Hot-pressing printing wheel for cable

A thermal embossing and character wheel technology, which is applied in the field of printing wheels, can solve the problems of high cost and idleness of printing wheels, and achieve the effects of improving use efficiency, fast assembly, and saving procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

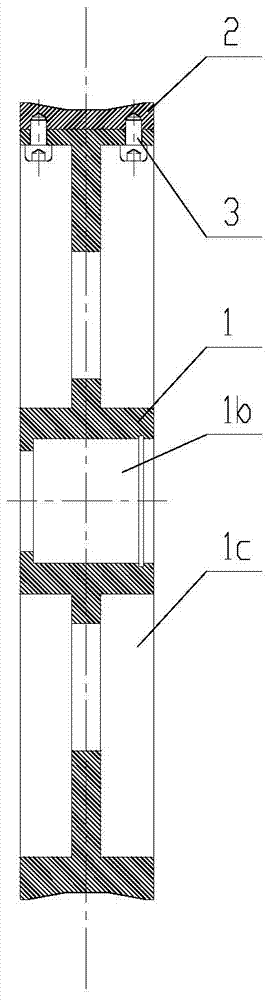

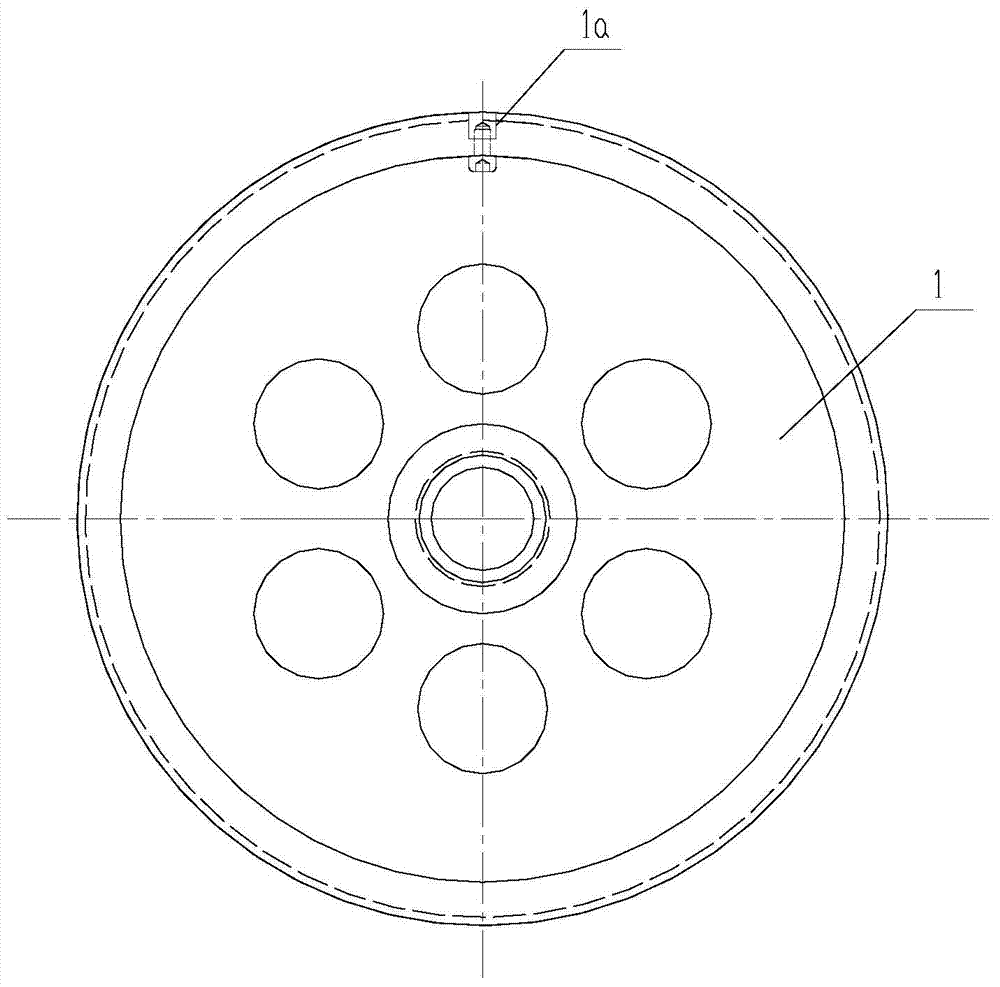

[0016] like figure 1 and figure 2 As shown, a cable thermal embossing wheel includes a wheel body 1, and in the circumferential direction, the middle part of the wheel body 1 is a concave arc-shaped structure. The center of the wheel body 1 is provided with a connecting shaft installation hole 1b, and six weight-reducing holes 1c are evenly distributed on the wheel body 1 .

[0017] The wheel body 1 is provided with a notch 1a in the radial direction, and a block replacement part 2 is connected to the notch 1a by screws, and the outer contour shape of the block replacement part 2 corresponds to the contour shape of the wheel body 1 .

[0018] The circumference of the wheel body 1 is printed with product model specification, manufacturer's name, etc., which are relatively fixed, and the production date and order number are printed on the block replacement p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com