Patents

Literature

80results about How to "Reduce white mouth tendency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nodular cast iron inoculant and preparation method thereof and application in smelting nodular cast iron

ActiveCN103484749AIncrease the number of ballsIncrease the number ofTrace element compositionAdhesive

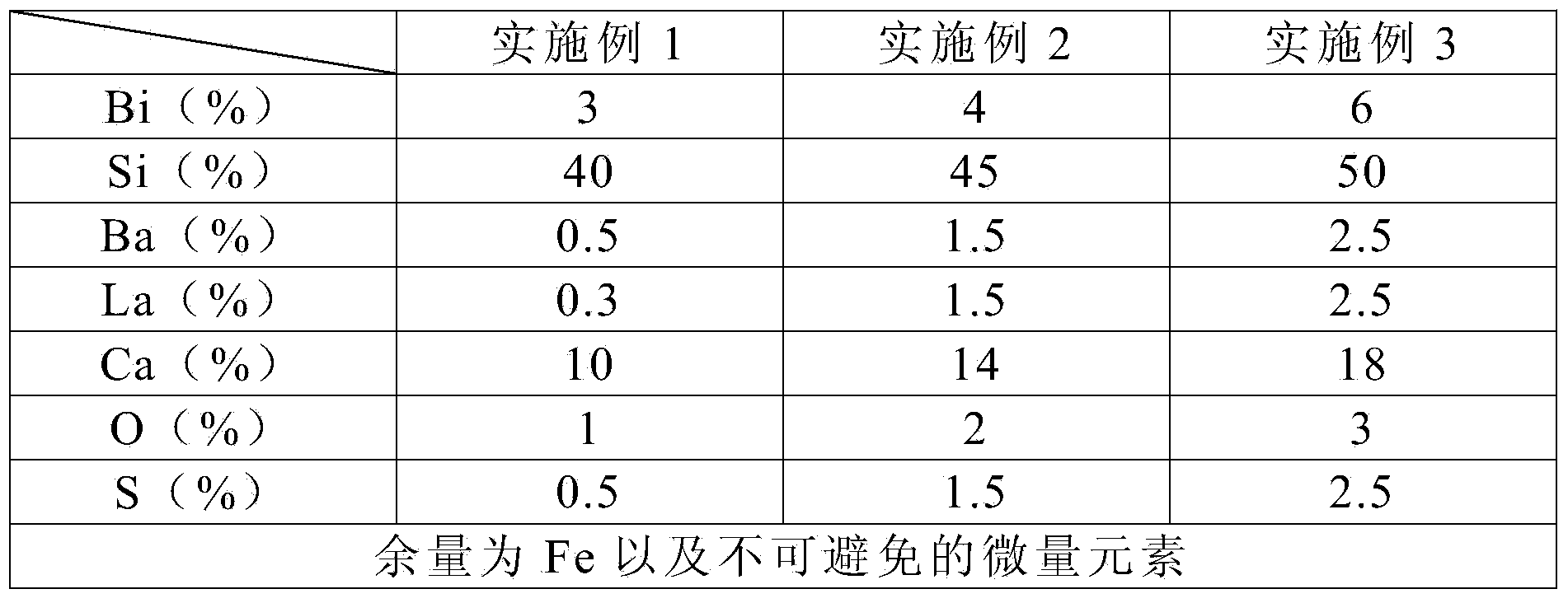

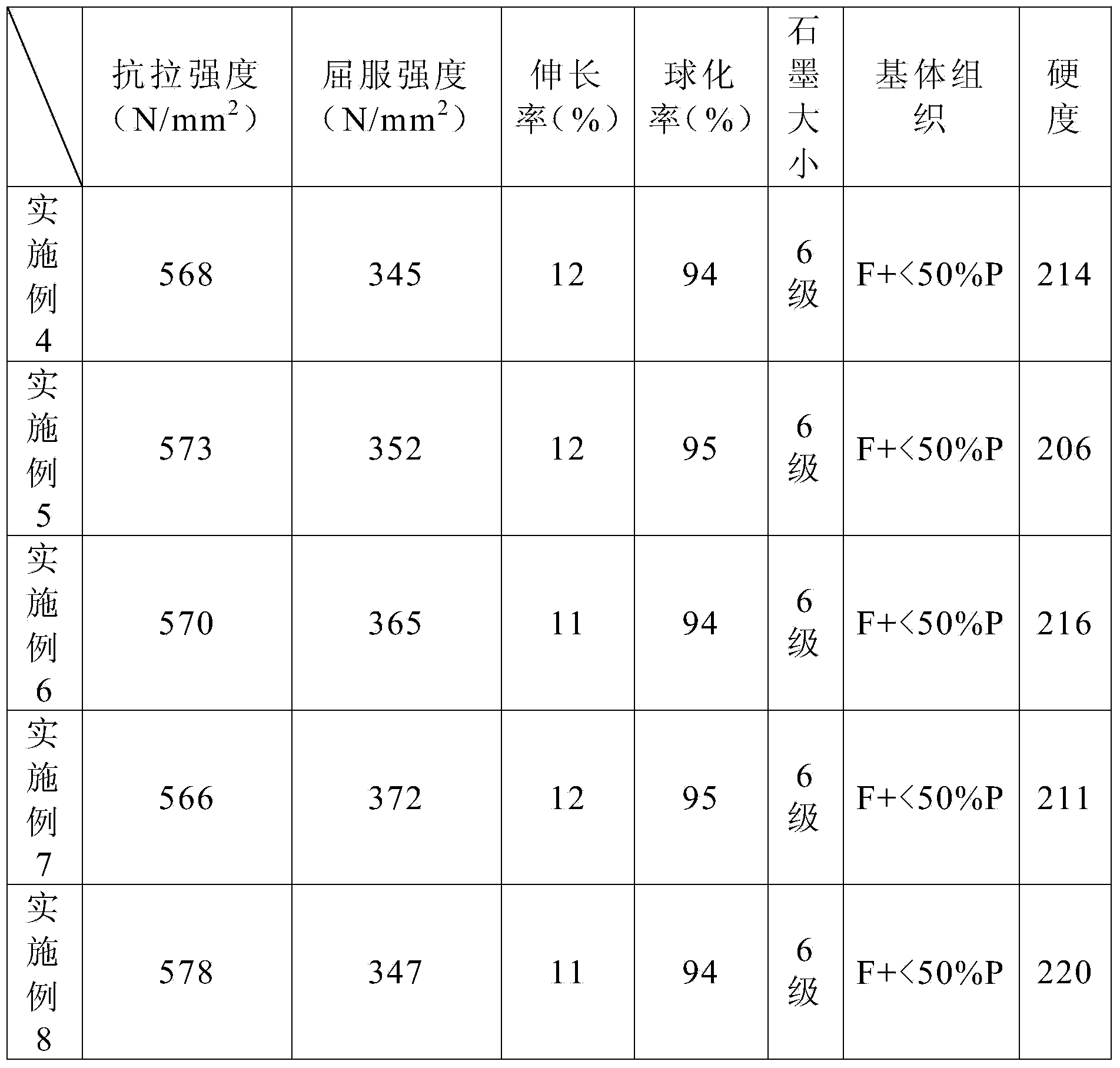

The invention relates to a nodular cast iron inoculant and a preparation method thereof and an application in smelting nodular cast iron. The nodular cast iron inoculant consists of 3-6% of Bi, 40-50% of Si, 0.5-3% of Ba, 0.1-3% of La, 10-18% of Ca, 1-3% of O, 0.5-3% of S and the balance of Fe and unavoidable trace elements. The nodular cast iron inoculant is prepared by the steps of mechanically mixing a metal oxide, a metal sulfide and a silicon iron-based alloy; adding an adhesive into a grinding device, and pressing the mixture into a cluster; breaking the cluster, screening and wrapping with an aluminum foil. In use, when the output molten iron accounts for about 1 / 2 of the lip-pour ladle, the inoculant is added to perform inoculation treatment on the nodular cast iron once or multiple times. The inoculant provided by the invention contains the trace elements such as O, S, Bi and the like and is low-silicon and efficient, and multiple heterogeneous nucleation mass points are formed in the iron liquid, thereby increasing the graphite quantity, improving the shock resistance, mechanical property and yield, increasing the utilization rate of foundry returns, and increasing the economic benefits.

