Steel slag wind-crushing system

A technology for processing systems and steel slag, applied in the direction of recycling technology, etc., can solve problems such as environmental adverse effects, limited resource loss, and increased operating costs, and achieve the effects of improving the level of automation control, solving hot deformation, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

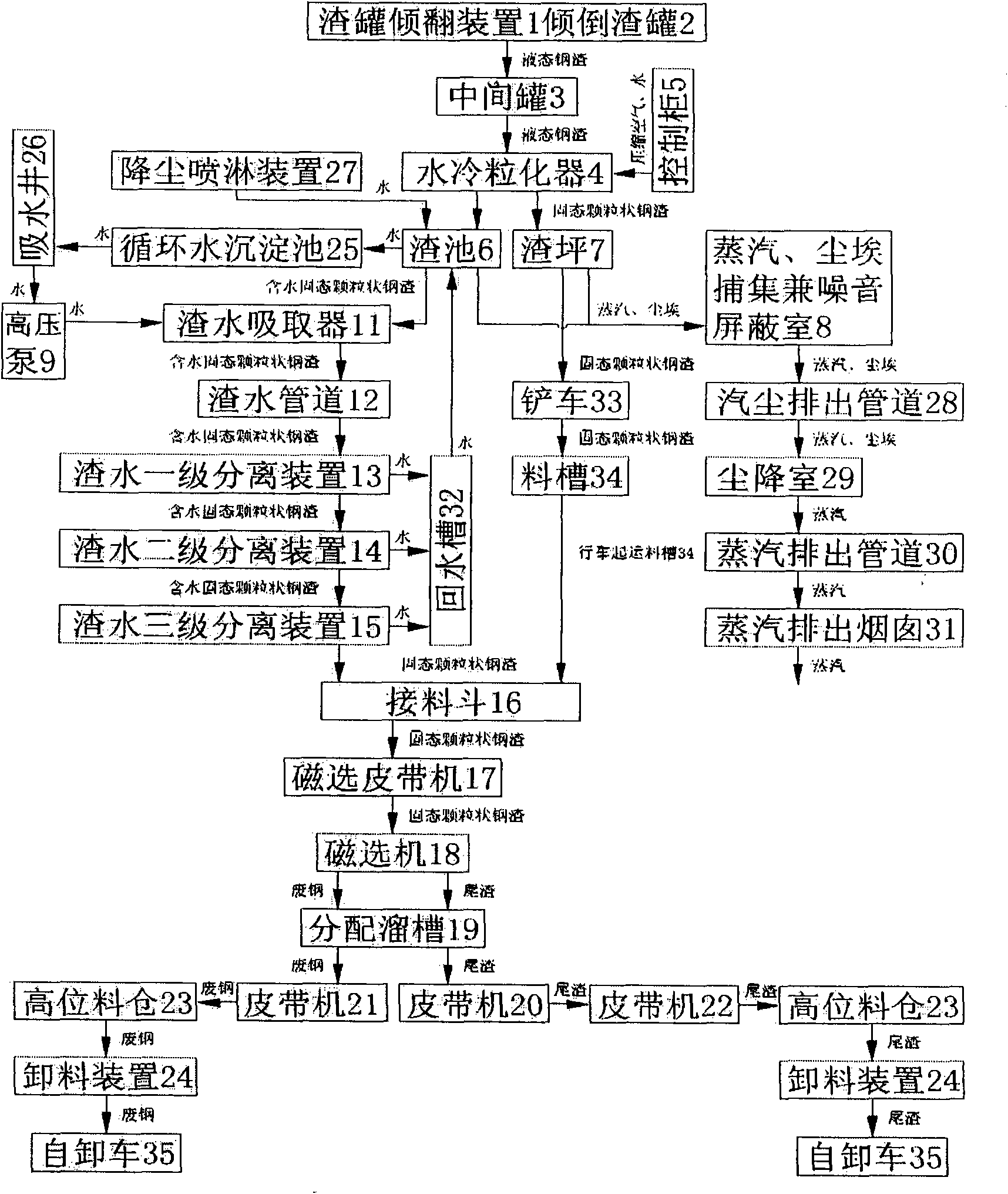

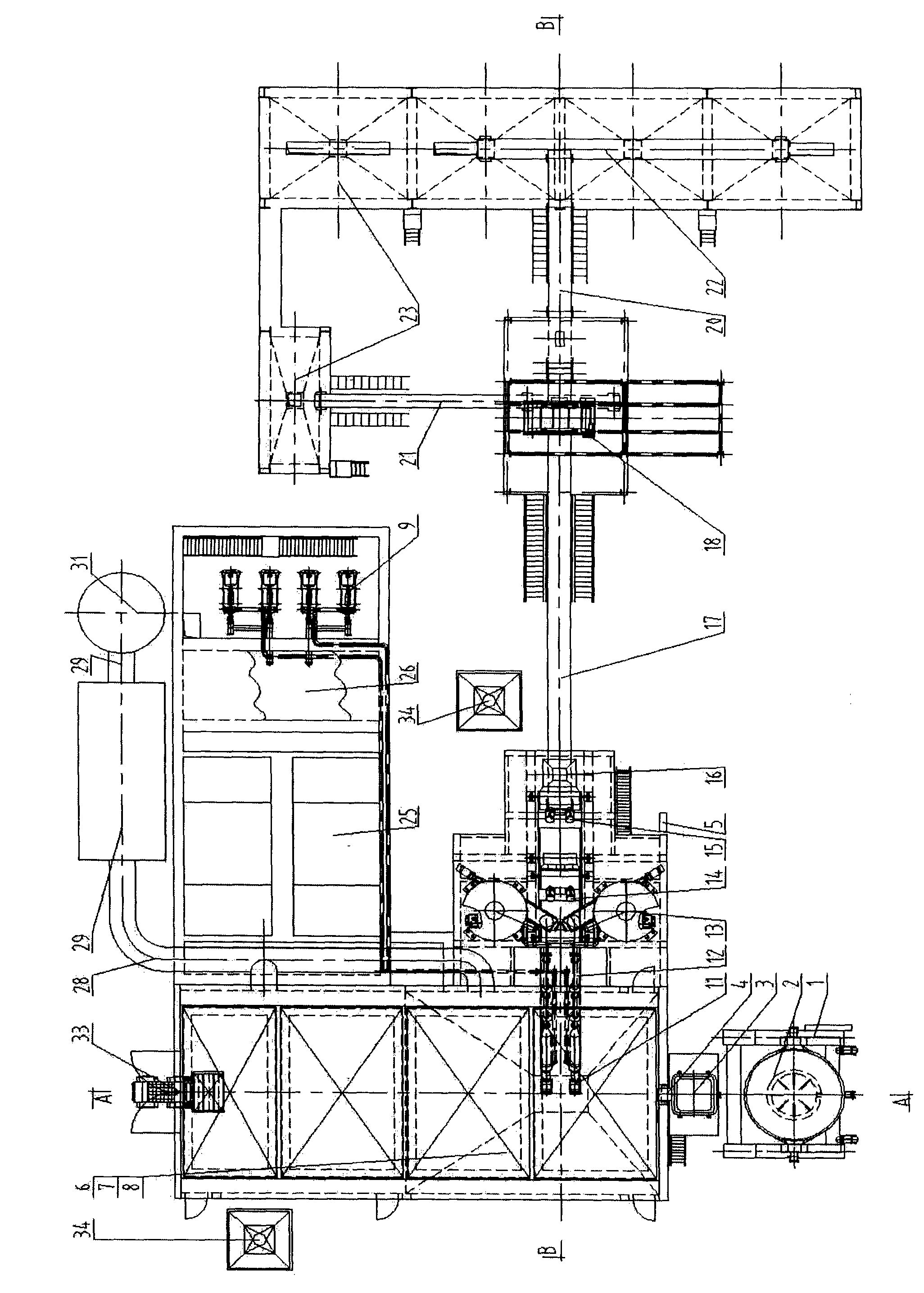

[0031] Such as image 3 The steel slag wind-crushing treatment system shown includes a steel slag pretreatment device, a slag-steel separation device, and a product conveying, loading and unloading device. The pretreatment device includes a tundish 3, a water-cooled granulator 4, a slag pool 6, a slag floor 7, and a control cabinet 5 connected in sequence, and the slag-steel separation device and product conveying, loading and unloading device include a magnetic separation belt conveyor 17 connected in sequence , magnetic separator 18, distribution chute 19, tailings belt conveyor 20, scrap steel belt conveyor 21, belt conveyor 22, high-level feed bin 23 and unloading device 24, it is characterized in that: the slag pond 6 in the steel slag pretreatment device and A slag water suction and separation device is provided between the magnetic separation belt conveyor 17 in the slag-steel separation device located on the right outer side of the slag pool 6; in addition, a water cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com