Automatic put and automatic recovery control system

A self-switching, self-recovery, control system technology, applied in emergency power supply arrangements, electrical components, circuit devices, etc., can solve the problems of inability to meet the requirements of power system safety automatic devices, high price, and logic failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

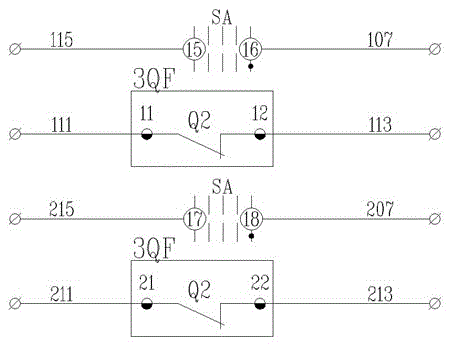

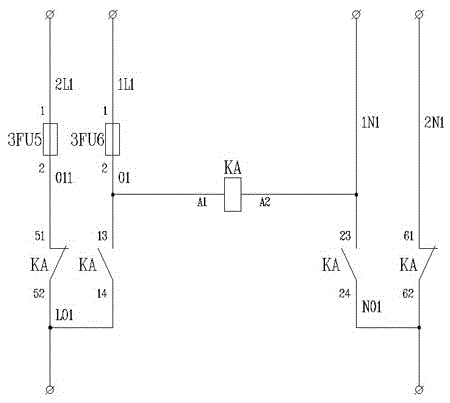

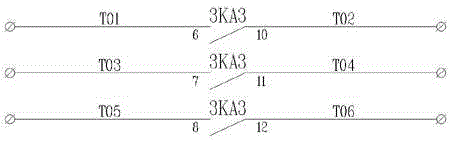

[0064] Embodiment 1, a kind of self-injection and self-recovery control system, refer to figure 1 , figure 2 , image 3 , Figure 4 , 1# incoming line cabinet, bus coupling cabinet, and 2# incoming line cabinet are connected to the background safety automatic device through the bus. The 1# incoming line cabinet is 1# voltage sampling unit, 1# current sampling unit, 1# multiple Function measurement and control module power supply unit, 1# switch state upload unit are respectively connected with 1# multi-function measurement and control module communication unit, 1# multi-function measurement and control module communication unit is connected with 1# circuit breaker control unit, 1# voltage sampling unit is connected with 1# self-injection Self-resetting unit, 1# self-transfer and self-recovery unit is connected to 1# circuit breaker control unit, and the power switching unit of the bus coupler cabinet is respectively connected to 1# self-transfer and self-recovery unit, 1# c...

Embodiment 2

[0068] Embodiment 2, a kind of self-injection self-recovery control system, refer to Figure 1 to Figure 27 , on the basis of Embodiment 1, the 1# multifunctional measurement and control module power supply circuit is that the 1 and 2 ends of the multifunctional measurement and control module 1PD are respectively connected to the live wire and the neutral wire of the alternating current;

[0069] The 1# current sampling unit is the 5, 7, 9 terminals of the multifunctional measurement and control module 1PD, the S2 terminals of the current transformers 1TAa, 1TAb, 1Tac are short-circuited and grounded, and the 4, 6 and 8 terminals of the multifunctional measurement and control module 1PD Connect to S1 terminal of current transformer 1TAa, 1TAb, 1Tac respectively;

[0070] The 1# switch status uploading unit is that terminal 71 of the multi-functional measurement and control module 1PD is connected to terminal 5 of the intermediate relay 1KA5, terminal 72 is connected to termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com