Owner:宁波康发铸造有限公司

Vanadium titanium cast iron brake drum and preparation method thereof

The invention relates to a manufacturing technique of an automotive vanadium titanium cast iron brake drum with high strength and high abrasive resistance, and particularly relates to a preparation method of a vanadium titanium cast iron brake drum. The preparation method comprises the following steps: melting base iron, namely b y taking vanadium titanium pig iron, steel scrap, foundry returns, a carburant, ferrosilicon, ferromanganese and ferrochrome as furnace charge, adding the carburant to the furnace bottom; smelting the furnace charges by using a medium-frequency induction furnace to prepare the base iron; heating and purifying molten iron in an overheating manner after the molten iron is molten down, and then carrying out heat preservation at 1520-1530 DEG C; and carrying out drossing, adding a slag conglomeration agent to the surface to carry out heat preservation after drossing, and then adding a little of furnace charge, and adjusting the ingredients and the like of the molten iron. A little of furnace charge is added at the later smelting stage to increase the heterogeneous core technology, so that the chilling tendency of the molten iron is relieved, the graphitization ability of the molten iron is improved, and the inoculation effect is improved. A secondary inoculation treatment process of a launder and a pouring cup is adopted, so that the inoculation effect is improved, the graphite form is improved, carbide and ferrite are removed, and the content of pearlite is improved.

Owner:陈国

Low-alloy gray cast iron material for truck brake drums and preparation method thereof

The invention discloses a low-alloy gray cast iron material for truck brake drums and a preparation method thereof, belonging to the technical field of gray cast iron materials. The material mainly comprises the following chemical components in percentage by mass: 3.00-3.70% of C, 1.5-2.8% of Si, 0.38-1.5% of Mn, at most 0.04% of S, at most 0.08% of P, 0.02-0.04% of Mg, 0.20-0.50% of Cr, 0.2-0.5% of V, 0.2-0.45% of Mo, 0.04-0.10% of Sn and the balance of iron. The method comprises the following steps: (1) molten iron smelting; (2) inoculation; and (3) casting. The invention aims to provide a low-alloy gray cast iron material for truck brake drums, which has the advantages of excellent resistance, excellent wear resistance and ideal comprehensive mechanical properties, and a preparation method thereof. The method is used for preparing the gray cast iron material.

Owner:临沂新科绿色建材有限公司

As-cast pearlite ductile iron material for crankshaft, and preparation method of the same

