Molecular weight grading and purifying method of polyhydroxyalkanoate

A polyhydroxyalkanoate and purification method technology, applied in the field of biomedicine, can solve the problems of complex chemical composition of polyester, wide molecular weight distribution, difficult purification and other problems, and achieve the effects of narrow molecular weight distribution, uniform and accurate molecular weight, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

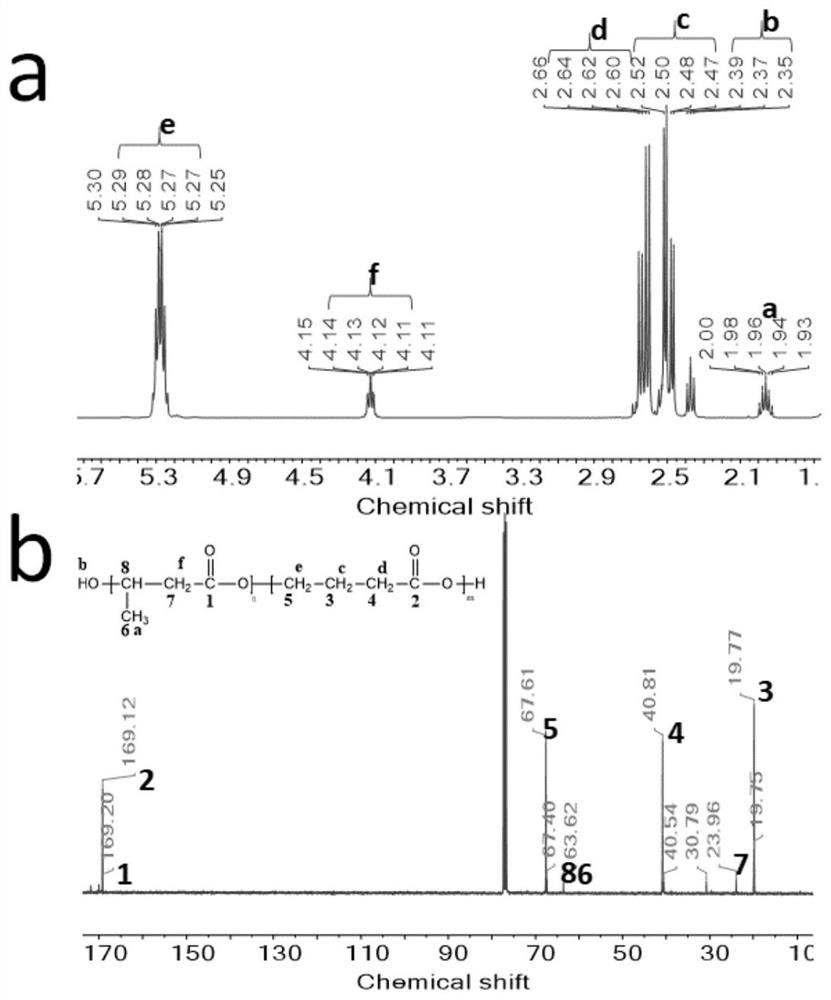

[0051] This embodiment provides a method for molecular weight classification and purification of polyhydroxyalkanoate, poly 3-hydroxybutyrate-co-4 hydroxybutyrate is used as raw material for molecular weight classification and purification, and its 3-hydroxybutyric acid monomer and The ratio of 4-hydroxybutyric acid monomer is (4 ~ 1): (1 ~ 4), using liquid phase permeation gel chromatography (GPC), hydrogen nuclear magnetic resonance spectrum (H-NMR) and thermogravimetry (TGA) on The purity of the poly 3-hydroxybutyrate-co-4 hydroxybutyrate obtained is characterized, and the characterization method of the specific initial poly 3-hydroxybutyrate-co-4 hydroxybutyrate in H-NMR is that 3 mg of poly-3 -Hydroxybutyric acid-co-4 hydroxybutyrate raw material is dissolved in 0.6 ~ 1mL deuterated chloroform, under the strong madness of scanning 32 ~ 64 times, there is no impurity peak in the hydrogen spectrum, indicating that the purity of the screened product is greater than 85%. Poly...

Embodiment 2

[0057] This embodiment provides a method for molecular weight classification and purification of polyhydroxyalkanoate, poly 3-hydroxybutyrate-co-4 hydroxybutyrate is used as raw material for molecular weight classification and purification, and its 3-hydroxybutyric acid monomer and The ratio of 4-hydroxybutyric acid monomer is (4 ~ 1): (1 ~ 4), using liquid phase permeation gel chromatography (GPC), hydrogen nuclear magnetic resonance spectrum (H-NMR) and thermogravimetry (TGA) on The purity of the poly 3-hydroxybutyrate-co-4 hydroxybutyrate obtained is characterized, and the characterization method of the specific initial poly 3-hydroxybutyrate-co-4 hydroxybutyrate in H-NMR is that 3 mg of poly-3 -Hydroxybutyric acid-co-4 hydroxybutyrate raw material is dissolved in 0.6 ~ 1mL deuterated chloroform, under the strong madness of scanning 32 ~ 64 times, there is no impurity peak in the hydrogen spectrum, indicating that the purity of the screened product is greater than 85%. Poly...

