Patents

Literature

65results about How to "Hinder formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

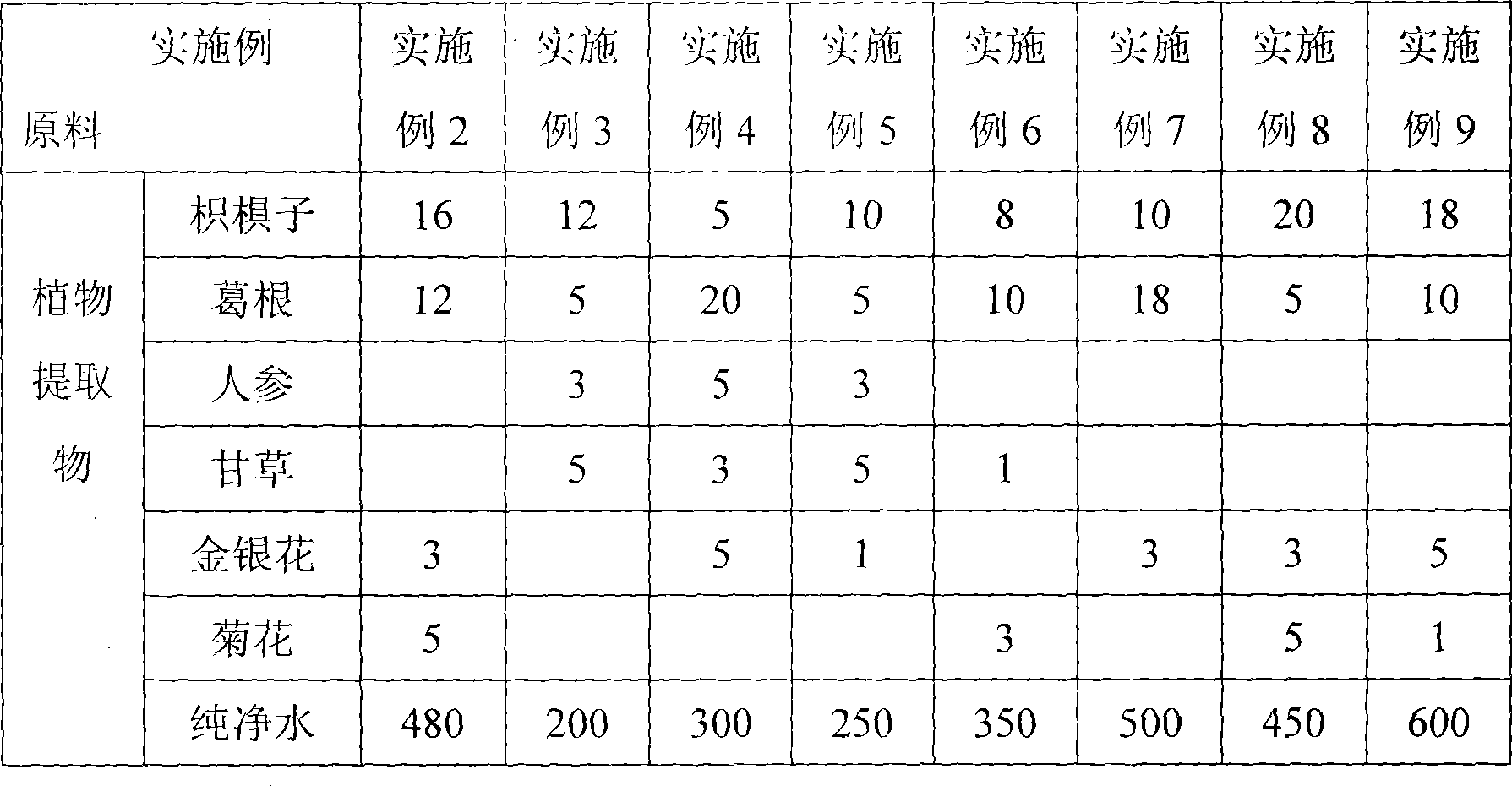

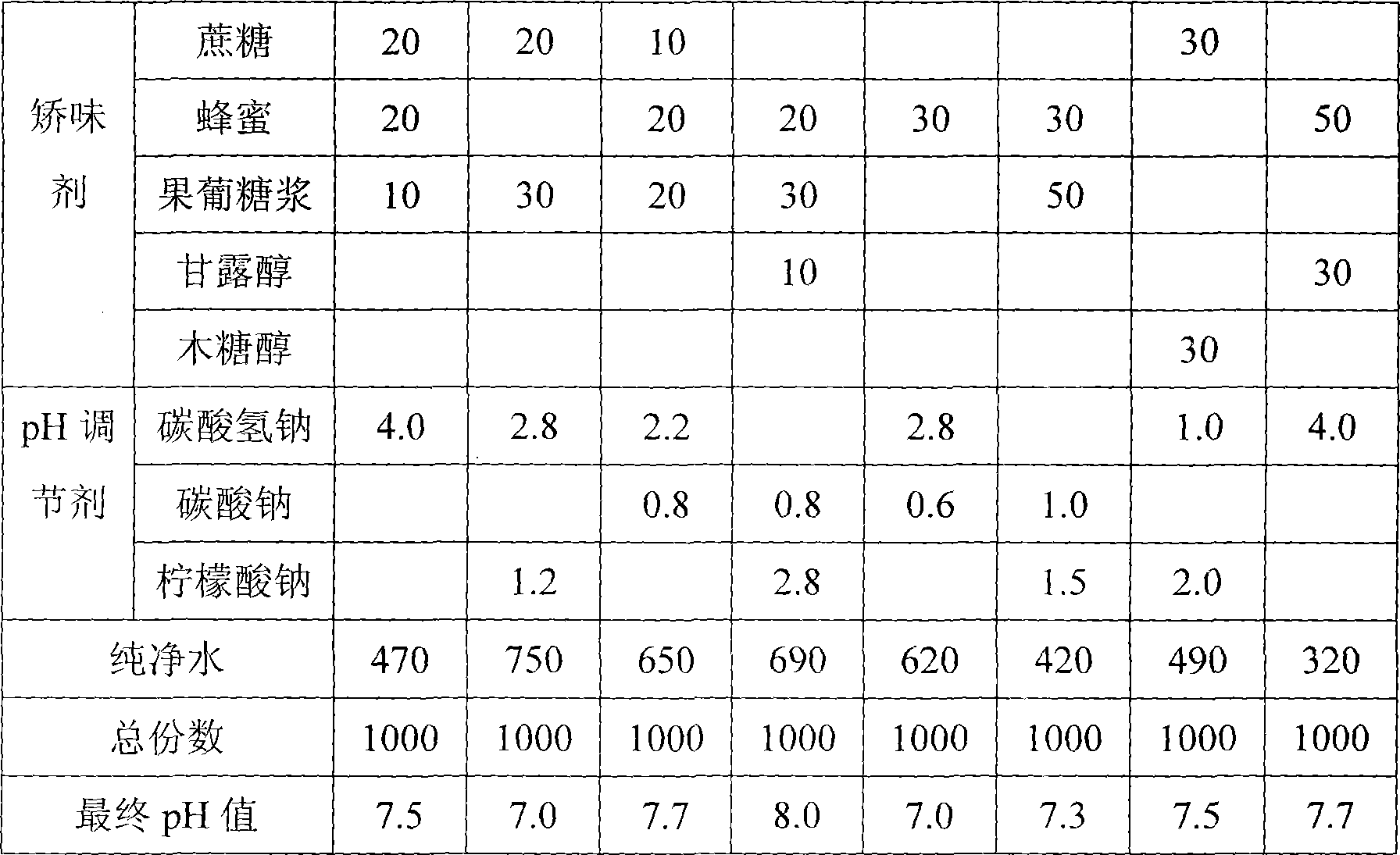

Weak alkali plant alcohol intoxication-alleviating beverage and method for preparing same

InactiveCN101518351AThe hangover function is obviousSignificant hangover functionNervous disorderFood preparationVascular diseaseAlcohol

The invention discloses a weak alkali plant alcohol intoxication-alleviating beverage and a method for preparing the same. The beverage comprises the following components: plant extract, corrective, pH adjusting agent and pure water. The preparation method comprises the following steps that: firstly, the plant extract is decocted and filtered, and the obtained filtrate is cooled down to obtain the plant extract; secondly, the plant extract is mixed with the corrective, and the mixture is dissolved in water; and thirdly the mixed solution is added with proper amount of pH adjusting agent so as to adjust the pH value of the mixed solution to between 6.5 and 8.5, and the mixed solution is subjected to constant volume, filtering, homogenization, sterilization, filling, packaging and checking-up to obtain the weak alkali plant alcohol intoxication-alleviating beverage. The weak alkali plant alcohol intoxication-alleviating beverage has the advantages of removing alcohol toxins, alleviating the alcohol intoxication and protecting the liver, replenishing vital essence and clearing heat, promoting urination and releasing toxin and effectively preventing cardio-cerebral-vascular diseases, osteoporosis, gout, hypertension, high blood fat and the like, along with strong controllability of the production process, good quality reproductivity, fresh and good taste and the suitability for taking at four seasons.