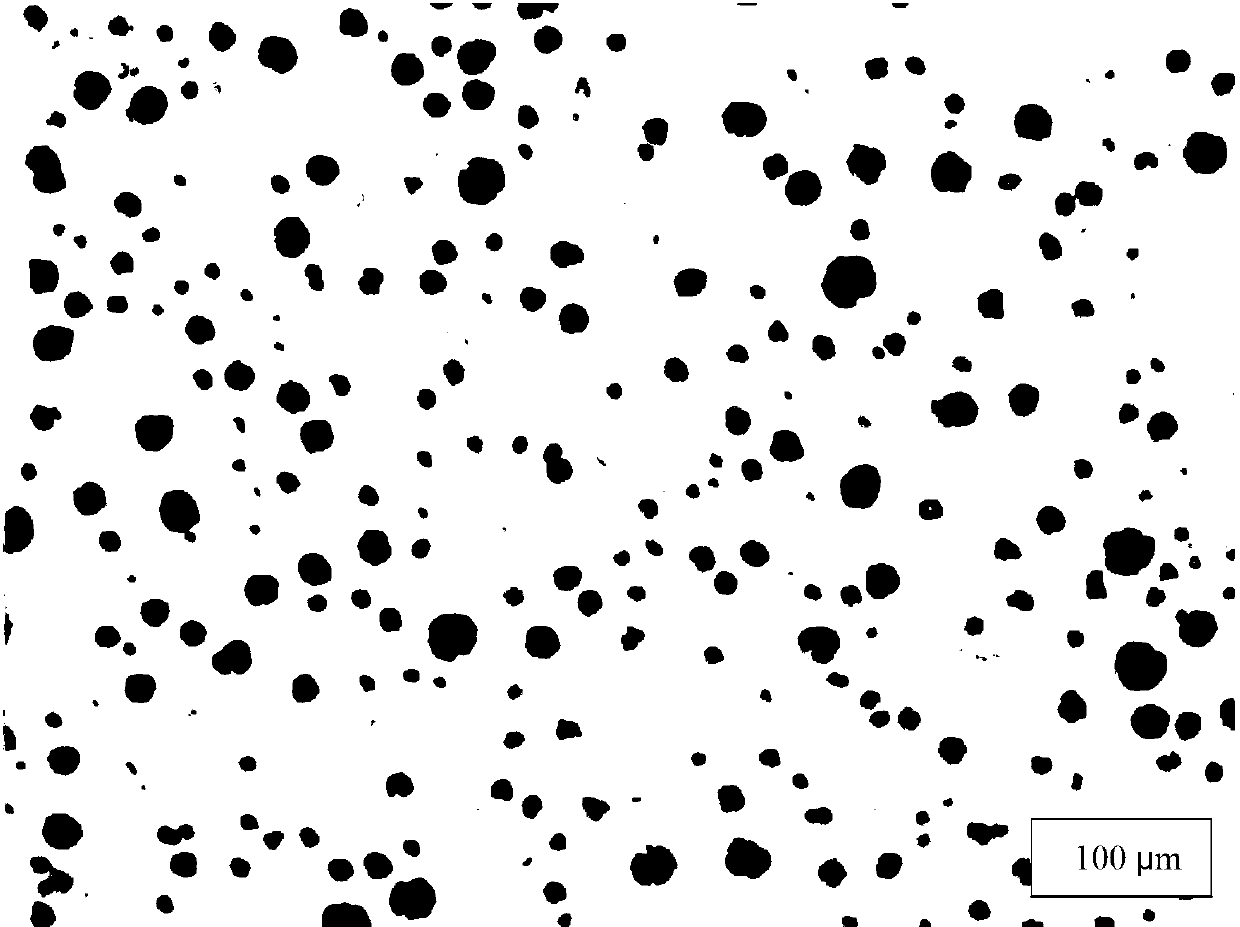

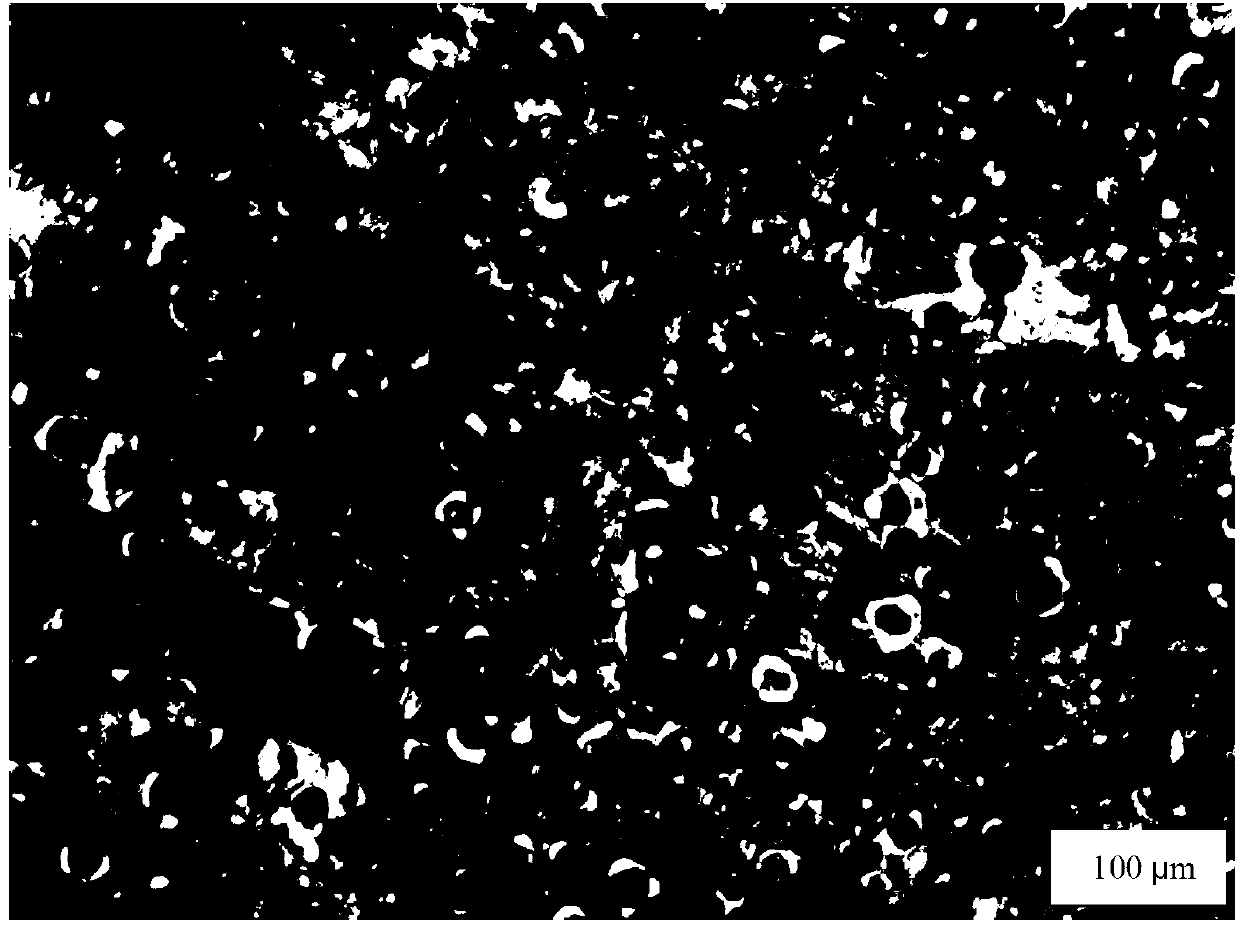

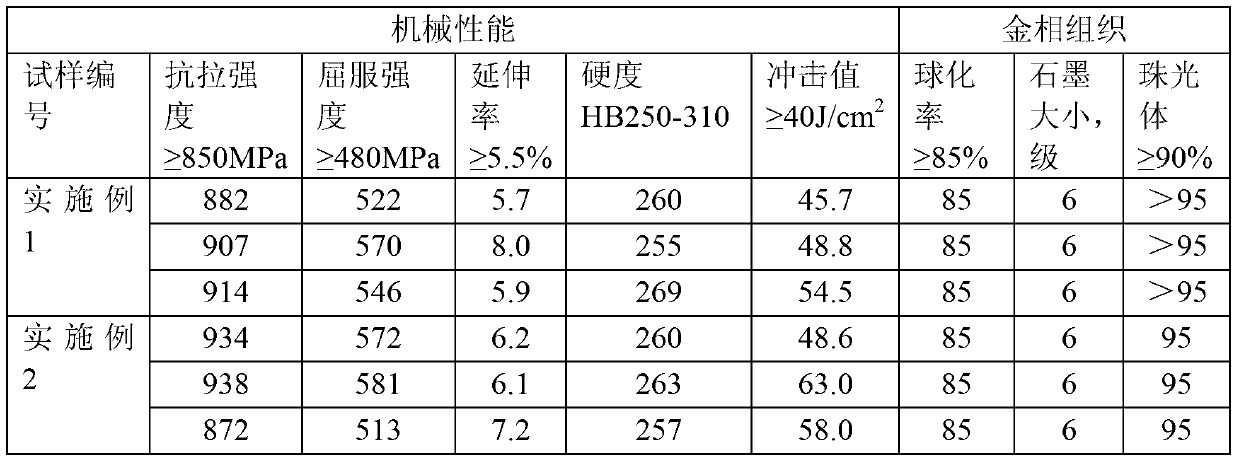

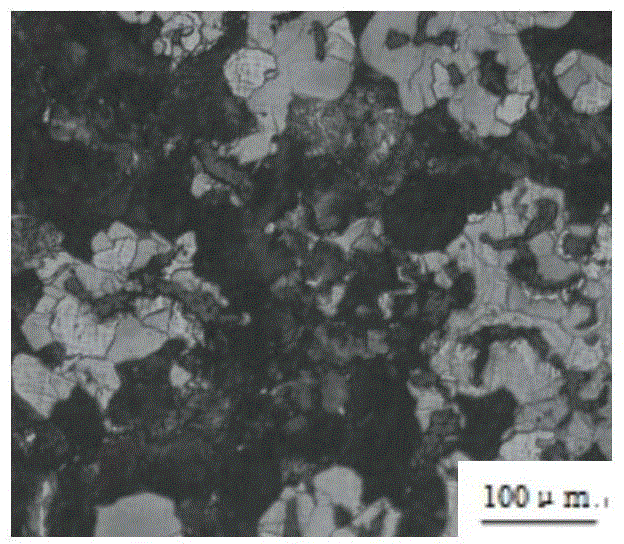

The invention relates to an as-cast pearlite ductile iron material for crankshaft, and a preparation method of the same. The material is composed of the following elements by mass percent: C: 3.40-3.75%, Si: 2.25-2.60%, Mn: 0.15-0.35%, S: less than 0.015%, P: less than 0.04%, Cu: 0.9-1.1%, Sn: 0.01-0.03%, Mg: 0.03-0.05%, and the balance of Fe. The material is prepared by the steps of using Q10 cast iron, scrap returns and steel scrap as the raw materials for smelting, performing spheroidizing and ladle inoculation, performing metal-stream inoculation while casting, and then, cooling naturally. The obtained material is steady in texture; for the material, the impact value is not less than 40J / cm2, the strength of extension is not less than 850MPa, the yield strength is not less than 480MPa, the ductility is not less than 5.5%, the hardness is HB250-310, the rate of spheroidization is not less than 85% and the pearlite content is not less than 90%; the material can be used for manufacturing gasoline engine turbocharging high-effect crankshafts for cars.

Owner:上海圣德曼铸造海安有限公司

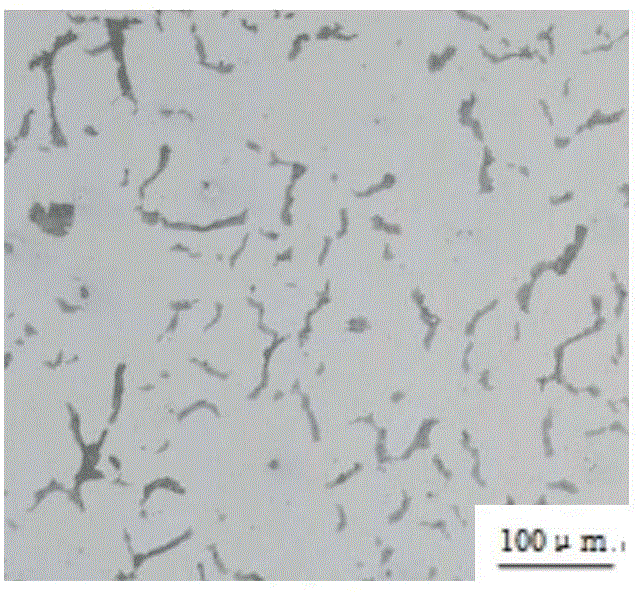

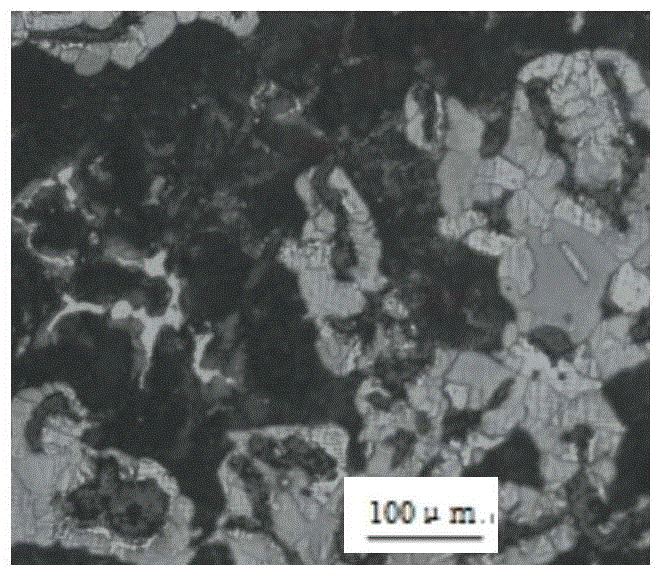

Alloy vermicular graphite cast iron for railway vehicle brake disc and smelting method of alloy vermicular graphite cast iron

The invention relates to alloy vermicular graphite cast iron for a railway vehicle brake disc and a smelting method of the alloy vermicular graphite cast iron. The vermicular graphite cast iron is composed of, by mass, 3.3%-3.5% of C, 2.3%-2.5% of Si, 0.4%-0.7% of Mn, 0.6%-1.0% of Cu, 0.2%-0.6% of Mo, 0.6%-1.0% of Ni, 0-0.07% of P, 0-0.02% of S and the balance Fe. The vermicular graphite rate of the vermicular graphite cast iron brake disc is higher than or equal to 75% and the pearlite content is 50% to 60%. According to the alloy vermicular graphite cast iron for the railway vehicle brake disc and the smelting method of the alloy vermicular graphite cast iron, the stress threshold value when a disc body is cracked and extended due to thermal stress concentration can be increased, and the mechanical property of the railway vehicle brake disc is improved.

