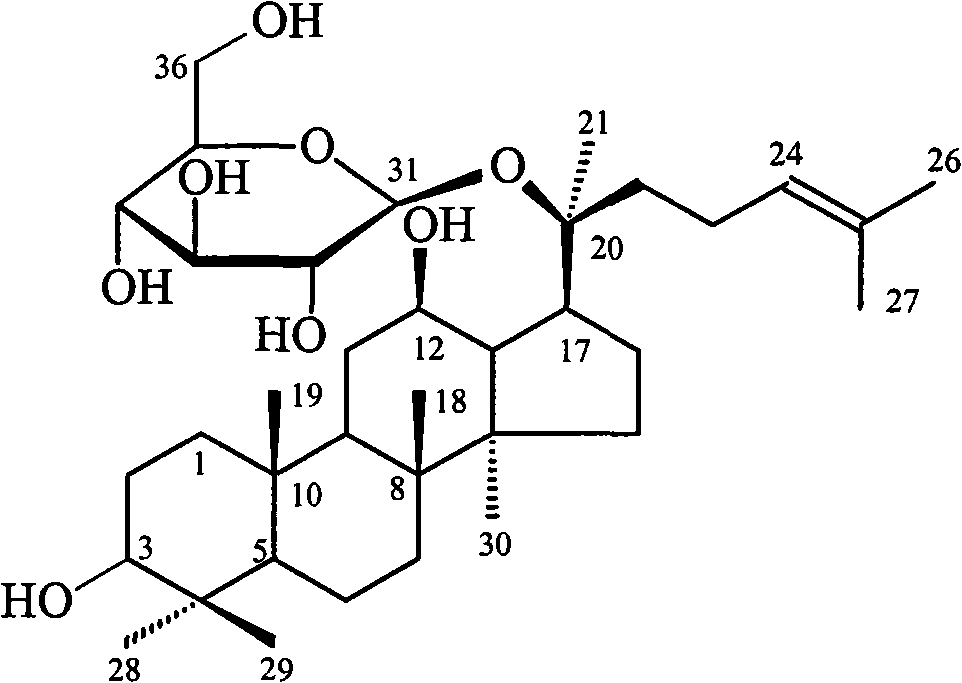

Method for purifying panaxoside compound-K by applying macroporous resin

A technology of ginsenosides and macroporous resins, applied in the directions of organic chemistry, steroids, chemical/physical processes, etc., can solve problems such as inability to apply on a large scale, achieve process safety and environmental protection, easy operation, high yield and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 50L of fermentation liquid [Pei Zhou, et al.CN200410018000.0, CN1570133A[P], Example 1], filter through a filter cloth to obtain 6800g of wet bacteria, cold soak in 50L of industrial ethanol and fully stir and extract for 24 hours, filter through a filter cloth Suction filtration to obtain an ethanol extract containing 62.5 g of ginsenoside compound-K. Concentrate the ethanol extract to 2.5L under reduced pressure, add 65g of activated activated carbon powder, decolorize at room temperature for 12 hours, filter with suction, collect the filtrate, add 2.5L of water to dilute to obtain the sample solution, and use D101 macroporous resin column for sample adsorption. The column volume is 4L, the adsorption capacity of ginsenoside compound-K is about 15mg / ml wet resin, and the flow rate is 1L / h. After sample loading, first elute with 12L 50% ethanol water solution to remove pigment and impurities, then elute with 6L 80% ethanol water solution to obtain the ginsenoside ...

Embodiment 2

[0026]Take 100L of fermentation broth, filter with filter cloth to get 15kg of wet cells, cold-soak in 120L of industrial ethanol and fully stir and extract for 24 hours, filter with filter cloth to obtain ethanol extract, which contains 140g of ginsenoside compound-K. Concentrate the ethanol extract to 3L under reduced pressure, add 14g of activated activated carbon powder, reflux for 0.5 hours for decolorization, filter with suction, collect the filtrate, add 1L of water to dilute to obtain the sample solution, and use HP41 macroporous resin column for sample adsorption, column volume It is 7L, the adsorption capacity of ginsenoside compound-K is about 20mg / ml wet resin, and the flow rate is 1L / h. After loading the sample, first elute with 20L of 35% aqueous methanol to remove pigment and impurities, and then elute with 8L of 75% aqueous methanol to obtain the ginsenoside compound-K component. The solvent was recovered under reduced pressure to obtain 120 g of crude ginsenos...

Embodiment 3

[0028] Take 100L of fermentation broth, filter with filter cloth to get 15kg of wet cells, cold-soak in 120L of industrial ethanol and fully stir and extract for 24 hours, filter with filter cloth to obtain ethanol extract, which contains 140g of ginsenoside compound-K. Concentrate the ethanol extract to 3L under reduced pressure, add 70g of activated activated carbon powder, decolorize at 60°C for 1 hour, filter with suction, collect the filtrate, add 1.5L of water to dilute to obtain the sample solution, and load the sample on the AB-8 macroporous resin column Adsorption, the column volume is 7L, the adsorption capacity of ginsenoside compound-K is about 20mg / ml wet resin, and the flow rate is 1.5L / h. After loading the sample, first elute with 20L 20% isopropanol aqueous solution to remove pigment and impurities, and then elute with 8L 60% isopropanol aqueous solution to obtain the ginsenoside compound-K component. The solvent was recovered under reduced pressure to obtain 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com