Patents

Literature

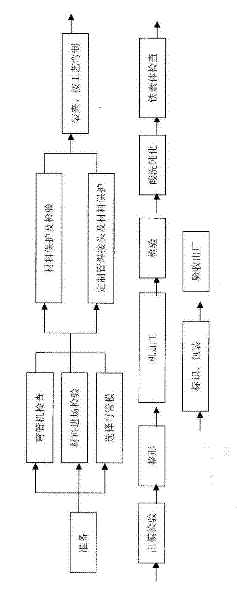

112results about How to "Short procurement cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

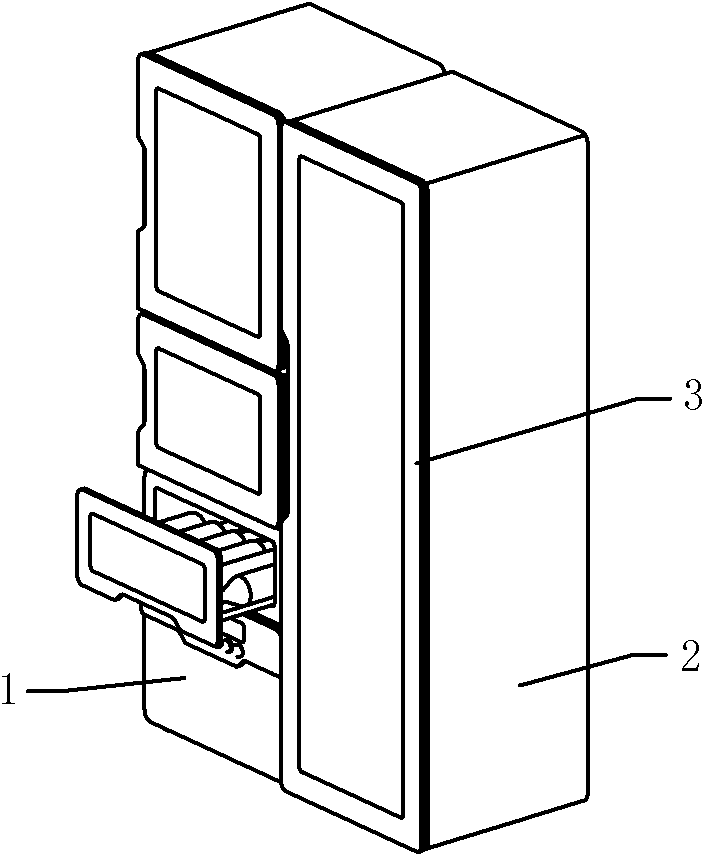

Module combined refrigerator

InactiveCN101915487AMeet usabilityMeet needsLighting and heating apparatusDomestic refrigeratorsComputer moduleElectric control

The invention provides a module combined refrigerator which comprises a refrigeration system and an electric control system, wherein, the refrigerator is composed of a mainframe room and two or more cold rooms, and the mainframe room and the cold rooms are independent and separated from each other; the cold rooms comprise door bodies and insulation boxes; the mainframe room is internally equipped with two or more refrigeration system interfaces and electric control system interfaces, and the cold rooms are internally equipped with refrigeration system joints and electric control system joints which are correspondingly connected with the refrigeration system interfaces and the electric control system interfaces in the mainframe room; and the mainframe room is equipped with a compressor, a condenser, a capillary tube and a main controller, and the cold rooms are equipped with evaporators. By means of a plurality of combined module units in the mainframe room, the module combined refrigerator can simultaneously meet the combined use requirements for a refrigerating room, a cold room, a soft-freezing room, a wine cabinet and the like, thus meeting the personalized need of customers, reducing development expense, shortening design and production cycle, saving warehousing floor space, and facilitating storage and transportation.

Owner:广东安博基业电器有限公司

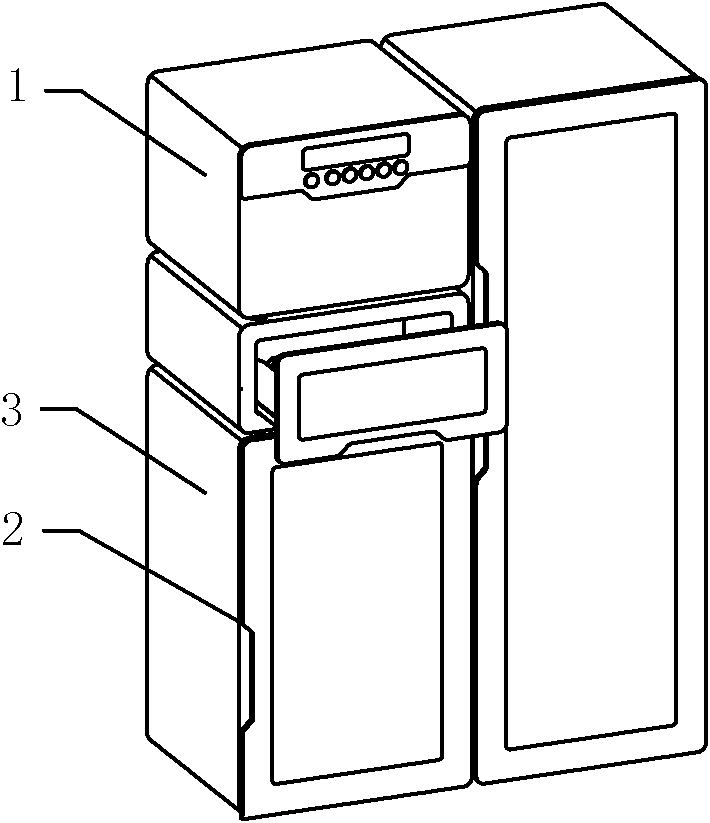

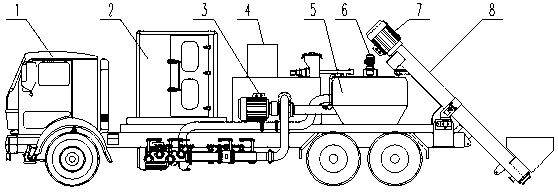

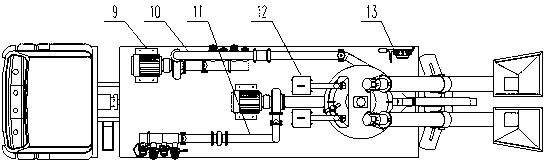

Electric drive sand mixing truck

InactiveCN103912259ASimple structureHigh localization rateFluid removalItem transportation vehiclesAutomatic controlElectric discharge

The invention belongs to the technical field of petroleum drilling and recovery and particularly relates to an electric drive sand mixing truck. The electric drive sand mixing truck comprises a truck chassis, a control room, a transformer, an electric discharge pump, an electric suction pump, a mixing tank stirring device, a sand conveying auger, a dry feeding system, a liquid feeding system, a suction manifold and a discharge manifold. The control room comprises a sand mixing truck automatic control system and a motor drive device. The electric drive sand mixing truck has the advantages that a motor is used as power source; compared with traditional sand mixing trucks using diesel engines and torque converters as main power output, the electric drive sand mixing truck is simple in structure, novel and reasonable in design, low in cost, low in noise, low in discharge, simple to control, high in sand-liquid matching precision, and convenient to popularize and use.

Owner:四机赛瓦石油钻采设备有限公司

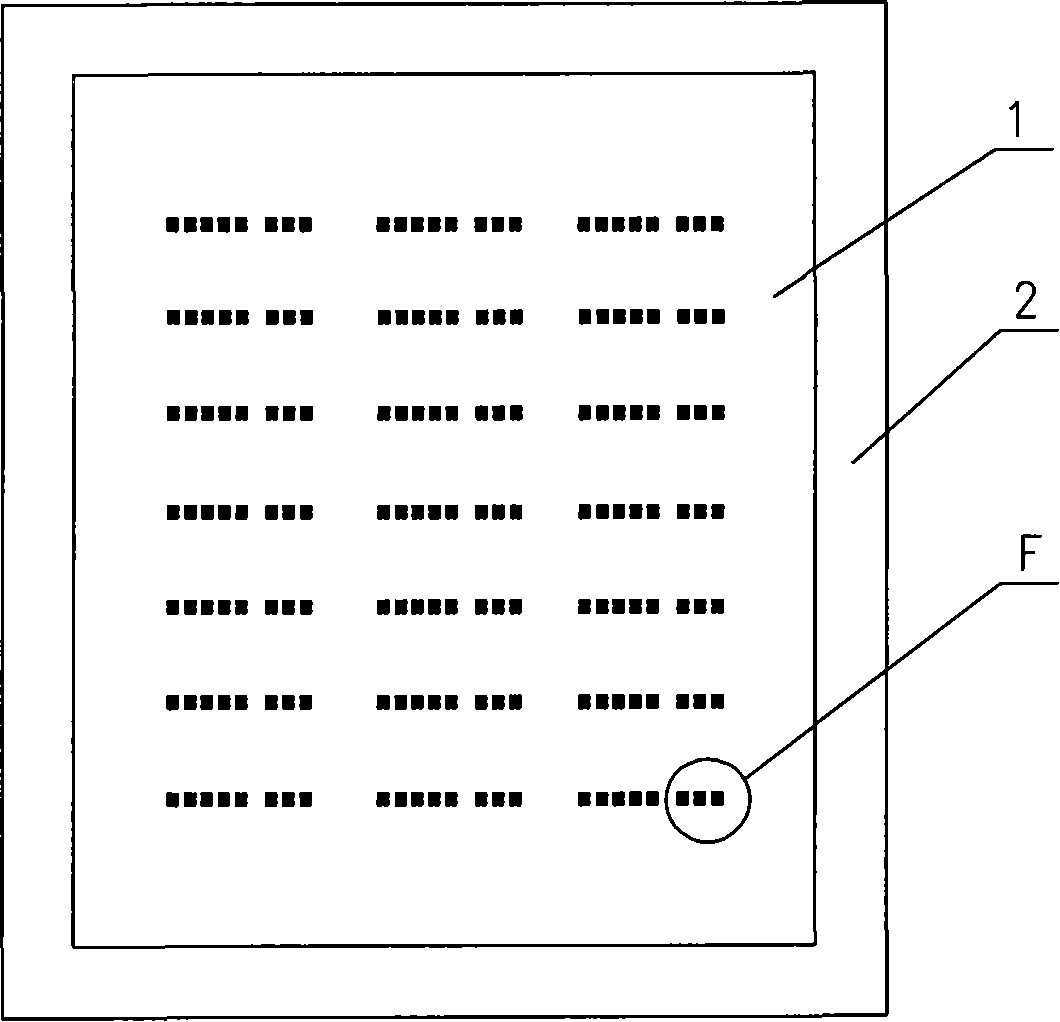

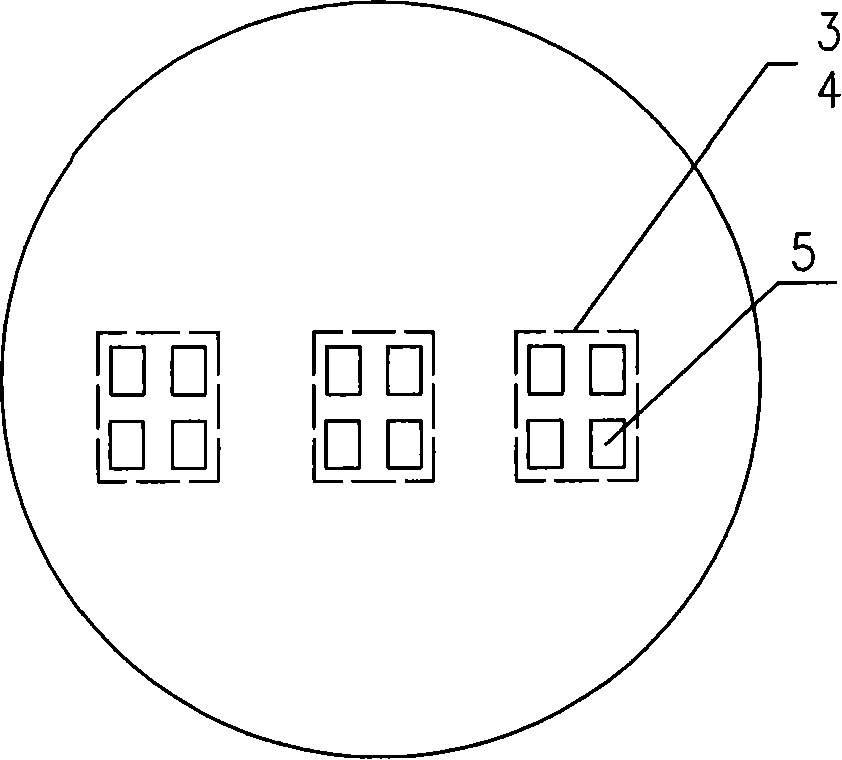

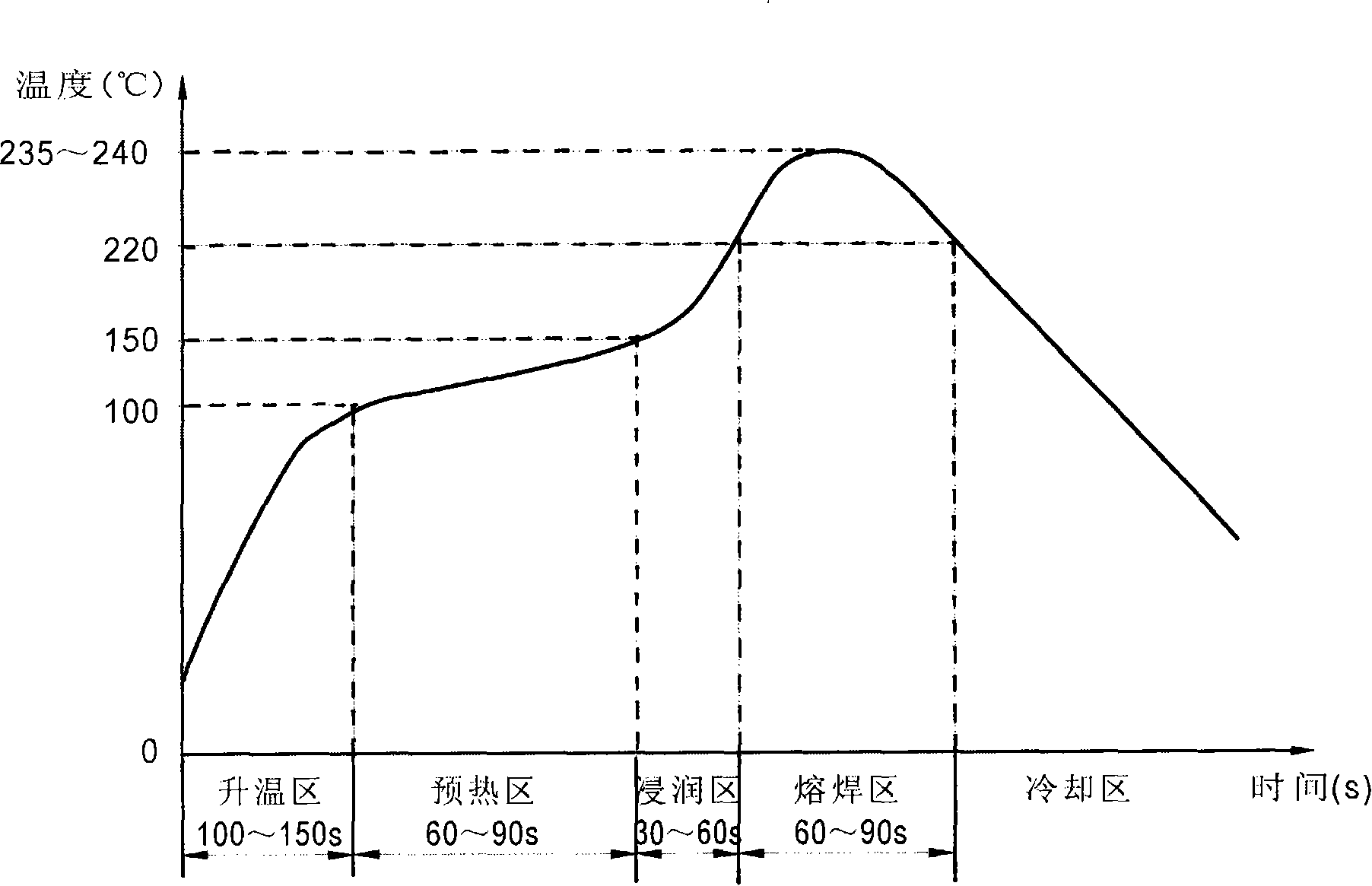

Solder tray local tin plating method on circuit board

InactiveCN101252815AImprove mechanizationReduce manufacturing costPrinted circuit assemblingTinningEngineering

The invention discloses a method for local tinning to the bonding pad on a circuit substrate, which enables lead-free tin plasma to be brushed to the spot welding position bonding pad of the circuit substrate through a steel mesh; the circuit substrate brushed with the lead-free tin plasma passes through the five areas of a reflow soldering machine for operating parameters in sequence, to form liquid tin coating covered in the entire spot welding position bonding pad, and after the circuit substrate cools, solid tin coating is formed in the spot welding position bonding pad. The invention utilizes the steel mesh to brush the lead-free tin plasma to the bonding pad of a common substrate, and utilizes the reflow soldering machine and depends on the wetting property of soldering flux, and the diffusion and the self positioning effect of the tin plasma to accomplish the tinning process of the bonding pad, the tin coating meets the process requirements of the thickness and the smoothness, and provides good basic conditions for the subsequent spot welding working procedure, and the manufacturer does not require to purchase special substrates for the substrate supplier, therefore, the production efficiency can be greatly improved, the qualified rate of the product can be increased, and the production cost of the enterprise can be reduced.

Owner:MORNSUN GUANGZHOU SCI & TECH

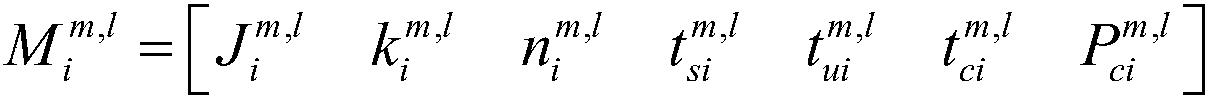

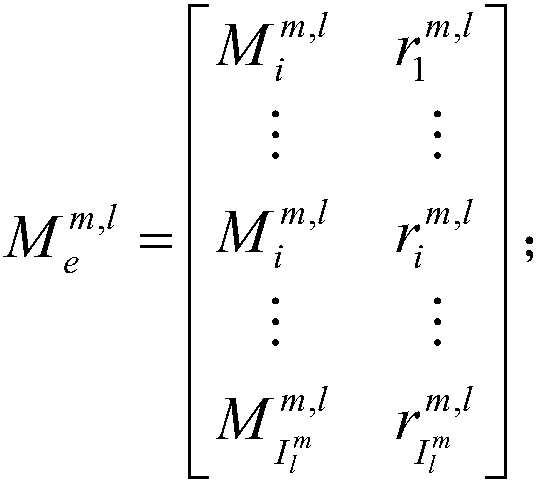

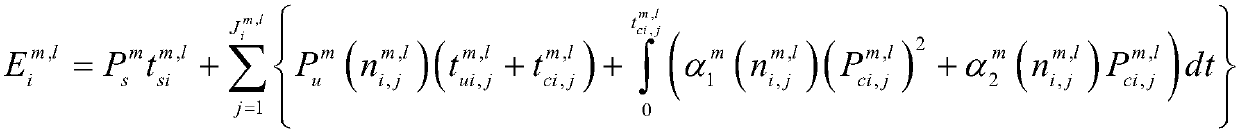

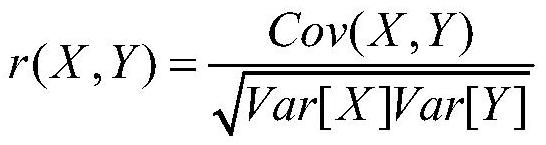

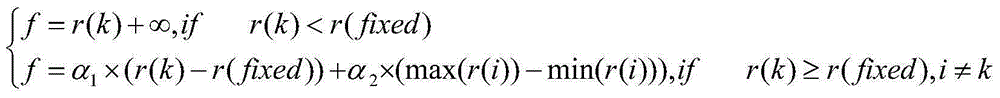

Machine tool selection method facing highest energy efficiency during whole usage stage of machine tool

ActiveCN107065778AThe energy efficiency selection method is objectiveThe energy efficiency selection method is trueProgramme controlComputer controlHigh energyEngineering

The present invention discloses a machine tool selection method facing the highest energy efficiency during the whole usage stage of a machine tool. The method comprises the following steps of establishing an expected processing workpiece set WT; establishing a candidate machine tool set MT; establishing an inherent energy efficiency characteristic matrix for each candidate machine tool in the candidate machine tool set MT; according to the inherent energy efficiency characteristic matrix of each candidate machine tool, establishing an inherent energy efficiency characteristic correlation matrix E containing all candidate machine tools; establishing a processing characteristic matrix for each candidate machine tool in the candidate machine tool set MT; for each candidate machine tool, calculating an equivalent parameter; according to the processing characteristic matrix and the equivalent parameter, constructing an equivalent processing characteristic matrix for each candidate machine tool; according to the equivalent processing characteristic matrix of each candidate machine tool, separately establishing an equivalent processing characteristic correlation matrix for each candidate machine tool to process the all workpieces in the expected processing workpiece set WT; according to the inherent energy efficiency characteristic matrixes and the equivalent processing characteristic correlation matrixes, calculating the energy efficiency of the candidate machine tool MT<m>, and selecting the candidate machine tool having the highest energy efficiency as the purchase machine tool.

