Patents

Literature

34results about How to "Avoid poisonous" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

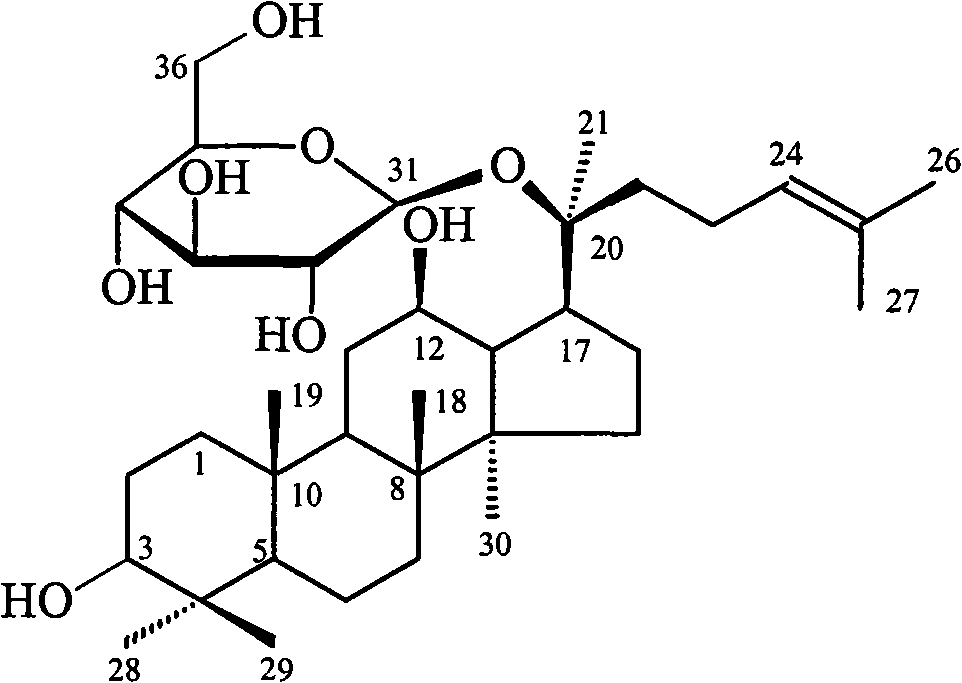

Method for purifying panaxoside compound-K by applying macroporous resin

ActiveCN101921304AReduce usageEasy to operateIon-exchange process apparatusIon-exchanger regenerationHigh concentrationMicroorganism

The invention relates to a method for separating and purifying a panaxoside compound-K from microorganism zymocyte by applying macroporous resin for preparing a raw medicine. The purifying yield reaches more than 72 percent, and the content of the panaxoside compound-K in a product is more than 96 percent. The method mainly comprises the following steps of: adding ethanol into zymocyte for extracting and concentrating; decoloring by active carbon and filtering; after adding water into filter liquor for diluting, leading the filter liquor to pass through a macroporous resin chromatographic column; washing by a low-concentration organic solvent aqueous solution for removing pigment and high-polarity saponin; eluting by a high-concentration organic solvent aqueous solution to obtain a panaxoside compound-K component; and finally crystallizing to obtain the panaxoside compound-K raw medicine with the content of more than 96 percent. The invention can provide a great amount of qualified raw medicine samples for the pharmaceutical development of the panaxoside compound-K.

Owner:ZHEJIANG HISUN PHARMA CO LTD

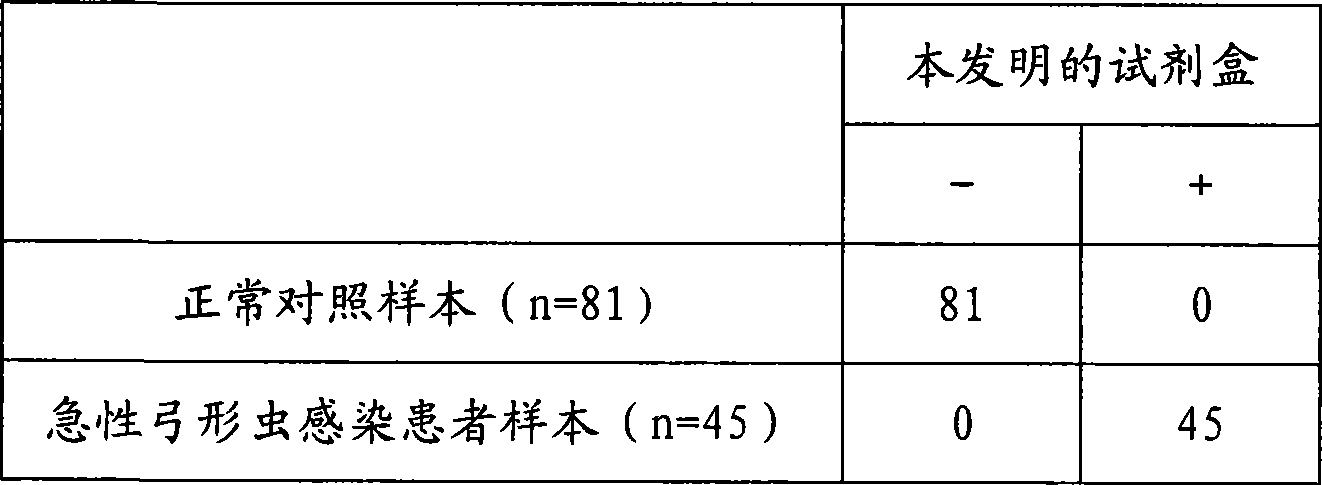

Chemiluminescence immune analysis determination reagent kit for detecting Toxoplasma Gondi IgM antibody

The invention discloses a toxoplasma gondii IgM antibody detection kit combined with the FITC-anti-FITC indirect coating technology and the chemiluminescent immunoassay technology, and a preparation method thereof. The kit of the invention is composed of a negative control, a positive control, solid-phase vectors for anti-FITC antibodies, anti-human Mu-chain monoclonal antibodies of FITC markers, toxoplasma gondii antigens which are marked by horse radish peroxidase, chemiluminescent substrates and concentrated washing solutions. The kit of the invention can be used as the aided detection index for prenatal prepotency diagnosis, and has vital significances for improving the birth population quality and doing the family planning and the prepotency well.

Owner:CHEMCLIN DIAGNOSTICS CO LTD

Neutral blockage removing agent composition used for oil recovery formation in oilfield and preparation method thereof

ActiveCN104194758ALow corrosion rateUnblocking safetyDrilling compositionButanedioic acidSuccinic acid

The invention relates to a neutral blockage removing agent composition used for an oil recovery formation in an oilfield. The neutral blockage removing agent composition is prepared from the following raw materials in parts by weight: 10-14 parts of polyepoxysuccinic acid amine, 35-40 parts of diethylenetriaminepentaacetic acid amine, 33-37 parts of hydroxyl succinic acid amine, 20-25 parts of polyacrylamide, 7-10 parts of sodium polyaspartate, 10-14 parts of sodium gluconate, 10-15 parts of activated clay, 20-25 parts of potassium peroxodisulfate, 9-11 parts of hydroxyl butanedioic acid amine, 4-7 parts of sodium salicylate, 5-9 parts of hexamethylene tetramine, 0.2-0.3 part of vanadium pentoxide, 2-5 parts of starch, 5-8 parts of alpha-sulphonated fatty acid methyl ester and derivative thereof (MES) and 0.1-0.3 part ofdiethyl ethanolamine. The neutral blockage removing agent composition is used for the blockage removal of an oil pumping well and a screw pump well in the oilfield, can effectively solve the problems of cleaning blockage removal of the oil pumping well and the screw pump well in the oilfield and the corrosion of oil recovery equipment, has high blockage removing speed, is neutral and is free of corrosion; waste liquid for blockage removal can be degraded and does not need to be discharged onto the ground to be subjected to sewage treatment, no corrosion, dead angle, precipitation or secondary well blockage are generated, and more safety and more reliability are realized as compared with traditional pickling blockage removing, biological blockage removing and solvent blockage removing.