Owner:武汉市久共合生物科技有限公司

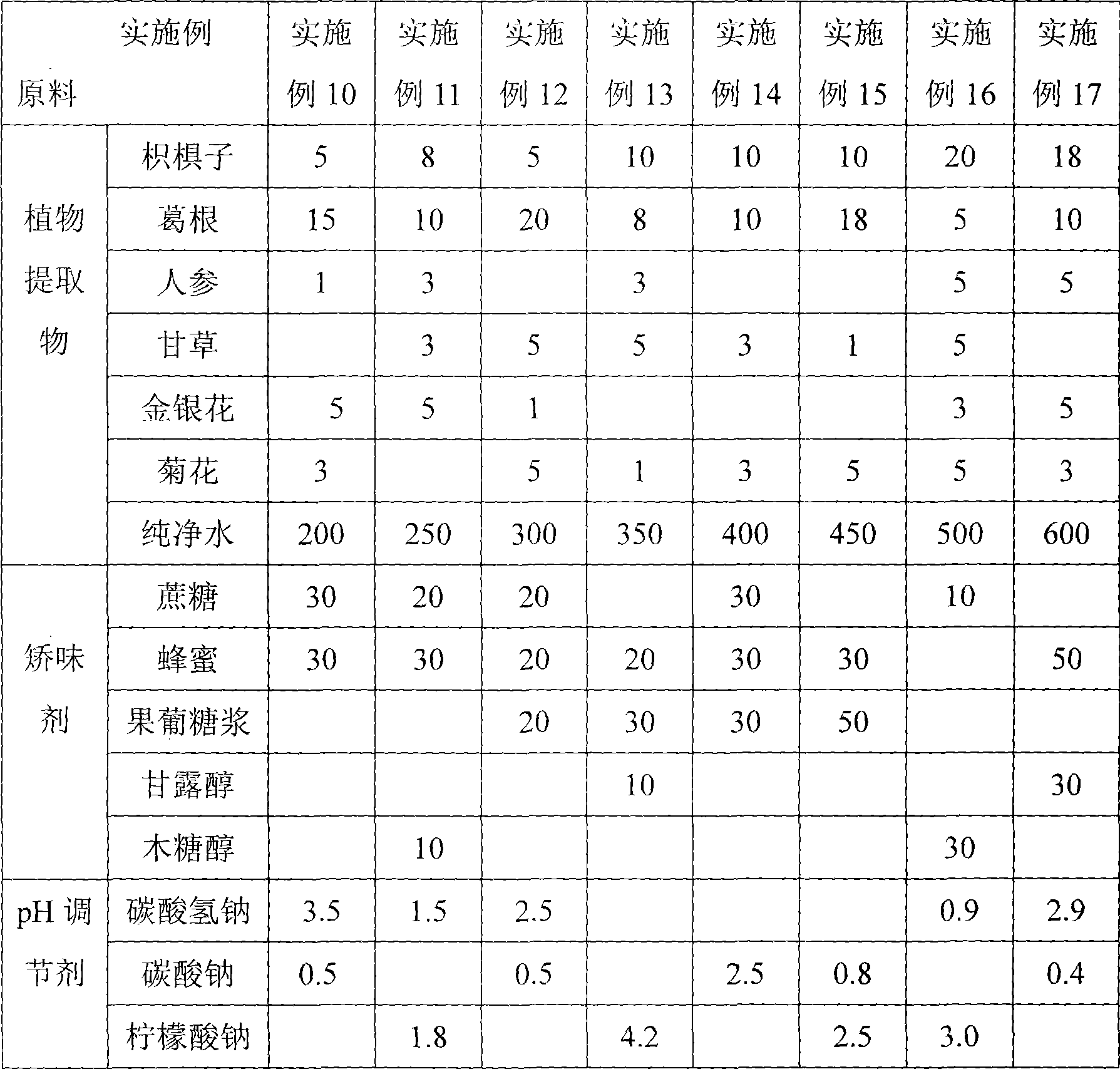

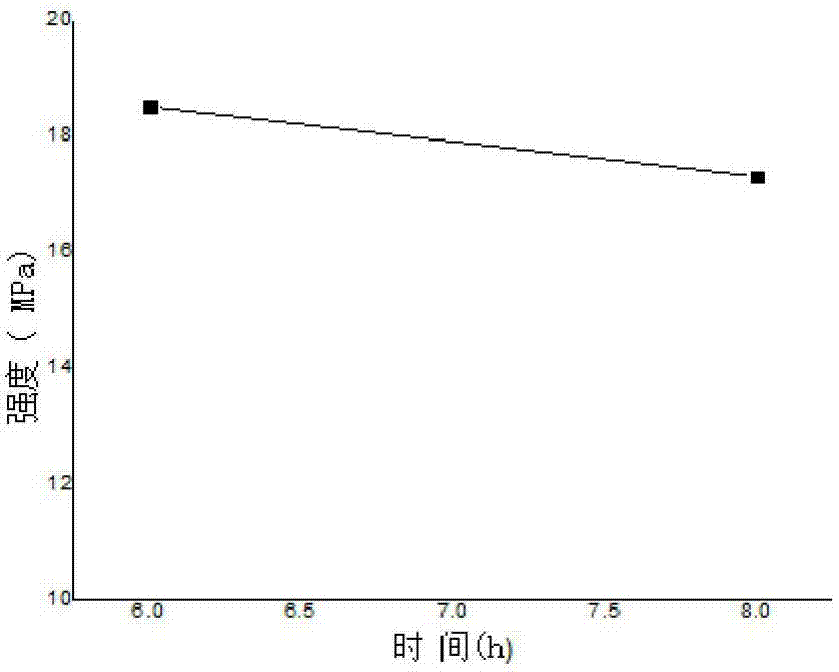

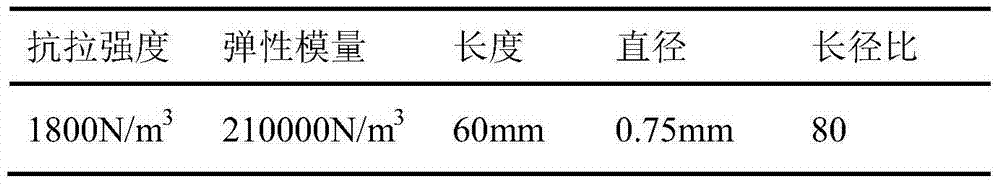

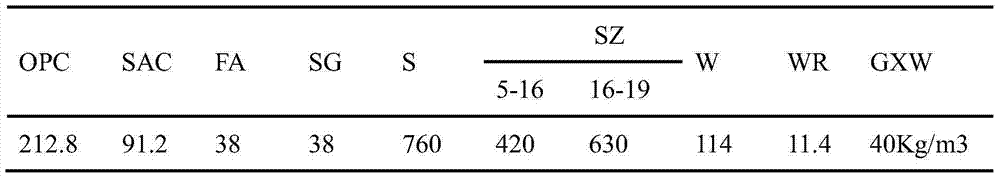

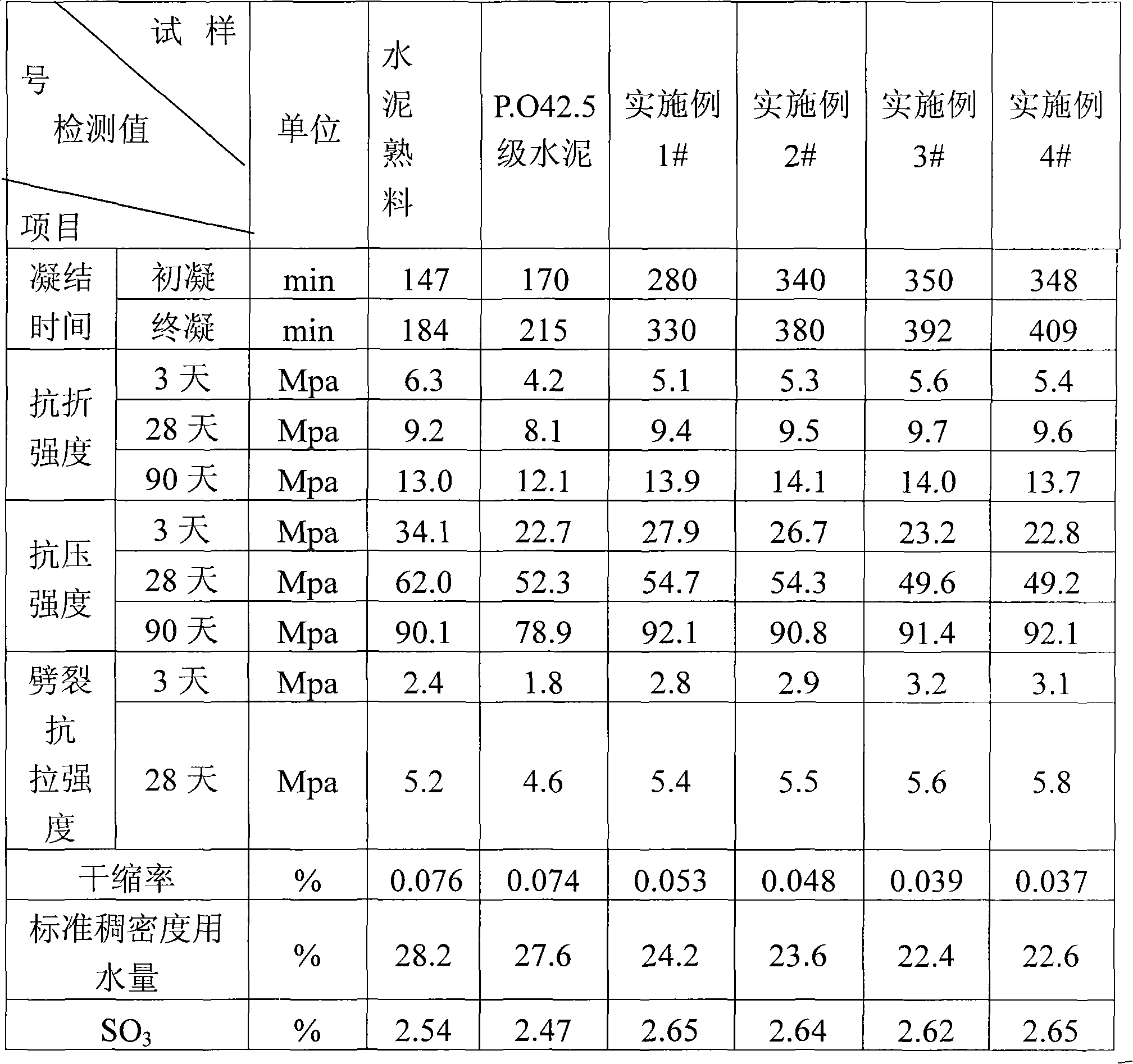

Steam-curing-free early-strength steel fiber concrete pipe segment and preparation method thereof

InactiveCN104773988AHarden fastSimplify maintenanceSolid waste managementFiberCALCIUM HYDROXIDE SOLUTION

The invention discloses a steam-curing-free early-strength steel fiber concrete pipe segment comprising ordinary Portland cement, early-strength sulphoaluminate cement, fly ash, slag, fine aggregate, coarse aggregate, water, a polycarboxylic acid type water reducer and end hook type steel fibers. The invention also discloses a preparation method of the steam-curing-free early-strength steel fiber concrete pipe segment. The steam-curing-free early-strength steel fiber concrete pipe segment is quick in coagulation and hardening and high in early strength, can reach the strength of 15MPa required by pipe segment demolding in 6-8 hours, and can be prepared into a concrete pipe segment for an underground structure by performing water curing in a 20 DEG C saturated calcium hydroxide solution for 24 hours and then performing natural curing for 28 days. The steam-curing-free early-strength steel fiber concrete pipe segment does not need steam curing, so that the curing mode of the pipe segment can be simplified, the curing time is shortened, a lot of manpower and resources are saved, and the popularization and application values are high.

Owner:SOUTHEAST UNIV +1

Boro-carburizing microalloying method of shearer cutter

InactiveCN101323944ADense tissueHigh strengthSolid state diffusion coatingProcess efficiency improvementManganeseRoom temperature

The invention relates to a borocarbon diffusion micro alloying method for the pick of a coal mining machine. Alloy steel 35CrMo is adopted as pick material, and the method comprises the following processing steps that: step 1, acid cleaning; step 2, carburization, titanizing and manganizing treatment: carburizer and lanthana powder are carried out and evenly stirred and sent into an infiltration box; titanium powder and manganese power are adopted to coat on the cutting part at the tooth tops of the pick that is then vertically put into the infiltration box which is compacted and sealed; then the infiltration box is sent into a heating furnace, the temperature is rised to 650 DEG C + / - 10 DEG C, is kept for 1.5 to 2.5 hours, then continuously rised to 910 DEG C + / - 10 DEG C and is kept for 8 to 10 hours; then the temperature is lowered to 850 DEG C + / - 10 DEG C and is kept for 1.5 to 2.5 hours and continuously lowered to less than 800 DEG C and taken out of the furnace; the taken-out infiltration box is cooled to room temperature and opened; step3, boronizing, tungstenizing and chromizing treatment; step 4, salt-bath treatment; step 5, annealing treatment; step 6, tempering treatment; step 7, shot-peening treatment. The method of the invention is capable of improving the intensity, hardness and high-temperature abrasion resistance at the tooth tops of the pick of the coal mining machine and causes the handle of the pick to be difficult to break.

Owner:JIANGYIN XINHONG SCI & TECH

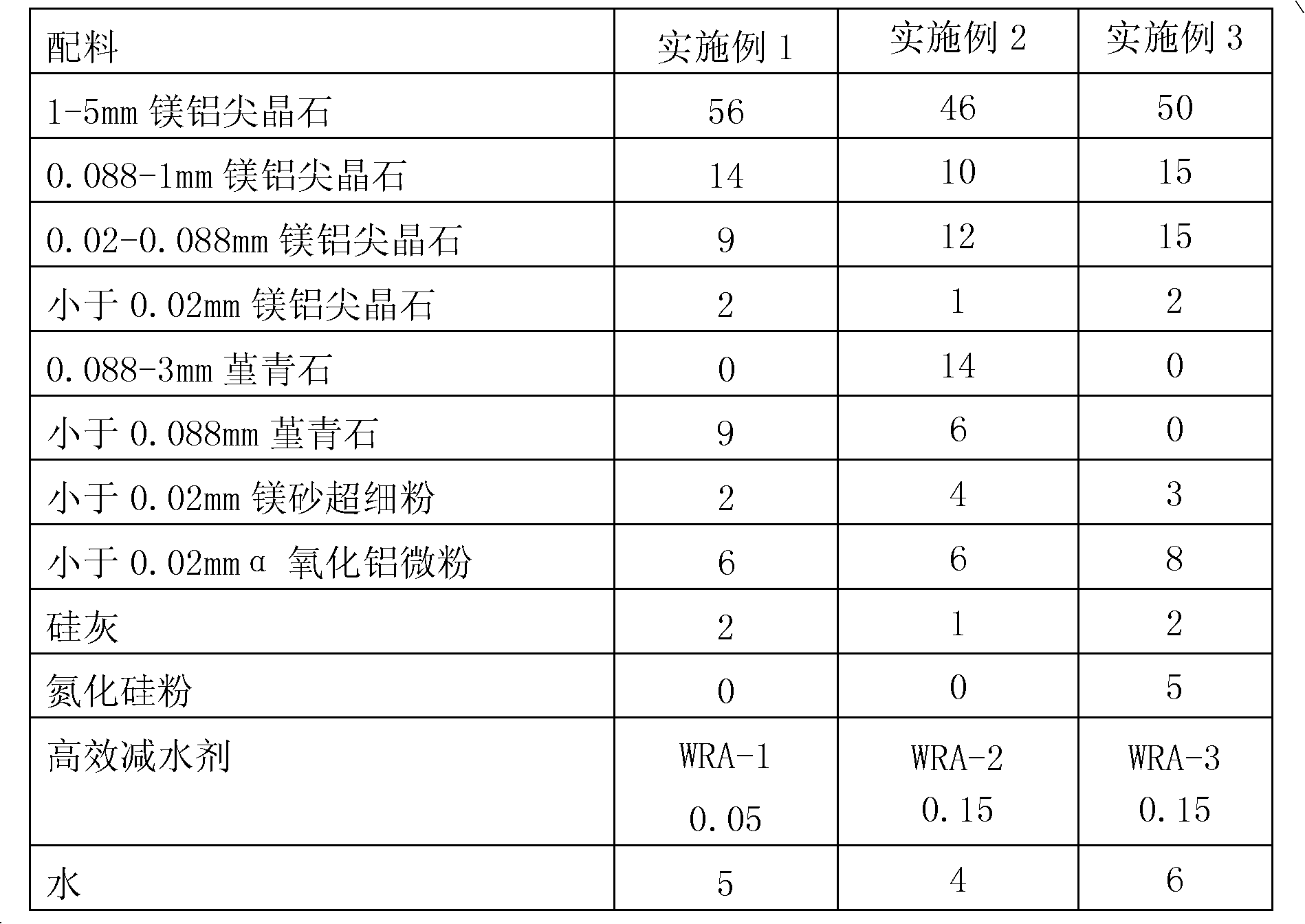

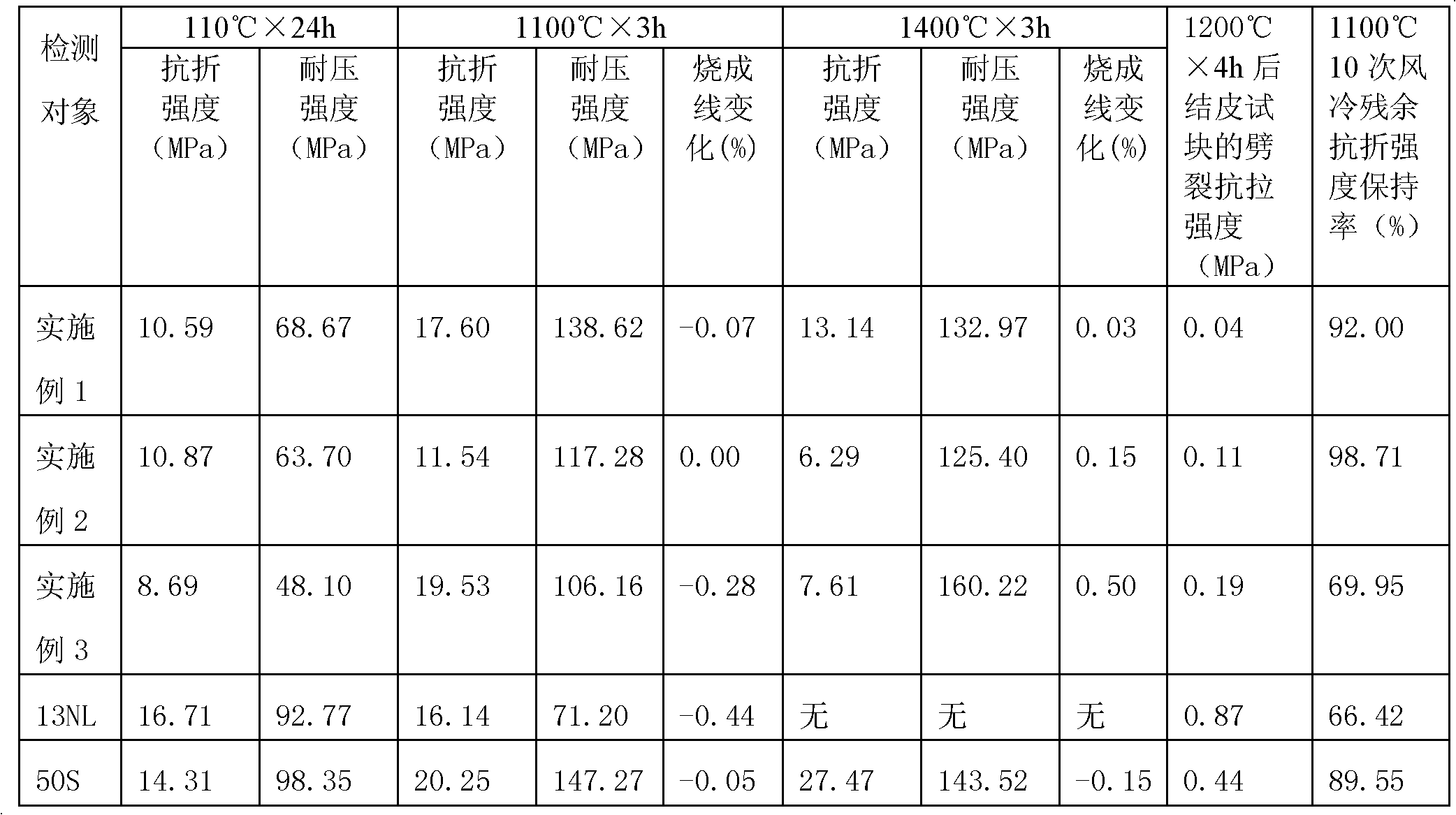

Anti-skinning unshaped refractory material made of magnesium aluminate spinel used for cement kiln and preparation method and application of anti-skinning unshaped refractory material

The invention discloses an anti-skinning unshaped refractory material made of magnesium aluminate spinel used for a cement kiln and a preparation method and application of the anti-skinning unshaped refractory material. The anti-skinning unshaped refractory material comprises raw materials as follows: quaternary mixed magnesium aluminate spinel with the particle diameter below 5mm, secondary mixed cordierite with the particle diameter below 3mm, superfine magnesia powder with the particle diameter smaller than 0.02mm, alpha-alumina micropowder with the particle diameter smaller than 0.02mm, silicon micropowder, silicon nitride powder, a high-efficiency water-reducing agent and water. According to the anti-skinning unshaped refractory material disclosed by the invention, with the magnesium aluminate spinel as the main crystalline phase and a superfine magnesia powder-silicon micropowder-silicon nitride powder-water system to substitute a pure calcium aluminate cement bonding agent, a complex-phase structure with the magnesium aluminate spinel as the main crystalline phase and the cordierite as the secondary crystalline phase is formed under high temperature, so that the refractory material has certain high-temperature resistance and good anti-skinning and anti-heat shock performances, can be used as the anti-skinning unshaped refractory material for a novel dry-process cement rotary kiln and a cement presintering production process, and has broad application prospect.

