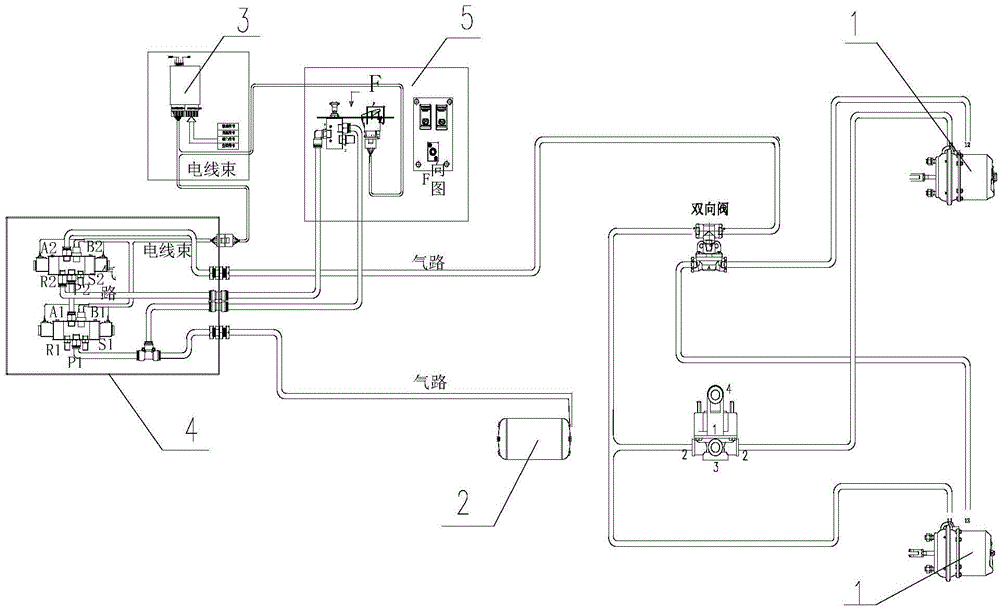

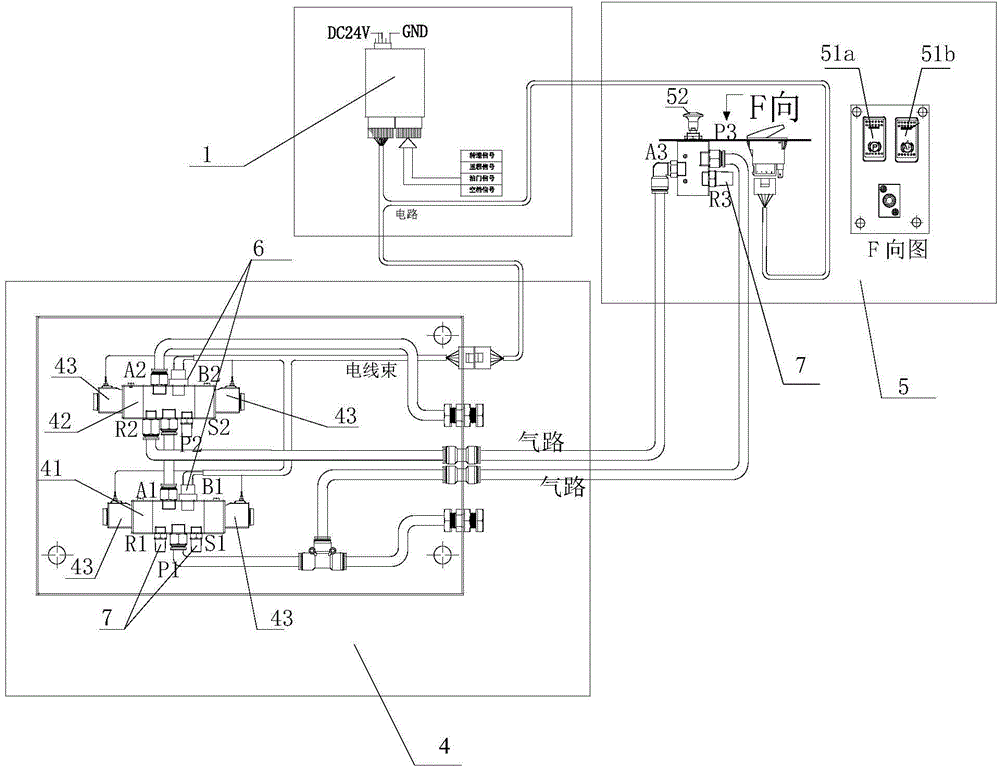

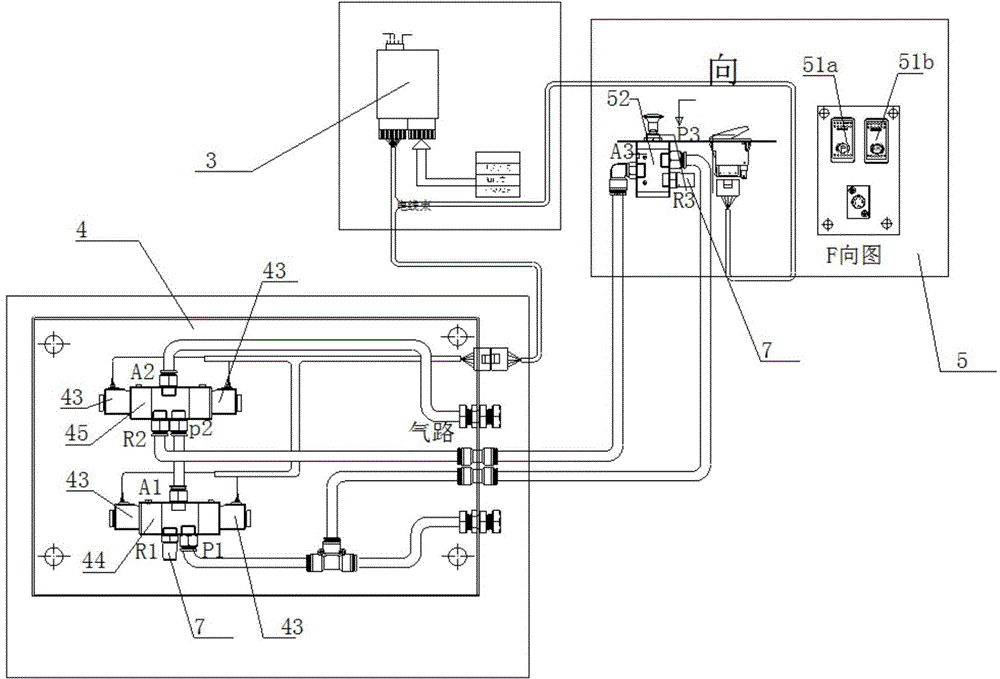

Automatic parking system and method based on pneumatic braking

ActiveCN104590225AReduce work intensityImprove securityBraking action transmissionAutomatic initiationsAutomatic controlCAN bus

The invention relates to an automatic parking system and method based on pneumatic braking. The system comprises a hand braking air chamber, a hand braking air cylinder, an ECU controller, an air path control assembly and a mode conversion control assembly. The hand braking air chamber is connected with the air path control assembly. The input end of the ECU controller is connected with an automobile conversional circuit or a CAN bus module, and receives engine rotating speed signals, mileage signals, accelerator signals and gear signals. The output end of the ECU controller is