Owner:CHONGQING UNIV

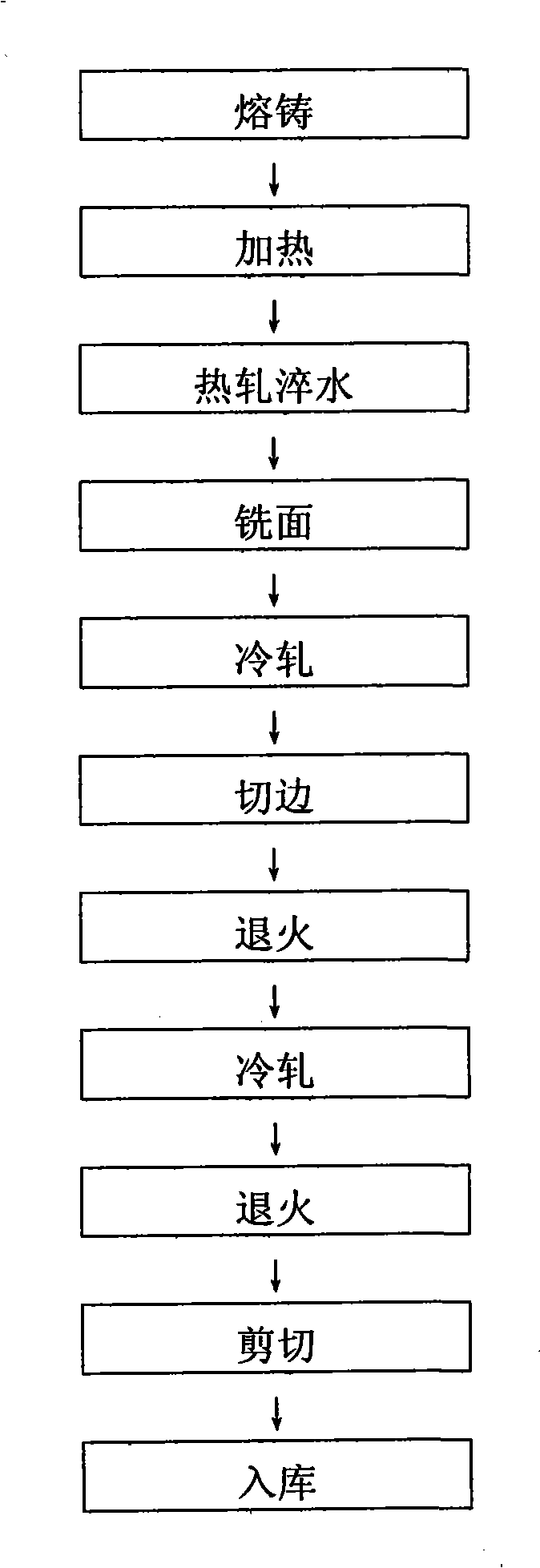

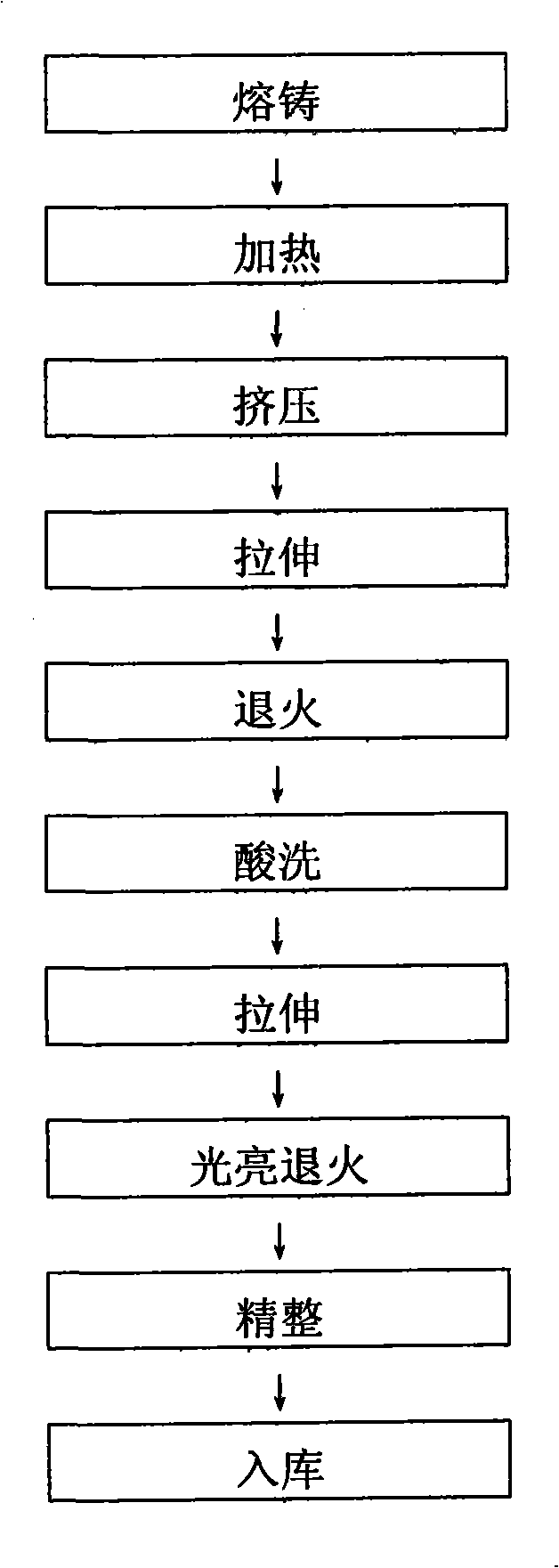

Nisiloy bronze alloy material and processing technique thereof

ActiveCN101289716ALow costSimple processTemperature control deviceMetal rolling arrangementsBronzeMachining process

The invention discloses nickel, silicon and bronze alloy materials and a technology for processing the same, wherein the nickel, silicon and bronze alloy materials are alloys taking the Cu-Ni-Si component system as a base, which are formed by main alloys of bronze, nickel and silicon, microelements such as manganese and iron and impurities; different materials are made by the rolling mill processing method and the extrusion-extension processing method; the nickel, silicon and bronze alloy materials processed by the invention have the advantages of low cost, simple process, high technical level and good quality; moreover, as for plates and bands made by the rolling mill processing method, the mechanical property reaches between Rm480 and 580 MPa, the Vickers hardness reaches between HV100 and 150, and A is more than or equal to 10 percent; as for bars or section bars made by the extrusion-extension processing method, the mechanical property is more than or equal to 240 MPa, the Vickers hardness reaches between HV100 and 150, and A is more than or equal to 20 percent.

Owner:中铝洛阳铜加工有限公司

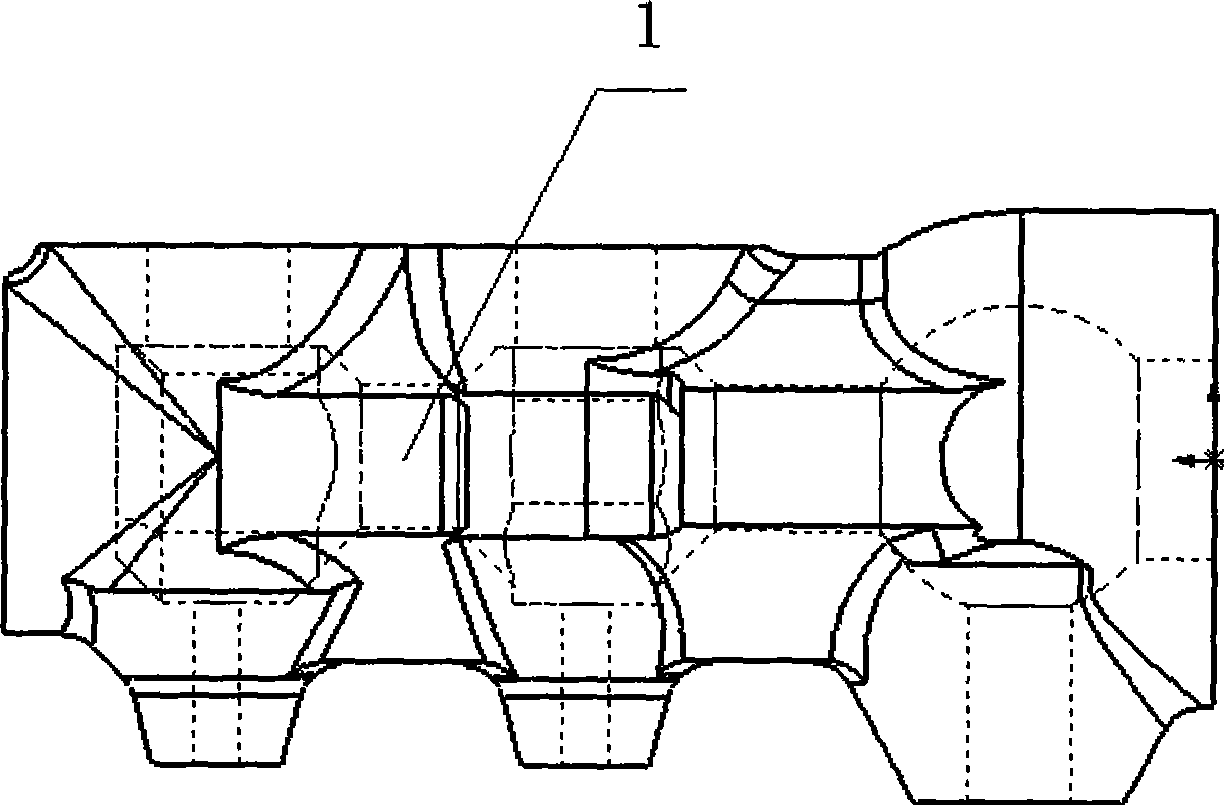

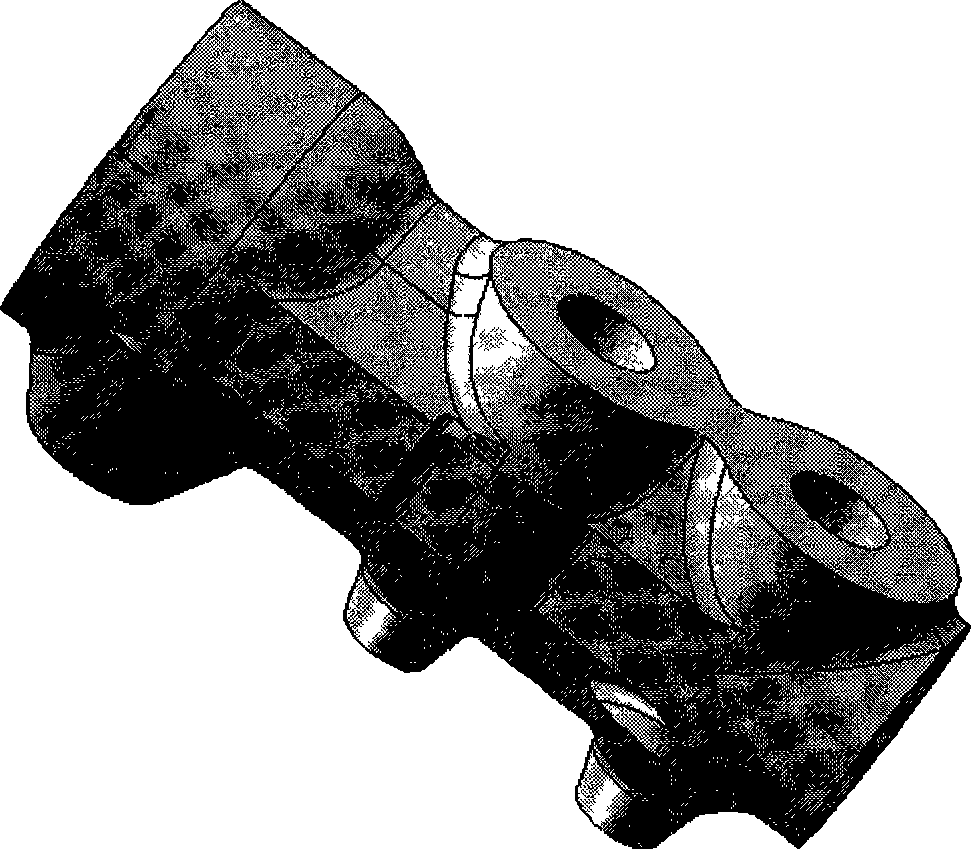

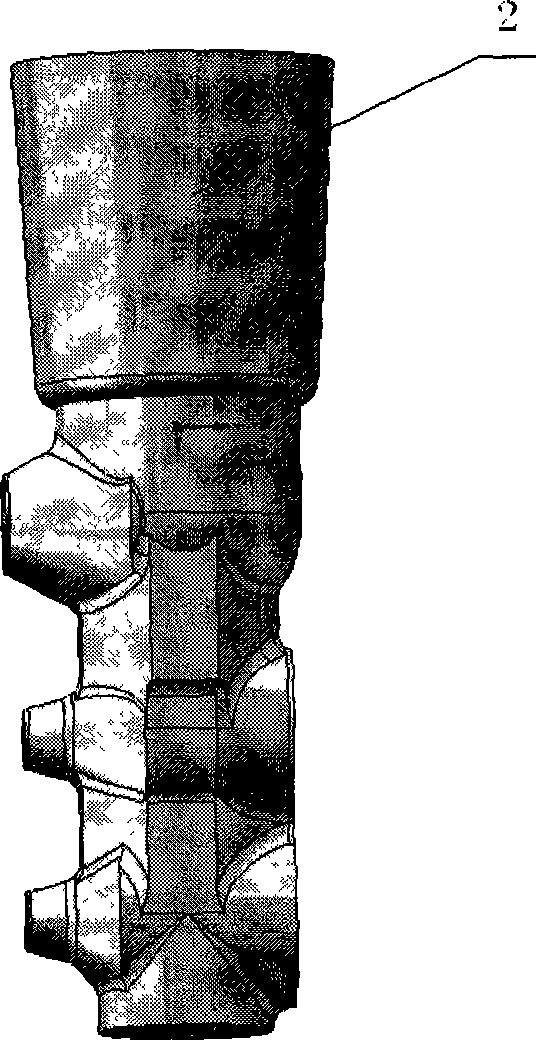

Method for foundry production of ultra-supercritical main steam control valve for nuclear power unit

ActiveCN101476085AShort procurement cycleReduce manufacturing costFurnace typesMolten metal conveying equipmentsNuclear powerControl valves

The invention relates to a method of producing supercritical main stop governing valve by casting, and the method achieves the aim of replacing forging by casting by the improving of molten steel components control, pouring mode and heat treatment process, which greatly reduces the production cost. The pouring mode is the bottom pouring mode in a vertical state with a casting head on the upper part of the pouring position and an insulating sleeve is provided outside the casting head.The heat treatment process comprises techniques of quenching and double tempering. In order to obtaining casting parts with compact tissue, middle cavities of the casting parts are full of molten steel, axial cord shrinkage and shortage parts of the middle portion are removed by using a deep hole drilling, and the casting parts are then reprocessed for satisfying the requirements of the size of the middle cavities. Mechanical properties of the casting products comprises a yield strength delt0.2>=520MPa, a tensile strength deltb>=680-850MPa, a tensile stretch delt5>=15%, a reduction in cross section psi >=40% and an impact energy AkU >= 30J.

Owner:LIAONING FU-AN HEAVY INDUSTRY CO LTD

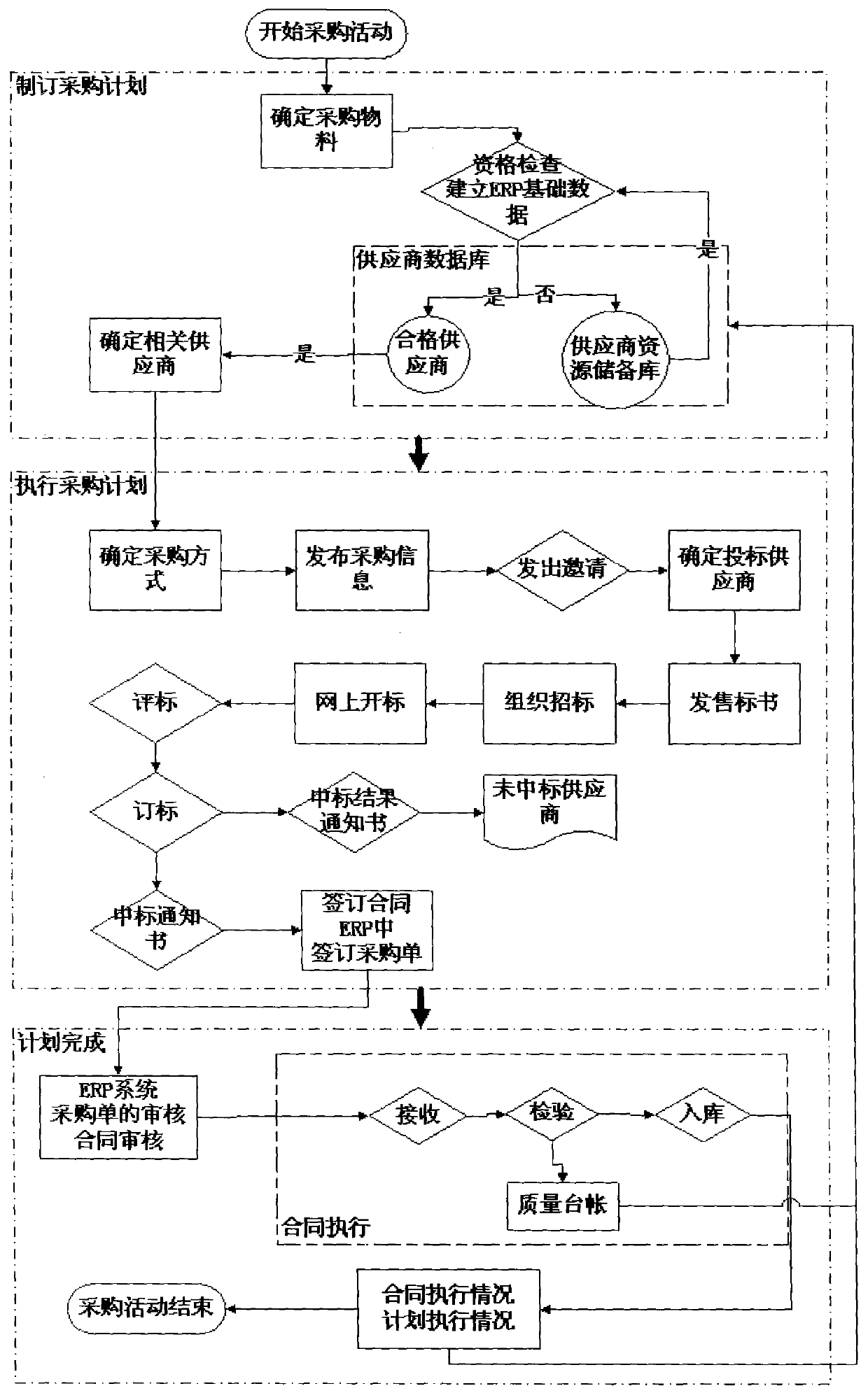

Purchasing method by bidding purchasing system on Internet

A method for making purchase by utilizing network bidding-purchasing system includes preparing purchase plan, executing purchase plan and finalizing purchase plan, displaying offer from different suppliers simultaneously on network and displaying the bidding-winning situation timely on network for making the total bidding process be publicly and transparently on network.

Owner:TIANJIN PIPE (GROUP) CORP

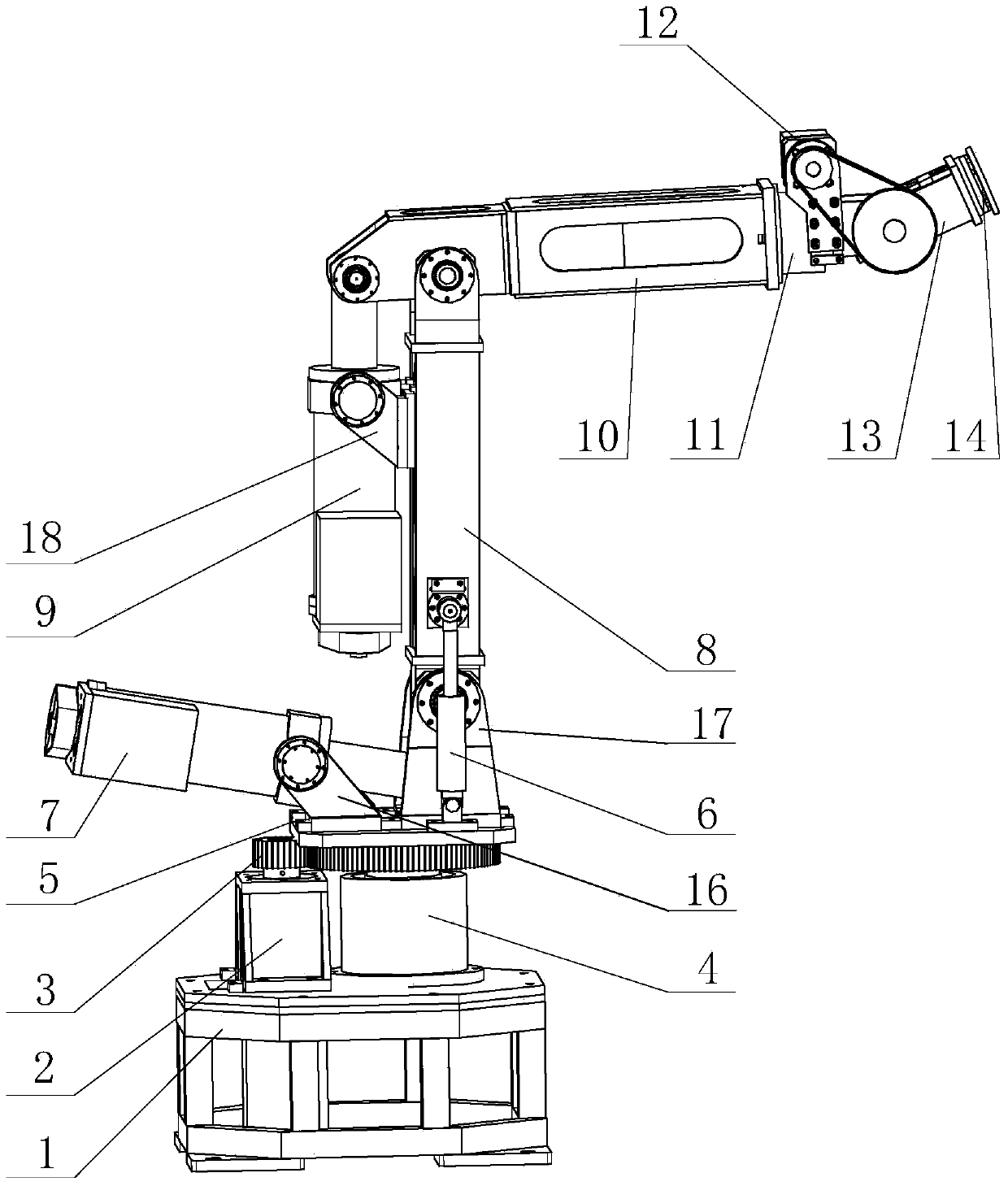

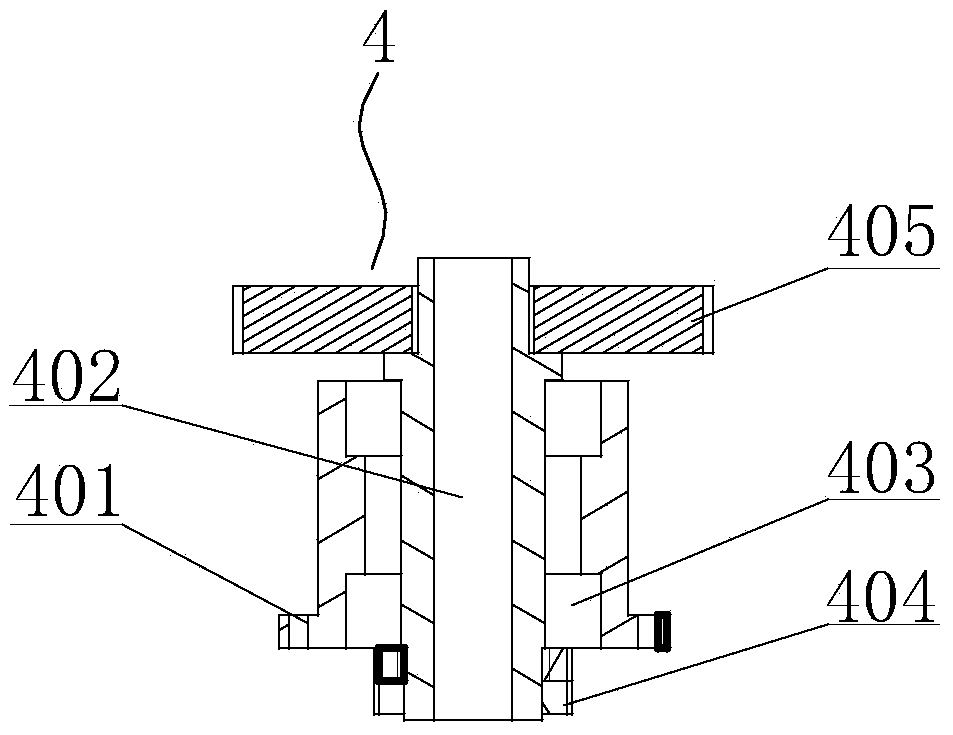

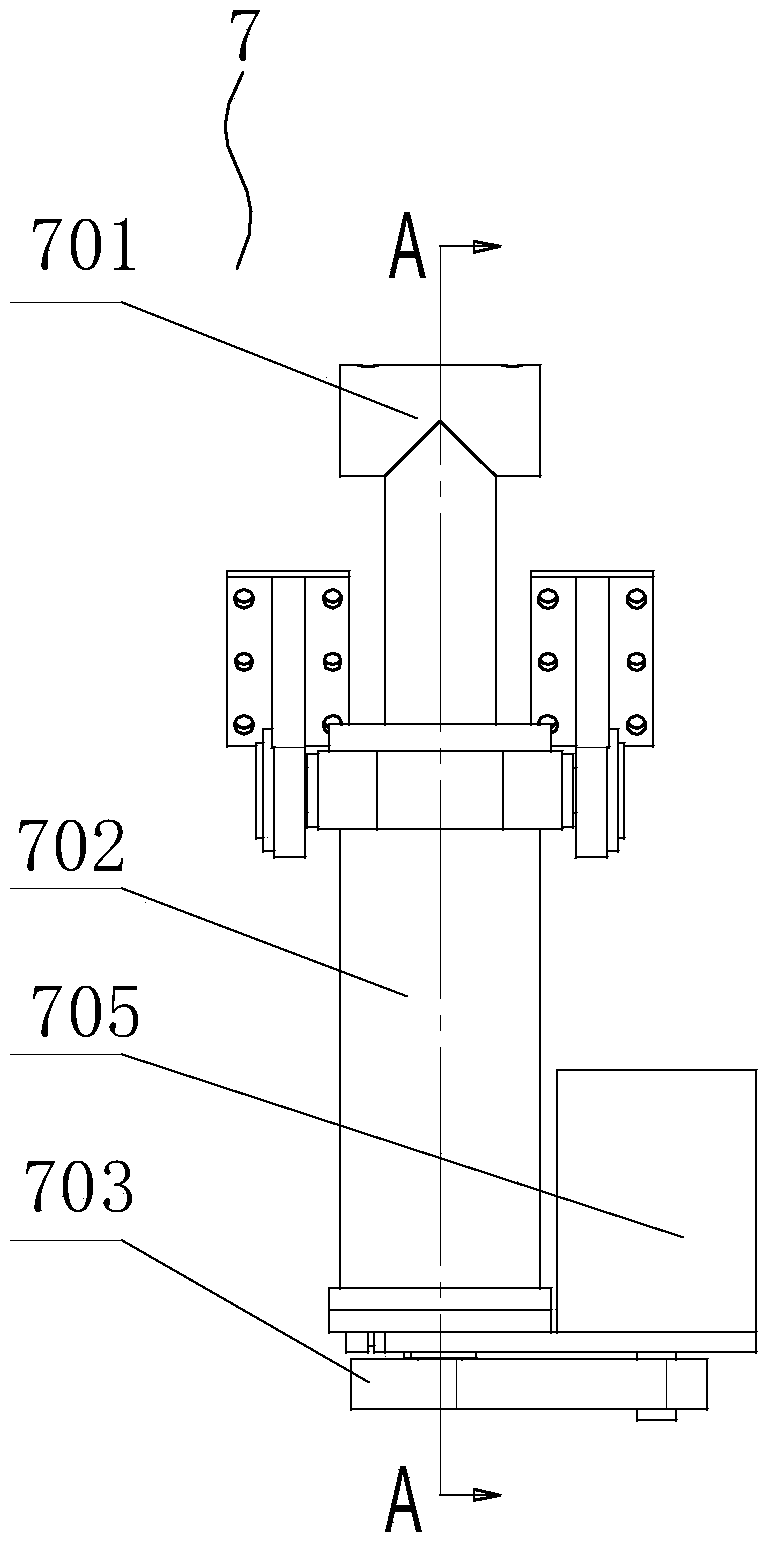

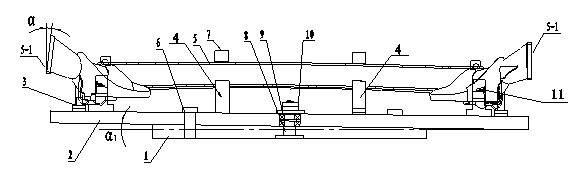

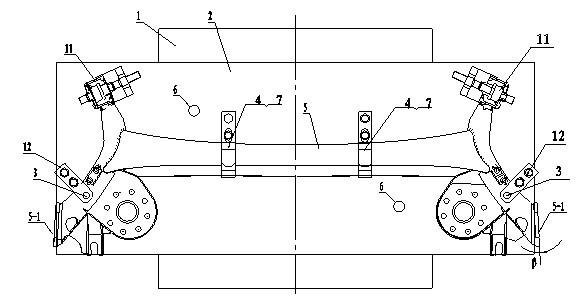

Six-shaft joint mechanical hand

InactiveCN103737607ALow costSimple structureProgramme-controlled manipulatorJointsControl systemIndustrial machine