Owner:CHINA BUILDING MATERIALS ACAD +1

Anti-cracking reinforced ecological cement

InactiveCN101134645AProlong initial setting timeReduce early thermal cracksSolid waste managementGypsumFiber

The anticracking high strength ecological cement is produced with Portland clinker 35-80 wt%, fly ash 5-30 wt%, ferroalloy slag 1.0-30 wt%, boiler slag 5-40 wt%, gangue 10-40 wt%, grinding aid 0.1-2.0 wt%, gypsum 0.5-10 wt%, reinforcing fibrous inorganic mineral material 1-20 wt% and polymer fiber 0.01-10 wt%, and through grinding and mixing. Compared with available technology, the anticracking high strength ecological cement of the present invention has the advantages of low hydration heat, low shrinkage, low water demand, high early strength, etc.

Owner:JIANGXI GANFENG CEMENT

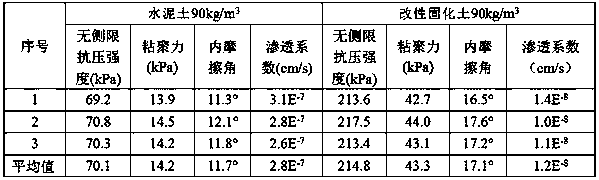

Sulphate corrosion resistant curing agent for marine facies sludge curing

InactiveCN107935509AImprove strength and compactnessReduce porositySludge treatment by de-watering/drying/thickeningCorrosion resistantSeawater

The invention discloses a sulphate corrosion resistant curing agent for marine facies sludge curing. The curing agent is prepared from the following raw materials in parts by weight: 2.3 to 2.7 partsof Portland cement, 2.4 to 2.9 parts of S95 granulated blast furnace mineral waste residues, 1.0 to 1.5 parts of quicklime, 1.8 to 2.4 parts of fly ash, 1.0 to 1.5 parts of early strengthening agents,0.1 to 0.3 part of gypsum and 0.2 to 0.5 part of liquid excitants. By reducing the cement mixing quantity and increasing the mixing quantity of granulated blast furnace mineral waste residue and flyash, the activity of the fly ash and blast furnace mineral waste residue powder is excited through the dual effects of early strengthening agents and liquid excitants; the intensity and the compactness of the curing soil are improved; the porosity is reduced; the formation of a water passage is prevented; in addition, a hydrophobe layer is formed in the soil body; the seawater erosion can be effectively prevented; the curing soil intensity and stability are improved.

Owner:福建港湾岩土工程集团有限公司

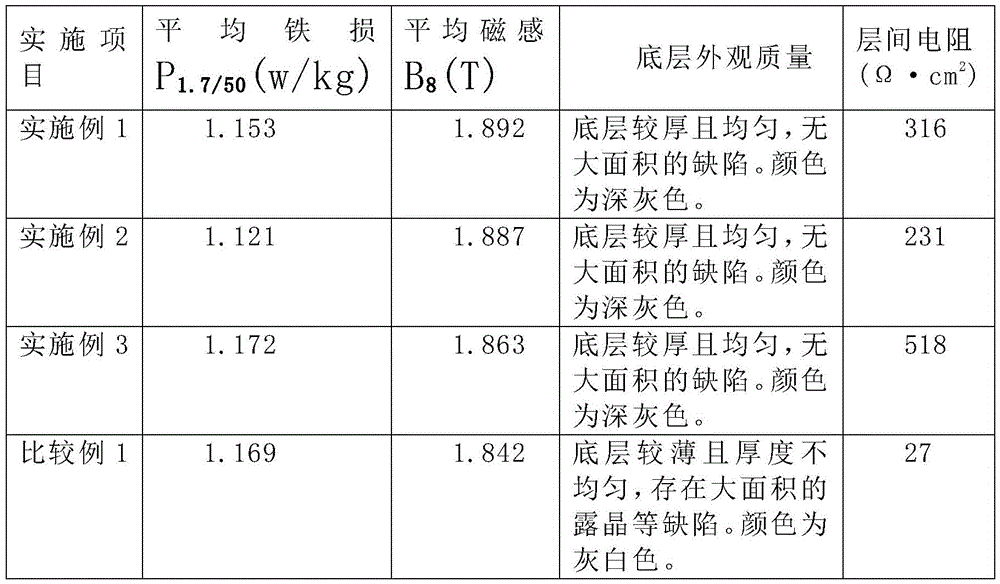

Method for improving quality of bottom layer of oriented silicon steel

ActiveCN105525087AReduce iron lossEnhanced inhibitory effectFurnace typesHeat treatment furnacesChemical compositionContinuous annealing

The invention discloses a method for improving quality of a bottom layer of oriented silicon steel. The method comprises the following steps: (1) regulating chemical components of steel billet; (2) grinding the surface of a steel plate by use of a metal brush roller after pickling the steel plate; (3) using ultrasonic waves to clean the steel plate before continuous annealing; and flushing the steel plate with clear water after cleaning; (4) regulating conditions for recovery annealing; (5) adding titanium dioxide and magnesium carbonate into an isolating coating which takes magnesium oxide as a main component; and (6) regulating conditions for high-temperature annealing of a steel coil. The method disclosed by the invention can solve the problem that the bottom layer of the current oriented silicon steel is poor in quality or is unstable in quality, and has a very good industrial application prospect.

Owner:GUANGDONG YINGQUAN HIGH TECH MATERIALS CO LTD

Instant mulberry alcohol relieving beverage and preparation method thereof

InactiveCN102422923AReduce concentrationEasy to removePre-extraction tea treatmentBiotechnologyAlcohol

The present invention provides an instant mulberry alcohol relieving beverage. The beverage is prepared by blending the following eight raw materials and 10-20 parts by weight of black tea, wherein the raw materials comprise, by weight, 20-40 parts of fresh ginger, 20-40 parts of mulberry, 5-10 parts of raosin tree seed, 10-15 parts of lobed kudzuvine flower bud, 2-4 parts of sanchi, 3-5 parts ofcapillary wormwood herb, 3-5 parts of cape jasmine and 1-2 parts of ginseng. According to the present invention, the instant alcohol relieving beverage of the present invention is prepared by the pure natural raw materials, and does not contain chemical preservatives; the instant alcohol relieving beverage of the present invention has effects of alcohol relieving, vomiting stopping, thirst quenching, restlessness eliminating, wind-evil dispelling, collateral dredging, urine and stool smoothening, sobering and nerve calming; the instant alcohol relieving beverage of the present invention provides double effects of alcohol relieving and liver protecting, and has characteristics of rapid alcohol relieving and wide application people range.

Owner:ANHUI PROVINCE TIANXU TEA

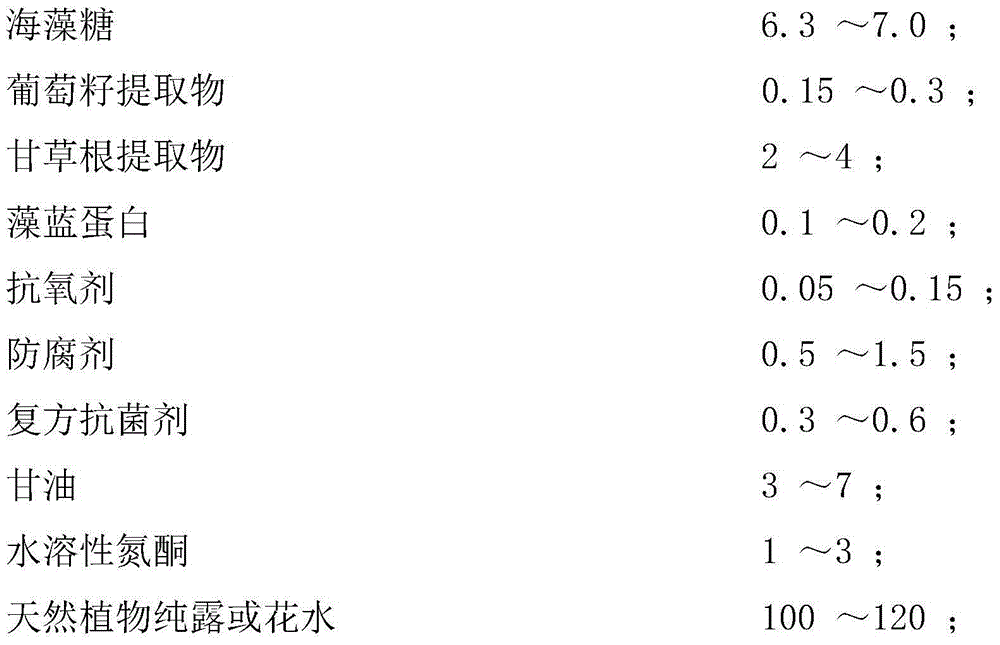

Preparation method and product of deep sea fish skin collagen polypeptide peeling mask

InactiveCN104083299AIncrease added valueReduce pollutionCosmetic preparationsToilet preparationsAntioxidantPolyethylene glycol

The invention discloses a collagen polypeptide peeling mask which is mainly prepared from the following raw materials in parts by weight: 2-5 parts of hydroxyethyl cellulose, 3-7 parts of arbutin, 1-1.5 parts of sodium alga acid, 4-5 parts of polyethylene glycol, 3.5-4.0 parts of fish skin collagen polypeptide, 6.3-7.0 parts of trehalose, 0.15-0.3 part of grape seed extract, 2-4 parts of licorice root extract, 0.1-0.2 part of phycocyanin, 0.05-0.15 part of antioxidant, 0.5-1.5 parts of preservative, 0.3-0.6 part of compound antibacterial agent, 3-7 parts of glycerinum, 1-3 parts of water-soluble azone and 100-120 parts of natural hydrosol or flower water. The preparation method comprises the following steps: obtaining an intermediate product solution A; obtaining an intermediate product solution B on the basis of the intermediate product solution A; obtaining an intermediate product solution C on the basis of the intermediate product solution B; and finally, adding the residual raw materials into the intermediate product solution C, pouring the obtained materials into a mold for molding, drying at the temperature of 50 DEG C, thereby obtaining the collagen polypeptide peeling mask. The invention also discloses a preparation method of the collagen polypeptide peeling mask.

Owner:吴雪琴

Hangover-alleviating tablet and preparation method thereof

InactiveCN107510798AEasy dischargePromote decompositionHydrolysed protein ingredientsClimate change adaptationCelluloseDiabetes mellitus

The invention discloses a hangover-alleviating tablet and a preparation method thereof, which belongs to the field of hangover-alleviating tablets. The hangover-alleviating tablet is prepared from the following components in parts by weight: 20 to 30 parts of corn oligopeptide, 18 to 25 parts of radix puerariae, 8 to 12 parts of rhizoma curcumae longae, 10 to 15 parts of fermented soybean powder, 8 to 10 parts of black pepper powder, 6 to 8 parts of ground black pepper, 6 to 8 parts of sorbitol, 4 to 6 parts of xylitol, 4 to 6 parts of sucralose, 0.1 to 0.3 part of edible essence, 1 to 3 parts of microcrystal cellulose, and 0.5 to 1 part of magnesium stearate. The preparation method comprises the following steps: preparing raw materials, drying, crushing, mixing, granulating, tabletting, and the like. The hangover-alleviating tablet has excellent hangover-alleviating efficacy, but also can prevent fatty liver, cardiovascular disease, hypertension and diabetes caused by alcohol, and has efficacies for resisting allergies, alleviating the pain of alcohol allergic patients and alleviating the unfavorable symptoms caused by the alcohol.

Owner:HUNAN KANG QI YI BAI BIOLOGICAL TECH CO LTD

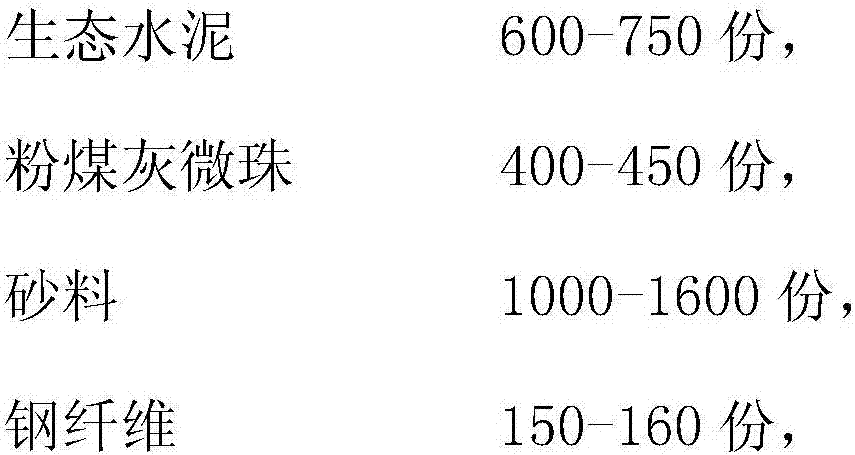

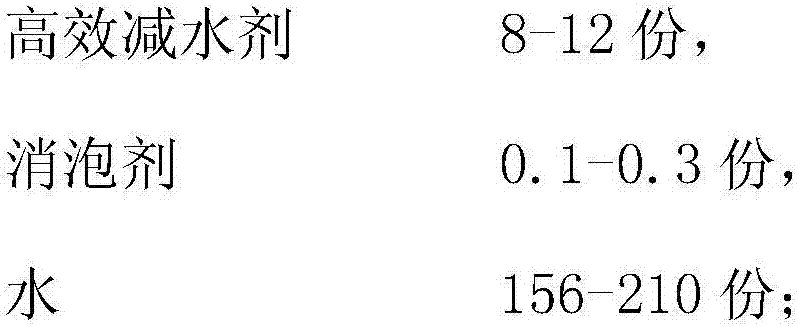

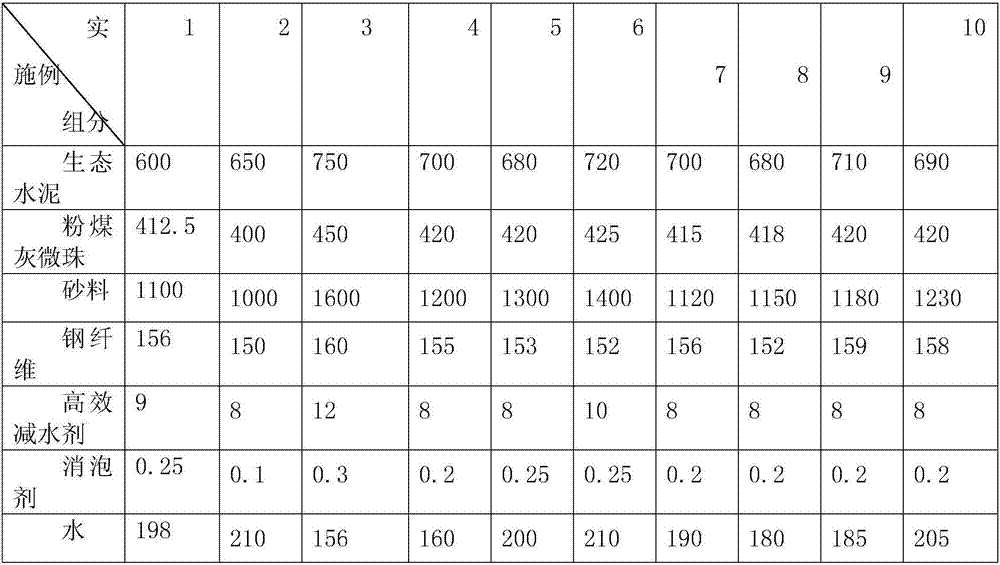

Eco-concrete with compressive strength of 120-200 MPa and preparation method thereof