Owner:CHANGZHOU LANGRUI CASTING +1

Hydraulic pump body casting process

InactiveCN104911458ANo shrinkage cavityHigh tensile strengthFoundry mouldsFoundry coresHydraulic pumpEngineering

The invention discloses a hydraulic pump body casting process, the process steps are as follows: moulding-casting material pretreatment-melting-spheroidizing treatment-pouring-heat treatment-stabilizing treatment-gas nitriding treatment-machining-inspection and storing-finished product; and the casting process is simple and practical, and low in cost, the casted hydraulic pump body is dense in tissue, free of shrinkage porosity and cavity, white cast and crack defects, good in tensile strength, and high in hardness.

Owner:SUZHOU JIN YUAN OIL MACHINERY

High-strength sulfur-oxygen nucleating agent

The invention provides a high-strength sulfur-oxygen nucleating agent. The high-strength sulfur-oxygen nucleating agent comprises the following elements in percentages by mass: 70-76% of Si, 0.2-1.0%of Ca, 0.3-0.5% of Ba, 1.5-2.0% of La, 0.5-1.5% of Al, 0.3-0.9% of S, 0.3-0.9% of O, 0.5-1.5% of Sb and the balance of iron. The sulfur-oxygen nucleating agent is prepared from the following raw materials in parts by weight: 2-4 parts of steel scrap, 130-140 parts of silicon iron, 1-1.4 parts of silicon barium, 1-1.8 parts of calcium silicon, 2-4 parts of pure lanthanum, 1.5-2.5 parts of stibonium, 1-2 parts of FeS and 1-1.4 parts of FeO. By the prepared high-strength sulfur-oxygen nucleating agent, the number of graphite nodules in nodular cast iron can be increased obviously, the strength and toughness of the nodular cast iron can be improved, the chilling tendency of the nodular cast iron is relieved obviously, the nodularity, the number of graphite nodules and the number of ferrites ofthe nodular cast iron are increased, shrinkage in a casting process is eliminated, and complicated castings with excellent quality can be formed.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

High-strength-and-toughness cast iron heavy-duty automobile brake drum and making technology thereof

InactiveCN103866177AImprove thermal fatigue resistanceImprove deformation resistanceBraking drumsThermal fatigueAlloy

The invention discloses a high-strength-and-toughness cast iron heavy-duty automobile brake drum. The brake drum is characterized in that brake drum comprises 3.55-3.85wt% of C, 2.35-2.75wt% of Si, 0.45-0.85wt% of Mn, 0.02-0.06wt% of P, 0.01-0.04wt% of S, 0.06-0.12wt% of Ti, 0.02-0.08wt% of Sn, 0.01-0.04wt% of Sb, 0.008-0.05wt% of Mg, 0.015-0.035wt% of RE, and the balance Fe. The making technology of the brake drum sequentially comprises the following steps: weighing raw materials in proportion, carrying out alloy melting, carrying out creeping and inoculation, carrying out cast molding, cleaning, and machining. Compared with the prior art, the technology has the advantages of best thermal fatigue resistance, good deformation resistance, good cooperation of strength, ductility, hardness and wear resistance, and good casting and machining properties.

Owner:金建平

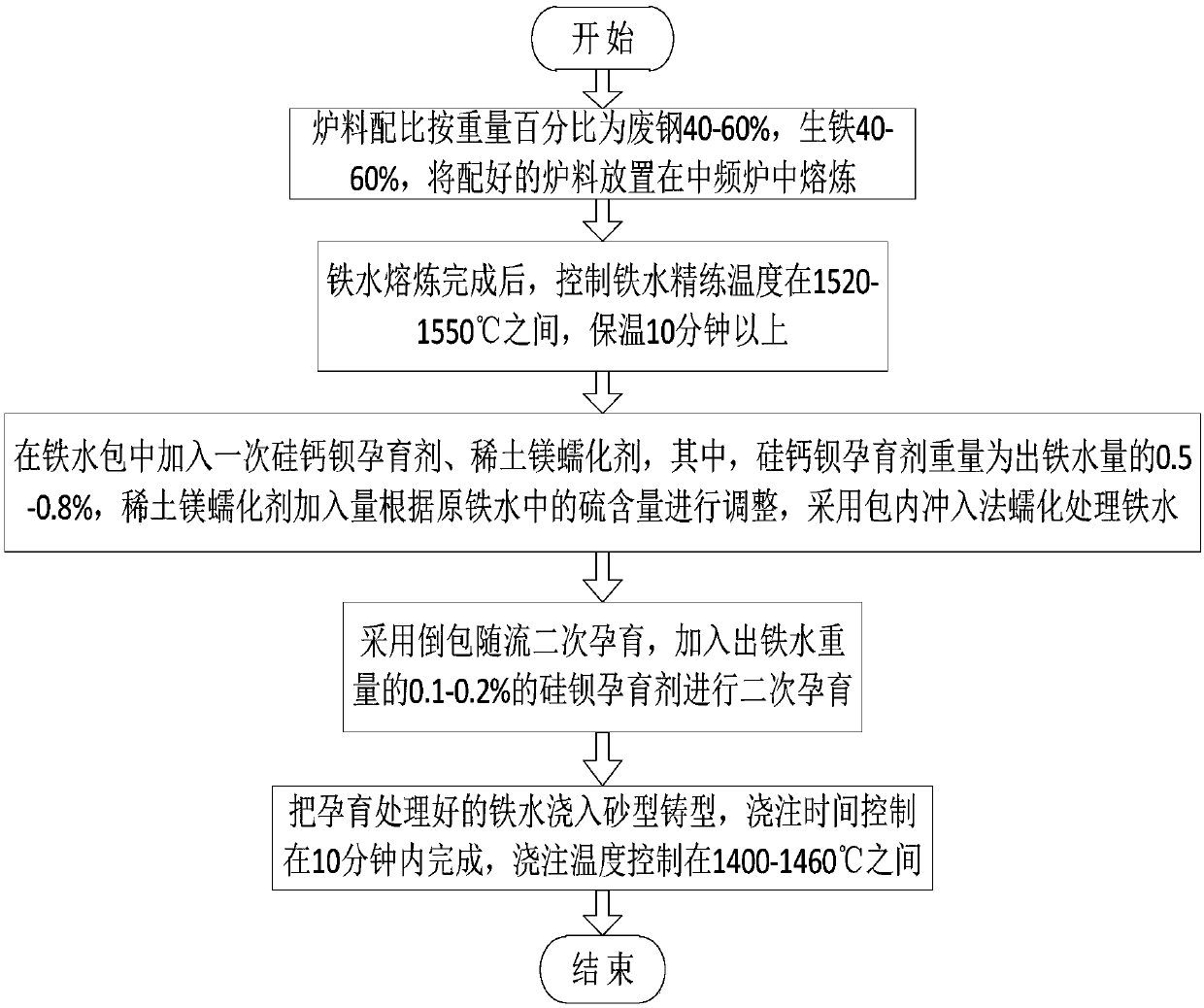

Casting process for high-strength vermicular graphite cast iron materials

The invention discloses a casting process for high-strength vermicular graphite cast iron materials. The casting process specifically comprises the steps of a, a furnace charge comprises, by weight, 40%-60% of a steel scrap and 40%-60% of raw iron, and the proportioned furnace charge is put into a medium-frequency furnace for smelting; b, after molten iron smelting is completed, the molten iron refining temperature is controlled to be 1520DEG c-1550DEG c, and heat preservation is carried out for more than 10 minutes; and c, a primary silicon-calcium-barium nucleating agent and a rare-earth magnesium vermicularizing agent are added into a molten iron ladle, wherein the weight of the silicon-calcium-barium nucleating agent is 0.5%-0.8% of the amount of the produced molten iron, and the molten iron undergoes the vermicularizing treatment by adopting an in-ladle pour-over method; d, the ladle stream secondary inoculation process is adopted, the silicon-barium inoculant with the weight accounting for 0.1%-0.2% of the weight of the produced molten iron is added for secondary inoculation; and e, the inoculated molten iron is poured into a sand mold casting mold, the casting time is controlled within 10 minutes, and the casting temperature is controlled between 1400DEG c-1460 DEG c. According to the casting process, the shrinkage porosity tendency of a product is reduced, forming of nucleation when the molten iron is solidified can be promoted, and the performance of the vermicular graphite cast iron materials can be improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