The invention discloses a six-shaft joint mechanical hand and relates to the industry mechanical hand technology. The six-shaft joint mechanical hand comprises a mechanical hand body and a control system; the mechanical hand body is connected with the control system through a data line; the mechanical hand body comprises a base, a first shaft servo motor and a speed reducer thereof, a first shaft rotary shaft, a second shaft base, a lower hand servo cylinder, a lower arm, an upper arm servo cylinder, an upper arm, a fourth shaft rotary shaft, a fifth shaft servo motor and a speed reducer thereof, a fifth shaft rotary base, a sixth shaft rotary shaft and a sixth shaft servo motor and a speed reducer thereof; the control system comprises a programmable controller, a movement control module, a servo driver, an alarming device, a hand box, a touch screen, a limit switch and a sensor. The six-shaft joint mechanical hand has the advantages of achieving six-shaft joint control through the control system, being simple in structure, achieving domestic production, reducing products, shortening the purchasing cycle, being suitable for small and medium businesses to use and high in positioning accuracy, improving the production quality and the production efficiency and having a good application prospect in the industry mechanical hand technology field.

Owner:LIUZHOU GAOHUA MACHINE

Distributed power supply system of relay protection device

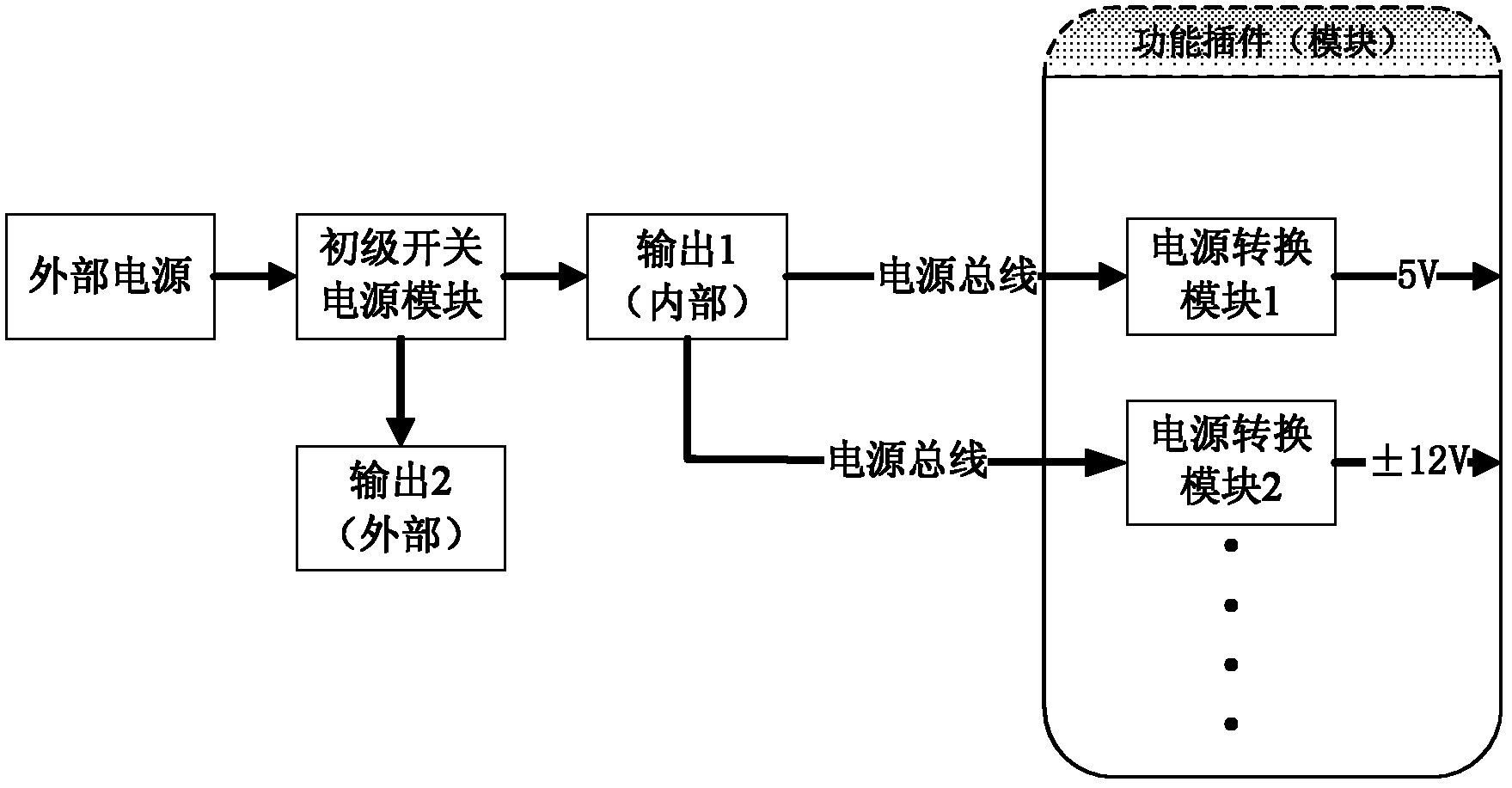

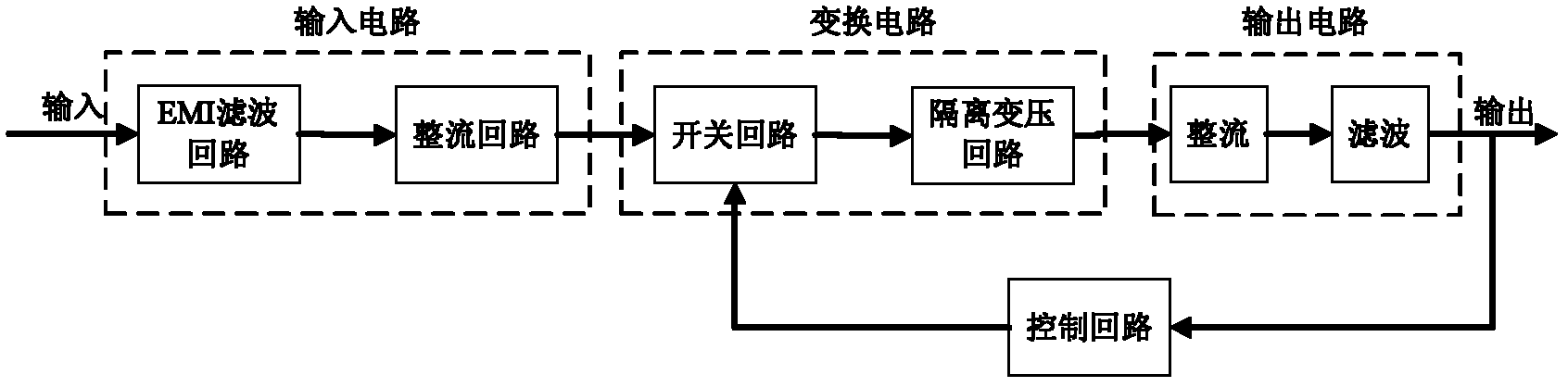

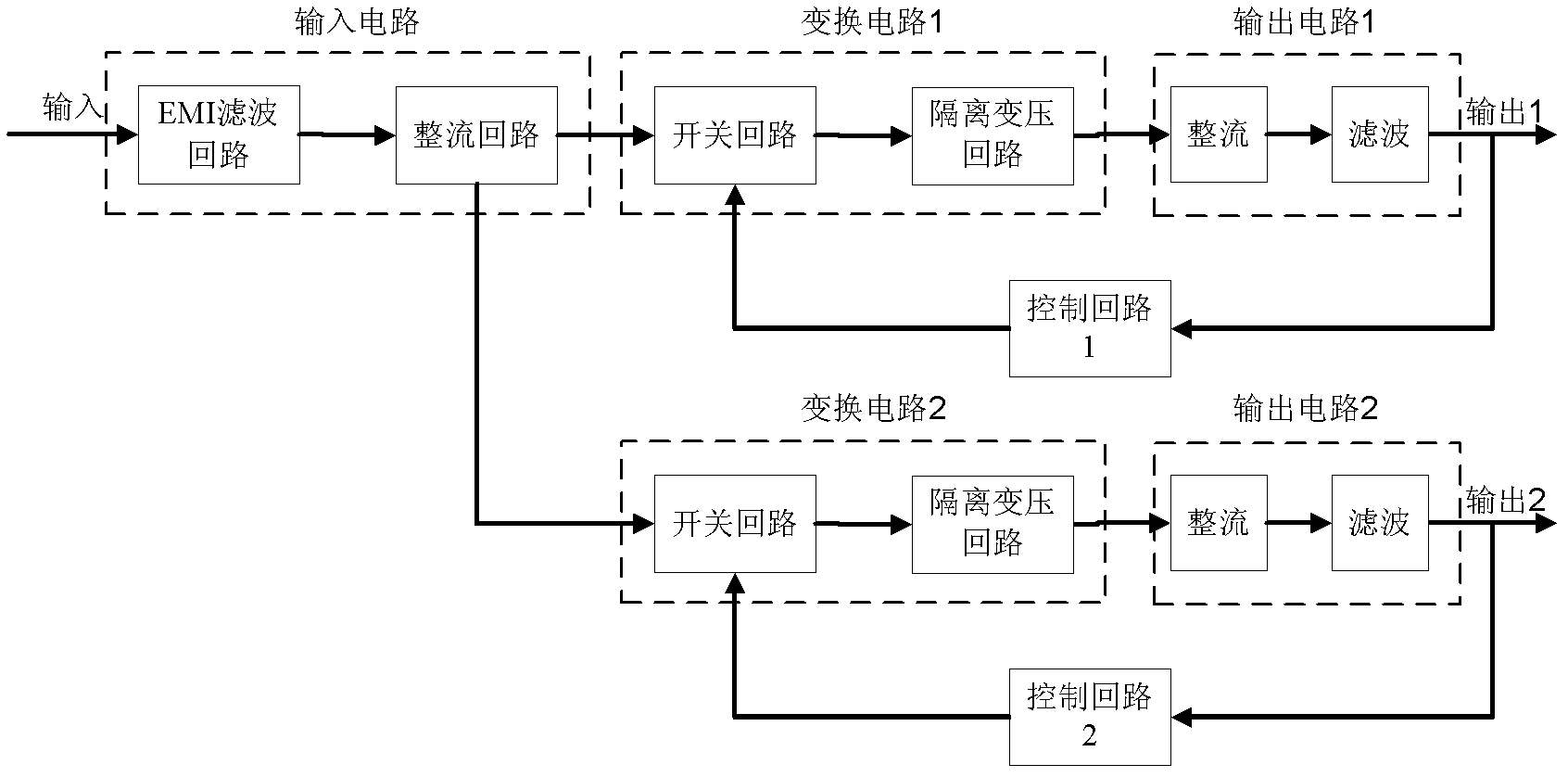

ActiveCN102593784ATroubleshoot timing issuesAvoid abnormal failureEmergency protection for supplying operative powerReusabilityComputer module

The invention discloses a distributed power supply system of a relay protection device. In the power supply system, a primary power source module is designed with two paths of separated 24V DC voltage outputs, wherein one path of output is used for internal power supply and the other path of output is used for external power supply. The path of output used for internal power supply is output to each functional insert (module) via a power source bus, and then the internal 24V DC is converted to be at a voltage level needed by the functional module via a secondary power source conversion module. Through the distributed power supply system of the relay protection device, some problems of a centralized power supply are effectively solved; the design complexity of the primary power source module is simplified and the reliability and the design reusability of the power supply are improved; and meanwhile, the backplane resource of the relay protection device is saved and the development cycle of the product is shortened.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

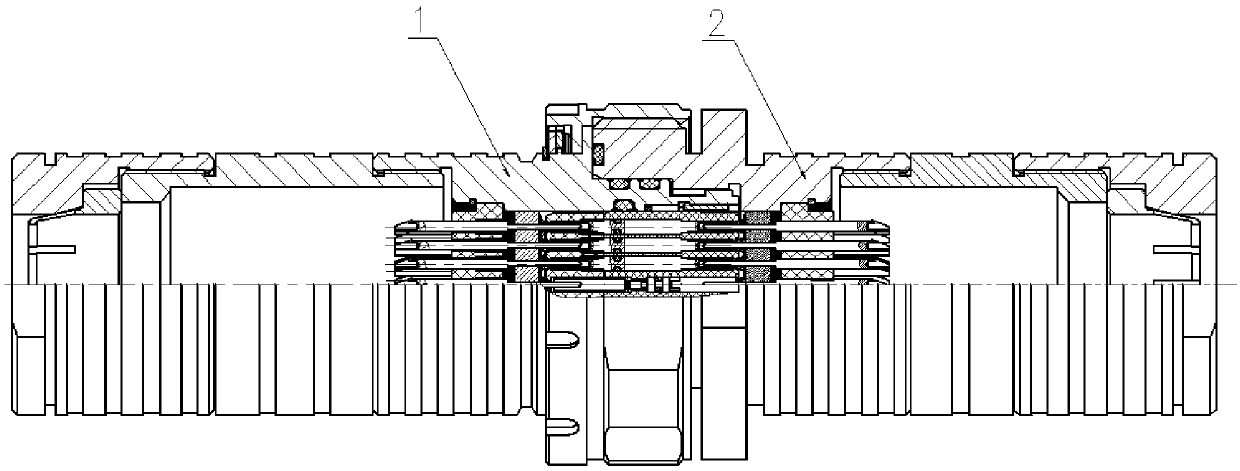

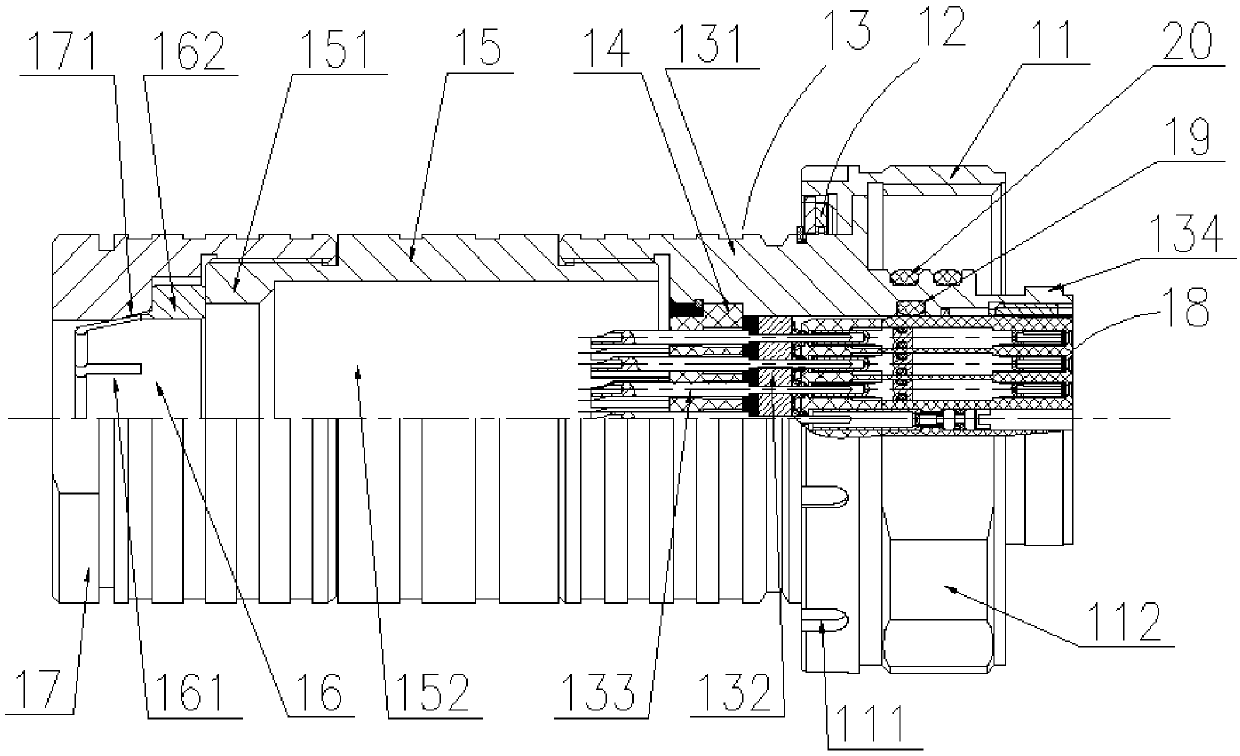

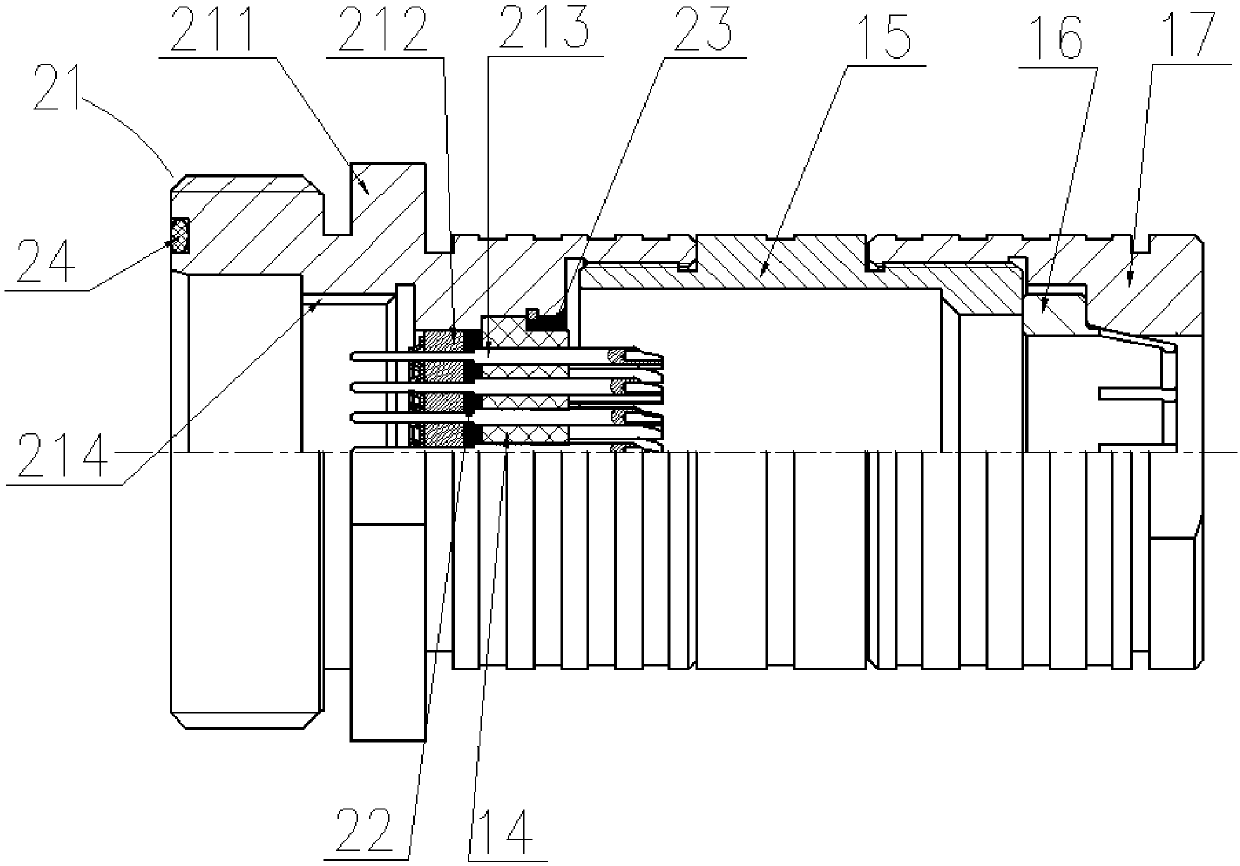

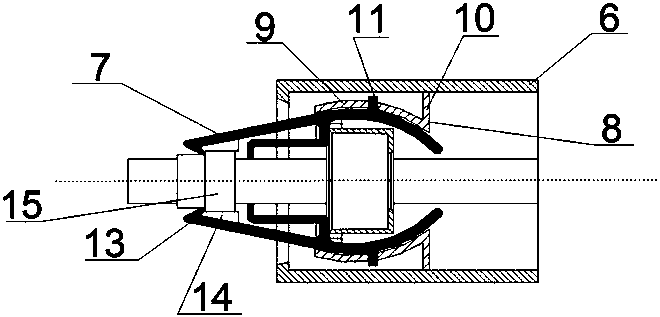

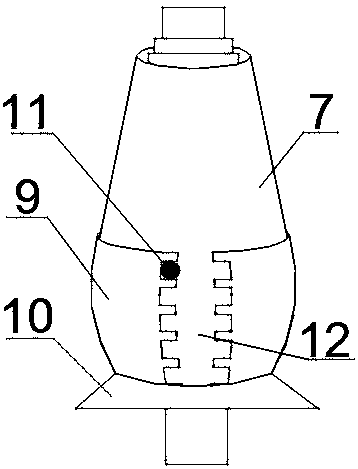

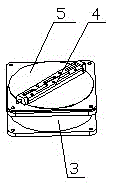

Circular underwater sealing electric connector capable of being plugged in blind manner

PendingCN109560420ASelf-sealingImprove maintainabilityEngagement/disengagement of coupling partsRelieving strain on wire connectionElectricityUnderwater

The invention relates to a circular underwater sealing electric connector capable of being plugged in a blind manner. The electric connector comprises a plug and a socket, wherein the plug comprises aconnecting nut, an anti-loose mechanism and a plug sealing-connecting assembly; and the socket comprises a socket sealing-connecting assembly. The circular underwater sealing electric connector capable of being plugged in the blind manner provided by the invention has the advantages that due to the fact that the plug and the socket are both sealed by sintering and forming a glass sintering layerand a contact part, and a sealing jack insulation assembly is arranged at the plugging end of the plug, so that the internal structure of the jack insulation assembly can realize self-sealing, and theoutside of the jack insulation assembly is sealed with the plug shell; when water enters the plugging end plane of the plug, the sealing structure of the jack insulation assembly plays an isolating role, so that short circuit in the plug caused by water entrance to the internal structure of the plug can be avoided; and after water entrance, the electric connector can be used as normal by only performing a simple operation on the plug, so that high product maintainability and high reliability are achieved, and the electric connector is suitable for application occasions with high-reliability sealing requirements.

