Patents

Literature

178results about How to "Process safety and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for purifying panaxoside compound-K by applying macroporous resin

ActiveCN101921304AReduce usageEasy to operateIon-exchange process apparatusIon-exchanger regenerationHigh concentrationMicroorganism

The invention relates to a method for separating and purifying a panaxoside compound-K from microorganism zymocyte by applying macroporous resin for preparing a raw medicine. The purifying yield reaches more than 72 percent, and the content of the panaxoside compound-K in a product is more than 96 percent. The method mainly comprises the following steps of: adding ethanol into zymocyte for extracting and concentrating; decoloring by active carbon and filtering; after adding water into filter liquor for diluting, leading the filter liquor to pass through a macroporous resin chromatographic column; washing by a low-concentration organic solvent aqueous solution for removing pigment and high-polarity saponin; eluting by a high-concentration organic solvent aqueous solution to obtain a panaxoside compound-K component; and finally crystallizing to obtain the panaxoside compound-K raw medicine with the content of more than 96 percent. The invention can provide a great amount of qualified raw medicine samples for the pharmaceutical development of the panaxoside compound-K.

Owner:ZHEJIANG HISUN PHARMA CO LTD

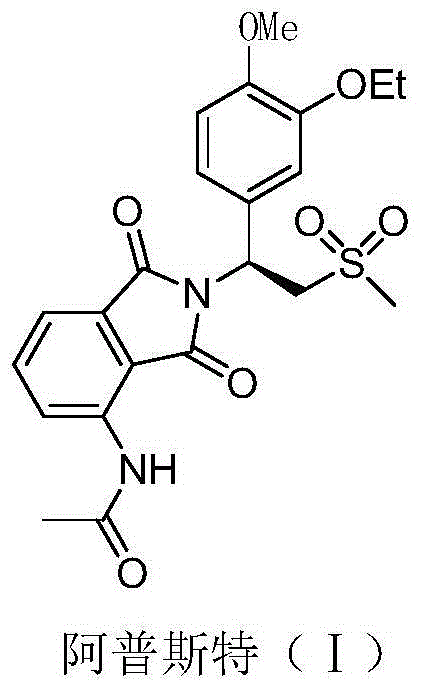

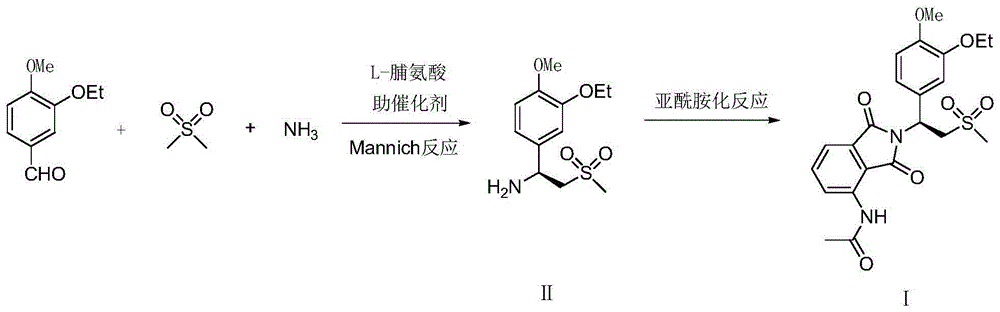

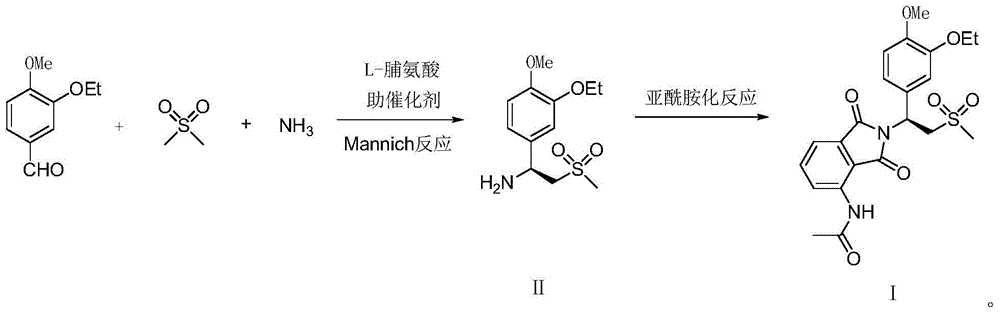

Preparation method for apremilast and intermediate of apremilast

ActiveCN104447443AHigh purityRaw materials are easy to getOrganic chemistryOrganic compound preparationMannich reactionPhthalic anhydride

The invention relates to a preparation method for apremilast and an intermediate of the apremilast. The preparation method comprises the following steps: enabling 4-methoxy-3-ethoxybenzaldehyde to have Mannich reaction with methylsulfonylmethane and ammonia under the action of L-proline and a promoter to obtain an intermediate, (S)-1-(4-methoxy-3-ethyoxyl)phenyl-2-(methylsulfonyl)ethylamine (II), and then amidating the intermediate (II) and 3-acetamido-phthalic anhydride to prepare the apremilast (I). According to the preparation method for the apremilast and the intermediate of the apremilast, the raw materials are easily available, the flow path is short, the process is simple and convenient, the product has high optical purity, and the industrial production is safe and environmentally friendly.

Owner:XINFA PHARMA

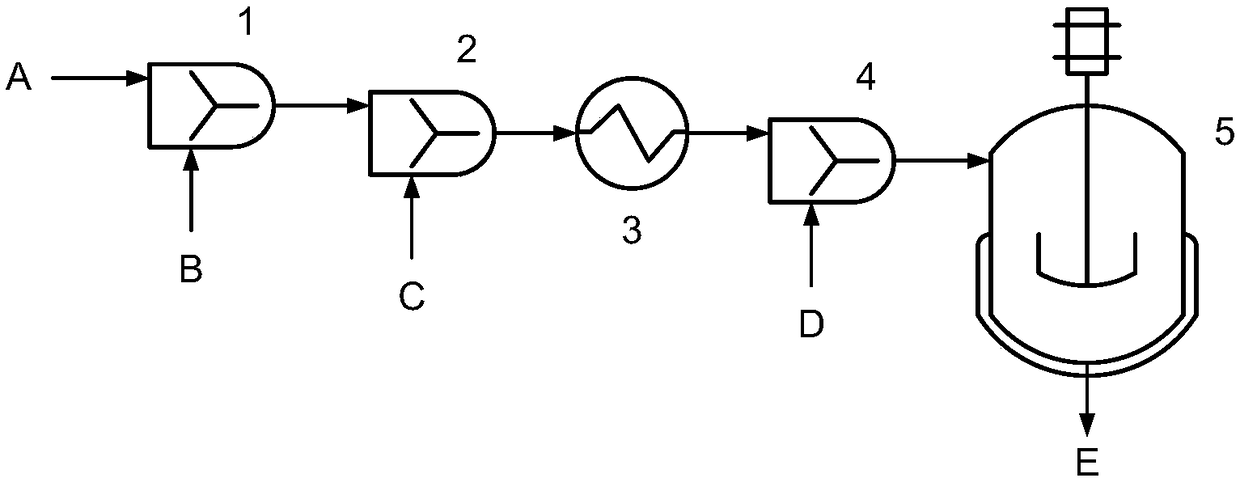

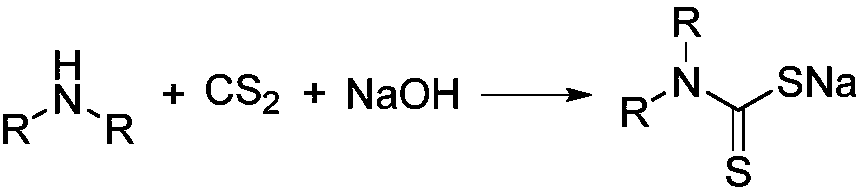

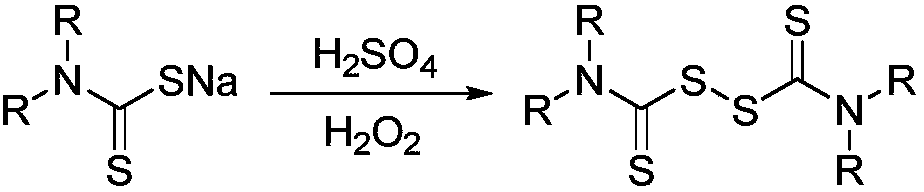

Micro-reaction method for continuous synthesis of thiuram disulfide

The invention discloses a method for producing thiuram disulfide as thiofide by a continuous micro-reaction system. According to the method, three processes including secondary amine-NaOH solution mixing, CS2-secondary amine condensation reaction and sodium dithiocarbamate oxidation reaction are sequentially completed by a micro-mixer and a micro-reactor which are connected in series; reaction materials are efficiently mixed by the micro-reaction device, and side reactions such as overoxidation and the like are avoided; by means of a series-integrated operation mode, production efficiency is improved, and product stability is improved. The method can be applied to production of multiple thiuram vulcanizing agents such as tetramethyl thiuram disulfide, tetraethylthiuram disulfide, tetrabutylthiuram disulfide and the like, the yield can reach 98% or higher, and product purity is high.

Owner:WILLING NEW MATERIALS TECH CO LTD +1

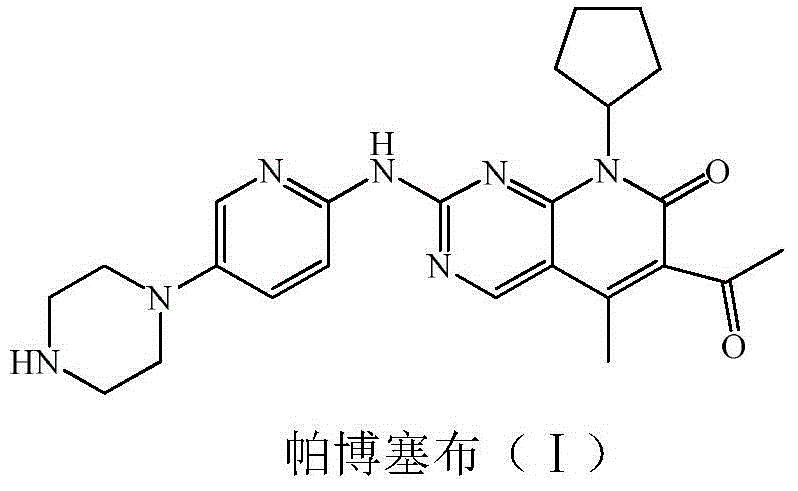

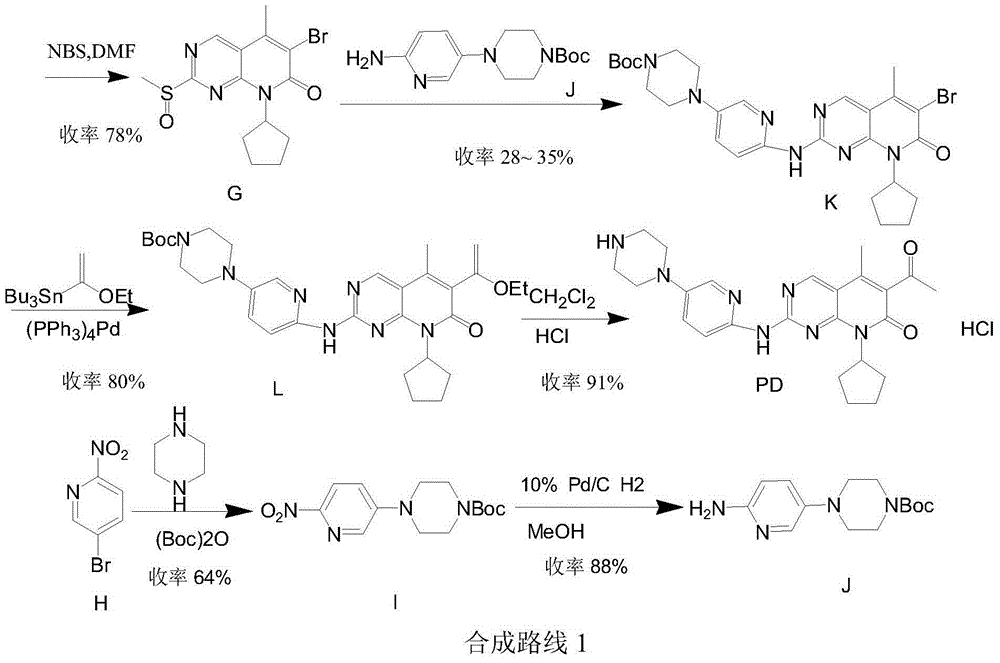

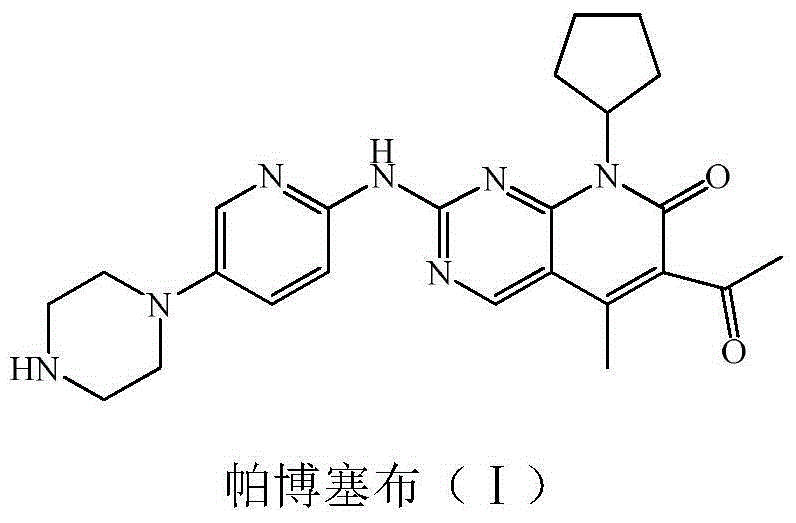

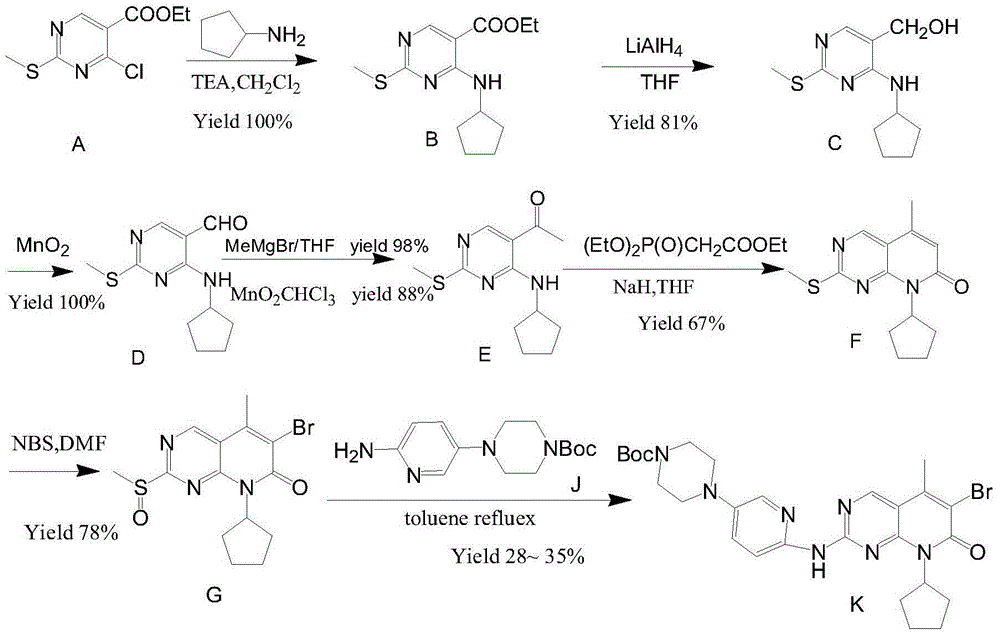

Low-cost preparation method for palbociclib

ActiveCN104610254ARaw materials are easy to getSimple processOrganic chemistryBulk chemical productionKetoneCarboxylic acid

The invention relates to a low-cost preparation method for palbociclib. The low-cost preparation method comprises the following steps: by taking 2,4-dichloro-5-cyanopyrimidine as an initial raw material, performing cyano Grignard and hydrolysis so as to obtain 5-acetyl-2,4-dichloropyrimidine, protecting carbonyl, performing amination, removing carbonyl, performing acylation reaction by using diketene and amino so as to obtain 5-acetyl-4-acetoacetamide-2-chloropyrimidine, performing intramolecular dehydration on the product so as to obtain 6-acetyl-8-cyclopentyl-5-methyl-2-chlorine-8H-pyridino-[2,3-d] pyrimidine-7-ketone, protecting 6 acetyl groups by using carbonyl, further realizing reaction with an aminopyridine derivative so as to obtain 4-{6-[(6-1,1 dialkoxyl) ethyl-8-cyclopentyl-5-methyl-7-keton-7,8 dihydropyridino-[2,3-d]pyrimidine-2-amino]-pyridine-3-yl}-piperazine-1-carboxylic acid tert-butyl ester, and finally performing acid hydrolysis and neutralization to obtain palbociclib free alkali. By adopting the low-cost preparation method, the raw materials are easy to obtain, the cost is low, and the environment can be protected.

