Patents

Literature

32results about How to "Increase the number of balls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

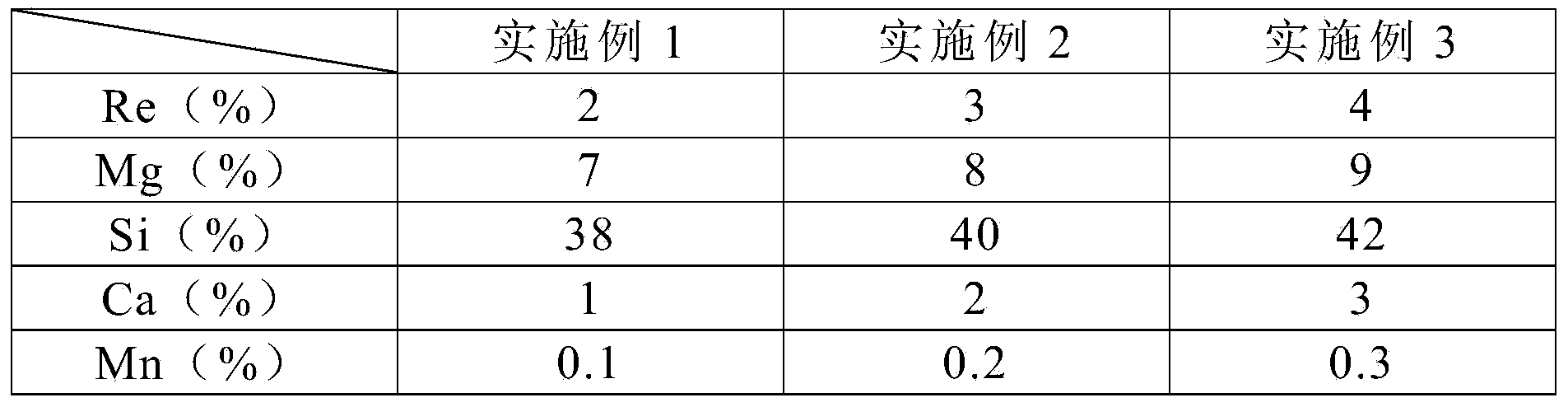

Nodular cast iron inoculant and preparation method thereof and application in smelting nodular cast iron

ActiveCN103484749AIncrease the number of ballsIncrease the number ofTrace element compositionAdhesive