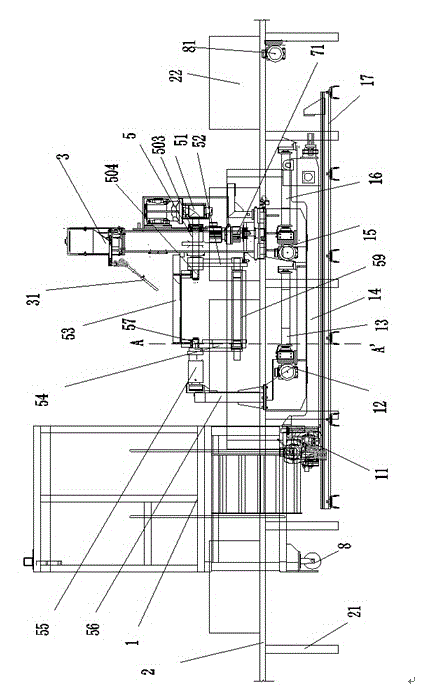

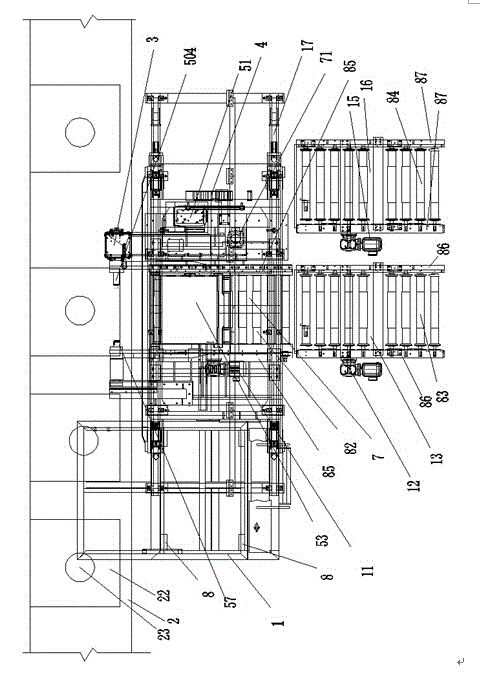

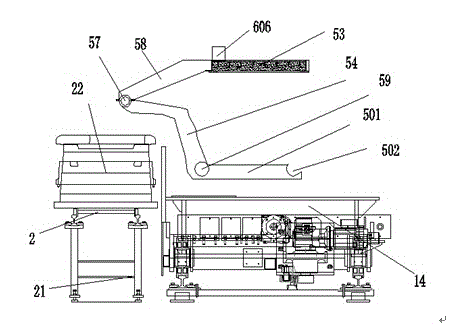

High-precision full-automatic casting machine

ActiveCN104439222AGuaranteed continuityImprove pouring qualityMolten metal supplying equipmentsMetallurgyThermal insulation

The invention discloses a high-precision full-automatic casting machine. The high-precision full-automatic casting machine comprises a casting ladle system, a casting ladle transverse moving and longitudinal moving system, a servo tilt-rotating mechanism, a detection unit and a control unit. The casting ladle system comprises a casting ladle made of thermal insulation materials and a casting ladle moving device. The casting ladle transverse moving and longitudinal moving system comprises a track system and a casting vehicle. The detection unit comprises a load sensor. The load sensor is used for detecting the weight of molten metal in the casting ladle of the casting machine and generating a signal representing the detected weight. The control unit is provided with a first arithmetic unit, a second arithmetic unit and a driving indication unit. The casting machine can effectively shorten the casting time and improve the casting stability.

Owner:山东时风(集团)有限责任公司

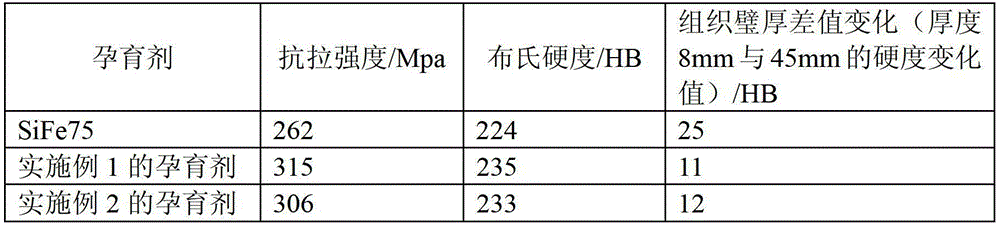

High-intensity gray pig iron inoculator and preparation method thereof

The invention discloses a high-intensity gray pig iron inoculator and a preparation method thereof and belongs to the technical field of casting. The high-intensity gray pig iron inoculator comprises the following chemical components in percentage by weight: 65 to 72 percent of Si, 0.5 to 1.2 percent of Al, 0.5 to 1.5 percent of Zr, 0.6 to 1.8 percent of RE, 4.0 to 6.0 percent of Mn, 0.4 to 1.2 percent of Sn (or 0.1 to 0.4 percent of Sb), less than 0.2 of C, less than 0.02 of S, less than 0.05 of P, and the balance of iron and unavoidable impurities. The inoculator can obviously reduce chilling tendency, refine graphite and reduce wall thickness and sensitivity of tissues and obviously increase pearlite content, so that tensile strength of gray pig iron is improved. For base iron with the same components, compared with a common 75 silicon iron inoculator, the high-intensity gray pig iron inoculator has the advantage that the tensile strength of cast iron applying the high-intensity gray pig iron inoculator can be improved by 30 to 60MPa.

Owner:SHANDONG HUIFENG CASTING TECH

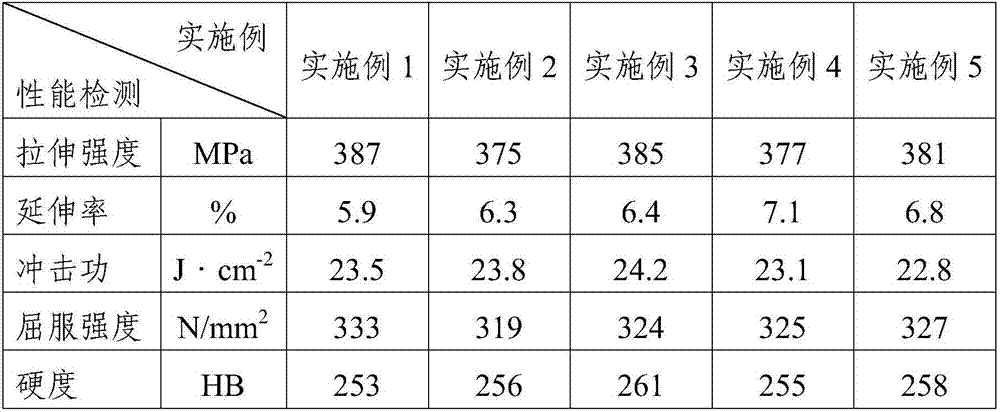

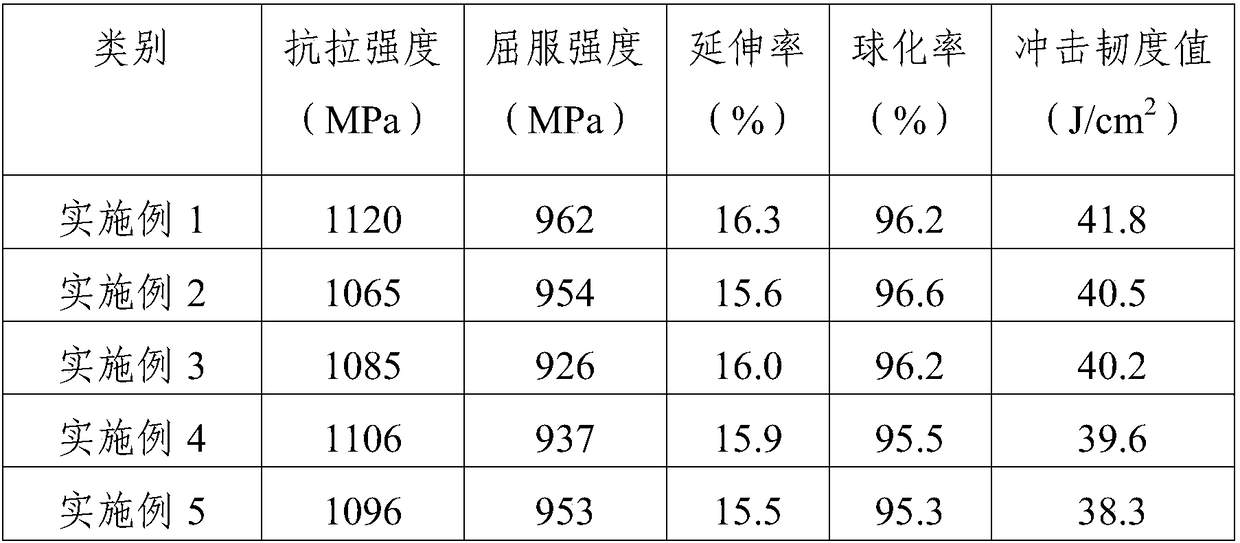

Preparation method of high-strength and high-tenacity nodular cast iron

ActiveCN108624806AGood composition uniformityImprove uniformityProcess efficiency improvementDuctile ironImpurity