Owner:兰州熙瑞化工科技有限公司

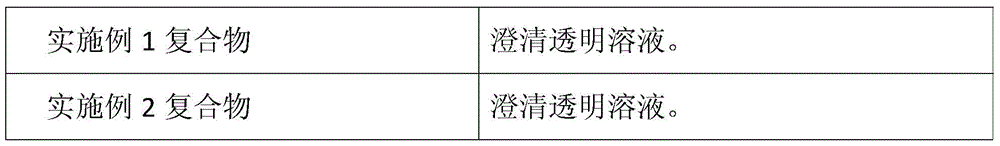

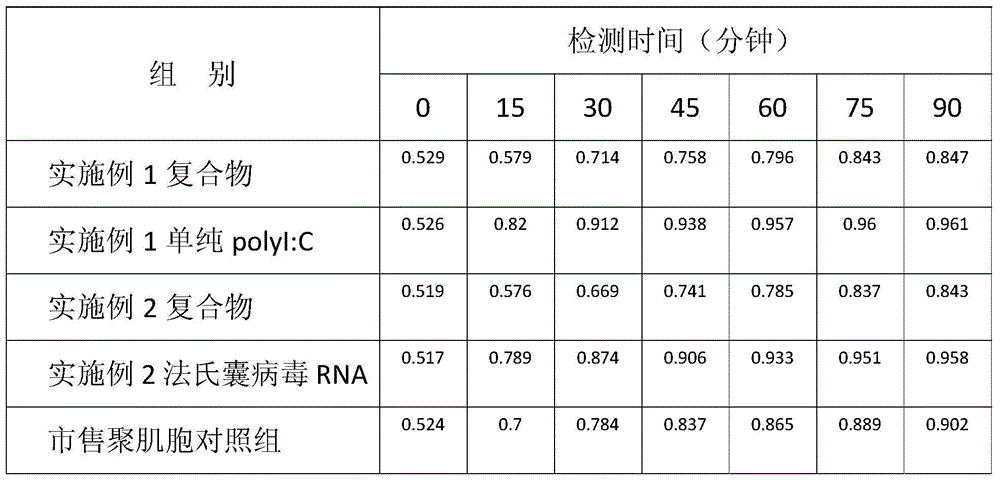

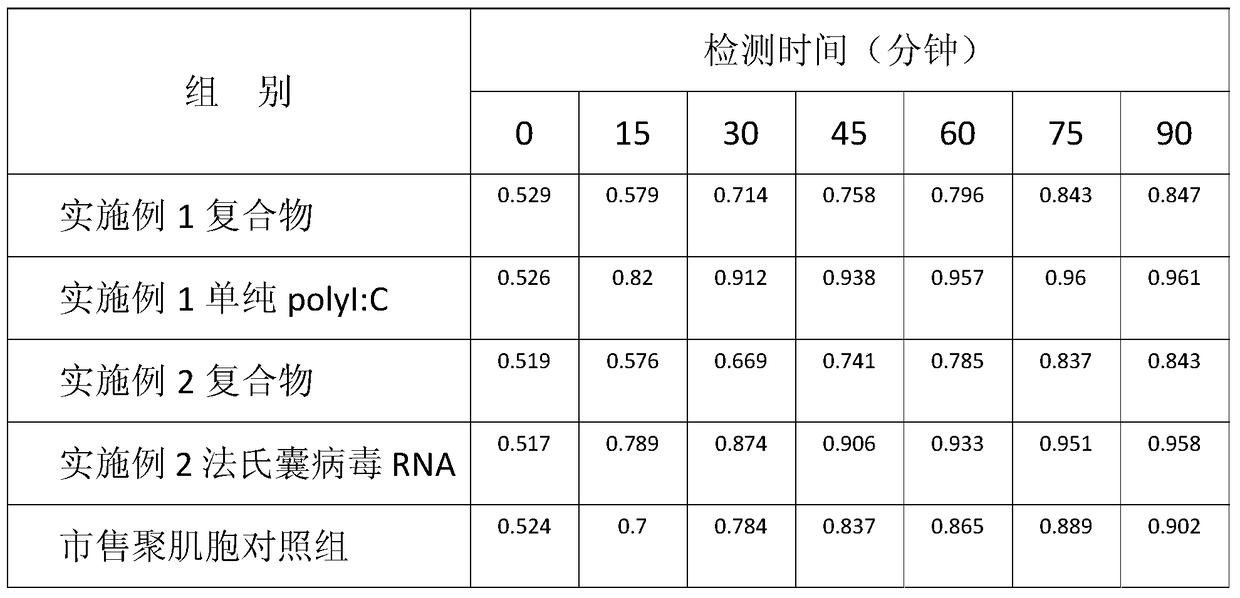

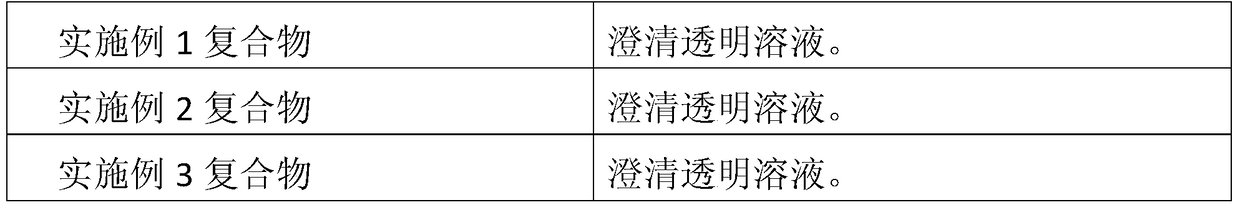

Double-strand oligonucleotide-epsilon-polylysine compound with immune regulation function and preparation and use method of double-strand oligonucleotide-epsilon-polylysine compound

ActiveCN105664152ASimple preparation processStrong resistance to enzymatic degradationSsRNA viruses negative-senseViral antigen ingredientsAntigenChemistry

The invention provides a double-strand oligonucleotide-epsilon-polylysine compound with an immune regulation function and a preparation and use method of the double-strand oligonucleotide-epsilon-polylysine compound and also provides immunogen composition with functions of triggering immunoenhancement reaction and changing the immunoreaction type and a preparation and use method of the immunogen composition. The immunogen composition comprises the double-strand oligonucleotide-epsilon-polylysine compound and an antigen. The compound contains a compound formed through composition of double-stranded polynucleotide, a cation epsilon-polylysine and metal cations. The compound has the pharmacological activity of immunoregulation. The preparation process of the compound is simple. The compound has good water solubility and a bio-enzyme degradation resisting function. The immunogen composition can trigger the immunoenhancement reaction and change the immunoreaction type.

Owner:辽科生物(沈阳)有限公司

Ginkgo juice beverage and preparation method thereof

The invention discloses a ginkgo juice beverage and a preparation method thereof. The ginkgo juice beverage comprises the following components in percentage by weight: 10-30% of ginkgo normal juice, 2.5-8% of saccharose, 0.1-0.35% of citric acid and the balance of purified water. The beverage is prepared by the following steps of: weighing the ginkgo normal juice according to the formula and slowly pouring into an allocating tank; then, respectively dissolving saccharose and citric acid by using purified water and adding purified water to 100%; heating to 50 DEG C, and adequately and uniformly stirring; filtering by a frame filter and homogenizing the filtrate by a Fluko efficient dispersing emulsifying machine for 8-12 minutes at a high speed so as to further uniformly refine the feed liquid; filling the homogenized beverage in a high-temperature resisting glass bottle, sealing, and sterilizing in a sterilizing pot for 15 minutes at 120-121 DEG C, taking out and naturally cooling; and inspecting and packaging to obtain the finished product. The product disclosed by the invention is clear in liquid, is rich and pleasant, fresh in taste and agreeable in sweet and sour tastes, and has special fragrance of ginkgo and good market prospect.

Owner:徐州绿之野生物食品有限公司

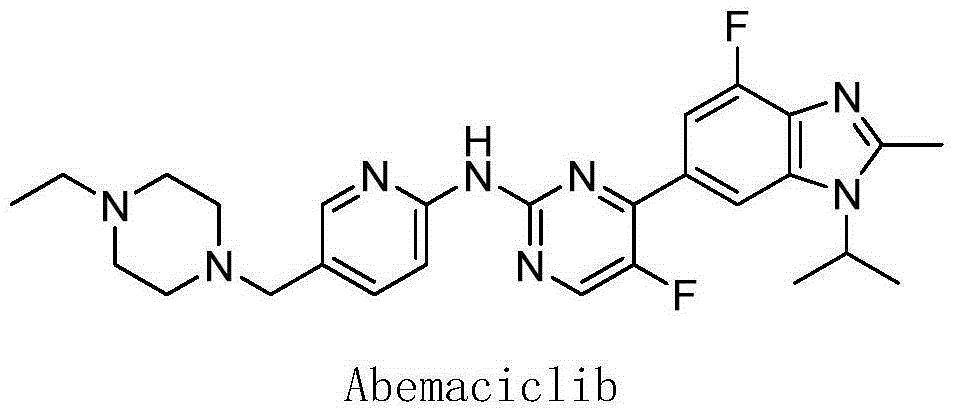

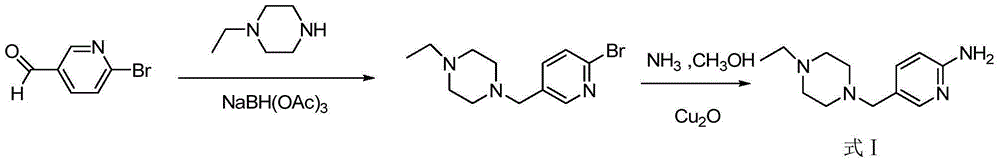

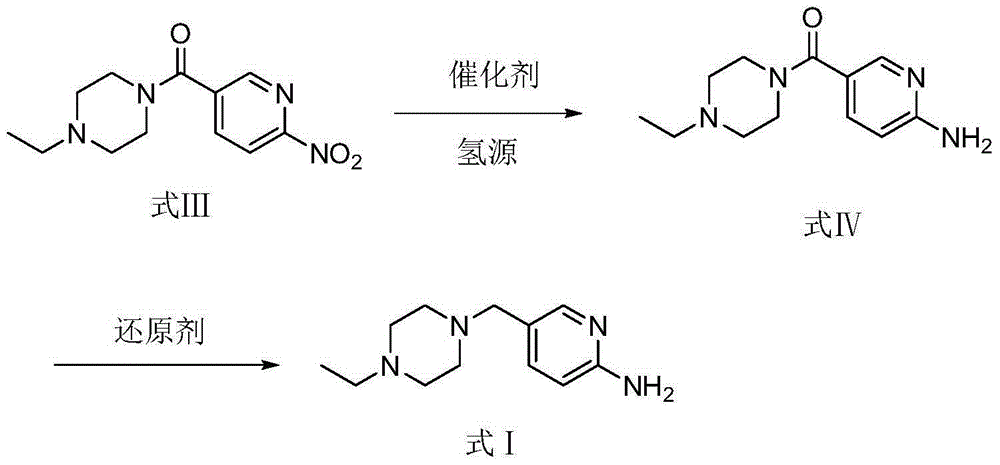

Preparation method of Abemaciclib intermediate

The invention belongs to the field of medicine and chemical industry, and concretely relates to a preparation method of an Abemaciclib intermediate. Nitro and carbonyl of 5-(4-ethyl piperazine-1-carbonyl)-2-nitropyridine are reduced successively, and the Abemaciclib intermediate 5-(4-ethyl-piperazin-1-yl)methyl)pyridin-2-amine is obtained; the raw materials and reagents are easy to obtain, reaction conditions are mild, usage of reagents with toxicity or irritation or strong corrosivity is avoided, the method is green and environmentally friendly, and the preparation is simple and easy to operate; the product has high yield and high purity, and is especially suitable for industrial production.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

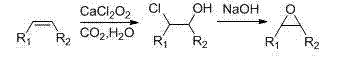

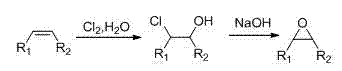

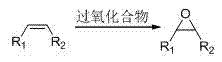

Preparation process of epoxy compound

InactiveCN103896885ASafety scale-up productionAvoid poisonousOrganic chemistryEpoxyCombinatorial chemistry

The invention discloses a preparation process of an epoxy compound. The preparation process comprises the steps of enabling alkene to react with a halogenating agent in water or a mixed solvent, and performing alkali treatment to obtain the epoxy compound. The epoxy compound can be prepared through a one-pot method by preparing halogenated alcohol through reaction between a halogenating reagent containing NBS and alkene and then enabling the halogenated alcohol to react with alkali without the separation of intermediates. The preparation process disclosed by the invention avoids highly-toxic and high-explosive reagents applied to a conventional process method, so that the production of the epoxy compound can be safely amplified.