InactiveCN107500574AImprove performanceHigh strengthSolid waste managementCement productionFiberAlkaline earth metal

The invention discloses eco-concrete with compressive strength of 120-200 MPa and a preparation method thereof. The eco-concrete consists of the following components in parts by weight: 600-750 parts of eco-cement, 400-450 parts of fly ash microspheres, 1000-1600 parts of sand, 150-160 parts of steel fibers, 8-12 parts of a high-efficiency water reducing agent, 0.1-0.3 part of a defoaming agent and 156-210 parts of water. The eco-cement consists of a powder material and an additive, wherein the powder materials is at least one selected from a group consisting grey rock, limestone, volcano ash, volcano pumice, basalt, illite, montmorillonite, feldspar, shale, kaolin, clay, wollastonite, gangue, silica fume and fly ash, and the additive is at least one selected from a group consisting of halides, carbonates, sulfates, alkaline substances of amine, silicates, aluminates, alkali metal hydroxides and alkaline-earth metal hydroxides. The eco-concrete has low costs, is energy saving and environmentally friendly, has easily achievable raw materials, has good fluidity, and is easy for construction.

Owner:CHONGQING LONGZHE HIGH TECH MATERIAL

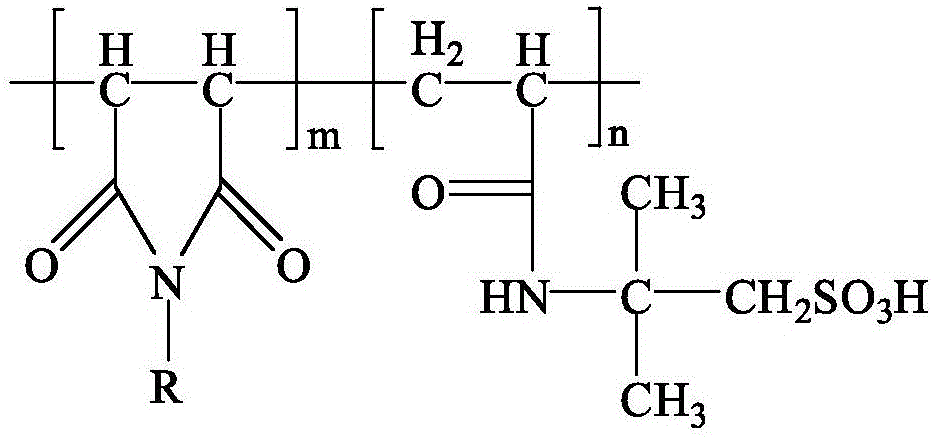

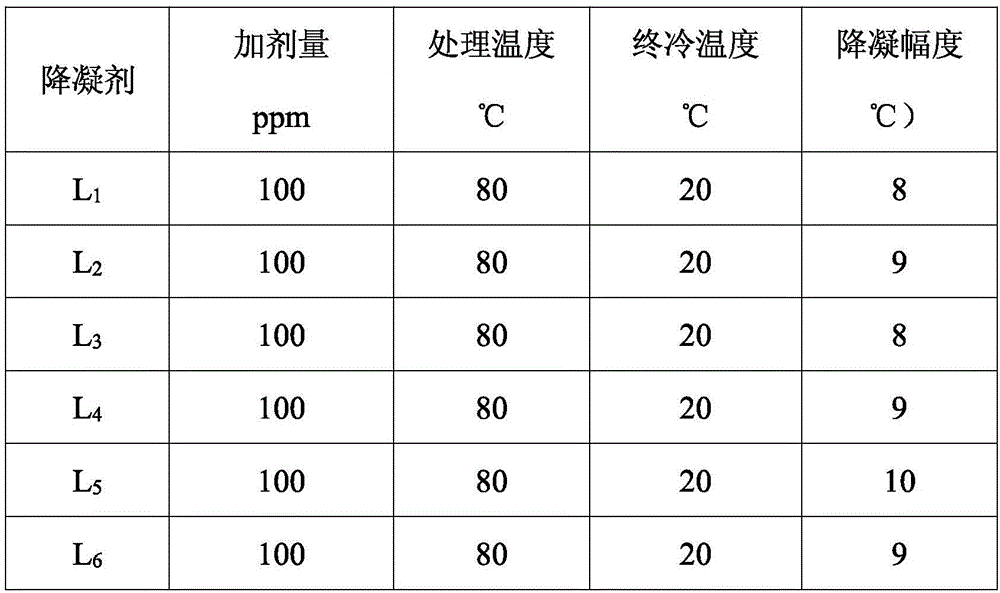

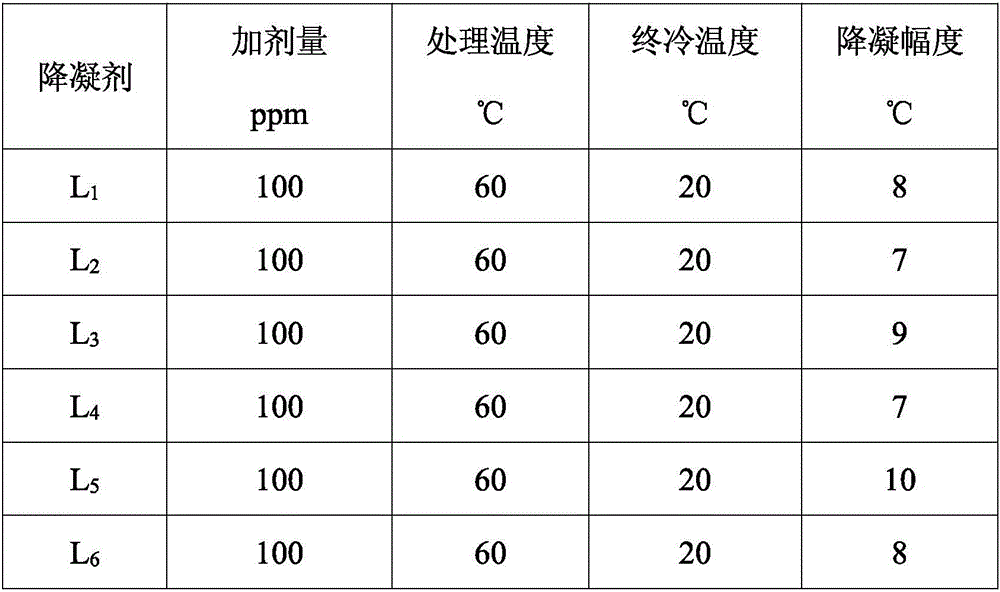

High-wax thick oil pour point depressant and preparation method thereof

ActiveCN106367055AHigh electronegativityPrevent Mutual AgglomerationDrilling compositionSalt resistanceWax

The invention discloses a high-wax thick oil pour point depressant and a preparation method thereof, and belongs to the field of polymer material preparation. The pour point depressant is formed by copolymerizing maleic anhydride and 2-acrylamido-2-methylpropanesulfonic acid according to a molar ratio of 1:0.01-1, and has a molecular weight of 3000-100000 g / mol. The pour point depressant has good temperature and salt resistance, the resisting temperature reaches 140 DEG C, and the resisting salinity reaches 200000 mg / L; and the pour point depressant also has a good pour point depression effect, and can reduce the freezing point of thick oil with the wax content of 30-40% by 6 DEG C or above. The pour point depressant can be widely applied to pour point depression of high-wax thick oil wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ginger-containing dealcoholic instant drink and preparation method thereof

The invention provides ginger-containing dealcoholic instant drink. The ginger-containing dealcoholic instant drink is prepared from the following six raw materials and ingredient in parts by weight: 20-40 parts of ginger, 20-40 parts of hawthorn, 5-10 parts of dried tangerine or orange peel, 10-15 parts of flower of kudzuvine, 2-4 parts of pseudo ginseng and1-2 parts of ginseng and 10-20 parts of green tea ingredient. The dealcoholic instant drink provided by the invention is in pure natural raw material composition, contains no chemical antiseptic agent, has dealcoholic and liver protectingeffects and also has the characteristics of fast dealcoholic speed and wide suited crowd.

Owner:ANHUI PROVINCE TIANXU TEA

Application of melia azedarach leaf extract in whitening product

InactiveCN106344456AInhibitory activityHinder formationCosmetic preparationsToilet preparationsAlcoholFreeze-drying

The invention provides application of melia azedarach leaf extract in a whitening product. A preparation method of the melia azedarach leaf extract comprises the following steps: smashing melia azedarach leaves; putting the melia azedarach leaves in a supercritical CO2 extracting device, and extracting for 2 hours, thus obtaining medicine residues; adding 75 percent of alcohol in the medicine residues; leaching twice under 60 DEG C; merging leaching solutions; carrying out vacuum concentration and freeze drying, thus obtaining the melia azedarach leaf extract. The melia azedarach leaf extract provided by the invention contains whitening active ingredients, is capable of obviously inhibiting the activity of tyrosinase and hindering the formation of melanin, is safe in source, and has very good whitening development application value.

Owner:广东真丽斯化妆品有限公司

Pore refining cleansing water and preparation method thereof

InactiveCN105816373AGood effectRemarkable effect of refining poresCosmetic preparationsMake-upIrritationHamamelis virginiana

The invention provides pore refining cleansing water. The pore refining cleansing water is prepared from the following raw material components in percent by weight: 5 to 20 percent of polyoxyethylenesorbitol monolaurate, 5 to 20 percent of a moisturizer, 2 to 5 percent of compound fruit acid, 0.5 to 2 percent of a witch hazel extract, 0.5 to 1 percent of a peppermint extract, 1 to 3 percent of a sweet birch leaf extract, 0.2 to 1 percent of a licorice extract, 0.2 to 1 percent of a mulberry extract, 0.2 to 1 percent of phenoxyethanol, 0.02 to 0.16 percent of sodium citrate and the balance of deionized water. The cleansing water comprises four components that are the compound fruit acid, the witch hazel extract, the peppermint extract and the sweet birch leaf extract with pore refining effect, the four components matched at an optimum mixture ratio for use has better efficacy than single component which is individually used, the pore refining effect is very obvious, and the cleansing water is thorough in cleansing, does not has residue, irritation and oily feel, can effectively prevent skin from aging, preserves moisture, tenders skin, and unclogs pores; meanwhile the invention further provides a preparation method of the cleansing water.

Owner:CANTON DAMEKISS DAILY CHEM FACTORY LIMITED

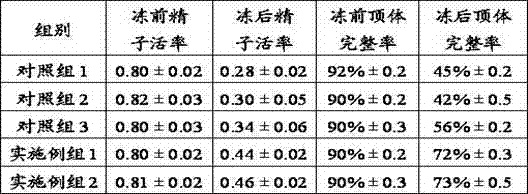

Frozen semen diluent of equus animals and preparation method thereof

The invention discloses a frozen semen diluent of equus animals and a preparation method thereof. The diluent at least comprises a basic solution prepared from the following raw materials: D-lactose monohydrate, prostaglandin, EDTA (Ethylene Diamine Tetraacetic Acid), a bee pollen aqueous solution, hyaluronic acid and squalane. The diluent also comprises egg yolk liquid, glycerin, penicillin and streptomycin. The preparation method comprises the following steps: (1) preparing the bee pollen aqueous solution; (2) preparing the basic solution; (3) adding the egg yolk liquid, the glycerin, the penicillin and / or the streptomycin. By adopting the technical scheme, the preparation method disclosed by the invention has the benefits that the bee pollen aqueous solution, the hyaluronic acid, the squalane and the like are creatively combined for preparation of the frozen semen diluent of the equus animals to ensure that the forming of large ice crystals in semen freezing process is prevented to the maximum limit, so that the damage of ice crystallization to semen is avoided, the survival rate and the acrosome intact rate of frozen semen are remarkably increased, the quality of the frozen semen is further improved and the freezing tolerance of spermatid is increased.

Owner:ILI RUIDE JUNFA BIOTECH +2

Method for preparing base of vertical annealing furnace

ActiveCN102489669AGood spherical effectReduce white mouth tendencyFoundry mouldsFoundry coresCompressive strengthLost-foam casting

The invention discloses a method for preparing a base of a vertical annealing furnace. The method provided by the invention is characterized in that a lost foam casting technology is adopted; molten iron is injected into a mold from the bottom to form a casting; a pour-over spheroidizing technology is adopted; and a spheroidizing inoculation technology is adopted. The base obtained by the method has advantages of good mechanical properties, good flexibility, high tensile strength, high compression strength, low rejection rate, high heat resistance, high fatigue resistance, and large elongation.

Owner:SICHUAN CHUANJIAN PIPES

Multifunctional health-care beverage and preparation method thereof

InactiveCN110012990AKeep natural activityReduce absorptionMicroorganism based processesVinegar preparationMaterials preparationAlcohol

The invention discloses a multifunctional health-care beverage. The beverage is prepared from the following raw materials in parts by weight: 10-40 parts of kudzuvine roots, 2-5 parts of raisin tree seed extract, 2-5 parts of perilla extract, 10-15 parts of hawthorn fruits, 17-23 parts of Chinese wolfberry fruits, 12-17 parts of stevia and 1-3 parts of cassia seeds. The preparation method of the beverage comprises the following steps: (1) material preparation; (2) raw material pretreatment; (3) mixing; (4) enzymolysis; (5) alcohol fermentation; (6) vinegar fermentation; (7) separating; (8) spraying; (9) ageing; (10) filtration; (11) blending; (12) homogenization; (13) fine filtration; (14) sterilization; and (15) filling. The multifunctional health-care beverage has the effects of relieving hangover, protecting liver, nourishing stomach, reducing blood sugar, reducing blood fat and the like, the natural activity of the preparation raw materials is kept in the preparation process, and the production method is simple, short in cycle and low in labor intensity.

