Method for inactivating listeria monocytogenes on preservative film

A technology of Listeria monocytogenes and plastic wrap, which is applied in the field of inactivation of Listeria monocytogenes on plastic wrap, can solve the problems of no food plastic wrap, etc., and achieve good sterilization effect, low cost, and wide source of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

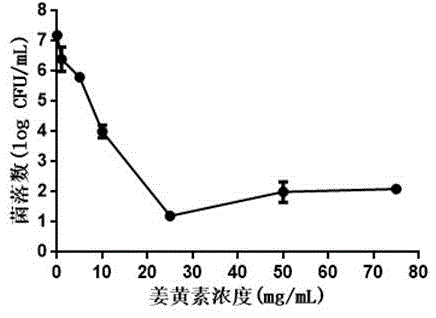

[0036] Photosensitizer concentration experiment

[0037] Pretreatment: The aseptic cling film sample used for the photosensitivity test is divided into discs with a radius of 2.0 cm each to simplify the experimental process and minimize the lighting area. Each package sample is in 25mL Listeria monocytogenes suspension (1×10 7 CFU / mL) is soaked in water so that bacteria can adhere to the surface of the plastic wrap. To make the bacterial cells adhere better, place the soaked sample in a 6-well cell culture plate for 10 minutes.

[0038] Treatment of photosensitizer concentration: dilute curcumin with PBS, prepare curcumin solutions with final concentrations of 0, 1, 5, 10, 25, 50, and 75 mg / L, and prepare for use; then, the liquid with Listeria monocytogenes adhered The packaged samples were incubated with 1-75mg / L curcumin solution for 10 minutes under dark conditions. The blank sample was incubated with PBS buffer for the same length of time. After incubating with the curcumin...

Embodiment 2

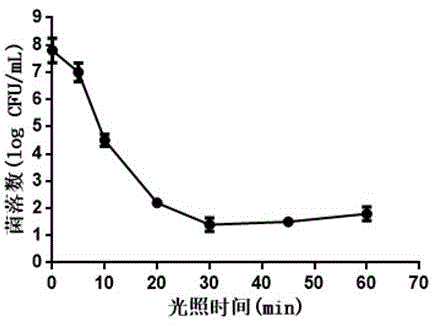

[0041] Light time test

[0042] Pretreatment: The aseptic cling film sample used for the photosensitivity test is divided into discs with a radius of 2.0 cm each to simplify the experimental process and minimize the lighting area. Each package sample is in 25mL Listeria monocytogenes suspension (1×10 7 CFU / mL) is soaked in water so that bacteria can adhere to the surface of the plastic wrap. To make the bacterial cells adhere better, place the soaked sample in a 6-well cell culture plate for 10 minutes.

[0043] Illumination time treatment: Incubate the package sample with the Listeria monocytogenes bacterial solution in a 10mg / L curcumin solution for 10 minutes under dark conditions. The blank sample was incubated with PBS buffer for the same length of time. After incubating with the curcumin solution, place all the packaged samples in the sample chamber of the bromine tungsten lamp and irradiate them for 0, 5, 10, 20, 30, 45, and 60 minutes. The blank sample does not require l...

Embodiment 3

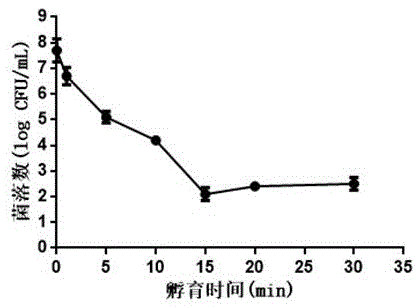

[0046] Incubation time test

[0047] Pretreatment: The aseptic cling film sample used for the photosensitivity test is divided into discs with a radius of 2.0 cm each to simplify the experimental process and minimize the lighting area. Each package sample is in 25mL Listeria monocytogenes suspension (1×10 7 CFU / mL) is soaked in water so that bacteria can adhere to the surface of the plastic wrap. To make the bacterial cells adhere better, place the soaked sample in a 6-well cell culture plate for 10 minutes.

[0048] Incubation time treatment: Incubate the package sample with the Listeria monocytogenes bacterial solution in a 10mg / L curcumin solution under dark conditions for 0, 1, 5, 10, 15, 20, 30 minutes. The blank sample was incubated with PBS buffer for the same length of time. After incubating with the curcumin solution, place all the packaged samples in the sample chamber of the bromine tungsten lamp and illuminate for 10 minutes. The blank sample does not require light. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com