Owner:杭州航天电子技术有限公司

Method for processing automobile rear torsion beam on horizontal boring machine

InactiveCN102189281AMeet processing needsReduce processing investment pressureMilling cutterAutomotive engineering

The invention discloses a method for processing an automobile rear torsion beam on a horizontal boring machine to solve the problem that the automobile rear torsion beam is required to be processed on special equipment or a five-axle processing center. The method is characterized in that: a boring cutter is changed into a disc milling cutter, and a space angle to be processed is synthesized by using a rotary table of the horizontal boring machine and a tool angle, so that the outer sides of hub supports on two sides of the automobile rear torsion beam are processed. By organically combining the ingenious design of a tool and the functions of a cutter and the rotary table of the boring machine, the space angle machining of the automobile rear torsion beam is finished on a common horizontalboring machine. By using the method, the investment pressure of early-stage sample piece processing can be reduced, the equipment purchasing cycle can be shortened, and the demand of the sample pieceprocessing can be met. The method is also suitable for the small scale production of the automobile rear torsion beam products.

Owner:GREAT WALL MOTOR CO LTD

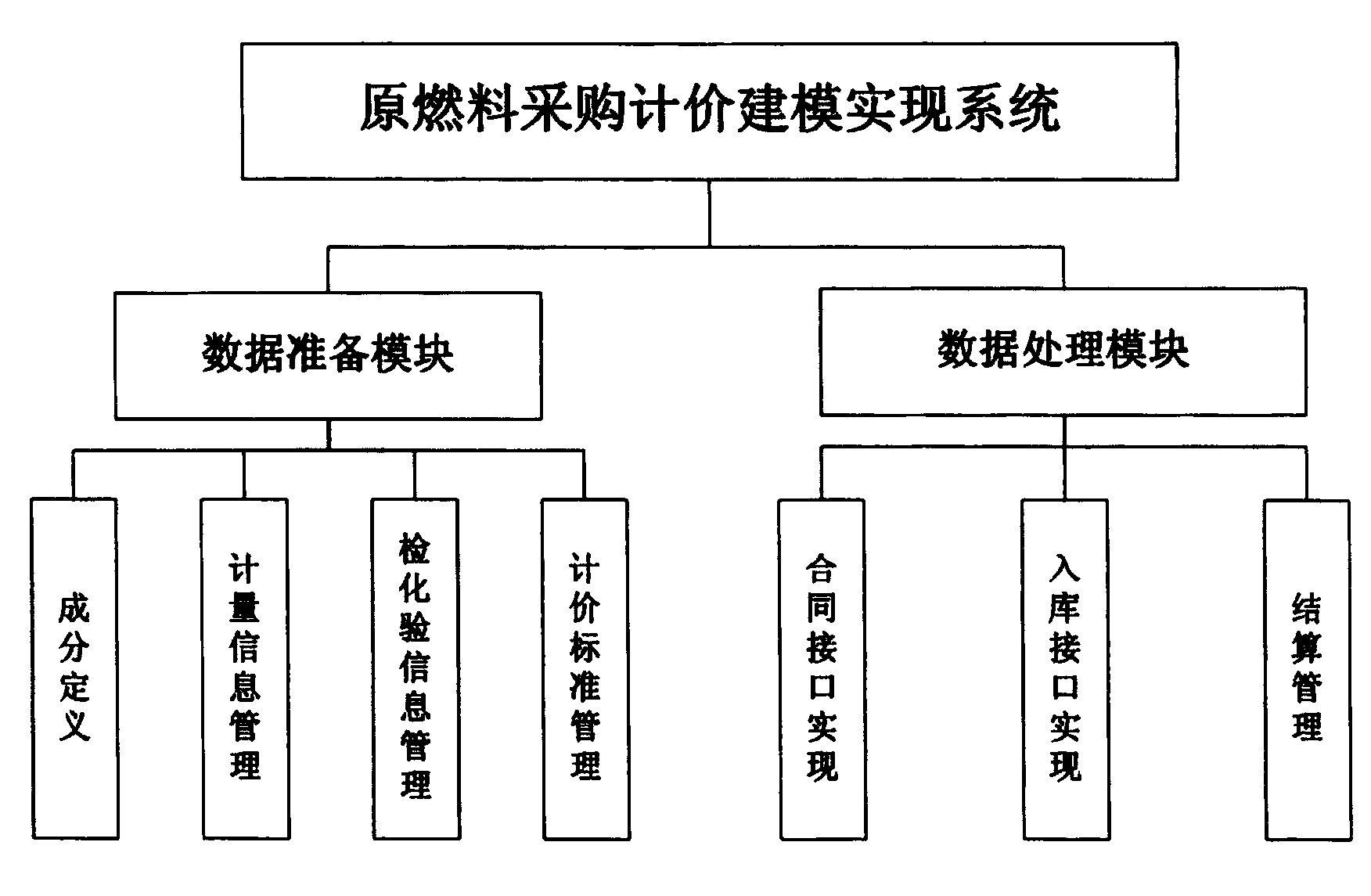

Modeling implementation system based on steel crude fuel purchasing valuation

ActiveCN103578023AAchieve accuracyAchieve normativeBuying/selling/leasing transactionsSpecial data processing applicationsSupply managementModel implementation

The invention discloses a modeling implementation system based on steel crude fuel purchasing valuation. The modeling implementation system comprises a data preparation module and a data processing module, wherein the data preparation module is used for providing steel crude fuel composition definition information, valuation standard and rule information and collection, checking and matching information, including metrical information and checking and testing information, of various data; the data processing module is used for reading corresponding valuation standard information and valuation rule information in the data preparation module according to business-related information set in an information system, matching the valuation standard information and the valuation rule information with the complete metrical information and the checking and testing information in a combined mode, and contrasting actual checking and testing result values according to material information and predetermined valuation standards and valuation rules to obtain a settlement valuation model of crude fuel. The modeling implementation system based on steel crude fuel purchasing valuation can realize accurate and efficient processing of crude fuel settlement valuation for an iron and steel enterprise, can be adapted to rapid configuration after crude fuel settlement management rules change, and can realize crude fuel settlement management and systematic management of a purchasing and supply management system and a peripheral management system.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

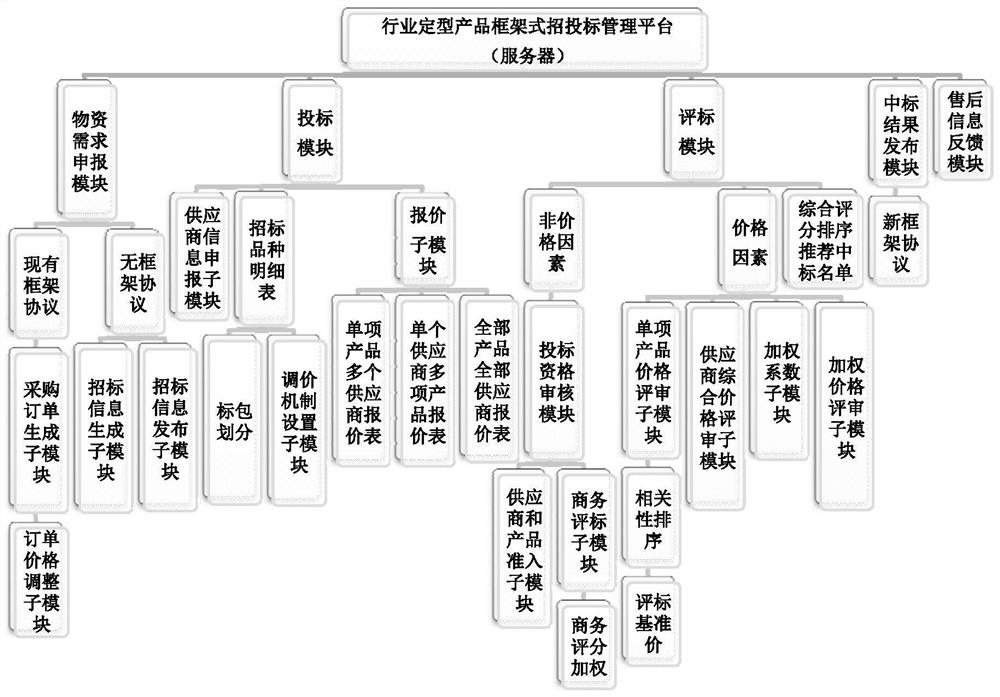

Frame-type bidding and tendering management platform for industrial shaped products

PendingCN111833158ARaise the standard levelAchieve accuracyOffice automationBuying/selling/leasing transactionsProduct priceIndustrial engineering

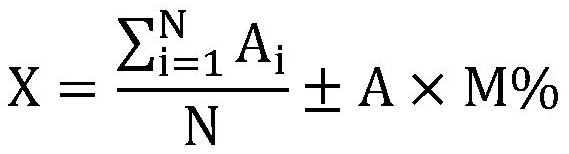

The invention provides a frame-type bidding and tendering management platform for industrial shaped products. The frame-type bidding and tendering management platform comprises a server, and a biddingmodule and a bidding evaluation module which are respectively in communication connection with the server, wherein the bidding module comprises a frame type bid inviting variety detail list; the quotation sub-module is used for filling and reporting bidding prices by suppliers on the basis of the frame-type bidding variety detail list; the bid evaluation module comprises a single product price evaluation sub-module which calculates a single product quotation score for each supplier for the single product quotation of each supplier; the supplier comprehensive price review sub-module is used for calculating a comprehensive quotation score of each supplier based on the single product quotation score of each single product of each supplier; the weight coefficient sub-module is used for calculating the price weight of a single product; and the weighted price review sub-module is used for calculating the weighted price score of the supplier based on the comprehensive quotation score of thesupplier and the price weight of the single product.

Owner:SINOPEC ENG +1

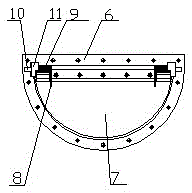

Cylindrical gear pair quasi-static transmission error test bench, test method and data processing method

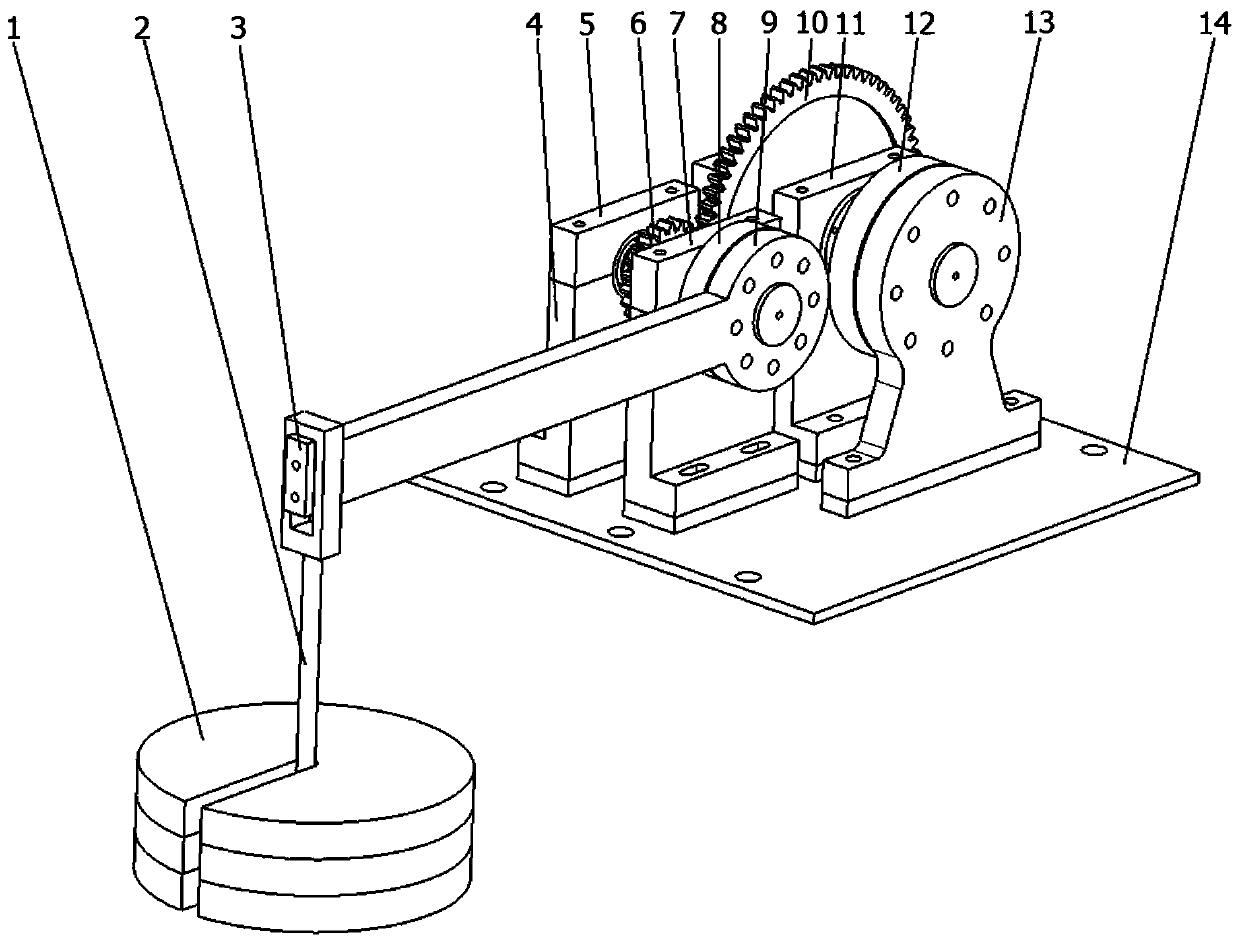

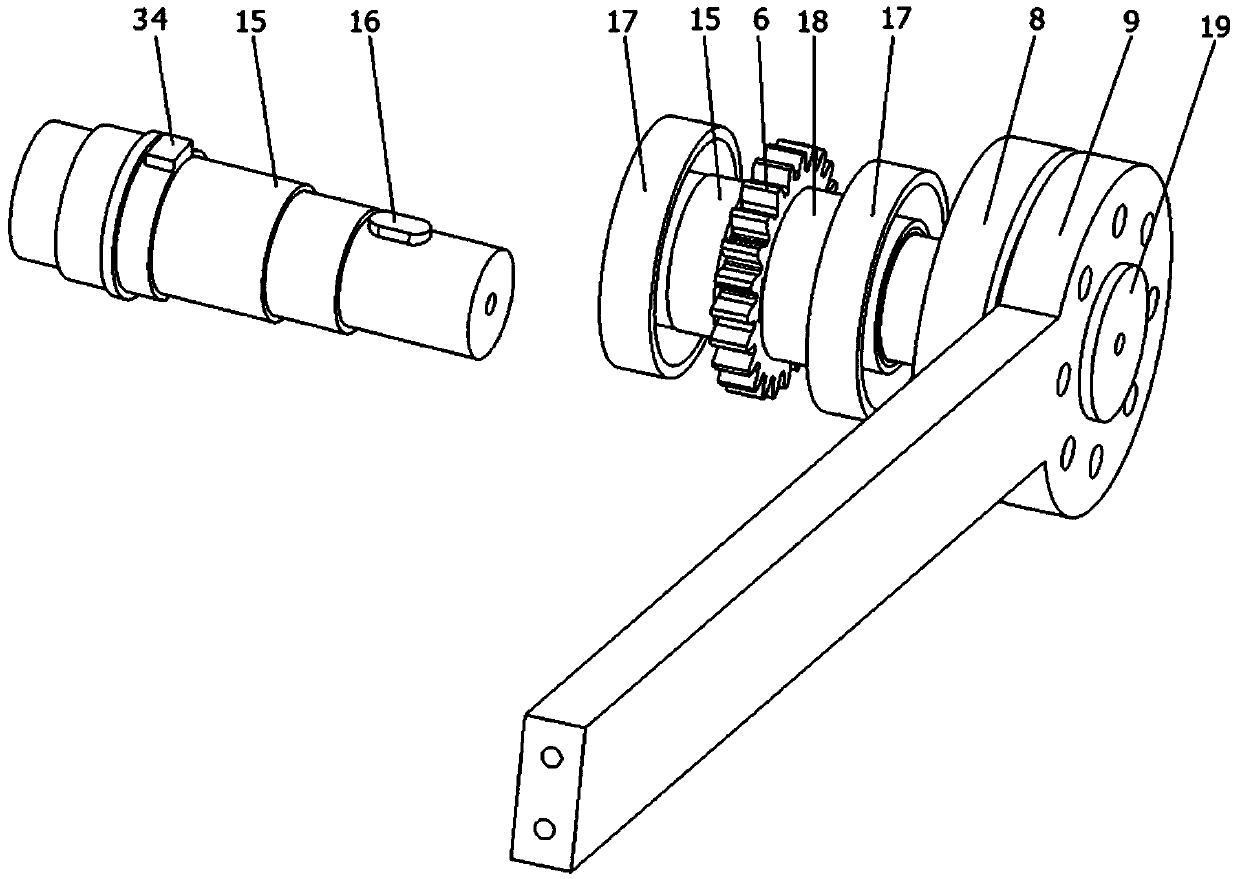

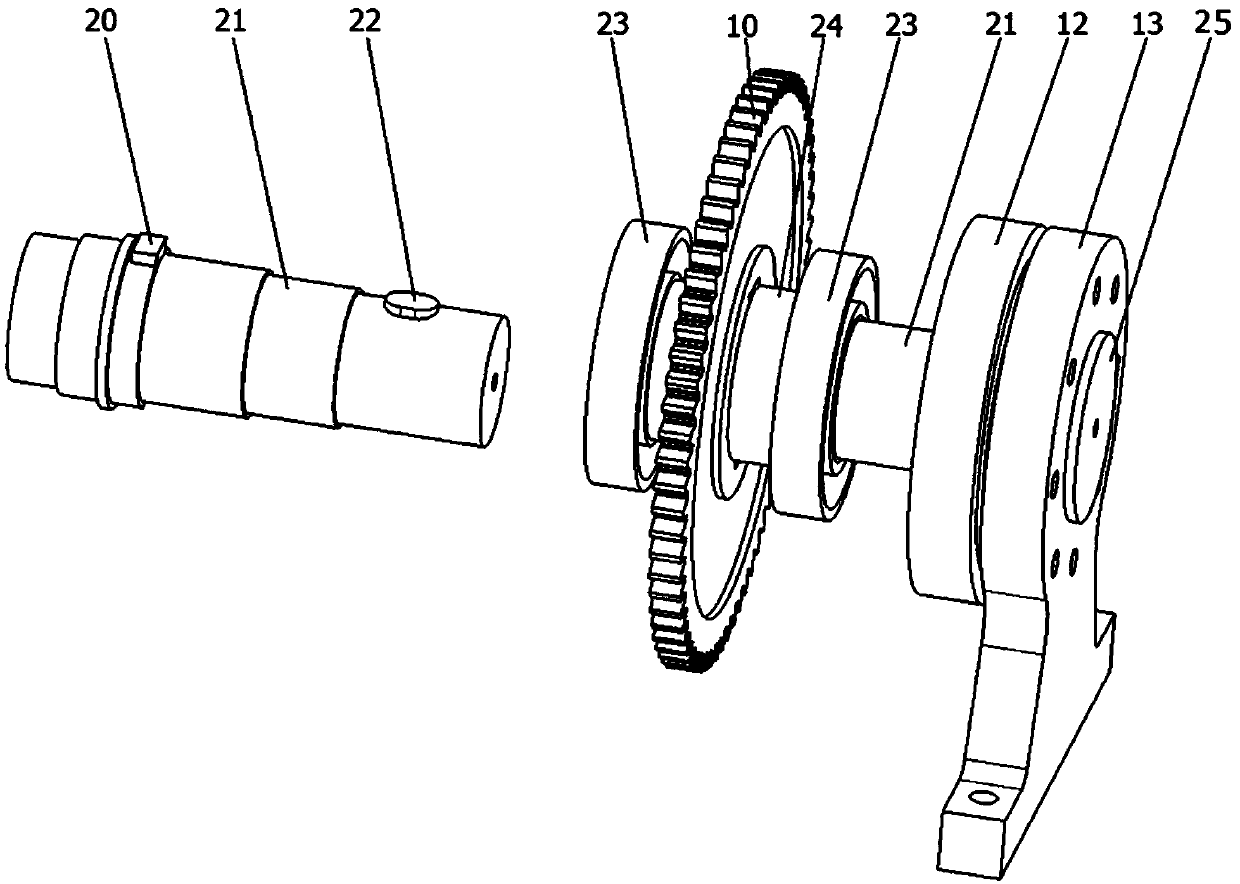

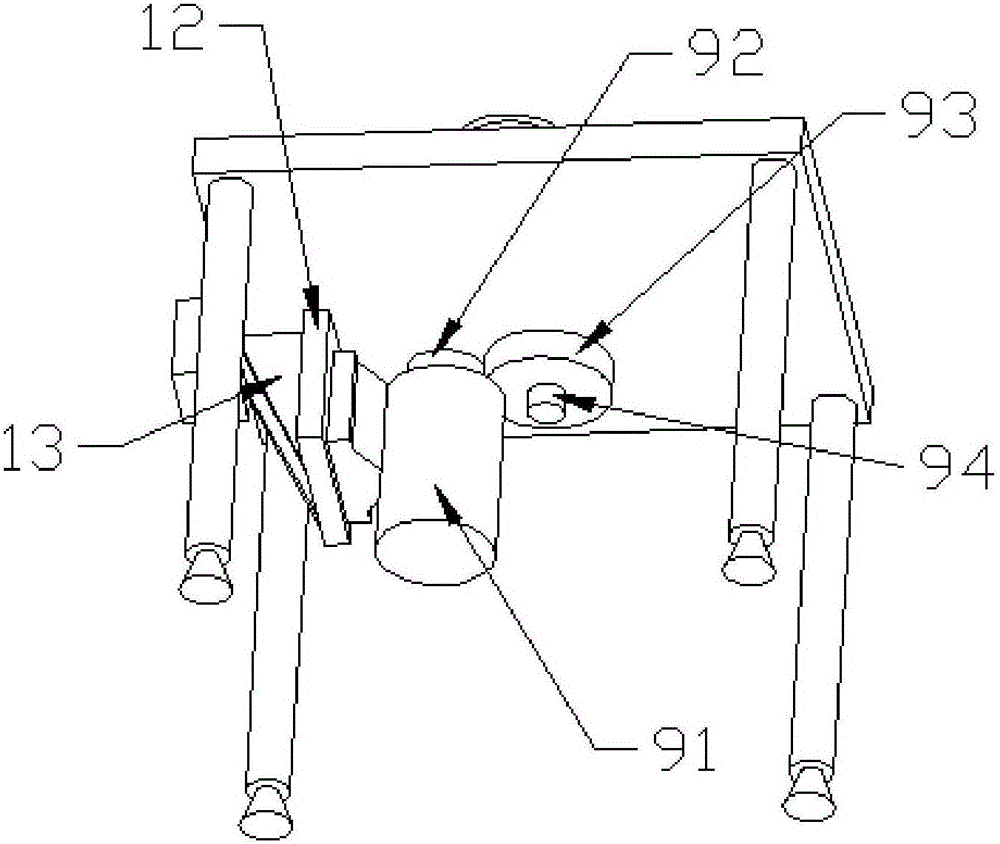

ActiveCN108827626ASimple structureCompact structureMachine gearing/transmission testingDrive shaftTest measurement