Owner:湖南安顺生物科技有限公司

Aluminum plated steel plate having excellent coating performance and used in hot formed part, manufacturing method thereof and hot formed part

ActiveCN111575622AInhibition formationImprove adhesionHot-dipping/immersion processesElectrophoretic coatingsCrazingAlclad

The invention discloses an aluminum plated steel plate having excellent coating performance and used in a hot formed part, a manufacturing method thereof and a hot formed part. The manufacturing method comprises the following steps of cold rolled strip steel washing, continuous annealing, hot dip coating, plating thickness control, alloying, cooling and oil coating. A plating solution used by hotdip coating comprises, by weight percentage, 3.0-6.0% of Si, total content 0.5-2.5% of one or more of Sn, Cu and Mo, and the rest Al and inevitable impurity. The aluminum plated steel plate is used for manufacturing the hot formed part, the uneven paint appearance caused by micro-crack forming is eliminated, and the later corrosion resistance of the paint is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

High-performance geopolymer concrete and preparation method thereof

PendingCN113998929AHinder formationInhibition of autogenous shrinkageCement productionGeopolymerPolymer concrete

The invention discloses a high-performance geopolymer concrete and a preparation method thereof. The geopolymer concrete is prepared from, by mass, 1550 to 1600 parts of mineral powder, 155 to 165 parts of silica fume, 250 to 270 parts of fly ash, 500 to 1200 parts of fine aggregate, 200 to 800 parts of ceramic ball aggregate, 867 to 892 parts of an exciting agent, 78 to 234 parts of fiber, 20 to 24 parts of a water reducing agent and 0 to 109 parts of water. Ceramic balls and the steel fibers are co-doped into the geopolymer concrete, the fibers can effectively hinder the formation of microcracks in the concrete and significantly improve the tensile strength, bending resistance and impact resistance of the concrete, and the ceramic ball aggregate can inhibit the self-constriction phenomenon of the geopolymer concrete and promote the performance of good volume stability and durability, high hardness and small density of the concrete, and is compounded with other raw materials of the concrete to effectively improve the defects of self-constriction and high brittleness of the existing geopolymer concrete.

Owner:GUANGZHOU UNIVERSITY

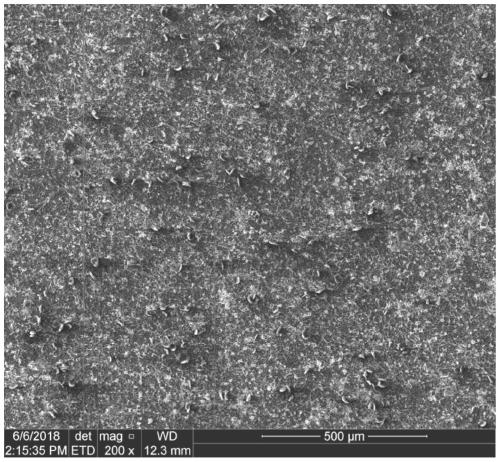

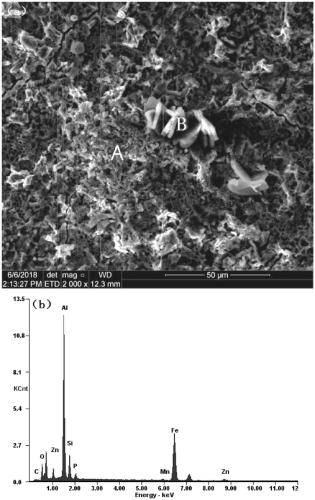

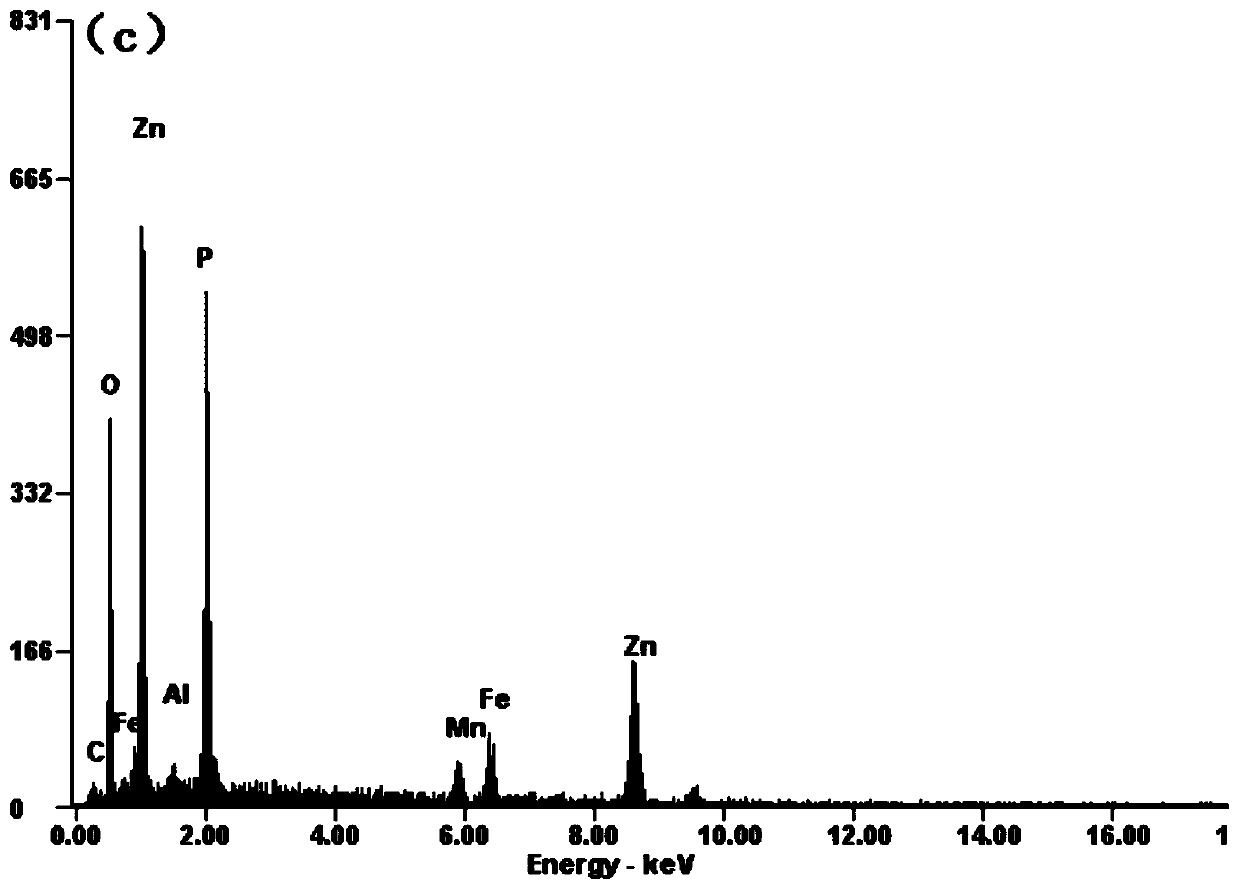

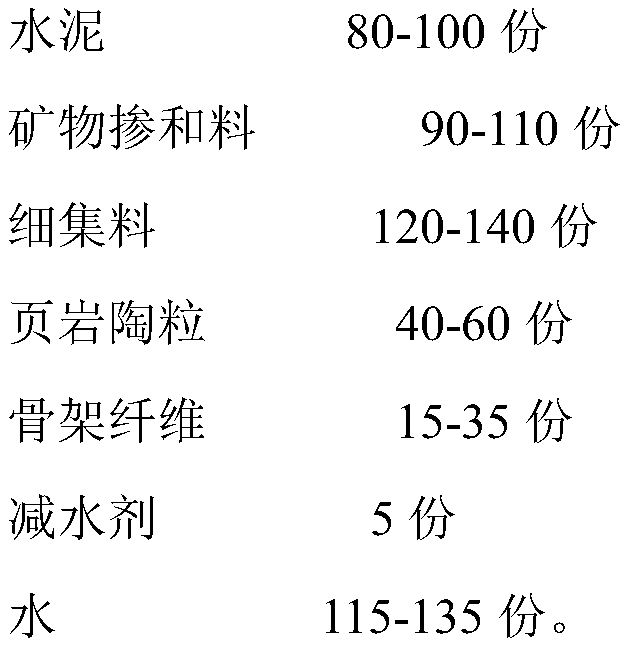

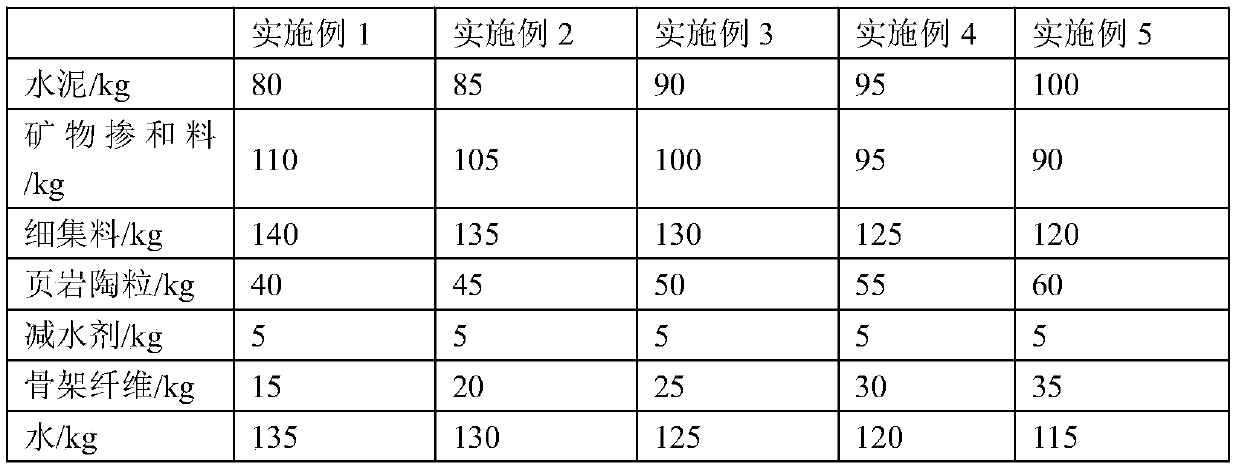

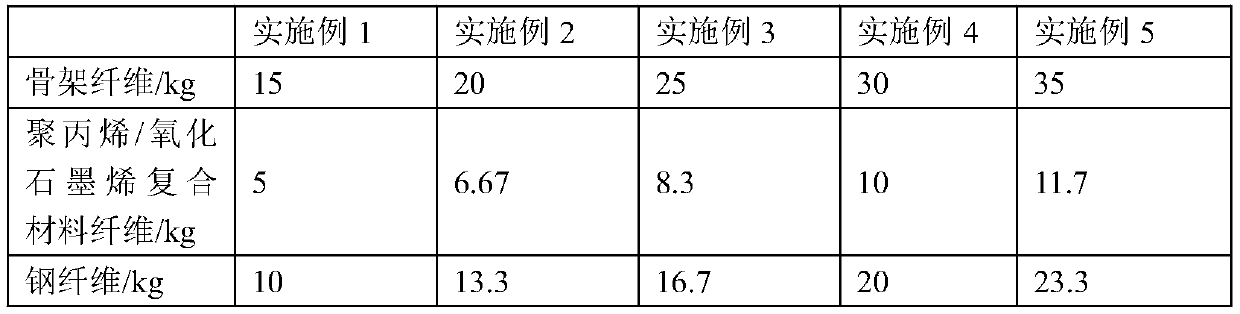

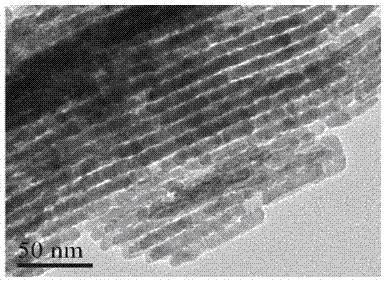

High-strength light aggregate concrete and preparation process thereof

InactiveCN110937861AHigh compressive strengthLightweight and high strengthAggregate (composite)Oxide composite

The invention discloses high-strength light aggregate concrete and a preparation process thereof. The high-strength light aggregate concrete comprises cement, a mineral admixture, fine aggregate, shale ceramsite, skeleton fibers, a water reducing agent and water, wherein the skeleton fibers comprise polypropylene / graphene oxide composite material fibers and steel fibers, the strength of the concrete can be improved by doping the skeleton fibers in the concrete, and the concrete is more stable in performance and not prone to cracking in the using process. The preparation process disclosed by the invention comprises the following steps: preparing polypropylene / graphene oxide composite material fibers, preparing skeleton fibers and blending the components. According to the preparation processdisclosed by the invention, the polypropylene / graphene oxide composite material fibers which are uniformly mixed and stable in performance can be prepared, and the polypropylene / graphene oxide composite material fibers and the steel fibers are uniformly dispersed in the concrete, so that the stability of the concrete is improved.