Owner:CHEN STONE GUANGZHOU CO LTD

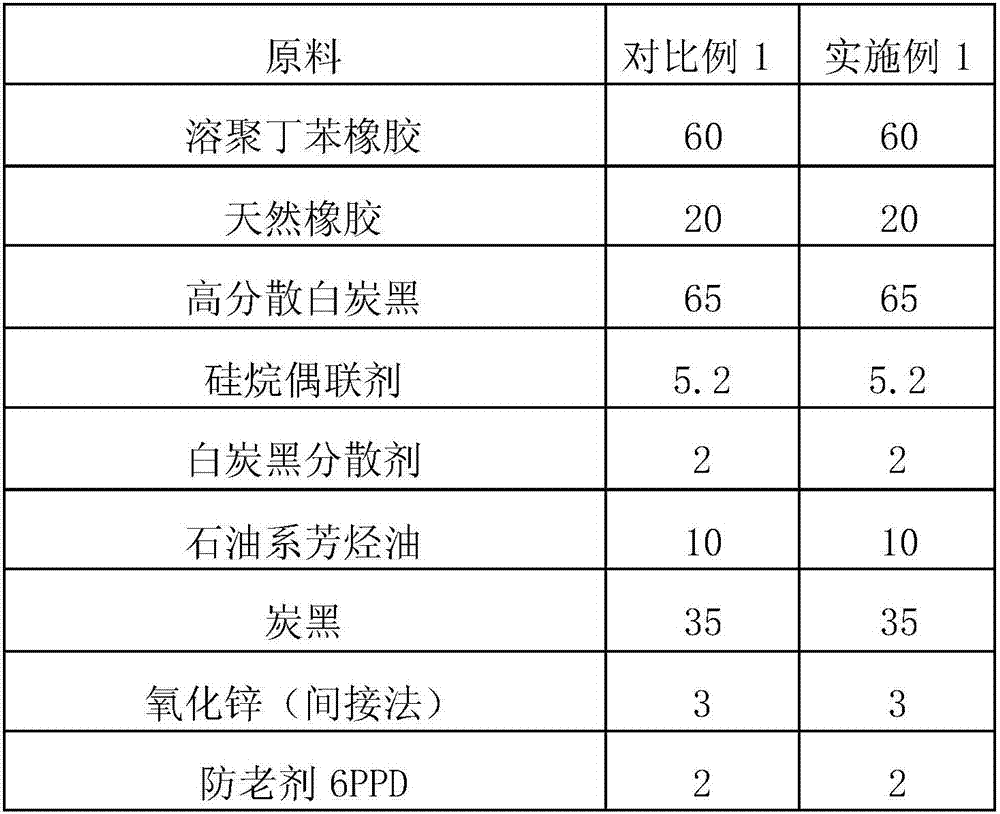

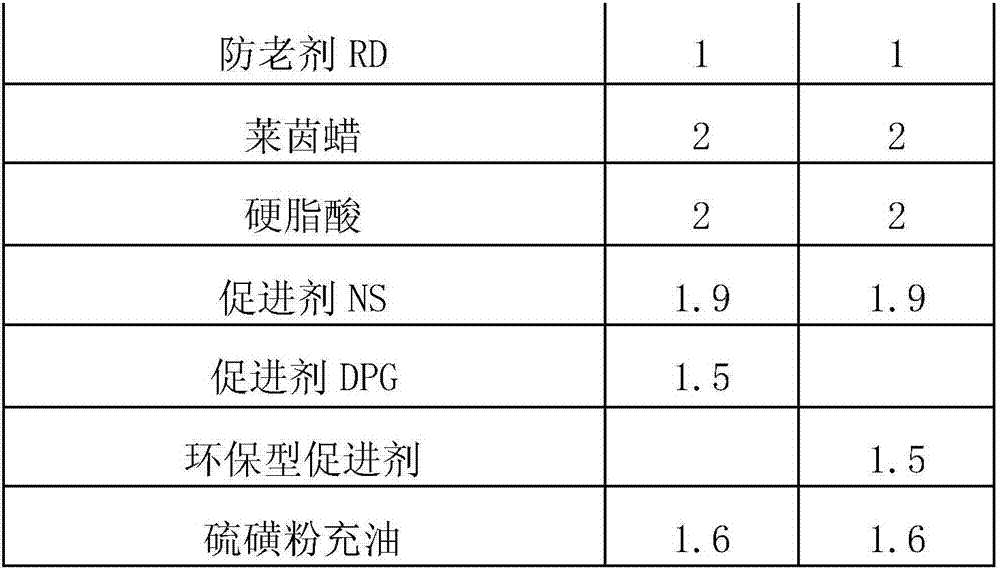

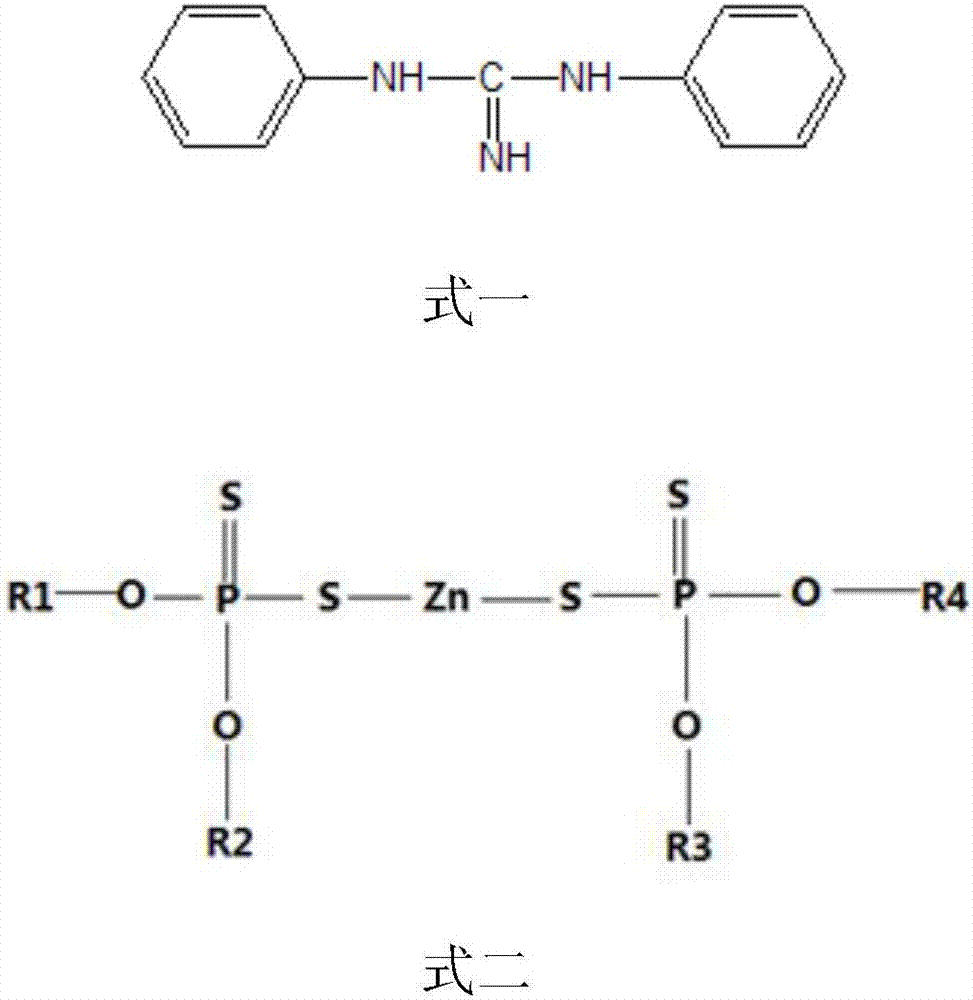

Tire tread and preparation method thereof

InactiveCN107129609AExtended scorch timeHigh modulusSpecial tyresRolling resistance optimizationRolling resistanceCompounds of zinc

The invention relates to tire tread which comprises 1-60 parts of solution polymerized styrene-butadiene rubber, 1-40 parts of natural rubber, 1.5 parts of environment-friendly promoter, 10-100 parts of high-dispersion white carbon black, 1-8 parts of silane coupling agent, 10-50 parts of carbon black and 1-20 parts of petroleum-series aromatic hydrocarbon oil. Preferably, the environment-friendly promoter is a compound of zinc dialkyl dithiophsophate and a carrier. The invention further provides a preparation method of the tire tread. The preparation process is divided into three adding and mixing stages, and the environment-friendly promoter is added at the productive stage. The tire tread and the preparation method have the advantages that combined use of the solution polymerized styrene-butadiene rubber, the natural rubber, the high-dispersion white carbon black, the silane coupling agent and the environment-friendly promoter is considered important for promoting scorching time, improving modulus and wear performance and lowering rolling resistance. By using the environment-friendly promoter, toxic, allergic and carcinogenic risks in the operation process can be avoided.

Owner:SHANDONG LINGLONG TIRE

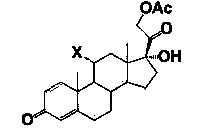

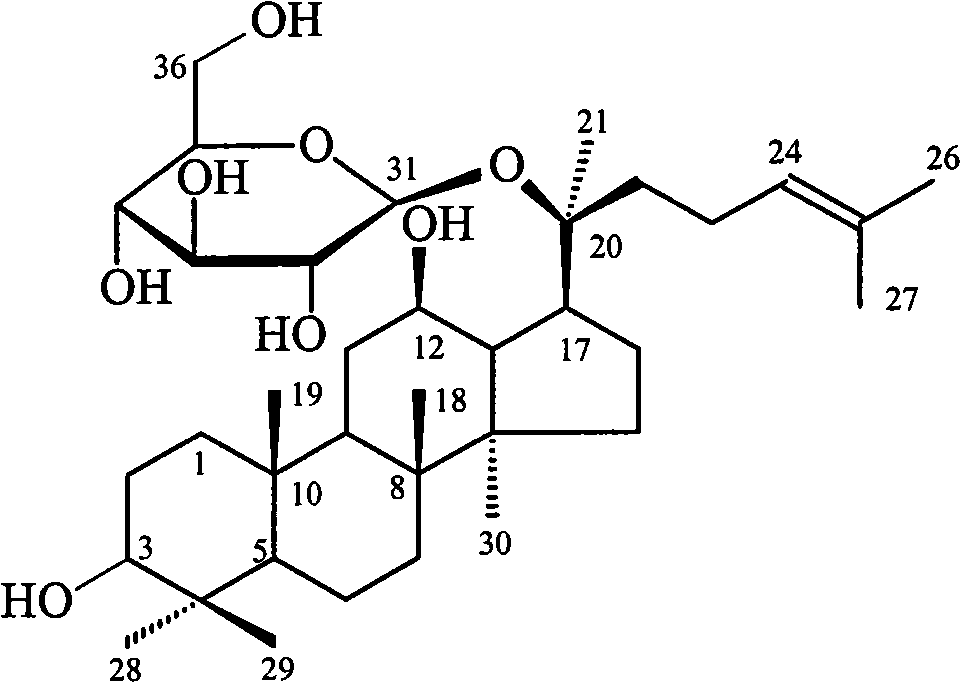

Synthetic method for preparing steroid compounds from 3,17-diketone steroids

InactiveCN103450305AAvoid poisonousAvoid the disadvantages of being volatileSteroidsWittig reactionDrug

The invention discloses a synthetic method of steroid type drugs and intermediates, in particular relates to a synthetic method for preparing 17-hydroxy-20-ketone steroid compounds from 3,17-diketone steroids, and belongs to the field of synthesis of drugs. The method takes 3,17-diketone steroids as raw materials and adopts a conventional, environment-friendly, low-toxicity reagent, and the steroid type drugs such as cortisone, hydrocortisone, metacortandracin, or hydroprednisone, or intermediates 17alpha-hydroxy-20-ketone compounds are prepared simply and conveniently at high yield by selective protection of C3 or (and) C11-ketone group, Wittig reaction of C17, selective oxidization of 17(20)-position double bonds and halogenating replacement. The aftertreatment is simple, few three wastes are generated, the reaction selectivity is good, the yield is high, and byproducts anti-pregnancy steroidal drugs and steroidal compounds can be obtained. The raw materials are easy to get, the cost is low and the synthetic process is simple; the synthetic method is suitable for industrial production.