connected with the air path control assembly and the mode conversion control assembly through wiring harnesses respectively. The air path control assembly is connected with the ECU controller through a wiring harness. The air path control assembly is connected with the hand barking air chamber and the hand braking air cylinder through air pipes respectively. The mode conversion control assembly is connected with the air path control assembly through an air pipe. According to the automatic parking system and method based on pneumatic braking, the actions are automatic and intelligent, the automatic control level of the whole vehicle is effectively improved, and the traveling and parking safety is greatly improved.

Owner:扬州市奥特瑞汽车电子科技有限公司

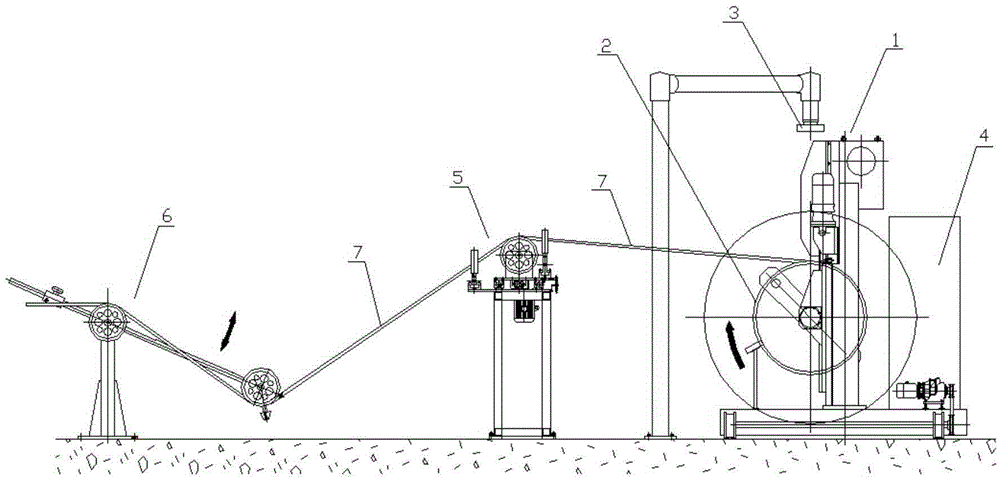

Novel automatic deviation correction and cable arranging system based on industrial camera visual image processing