Owner:XINFA PHARMA

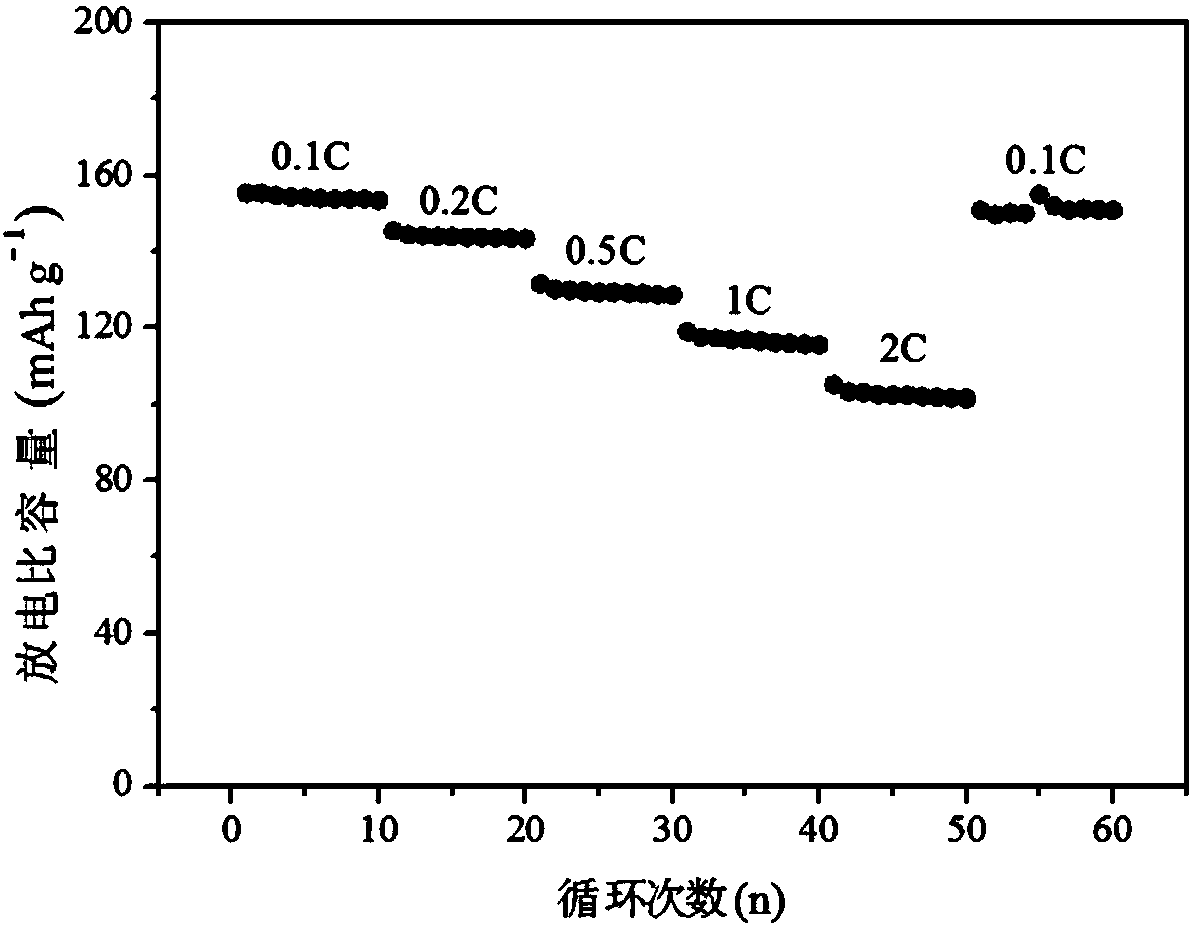

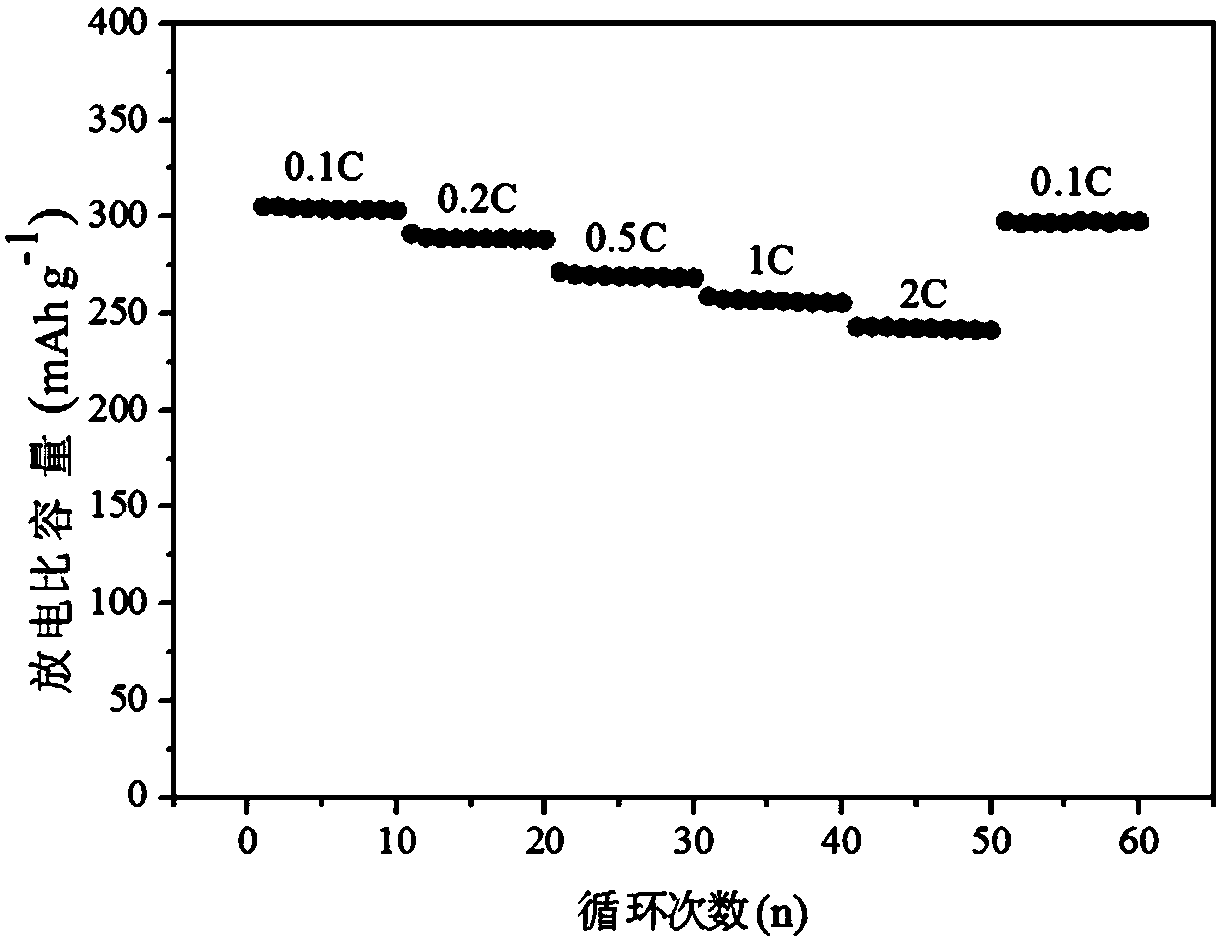

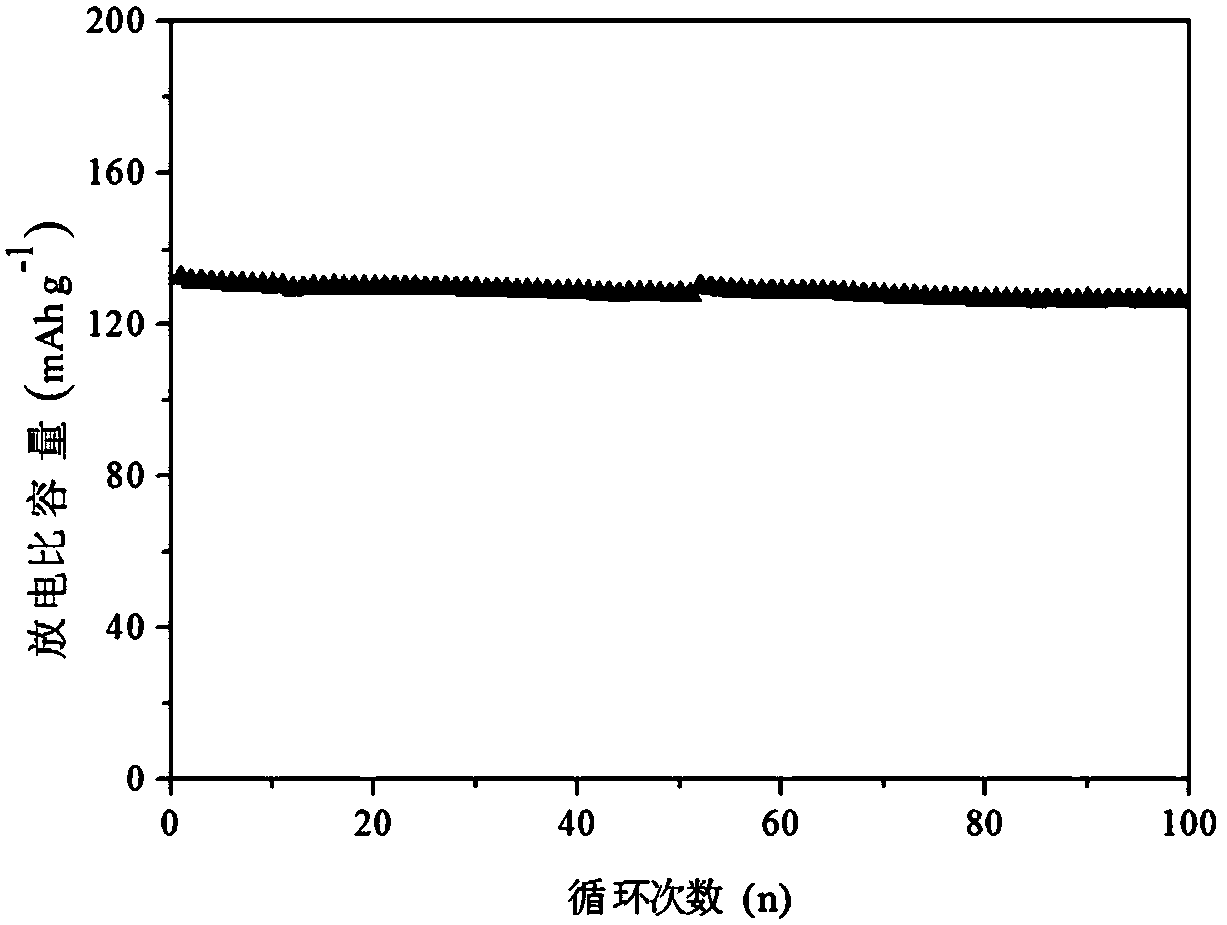

Lithium-ion battery electrode prepared by water-based binder

ActiveCN108470884AImproved magnification performanceImprove cycle performanceCell electrodesSecondary cellsWater basedCopper foil

The invention discloses a lithium-ion battery electrode prepared by a water-based binder. The lithium-ion battery electrode is prepared by coating an aluminum foil or copper foil with an electrode slurry, and the thickness is 50-300 [mu]m; a formula of the electrode slurry comprises 60.0-96.0 parts by weight of an active material, 1.0-20.0 parts by weight of a conductive agent, 1.0-7.5 parts by weight of a binder, 1.0-7.5 parts by weight of a thickener, and 30.0-400.0 parts by weight of a dispersion medium. The active material is selected from lithium iron phosphate, lithium manganate, lithiumcobaltate, graphite and lithium titanate; the binder is an acrylic acid / styrene / methyl acrylate / styrene block copolymer. The binder has extremely high adhesion with active material particles, and hasextremely high elasticity. At the same time, the liquid absorption rate of an electrolyte solution can be improved, the conduction velocity of lithium ions is accelerated, and the performance of thelithium-ion battery electrode is greatly improved.

Owner:ZHEJIANG UNIV

Rapid zinc series, zinc-calcium series or iron series clean phosphatizing liquid under room-temperature with multiple styles

InactiveCN1680623ASolution to short lifeImprove the quality of phosphatingMetallic material coating processesPhytic acidSurface-active agents

A phosphate solution of Zn Zn-Ca and Fe series. Contents of it are H3PO4, nitrate and their Zn2+,Ca2+,Mn2+,Ni2+ salts, ammonium molybdate, ammonium wolframate, phytic acid, H2O2 and non-ionic surface active agent. pH is 2.0-5.8.

Owner:余取民

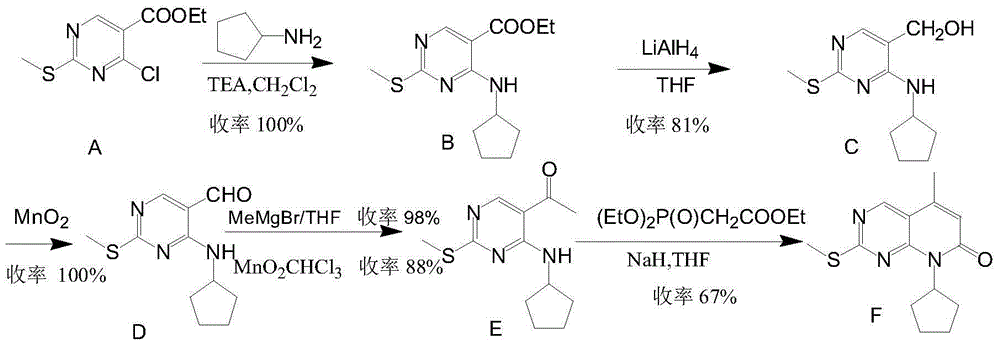

Preparation method of palbociclib

ActiveCN104478874AHigh yieldRaw materials are cheap and easy to getOrganic chemistry2-PyridoneMethyl group

The invention relates to a preparation method of palbociclib. The method comprises the following steps: carrying out N-acetoacetylation reaction by using cyclopentylamine and an acetoacetylation agent to obtain N,N-di(acetoacetyl) cyclopentylamine (II), carrying out intramolecular condensation on N,N-di(acetoacetyl) cyclopentylamine (II) in the presence of an alkaline reagent to obtain N-cyclopentyl-3-acetyl-4-methyl-6-hydroxy-2-pyridone (III), enabling N-cyclopentyl-3-acetyl-4-methyl-6-hydroxy-2-pyridone (III) to react with a formylation reagent to prepare N-cyclopentyl-3-acetyl-4-methyl-5-formyl-6-chlorine-2-pyridone (IV), carrying out pyrimidine ring reaction by using N-cyclopentyl-3-acetyl-4-methyl-5-formyl-6-chlorine-2-pyridone (IV) and N-(5-(4-tert-butoxy carbonyl-1-hexahydropyrazinyl)-2-pyridyl) guanidine sulfate (V), and then hydrolyzing under the alkaline condition to prepare palbociclib. The preparation method of palbociclib is easily available in raw materials, short in process, simple and convenient to operate and safe and environmentally friendly in process.