Embodiment 3

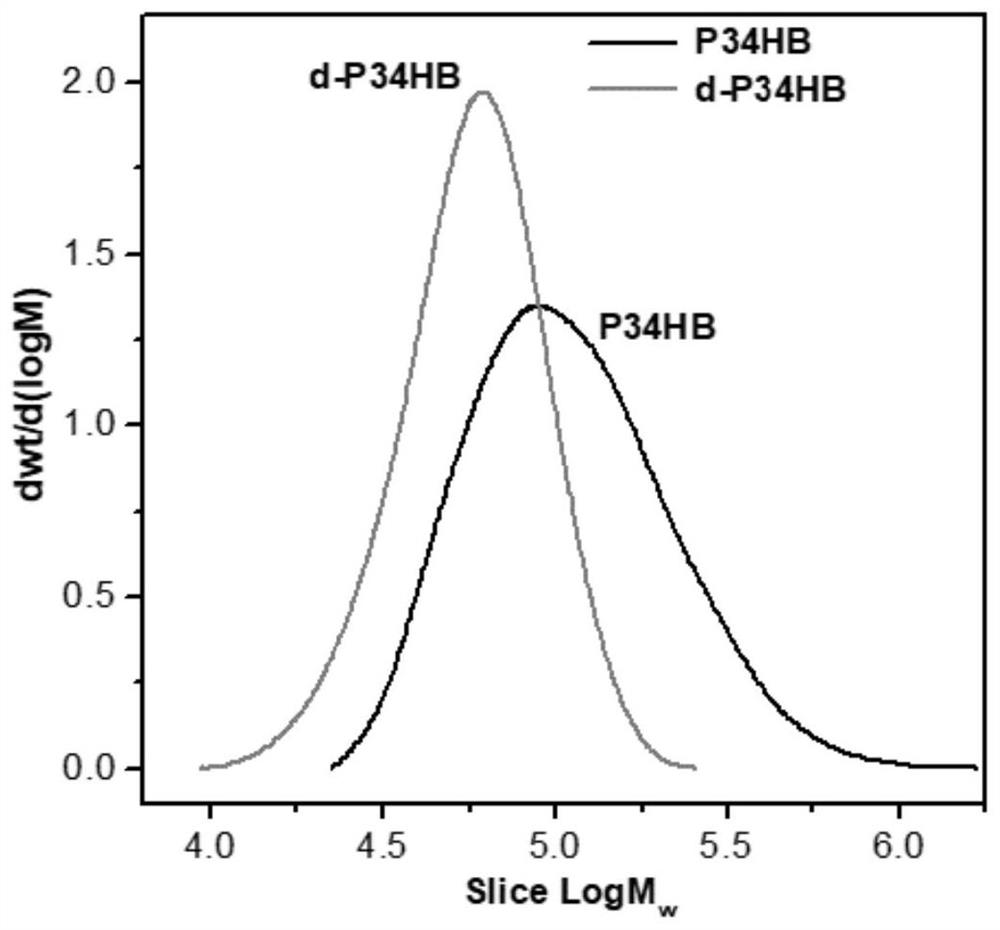

[0063] This embodiment analyzes the molecular weight of poly-3-hydroxybutyrate-co-4 hydroxybutyrate through molecular weight fractionation and purification in Example 1:

[0064] Take 5 mg of the poly-3-hydroxybutyrate-co-4 hydroxybutyrate and 5 mg of poly-3-hydroxybutyrate-co-4 hydroxybutyrate raw materials that have undergone molecular weight fractionation and purification in Example 1, and add 1 ml of DMF respectively to fully dissolve , placed in the liquid phase permeation gel chromatography (GPC) of DMF mobile phase to test the molecular weight of the polymer.

[0065] Analysis results such as image 3 , Curve d-P34HB corresponds to the polymer molecular weight of poly 3-hydroxybutyrate-co-4 hydroxybutyrate in Example 1 after molecular weight fractionation and purification, and curve P34HB corresponds to poly 3-hydroxybutyrate-co-4 hydroxybutyrate co-4 hydroxybutyrate base polymer molecular weight, given by image 3 It can be seen that the abscissa value corresponding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com