InactiveCN105384003AImprove automation control levelReduce investmentFilament handlingImaging processingAutomatic control

The invention discloses a novel automatic deviation correction and cable arranging system based on industrial camera visual image processing. The system comprises a self-propelled portal crane and an industrial camera. The industrial camera is fixedly installed on the ground on one side of the self-propelled portal crane through a support. A lens of the industrial camera is aligned with a reeling cable disc. The industrial camera is connected with a control system through a wire, wherein the control system is fixed to the ground on the other side of the self-propelled portal crane. The phenomena that under the conditions that a deformation cable disc and a cable disc with irregular cable intervals are used, cables are arranged in a disorderly manner and stacked, and the cable arranging process and the reversing point switching process need manual intervention are reduced, the automatic deviation correction function is achieved in the cable arranging process, the automatic control level of a cable reeling and arranging equipment system is increased, production efficiency is improved, manpower resource input is reduced, and production and labor intensity is relieved.

Owner:8TH RES INST OF CETC

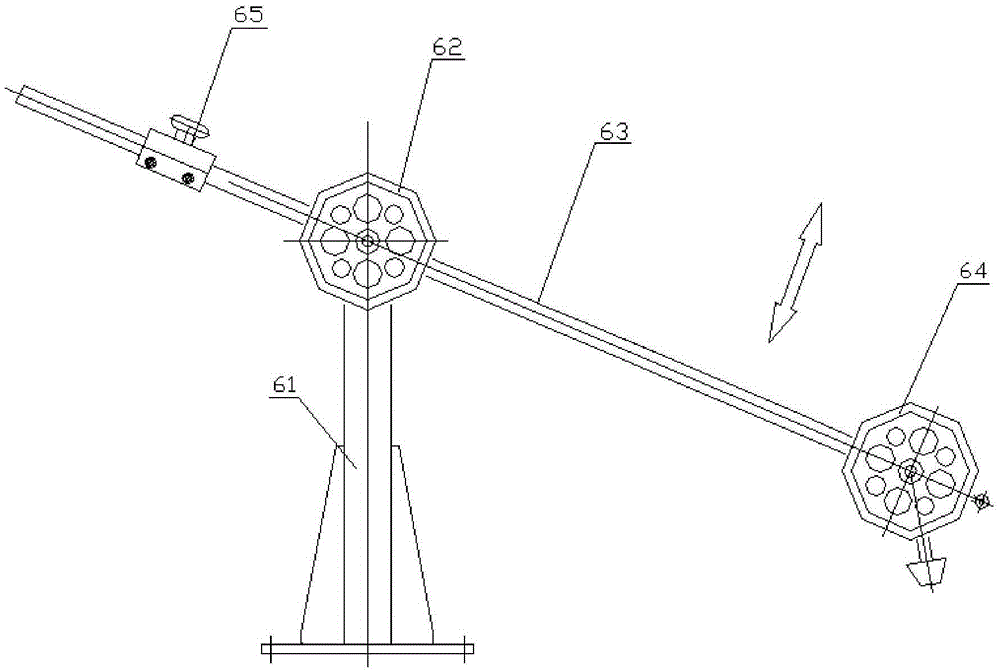

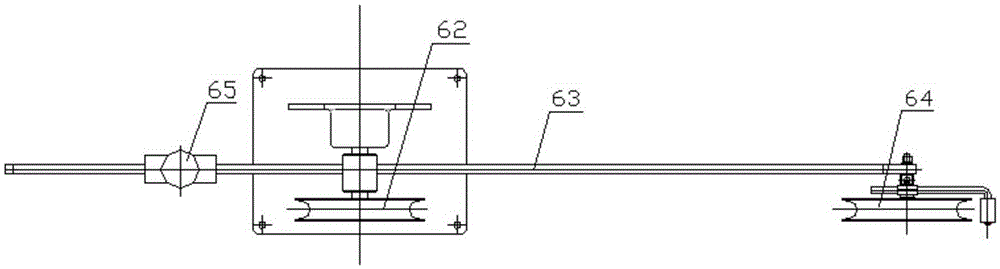

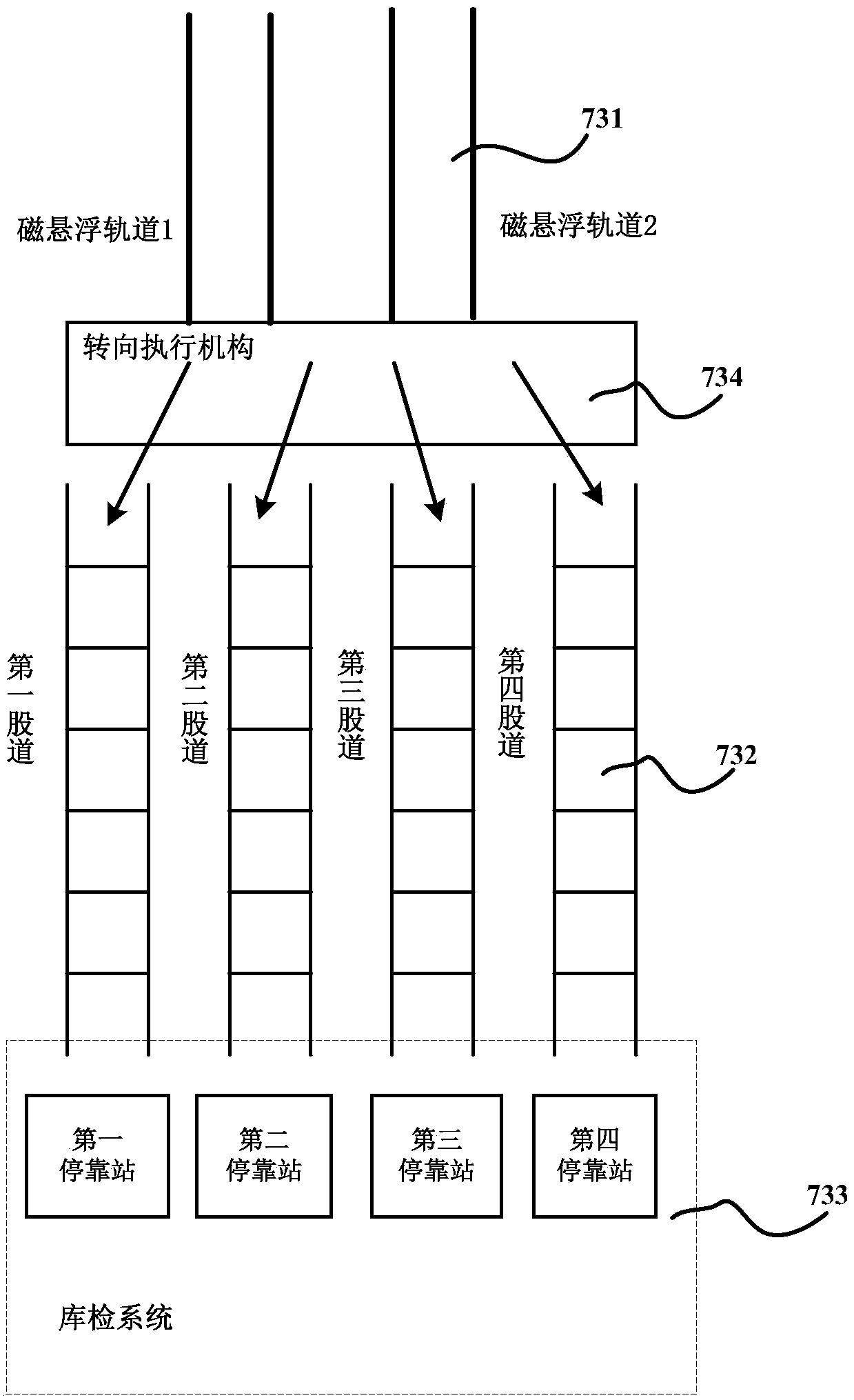