Owner:泸州临港思源混凝土有限公司

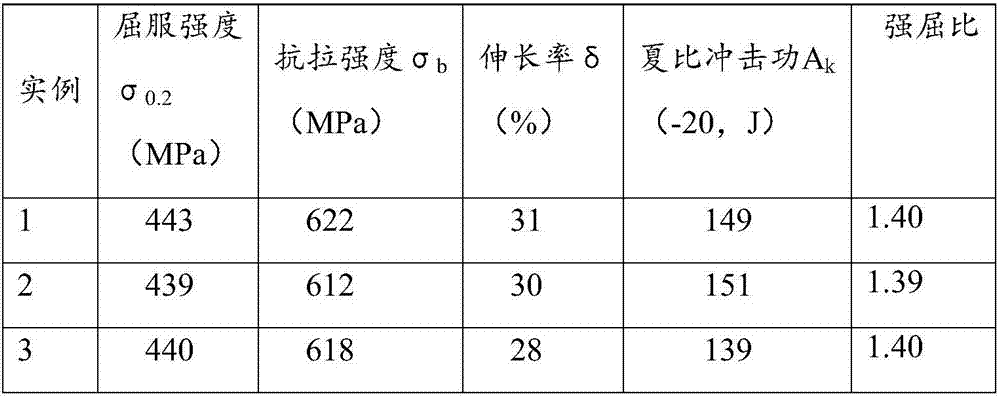

Rare earth microalloyed anti-seismic and hot-rolled H-shaped steel and preparation method of H-shaped steel

The invention discloses a preparation method of a rare earth microalloyed shock-resistant hot-rolled H-shaped steel, which includes: during the smelting process of the converter, controlling the w[S] of the molten iron in the converter to be ≤ 0.009%, increasing the tapping temperature of the converter to about 1600°C, Control the amount of slag in the converter; extend the refining time of the LF furnace during the LF refining process; during the VD vacuum refining process, the argon blowing time of the VD furnace should not be less than 10 minutes; the casting speed range of the continuous casting machine is 0.80m / min~0.9m / min, The superheat degree of the steel type is less than 25°C; in the rolling process, the heating temperature is 1210-1250°C, the starting rolling temperature is ≤1200°C, and the final rolling temperature is 870-890°C to obtain H-shaped steel. The invention also discloses a rare earth micro-alloyed shock-resistant hot-rolled H-shaped steel. The invention adopts the narrow component design, and the obtained H-shaped steel can meet the requirements of the yield strength and tensile strength of the shock-resistant hot-rolled H-shaped steel.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

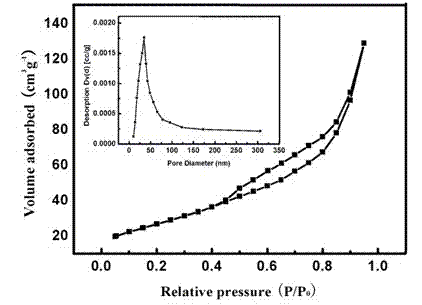

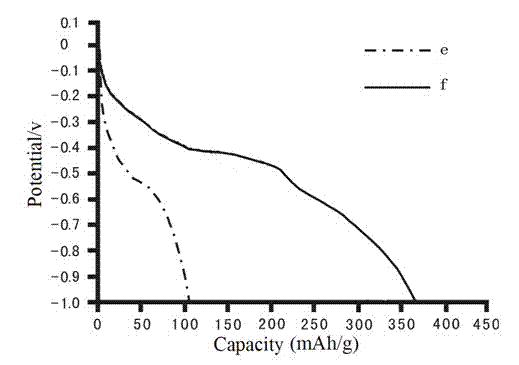

Preparation method of cathode material for high-power alkaline manganese battery

ActiveCN102364730AImprove deep discharge capabilityIncrease profitCell electrodesElectrical batteryManganese

The invention relates to a preparation method of a cathode material for a high-power alkaline manganese battery. The preparation method comprises the following steps of: dissolving a manganese salt solution, a bismuth salt solution and a template agent in water by using inorganic manganese salt as a raw material, mesoporous silicon dioxide as the template agent and bismuth salt as a doping agent, uniformly mixing, attaching the manganese salt onto a template by a liquid phase immersion method, and drying the solution; and calcining to ensure that the manganese salt is subjected to an oxidation reduction reaction to generate bismuth-doped mesoporous manganese dioxide, removing the template by using a sodium hydroxide solution, filtering for separation, washing by using distilled water, precipitating, drying, and thus obtaining a bismuth-doped mesoporous manganese dioxide electrode material. The bismuth-doped mesoporous manganese dioxide electrode material prepared by the method is used as the cathode material for the high-power alkaline manganese battery and has a discharging property which is much more than the property of the conventional manganese dioxide, so that the utilization rate of an active ingredient in the cathode material of the alkaline manganese battery is greatly improved.

Owner:武汉格罗夫新能源汽车研究院有限公司

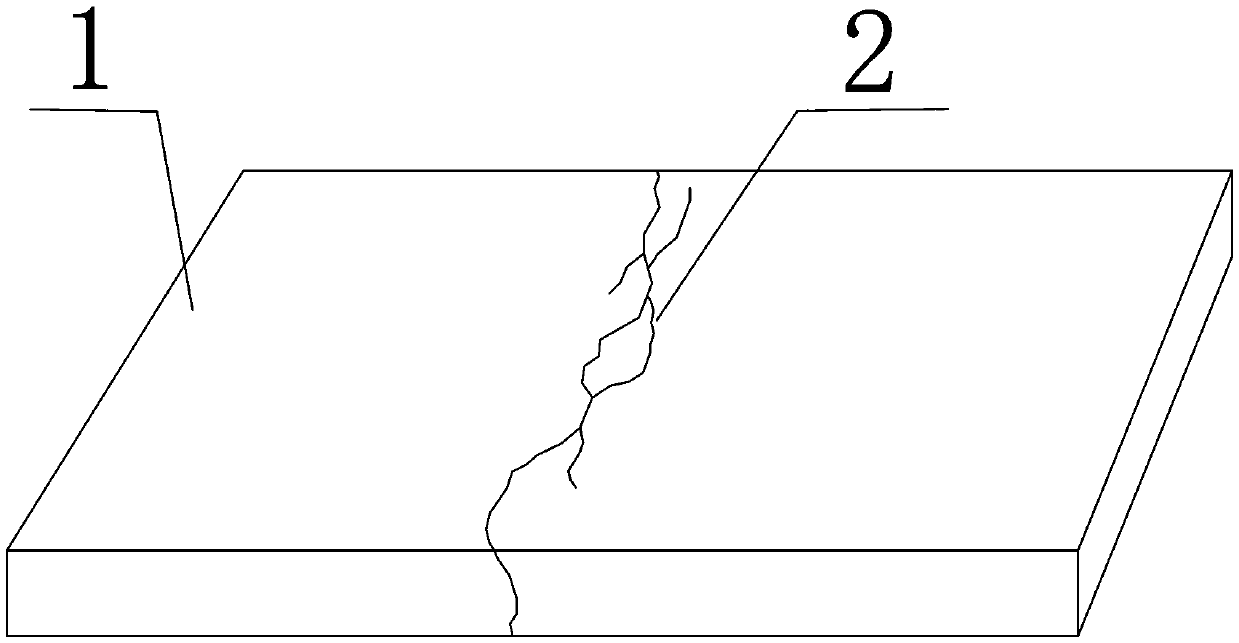

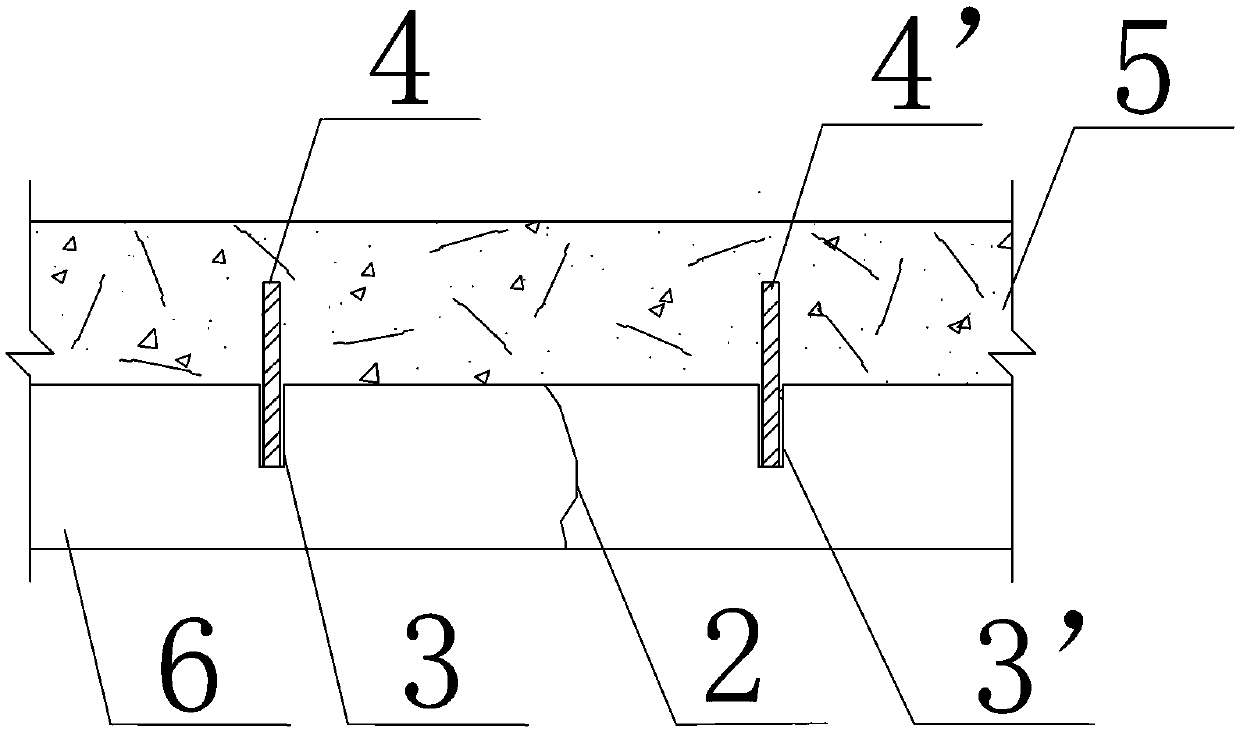

Restoration structure and method for damaged concrete pavement panel

InactiveCN105507111AImprove wear resistanceImprove bending resistanceIn situ pavingsPaving detailsRestoration methodRoad surface

The invention provides a restoration structure and method for a damaged concrete pavement panel. The restoration structure for the damaged concrete pavement panel comprises the concrete pavement panel with the planed surface, multiple pairs of rebar embedding holes, rebars and a steel fiber reinforced concrete cover. The rebar embedding holes are formed in the two sides of a broken slab crack in pairs and distributed in the extension direction of the broken slab crack. The rebars are vertically inserted and fixed into the rebar embedding holes in a binding mode. The steel fiber concrete cover is poured and fixed to the concrete pavement panel. The restoration method for the damaged concrete pavement panel includes the steps that 1, planing is conducted; 2, the multiple pairs of rebar embedding holes are drilled; 3, construction glue is poured into the rebar embedding holes, and the rebars are vertically embedded; 4, steel fiber reinforced concrete is poured to form the steel fiber reinforced concrete cover, and finally the restoration structure for the damaged concrete pavement panel is formed. According to the restoration structure and method for the damaged concrete pavement panel, the service life and the maintenance period of a road are prolonged, and meanwhile the long-term use cost is reduced.

Owner:ZHENGZHOU UNIV

Preparation of novel environment-friendly efficient gas hydrate inhibitor and application thereof

ActiveCN111057529AHas nucleationUniform and stable slurryPipeline systemsDrilling compositionActive agentPyrrolidinones

The invention relates to the technical field of oil and gas production, in particular to preparation of a novel environment-friendly efficient gas hydrate inhibitor and an application thereof. The novel environment-friendly efficient gas hydrate inhibitor is prepared from a 2-vinylpyridine-N-vinyl-2-pyrrolidone copolymer with the mass concentration of 0.6 percent to 1.0 percent, a nonionic surfactant with the mass concentration of 1.8% to 3.4%, glycol ethers with the mass concentration of 4.1% to 5.8%, a water-soluble monomer with the mass concentration of 2.4% to 4.2% and the balance deionized water. The preparation method of the inhibitor comprises the following steps: oil phase preparation, water phase preparation, mixed reaction and the like. The inhibitor prepared by the invention hasa good inhibition effect, can effectively inhibit hydrate nucleation, enables the generated hydrate to be in a uniform and stable slurry state, disenables a hydrate aggregation phenomenon, has the advantages of low toxicity, no volatilization, easy degradation, environmental friendliness and the like, and has a good application prospect.

