Method for foundry production of ultra-supercritical main steam control valve for nuclear power unit

A technology for nuclear power plant and foundry production, which is applied in foundry equipment, equipment for feeding molten metal into casting molds, and manufacturing tools, etc. It can solve the problems of long smelting time, large thermal section, and increase the difficulty of smelting, so as to improve the utilization of resources. efficiency, reducing production costs and shortening the procurement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

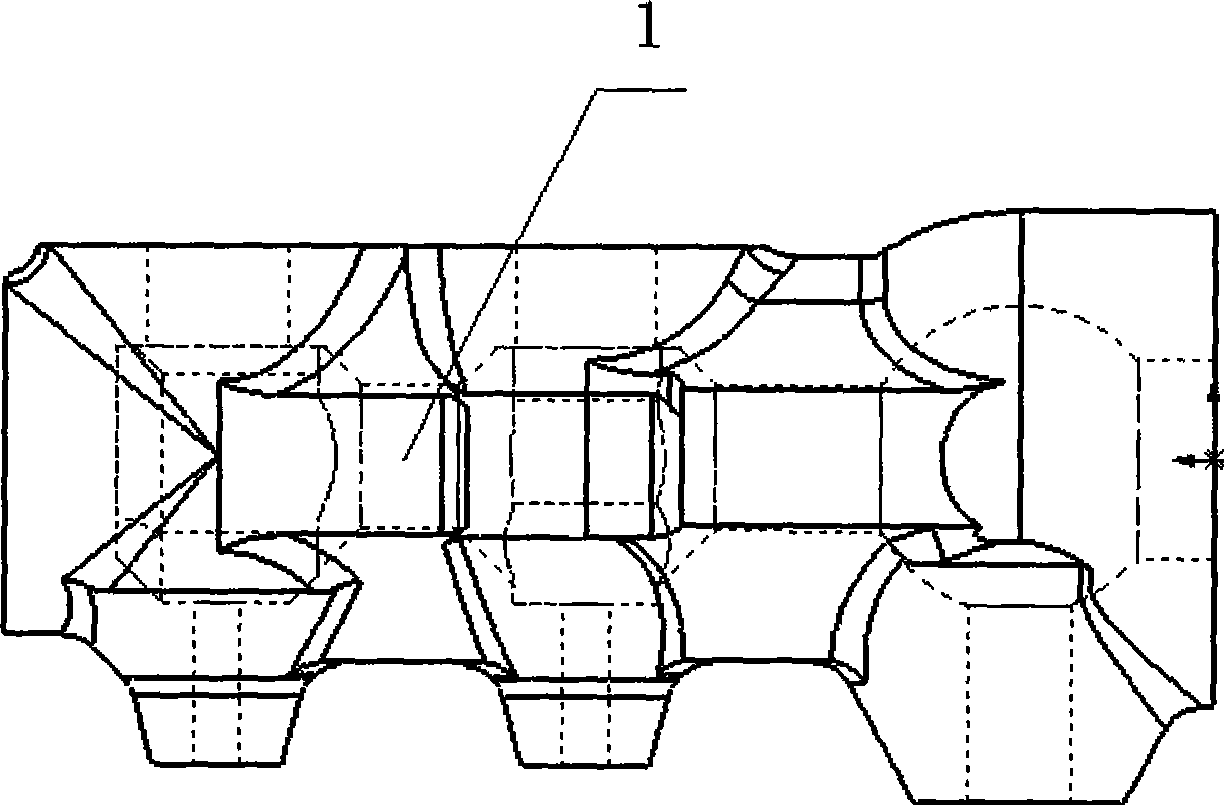

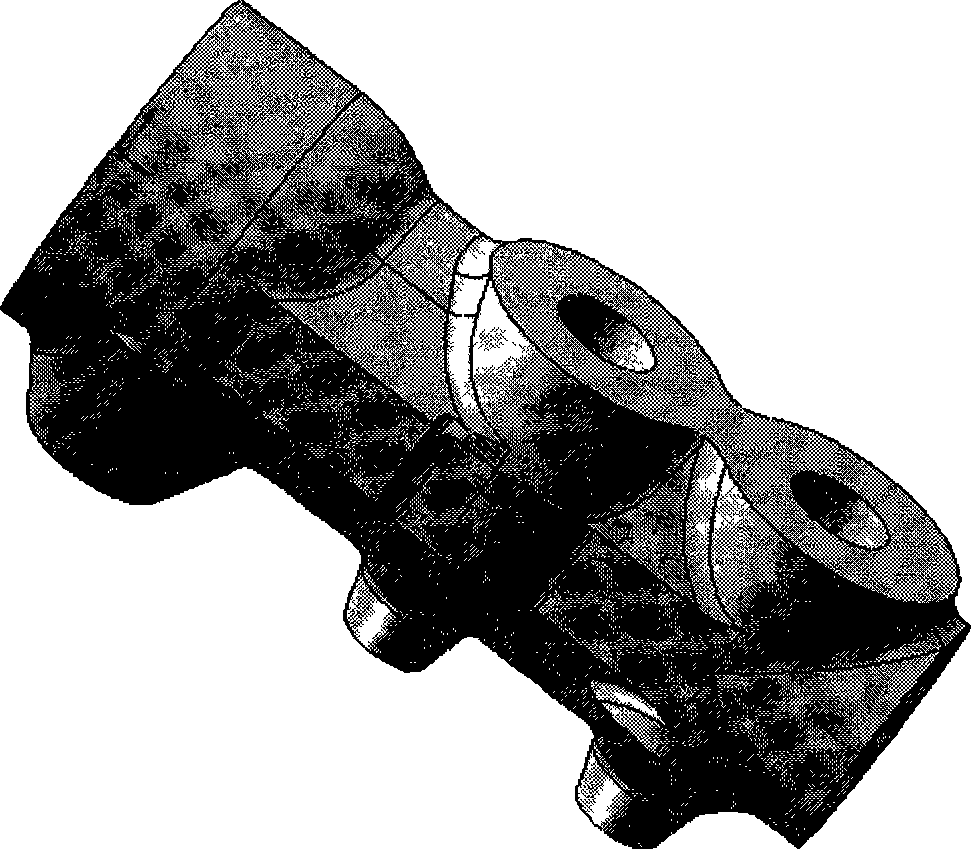

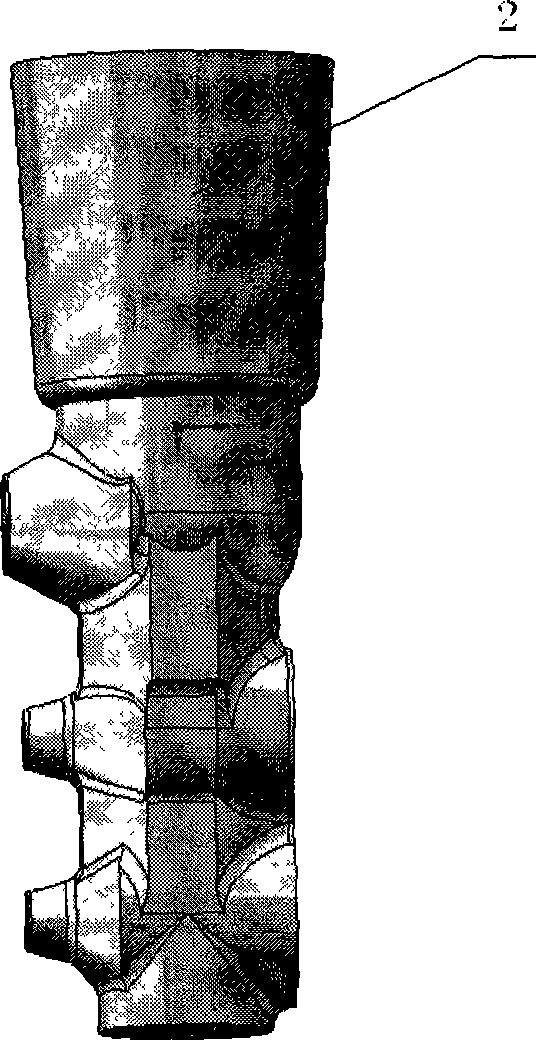

[0032] Describe casting method of the present invention in detail below in conjunction with accompanying drawing.

[0033] The method includes tooling preparation, molten steel smelting, composition control of molten steel, pouring, solidification shrinkage, cooling and unpacking, heat treatment, processing and inspection processes. Firstly, after the preliminary determination of the process plan, the simulation is carried out by Huazhu CAE simulation software to verify the rationality of the process in theory. First, establish a three-dimensional model of the casting according to the casting process plan, and then use Huazhu CAE casting solidification analysis computer software to simulate the solidification process to visualize the solidification process, verify the size of the riser, and predict defects; through the demonstration of the solidification process, adjust the technical parameters of the casting. Finally, after the simulation process and the plan is confirmed, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com