Bending equipment of urea-level stainless steel pipe and bending method

A stainless steel tube, urea grade technology, applied in the field of 316Lmod pipeline processing of petrochemical urea plant, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

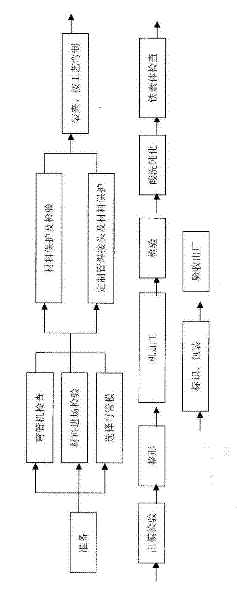

Method used

Image

Examples

Embodiment

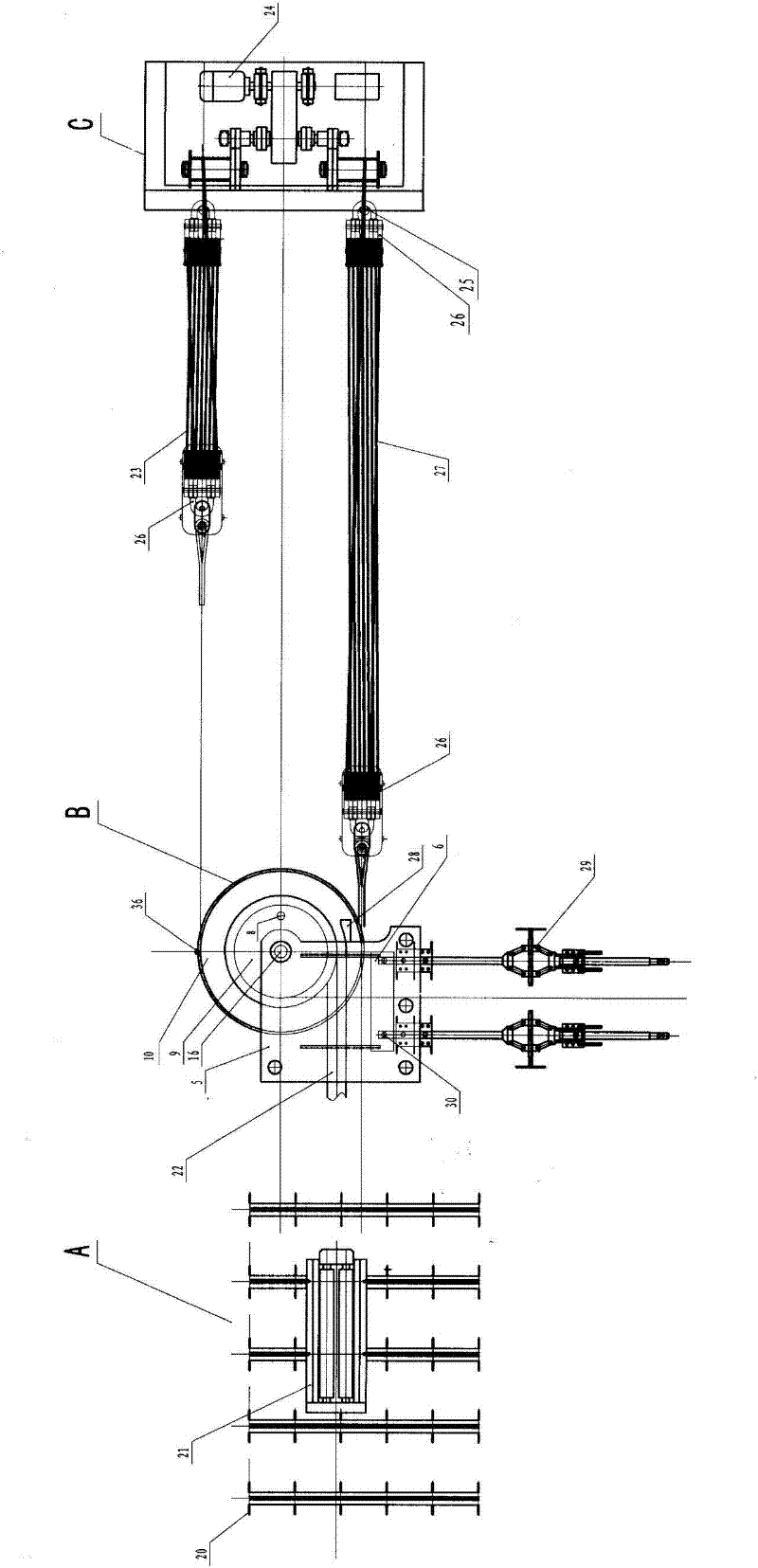

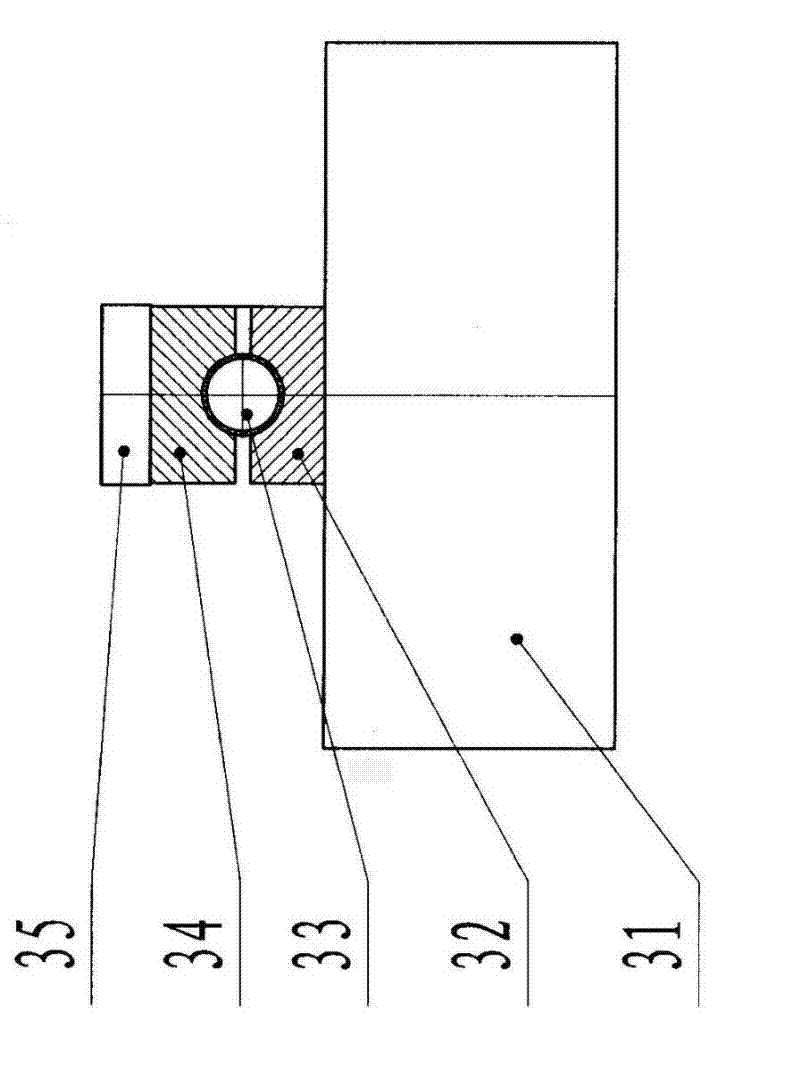

[0085] Example: Take the 10″φ273.1×25.4 316Lmod 90°R=5D=1270 standard elbow as an example.

[0086] 1. Incoming material inspection:

[0087] 1. Check whether the mark on the pipe is φ273.1×25.4, and whether the material mark, furnace number, and batch number are consistent with the list of incoming materials.

[0088] 2. Measure the length, outer diameter and wall thickness of the pipe (using an ultrasonic thickness gauge).

[0089] 2. Production:

[0090] The production adopts cold bending, and all the production processes adopt effective means to isolate the carbon steel and control the ferrite content.

[0091] (1) This specification needs to use the extension pipe to bend the standard bend (American standard)

[0092] 1. Calculate φ273.1×25.4 90°R=5D=1270. The standard elbow development length is 1995mm, and the shortest length of the elbow bending is 1995+200=2195mm, due to the need for appropriate processing allowance and removal of ferrite Exceeding part;

[0093]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com