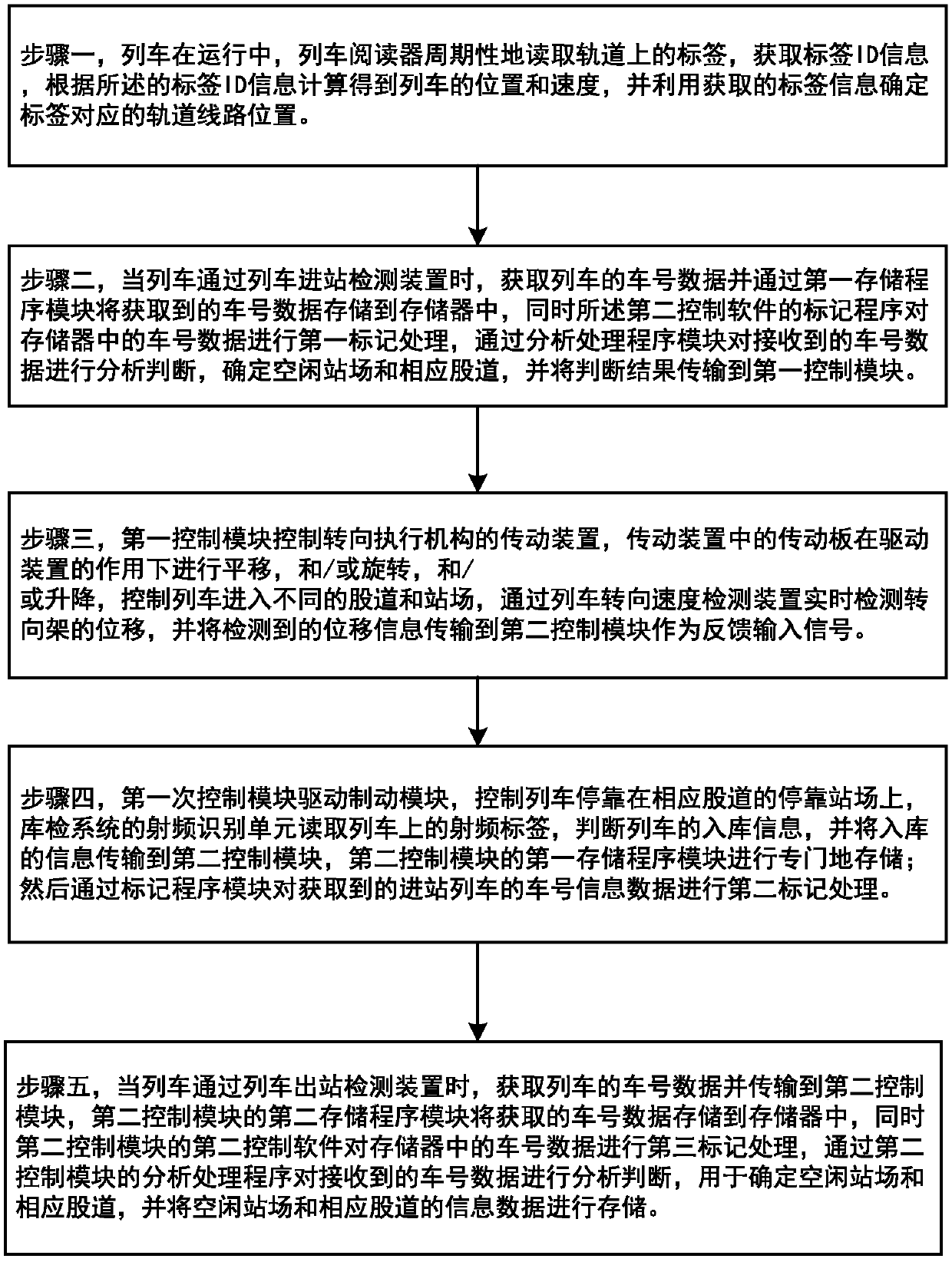

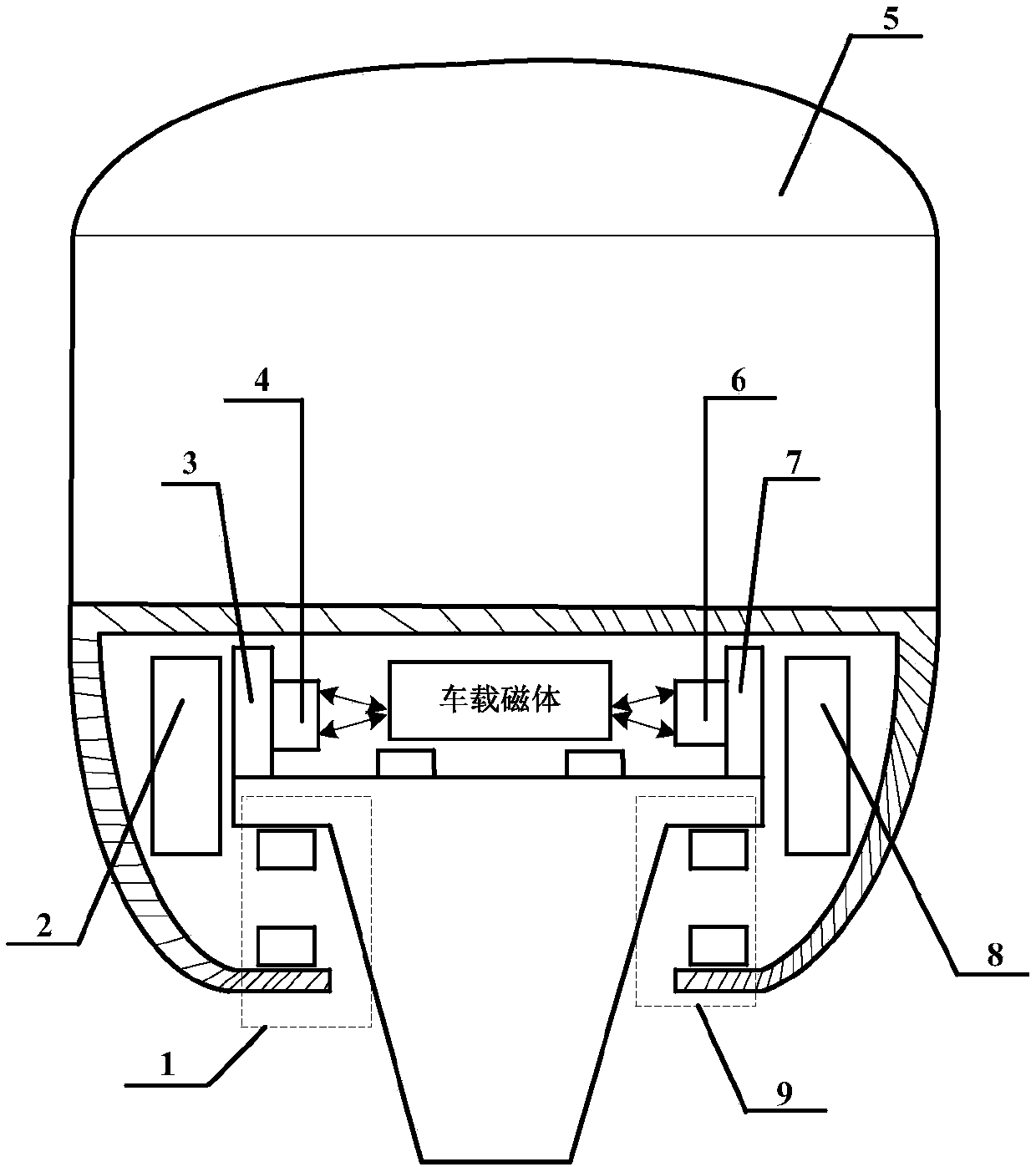

Automatic stopping control system and automatic stopping control method for train station

ActiveCN107933572AImprove automation control levelNo manual adjustment requiredSliding/levitation railway systemsRoute devices for controlling vehiclesInterference resistanceControl system

The invention discloses an automatic stopping control system and an automatic stopping control method for a train station. The system comprises a first control module and a second control module, wherein the first control module is used for controlling the running state of a train, and the second control module is used for controlling the train to enter the station or leave the station. The methodcomprises the steps of determining the position of a track line, judging and processing train occupation, performing data marking, storage and steering control, and the like. The automatic stopping control system and the automatic stopping control method disclosed by the invention have the advantages that automatic stopping station identification and automatic entering and leaving statistics of amagnetic suspension train are realized, artificial regulation and control are not needed, the data processing efficiency and the program design reliability are improved, the steering control on the train is more flexible and reliable, and the whole interference resistance of the system is good.