Owner:XINFA PHARMA

Method for preparing lactic acid through catalyzing glycerol by supported catalyst

InactiveCN104045545ALow reaction temperatureLow reaction pressurePreparation from carboxylic acid saltsCarboxylic preparation by oxidationActivated carbonPtru catalyst

The invention relates to the technical field of lactic acid preparation and particularly relates to a method for preparing lactic acid through catalyzing glycerol by a supported catalyst. According to the method, the selectivity of lactic acid can reach 70-90%, and the conversion ratio of glycerol can reach 72-100%. The method is characterized in that reaction is carried out on glycerol which serves as a raw material in a high-pressure reactor under anaerobic and alkali source provided alkaline conditions in the presence of supported copper oxide which serves as a catalyst, thereby obtaining lactic acid, wherein a support of the supported copper oxide catalyst contains metal oxides, including MgO, ZrO2, TiO2, CeO2 and ZnO, activated charcoal or hydroxyapatite; the supported copper oxide catalyst is easy to prepare, low in cost and relatively long in service life. The method has the advantages that the reaction temperature and reaction pressure are low, the catalyst activity is high, the selectivity is good, the reaction rate is high, and the process flow is safe and environmental-friendly and the like, so that the industrial prospect is good.

Owner:JIANGSU UNIV

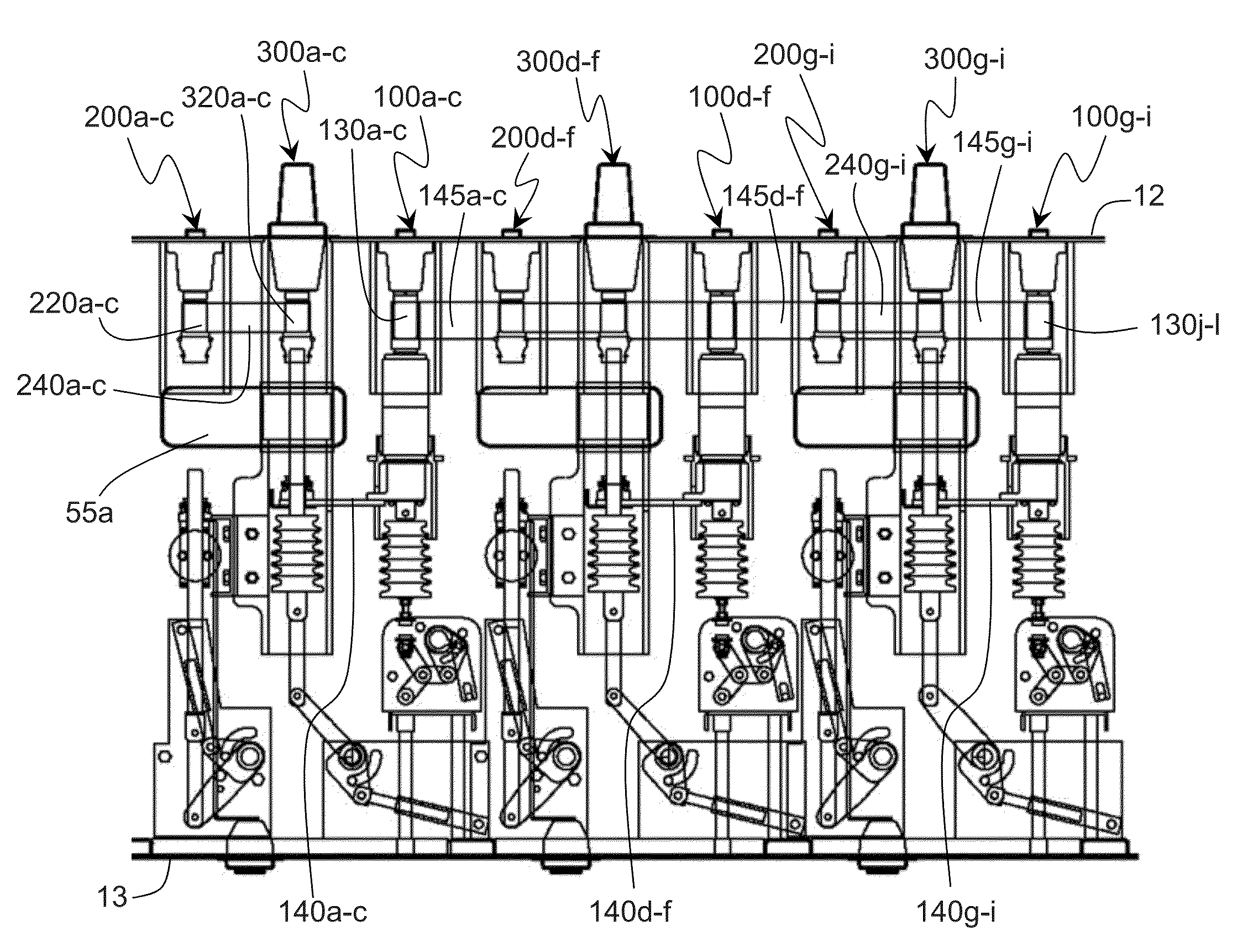

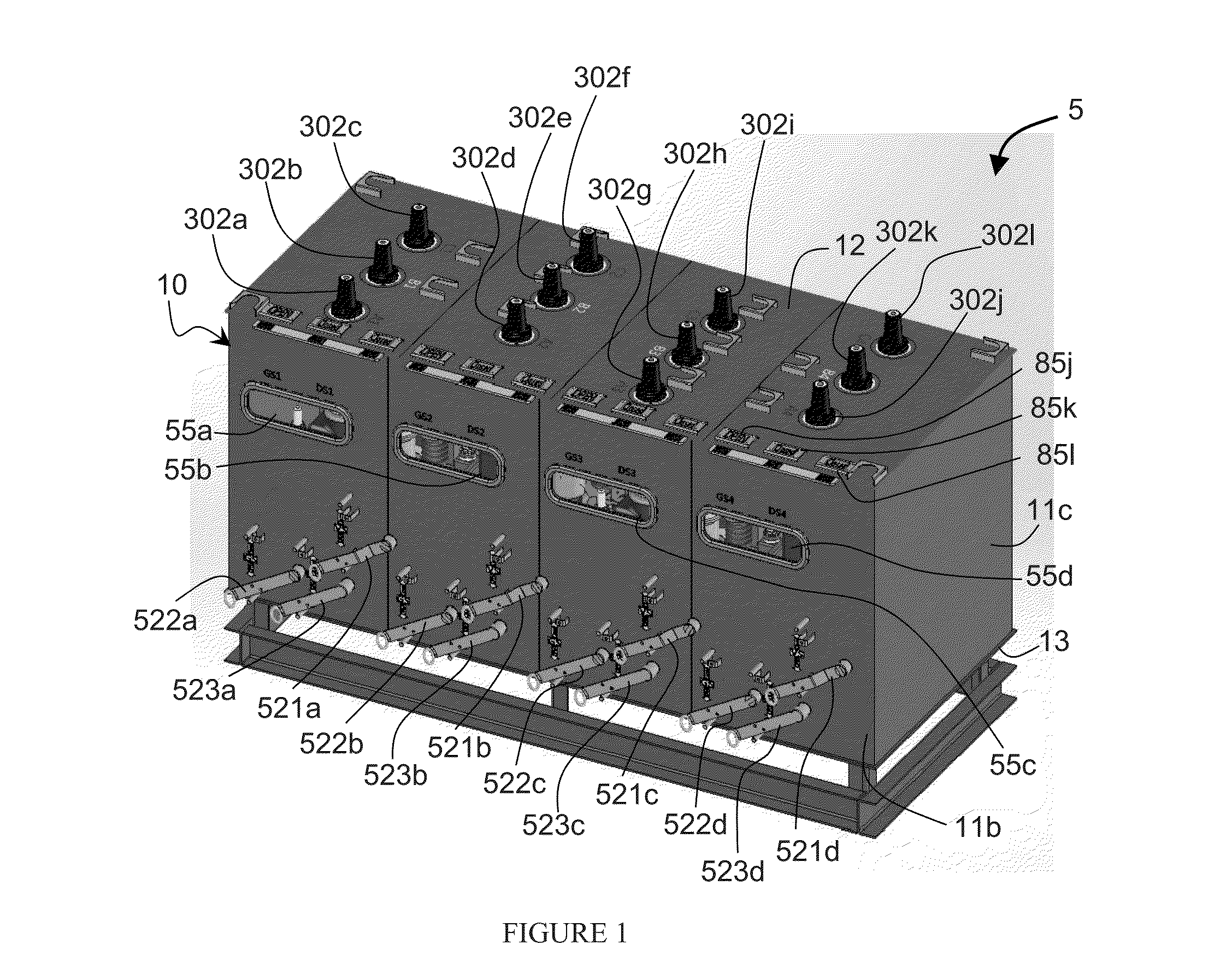

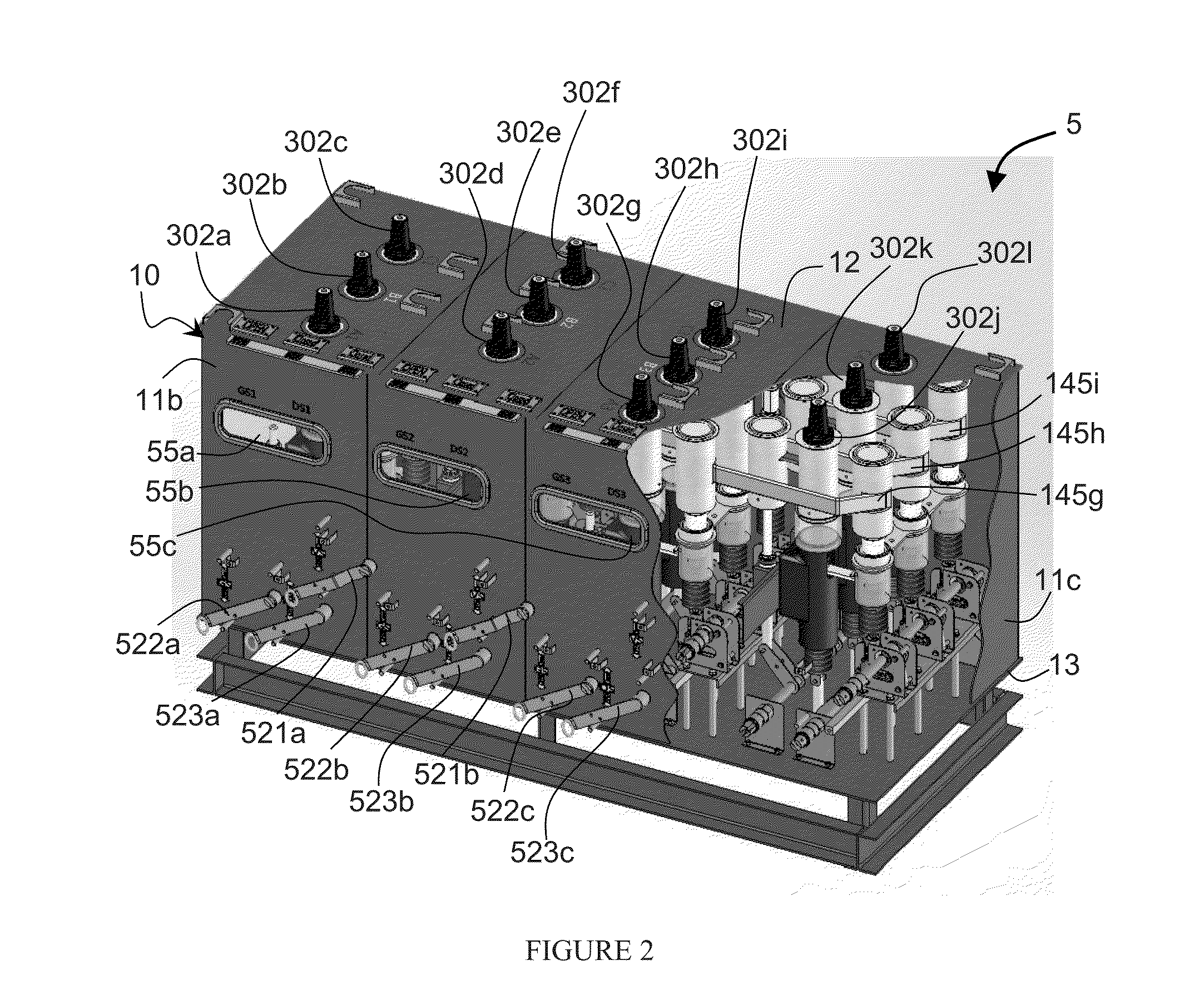

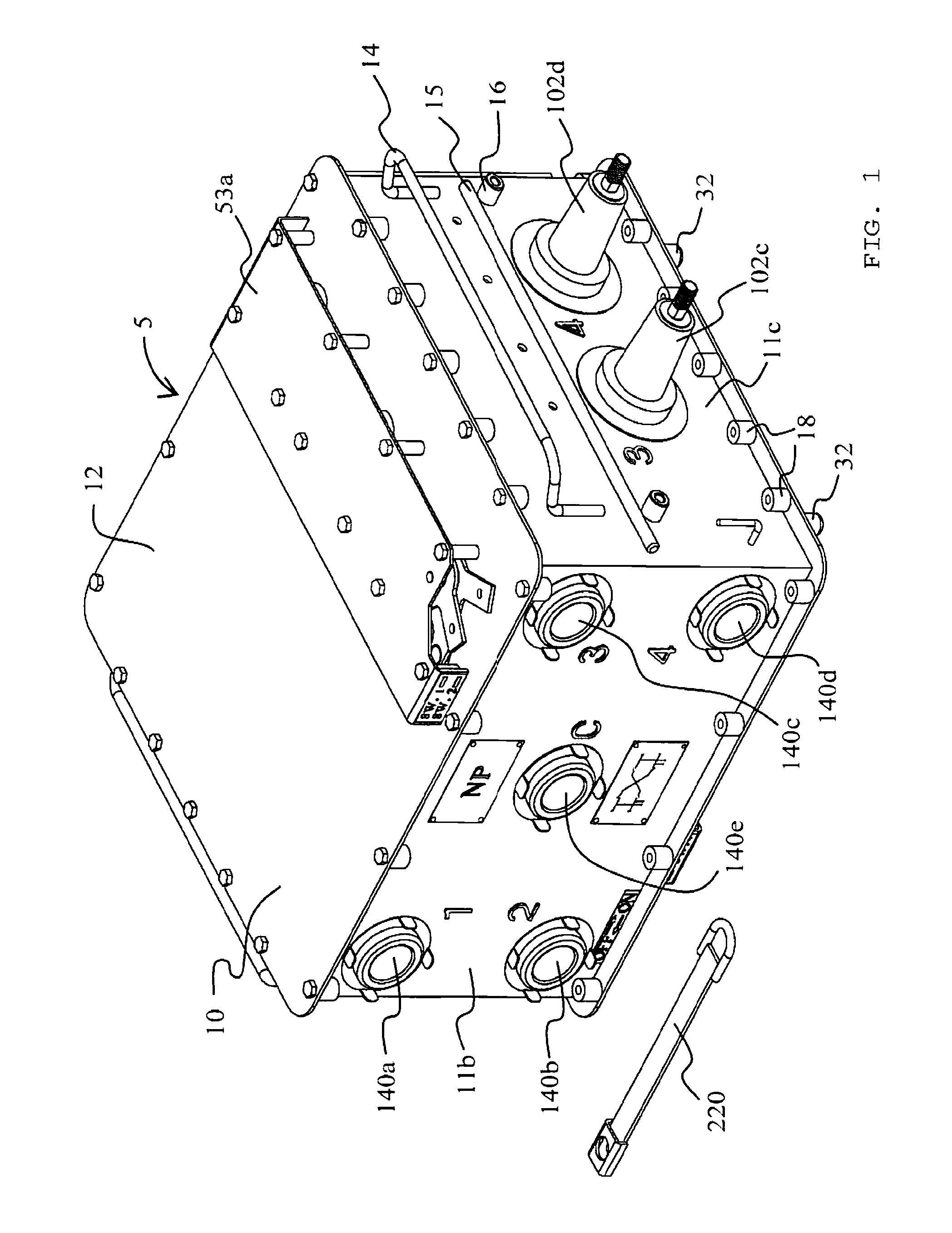

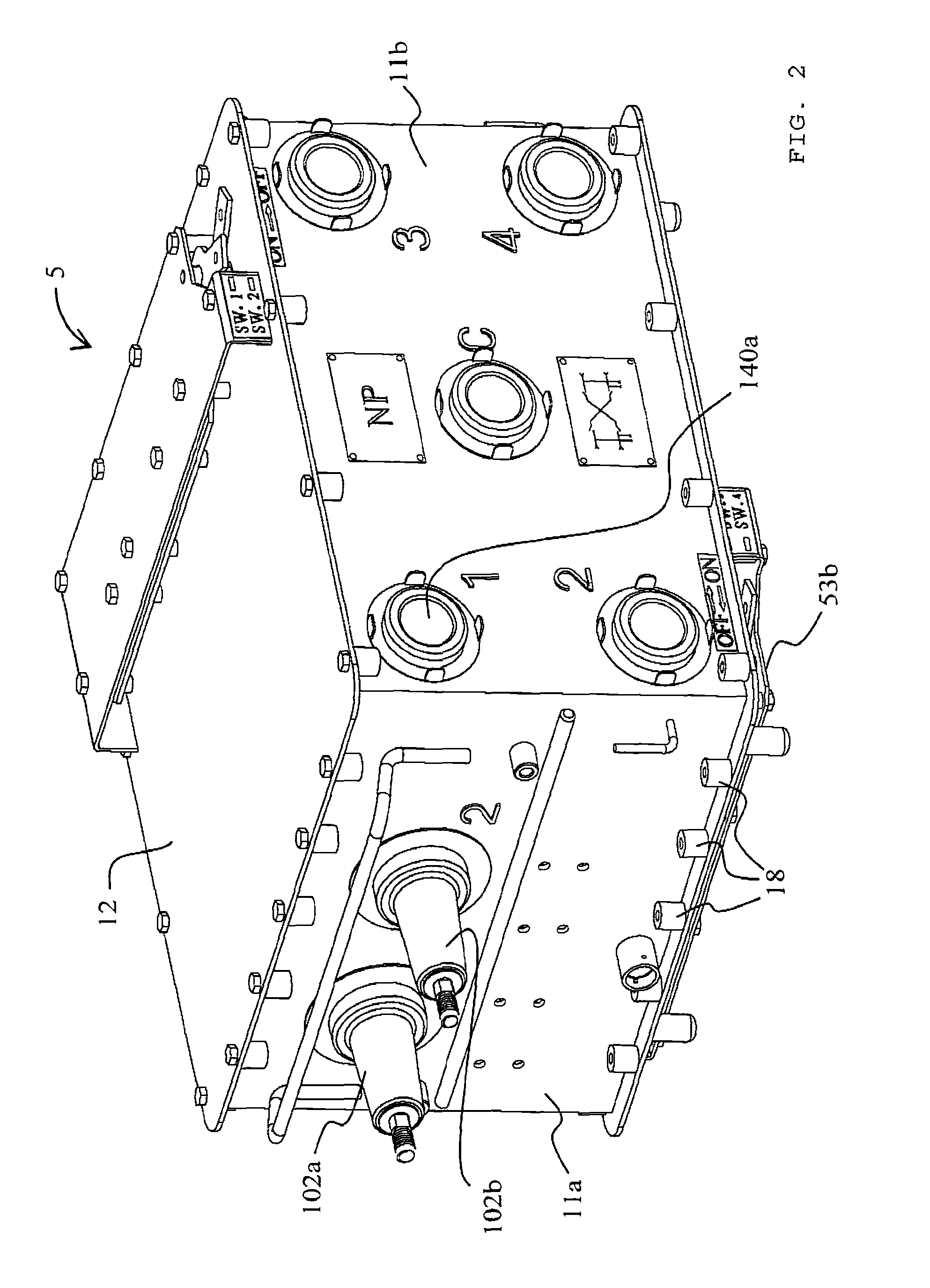

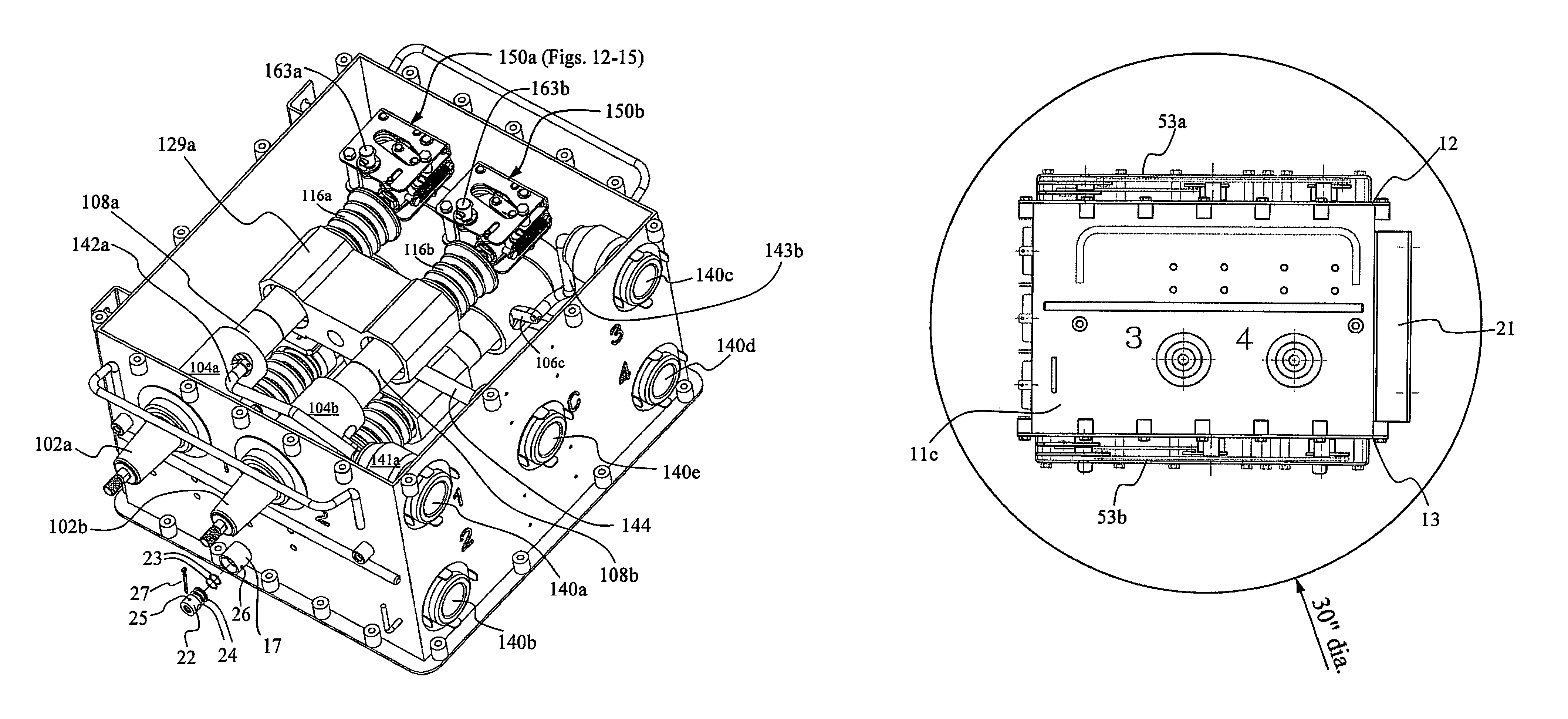

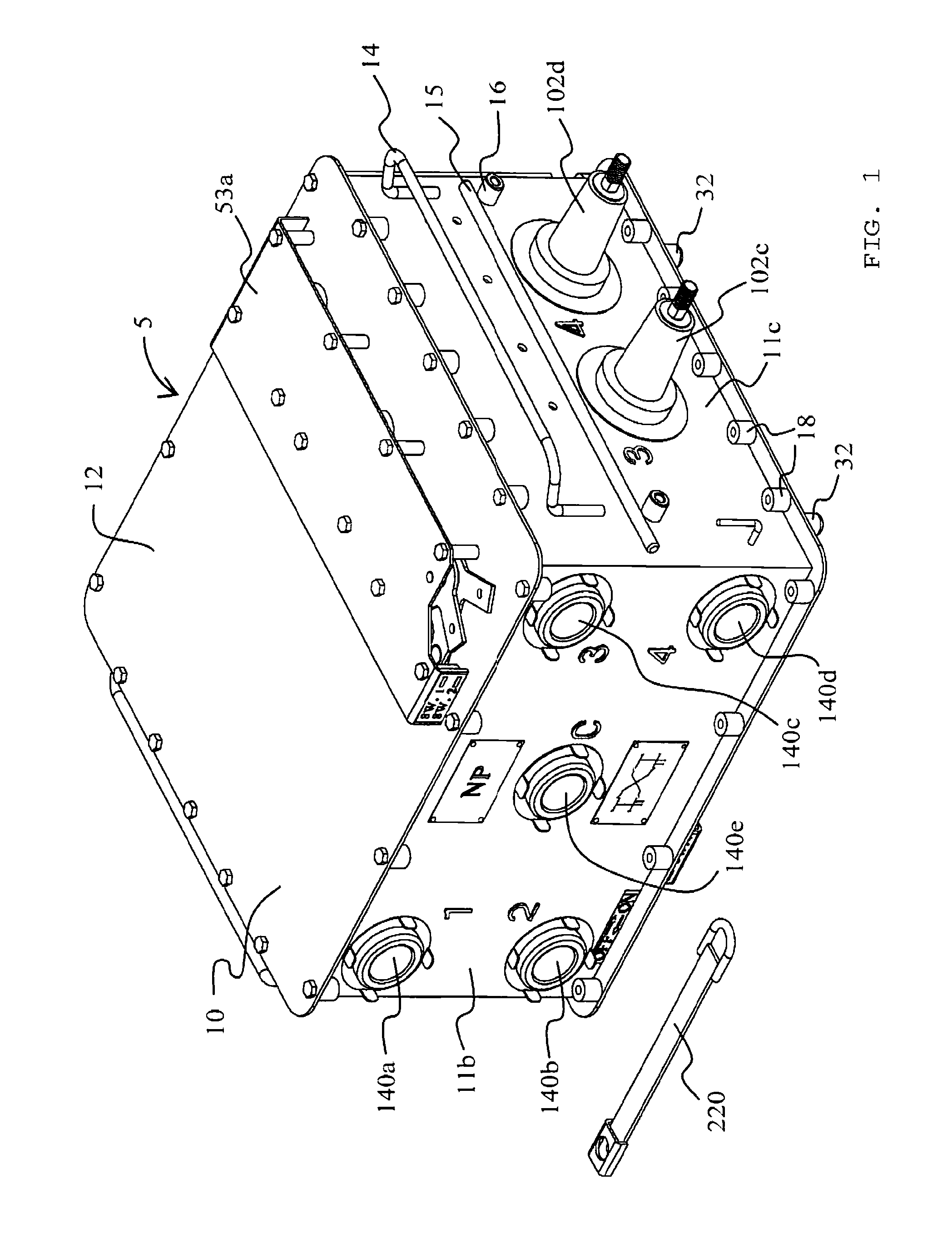

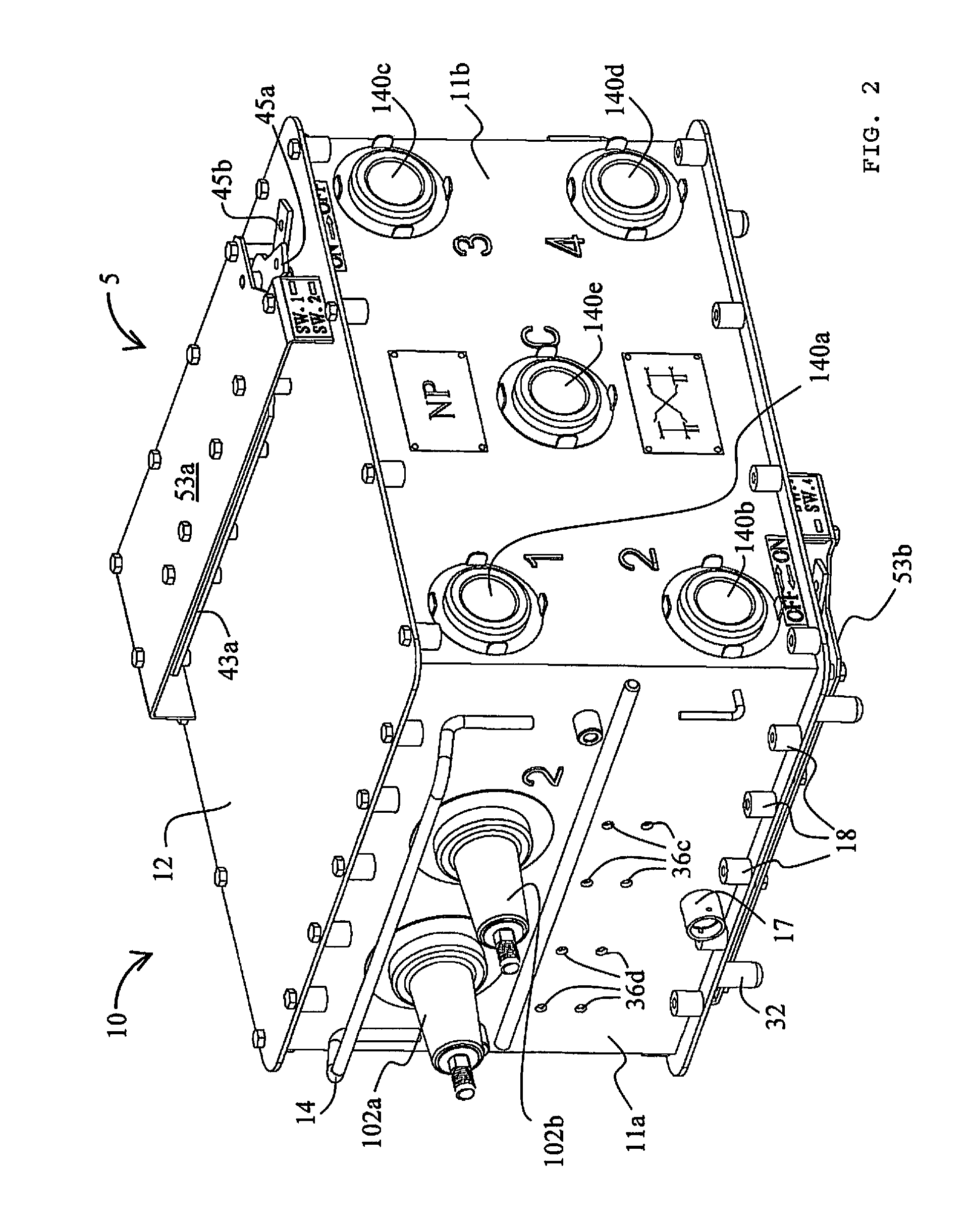