Owner:郑州洁灵科技有限公司

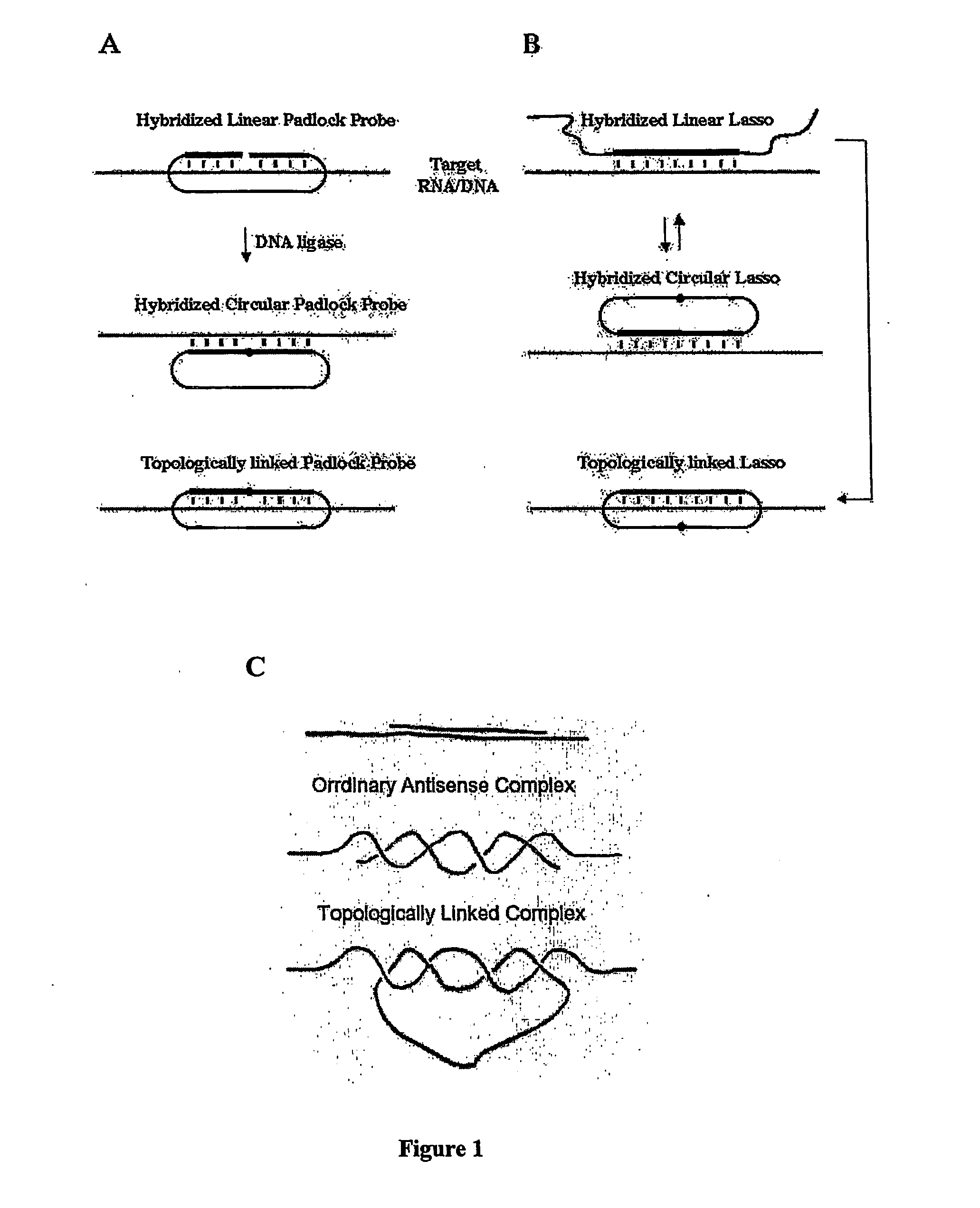

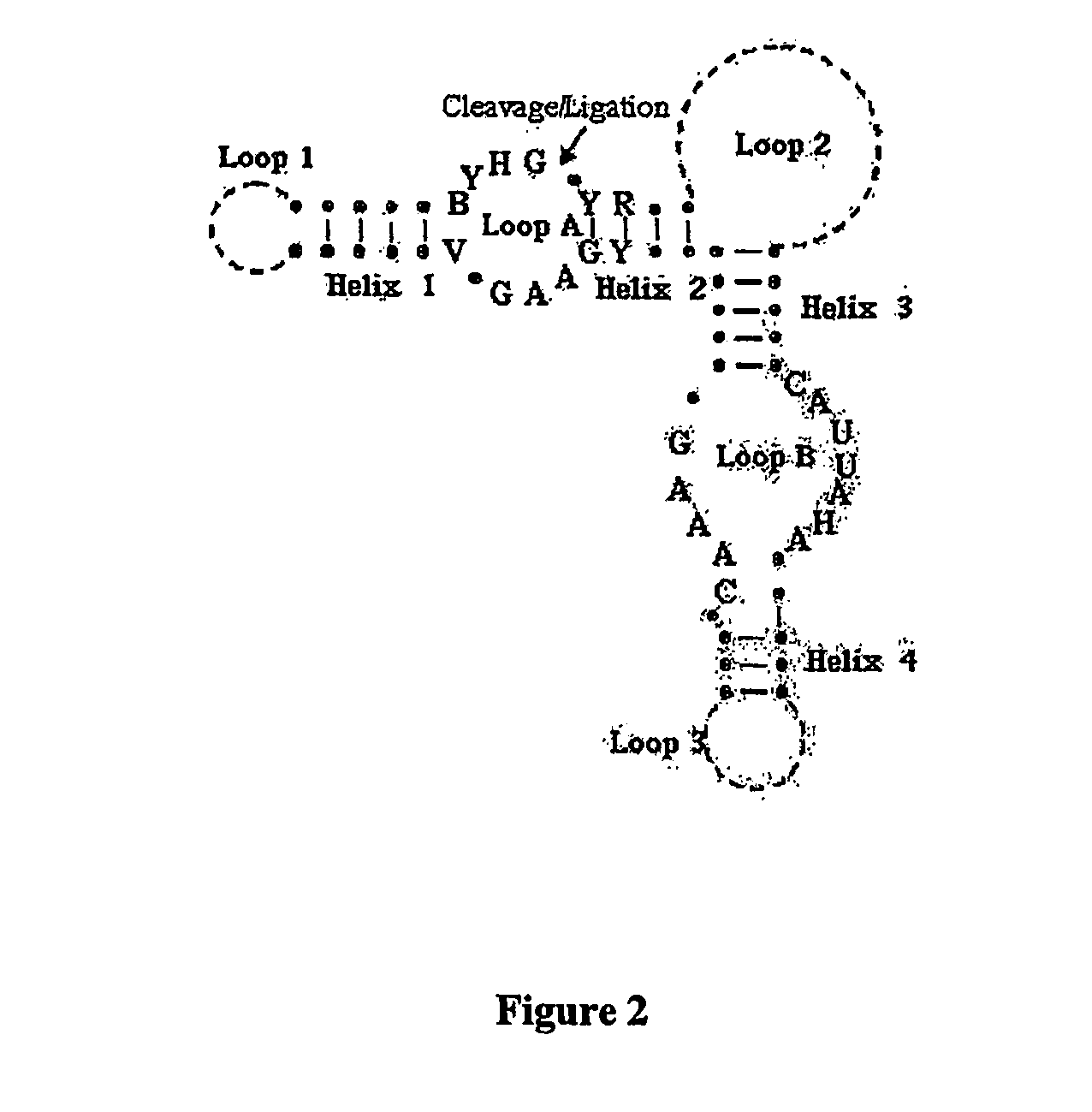

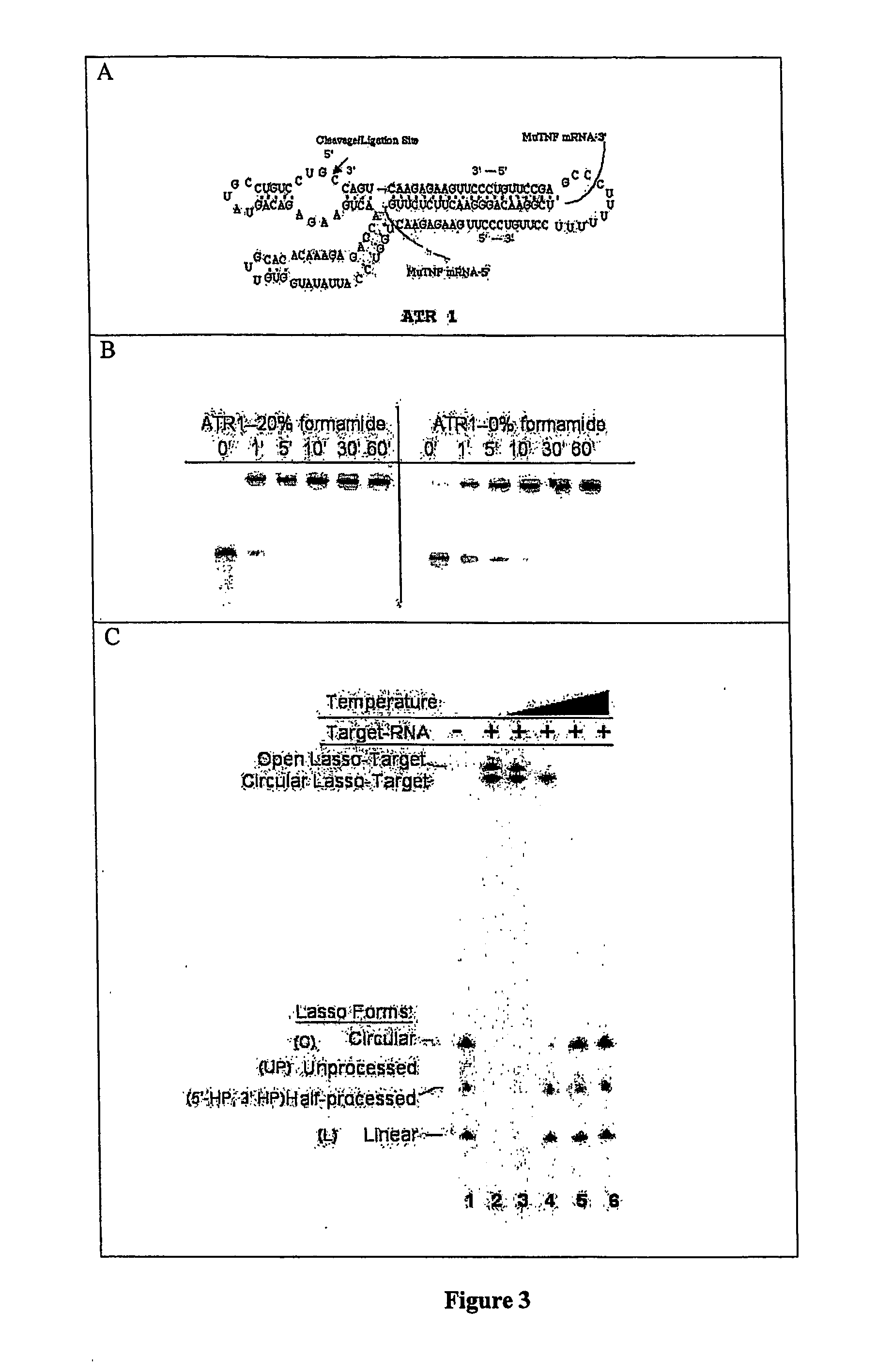

Polynucleotides capable of target-depedent circularization and topological linkage

InactiveUS20070105108A1Hinder formationStrong specificitySugar derivativesMicrobiological testing/measurementNucleotidePolynucleotide

The invention provides allosterically regulatable polynucleotides capable of target-dependent circularization and topological linkage to a target nucleic acid molecule. Polynucleotides of the invention include a target binding sequence and a regulatory element which prevents circularization in the absence of the target binding. Polynucleotides may include a catalytic domain, allowing circularization to proceed via catalysis when the target binding sequence of the polynucleotide is bound to the target. Topologically linked polynucleotides may be used for detection of target molecules or to inhibit transcription or translation of the target.

Owner:SOMAGENICS INC

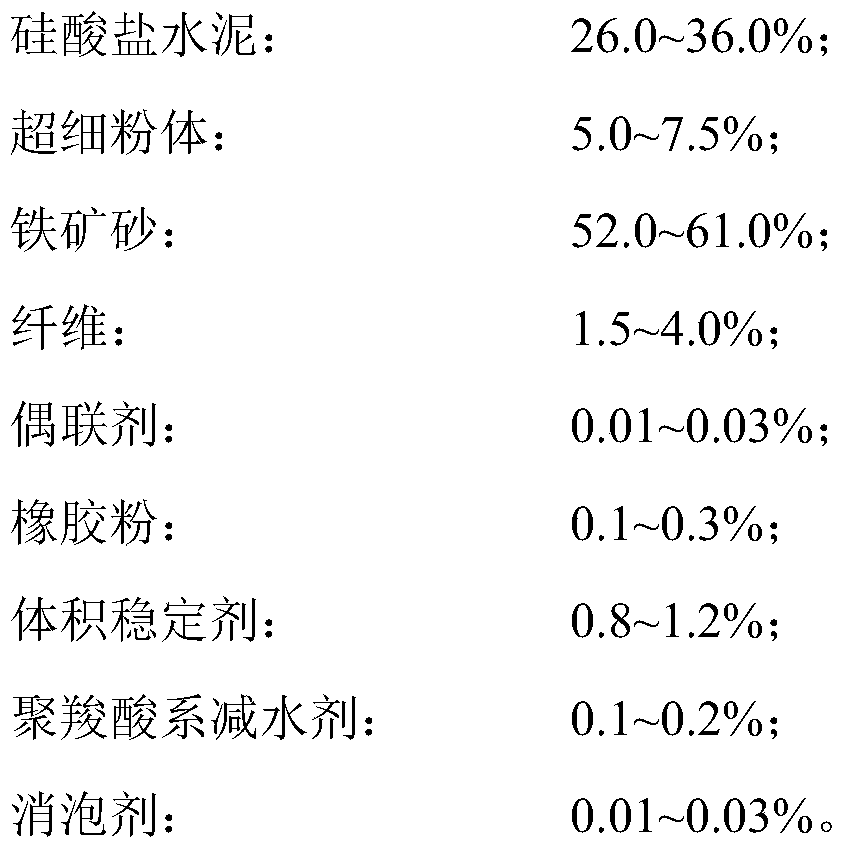

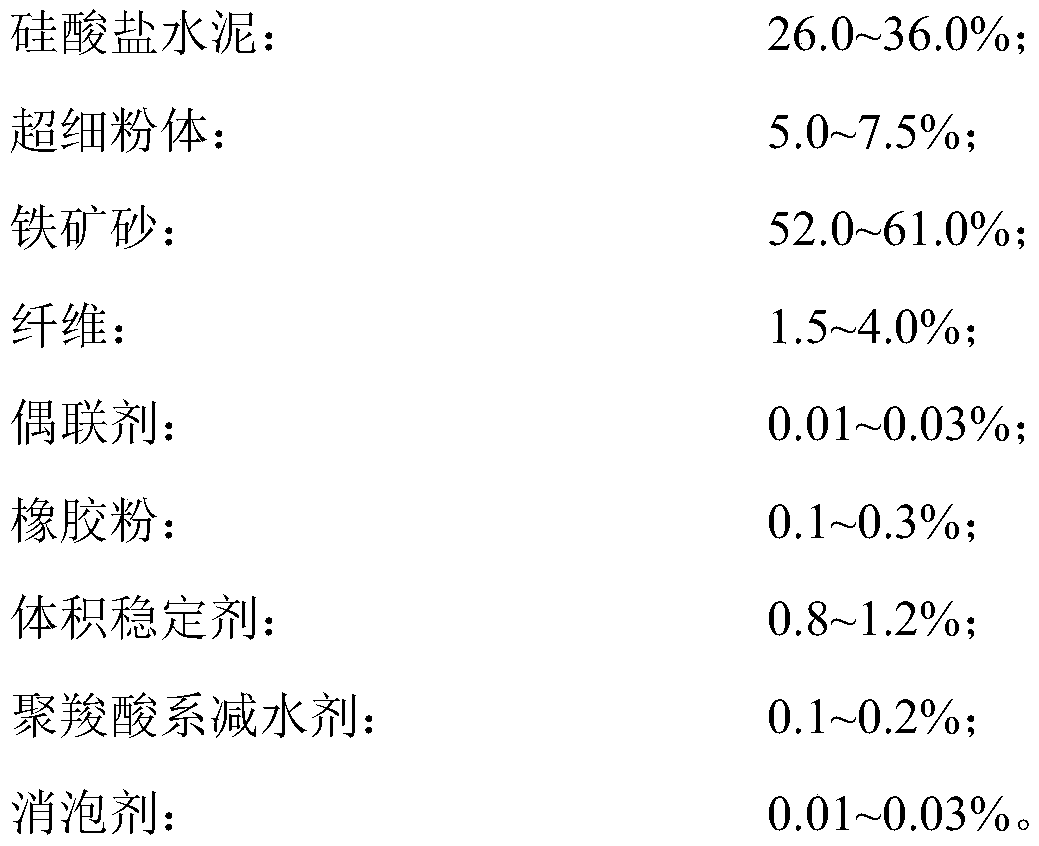

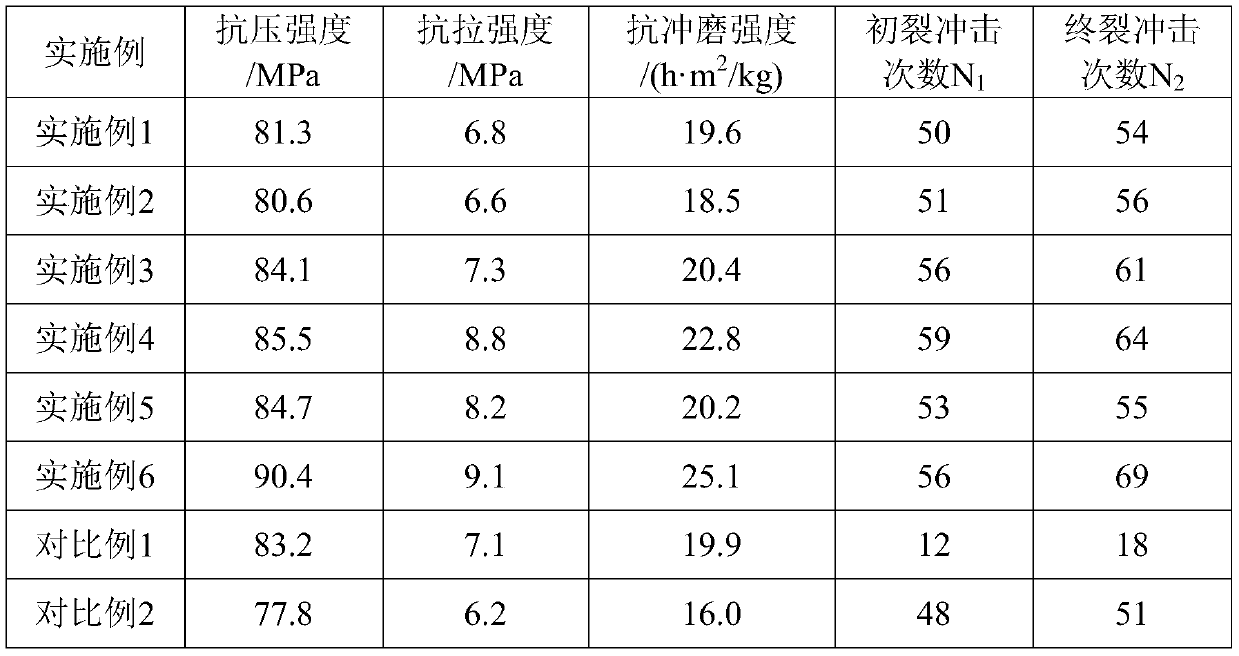

High-toughness impact-resistant and wear-resistant repairing material

The invention provides a high-toughness impact-resistant and wear-resistant repairing material which is mainly prepared from 26.0 to 36.0 percent of portland cement, 5.0 to 7.5 percent of ultrafine powder, 52.0 to 61.0 percent of iron ore, 1.5 to 4.0 percent of fiber, 0.01 to 0.03 percent of a coupling agent, 0.1 to 0.3 percent of rubber powder, 0.8 to 1.2 percent of a volume stabilizer, 0.1 to 0.2 percent of a polycarboxylate water reducing agent, 0.01 to 0.03 percent of a defoaming agent and the like. The high-toughness impact-resistant and wear-resistant repairing material provided by the invention has the advantages of low price, convenient construction, high impact toughness, high impact strength, high bonding strength, low shrinkage and high crack resistance, has a linear expansion coefficient close to that of concrete, cannot fall off from a base material, and can replace organic materials such as epoxy resin mortar and the like.