Owner:成都天府轨谷科技有限公司

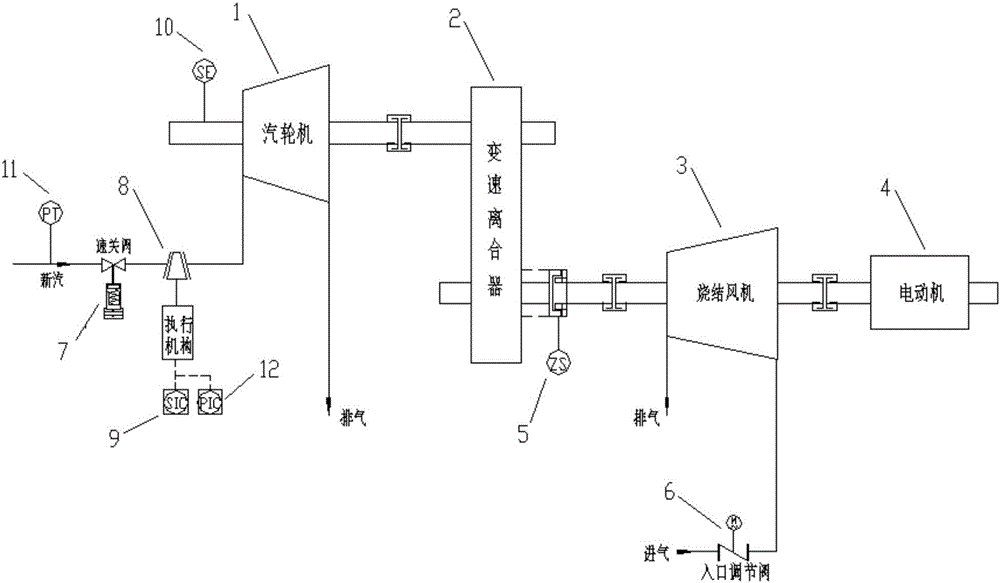

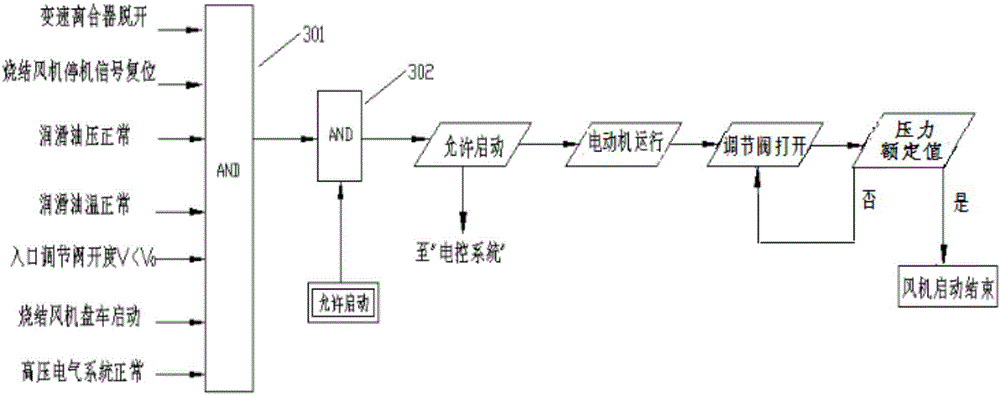

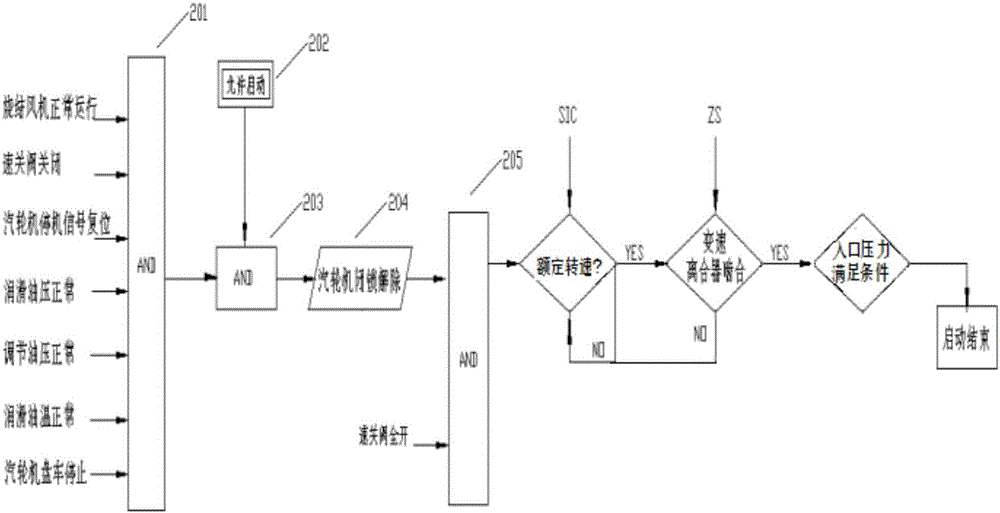

Full-automatic starting system and method for sintering waste heat recycling and sintering draught fan combined unit

ActiveCN106403626AImprove automation control levelImprove advancedIncreasing energy efficiencyMachines/enginesStart timeEconomic benefits

The invention discloses a full-automatic starting system for a sintering waste heat recycling and sintering draught fan combined unit. The full-automatic starting system comprises a double-output-shaft sintering draught fan, a motor, a variable-speed clutch, a steam turbine, an inlet pressure transmitter, a fast closing valve, a rotating speed sensor, a rotating speed PID controller and a pressure PID controller. A full-automatic starting method includes the steps that firstly, the sintering draught fan is started; secondly, after the sintering draught fan runs normally, pressure of inlet steam of the steam turbine is detected; and thirdly, the steam turbine is started, a PLC system controls the opening degree of a main throttle valve so as to control the rotating speed of the unit till the inlet steam of the steam turbine reaches a proper condition. The full-automatic starting system and method achieve full-automatic one-button starting of the whole unit, the safety in the unit starting process is guaranteed, the starting time of the whole unit is greatly shortened and is shortened from 120 min to 90 min, and mistaken operation and possible losses in the operating process of manual unit starting are avoided. Meanwhile, conditions are provided for enterprises to save the labor cost, and generated direct and indirect economic benefits are great.