Owner:ZHENGZHOU UNIV

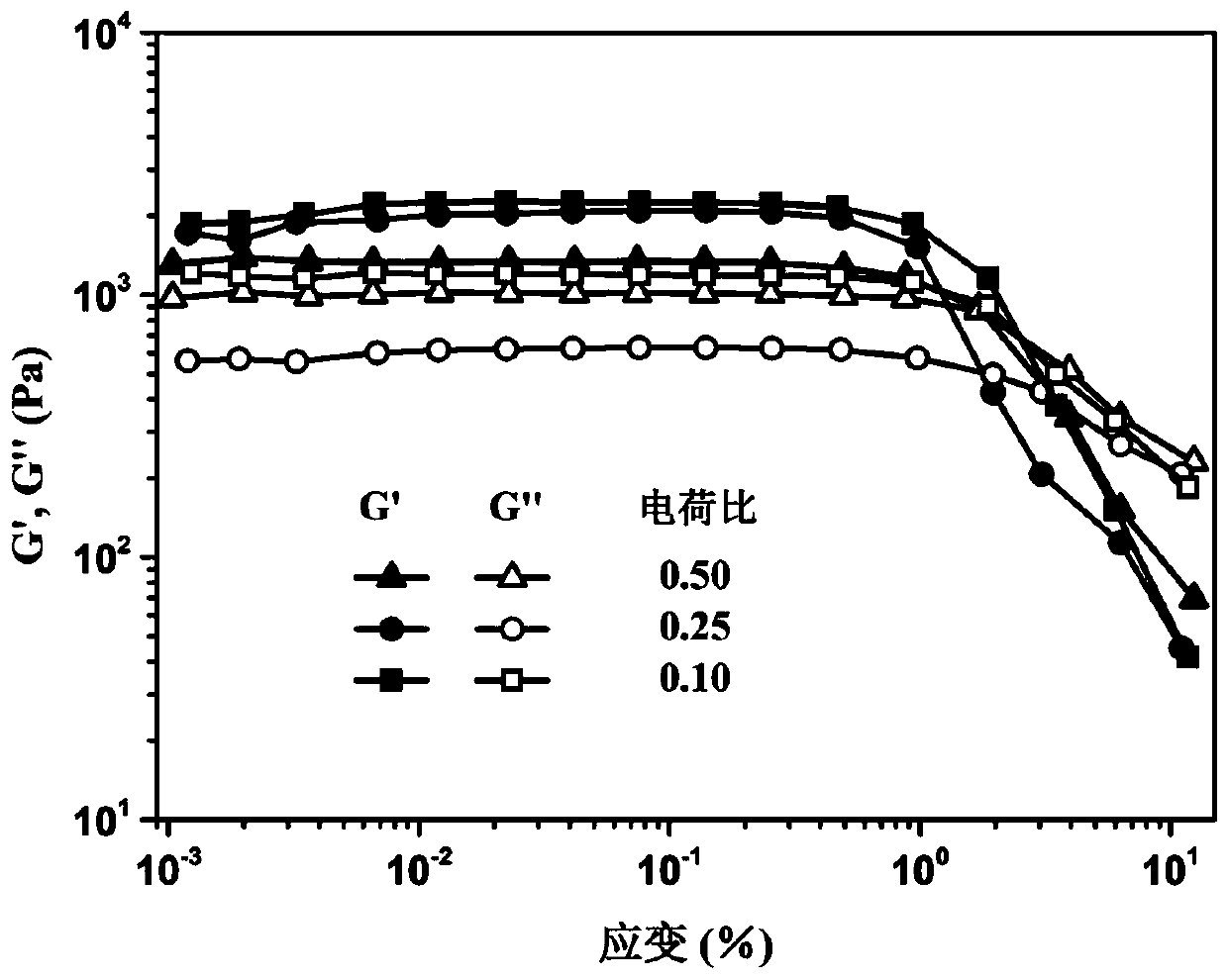

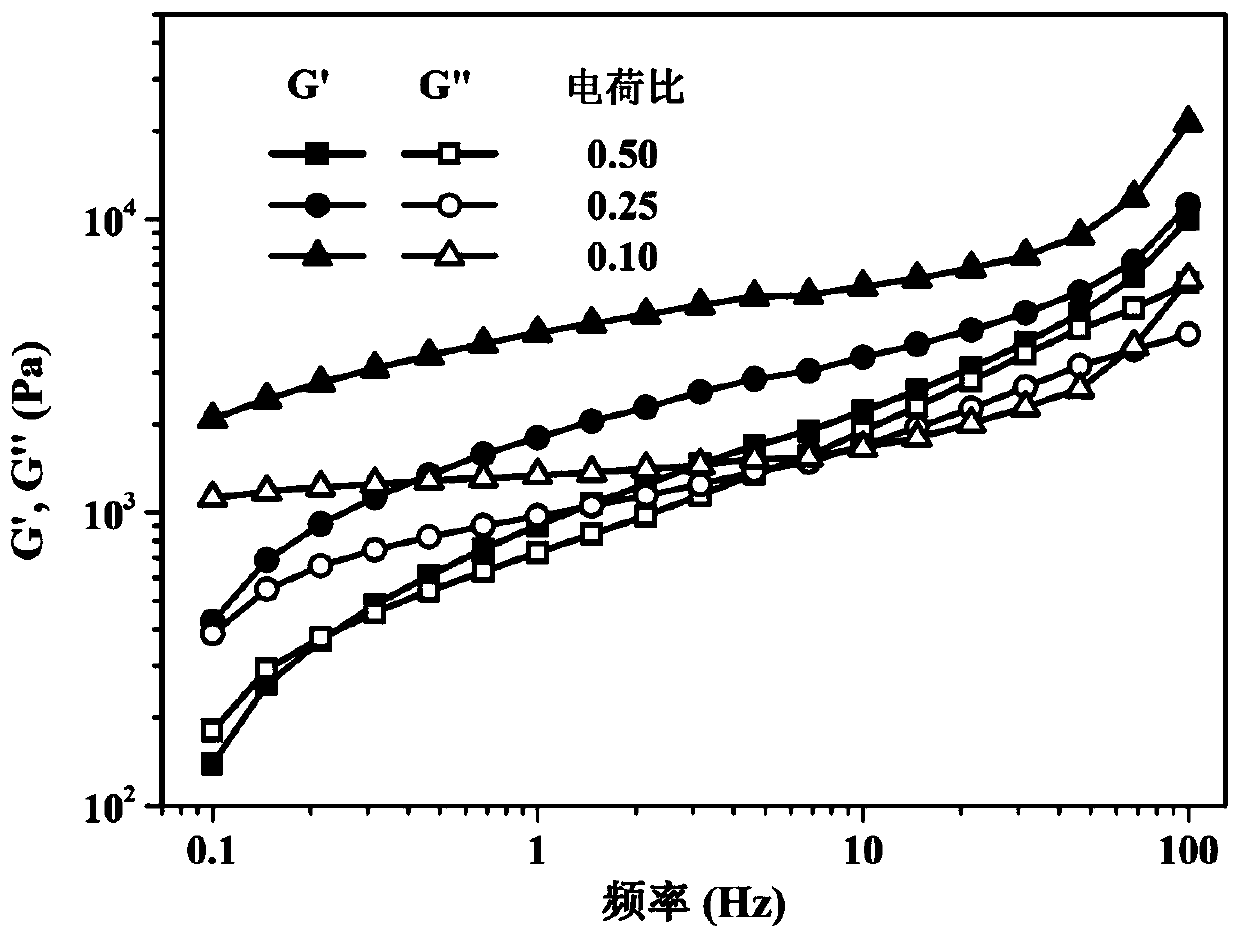

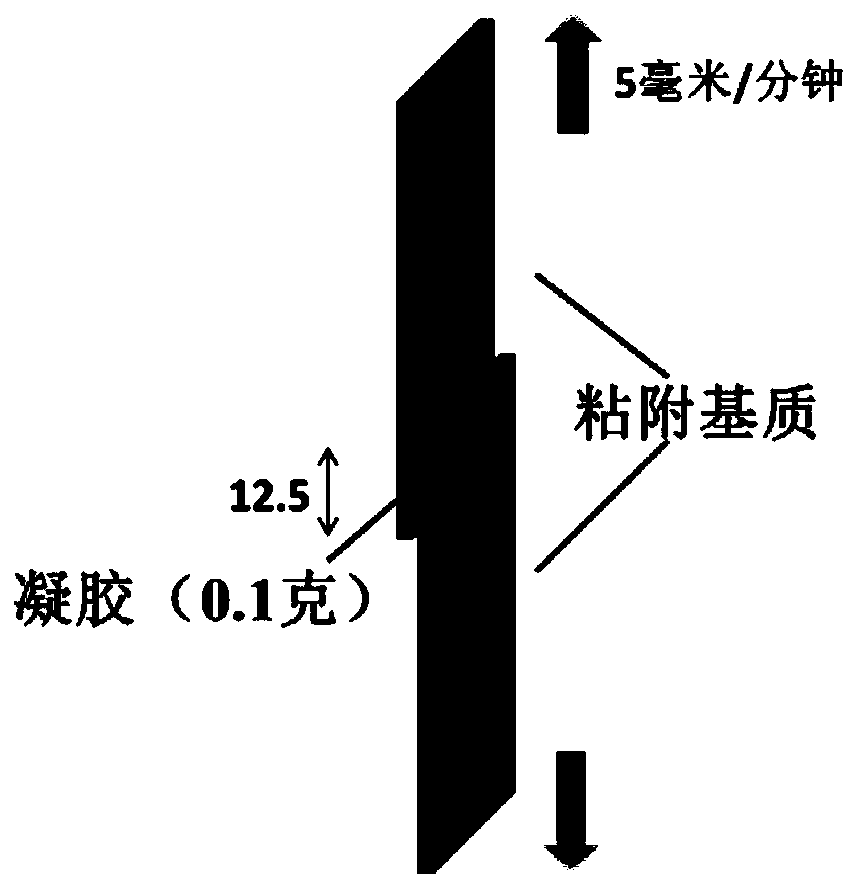

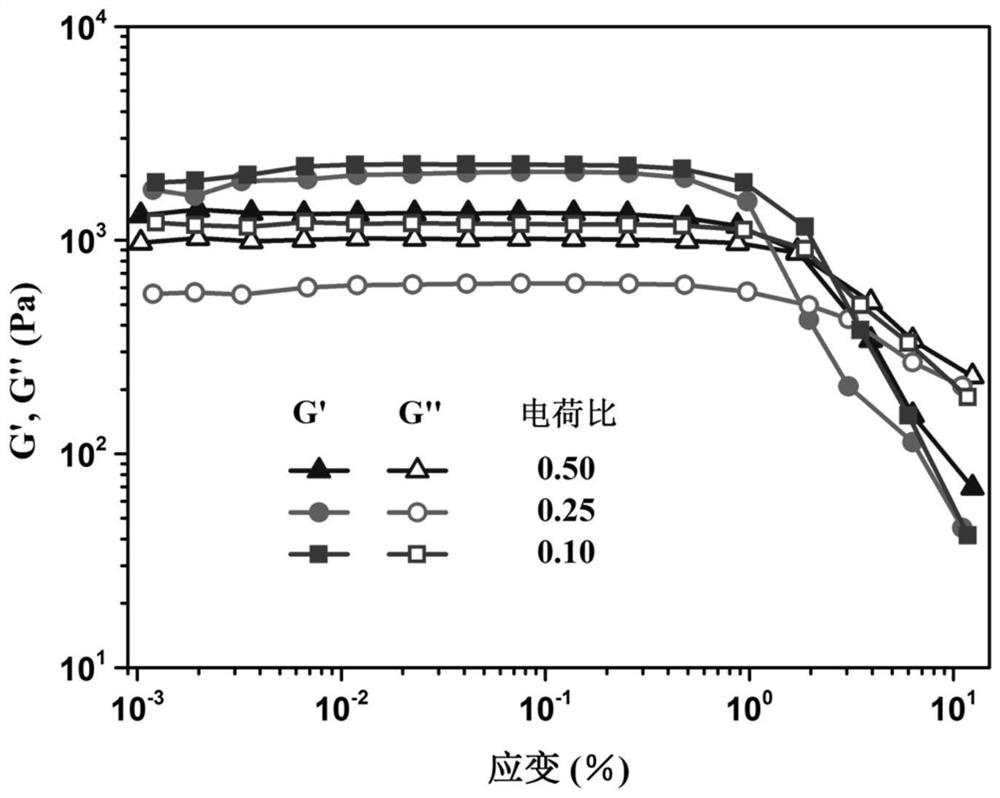

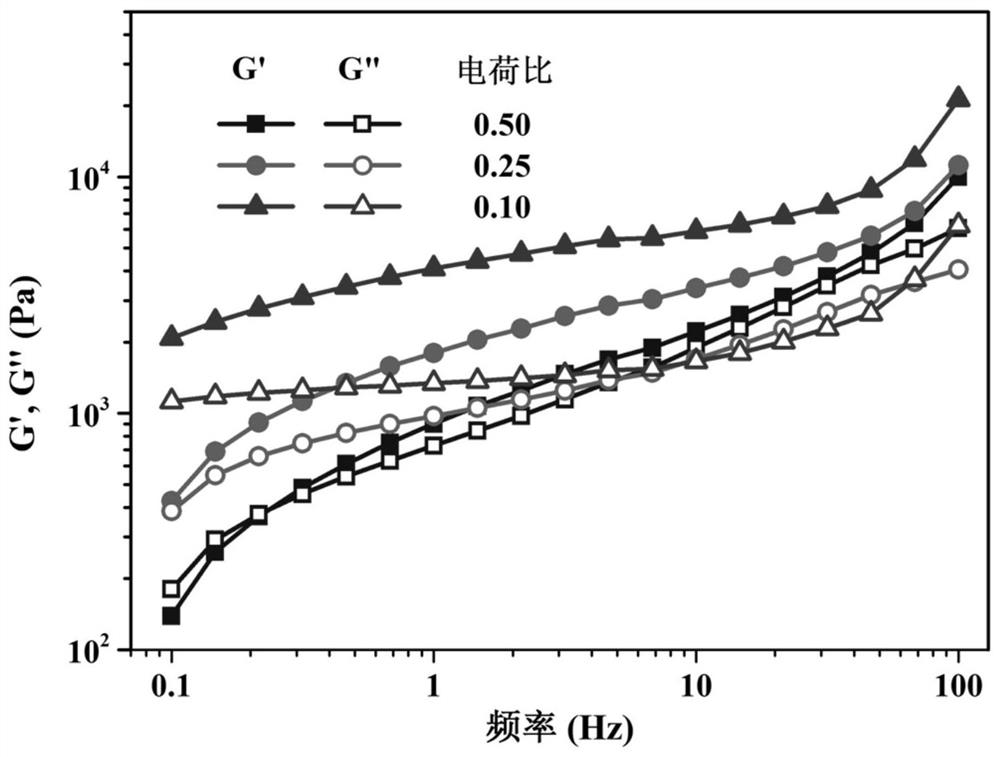

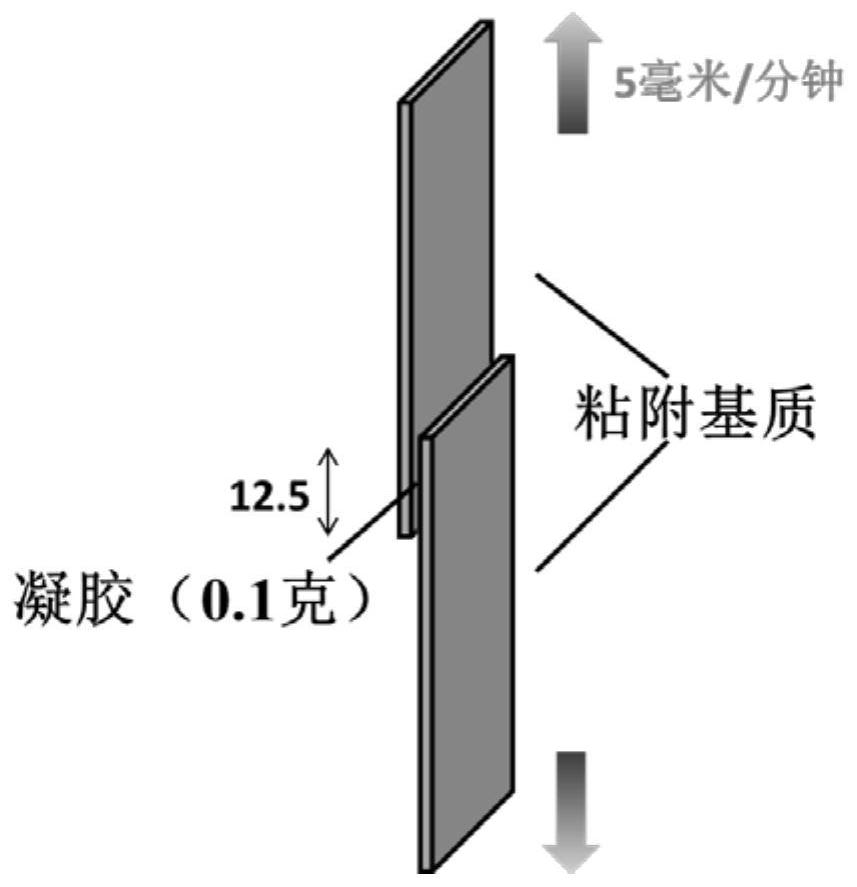

Adhesive hydrogel and preparation method thereof

The invention provides adhesive hydrogel and a preparation method thereof, and relates to the field of polymer materials. The method comprises the following steps: (1) mixing a cationic monomer, a photoinitiator, an anionic component and water to obtain a precursor solution; (2) defoaming the precursor solution; (3) irradiating the precursor solution obtained in the step (2) with ultraviolet lightto initiate cationic monomer polymerization, and reacting the generated cationic monomer polymer with the anionic component to form the adhesive hydrogel; wherein in the step (1), the anionic component comprises glycosaminoglycan and derivatives thereof. The adhesive hydrogel disclosed by the invention is soft in texture, can be used for bonding various surfaces, is high in adhesion strength andhas self-healing performance, and the practicability of the gel is improved.

Owner:TIANJIN POLYTECHNIC UNIV

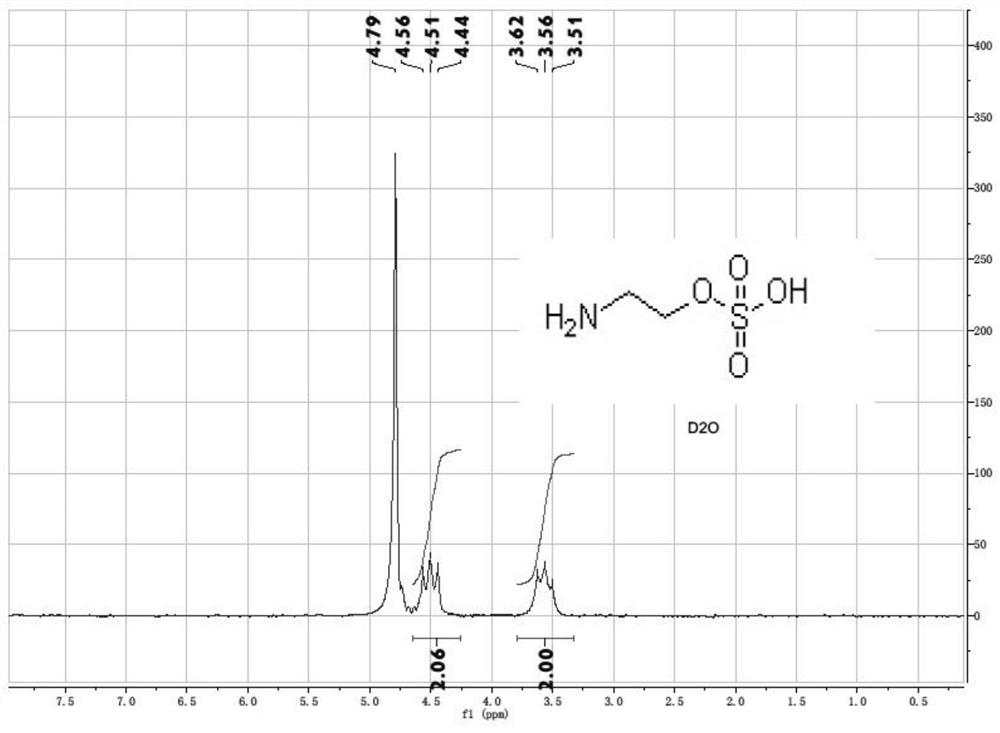

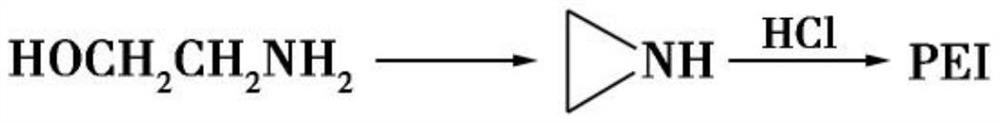

One-step synthesis method of polyethyleneimine