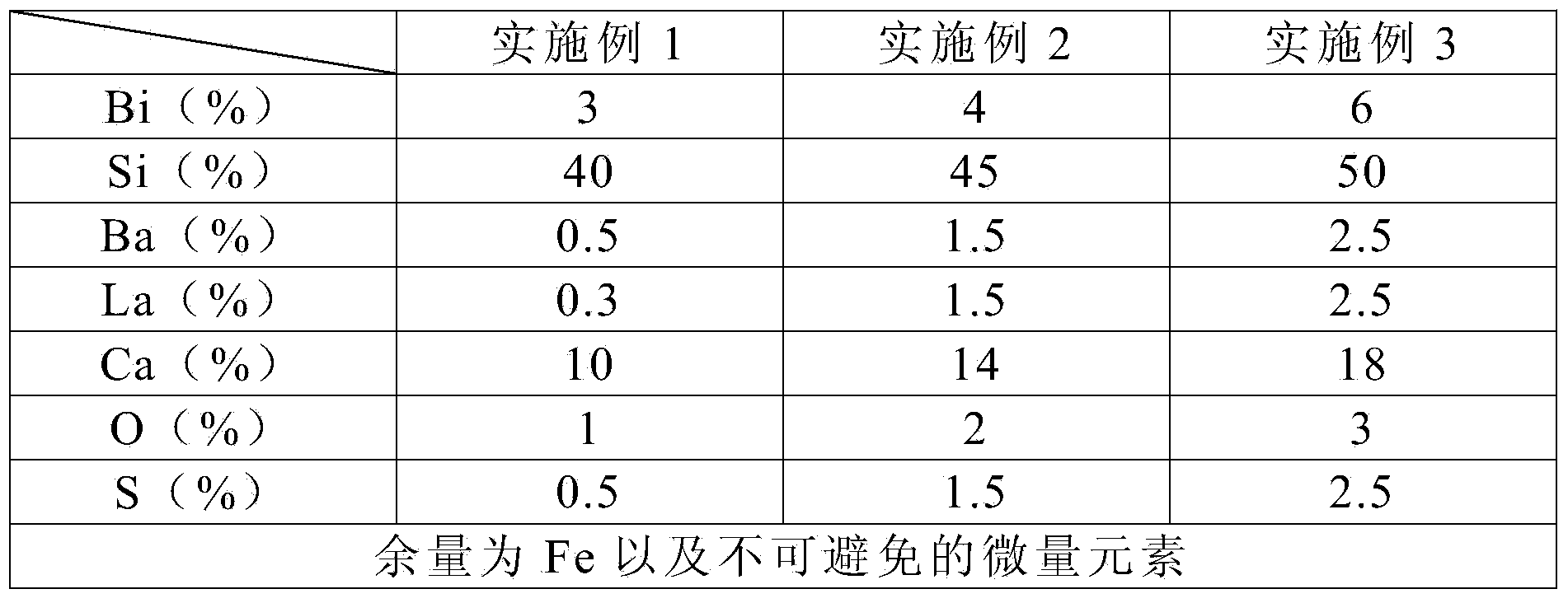

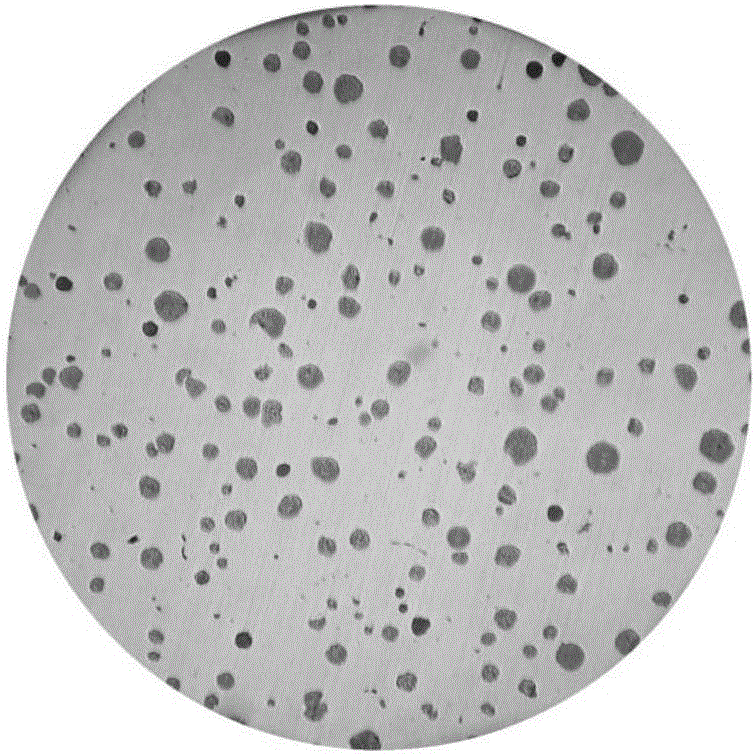

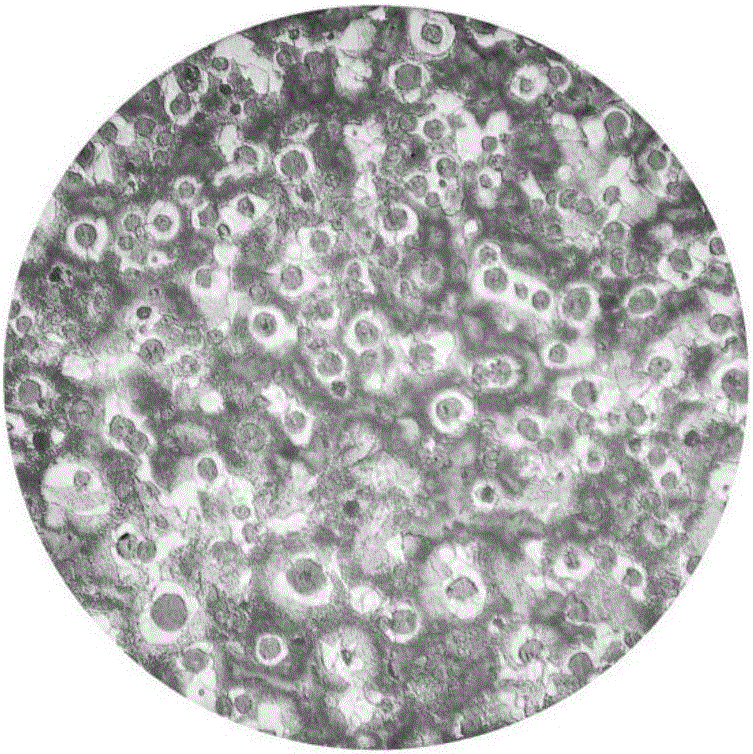

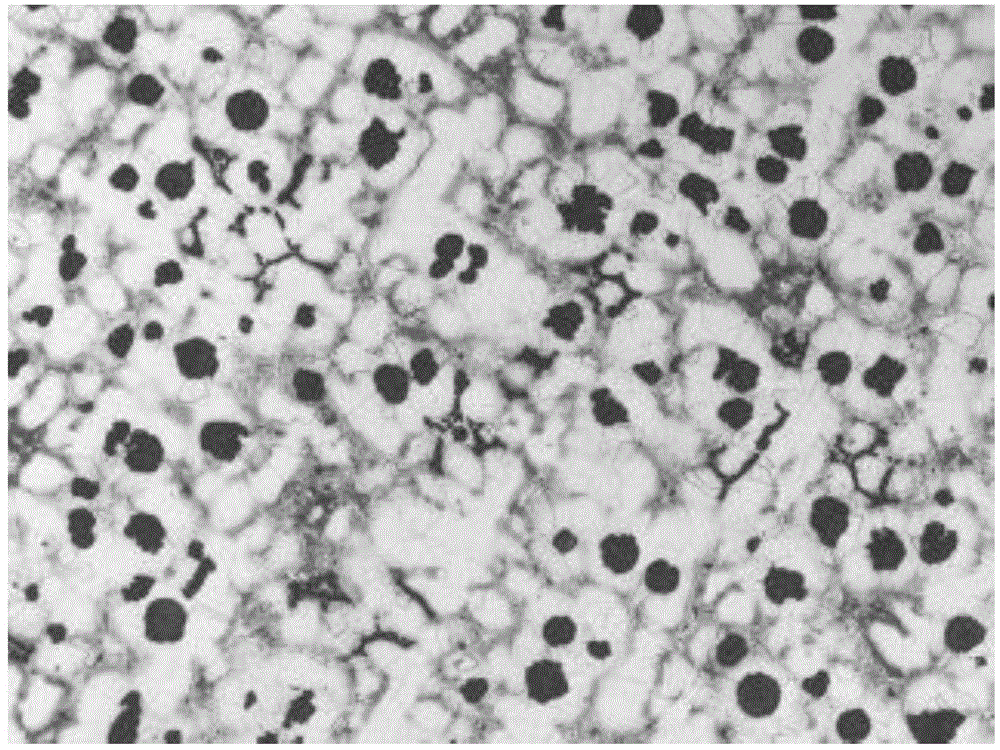

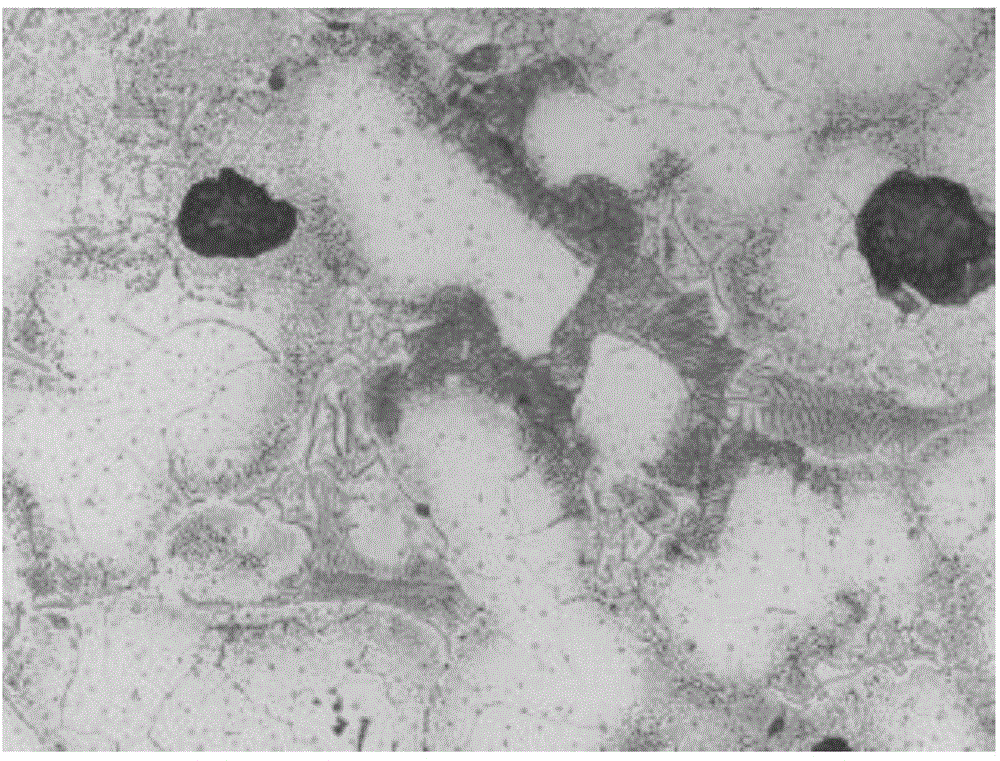

The invention relates to a nodular cast iron inoculant and a preparation method thereof and an application in smelting nodular cast iron. The nodular cast iron inoculant consists of 3-6% of Bi, 40-50% of Si, 0.5-3% of Ba, 0.1-3% of La, 10-18% of Ca, 1-3% of O, 0.5-3% of S and the balance of Fe and unavoidable trace elements. The nodular cast iron inoculant is prepared by the steps of mechanically mixing a metal oxide, a metal sulfide and a silicon iron-based alloy; adding an adhesive into a grinding device, and pressing the mixture into a cluster; breaking the cluster, screening and wrapping with an aluminum foil. In use, when the output molten iron accounts for about 1 / 2 of the lip-pour ladle, the inoculant is added to perform inoculation treatment on the nodular cast iron once or multiple times. The inoculant provided by the invention contains the trace elements such as O, S, Bi and the like and is low-silicon and efficient, and multiple heterogeneous nucleation mass points are formed in the iron liquid, thereby increasing the graphite quantity, improving the shock resistance, mechanical property and yield, increasing the utilization rate of foundry returns, and increasing the economic benefits.

Owner:宁波康发铸造有限公司

Novel as-cast 500-7 nodular cast iron

InactiveCN103484753AShorten the production cycleReduce coal consumptionTrace element compositionDuctile iron