Three-phase, multi-way vacuum interrupter switchgear with internal ground switches

ActiveUS20130292358A1Process safety and environmental protectionSwitch power arrangementsHigh-tension/heavy-dress switchesElectricityDistribution system

A three-phase vacuum interrupter switch assembly for power distribution systems comprises an outer case having at least one window and containing a plurality of component assemblies. The case interior is preferably free of oil and / or SF6 gas. Each component assembly comprises three internal disconnect switch assemblies, three vacuum interrupter bottle switch assemblies and three ground switch assemblies. Each vacuum interrupter bottle switch is coupled in electrical series with a corresponding internal disconnect switch assembly. Because the open / closed state of a bottle switch is not directly observable owing to its sealed interior, a direct visible indication of the state of the three-phase vacuum interrupter switch assembly is provided by a visually detectable contact rod of the corresponding internal disconnect switch that is visible through the case window. To prevent potentially serious damage caused by arcing between the contacts of the internal disconnect switch, the internal disconnect switch is prevented from opening or closing when the bottle switches are closed.When the component assembly is deactivated, some residual current may still remain. The ground switch assembly associated with the component assembly grounds such residual current as part of the deactivation process so that it is safe to have maintenance work performed. An interlocking mechanism ensures that the disconnect switch assembly, vacuum interrupter bottle switch assembly and ground switch assembly of each component assembly are opened and closed in a sequence that ensures proper and safe operation.