The invention relates to a one-step synthesis method of polyethyleneimine. The method comprises the following steps: (1) synthesizing monomer ethyleneimine, reacting ethanolamine with concentrated sulfuric acid or hydrogen chloride, and treating with strong base to obtain monomer ethyleneimine and an inorganic salt byproduct; and (2) synthesizing polyethyleneimine, namely directly polymerizing the monomer ethyleneimine obtained in the step (1) under the conditions of an acid catalyst and a polyhaloalkane catalyst without separation treatment to generate polyethyleneimine. According to the one-step synthesis method, on one hand, the use and storage risk and harm caused by high reactivity, corrosivity, toxicity, flammability and explosiveness of the ethyleneimine are avoided; on the other hand, special treatment for removing residual ethyleneimine in the monomer separation process is also avoided. According to the method disclosed by the invention, an intermediate separation step is not needed, so that the possible risks of poisoning, combustion and explosion to operators are greatly reduced, and the pressure of environmental protection is also greatly reduced.

Owner:上海氟聚化学产品股份有限公司

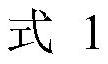

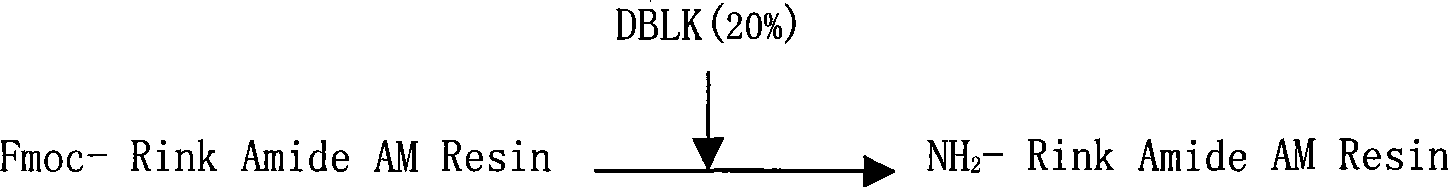

Solid phase synthetic technique for thymosin alpha1

ActiveCN101104638BEasy to purifyHigh purityThymopoietinsPeptide preparation methodsAcetic anhydrideFluoroacetic acid