The invention discloses a cylindrical gear pair quasi-static transmission error test bench, a test method and a data processing method. The cylindrical gear pair quasi-static transmission error test bench is characterized by comprising a loading component, a rotation locking component, a test bench support component, a driving axle component and a driven axle component. The driving axle componentand the driven axle component which are connected to each other are successively disposed on the test bench support component. The loading component is mounted on a driving shaft end in the driving axle component. The rotation locking component is mounted on a driven shaft end in the driven axle component. The cylindrical gear pair quasi-static transmission error test bench has beneficial effectsthat 1) the test bench has only one cylindrical gear pair and a support mechanism for the meshing transmission of the cylindrical gear pair, and is compact in structure, small in occupied space, and convenient to maintain; 2) the test bench is loaded by a weight and does not require driving equipment such as a motor, a magnetic powder brake and the like so as to save funds and shorten an equipmentprocurement cycle; 3) test measurement can be performed just by normally meshing and loading a gear equipped with a strain gage.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

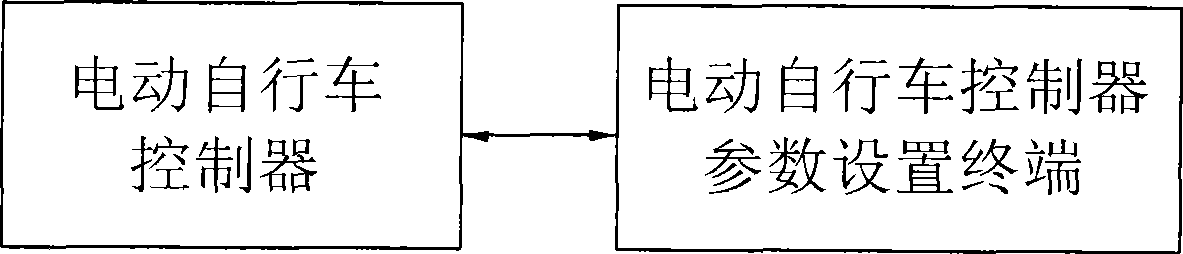

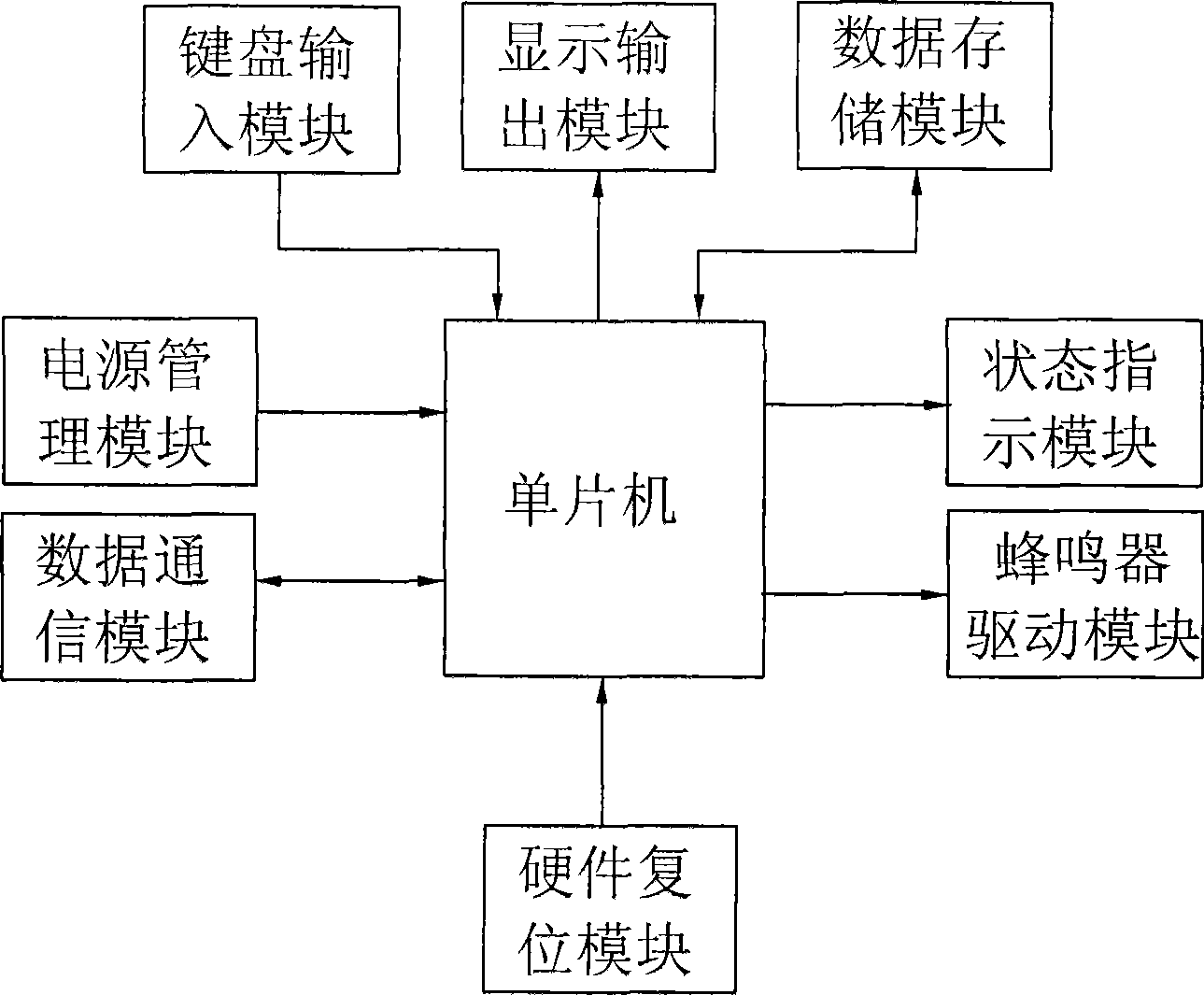

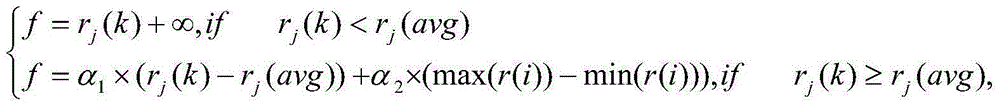

Parameter setting system and method of electric bicycle controller

InactiveCN101486322AReduce typesShort procurement cycleSpeed controllerCycle control systemsComputer terminalEmbedded system

The invention relates to a parameter setting system and a method for an electric bicycle controller. The parameter setting system for the electric bicycle controller comprises the electric bicycle controller in which a memory is arranged, and a communication port of the electric bicycle controller is connected with a communication port of a parameter setting terminal of the electric bicycle controller. The method comprises that: by establishing a communication mode between the electric bicycle controller and the parameter setting terminal of the electric bicycle controller, the parameter setting terminal of the electric bicycle controller sends a control parameter table to the electric bicycle controller, and the electric bicycle controller stores the received control parameter table into a memory inside the electric bicycle controller. Through once operation, the system and the method can finish total parameter setting of the electric bicycle controller, have the characteristics of simple operation and convenient use, and are convenient for electric bicycle factories to design, produce, maintain and manage.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

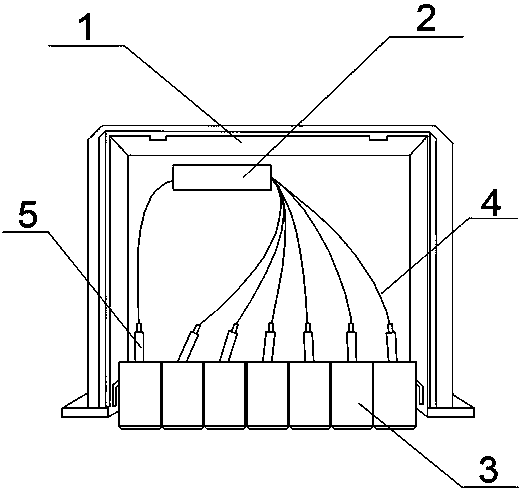

Novel loose-item-free chip-type optical divider

The invention discloses an optical divider flange assembly with a rotary inner core and a casing in nested pair. Due to the fact that the inner core is rotatable and adjustable in the casing, the inlet direction of a ceramic ferrule can be adjusted according to the fiber introducing direction, so that bending and abrasion to the optical fiber at an inlet of the ceramic ferrule can be avoided, occupation of the space in a divider box by a fiber bundle can be reduced, long-term efficient use of the optical divider can be ensured, signal transmission failure caused by damage to the fiber can be avoided in the operation process, and the shortcomings of long production cycle and high cost caused by the fact that loose items must be purchased before production of the chip-type optical divider, and need to be threaded and assembled manually in the production process can be overcome.

Owner:SICHUAN TIANYI COMHEART TELECOM

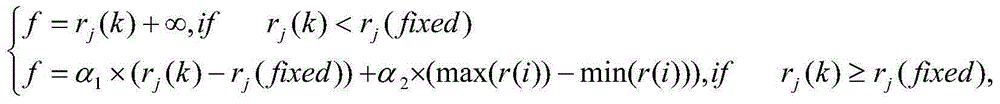

Protocol inventory matching and optimal allocation method

ActiveCN104992251AShort procurement cycleThe calculation result is accurateForecastingLogisticsIntelligent algorithmsMatch problem

The invention discloses a protocol inventory matching and optimal allocation method. According to the method, protocol inventory matching is solved based on a branch definition algorithm, and balanced matching of a region and a schedule, considered by a protocol inventory, is finished; and the method comprises protocol inventory modeling and establishment of a protocol inventory intelligent algorithm. According to the method disclosed by the invention, the balanced matching of the region and the schedule, considered by the protocol inventory, is finished by the method for solving the protocol inventory matching problem based on the branch definition algorithm; the balance of the region and the schedule can be considered; a calculation result is accurate and a purchasing period of a supply chain is short; and meanwhile, an executing result can be comprehensively analyzed and evaluated, deviation overflow in a decision-making process can be explained, and the requirements are met.

Owner:STATE GRID CORP OF CHINA +2

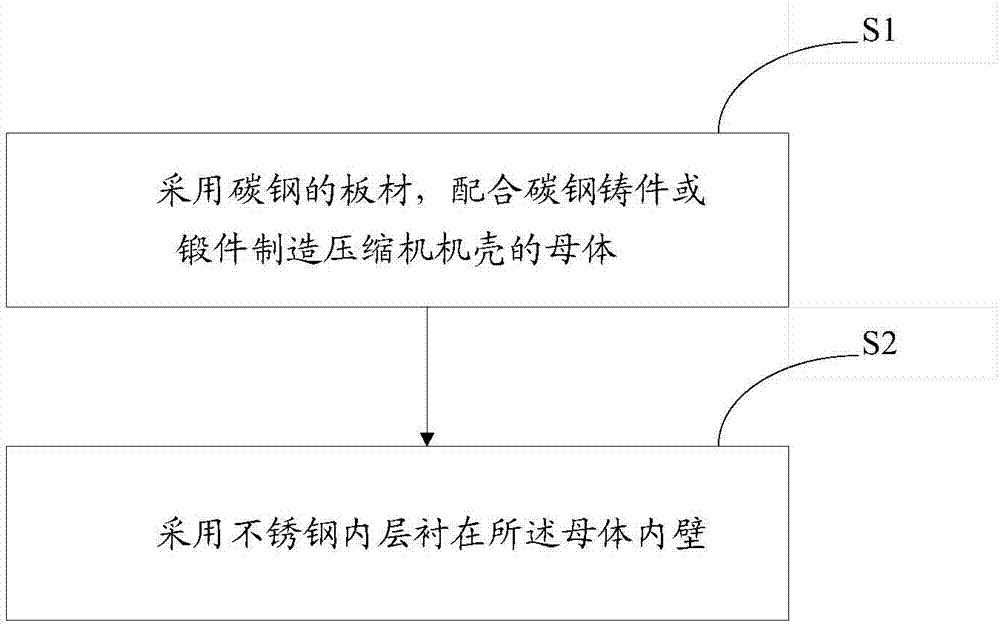

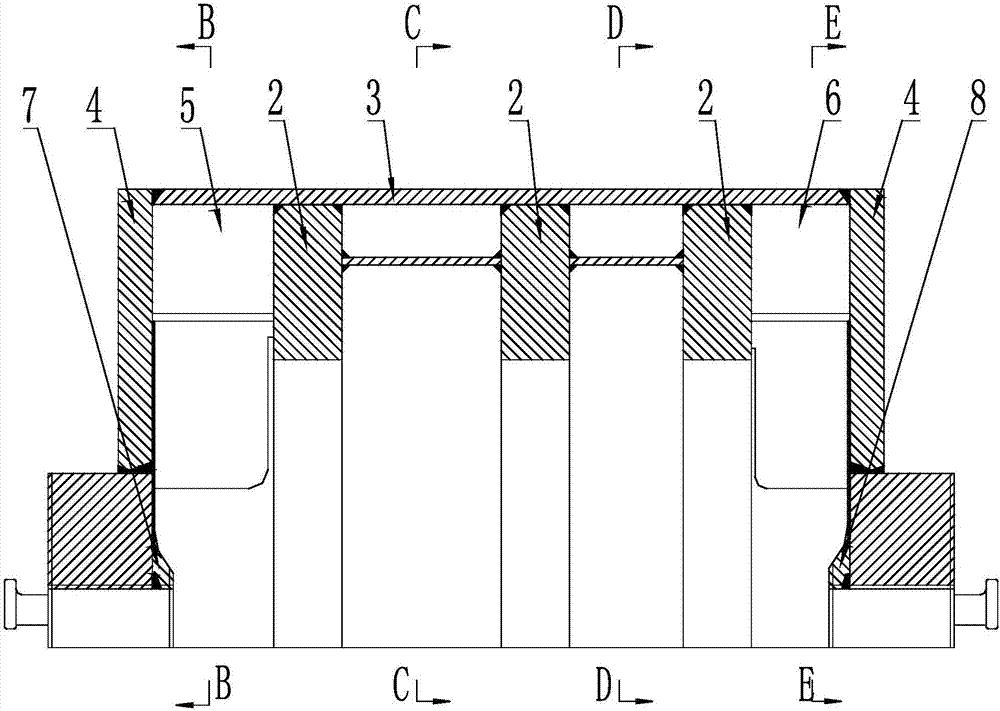

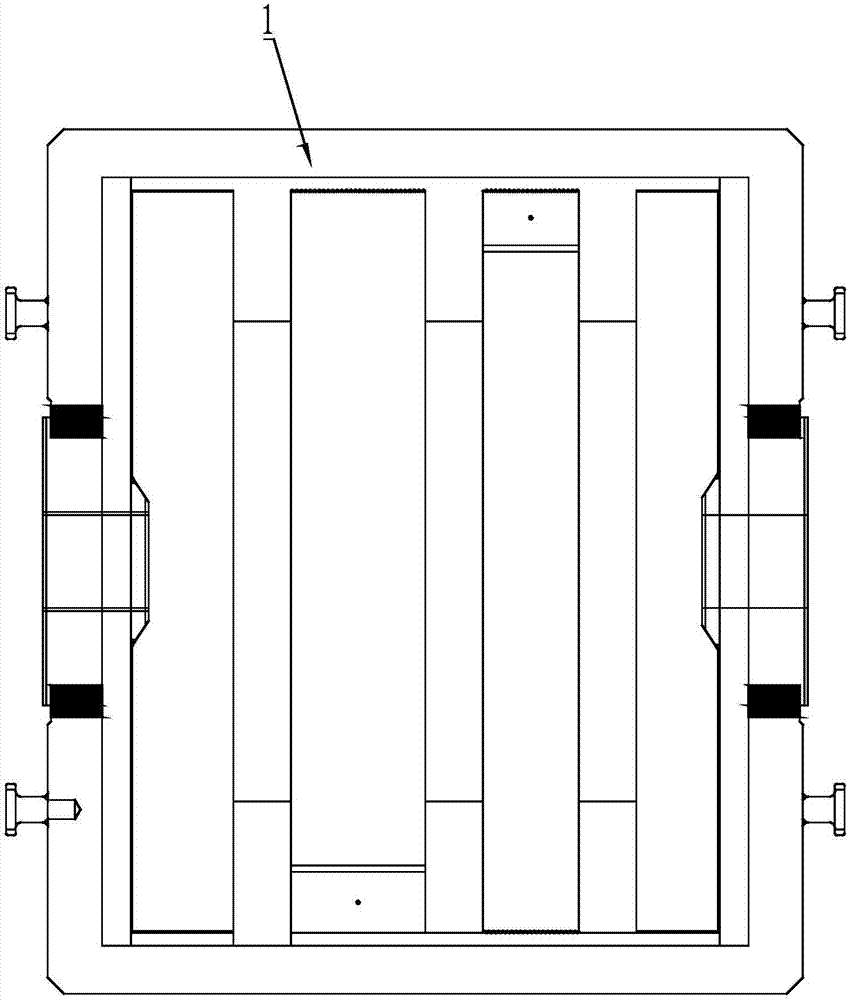

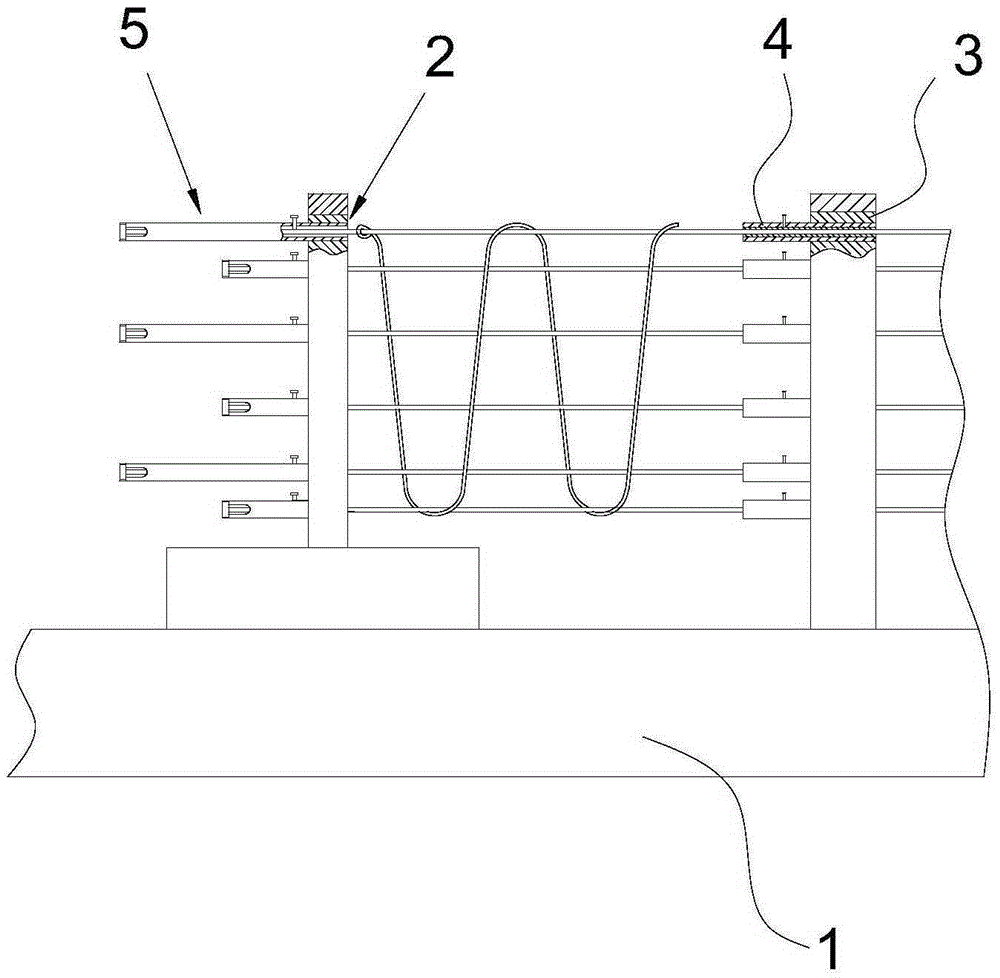

Manufacturing method of compressor shell and compressor shell

The invention discloses a manufacturing method of a compressor shell. The manufacturing method of the compressor shell comprises the following steps: a carbon steel plate is adopted to match with a carbon steel casting or forging to manufacture a parent body of the compressor shell; and a stainless steel inner layer is lined on the inner wall of the parent body. The invention further discloses the compressor shell manufactured by adopting the manufacturing method. The compressor shell manufactured by adopting the method has the characteristics of good manufacturability, short manufacturing period, high manufacturing precision and good product quality.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

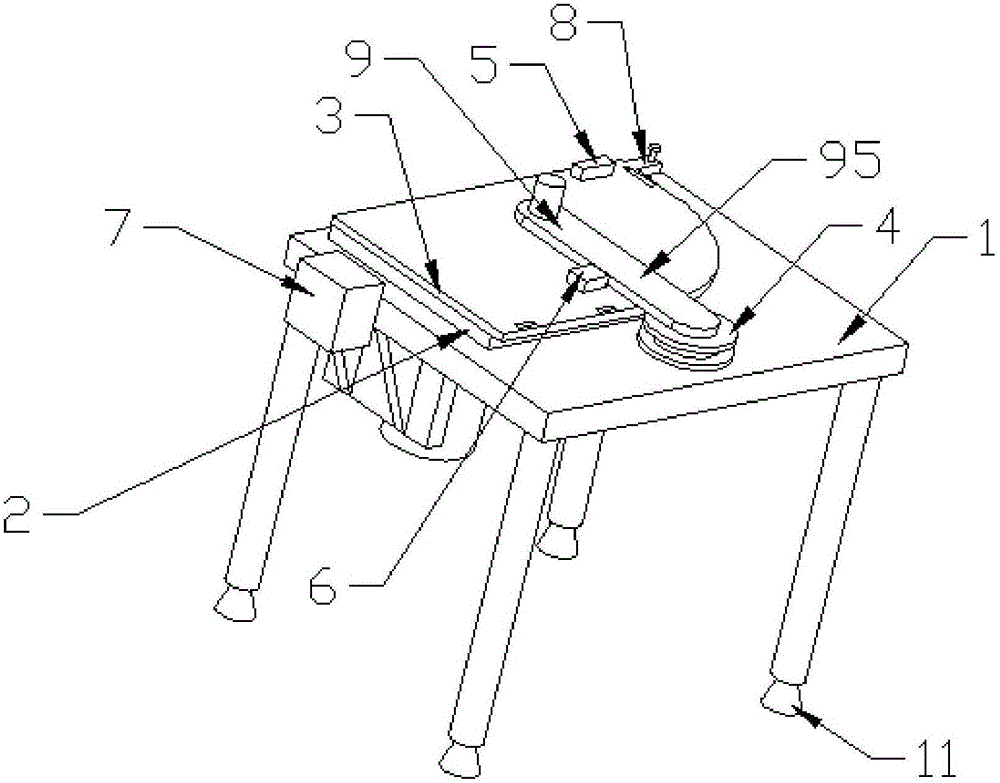

Limiting device for cage rolling machine

InactiveCN105364389AEliminate pre-assembly processIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