Owner:IMPACT POWER LLC A DELAWARE LLC

Normal temperature calcium-manganese phosphorizing liquid

InactiveCN102747356ASolution to short lifeProblems causing significant reduction in coating adhesionMetallic material coating processesBenzoic acidLiquid temperature

The invention discloses normal temperature calcium-manganese phosphorizing liquid, which comprises Mn<2+>, Ca<2+> and sodium benzoate or benzoic acid or nickel nitrate. The environment-friendly calcium-manganese phosphorizing liquid provided by the invention can be used at normal temperature, and has the advantages of no surface adjusting process before phosphorizing and no washing process after phosphorizing, simple operation, long service life and excellent effect, when the generated phosphorizing membrane is taken as a coating basement, the coating has good adhesive force, thereby overcoming the problems of complicated conventional phosphorizing process, higher phosphorizing liquid temperature, large consumption of water and phosphate, much harmful wastewater and the like. The phosphorizing liquid is suitable for surface treatment before coating the surface of black metal steel, and the generated phosphorizing film is used as a basement of the coating.

Owner:CHANGSHA UNIVERSITY

Process for the preparation of acyl aromatic ethers

An improved process for the preparation of acyl aromatic ethers useful as important intermediates for drugs and pharmaceuticals by reacting an aromatic ether with an acylating agent selected from a C2-C8 acid anhydrides, employing nano- and microcrystalline zeolite beta as catalyst is disclosed.

Owner:COUNCIL OF SCI & IND RES

Manufacturing method for warm rolling of stainless steel/carbon steel composite board

The invention relates to the technical field of composite board production, in particular to a manufacturing method for warming rolling of a stainless steel / carbon steel composite board. According tothe method, a selected stainless steel board blank and a carbon steel board blank are subjected to surface treatment, then the composite contact side of stainless steel and carbon steel is coated withan impervious layer, drying is carried out at room temperature, then the two blanks are arranged in an aligning manner and symmetrically combined into a blank, the periphery of the composite blank obtained after combination is welded and sealed and subjected to vacuumizing treatment, then the composite blank is placed into a heating furnace to be subjected to multi-pass rolling, the composite blank is cooled in air after being rolled, and cut face smoothness treatment is carried out. According to the method, the stainless steel board blank is coated with the impervious layer, at a specific heating temperature section and heat preservation time, the stainless steel is protected, and the situation that in the rolling process, due to element dispersing, performance of the composite board isreduced can be avoided. By means of the impervious layer, mutual dispersion between Cr and C elements in the rolling process at a high temperature can be effectively avoided.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing anti-oxidization active camellia olefera cake polysaccharide

InactiveCN102796203AImproves antioxidant activityTake advantage ofAntinoxious agentsCamellia oleiferaEthanol precipitation

The invention relates to a method for extracting polysaccharide, in particular to an anti-oxidization polysaccharide extraction method in which camellia olefera cakes are used as raw materials. The method comprises the following specific steps: crushing the camellia olefera cakes to 60-80 meshes; adding into an aqueous solution with pre-dissolved cellulase (the enzymatic activity is greater than 15,000 u / g) for extraction, wherein the mass ratio of the cake powder to the aqueous solution is 1: (20-40); the using amount of the cellulase is 0.3-0.4% of the weight of the cake powder; the extraction temperature is 45-55 DEG C; and the extraction time is 3-5 hours; filtering the extract, concentrating, adsorbing by using polyamide for 8-12 hours, and eluting with deionized water; collecting the eluent, concentrating, adding 3-5 times of ethanol, and precipitating for 12-36 hours; and centrifugating to obtain precipitates after ethanol precipitation, and freezing and drying to obtain the grey white polysaccharide. According to the method, camellia olefera processing waste is fully utilized; the technical process is safe and environment-friendly; no toxic chemical reagents are used; and a new way for fully utilizing the camellia olefera processing waste is supplied.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

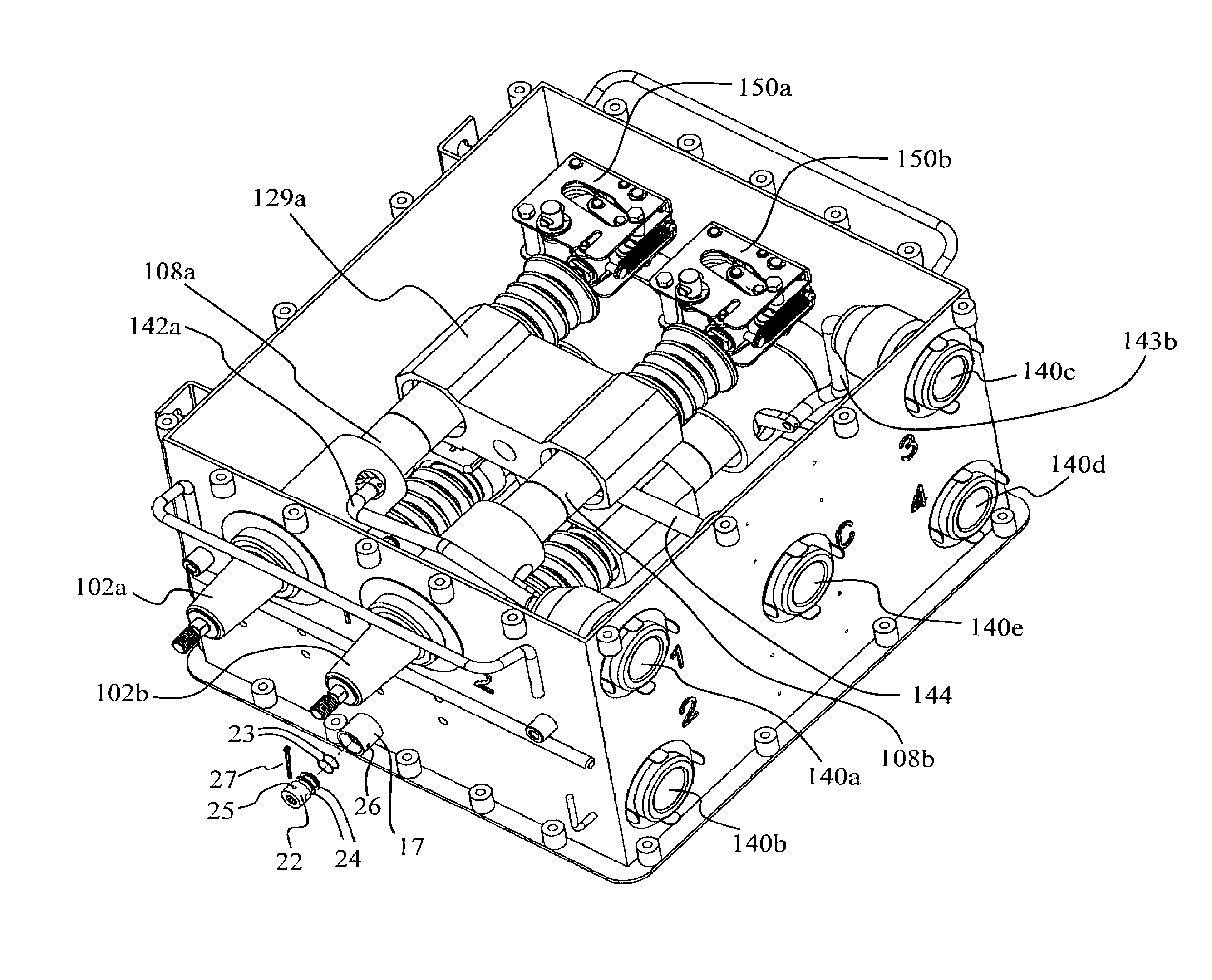

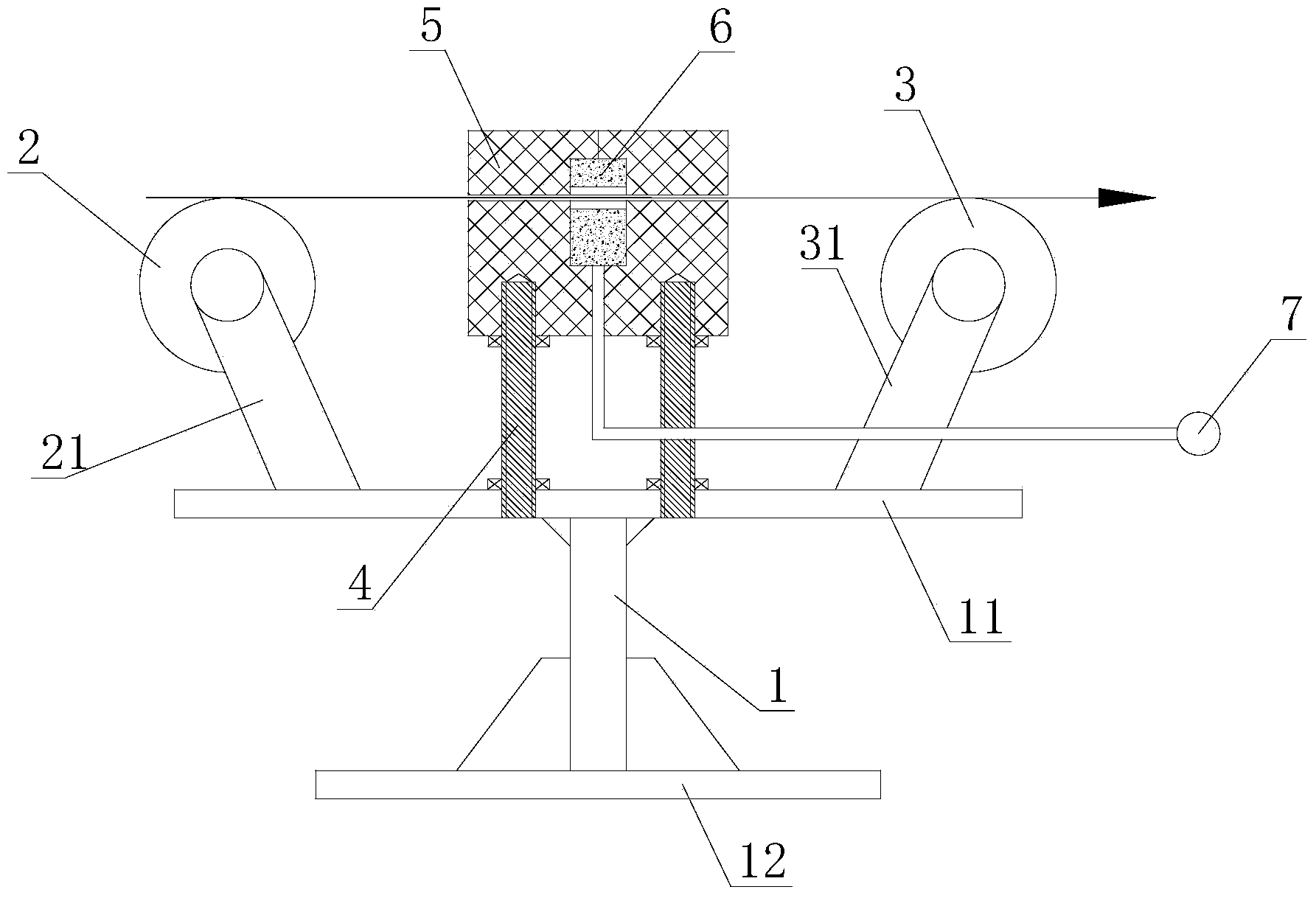

Vacuum Interrupter Switch For Power Distribution Systems

InactiveUS20100326960A1Process safety and environmental protectionMinimizes potential hazardsHigh-tension/heavy-dress switchesAir-break switchesDistribution systemBottle

A current interrupting switch for power distribution systems comprising an outer case and a plurality of vacuum interrupter bottle switches positioned in the case.

Owner:IMPACT POWER LLC A DELAWARE LLC

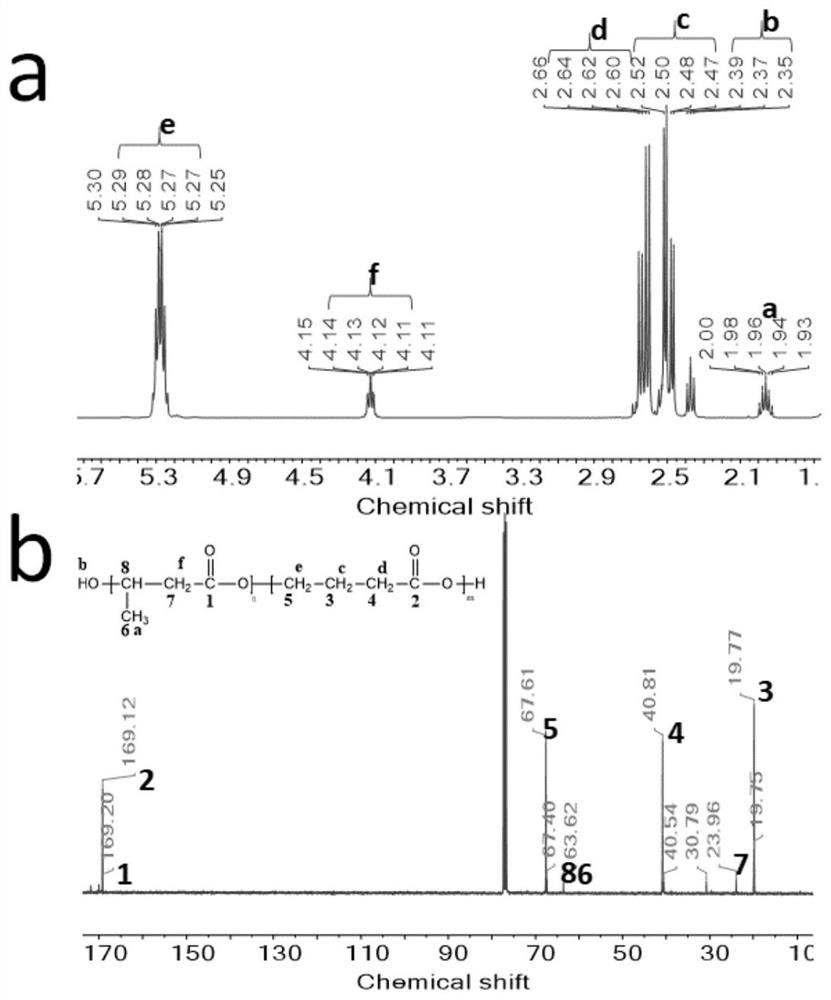

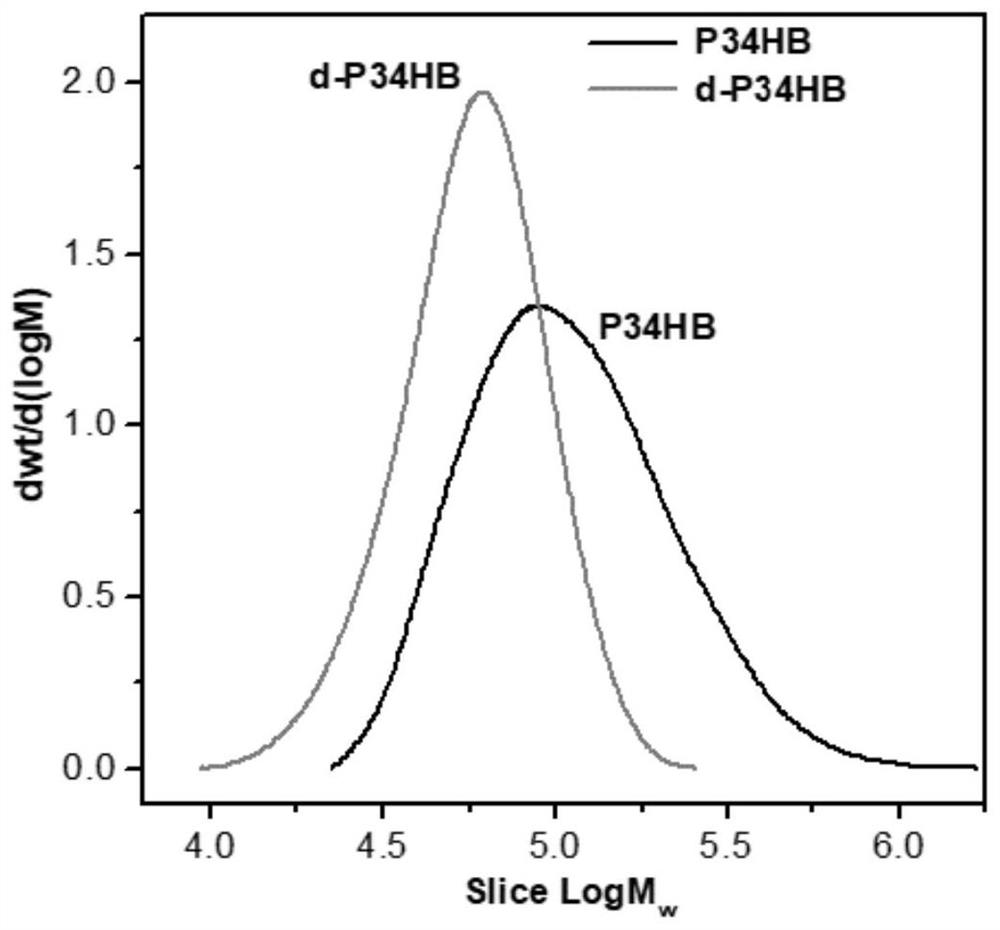

Molecular weight grading and purifying method of polyhydroxyalkanoate

ActiveCN113292713ASource securityUniform and accurate molecular weightPlastic recyclingPtru catalystSolvent