Owner:苏州天马医药集团天吉生物制药有限公司

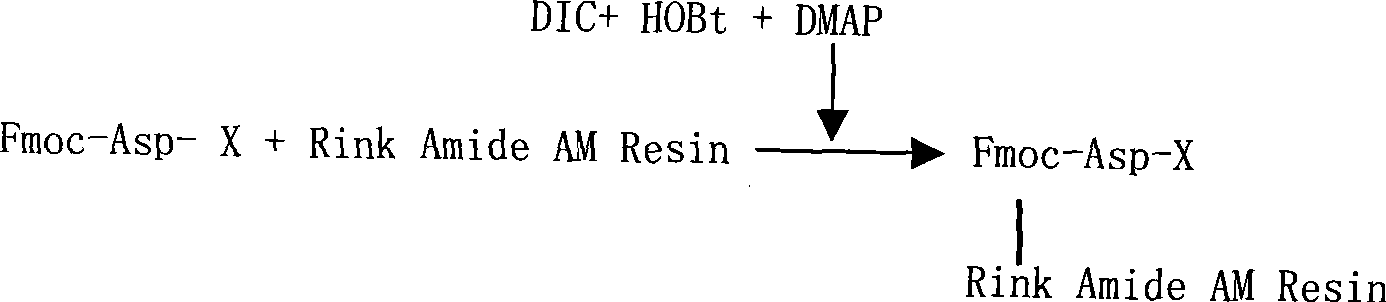

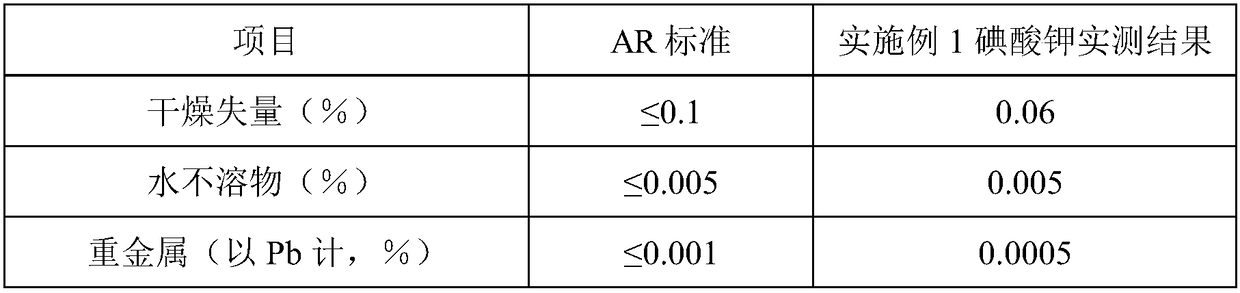

Potassium iodate preparation method

InactiveCN108083232AProduct particles are uniformAvoid poisonousIodine oxygen compoundsThermal insulationChemistry

The invention relates to a potassium iodate preparation method, which comprises: (1) dissolving potassium iodide containing a small amount of hydroiodic acid in water to prepare a potassium iodide aqueous solution with a mass concentration of 30-40%; (2) at a room temperature, respectively introducing the potassium iodide aqueous solution and 28-30 wt% hydrogen peroxide into the glass module of amicrochannel reactor by a feeding pump according to a mass ratio of (1.0-1.4):1, and carrying out a mixing reaction to obtain a first reaction liquid; (3) introducing the first reaction liquid and 28-30 wt% of hydrogen peroxide into the microchannel reactor according to a mass ratio of (39-48):1, and carrying out a reaction to obtain a second reaction liquid; and (4) collecting the second reactionliquid, heating to a temperature of 75-85 DEG C, filtering, carrying out cooling crystallization, carrying out thermal insulation at a temperature of 39-41 DEG C, adding crystal seed, crystallizing,cooling to a temperature of 4-6 DEG C, and carrying out thermal insulation to obtain the potassium iodate product. According to the present invention, the high-quality potassium iodate is quantitatively prepared by using the safe and environmentally-friendly reagents so as to achieve the high utilization rate of iodine.

Owner:SINOPHARM CHEM REAGENT

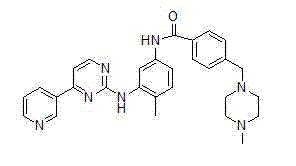

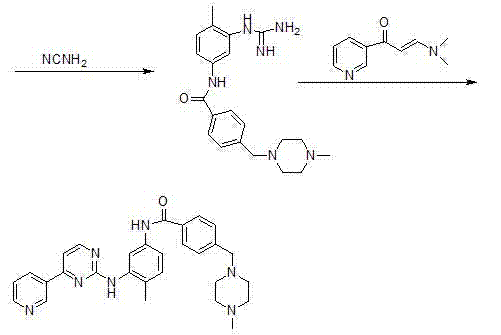

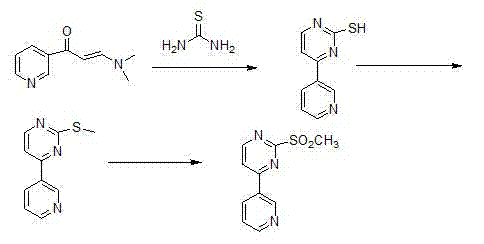

Preparation method of imatinib

The invention discloses a preparation method of imatinib, wherein the needed component imatinib is finally generated through conversion of an intermediate. According to the preparation method of the imatinib disclosed by the invention, the synthetic steps are fewer, the raw materials adopted are cheap and easy to obtain, the environment is less polluted, and the yield is high, so that the preparation method of the imatinib is appropriate for industrial production.

Owner:湖南欧亚药业有限公司

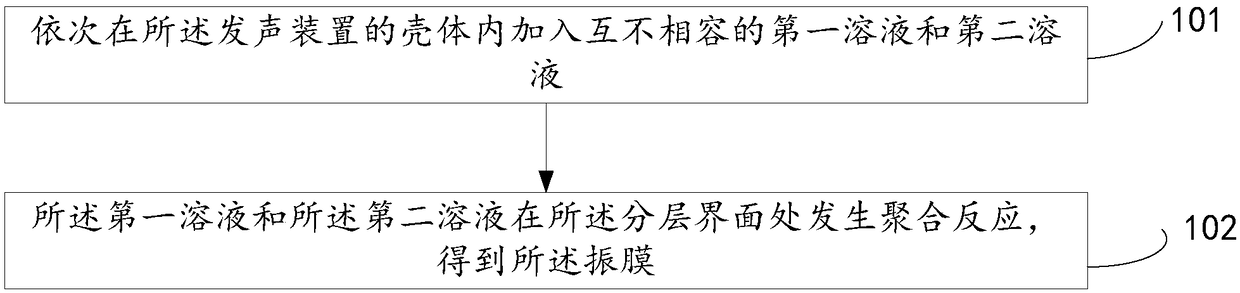

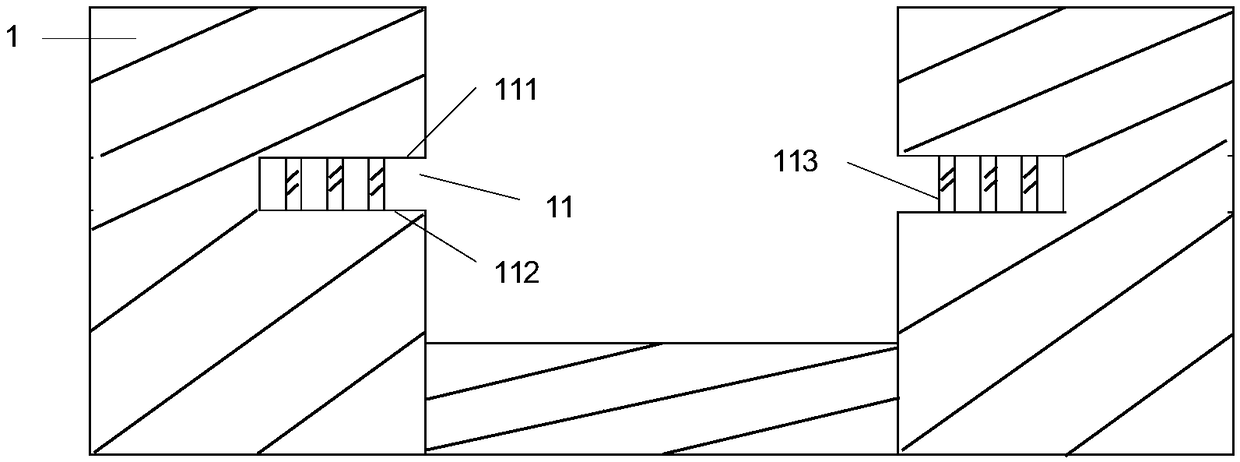

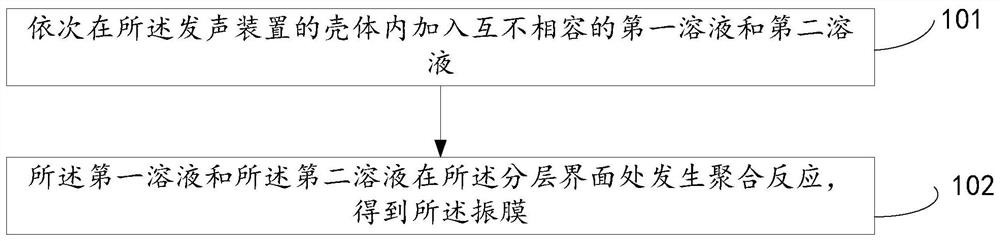

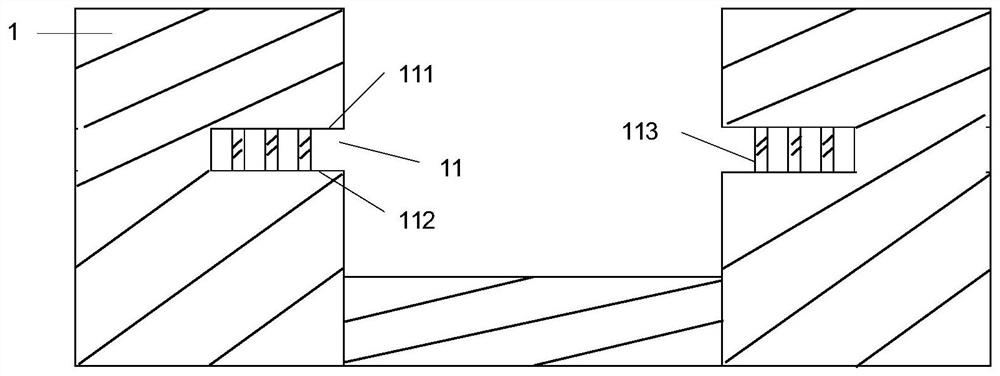

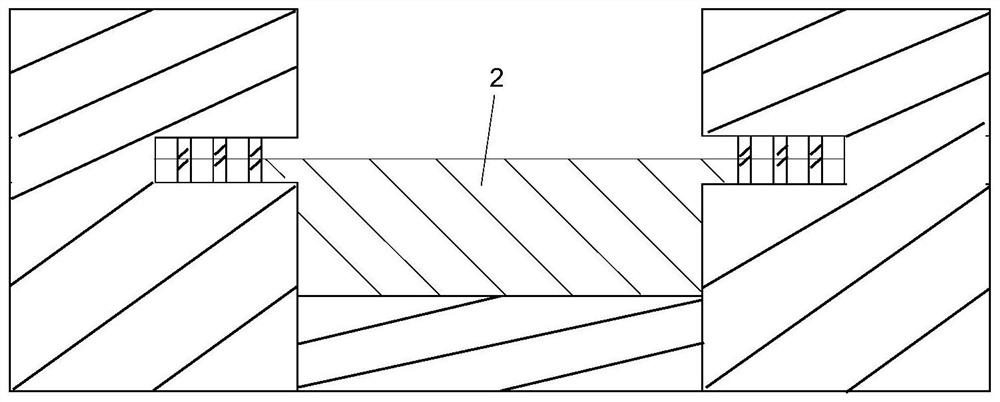

Diaphragm in sounding device, preparation method thereof, and sounding device

InactiveCN109511078AReduce manufacturing difficultyReduce manufacturing costNon-planar diaphragms/conesDiaphragm extensionsSounds deviceComputer engineering

The embodiments of the present application provide a diaphragm in a sounding device, a preparation method thereof, and a sounding device. The method comprises the following steps: circularly arrangedgrooves on the inner side wall of the housing of the sounding device; sequentially adding a first solution and a second solution that are mutually incompatible in the housing of the sounding device, wherein the layered interface of the first solution and the second solution is located at the position of the grooves; causing polymerization of the first solution and the second solution at the layered interface to obtain a diaphragm, wherein the edges of the diaphragm are located in the grooves and fill the grooves. The preparation method provided by the embodiment of the present application cannot only avoid the problem of low product yield caused by the high temperature injection molding, but also avoid the toxic problem caused by the use of glue.