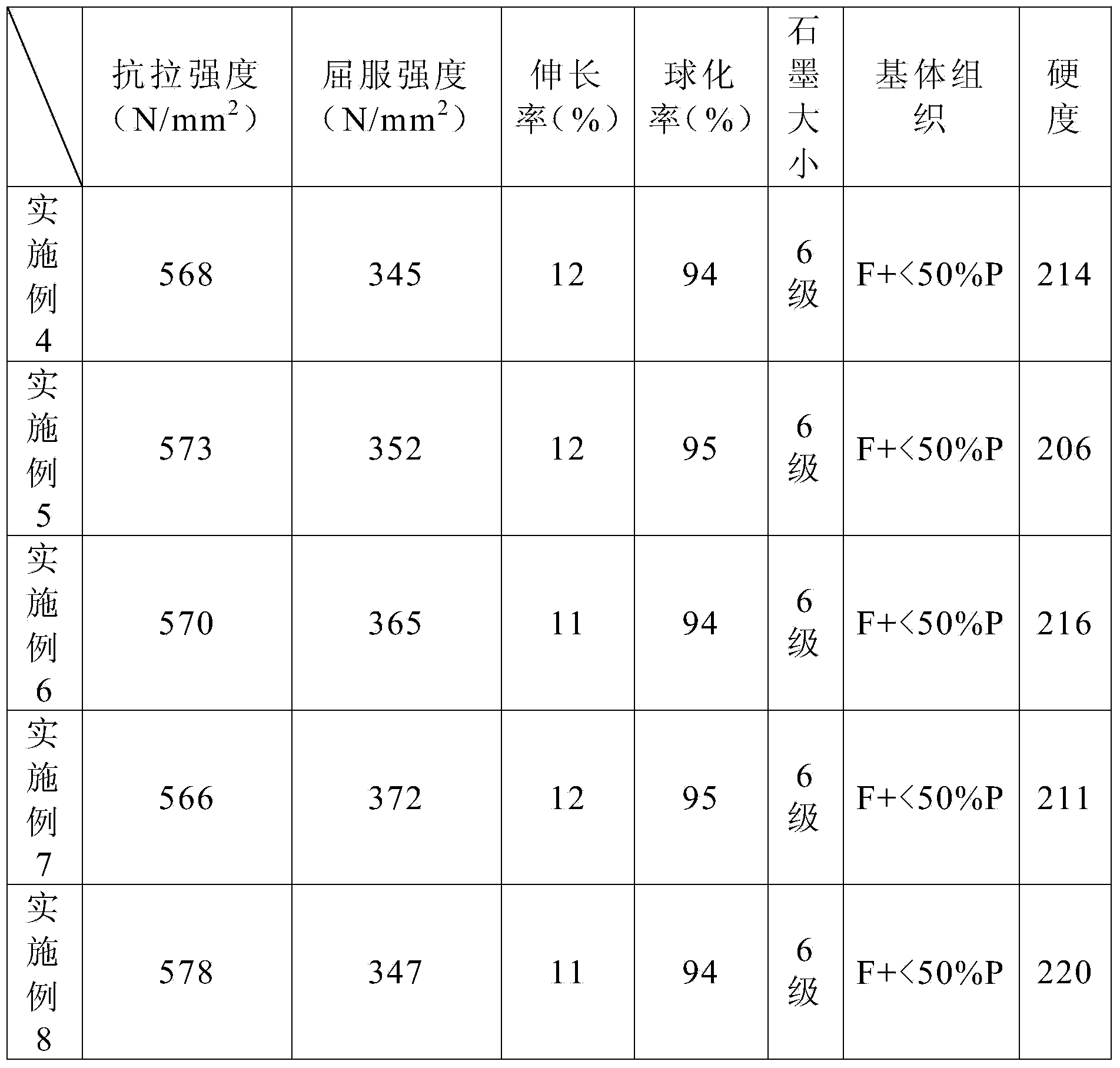

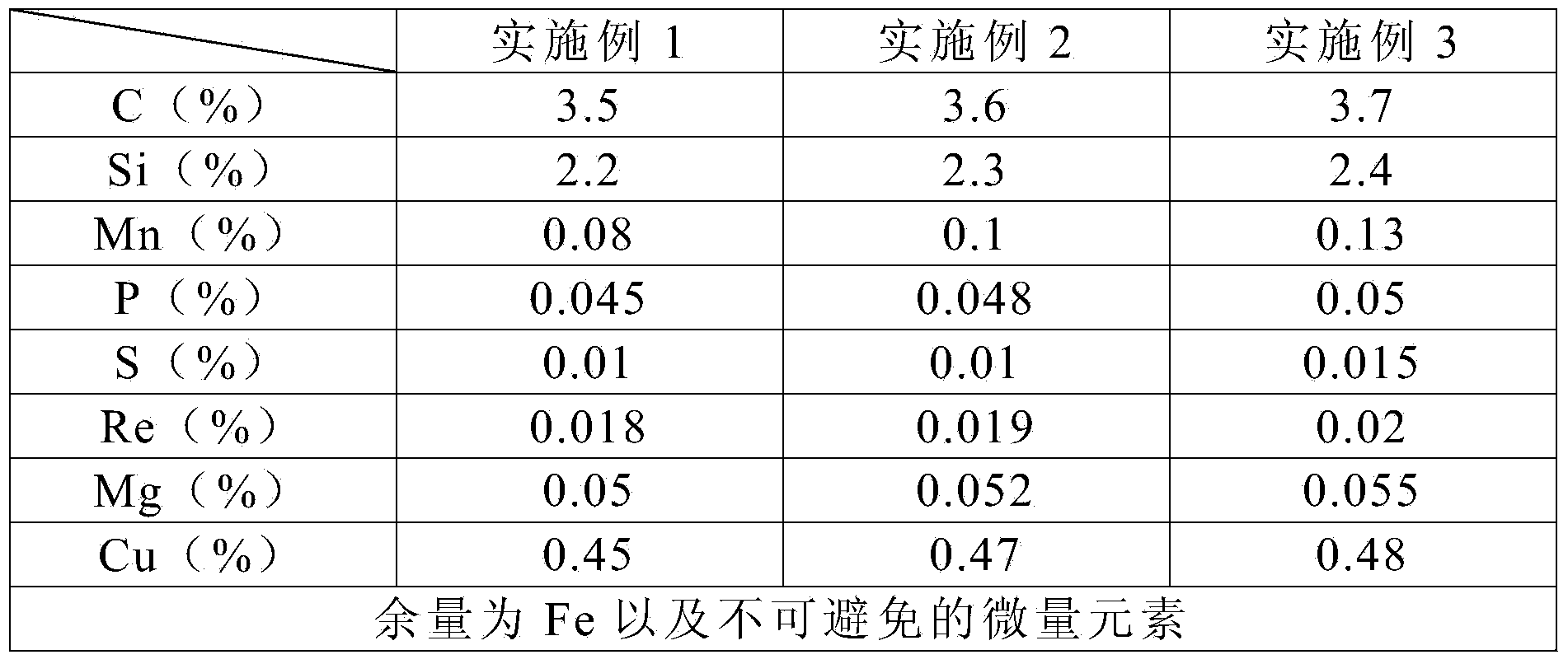

The invention relates to a novel as-cast 500-7 nodular cast iron which comprises the following components in percentage by mass: 3.5-3.7% of C, 2.2-2.4% of Si, 0.1-0.2% of Mn, 0.045-0.05% of P, 0.01-0.015% of S, 0.018-0.02% of Re, 0.05-0.055% of Mg, 0.45-0.48% of Cu, and the balance of Fe and inevitable microelements. The elements come from coke, limestone, new pig iron, returning iron, electrolytic copper, steel scrap and iron alloy. The preparation method comprises the following steps: weighing the raw materials according to the percentage by mass of the novel as-cast 500-7 nodular cast iron, smelting, spheroidizing and inoculating three times to obtain the novel as-cast 500-7 nodular cast iron. The novel as-cast 500-7 nodular cast iron has the advantages of short production cycle, low pollution, low cost and high strength, and can obtain a ferrite / pearlite mixed matrix under as-cast conditions.