The invention relates to the field of biological medicine, in particular to a molecular weight grading and purifying method of polyhydroxyalkanoate, which comprises the following steps: S1, dissolving a polyhydroxyalkanoate raw material in a good solvent, and adding a catalyst for heating degradation; S2, cooling the solution heated and degraded in the step S1 to room temperature, conducting mixing with a poor solvent, precipitating and separating out a degradation product, and collecting the degradation product after sedimentation; and S3, centrifuging the degradation product collected in the step S2, and washing and drying the degradation product to finish molecular weight grading and purification of the polyhydroxyalkanoate. The method is simple in step and convenient to operate, molecular weight grading can be carried out on polyhydroxyalkanoate while the polyhydroxyalkanoate is purified, and the polyhydroxyalkanoate obtained after grading and purification through the method is high in purity, uniform and accurate in molecular weight and narrow in molecular weight distribution and has a higher active terminal.

Owner:THE SIXTH AFFILIATED HOSPITAL OF SUN YAT SEN UNIV +1

Graphitized compound carbon fibers and preparation method thereof

ActiveCN105239207ALow viscosityImprove refinementArtifical filament manufactureStretch-spinning methodsFiberCarbon fibers

The invention discloses a preparation method of graphitized compound carbon fibers. The method comprises the following steps: charging materials by steps and mixing, centrifuging and spinning, spraying hot airflow, curing, carbonizing and graphitizing. The prepared graphitized compound carbon fibers have the characteristics that the average diameter is 0.5-4 microns, the average length is 0.1mm-120mm, the tensile strength is 0.7GPa-1.8GPa, the tensile modulus is 30GPa-80GPa, the heat conductivity is 1W / m.k-5W / m.k (radial) and the initial oxidization temperature is 500-650 DEG C. The graphitized compound carbon fibers have low manufacturing cost and can be widely applied to technical fields of heat preservation and heat insulation, activated adsorption, friction and the like.

Owner:ANHUI HONGCHANG NEW MATERIAL CO LTD

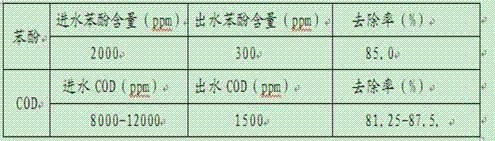

Treatment method of waste water produced by adopting castor oil to prepare decanedioic acid

InactiveCN102372378AHigh removal rateHigh temperature and high removal rateWater contaminantsMultistage water/sewage treatmentForeign matterEnvironmental resistance

The invention belongs to the treatment technical field of decanedioic acid produced waste water, and particularly relates to a treatment method of waste water produced by adopting castor oil to prepare decanedioic acid, which adopts the technical scheme that: scrap iron is firstly added into an oxidation pond to form a stationary bed layer of solids; then the waste water with the solid foreign matters being filtered is discharged into the oxidation pond, and simultaneously the hydrogen dioxide solution oxidant with the concentration of 30 percent is added to the oxidation pond; air is sent into the oxidation pond through a blower; finally sulfuric acid is added into the oxidation pond to adjust the pH value to be 3 to 4, three-phase catalytic oxidation reaction is carried out, the active ingredient of catalyst is green copperas, the reaction temperature is 50 DEG C to 60 DEG C, and the reaction time is 4h to 8h; and after the reaction is ended, the waste water after being treated is discharged into a waste water adjusting pond, flocculating agent is also added into the waste water adjusting pond, and the well-treated waste water can be obtained after filtering the suspended substances and precipitates The method has simple process and moderate reaction conditions, is free from requiring the high temperature and high pressure, is easy to operate, has fast reaction speed, less equipment investment, high treatment efficiency, high removal rate of phenol in the waste water and no secondary pollution, and is environment-friendly and safe.

Owner:SHANDONG TIANXING BIOTECH

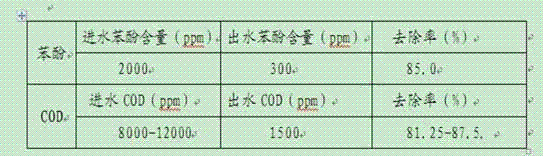

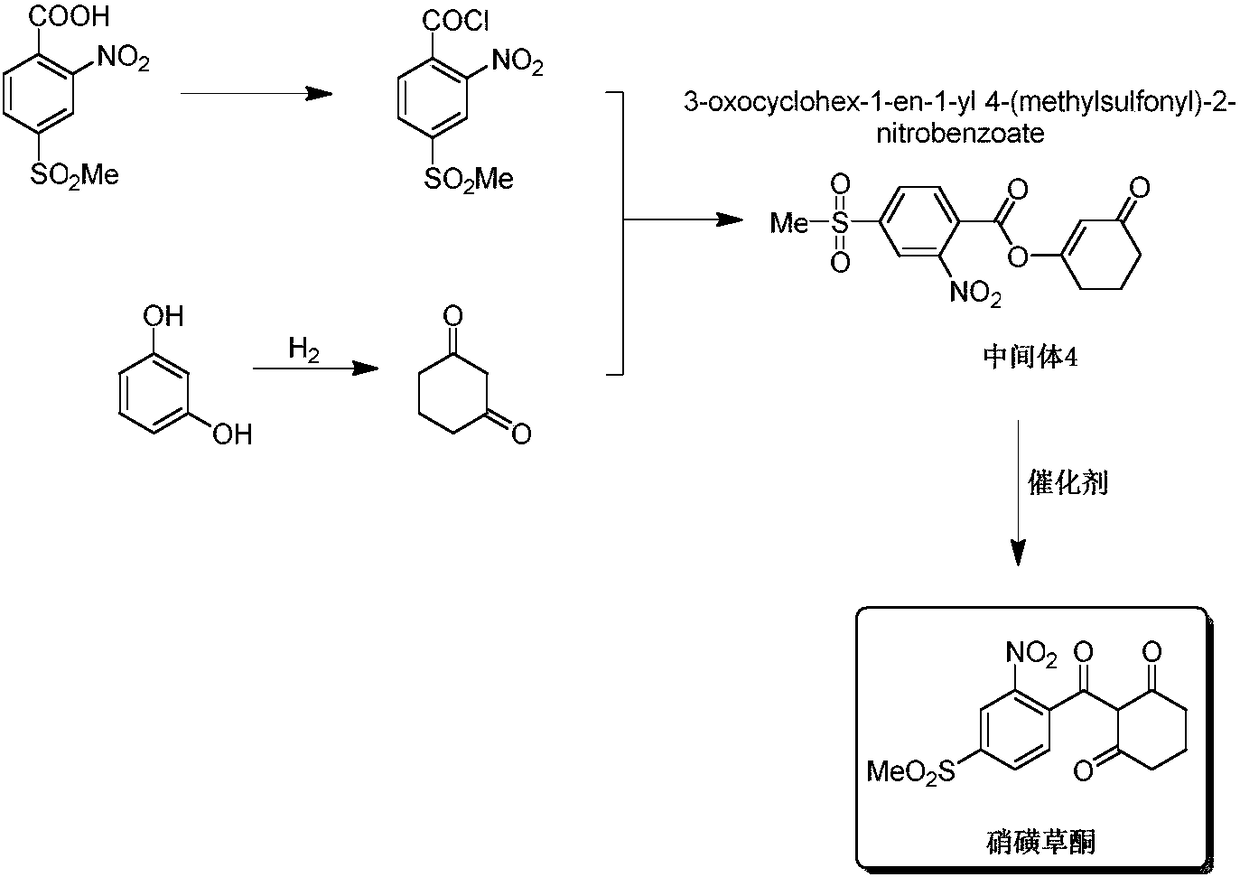

Preparation method of mesotrione

ActiveCN108440352AOptimizing Rearrangement Reaction ConditionsShort reaction timeOrganic chemistryOrganic compound preparationCyanideReaction temperature

The invention provides a preparation method of mesotrione. The preparation method comprises the following steps: taking p-methylsulfonyl o-nitrobenzoic acid as a raw material; after carrying out acylchlorination, carrying out condensation reaction with 1,3-cyclohexanedione to obtain an intermediate 2-nitryl-4-methylsulfonylbenzoic acid-[3'-carbonyl-1'-cyclohexenol]-ester; then carrying out rearrangement of enol ester under a common catalysis effect of inorganic alkali and tertiary amine type organic alkali with relatively strong basicity, so as to obtain an acrylated cyclic 1,3-dicarbonyl compound mesotrione. According to the method provided by the invention, a virulent cyanide catalyst is not used, the reaction temperature is relatively low and the reaction time is short; a solvent can be cyclically used, the total mol yield of a prepared mesotrione product can reach 95 percent and the content is 98.5 percent; the technology is safe and environmentally friendly, has a small amount ofthree wastes and is suitable for industrial production.

Owner:JIANGSU FENGSHAN GROUP

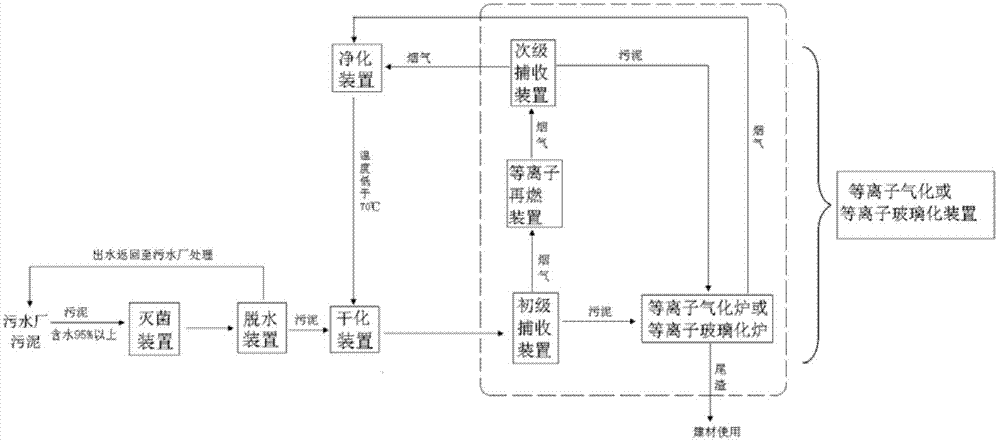

Sludge treatment process and system

ActiveCN104261645AComplete workmanshipReduction and RecyclingSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisWater contentChemistry

The invention discloses a sludge treatment process which comprises the following steps: (1) sterilizing sludge so as to kill microorganisms in the sludge; (2) dewatering and drying the sterilized sludge so as to reduce the water content of the sludge; (3) separating the dried sludge, carrying out high temperature plasma treatment on the separated sludge, and burning separated smoke; (4) carrying out sludge-smoke separation on smoke generated by reburning treatment, carrying out high temperature plasma treatment on the separated sludge again, and purifying and cooling the separated smoke. The invention further discloses a sludge treatment system capable of carrying out the sludge treatment process. The sludge treatment system comprises a sterilizing device, a dewatering device, a drying device, a plasma gasifying or plasma vitrifying device and a purifying device. The sludge treatment system can realize harmless, reducing and resourceful treatment for the sludge and does not generate secondary pollution, is safe and reliable, and can realize thorough treatment for the sludge.

Owner:山东博润环保科技有限公司

Synthetic method of 3, 5-dichloro-2-pentanone

ActiveCN105461533AProcess safety and environmental protectionEasy to industrializeCarbonyl compound separation/purificationPreparation from heterocyclic compoundsRetention timeEthyl Chloride

The invention discloses a synthetic method of 3, 5-dichloro-2-pentanone. Under the action of salt and a phase transfer catalyst, alpha-chloro-alpha'-acetyl-gamma-butyrolactone, which is used as a raw material, reacts with hydrochloric acid; and then, 3, 5-dichloro-2-pentanone is synthesized through a continuous steam distillation method. According to the characteristic of great boiling point difference between the raw material and the product, the technical scheme of reacting while separating is adopted. Therefore, purity of the product is raised, yield is greatly increased, and the hydrochloric acid solution in the reaction can be recycled. By adding the phase transfer catalyst, reaction speed of the raw material can be raised, and accumulation of the raw material in the reaction system is reduced. By adding salt, reaction distillation temperature can be increased, product separation speed is accelerated, and retention time of the raw material and the product in the reaction system is shortened. Thus, side reaction is minimized, and selectivity is enhanced.

Owner:大连科铎环境科技有限公司

Active material for cathode film, polyether polymer composition for cathode film, cathode film, and method for producing cathode film

InactiveUS20070031735A1Stable electrical characteristicsImprove productivitySecondary cellsSolid electrolyte cellsProduction rateLithium compound

The present invention relates to a technique for producing a cathode film having a thin and even thickness and having stable electrical characteristics at a high productivity by an extrusion molding method. That is, the present invention provides an active material for a cathode film comprising a lithium compound having a void fraction of 0.36 or less and a polyether polymer composition for a cathode film comprising a polyether polymer, an electrolytic salt compound which is soluble in the above polymer and the active material for a cathode film described above. The object described above can be achieved by extrusion-molding them.

Owner:ZEON CORP

Method for manufacturing mud rock sample by adopting white oil as refrigerant

InactiveCN104198240AIncrease success rateProcess safety and environmental protectionPreparing sample for investigationRock sampleWhite oil

The invention relates to a method for manufacturing a mud-rock sample by adopting white oil as a refrigerant. The method is characterized by comprising the steps of (1) drilling a mud rock sample column, namely (a) for mud cock and the mud cock with cracks, using the white oil as the refrigerant, and (b) drilling the mud rock sample column by adopting a common vertical rock sample drilling machine; (2) encapsulating a rock core column, namely (a) taking out the rock core column, putting the rock core column into heated absolute ethyl alcohol, and washing off the white oil on the surface and gaps of the rock core column, (b) sheathing a thermal shrinkable sleeve in time, and (c) baking the rock core column and the thermal shrinkage sleeve on an alcohol lamp simultaneously till the rock core column is tightly fastened by the thermal shrinkable sleeve; and (3) cutting a sample according to the permeability, namely (a) cutting the overlong rock core column of the mud rock and the thermal shrinkable sleeve on an end-surface cutting machine, wherein consistent length and permeability are required. The method has the advantages that the success rate of the sample can be increased, the rock core sample meeting the requirements can be processed, the environment-friendly effect is achieved and the labor efficiency is high.