Owner:GOERTEK INC

Electroless nickel plating process on magnesium alloy surface of a pre-electroplated zinc-nickel alloy

ActiveCN103898505BImprove bindingAvoid poisonousLiquid/solution decomposition chemical coatingSuperimposed coating processNickel saltNickel alloy

Owner:南通江海港建设工程有限公司

Magnesium alloy surface chemical nickel-plating combination solution for pre-electroplated zinc-nickel alloy

InactiveCN103898588AImprove corrosion resistanceBeautiful appearanceLiquid/solution decomposition chemical coatingBinding forceAlloy surface

The invention discloses a magnesium alloy surface chemical nickel-plating combination solution for a pre-electroplated zinc-nickel alloy. The combination solution is characterized by comprising an electroplated zinc-nickel plating solution and a chemical nickel-plating solution. The components of the electroplated zinc-nickel plating solution and the chemical nickel-plating solution are adjusted, and toxic and high-pollution components are not adopted, so that the plating process is environment-friendly and safe, and the prepared coating is high in corrosion resistance, beautiful in appearance and high in binding force of a substrate and the coating.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Secondary galvanizing pretreatment process for electroplating nickel on surface of magnesium alloy

InactiveCN103898587AAvoid poisonousImprove corrosion resistanceMetallic material coating processesTwo stepZinc

The invention discloses a secondary galvanizing pretreatment process for electroplating nickel on the surface of magnesium alloy. The secondary galvanizing pretreatment process comprises two steps of: zinc galvanizing and zinc electroplating. The pretreatment process disclosed by the invention has the advantages that pretreatment for nickel electroplating is carried out by adopting a secondary zinc galvanizing and coating process of zinc immersion and zinc electroplating, and by adjustment of the components for zinc immersion and zinc electroplating solution, components with toxicity and high pollution are not adopted, so that the plating process is environmentally friendly and safe and provides good basic plating layer for the following nickel plating.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Composition solution for electric nickel-plating on surface of magnesium alloy

InactiveCN103898568AAvoid poisonousImprove corrosion resistanceHot-dipping/immersion processesZincBinding force

The invention discloses a composition solution for electric nickel-plating on the surface of a magnesium alloy. The composition solution comprises a zinc immersion liquid, an electric zinc plating liquid and a nickel-electroplating liquid. By adjusting the components of the zinc immersion liquid, the zinc electroplating liquid and the nickel electroplating liquid, a plating process is environmental friendly and safe, and a prepared plated layer is high in corrosion resistance, attractive in appearance and high in binding force with a substrate.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Secondary zinc plating pretreatment composite solution for electroplating nickel on magnesium alloy surface

InactiveCN104213155AAvoid poisonousImprove corrosion resistanceMetallic material coating processesPotassium fluorideSulfate

The invention discloses a secondary zinc plating pretreatment composite solution for electroplating nickel on a magnesium alloy surface. The composite solution comprises a zinc immersion solution and a zinc electroplating solution, wherein the zinc immersion solution is composed of the following components: zinc sulfate with a concentration of 32-36 g / L, potassium pyrophosphate with a concentration of 200-210 g / L, sodium carbonate with a concentration of 8-10 g / L, potassium fluoride with a concentration of 3-5 g / L, ammonium bifluoride with a concentration of 2-3 g / L, and the balance being water; and the zinc electroplating solution is composed of the following components: ZnSO4.7H2O with a concentration of 32-36 g / L, KF with a concentration of 18-20 g / L, K4P2O7.3H2O with a concentration of 164-168 g / L, C6H17O7N3 with a concentration of 32-36 g / L, phytic acid with a concentration of 0.4-0.6 g / L, H2CSNH2 with a concentration of 4-6 g / L, and the balance being water.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

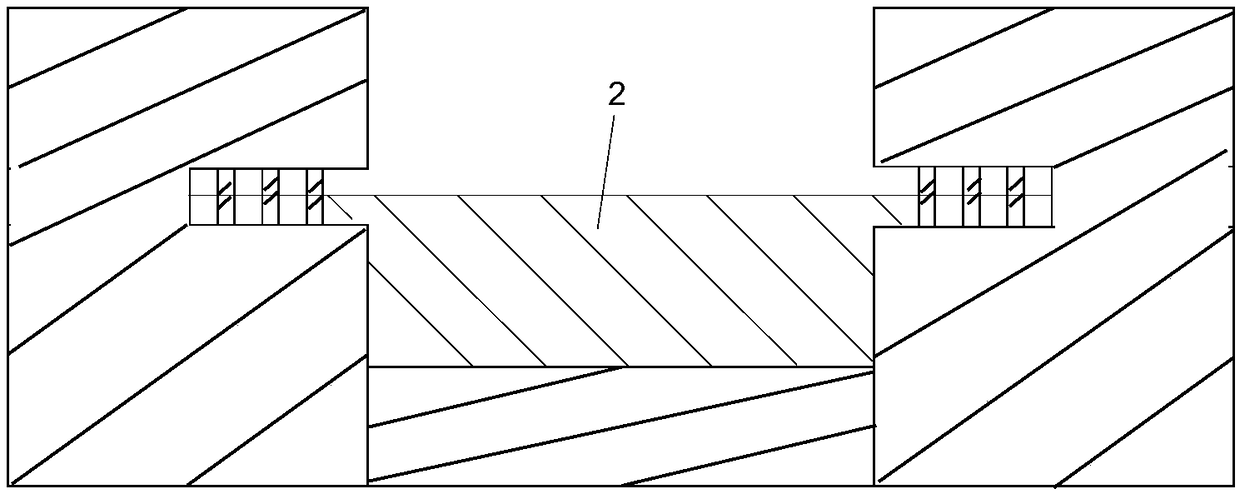

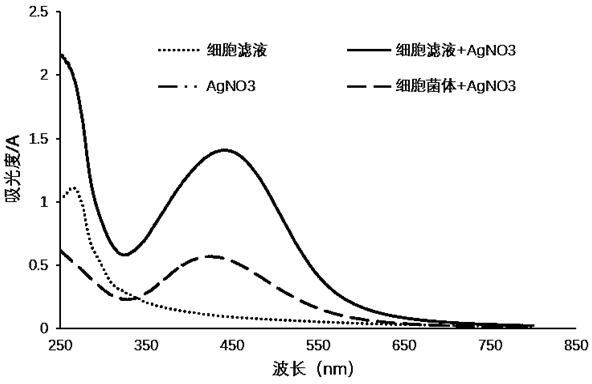

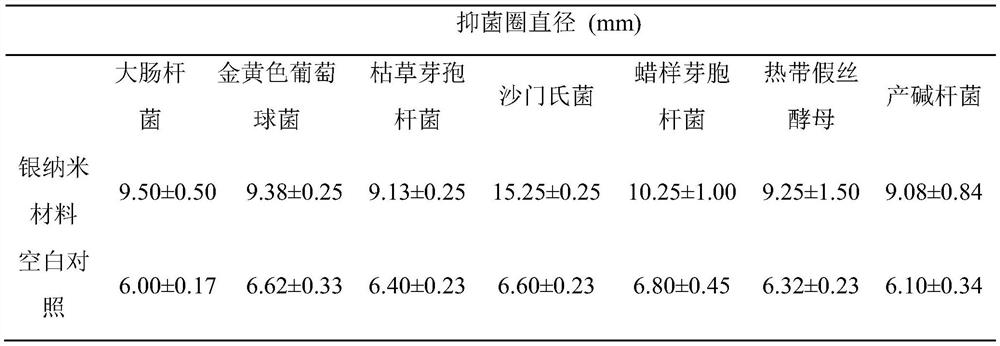

A kind of silver nano material and its biological preparation method and application

ActiveCN107354175BSimple processMild reaction conditionsBiocideMicroorganism based processesAntibacterial activityEndophytic fungus

The invention discloses a silver nanometer material and its biological preparation method and application. The method uses endophytic fungi isolated from the roots of Dendrobium officinale Fusarium solani D07 (preservation number CCTCC NO.M2017145) biological extracellular synthesis of the silver nanomaterial, the reaction conditions are mild, easy to control, avoiding the toxic or radioactive reagents in chemical and physical methods, and has the advantages of reliability and greenness. The silver nanometer material of the present invention is a round or oval nanoparticle material, has good dispersibility, narrow particle size distribution, particle size of 16-46nm, and good antibacterial effect. Utilizing the good antibacterial activity of the silver nanomaterials, the application of the silver nanomaterials to the preparation of antibacterial materials has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Diaphragm in sound-generating device and preparation method thereof, and sound-generating device

ActiveCN109769194BReduce manufacturing difficultyReduce manufacturing costDiaphragm constructionVibrating membraneAdhesive glue

Embodiments of the present application provide a diaphragm in a sound generating device, a manufacturing method thereof, and a sound generating device. Wherein, the method includes the following steps: the inner side wall of the shell of the sound generating device is provided with a groove, and a first solution and a second solution that are incompatible with each other are sequentially added into the shell of the sound generating device, and the first The layered interface of the solution and the second solution is located at the position of the groove; the polymerization reaction of the first solution and the second solution occurs at the layered interface to obtain the diaphragm, the The edges of the diaphragm are located in the groove and fill up the groove. The preparation method provided in the embodiment of the present application can not only avoid the problem of low product yield caused by high-temperature injection molding, but also avoid the problem of toxicity caused by the use of glue.