Owner:宁波康发铸造有限公司

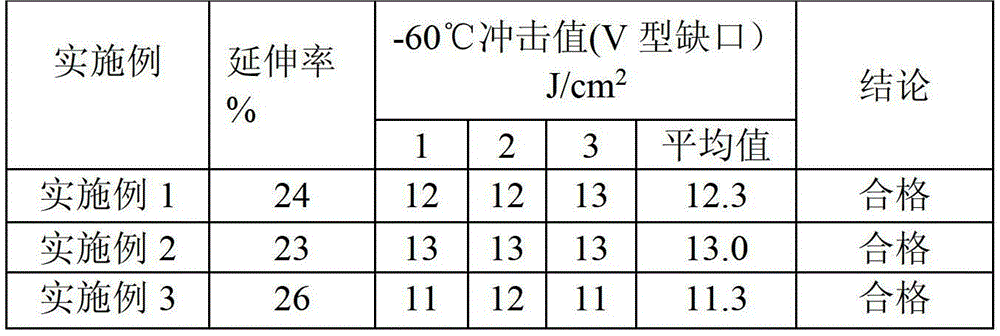

Preparation method of low temperature spherical iron casting for 3 MW wind power wheel hub as well as additive, nodulizing agent, inoculant and instantaneous inoculant for founding

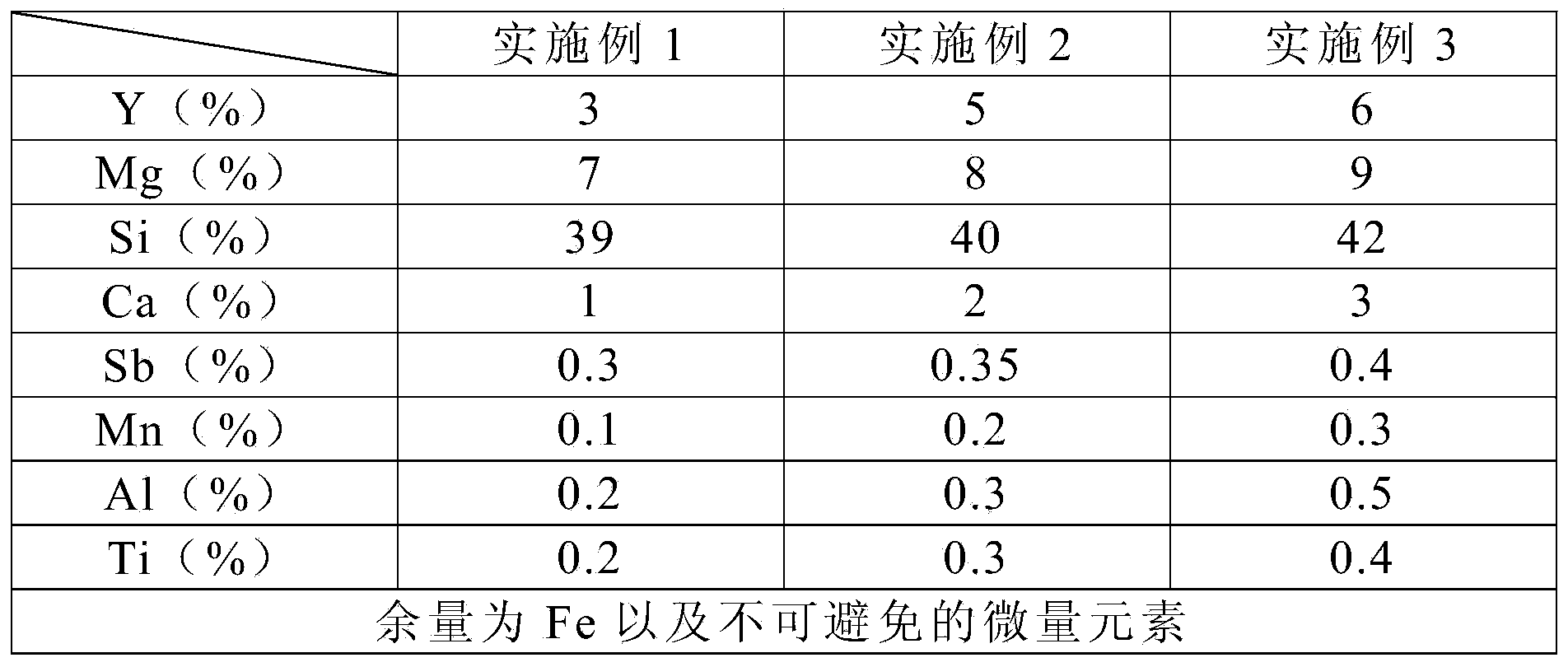

The invention relates to a preparation method of a low temperature spherical iron casting for a 3 MW wind power wheel hub as well as an additive, a nodulizing agent, an inoculant and an instantaneous inoculant for founding. The low temperature spherical iron comprises the following elements in percentages by weight: 3.6-3.9 percent of C, 1.7-2.5 percent of Si, 0.1-0.3 percent of Mn, less than 0.045 percent of P, less than 0.02 percent of S, 0.03-0.6 percent of Mg and the balance of trace impurity element. The preparation method of the low temperature spherical iron comprises the following steps of: (1) smelting; (2) nodulizing and inoculation, wherein the nodulizing agent consists of an A-type nodulizing agent and a B-type nodulizing agent, the A-type nodulizing agent comprises the following elements in percentages by weight: 5.5-6.5 percent of Mg, 44-48 percent of Si, 2-3 percent of Ba, 1-1.4 percent of Ca and the balance of Fe, and the B-type nodulizing agent comprises the following elements in percentages by weight: 6-7 percent of Mg, 42-45 percent of Si, 1.0-1.5 percent of Re and the balance of Fe, and stream inoculation is carried out in the nodulizing process and the inoculant comprises the following elements in percentages by weight: 72-76 percent of Si, 1.5-2.5 percent of Ca, 8-12 percent of Ba, less than 0.15 percent of Al and the balance of Fe; and (3) pouring: stream instantaneous inoculation is carried out in the pouring process and the instantaneous inoculant comprises the following elements in percentages by weight: 68-75 percent of Si, 0.75-1.25 percent of Ca, 1.5-2.5 percent of Bi, less than 0.15 percent of Al and the balance of Fe.