Owner:XIAN SHAANGU POWER

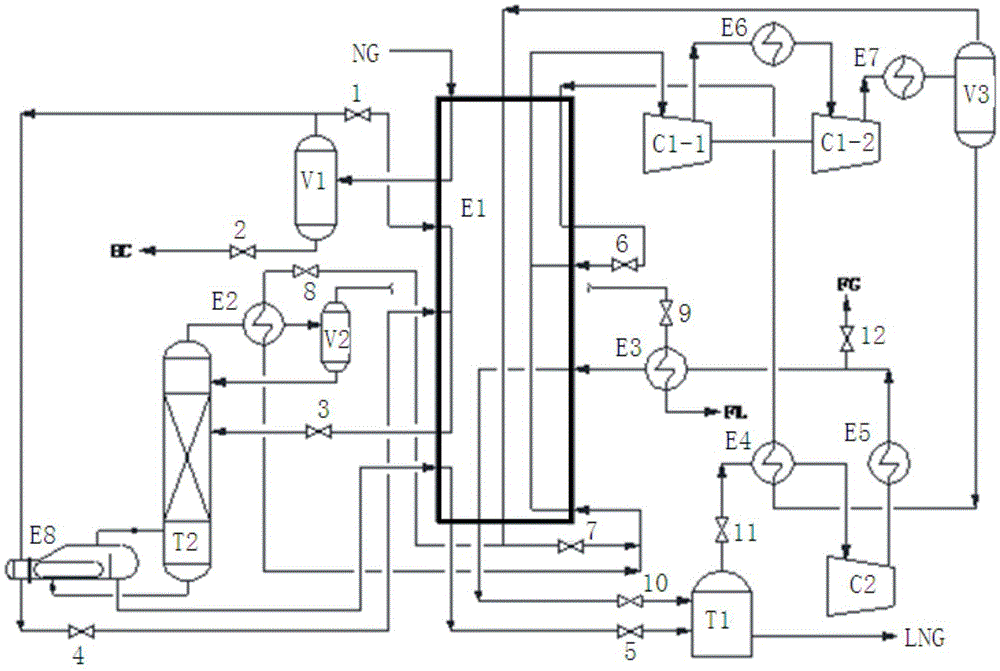

Low-temperature distillation and liquefying separation recovery system and method for coal bed gas high in nitrogen content, oxygen content and hydrogen content

ActiveCN105571269AIncrease productionHigh recovery rateSolidificationLiquefactionRecovery methodDistillation

The invention relates to a low-temperature distillation and liquefying separation recovery system and method for coal bed gas high in nitrogen content, oxygen content and hydrogen content. The low-temperature distillation and liquefying separation recovery system is provided with a cold box, a heavy hydrocarbon separation tank, a rectifying tower, an LCPM storage tank, a refrigerant compressor, a cooler, a final-stage gas-liquid separator, a flash gas compressor and a flash gas cooler. The low-temperature distillation and liquefying separation recovery method of the coal bed gas high in nitrogen content, oxygen content and hydrogen content comprises the steps that heavy hydrocarbon separation and liquefaction are conducted on feedstock gas after the feedstock gas is pre-cooled through a pre-cooling section of the cold box; the liquefied feedstock gas enters the rectifying tower for nitrogen removal, oxygen removal and hydrogen removal, and then the liquefied feedstock gas returns into the cold box to be further cooled and then enters the LCPM storage tank; after the gas mixed with refrigerants is compressed and cooled by two stages, the liquid-phase refrigerant separated by the final-stage gas-liquid separator is used for providing cold energy for the pre-cooling section of the cold box; the gaseous-phase refrigerant obtained after separation is used for providing cold energy for the liquefying section and the supercooling section of the cold box; purge gas is heated and then completely exhausted; and flash gas is pressurized and returns to the liquefying section of the cold box to be liquefied again after heat exchange is conducted between the flash gas and the liquid-phase refrigerant. By the adoption of the low-temperature distillation and liquefying separation recovery system and method, the recovery rate of methane can be increased, so that the processing capacity of a device is improved, the energy consumption of the system is reduced, and the production cost is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com