The invention discloses a preparation method of high-strength and high-tenacity nodular cast iron. The high-strength and high-tenacity nodular cast iron is prepared from, by mass, 3.6%-3.8% of C, 3.5%-3.8% of Si, 0.4%-0.6% of Mn, 0.01%-0.04% of Sn, 0.4%-0.6% of Ni, 0.3%-0.4% of Ti, 0.04%-0.01% of Sb, 0.02%-0.04% of RE, 0.16%-0.2% of P, no more than 0.02% of S, and the balance Fe and inevitable impurities. The tensile strength of the nodular cast iron is 1050-1180 MPa, the yield strength of the nodular cast iron is 780-820 MPa, the ductility of the nodular cast iron is 15%-16%, the nodularity of the nodular cast iron is 95%, and all properties of the nodular cast iron are excellent.

Owner:佛山市高明康得球铁有限公司

Microalloying high-strength gray pig iron piece and smelting method thereof

The invention provides a microalloying high-strength gray pig iron piece and a smelting method thereof and relates to the field of metal casting. The gray pig iron piece comprises, by weight percent, 2.92%-3.48% of C, 1.52%-2.36% of Si, 0.22%-0.78% of Mn, 0.15%-0.5% of Cr, 0.3%-0.78% of Cu, 0.011%-0.098% of Nb, 0.02%-0.1% of V, 0.015%-0.025% of Ti and the balance iron and other traces of unavoidable impurities. A casting piece base body is intensified through microalloying, the intensity and the rigidity of the casting piece are improved, a high-efficiency nucleating agent is added, graphite form, hardness and texture uniformity can be effectively improved, the sensibility is reduced, the mechanical performance of the gray pig iron piece is improved, by adopting the in-mold inoculation manner, the utilization rate of the nucleating agent can be improved, the inoculation effect is improved, and the cost is reduced.

Owner:HANSHAN ZHAOXIA CASTING

Nodular cast iron inoculant, and preparation method and application thereof

The invention discloses a nodular cast iron inoculant which comprises the following components in percentage by weight: 60-65% of Si, 3.5-6.0% of Zr, 1-2% of Ca, 0-1.4% of Al, 0.5-1.5% of Fe3O4, and the balance of Fe and inevitable minor elements. The nodular cast iron inoculant disclosed by the invention can improve the comprehensive properties of the nodular cast iron and enhance the inoculation efficiency.

Owner:成都宏源铸造材料有限公司

Vermicular graphite cast iron cylinder cover material of heavy-duty diesel oil engine and preparation technology thereof

A vermicular graphite cast iron cylinder cover material of a heavy-duty diesel oil engine comprises the following raw materials in percentage by weight: 3.60-3.90% of C, 1.90-2.50% of Si, 0.50-0.70% of Mn, 0.4-0.6% of Mo, 0.70-0.85% of Cu, 0.2-0.4% of Cr, 0.01-0.025% of Mg, 0.025-0.04% of Re, not greater than 0.070% of P, not greater than 0.015% of S, and the balance Fe and inevitable impurities.A preparation technology comprises the steps of pressing from the bottom of a ladle and nucleating by a ladle bottom pouring method; supplementing a nucleating agent while 78-85% of molten iron is output; and then nucleating along with stream. According to the preparation technology adopting the design, the comprehensive mechanical property of the material is obviously improved; and moreover, thevermicularity and the pearlite content are stable; and the production cost is decreased.