Owner:安徽瑞和新材料有限公司 +1

Hydrophobic multifunctional snow-melting agent and preparation method thereof

ActiveCN109135674AExtension of timeLowering the freezing pointOther chemical processesSnow meltingRoad surface

The invention discloses a hydrophobic multifunctional snow-melting agent and a preparation method thereof. The hydrophobic multifunctional snow-melting agent comprises a hydrophobic salts composite snow-melting agent, a hydrophobic composite freezing relieving agent and a hydrophobic composite ice layer softening agent according to the mass ratio of 6-7: 1-2: 1-2; the hydrophobic salts composite snow-melting agent is formed by carrying out slow release treatment and hydrophobic treatment on a salts snow-melting agent successively; the hydrophobic composite freezing relieving agent is formed bycarrying out slow release treatment and hydrophobic treatment on a freezing relieving agent successively; and the hydrophobic composite ice layer softening agent is formed by carrying out slow release treatment and hydrophobic treatment on an ice layer softening agent successively. An ice suppressing coating formed on a road surface by coating has various effects of greatly reducing a freezing point, relieving freezing and softening an ice layer.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

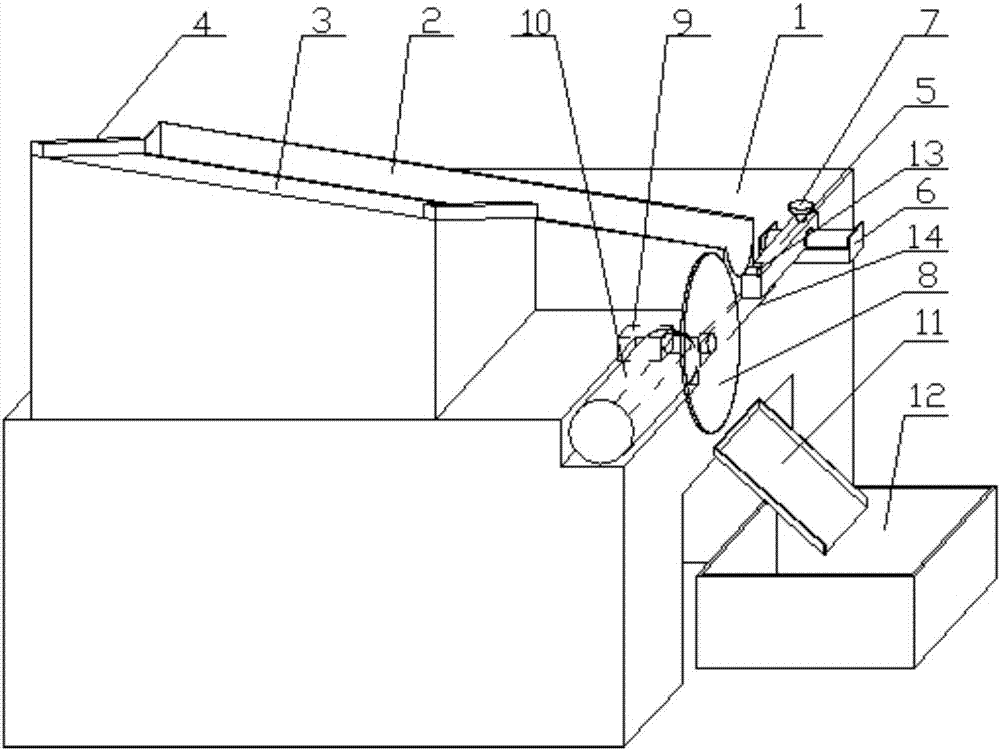

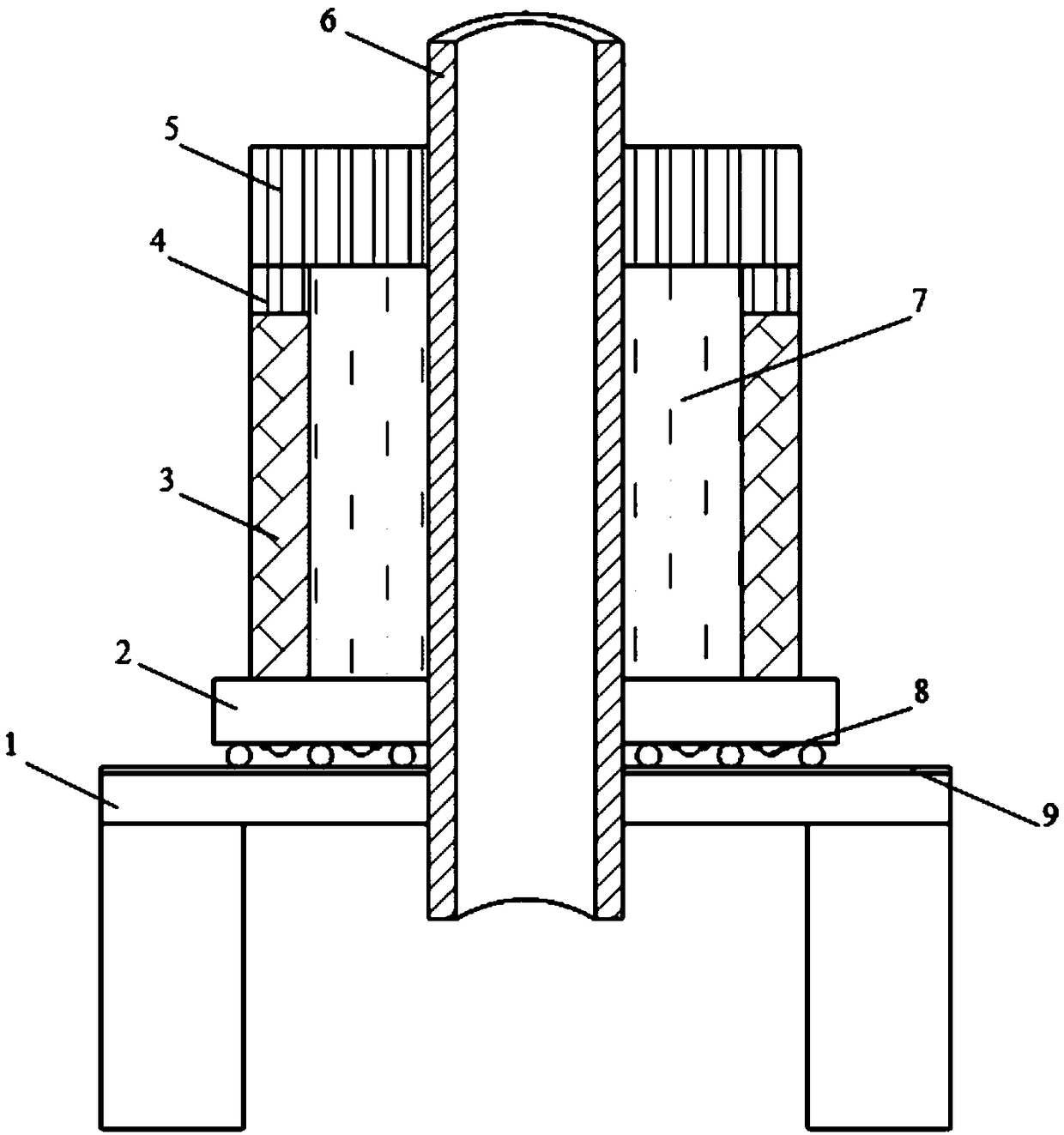

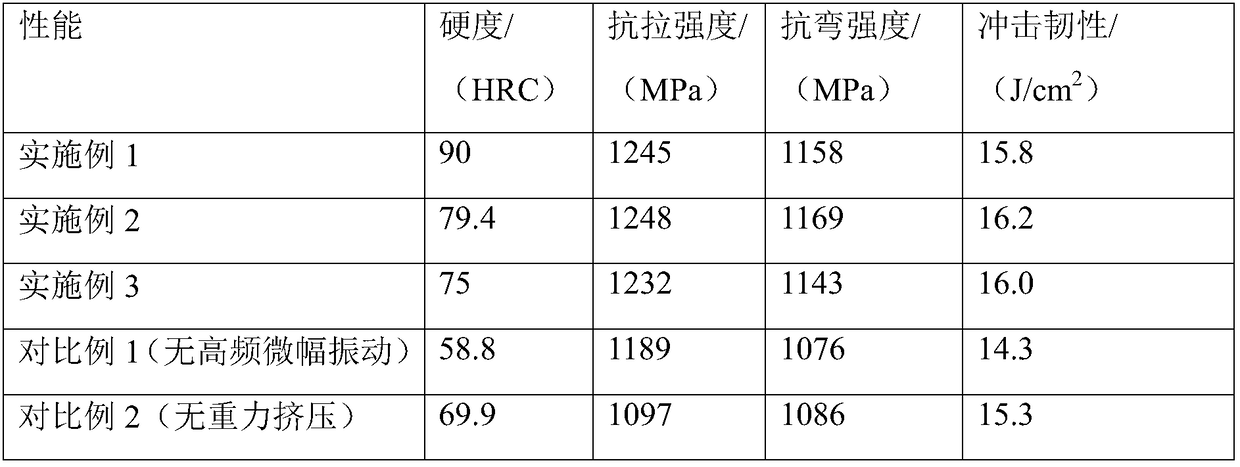

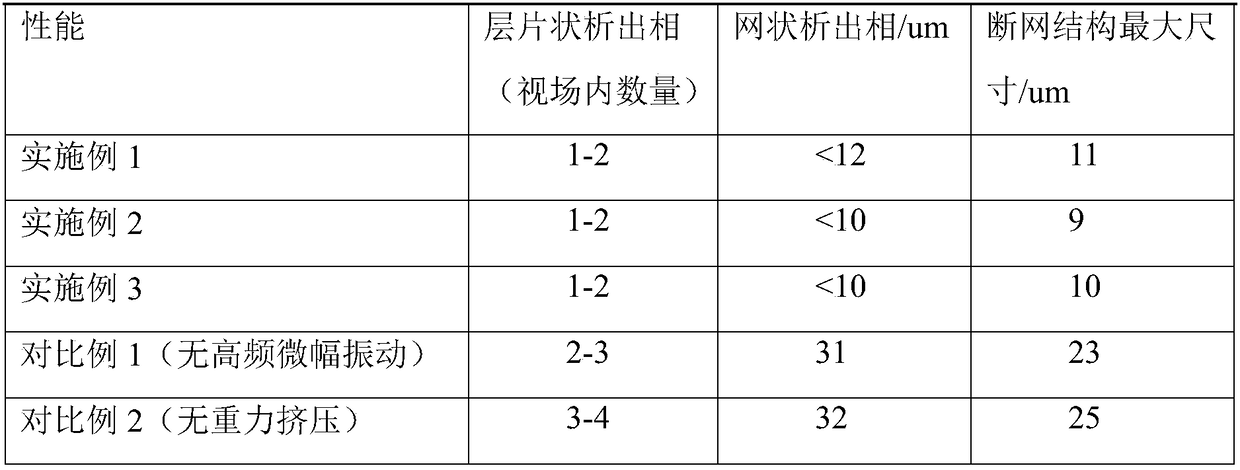

Roller roller-sleeve extrusion and vibration casting production method

The invention provides a roller roller-sleeve extrusion and vibration casting method. The solidification defect is eliminated through vibration in the metal liquid mold filling and solidifying process, inclusion and gas discharging is promoted, and forming of large network carbide is stopped. Meanwhile, distribution of components of a roller sleeve is uniform, and the problem that due to current high-speed steel roller network precipitates, the anti-stripping accident performance is poor is solved. Meanwhile, during metal solidification, pressure is loaded to incompletely or completely solidified metal, metal melt is solidified under the longitudinal pressure, and the solidified metal generates the forging and pressing effect. Compared with traditional static solidification, the density ofa cast and forged piece can be further improved, the problems that shrinkage cavities, loosening and the like are likely to happen to the roller sleeve are solved, and the hardness and abrasion resistance of the roller sleeve are improved. By means of the method, the hardness of the roller sleeve of a roller can reach 75-90 HRC, the density of the roller is improved by 3% or above compared with an ordinary production technology, the metal yield is improved by 15% or above, the service life of the single roller is prolonged by 20% or above, and the production cost is saved.

Owner:JIANGSU UNIV

High-quality hyaluronic acid raw pulp and preparation method thereof

InactiveCN108338945AEffectively helps regeneration abilityAids in regenerationCosmetic preparationsToilet preparationsFungicideYeast

The invention discloses high-quality hyaluronic acid raw pulp and a preparation method thereof. The hyaluronic acid raw pulp comprises, by weight, 55-85% of water phase, 10-30% of yeast, 10-40% of oilphase, 0.1-5% of emulsifier, 0.1-0.2% of preservative, 0.1-0.5% of fungicide, 0.1-1% of additive and 0.1-1% of thickener. The preparation process is simple, the hyaluronic acid raw pulp is convenientto use, safe and reliable, substances harmful to human body are not added, and a large quantity of natural extracts are used so that the use safety can be well ensured, and damage to the human body and skin is reduced; moisture of the skin can be kept, and the hyaluronic acid raw pulp is moist and soft and has the functions of regulating sebum secretion and moisturizing and whitening the skin. The hyaluronic acid raw pulp has the effect of treating cracking, sunburn and acne and can hinder the formation and deposition of pigments in the dermis layer and achieve the effect of whitening the skin and preventing and treating pigment plaques.

Owner:玫研(上海)生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com