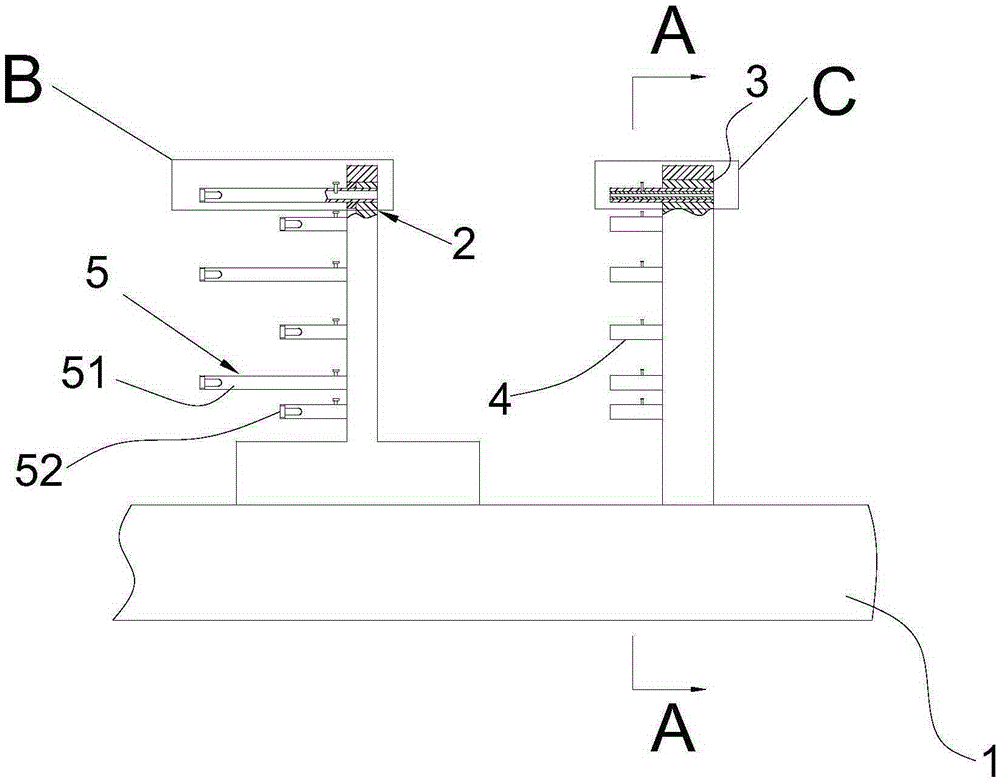

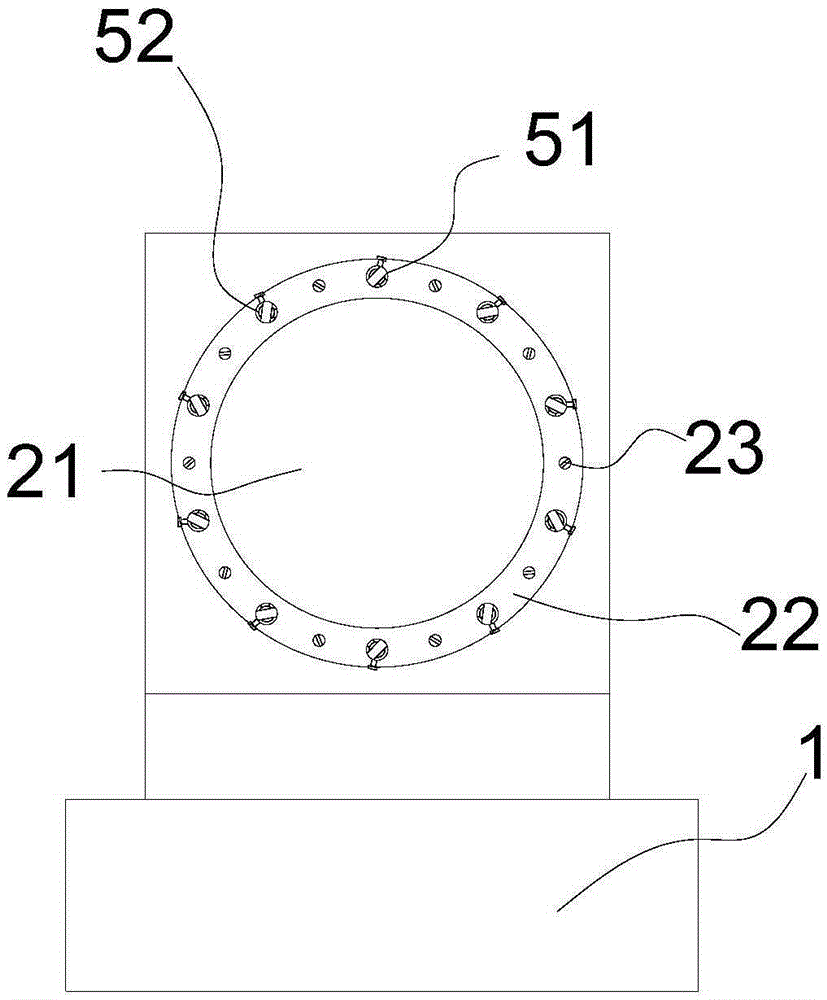

The invention relates to the field of tool equipment, in particular to a limiting device for a cage rolling machine. The cage rolling machine comprises a rail platform, a movable rotary disc and a positioning rotary disc. The movable rotary disc is connected to the rail platform in a sliding mode, and the positioning rotary disc is fixedly connected to the rail platform. The limiting device for the cage rolling machine comprises outer barrels and end barrels. The end barrels are evenly distributed circumferentially and penetrate through the movable rotary disc, and the outer barrels are evenly distributed circumferentially and penetrate through the positioning rotary disc. The outer barrels correspond to the end barrels one to one. The ends, away from the outer barrels, of the end barrels are provided with end covers, and first limiting bolts penetrate through the barrel walls of the end barrels. The limiting device has the following advantages that operation is easy; main reinforcements are not likely to loose; steel reinforcement cages which are good in stability and high in strength can be manufactured; vibration can be lowered through inner barrels, and welding quality is guaranteed; it is guaranteed that the reserved sections of the steel reinforcement cages are located in the same section through the end covers, a pre-assembling procedure is omitted, the limiting device can be directly conveyed to a site to be connected in a non-break-joint mode, labor cost is greatly reduced, and construction efficiency is improved.

Owner:孙鸿雁

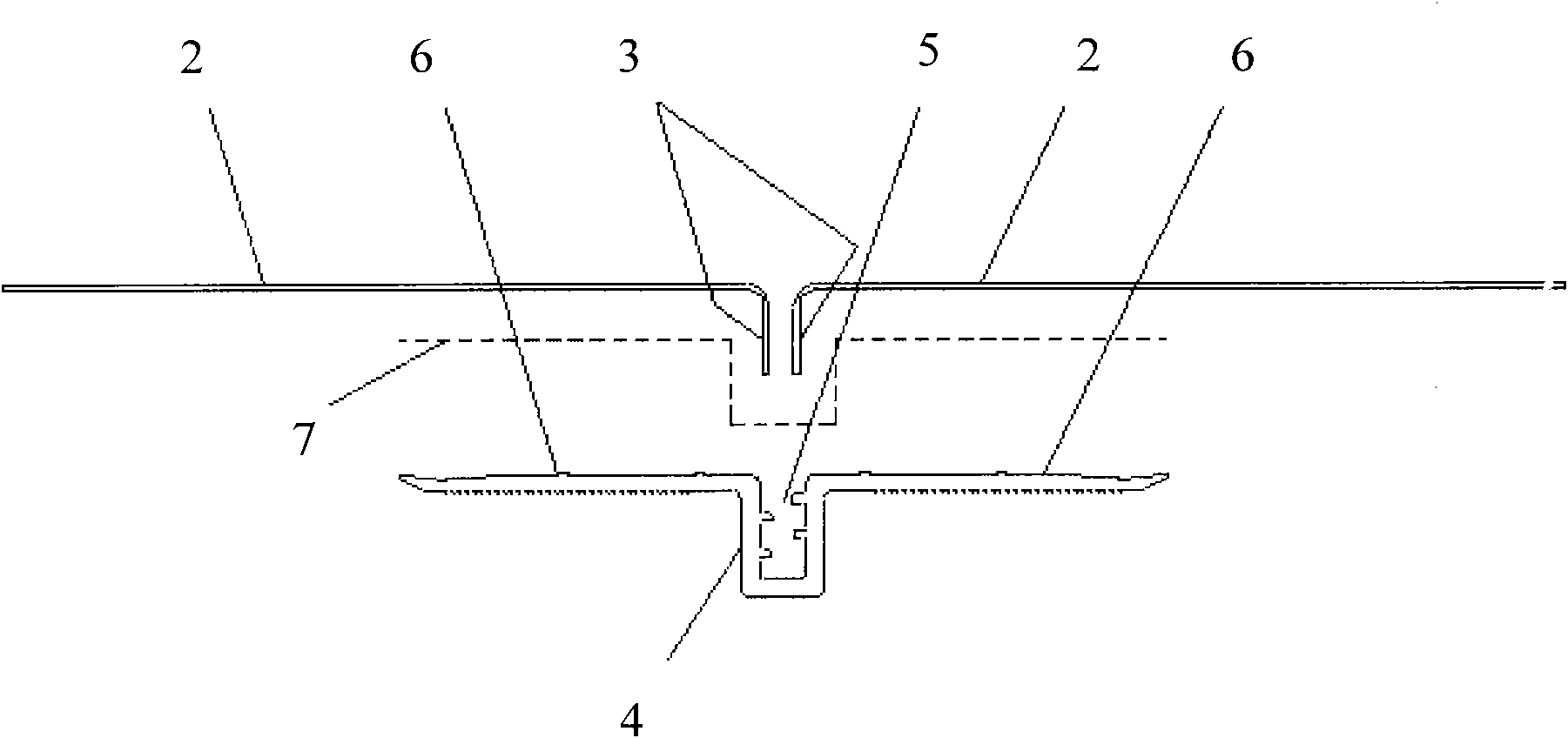

Refrigerator car

ActiveCN102107620AReduce the amount of processingWill not harmRefrigerated goods vehicleLoading-carrying vehicle superstructuresRear quarterRefrigerator car

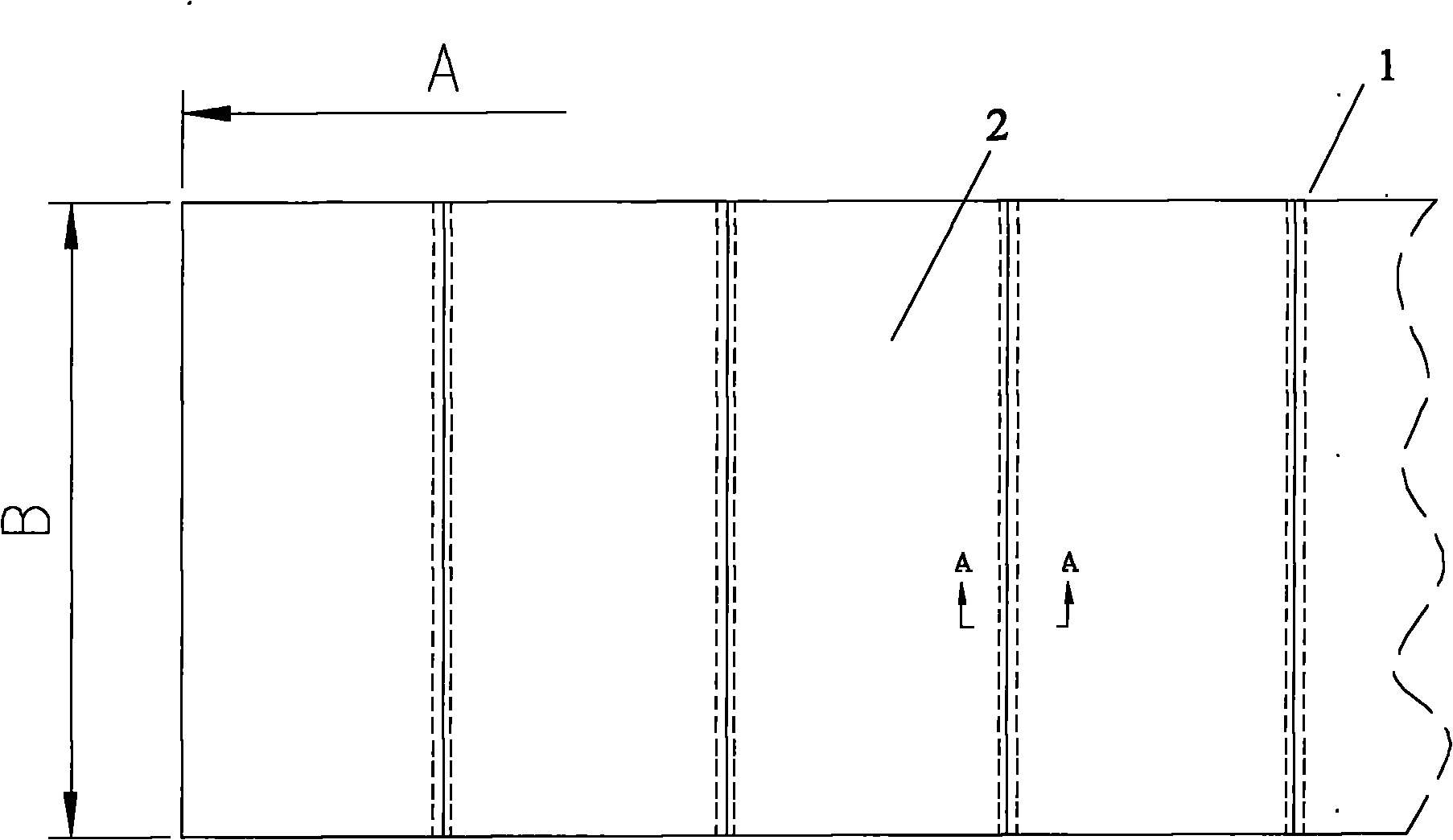

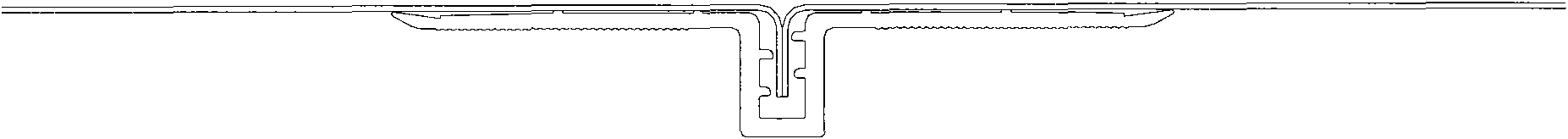

The invention discloses a refrigerator car. The cabinet body of the refrigerator car comprises a chassis, a pair of lateral boards, a front wall, a door end and a roof, wherein the pair of the lateral boards are arranged on the chassis; and the front wall and the door end are oppositely arranged on two ends of the pair of the lateral boards. The refrigerator car is characterized in that: the lateral boards or the roof or the front wall of the cabinet body comprises a plurality of metal plates with preset lengths and a plurality of connecting ribs, wherein each metal plate is provided with bent edges; each connecting rib comprises a buckle groove for accommodating bent edges of two parallel metal plates; and a pair of wing plates which extend towards two sides from the mouth of the buckle groove respectively are used for connecting the metal plates.

Owner:QINGDAO CIMC REEFER TRAILER

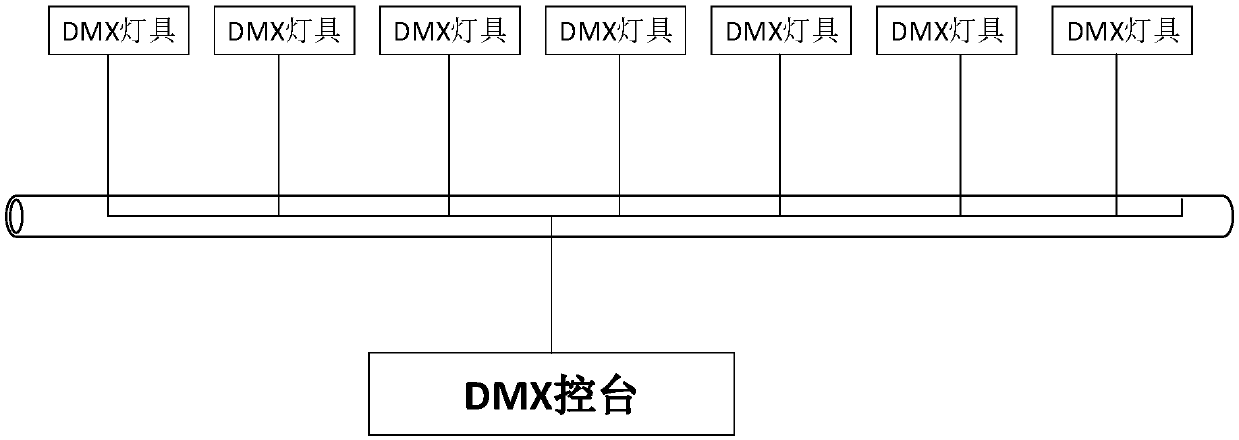

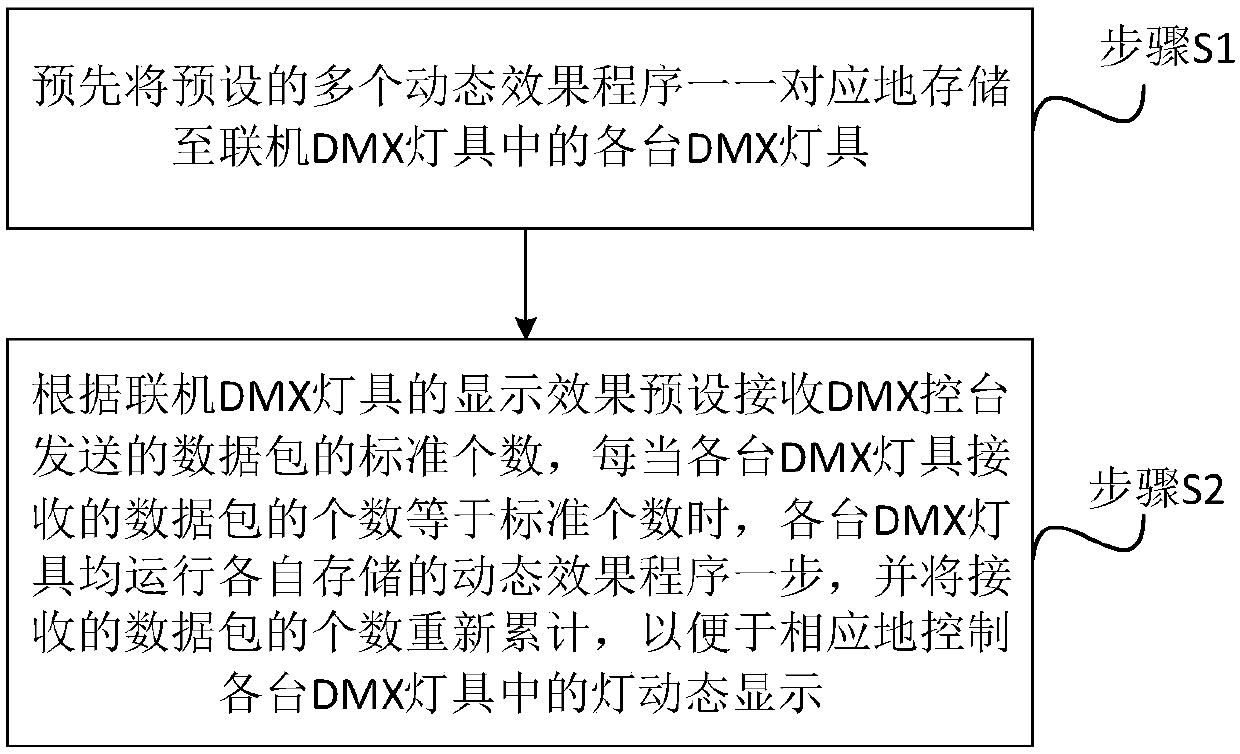

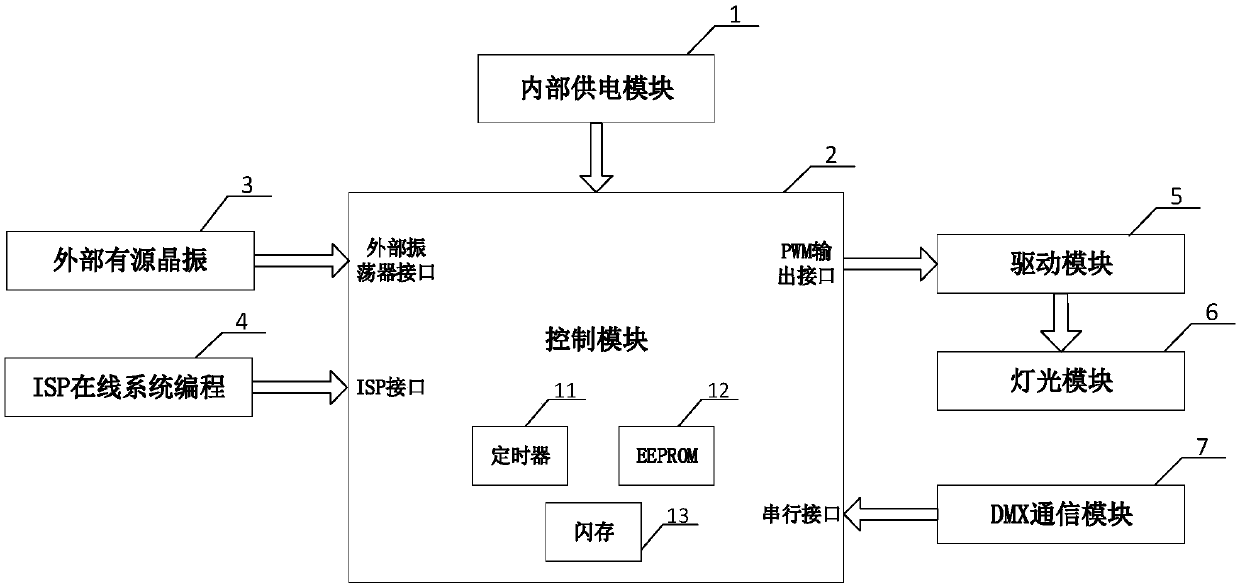

Method and system for synchronizing dynamic effect of online DMX lamp and DMX lamp

ActiveCN108040389AAchieving dynamismControl dynamic displayElectrical apparatusElectroluminescent light sourcesNetwork packetWorkload

The invention discloses a method and a system for synchronizing the dynamic effect of an online DMX lamp and a DMX lamp. The method includes the following steps: multiple preset dynamic effect programs are stored in DMX lamps of an online DMX lamp in advance in a one-to-one correspondence manner; the standard number of received data packets sent by a DMX console is preset according to the displayeffect of the online DMX lamp; and when the number of data packets received by each DMX lamp is equal to the standard number, each DMX lamp runs the dynamic effect program stored therein once, and thenumber of received data packets is re-calculated, so that the dynamic display of light in each DMX lamp can be correspondingly controlled. The performance quality of performers and the visual effectof the audience are improved. The workload is small, the difficulty is low, the debugging period is short, there is no need to change the hardware, and the purchasing cycle and the product cost are reduced. For an online DMX lamp running at high speed or for a long time, the probability of dynamic effect asynchronization is reduced.