Owner:DONGFENG COMML VEHICLE CO LTD

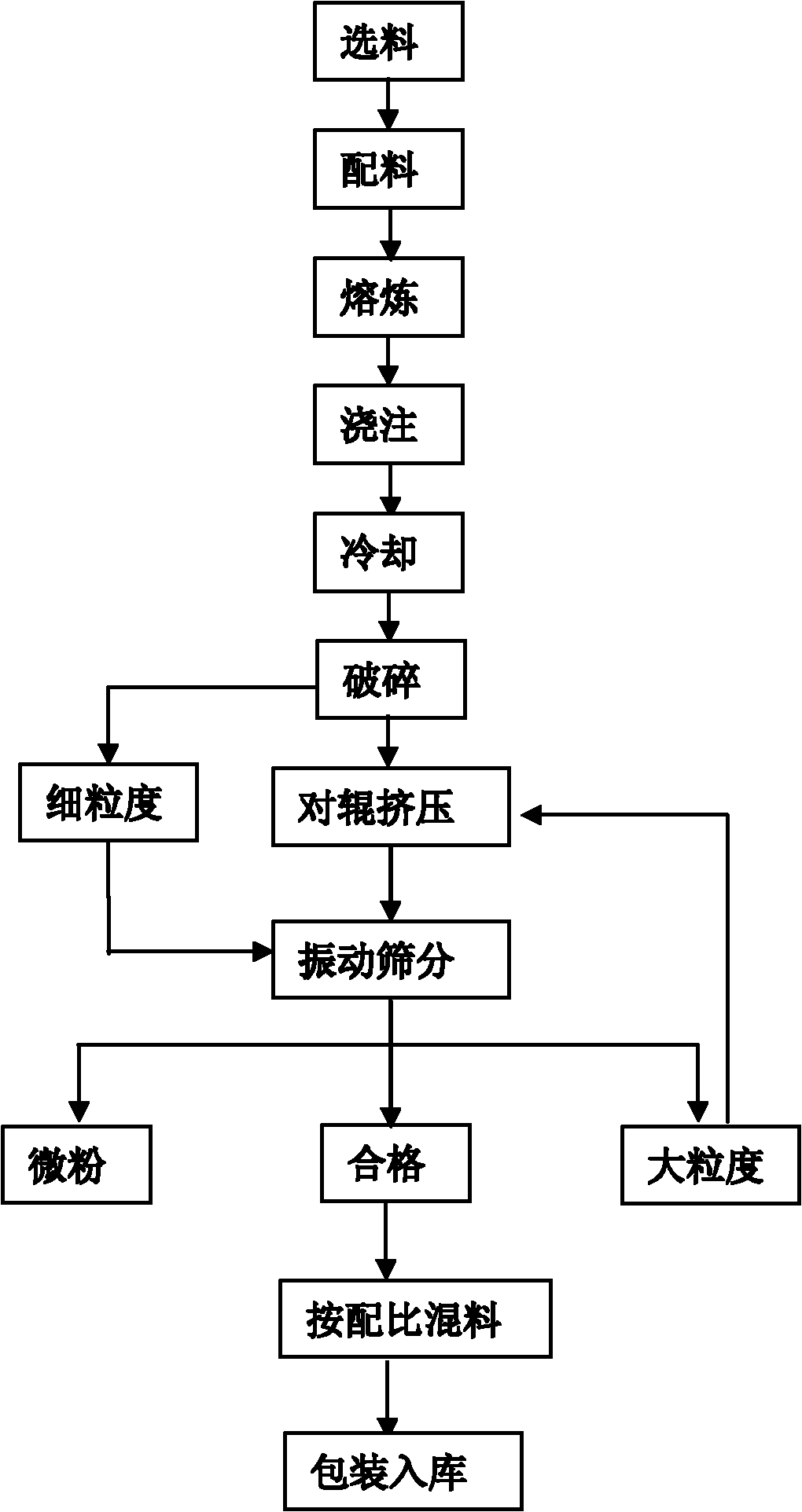

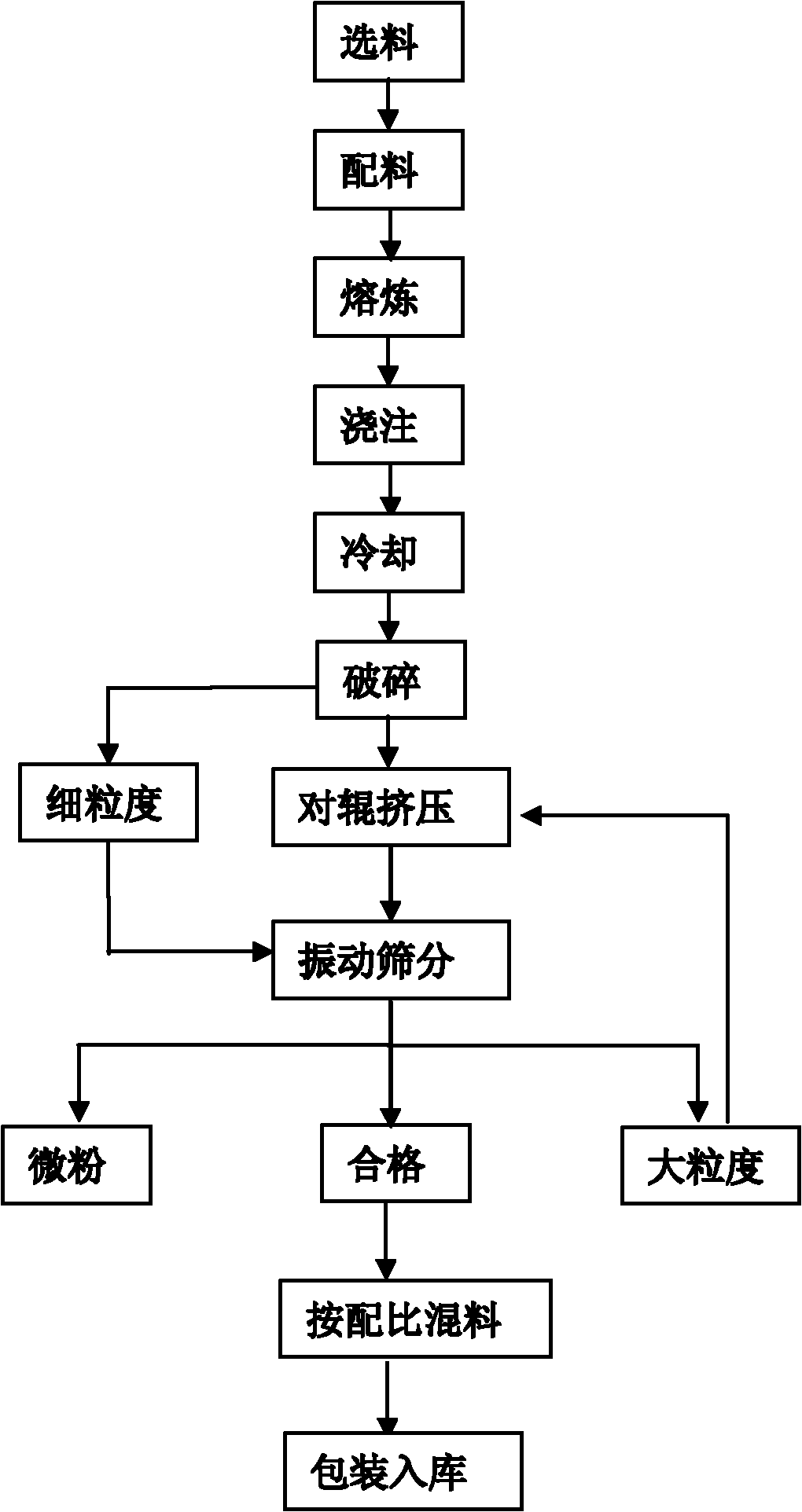

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Inoculant for ferritic nodular cast iron and preparation method of inoculant

InactiveCN103146985APromote nucleationImprove the straightness effectExtensibilityChemical composition

The invention discloses an inoculant for a ferritic nodular cast iron and a preparation method of the inoculant, and the inoculant can be used for solving the problems that the nodular graphite cast iron prepared by an existing inoculant is less in graphite nodule quantity, low in ferrite content and poor in extensibility and impact ductility. The inoculant for the ferritic nodular cast iron comprises the following chemical compositions in percentage by mass: 65-70% of Si, 1.0-5.0% of Bi, 2.0-5.0% of Ca, 1.0-4.0% of Ba, less than 0.5% of Al, less than 0.05% of T1, less than 0.4% of Mn, less than 0.02% of S, less than 0.05% of P, and the balance of Fe; and the inoculant is prepared by smelting and granulating the raw materials. The ferritic nodular cast iron produced by using the inoculant can accelerate graphite nucleation, reduce the chilling tendency, increase the graphite nodule quantity, improve the graphite nodule element integration action, further improve the ferrite content under a cast condition, and improve the extensibility and impact ductility of ductile iron.

Owner:SHANDONG HUIFENG CASTING TECH

Method for preparing base of vertical annealing furnace

ActiveCN102489669AGood spherical effectReduce white mouth tendencyFoundry mouldsFoundry coresCompressive strengthLost-foam casting

The invention discloses a method for preparing a base of a vertical annealing furnace. The method provided by the invention is characterized in that a lost foam casting technology is adopted; molten iron is injected into a mold from the bottom to form a casting; a pour-over spheroidizing technology is adopted; and a spheroidizing inoculation technology is adopted. The base obtained by the method has advantages of good mechanical properties, good flexibility, high tensile strength, high compression strength, low rejection rate, high heat resistance, high fatigue resistance, and large elongation.

Owner:SICHUAN CHUANJIAN PIPES

Preparation method of pipe mold powder for nodular cast iron and application thereof

Owner:成都宏源铸造材料有限公司

High-pressure internal thread ball valve and machining process thereof

InactiveCN109055807AHigh tensile strengthIncreased freezing temperature rangePlug valvesFurnace typesRare-earth elementEngineering

The invention provides a high-pressure internal thread ball valve. The high-pressure internal thread ball valve comprises a valve body, a valve cap, a valve rod, a valve ball and a pressing cap, and is characterized in that the valve body, the valve cap, the valve rod, the valve ball and the pressing cap are made from the same main material, wherein the main material comprises, by mass, 7-9% of Zn, 1-3% of Pb, 2-4% of Si, 0.12 -0.15% of Ti, 0.1-0.3% of Fe, 0.1-0.3% of Al, 0.15-0.19% of C, 0.05-0.07% of B, 1.0-2.0% of Cr, 0.01-0.03% of Sb, 0.25-0.28% of Mn, 0.05-0.07% of Nb, 0.01-0.03% of V, 0.001-0.002% of Bi, 0.003-0.005% of S, 0.005-0.006% of P, 0.01-0.02% of rare earth elements, and the balance Cu and inevitable impurities, and the sum of the components is 100%. A machining process of the high-pressure internal thread ball valve is simple and easy to implement, and low in cost, and the machined ball valve has good high-temperature resistance and corrosion resistance performance, andis long in service life.