Owner:JIANGSU JIXIN WIND ENERGY TECH

High-strength sulfur-oxygen nucleating agent

The invention provides a high-strength sulfur-oxygen nucleating agent. The high-strength sulfur-oxygen nucleating agent comprises the following elements in percentages by mass: 70-76% of Si, 0.2-1.0%of Ca, 0.3-0.5% of Ba, 1.5-2.0% of La, 0.5-1.5% of Al, 0.3-0.9% of S, 0.3-0.9% of O, 0.5-1.5% of Sb and the balance of iron. The sulfur-oxygen nucleating agent is prepared from the following raw materials in parts by weight: 2-4 parts of steel scrap, 130-140 parts of silicon iron, 1-1.4 parts of silicon barium, 1-1.8 parts of calcium silicon, 2-4 parts of pure lanthanum, 1.5-2.5 parts of stibonium, 1-2 parts of FeS and 1-1.4 parts of FeO. By the prepared high-strength sulfur-oxygen nucleating agent, the number of graphite nodules in nodular cast iron can be increased obviously, the strength and toughness of the nodular cast iron can be improved, the chilling tendency of the nodular cast iron is relieved obviously, the nodularity, the number of graphite nodules and the number of ferrites ofthe nodular cast iron are increased, shrinkage in a casting process is eliminated, and complicated castings with excellent quality can be formed.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Ferritic spheroidal graphite cast iron and preparation method thereof

The invention relates to the field of spheroidal graphite cast iron, in particular to ferritic spheroidal graphite cast iron and a preparation method thereof. The ferritic spheroidal graphite cast iron comprises, by mass, 3.5%-3.8% of carbon, 2.4%-2.7% of silicon, 0.29%-0.35% of manganese, 0.03%-0.04% of cerium, 0.045%-0.06% of magnesium, 0.08%-0.1% of yttrium, 0.01%-0.02% of molybdenum, 0.02%-0.03% of rhenium, not more than 0.04% of phosphorus, not more than 0.018% of sulphur and the balance iron. The preparation method particularly includes the steps of (1), melting raw materials by a medium-frequency induction furnace prior to desulfurization; (2), uniformly mixing silicon carbide powder with rare earth magnesium alloy, then pouring the mixture into a spheroidizing package, covering the spheroidizing package with a first inoculant for spheroidizing and primary inoculation treatment prior to secondary inoculation treatment, and casting so as to obtain a cast; (3), subjecting the cast to heat treatment so as to obtain the ferritic spheroidal graphite cast iron. The ferritic spheroidal graphite cast iron is high in spheroidizing ratio and strength and excellent in toughness and impact plasticity, and the preparation method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

High-wear-resistance long-life ductile iron and method of producing lower cylinder with ductile iron

ActiveCN106834901AImprove wear resistanceExtended service lifeFoundry mouldsFurnace typesHigh wear resistanceDuctile iron

The invention discloses high-wear-resistance long-life ductile iron, comprising, by weight, 3.80-3.88% of C, 2.20-2.30% of Si, 0.55-0.65% of Mn, < / =0.020% of P, < / =0.010% of S, 0.45-0.55% of Cu, 0.30-0.40% of Mo, 0.0040-0.0060% of La, 0.035-0.045% of Mg, and the balance of iron and unavoidable impurity. The invention is intended to provide the high-wear-resistance long-life ductile iron that has high rigidity and fatigue strength and has improved tensile strength and plasticity, and a method of producing a lower cylinder with the ductile iron.

Owner:GUANGDONG ZHONGTIAN CHUANGZHAN DUCTILE IRON CO LTD

Heat-resisting spheroidal graphite cast iron and preparation method thereof

ActiveCN103820700AImprove heat resistanceImprove high temperature oxidation resistanceThermal fatigueAlloy

The invention relates to heat-resisting spheroidal graphite cast iron and a preparation method thereof. The preparation method comprises the following steps: smelting alloy, wherein the alloy comprises the following ingredients by mass: 2.7-3.5% of C, 4.0-5.0% of Si, 1.5-3.5% of W, 0.02-0.05% of Mg, 0.1-0.5% of V, Re being less than 0.03%, 0.15-0.6% of Mo, 0.05-1.0% of Mn, 0 to 0.03% of P, 0 to 0.02% of S, and the balance of iron and unavoidable impurities, discharging molten iron, inoculating the molten iron, spheroidizing, and casting. The heat-resisting spheroidal graphite cast iron prepared by the preparation method is of excellent high-temperature oxidation resistance, high-temperature anti-cracking property and thermal fatigue performance, and is good in mechanical property, low in production cost, and suitable for producing parts of an engine emission system.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Copper-antimony alloy spheroidal graphite cast iron material for crank shafts and preparation method thereof

The invention discloses a copper-antimony alloy spheroidal graphite cast iron material for crank shafts and a preparation method thereof. The copper-antimony alloy spheroidal graphite cast iron material for the crank shafts comprises the following chemical components:3.60-3.90 of C, 2.00-2.80 of Si, 0.30-0.50 of Mn, no more than 0.06 of P, no more than 0.03 of S, 0.02-0.05 of Re, 0.02-0.06 of Mg, 0.40-0.60 of Cu, 0.01-0.05 of Sb and the balance of Fe. The copper-antimony alloy spheroidal graphite cast iron material for the crank shafts can ensure that the mechanical strength of the spheroidal graphite cast iron crank shaft is greatly enhanced, the defective rate of the copper-molybdenum alloy spheroidal graphite cast iron crank shaft and the potential risk of shrinkage porosity of the crank shaft core are reduced, the production cost is greatly lowered and the economic value of the copper-antimony alloy spheroidal graphite cast iron crank shaft is increased.

Owner:ZHEJIANG SUN STOCK

Production method of heat-resistant spheroidal graphite cast iron for gas inlet housing

The invention discloses a production method of heat-resistant spheroidal graphite cast iron for a gas inlet housing. The production method comprises a material preparation process, a smelting process, a spheroidizing process, an inoculating process and a casting process. The heat-resistant spheroidal graphite cast iron for the gas inlet housing comprises the following components in percentage by weight: 3.00 to 3.40% of C, 3.60 to 4.00% of Si, 0.30 to 0.60% of Mn, not greater than 0.050% of P, not greater than 0.020% of S, 0.010 to 0.030% of Re, 0.020 to 0.060% of Mg, 0.40 to 0.70% of Mo, and the balance of iron. The heat-resistant spheroidal graphite cast iron for the gas inlet housing, produced by the method, is high in high-temperature strength and has oxidation resistance, anti-growth resistance and other heat-resistant performances.