Owner:LETARON ELECTRONICS

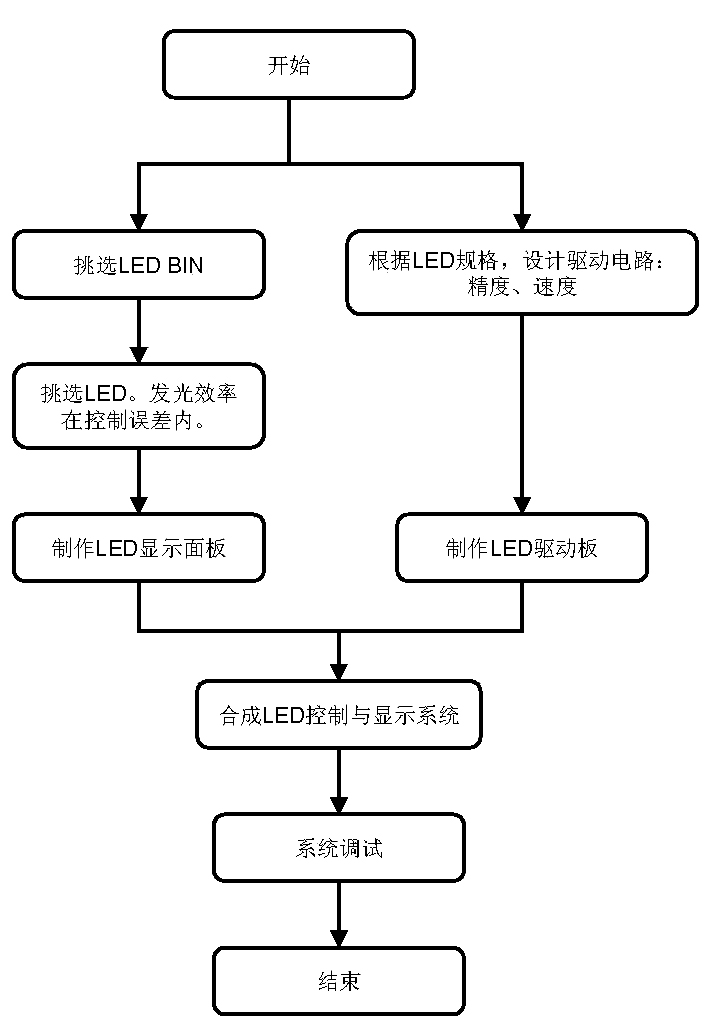

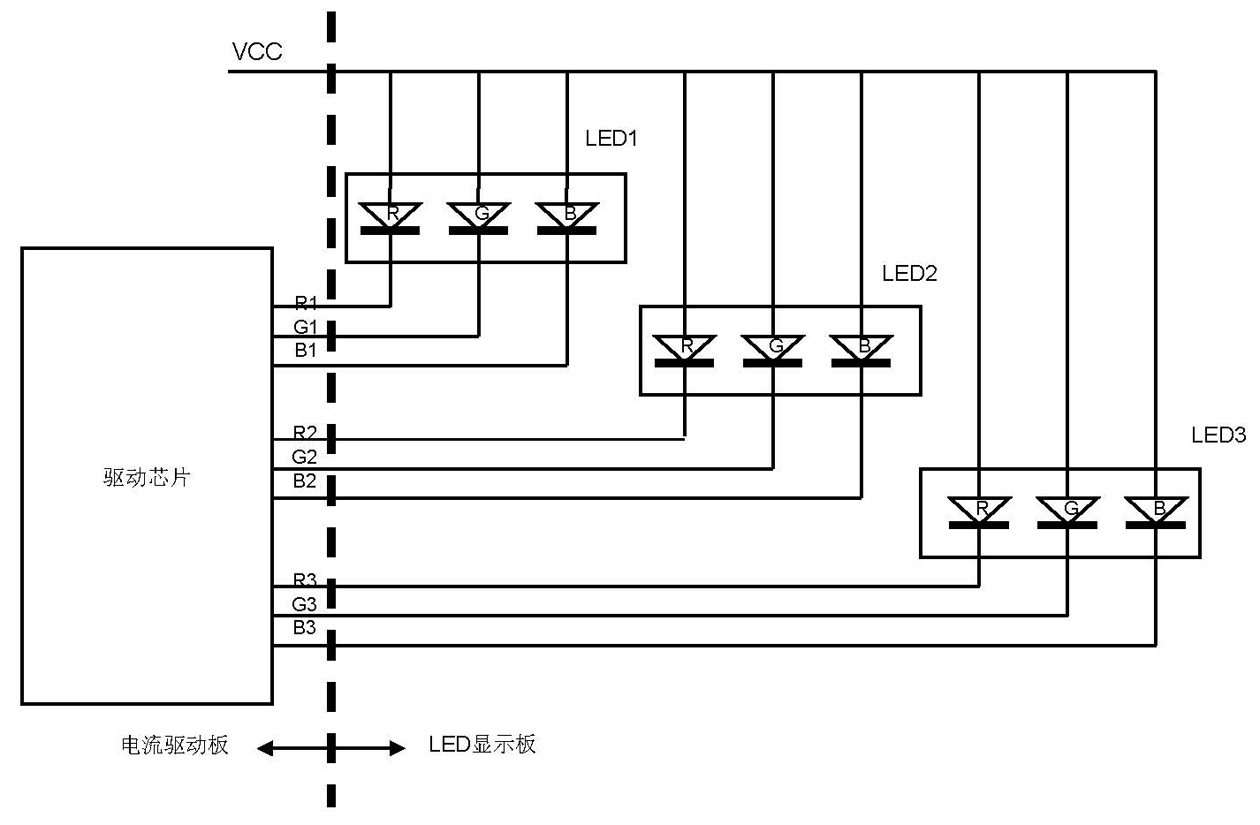

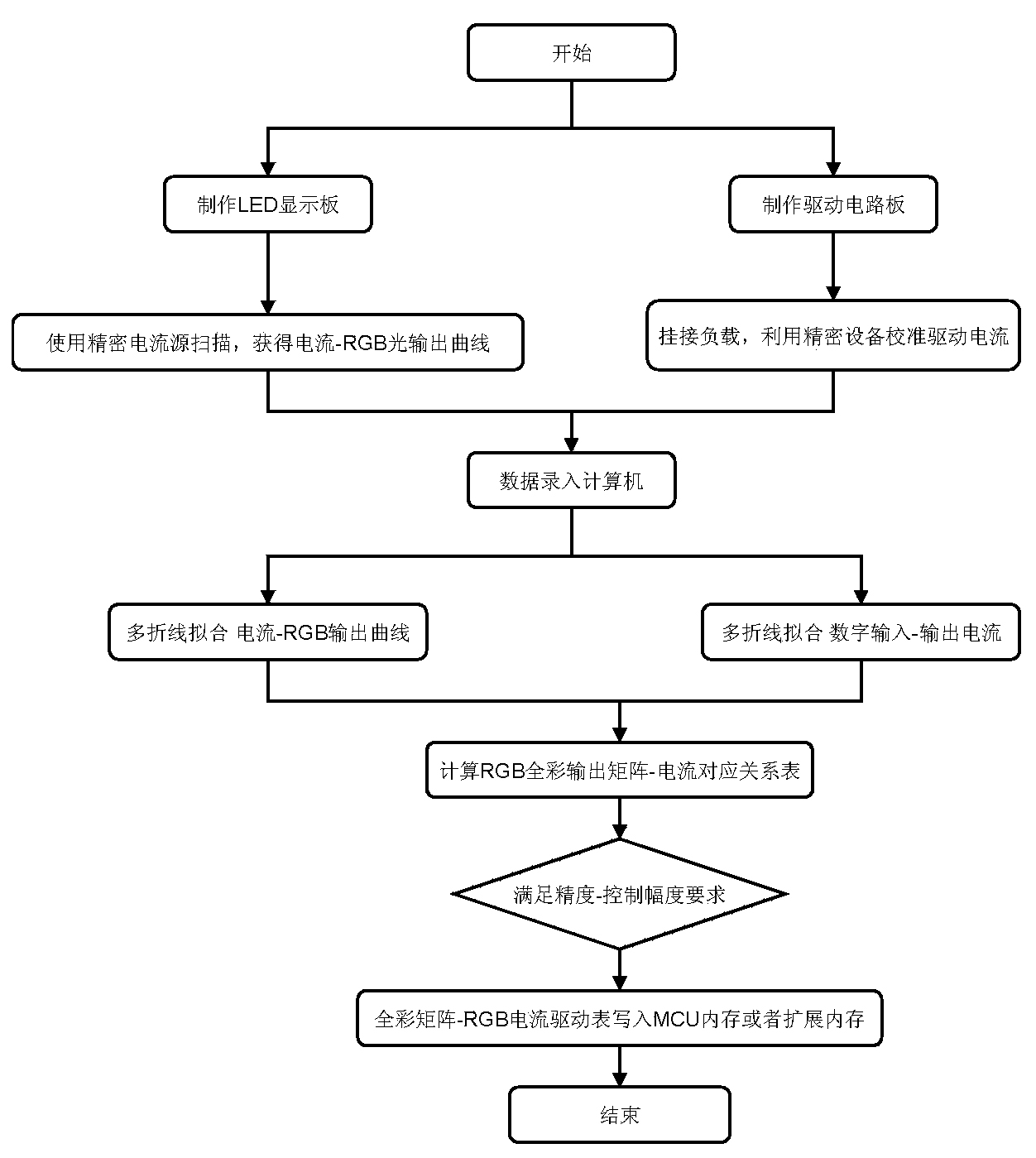

High-speed and high-precision control proposal and control circuit for LED (light emitting diode) brightness and color

InactiveCN102013225AHigh speedIndividually control brightnessCurrent/voltage measurementStatic indicating devicesDriving currentMuch Worse

The invention relates to a high-speed and high-precision control proposal and control circuit for LED (light emitting diode) brightness and color as well as an algorithm. The control circuit comprises the following five parts: a single LED scanning and data matrix, a full color and RGB (red-green-blue) corresponding matrix, a brightness control equation, a driving current calibration, multi-line segment approximation and full color display matrix, and an integral circuit proposal. According to the scheme of the invention, various errors in the course of design and creation can be eliminated, and high consistency and high precision of the color and brightness control are achieved. Although the device precision of the used circuit board is 1% or much worse, and various errors exist between the circuit boards, through the implementation of the scheme, the color and brightness errors of each LED and each LED module are 0.1% or more.

Owner:惠州市科信达电子有限公司

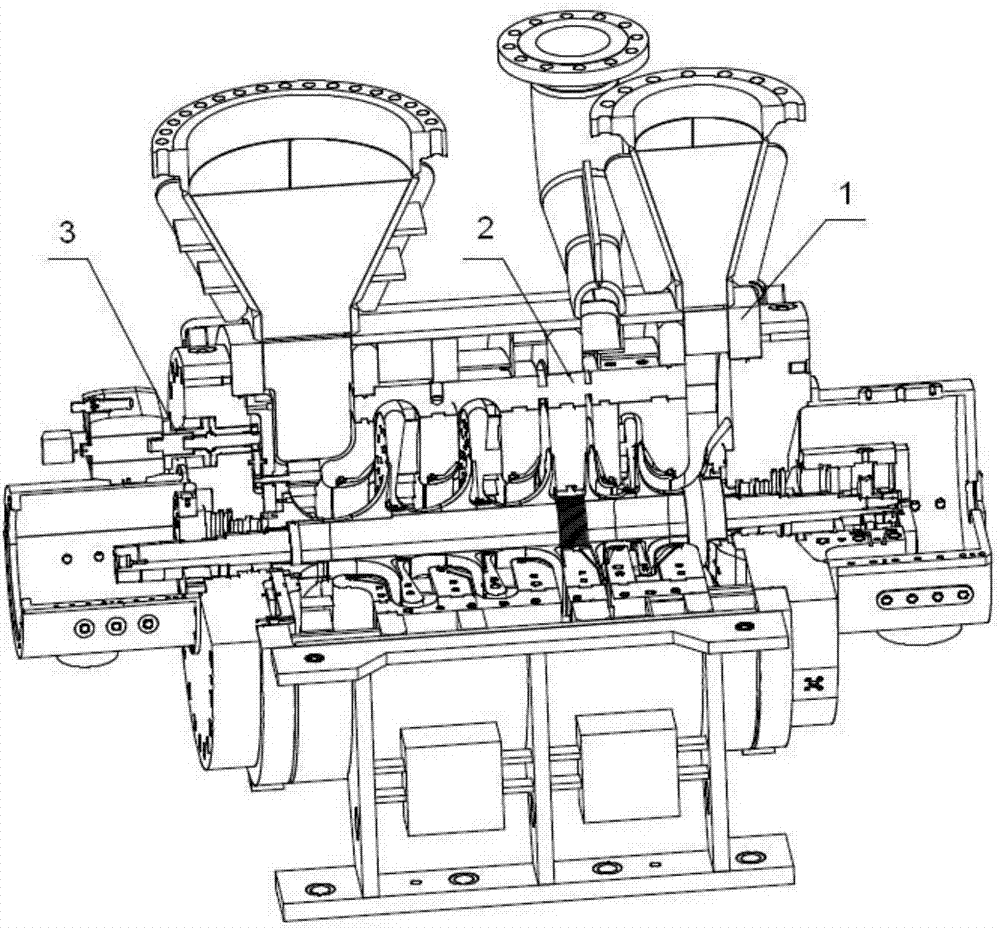

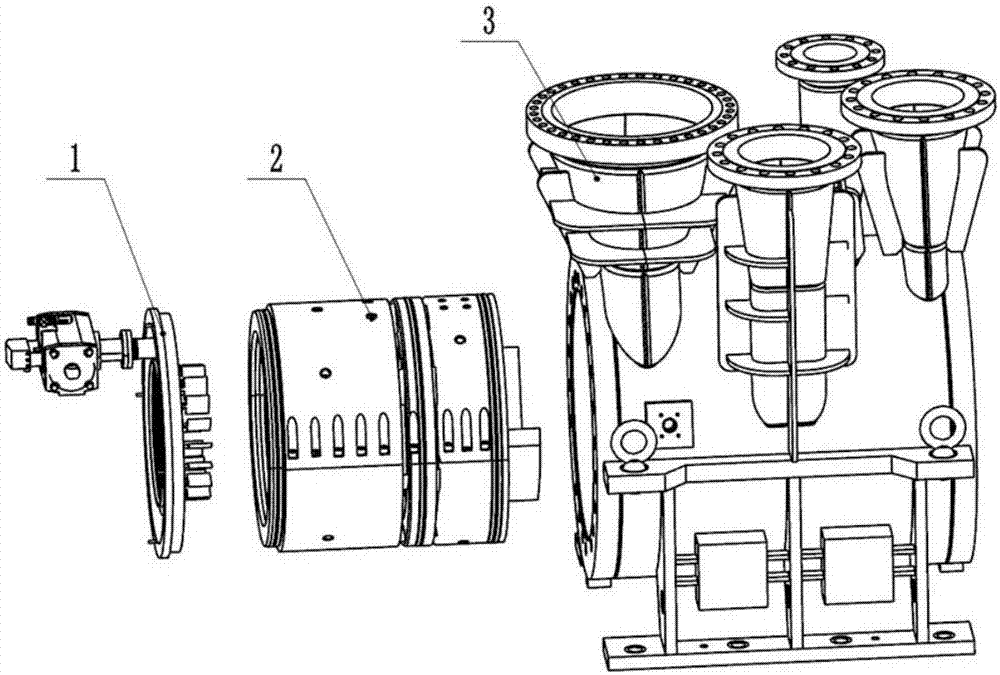

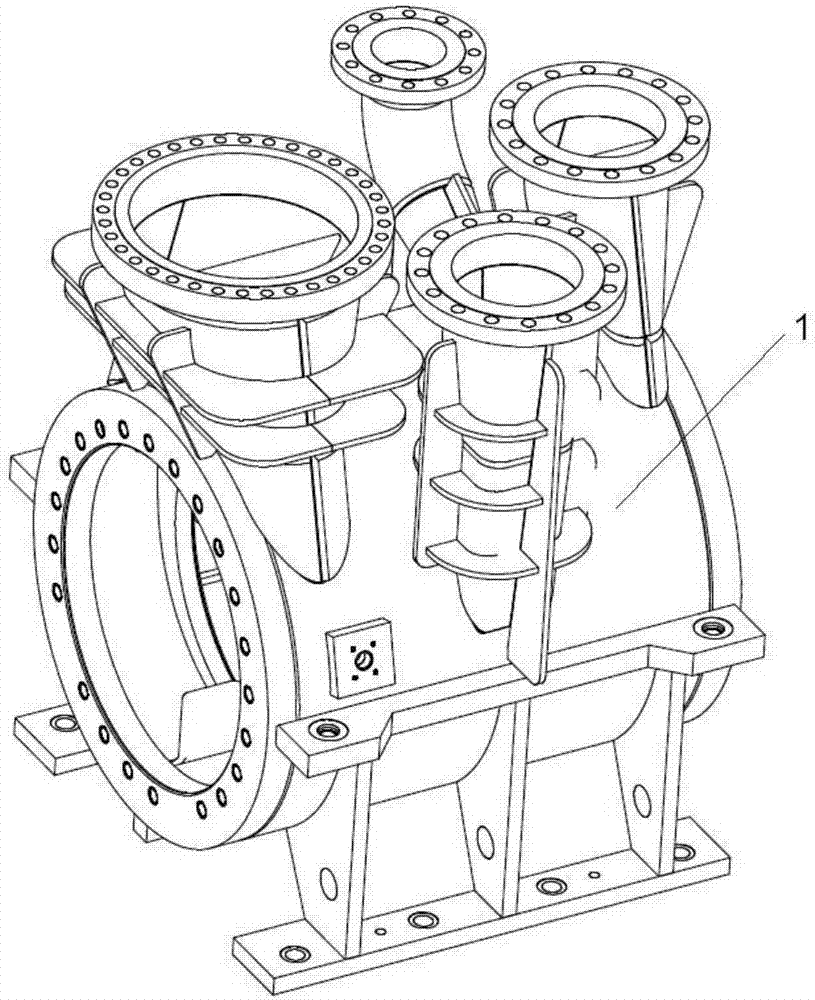

Barrel type refrigerant compressor

ActiveCN107956745AGood high pressure sealingMeet the arrangementPump componentsPumpsEngineeringHigh pressure

The invention relates to a barrel type refrigerant compressor. The compressor comprises a barrel type welding machine shell, an inner machine shell and an adjustable guide blade execution mechanism, wherein a volute chamber is arranged inside the barrel type welding machine shell; the inner machine shell is arranged inside the barrel type welding machine shell, and a connecting rib set is arrangedin the circumferential direction of the shell wall of the inner machine shell and is used for dividing the inner machine frame into at least two units of inner machine frame bodies; and the inner machine shell is arranged in the part, close to one side of the inner machine shell, of the barrel type welding machine shell. The barrel type refrigerant compressor has the advantages of being light inunit weight and low in unit cost, and the refrigerant compressor can also achieve high-pressure sealing performance and the single-layer arrangement of the unit.