Owner:JIANGSU HUATAI ELECTRIC POWER ELECTRONICS INSTR

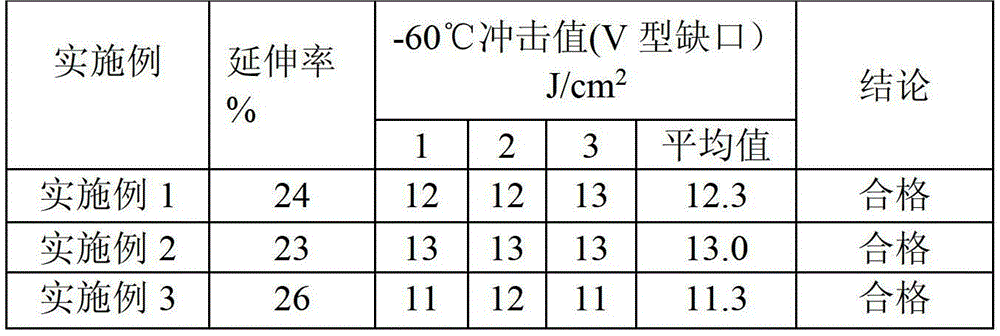

Production process of QT500-12 spheroidal graphite iron casting

The invention discloses a production process of a QT500-12 spheroidal graphite iron casting. The production process comprises the following steps: A, raw material selection: selecting 60-80 parts of scrap steel, 20-40 parts of scrap returns, 2.5-3.5 parts of a carburant, 0.4-1.0 part of 75# ferrosilicon, 0.3-0.6 part of copper, 1-1.2 parts of a spheroidizing agent, 0.8-1.2 parts of a 75# ferrosilicon inoculant and 0.2-0.4 part of a silicon-strontium inoculant; B, weighing; C, smelting; D, spheroidizing; E, secondary inoculation; and F, pouring. The overall performances of the QT500-12 spheroidal graphite iron casting produced by using the production process are improved, and the tensile strength is larger than or equal to 500Mpa on the premise that the elongation percentage is larger than or equal to 12%; the consistency of a matrix structure of the spheroidal graphite iron casting is also realized, and the local function of the spheroidal graphite iron casting is prevented from being deteriorated; and the weight of the spheroidal graphite iron casting is reduced on the premise that the elongation percentage and tensile strength indexes of the spheroidal graphite iron casting reach standards, so that the lightweight of the spheroidal graphite iron casting is realized.

Owner:山东力嘉轻量化科技有限公司

Spheroidizing agent for thick and large section nodular iron casting and preparing method of spheroidizing agent

The invention discloses a spheroidizing agent for a thick and large section nodular iron casting. With the total weight of the spheroidizing agent for the thick and large section nodular iron castingbeing 100%, the spheroidizing agent for the thick and large section nodular iron casting comprises, by weight, 7-8% of Mg, 1.5-3.0% of RE, 1.5-2.5% of Ca, 1.0-2.0% of Ba, 40-42% of Si, 0.3-0.8% of Bi,0.15-0.6% of Sb and the balance Fe. The advantages of each chemical component are maintained effectively, the effect of excessively high content and excessively low content on the spheroidizing effect of the thick and large section nodular iron casting is prevented, graphite nucleation can be promoted, chilling tendency is reduced, the amount and density of spherulitic graphite are increased, thesize of the spherulitic graphite is reduced, nucleated cast iron can be good in component uniformity, the melting point and the performance are sharply improved, and the elongation of ferrites is improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Preparing method and application of gray iron inoculant

The invention discloses a preparing method of gray iron inoculant. The preparing method comprises the following steps that 66-70% of Si, 1-3% of Zr, 1-2% of Ca, 0-2.5% of Mn, 0.5-1.5% of Fe3O4, 0.5-1% of carburant and the balance Fe and inevitable microelements are evenly mixed, smashed, melted, stirred, poured, quickly frozen and smashed for standby use. The invention further discloses application of the gray iron inoculant. By means of the gray iron inoculant, the comprehensive performance of gray iron can be improved, and the inoculating efficiency is improved.

Owner:成都宏源铸造材料有限公司

Preparation method of pipe powder for nodular cast iron and application of pipe powder

The invention discloses pipe powder for nodular cast iron. The formula of the pipe powder comprises the following components in percentage by weight: 62-70% of Si, 3-10% of Ba, 1-2% of Ca, 0.8-1.8% of Al, 0.5-1.5% of Fe3O4, the balance of Fe and inevitable microelements. According to the pipe powder for the nodular cast iron disclosed by the invention, the overall performance of the nodular cast iron can be improved, and the inoculation efficiency is improved.

Owner:成都宏源铸造材料有限公司

Preparation method and application of gray pig iron nucleating agent

The invention discloses a preparation method of a gray pig iron nucleating agent. The preparation method comprises the following steps that 66%-70% of Si, 1%-13% of Zr, 1%-2% of Ca, 0-2.5% of Mn, 0.5%-1.5% of Fe3O4 and the balance Fe and inevitable trace elements are evenly mixed, smashed, smelted, stirred, cooled and smashed for use. The invention further discloses application of the gray pig iron nucleating agent. According to the gray pig iron nucleating agent, the comprehensive performance of gray pig iron can be improved, and nucleating efficiency is improved.

Owner:成都宏源铸造材料有限公司

Wear-resisting, high-toughness and high-strength excavator bucket tooth and manufacturing method thereof

InactiveCN108486459AHigh strengthImprove toughnessSoil-shifting machines/dredgersWear resistanceToughness

The invention provides a wear-resisting, high-toughness and high-strength excavator bucket tooth and a manufacturing method thereof. The wear-resisting, high-toughness and high-strength excavator bucket tooth is prepared from the following element components in percentage by weight: 3.4 to 3.9 percent of C, 2.3 to 2.6 percent of Si, 0.65 to 0.9 percent of Mn, 0.2 to 0.4 percent of Mg, 1.2 to 1.6 percent of Cu, 0.35 to 0.5 percent of Cr, 0.05 to 0.1 percent of Ce, 0.05 to 0.11 percent of Mo, 0.1 to 0.25 percent of Te, 0.05 to 0.08 percent of Y, 0.008 to 0.02 percent of Nd, less than or equal to0.02 percent of P, less than or equal to 0.02 of S and the balance of Fe. The manufacturing method mainly comprises the steps of melting, carrying out spheroidization treatment and inoculation treatment, forging and carrying out heat treatment; the excavator bucket tooth prepared by the invention has good wear resistance and high strength and also has excellent toughness; the manufacturing methodis simple and efficient.

Owner:安徽省宁国市亚晨碾磨铸件有限责任公司

High-strength wear-resistant cast iron and stream inoculation technology thereof

The invention discloses a high-strength wear-resistant gray cast iron and an inoculation process thereof, and relates to the technical field of wear-resistant gray cast iron inoculation. The present invention includes the weight ratio of each component as follows: C: 4.28%, Cr: 0.05%, Mn: 1.57%, Si: 0.38%, Ti: 0.38%, P<0.02%, S<0.15%, B: 0.67 %, Ni: 0.96%, Mo: 0.082%, V: 0.11%, Sn: 0.09%, and the rest is Fe. The present invention adopts inoculation treatment in front of the furnace and in the ladle during the manufacture of gray cast iron, mixes and bakes the silicon-barium inoculant and rare earth ferrosilicon to 100-150°C, and then adds them into the molten iron along with the flow of the tapping trough for follow-up Flow inoculation treatment, promotes nucleation, inhibits growth, refines grains, promotes graphitization, reduces whitening tendency; improves the uniformity of the section, improves the mechanical properties of gray cast iron, and improves the wear resistance of gray cast iron.

Owner:马鞍山市万兴耐磨金属制造有限公司

Vermiculizer for preparing vermicular graphite cast iron and preparation method thereof

The invention discloses a vermiculizer for preparing vermicular graphite cast iron, and belongs to the field of cast iron material production. The vermiculizer solves the problems that an existing vermiculizer is not high in vermicular rate and is unstable in reaction during preparation of vermicular graphite cast iron. The vermiculizer is prepared by melting rare earth magnesium and a rare earth silicon-iron alloy, and consists of the following element components in parts by mass: 14-20 parts of rare earth, 36-40 parts of silicon, 4-10 parts of magnesium, the balance iron and a little impurity elements. A preparation method for the vermiculizer comprises the following steps of: (1) preparing the rare earth magnesium and the rare earth silicon-iron alloy into raw materials with grain size being about 5-10 mm; (2) weighing weight of each raw material according to component proportion of set elements; and (3) smelting for 60 minutes in a vacuum induction furnace, and cooling to obtain the rare earth magnesium-silicon-iron alloy vermiculizer. The vermiculizer can be used for producing vermicular iron parts.

Owner:HARBIN UNIV OF SCI & TECH

Preparation method and application of gray pig iron inoculant

Owner:成都宏源铸造材料有限公司

Nucleating agent for cast iron

The invention discloses a nucleating agent for cast iron and relates to the field of metal materials. The nucleating agent comprises, by weight, 50%-63% of Si, 15%-20% of Ga, 1.5%-2.5% of Al, 0.2%-0.8% of RE, 2.0%-3.0% of Mg, 0.2%-0.8% of Sn and the balance Fe and inevitable microelements. The nucleating agent can promote nucleation of graphite and improve the inoculation effect; the chilling tendency of the cast iron is obviously reduced; and the refining property of the graphite is better. It is shown through practice that the pearlite content of the inoculated cast iron is obviously increased, and therefore the tensile strength of gray cast iron is improved.

Owner:潘桂枝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com