Preparation method of oxygen-containing washing agent and oxygen-containing washing agent prepared by same

A technology of detergents and additives, applied in the field of oxygen-containing detergents, which can solve the problems of difficult uniform distribution of components and poor washing effect, and achieve the effects of uniform distribution of components, stable performance and excellent washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The invention provides a kind of preparation method of oxygen-containing detergent, comprises the following steps:

[0012] A, will contain the surfactant of 1-10 weight part, 10-70 weight part sodium carbonate, 1-40 weight part sodium sulfate, contain or do not contain the raw material composition of additional auxiliary agent in the reactor; Said additional The auxiliary agent contains 0-20 parts by weight of sodium bicarbonate, 0-30 parts by weight of sodium salt of silicic acid and 0-10 parts by weight of anti-dirt redeposition agent;

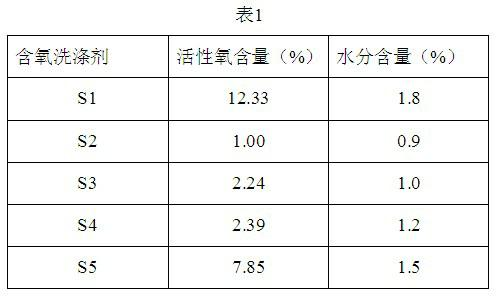

[0013] B. Add aqueous hydrogen peroxide solution to the reactor, control the reaction temperature in the reactor to 0-60°C, and mold and dry the product after the reaction is completed to obtain 100 parts by weight of active oxygen containing 1-12.33% oxygen detergent.

[0014] In the present invention, the surfactant is various surfactants commonly used in household detergents in the prior art, such as one or more selected from ani...

Embodiment 1

[0041] Add 70.0kg of light sodium carbonate, 1.0kg of sodium stearate and 1.0kg of anhydrous sodium sulfate into the reactor and stir for 5 minutes. Weigh 53.26kg of hydrogen peroxide aqueous solution (in the form of H 2 o 2 50.2wt% in total), add the aqueous hydrogen peroxide solution into the reactor through the spray pipe within 90 minutes, and control the reaction temperature at 0-5°C; after the addition of the aqueous hydrogen peroxide solution, continue the reaction for 10 minutes. The reaction product was granulated by a granulator, and then dried in a fluidized bed to obtain solid particles, namely the oxygen-containing detergent S1 of this embodiment, which was used as a detergent and disinfectant.

Embodiment 2

[0043] 50.0kg sodium carbonate monohydrate (on a dry basis), 4.0kg sodium dodecylbenzenesulfonate (LAS), 1.0kg fatty alcohol polyoxyethylene ether (AEO), 1.0kg alpha-olefin sulfonate sodium (AOS ), 5.0kg sodium metasilicate pentahydrate (on a dry basis), 8.0kg sodium carboxymethylcellulose (CMC), 13.0kg food grade sodium bicarbonate and 14.4kg sodium sulfate decahydrate (on a dry basis) In the reactor, stir for 5 minutes. Weigh 3.09kg of hydrogen peroxide aqueous solution (in the form of H 2 o 2 70.3wt% in total), add the aqueous hydrogen peroxide solution into the reactor through the sprayer within 30 minutes, and control the reaction temperature at 20-25°C; after the aqueous hydrogen peroxide solution is added, continue the reaction for 10 minutes. The reaction product is granulated by a granulator, and then dried in a fluidized bed to obtain solid particles. Then add 0.5 kg of amylase and 0.02 kg of lemon essence to the solid granules to obtain the oxygen-containing dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com