Owner:PETROCHINA CO LTD +1

Vacuum interrupter switch for power distribution systems

InactiveUS8284002B2Process safety and environmental protectionMinimizes potential hazardsHigh-tension/heavy-dress switchesAir-break switchesPower flowElectric power distribution

A current interrupting switch for power distribution systems comprising an outer case and a plurality of vacuum interrupter bottle switches positioned in the case.

Owner:IMPACT POWER LLC A DELAWARE LLC

Grease decoloring agent

ActiveCN103706322ABleaching excellentExcellent purificationOther chemical processesFatty-oils/fats refiningFiltrationResidual oil

The invention discloses a grease decoloring agent, relates to a purification and adsorption material, and especially relates to the grease decoloring agent of aluminum-based hydrate composite materials and a preparation method thereof. The grease decoloring agent is characterized by being prepared by selecting two or more than two aluminum-based hydrates having the adsorption property, carrying out mixing homogenization and then adding an acidic modifying agent for modification and activation. The grease decoloring agent is a mixture of the aluminum-based hydrate composite materials. The materials have the advantages of less using amount, good decoloring effect, easy filtration and separation, small residual oil rate and the like; moreover, the decolorizing agent does not contaminate products; after medium temperature roasting after decolorization, the decolorizing agent can be used in a raw material of a high temperature coating layer material, thereby reducing the decoloring agent cost; and the grease decoloring agent fully meets the requirements of food-grade grease on indicators of the chromaticity and the impurity content, and is easy to popularize and apply.

Owner:中铝郑州有色金属研究院有限公司

Process for producing soft-state copper clad steel conductor by adopting welding cladding method

ActiveCN103531301AImprove conductivityReduce energy consumptionCable/conductor manufactureCopper-clad steelMaterials science

The invention relates to a production process of a copper clad steel conductor and particularly provides a process for producing a soft-state copper clad steel conductor by adopting a welding cladding method. The process comprises the following steps: drawing, tempering at a low temperature, washing with acid, washing with water, neutralizing, drying, straightening and removing rust, cladding and welding, singly drawing, continuously drawing, tempering at a high temperature, drawing by a water tank, passivating, and carrying out online detection on the copper clad steel conductor by using a surface online flaw detection device, and carrying out take-up and winding. The process for producing the soft-state copper clad steel conductor by adopting the welding cladding method has the advantages of low production cost, safe and environment-friendly production process, and stable quality and high yield of the produced copper clad steel conductor.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

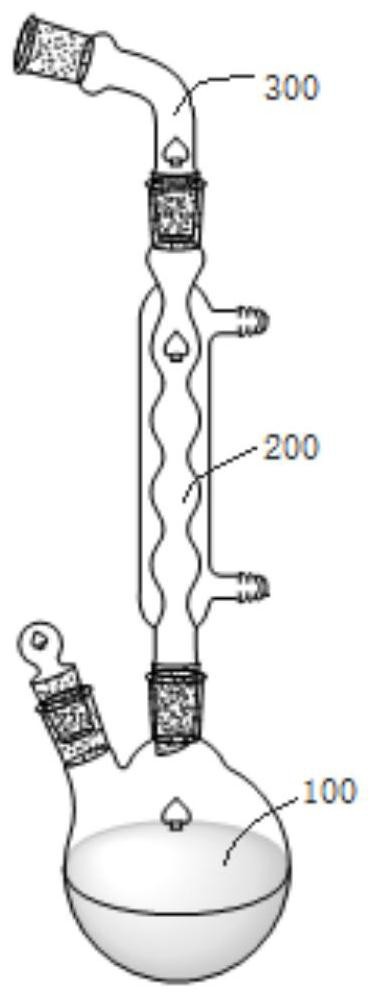

Preparation method of 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidyl]amino]benzoic acid, related intermediate and application thereof

ActiveCN101928277ASimple processLow costOrganic chemistryOrganic compound preparationBenzoic acidMethyl palmoxirate

The invention provides a preparation method of 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidyl]amino]benzoic acid. The preparation method comprises the following steps of: carrying out a guanidine-forming reaction on 3-amino-4-methyl toluic acid and cyanamide under the acidic condition of hydrochloric acid to generate 3-[(aminoiminomethyl)amino]-4-methyl-benzoic acid-hydrochloride, and then carrying out a cyclization reaction on the 3-amino-4-methyl toluic acid and cyanamide and 3-(dimethylamino)-1-(3-pyridyl)-2-propylene-1-one to generate the 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidyl]amino]benzoic acid, wherein a structural formula of the 3-[(aminoiminomethyl)amino]-4-methyl-benzoic acid-hydrochloride is shown as the description. The method has short route, simple operation, safe and environmentally-friendly process, repeatability, low cost, high yield, high stability and safety of a guanidine hydrochloride intermediate, suitability for large-scale industrial production and higher economic benefit and social benefit.

Owner:ZHEJIANG JIUZHOU PHARM CO LTD

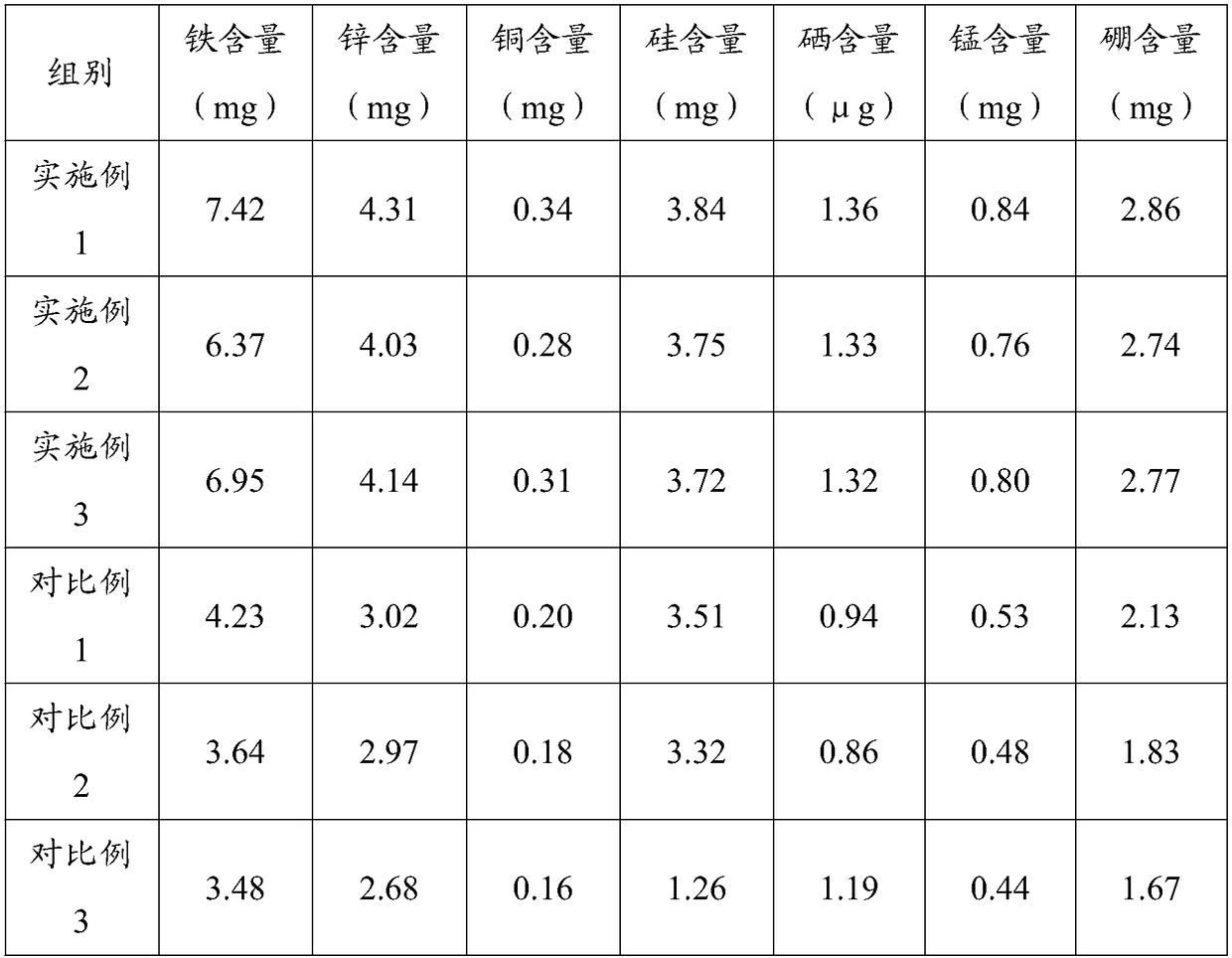

Multi-microelement enriched herba rhodiolae cultivation method

InactiveCN108401823AExcellent ability to repair soilImprove insecticidal effectAlkali orthophosphate fertiliserExcrement fertilisersPest controlNutrient solution

The invention discloses a multi-microelement enriched herba rhodiolae cultivation method. The method comprises a series of steps of soil preparation and sowing, field management, disease and pest prevention and harvesting at an appropriate timing. According to the method, by the combined application of a nutrient solution and a foliar fertilizer, the cultivation process is safe and environmentallyfriendly, the absorbing of each nutritious ingredient of herba rhodiolae plants can be effectively promoted, and the growth of the plants is promoted, so that the plants are rich in multiple kinds ofmicroelements to expand the medical functional potential of herba rhodiolae.

Owner:FOSHAN SANSHUI JIAXIN AGRI TECH RES INST GENERAL PARTNERSHIP

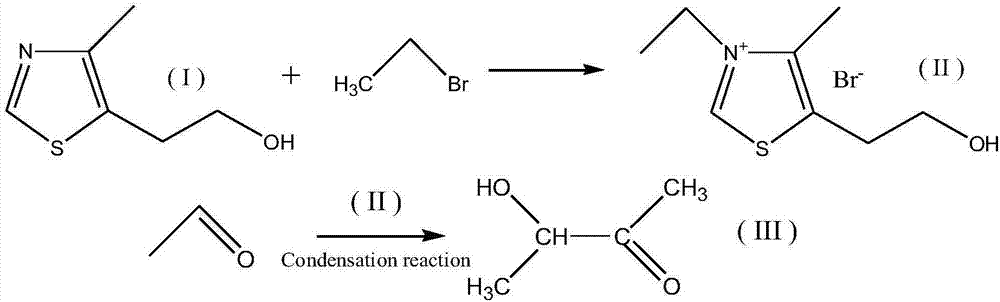

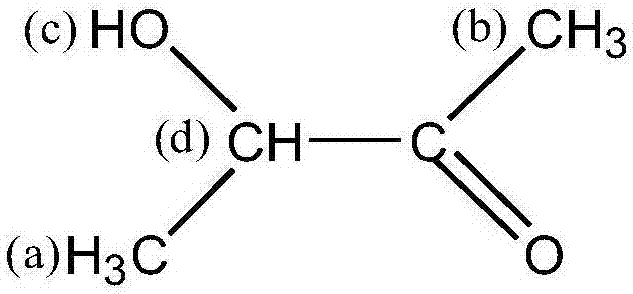

Acetoin synthesis method

InactiveCN107188793AReduce usageProcess safety and environmental protectionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolventDistillation

The invention provides an acetoin synthesis method. The method comprises 1, catalyst preparation: mixing 4-methyl-5-beta-hydroxyethyl thiazole (I) and bromoethane according to a mole ratio of 1: 1, carrying out heating reflux in an acetoin solvent in an oil bath for a reaction, then carrying out stirring cooling to the room temperature, carrying out rotary evaporation, recovering the solvent, standing the white precipitates, carrying out suction filtration and washing, carrying out acetoin recrystallization and carrying out drying to obtain a catalyst 3-ethyl-4-methyl-5-hydroxyethyl thiazole bromide (II) and 2, carrying out acetaldehyde condensation to obtain acetoin, adding the catalyst 3-ethyl-4-methyl-5-hydroxyethyl thiazole bromide (II) into an acetaldehyde solution, adjusting pH to 9-10, carrying out heating stirring for a condensation reaction in a pressure reactor until the pressure in the pressure reactor is 0 MPa, mixing the reaction solution, the recovered solvent and solutions collected in standing, suction filtration and washing processes, and carrying out reduced pressure distillation to obtain acetoin (III).

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

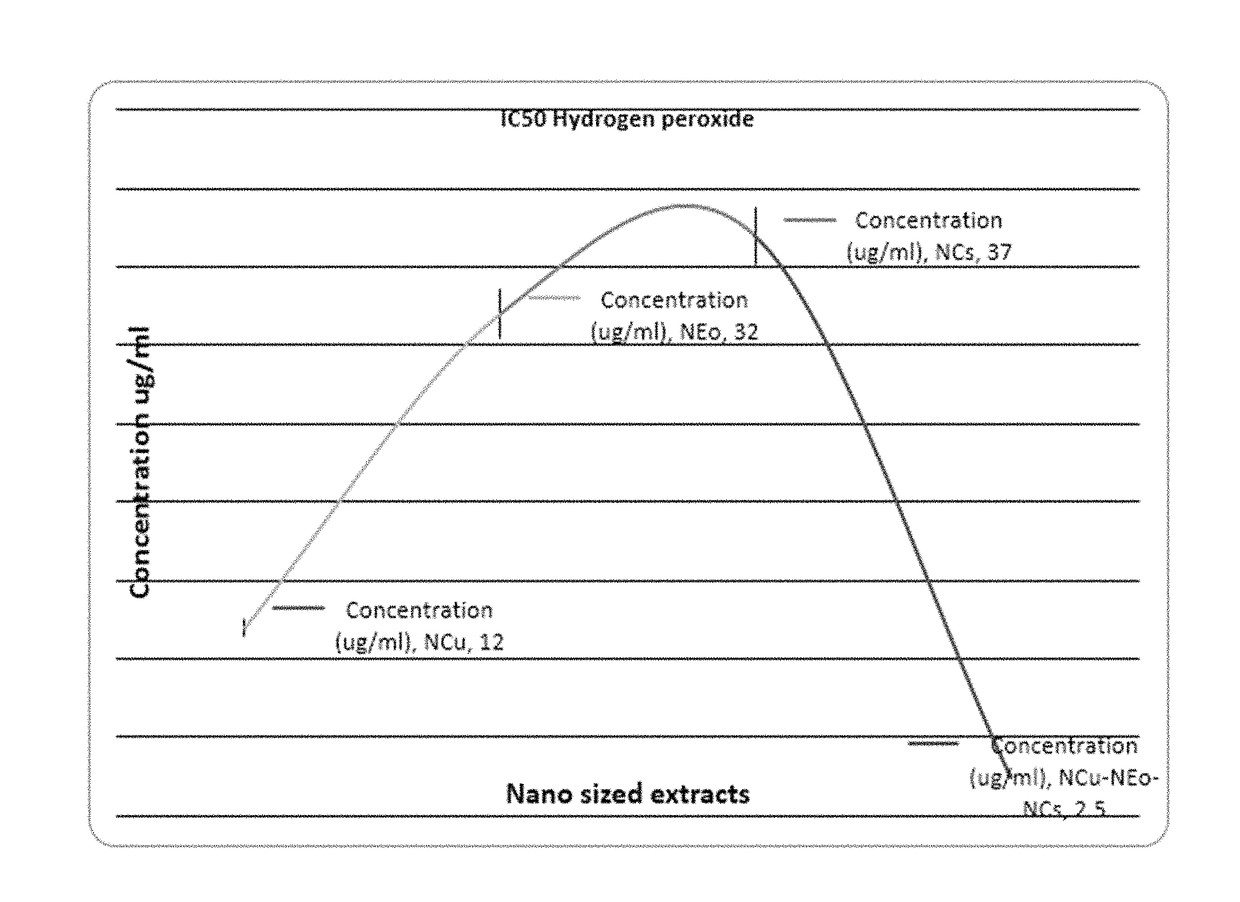

Multifunctional formulation comprised of natural ingredients and method of preparation/manufacturing thereof