Owner:RIYUE HEAVY IND

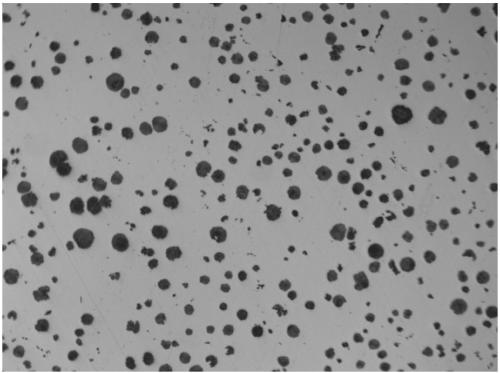

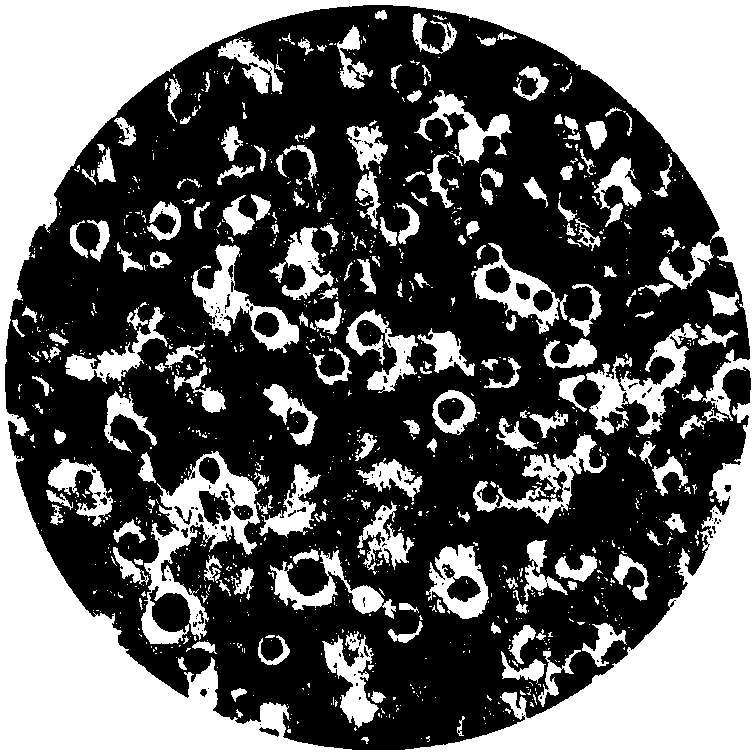

Control method for increasing number of graphite nodule by solid solution strengthening ferrite nodular cast iron with thick and large cross section

ActiveCN109402491AGuaranteed performanceGuaranteed uniformityProcess efficiency improvementPerformance indexSolid solution strengthening