Owner:GOERTEK INC

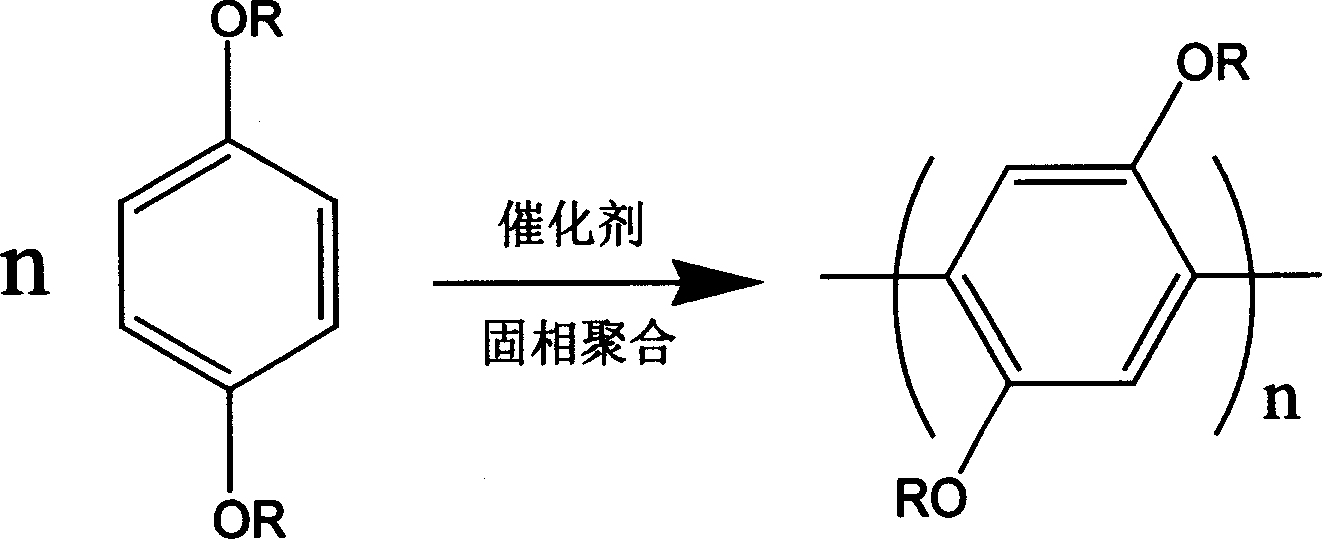

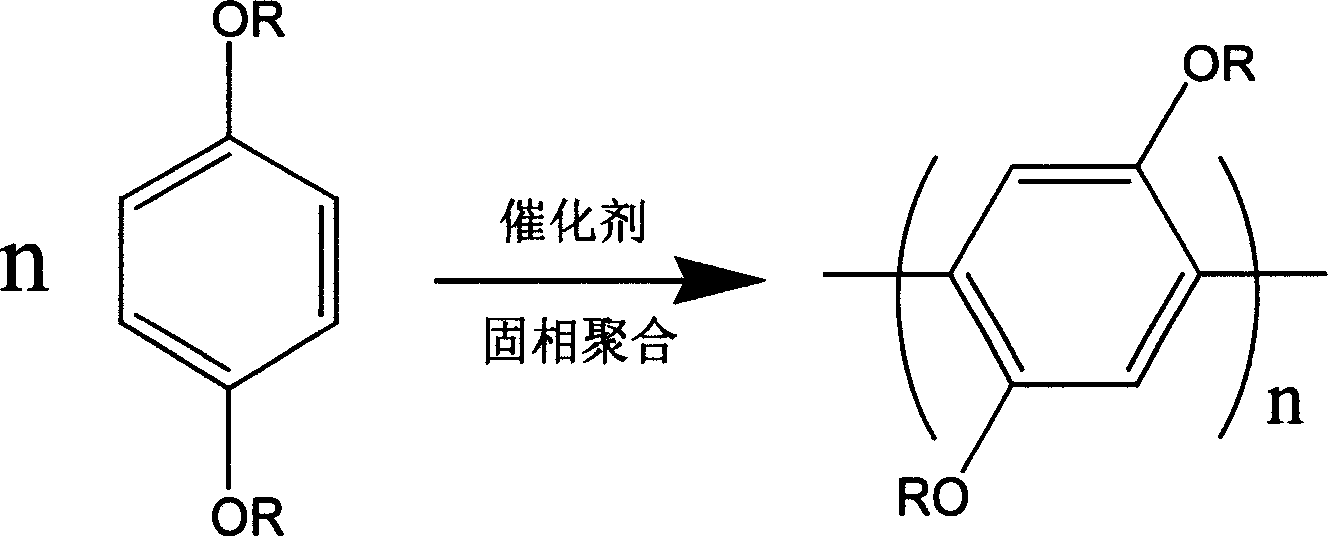

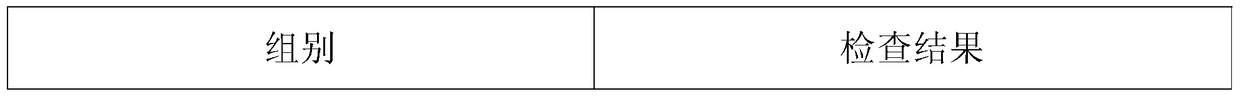

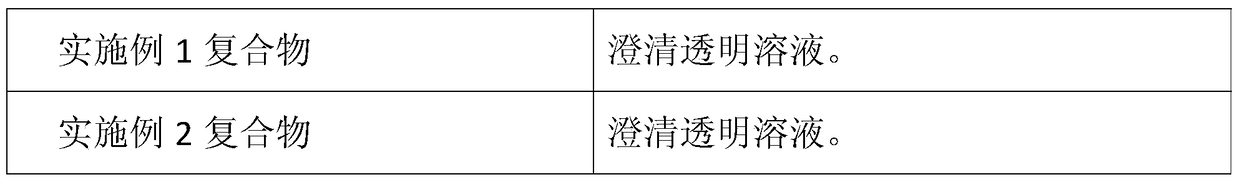

Preparation of poly(2,5-diakoxy-1,4-benzene)

2,5-dialkyloxy-1,4-benzene is prepared by solid state oxidized coupling polymerization, which includes: selecting p-dialkyloxylbenzene as monomer with C1-18 in alkyloxyl and metal chloride as catalyst, mixing and abrasing at 5-65deg.C and reacting for 10-30 minutes to obtain the crude product, separating and purifying to get poly(2,5- dialkyloxyl-1,4-benzene). Because of no solvent in polymerization, it reduces environment pollution, lower production cost, short polymerization time of only 10-30 minutes to increase productivity, increasing polymerization yield up to 90%. The obtained product has good structure regional mapping orderliness. Between phenyl cycles there are chain connections of contraposition. The obtained polymer has a fluorescence emission peak value of 405 nanometers or so, belonging to blue fluorescence emission materials. The conjugate polymers can be used to make electroluminescence parts of apparatus, organic thin-film transistor and other photoelectric conversion parts of apparatus.

Owner:WUHAN UNIV

Preparation of poly(2,5-diakoxy-1,4-benzene)

The invention discloses a method for preparing poly(2,5-dialkoxy-1,4-benzene) by solid-state oxidative coupling polymerization. The method uses p-dialkoxybenzene with an alkoxy carbon number of 1 to 18 as a monomer, uses metal chloride as a catalyst, and reacts at 5 to 65°C for 10 to 30 minutes under mixing and grinding to obtain a crude product; separation , and purification to obtain poly(2,5-dialkoxy-1,4-benzene). Because the present invention does not use a solvent during the polymerization reaction, the pollution of the environment is reduced; the production cost is reduced; the polymerization reaction time is short, only needing 10-30 minutes, so that the production efficiency is improved; the polymerization yield is improved, which can reach 90%; The polymer has good structural regioregularity, and all the benzene rings are linked in the para position. The fluorescence emission peak of the obtained polymer is about 405 nanometers, which belongs to the blue-violet light emission material. This conjugated polymer can be used in the manufacture of electroluminescent devices, organic thin film transistors and other photoelectric conversion devices.

Owner:WUHAN UNIV

A double-stranded polynucleotide-ε-polylysine complex with immunoregulatory effect and its preparation and use method

ActiveCN105664152BSimple preparation processImprove hydrophilicitySsRNA viruses negative-senseViral antigen ingredientsNucleotideAqueous solubility

Owner:北京加益维科生物科技有限公司

Adhesive hydrogel and preparation method thereof

Owner:TIANJIN POLYTECHNIC UNIV

Microbial enzymes racemization preparation method of DL-alanine

ActiveCN101575624BAvoid poisonousLow priceMicroorganism based processesFermentationPolarimeterSpecific rotation

The invention relates to a microbial enzymes racemization preparation method of DL-alanine, comprising the following steps: preparing a substrate, adjusting the PH value of the substrate to eight by ammonia or sulphuric acid, canning the obtained substrate in flasks, inoculating microorganisms saved on an inclined plane to the substrate by picking one loop of microorganisms with a transfering loop, culturing the substrate for 24h at 30 DEG C by a rotary shaker of which the rotation rate is 110rpm, merging the above cell supernatant, adding the cell supernatant in a substrate solution, reacting at 30 DEG C at PH value of 7.0 when a polarimeter is used to measure the specific rotation of the reaction system every hour, continuing to react when the specific rotation is zero and heating up to60-100 DEG C, destaining for 30min by adding active carbon, filtering, and vacuum concentrating and crystallizing by a rotary film evaporator to obtain the DL-alanine finished goods. The invention has the advantages of accessible raw materials, simple production process and mild conditions, and can greatly reduce the production cost of DL-alanine.

Owner:淮北新旗氨基酸有限公司

A double-stranded polynucleotide-ε-polylysine-sulfated glycan complex with immunomodulatory effect and its preparation and use method

ActiveCN105535964BSimple preparation processEnhance immune modulatory activitySsRNA viruses negative-senseViral antigen ingredientsSolubilityAntigen

The invention provides a double-strand polynucleotide-epsilon-polylysine-sulfuric acid glycan compound with an immune regulating function and a preparing and using method thereof. The invention further provides an immunogen composition with functions of triggering and enhancing immunoreaction and changing immunoreaction types. The immunogen composition contains the double-strand polynucleotide-epsilon-polylysine-sulfuric acid glycan compound and an antigen. The compound is formed by compounding double-strand polynucleotide and anion sulfuric acid glycan with cation epsilon-polylysine and metal cation. The compound has immune-regulating pharmacological activity. The preparing technology of the compound is simple. The compound has good water solubility and a function of resisting biological enzyme degradation. The immunogen composition can trigger and enhance the immunoreaction and change the immunoreaction types.

Owner:北京加益维科生物科技有限公司

3D blowing membrane

InactiveCN109016718AAvoid poisonousAvoid environmental problemsNon-macromolecular adhesive additivesSynthetic resin layered productsUltimate tensile strengthWear resistance

The invention discloses 3D blowing membrane. The 3D blowing membrane comprises an annular membrane body, wherein the annular membrane body comprises a TPU membrane layer, an anti-corrosion layer is attached to the upper end of the TPU membrane layer, an anti-impact layer is attached to the upper end of the anti-corrosion layer, a high-tenacity layer is attached to the upper end of the anti-impactlayer, a high-elasticity layer is attached to the upper end of the high-tenacity layer, a low temperature resisting layer is attached to the upper end of the high-elasticity layer, a high temperatureresisting layer is attached to the upper end of the low temperature resisting layer, an antibacterial layer is attached to the upper end of the high temperature resisting layer, and an flame retardinglayer is attached to the upper end of the antibacterial layer. According to the 3D blowing membrane, a common PVC material is replaced by a TPU material, so that the comprehensive performance of theblowing membrane is improved, and the TPU material is non-poisonous and environmentally friendly, has incomparable characteristics compared with other plastics and natural materials, can significantlyenhance characteristics of the strength, the tenacity, wear resistance, ageing resistance, weather change resistance and the like of the blowing membrane and products of the blowing membrane, and then is more suitable for being used for production and lives.

Owner:瑞年科技(广东)有限公司

Method for purifying panaxoside compound-K by applying macroporous resin

ActiveCN101921304BReduce usageEasy to operateIon-exchange process apparatusIon-exchanger regenerationHigh concentrationMacroporous resin

The invention relates to a method for separating and purifying a panaxoside compound-K from microorganism zymocyte by applying macroporous resin for preparing a raw medicine. The purifying yield reaches more than 72 percent, and the content of the panaxoside compound-K in a product is more than 96 percent. The method mainly comprises the following steps of: adding ethanol into zymocyte for extracting and concentrating; decoloring by active carbon and filtering; after adding water into filter liquor for diluting, leading the filter liquor to pass through a macroporous resin chromatographic column; washing by a low-concentration organic solvent aqueous solution for removing pigment and high-polarity saponin; eluting by a high-concentration organic solvent aqueous solution to obtain a panaxoside compound-K component; and finally crystallizing to obtain the panaxoside compound-K raw medicine with the content of more than 96 percent. The invention can provide a great amount of qualified raw medicine samples for the pharmaceutical development of the panaxoside compound-K.

Owner:ZHEJIANG HISUN PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com