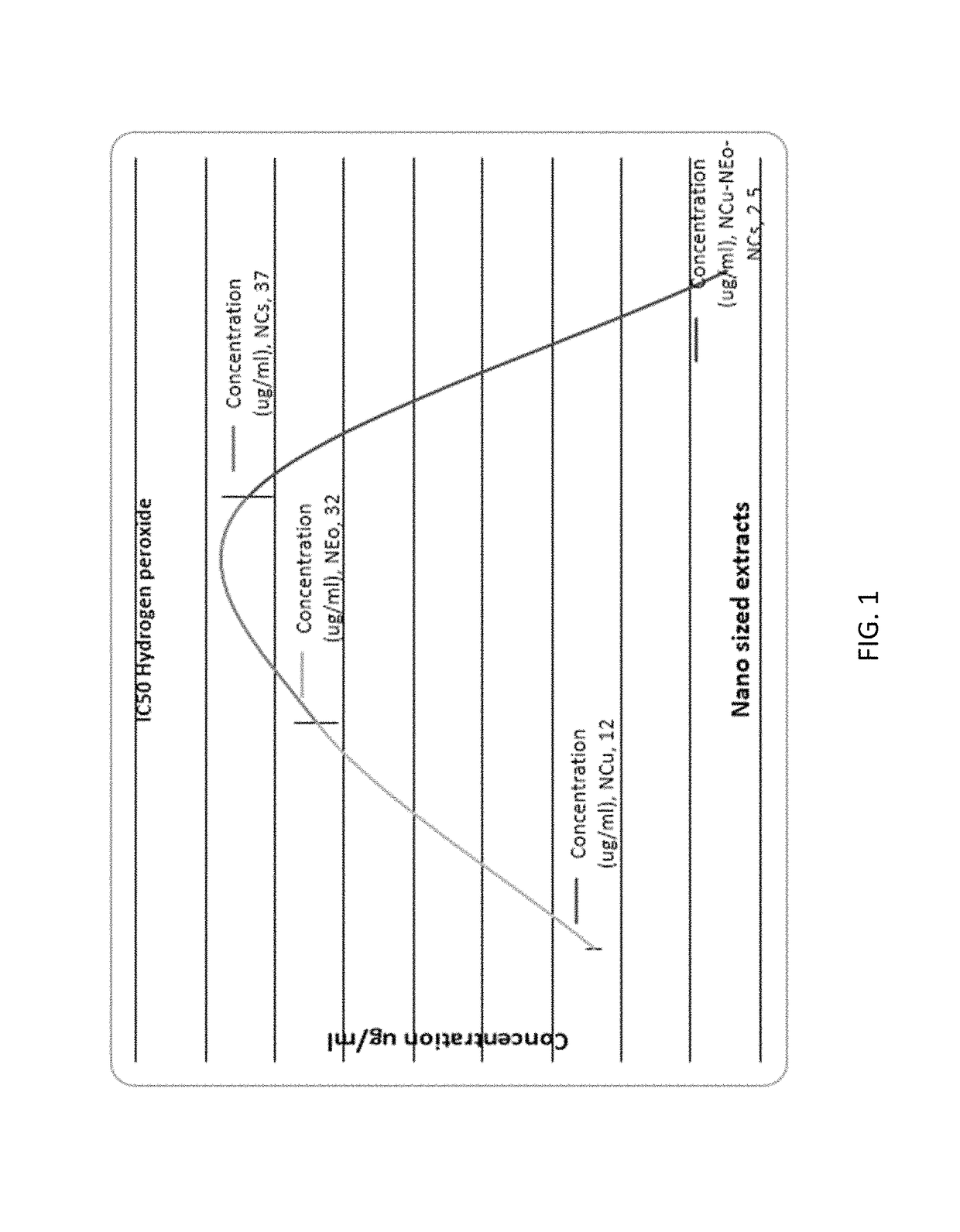

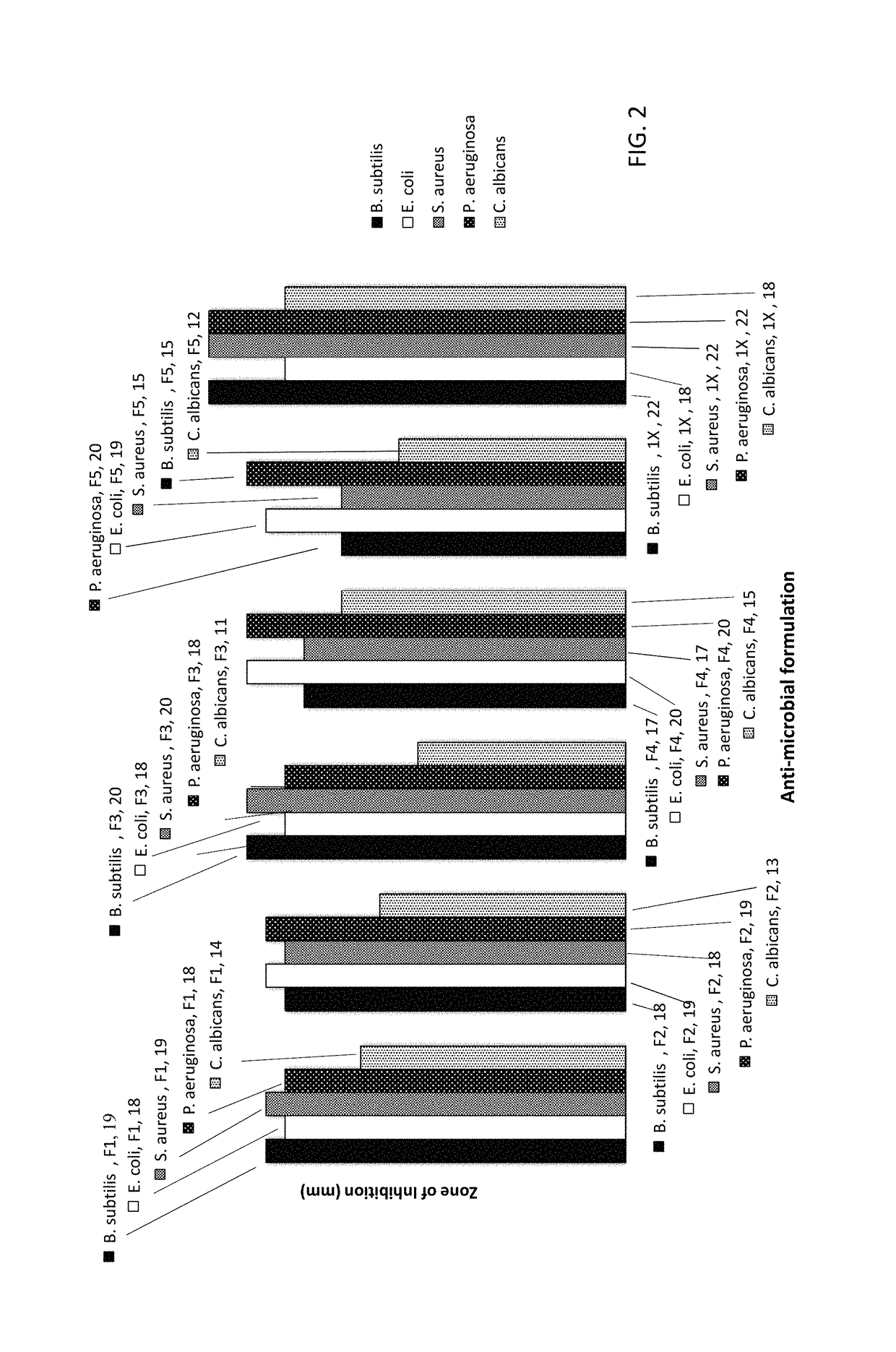

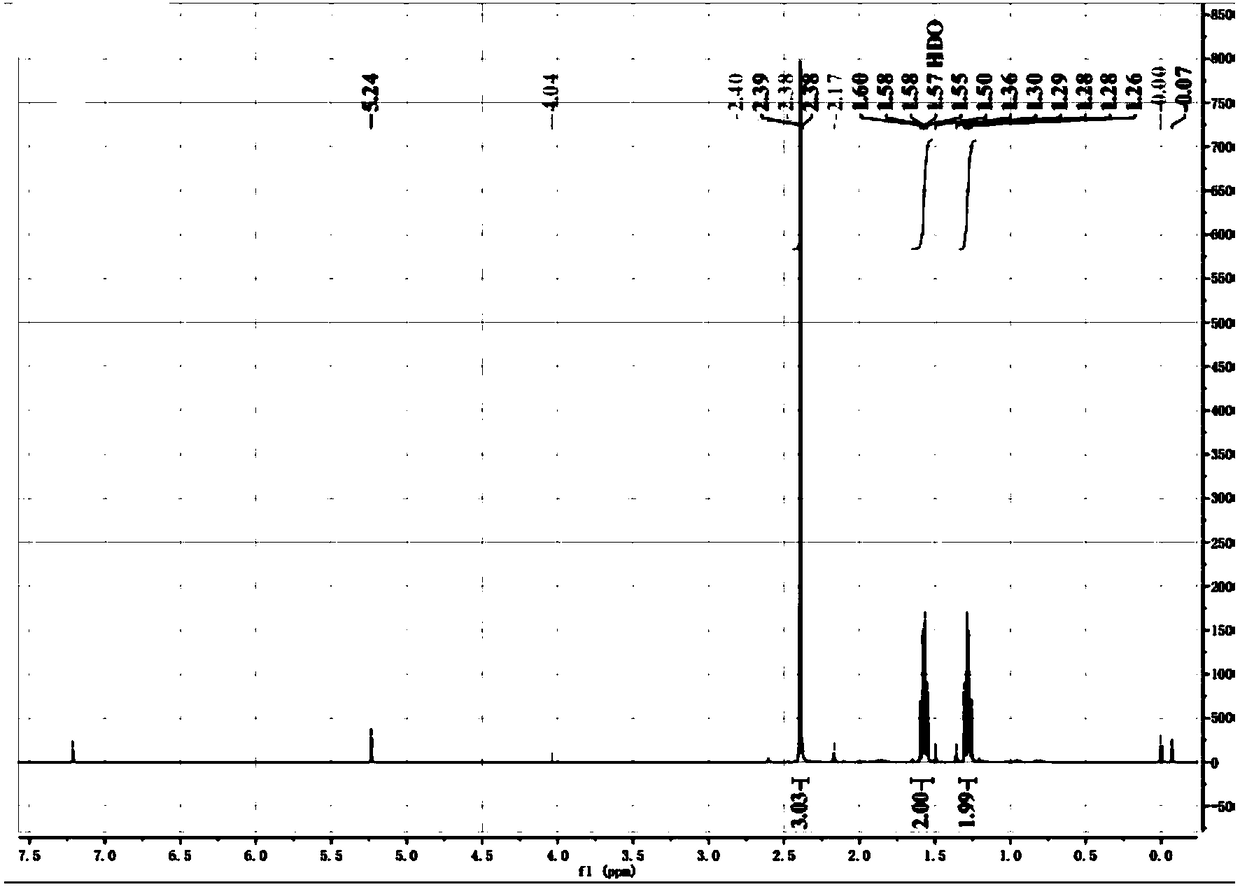

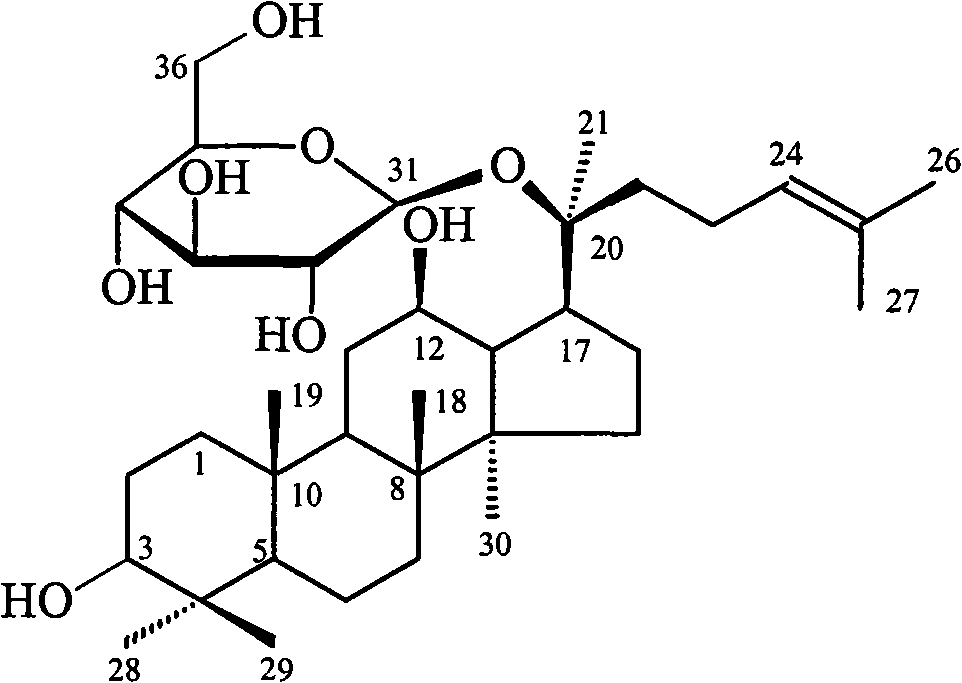

ActiveUS10076552B2Improve bioavailabilityEnhance anti-inflammatoryOrganic active ingredientsNon-adhesive dressingsTransdermal patchMelanoma

This invention relates to a pharmaceutical preparation for the treatment of compromised tissue such as skin wounds and ulcers in humans and animals and a method of preparation. This is a multifunctional natural matrix meant for the treatment of compromised tissues which also relates to the anti-cancer transdermal patch for melanoma therapy. Further, the invention comprises for the treatment of Alzheimer's, and multiple sclerosis also. The composition consists of water-solubilized nano-sized formulation of non-aqueous solvent extract of phyto-pharmaceuticals in herbal, animal or synthetic biocompatible gel or on matrix coated or both. The composition is used as a topical device for the treatment of compromised tissues in its preferred embodiment.

Owner:DATT LIFE SCI PVT LTD +1

Synthesis method for 1-chloro-1-acetyl cyclopropane

InactiveCN108440267AProcess safety and environmental protectionEasy to industrializeOrganic compound preparationCarbonyl compound preparationSynthesis methodsDistillation

The invention discloses a synthesis method for 1-chloro-1-acetyl cyclopropane. The synthesis method is characterized in that 3,5-dichloro-2-pentanone is taken as a raw material, and solvent oil is taken as a solvent to react with a 20% sodium hydroxide aqueous solution under action of a phase transfer catalyst crown ether, fluid separation and distillation can be performed to separate out 1-chloro-1-acetyl cyclopropane. Solvent oil which does not react with a system is added as the solvent, so that reaction is performed in two phases, and therefore, contact time between a product and alkalineis reduced, product purity is improved, and the yield is improved more greatly. Raw material reaction speed can be increased by adding the phase transfer catalyst, separation speed of the product anda water phase in a post-treatment process is quickened by adding the solvent, and dwell time, in the reaction system, of raw materials and product is integrally shortened, so that side reaction is reduced, and selectivity is improved.

Owner:LIANYUNGANG JINDUN AGROCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidyl]amino]benzoic acid, related intermediate and application thereof Preparation method of 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidyl]amino]benzoic acid, related intermediate and application thereof](https://images-eureka.patsnap.com/patent_img/a80a22c8-4078-4726-ba46-b0c4d0b99c59/000001.png)

![Preparation method of 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidyl]amino]benzoic acid, related intermediate and application thereof Preparation method of 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidyl]amino]benzoic acid, related intermediate and application thereof](https://images-eureka.patsnap.com/patent_img/a80a22c8-4078-4726-ba46-b0c4d0b99c59/000002.png)

![Preparation method of 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidyl]amino]benzoic acid, related intermediate and application thereof Preparation method of 4-methyl-3-[[4-(3-pyridyl)-2-pyrimidyl]amino]benzoic acid, related intermediate and application thereof](https://images-eureka.patsnap.com/patent_img/a80a22c8-4078-4726-ba46-b0c4d0b99c59/000003.png)