Inflating and deflating all-in-one machine for check-in of universal type aerostat

An aerostat, a general-purpose technology, applied in the field of machinery and equipment, can solve the problems of high requirements for human resources and personnel quality, increase the labor load of staff, and inconvenient operation and control methods, and achieve economical material selection, light weight, and easy processing. The effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

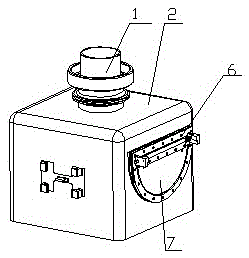

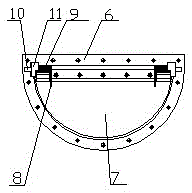

[0017] Such as figure 1 , 2 , 3, the present invention includes a sealing cylinder 1, an inflation unit and a deflation unit, the sealing cylinder 1 is provided with an air inlet, an A gas outlet 2 and a B gas outlet, and the inflation unit is installed on the air inlet of the sealing cylinder 1 , the deflation unit is installed at the B air outlet on the sealing cylinder 1.

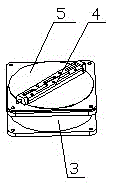

[0018] The inflatable unit includes a one-way fan 3, a hinge 4 and a pair of one-way valve blades 5. The one-way fan 3 is installed at the air inlet of the sealing cylinder 1, and the hinge 4 is installed on the one-way fan 3 through a mounting seat. A pair of one-way valve blades 5 are installed on a pair of leaf plates of the hinge 4 respectively, and are covered at the air outlet of the one-way fan 3 .

[0019] A pair of one-way valve blades 5 are installed on a pair of leaf plates of the hinge 4 respectively, and are sealed at the air outlet of the one-way fan 3 .

[0020] The deflation unit incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com