Owner:SHENYANG TURBO MASCH CORP

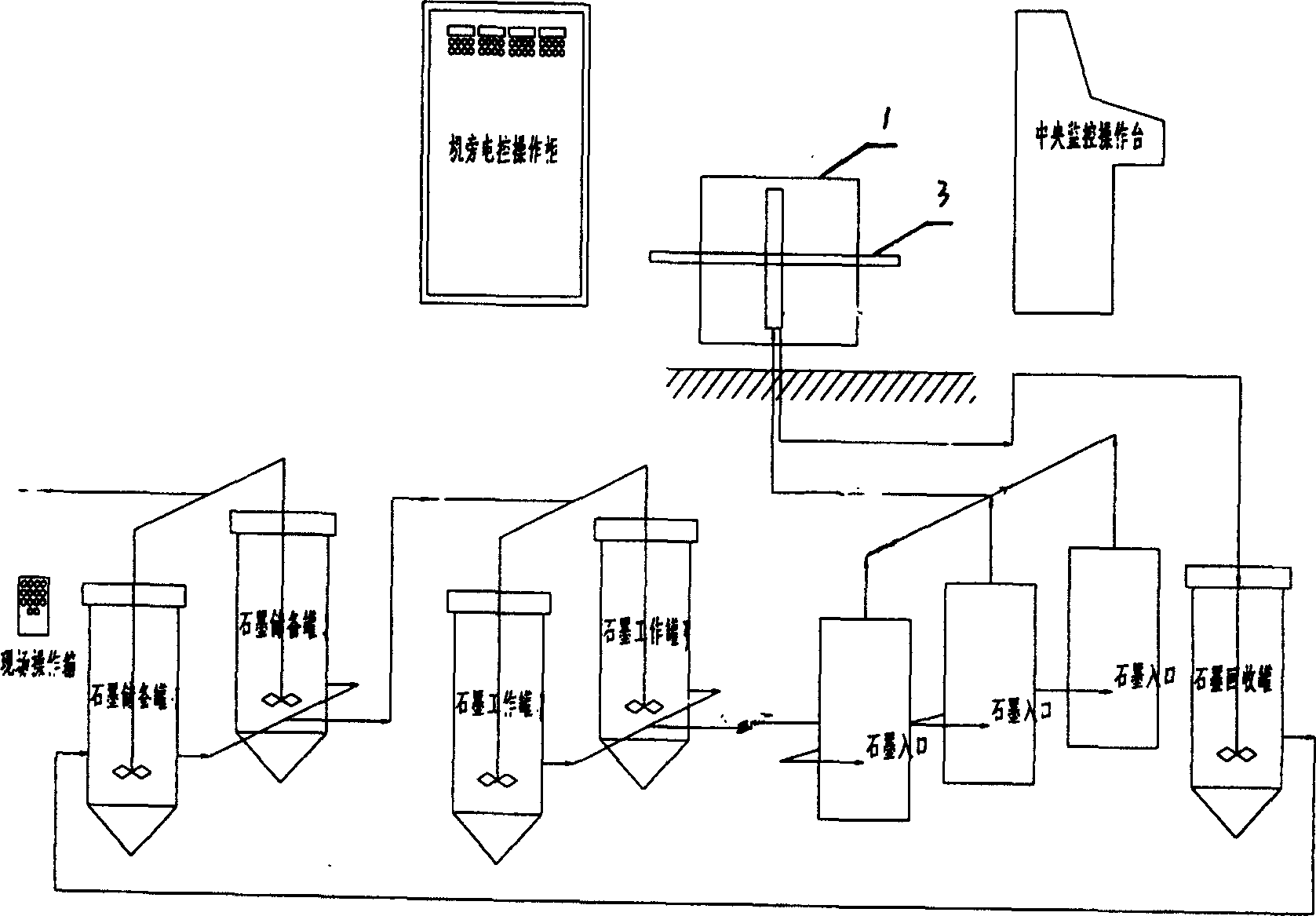

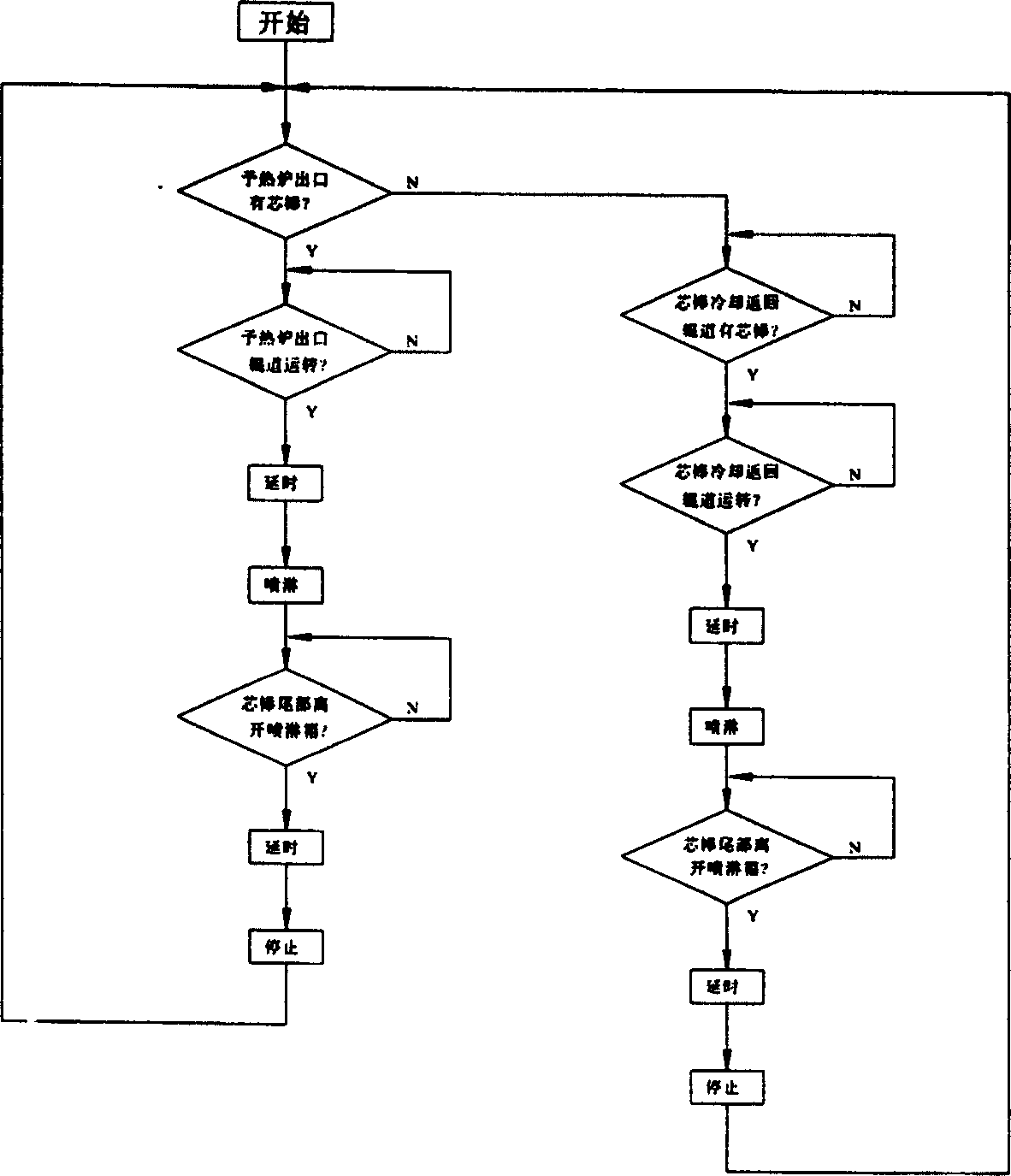

Core stick graphite lubricating system for seamless steel pipe rolling

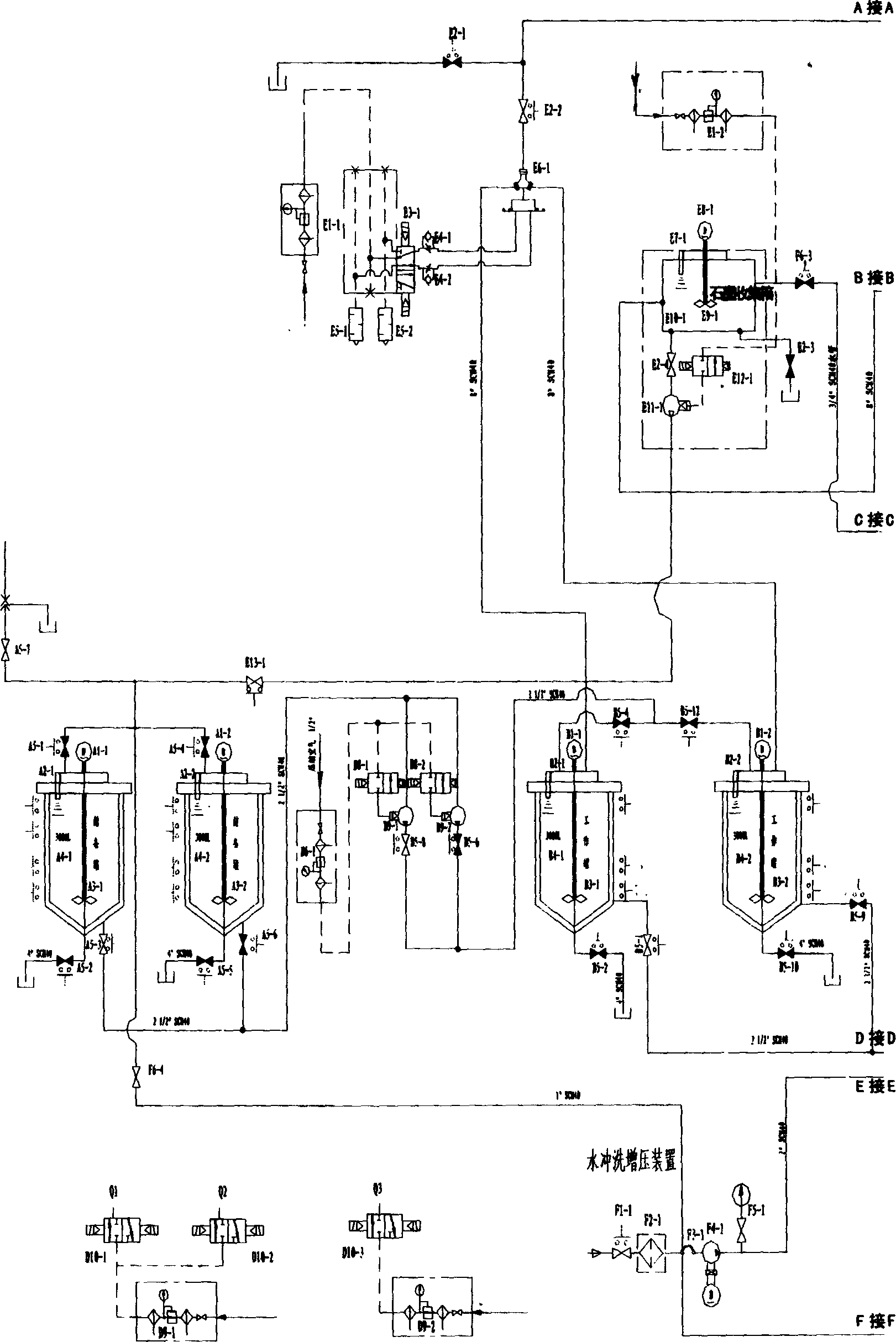

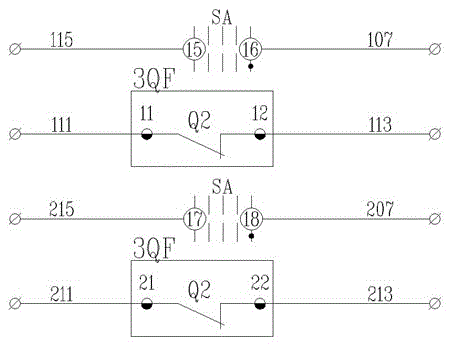

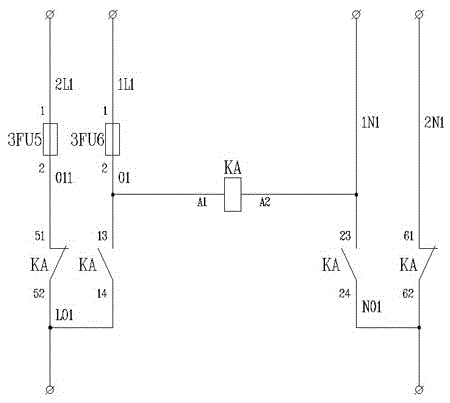

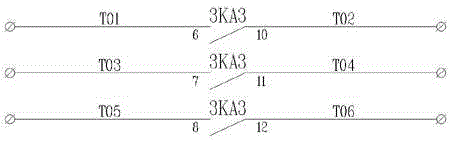

InactiveCN1781617AAvoid cloggingGuarantee unimpededMandrelsMetal rolling arrangementsElectrical controlGraphite

The mandrel lubricating graphite system for seamless steel pipe rolling consists of graphite storing unit, graphite operating unit, graphite circulating unit, graphite spraying unit and electric control unit connected together. The present invention has the advantages of high automation, high control precision, high operation reliability, simple maintenance, low cost, etc.

Owner:BUCCMA ACCUMULATOR TIANJIN

Automatic put and automatic recovery control system

ActiveCN105006881AMeet various needsGuaranteed electricity demandEmergency power supply arrangementsCommunication unitRemote control

The invention discloses an automatic put and automatic recovery control system. A No.1 wire inlet cabinet, a bus coupler cabinet and a No.2 wire inlet cabinet are connected with a background safety automatic device through buses. Wire inlet voltage signals of the No.1 wire inlet cabinet and the No.2 wire inlet cabinet are connected through a voltage sampling unit, a wire inlet breaker at a fault side is disconnected automatically when No.1 wire inlet or No.2 wire inlet is out of order, the bus coupler cabinet is input, when a wire input power supply recovers, the bus coupler cabinet is disconnected automatically, the wire inlet breaker is put, Through respective multifunctional measurement and control modules, collected power grid information of current signals, voltage signals of the No.1 wire inlet cabinet, the bus coupler cabinet and theNo.2 wire inlet cabinet, the switch state of the breaker and the like is uploaded to the background safety automatic device by utilization of the communication unit of the multifunctional measurement and control module through buses, and a control connection and disconnection instruction sent back from the background safety automatic device is received. Switching of a plurality of functional modes of automatic put and automatic recovery, automatic put and no automatic recovery, , and manual control and remote control of a switch cabinet and the like is achieved through a change over switch arranged at the bus coupler cabinet.

Owner:昇辉智能科技股份有限公司

Substrate applicable to corrugated denitration catalyst and forming preparation method of catalyst

ActiveCN108404998AImprove compactnessIncreasing the thicknessCatalyst carriersGas treatmentGlass fiberEngineering

The invention discloses a substrate applicable to a corrugated denitration catalyst and a forming preparation method of the catalyst. The substrate comprises, in weight percent, 53% -56% of SiO2, 27%-30% of CaO, 12%-15% of Al2O3 and 1%-3% of MgO. According to the substrate, a corrugated molding control technique is adjusted, and technical indexes of a felt are continually optimized and adjusted inthe using process, so that corrugated plates meeting corrugated catalyst requirements can be formed by domestic glass fiber felts.

Owner:QIYUAN XIAN DAE YOUNG ENVIRONMENTAL PROTECTION TECH CO LTD

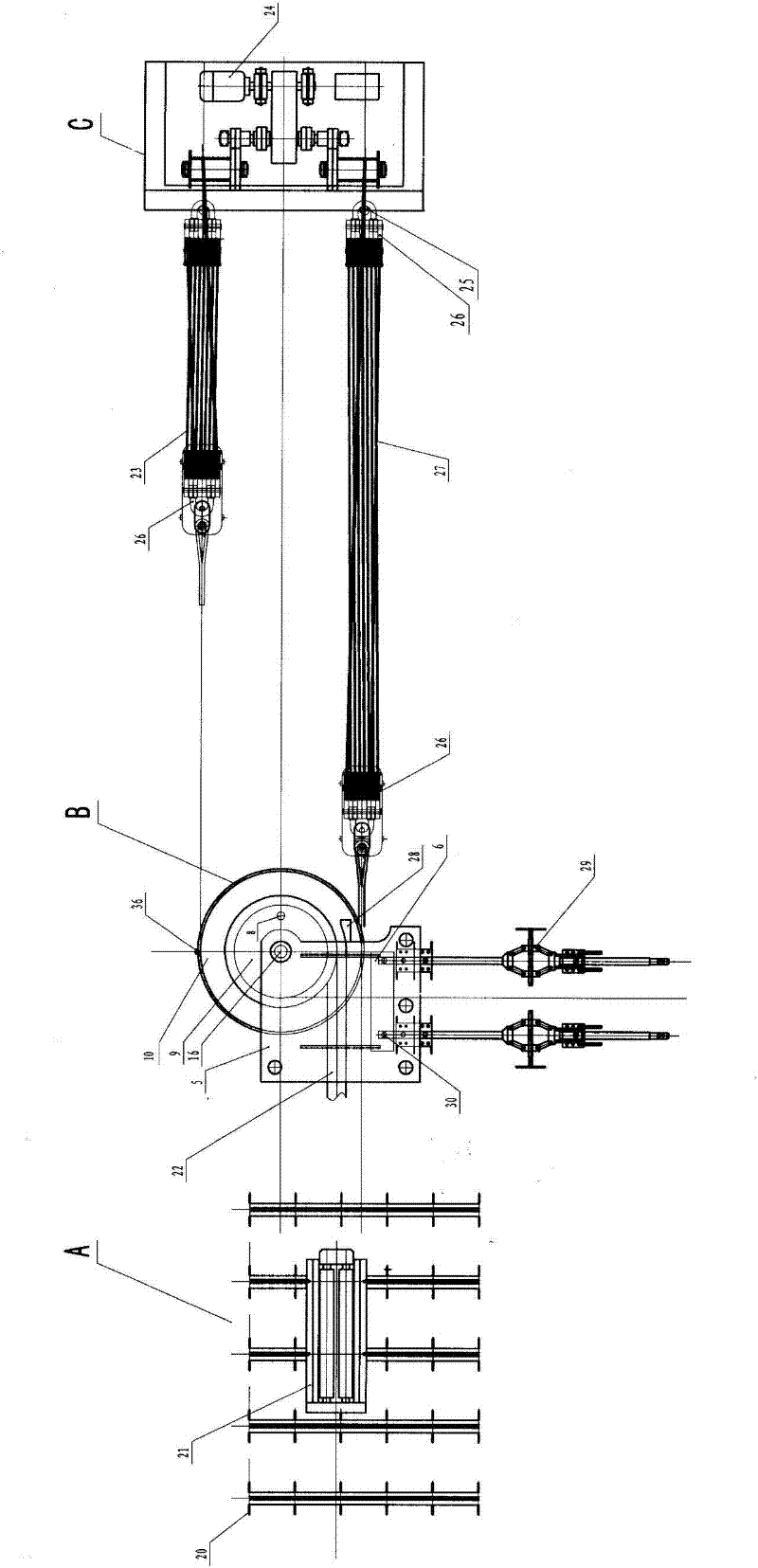

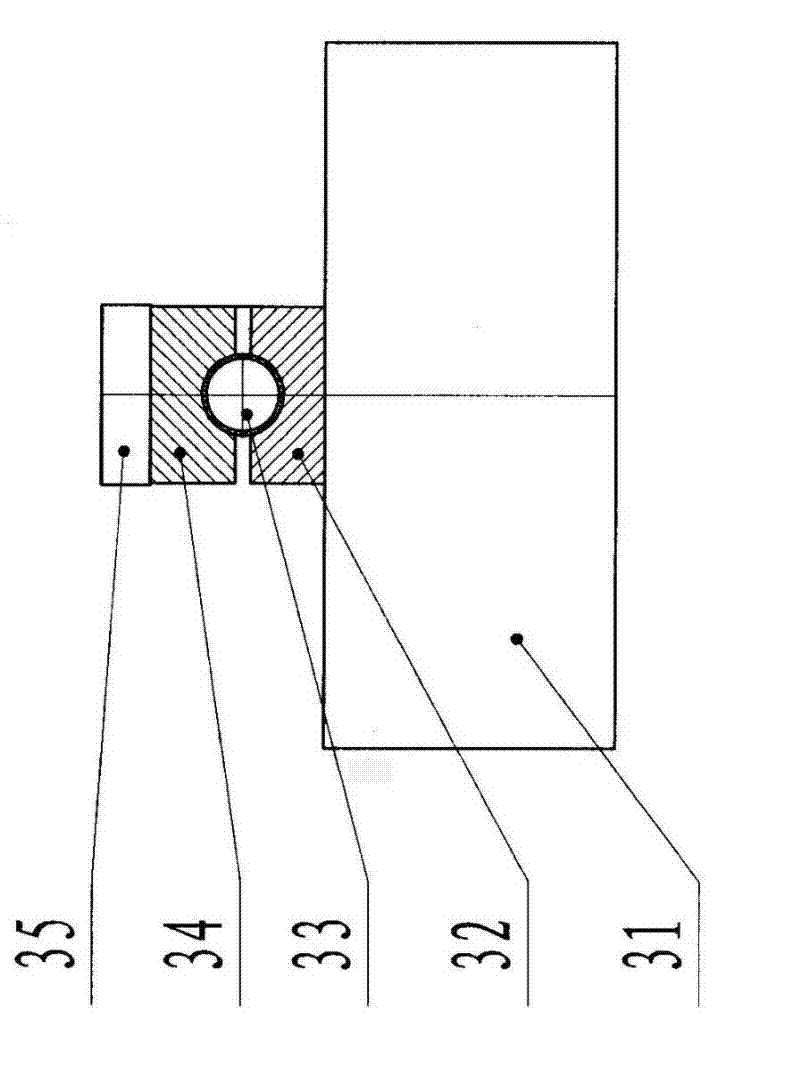

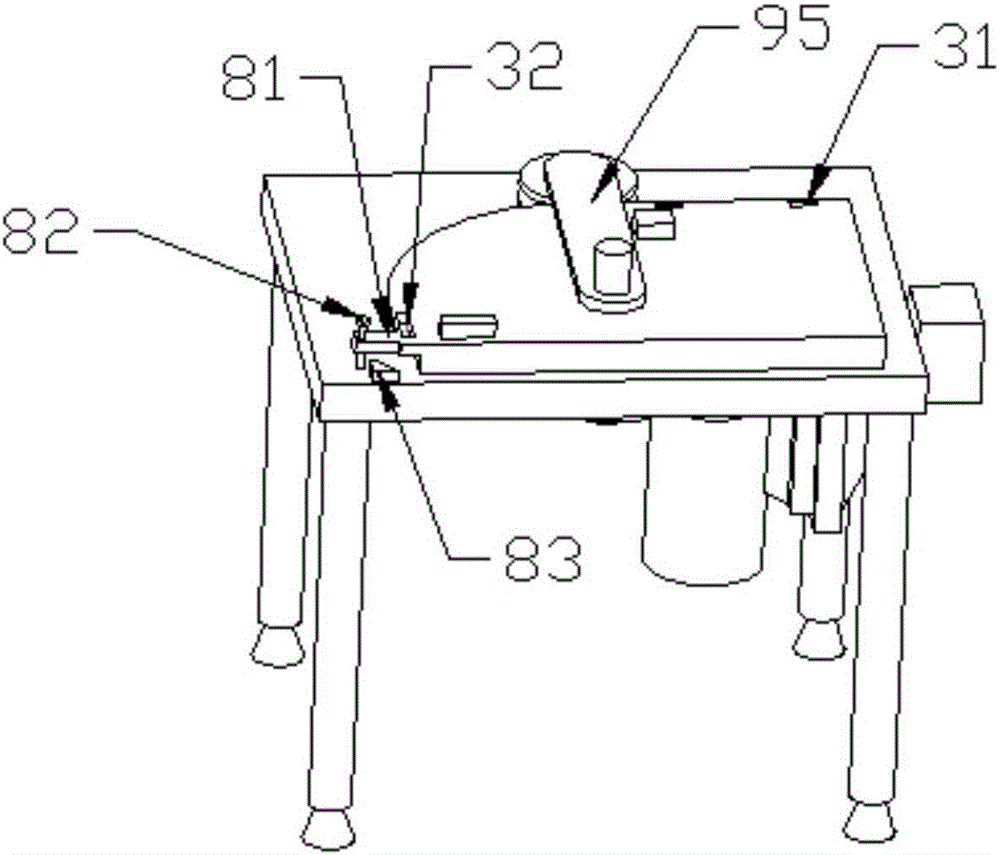

Bending equipment of urea-level stainless steel pipe and bending method

The invention relates to bending equipment of a urea-level stainless steel pipe and a bending method, wherein the bending equipment comprises a pushing part A, a bending part B, a pulling part C and a shaping device of the end part of a molded bending pipe, wherein the pushing part A, the bending part B, the pulling part C are arranged on a steel plate of a reinforced concrete foundation, wherein an oil cylinder of the pushing part A abuts against the tail end of the bent steel pipe inserted on the bending part B and pushes the bent steel pipe to move forwards; the pulling part C controls a steel wire rope to pull a rotating disc and a pipe bending mold to rotate by a winch, so as to carry out bending on the clamped and bent steel pipe; and the pushing part A and the pulling part C work synchronously to carry out push-pull type bending operation or only the pulling part C is started to carry out pure-pull type bending operation. The bending method comprises the following steps of: 1) material detection; 2) preparation work before bending; 3) pipe bending; 4) detection after out of the mold; 5) shaping of the end part of the bending pipe; 6) machining of a bending pipe facing machine; 7) detection; 8) acid cleaning and passivation; and 9) packaging and warehousing. Due to adoption the invention, the foreign imported product can be replaced, the purchasing period is shortened and the cost is reduced.

Owner:湖南四化建高压阀门管件有限公司

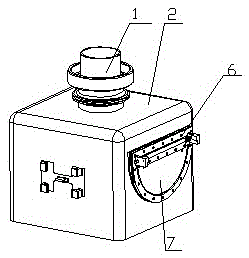

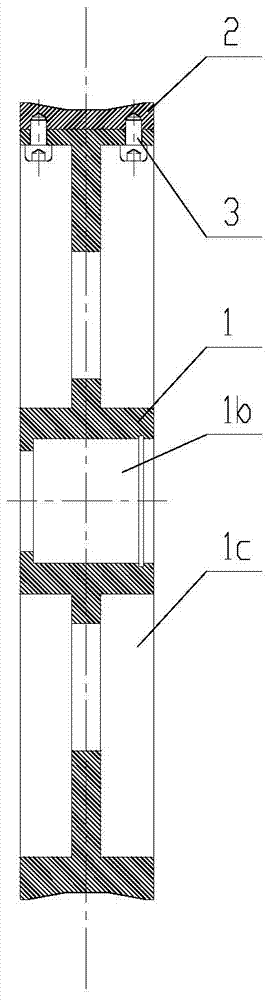

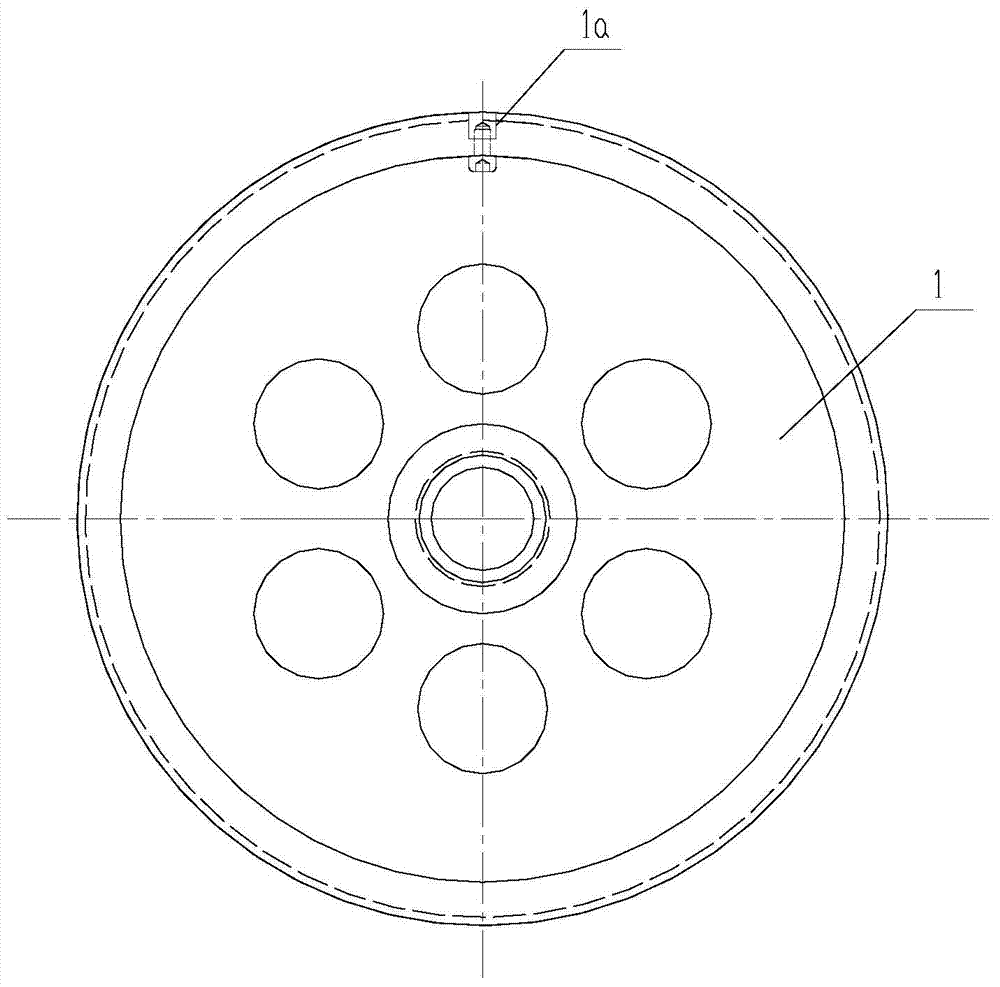

Inflating and deflating all-in-one machine for check-in of universal type aerostat

The invention relates to an inflating and deflating all-in-one machine for check-in of a universal type aerostat. The inflating and deflating all-in-one machine comprises a sealing cylinder (1), an inflating unit and a deflating unit, wherein a gas inlet, a gas outlet A (2) and a gas outlet B are formed in the sealing cylinder (1); and the inflating unit is mounted on the gas inlet of the sealing cylinder (1), and the deflating unit is mounted on the gas outlet B of the sealing cylinder (1). The inflating and deflating all-in-one machine has the advantages that the inflating and deflating all-in-one machine is compact in size and light in weight; the deflating unit of the all-in-one machine adopts a rotating type mechanical valve which is small in size and light in weight, so that the size and the weight of the all-in-one machine are greatly reduced, the appearance size of the all-in-one machine is only (200*200*200) mm, and the weight of the all-in-one machine is only 2.5kg; and the all-in-one machine is dual-purpose and excellent in performance.

Owner:CHINA SPECIAL TYPE FLIER RES INST

90-degree bending device

The invention provides a 90-degree bending device, which belongs to the field of auxiliary equipment for garbage bin processing, and includes a positioning assembly, a driving assembly, a fixed frame, a track plate, a positioning plate and a track wheel. The drive assembly drives the track wheel to rotate around the track plate, and the track wheel and The track plate is set tangentially. The positioning plate is set at the lower end of the track plate and indented inward. The indented space is consistent with the size of the parts to be bent. The positioning component can realize the positioning of the parts to be bent and ensure the bending accuracy. As the load bearing of all parts, the frame basically fixes the parts. The invention skillfully utilizes the tangency between the track wheel and the track plate and the drop setting between the track plate and the positioning plate, so that the bending precision is high, the labor intensity is reduced, and the work efficiency is improved.

Owner:天津东方奇运汽车制造有限公司

Hot-pressing printing wheel for cable

InactiveCN104505201AImprove efficiencyReduce procurement costsConductor/cable markingMechanical engineeringHot pressing

The invention discloses a hot-pressing printing wheel for a cable. The hot-pressing printing wheel for the cable comprises a wheel body (1), wherein at least one block replacement part (2) is detachably fixed at the contour edge of the wheel body (1); the outer contour shape of the block replacement part (2) corresponds to the contour shape of the wheel body (1). The using efficiency of the printing wheel can be greatly improved, so that the purchasing cost of the printing wheel is reduced; moreover, the printing wheel can be quickly assembled, and the purchasing period is shortened.

Owner:CHONGQING TAISHAN CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com