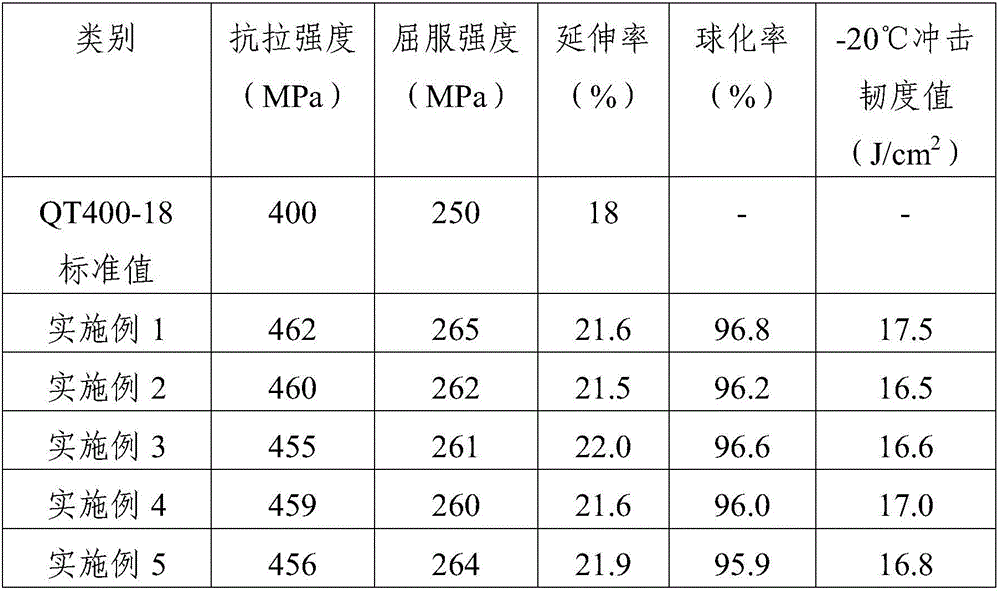

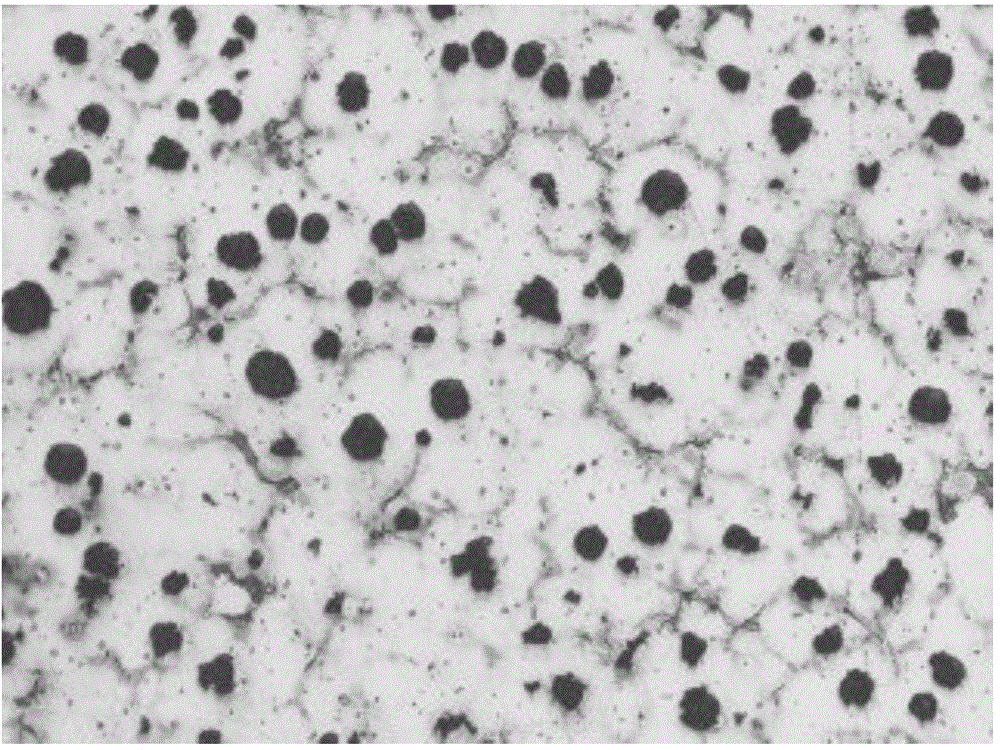

The invention discloses a control method for increasing the number of graphite nodules by solid solution strengthening ferrite nodular cast iron with a thick and large cross section, which comprises the following steps: selecting materials: 50-70 percent of pig iron and 30-50 percent of scrap steel; smelting: adding the materials into an electric furnace for smelting, wherein the tapping temperature of the molten iron is 1420-1450 DEG C; spheroidizing: adding a spheroidizing agent, adding a covering agent on the spheroidizing agent, and then spheroidizing, wherein the spheroidizing temperatureis 1420-1450 DEG C; inoculating: adding a silicon-aluminum-calcium-barium type inoculant during a primary inoculation, and respectively adding the inoculant on the surface of the covering agent and the other side of a ladle dam before tapping, wherein the distribution proportion is 50 percent; adding a trace amount of alloy Sb along with the flow of the molten iron during casting, wherein the adding amount of the alloy Sb is 0.003-0.005% of the total amount of the molten iron, molding, casting and cooling: ensuring that the casting opening temperature is controlled to be <= 300 DEG C, and thecasting is obtained by air cooling after the casting is opened. The control method has the advantages of obtaining higher number of the graphite nodules, ensuring a metallographic structure and goodconsistency of performance indexes, thereby improving the quality of the castings and prolonging the service life.

Owner:宁波日星铸业有限公司

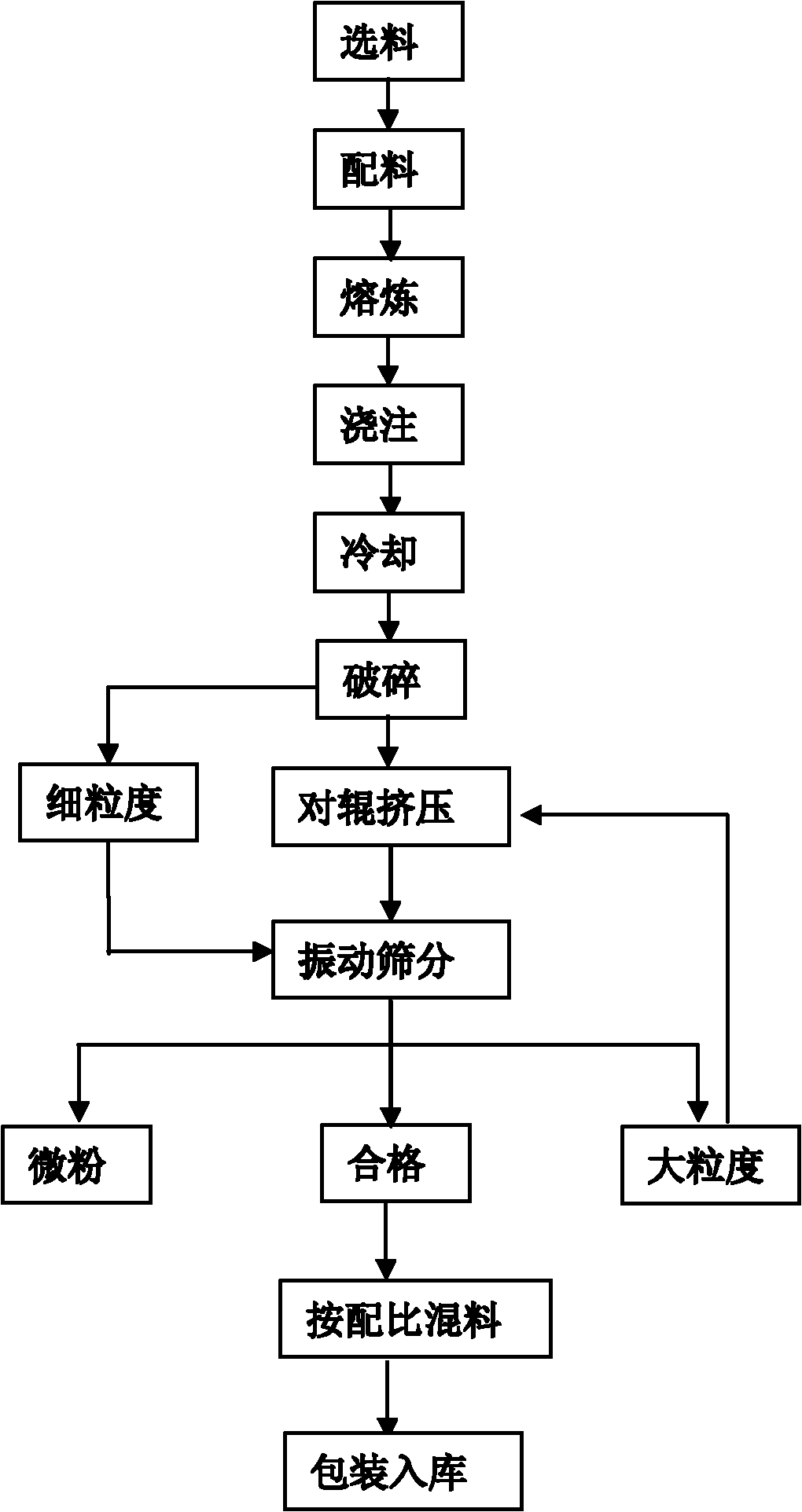

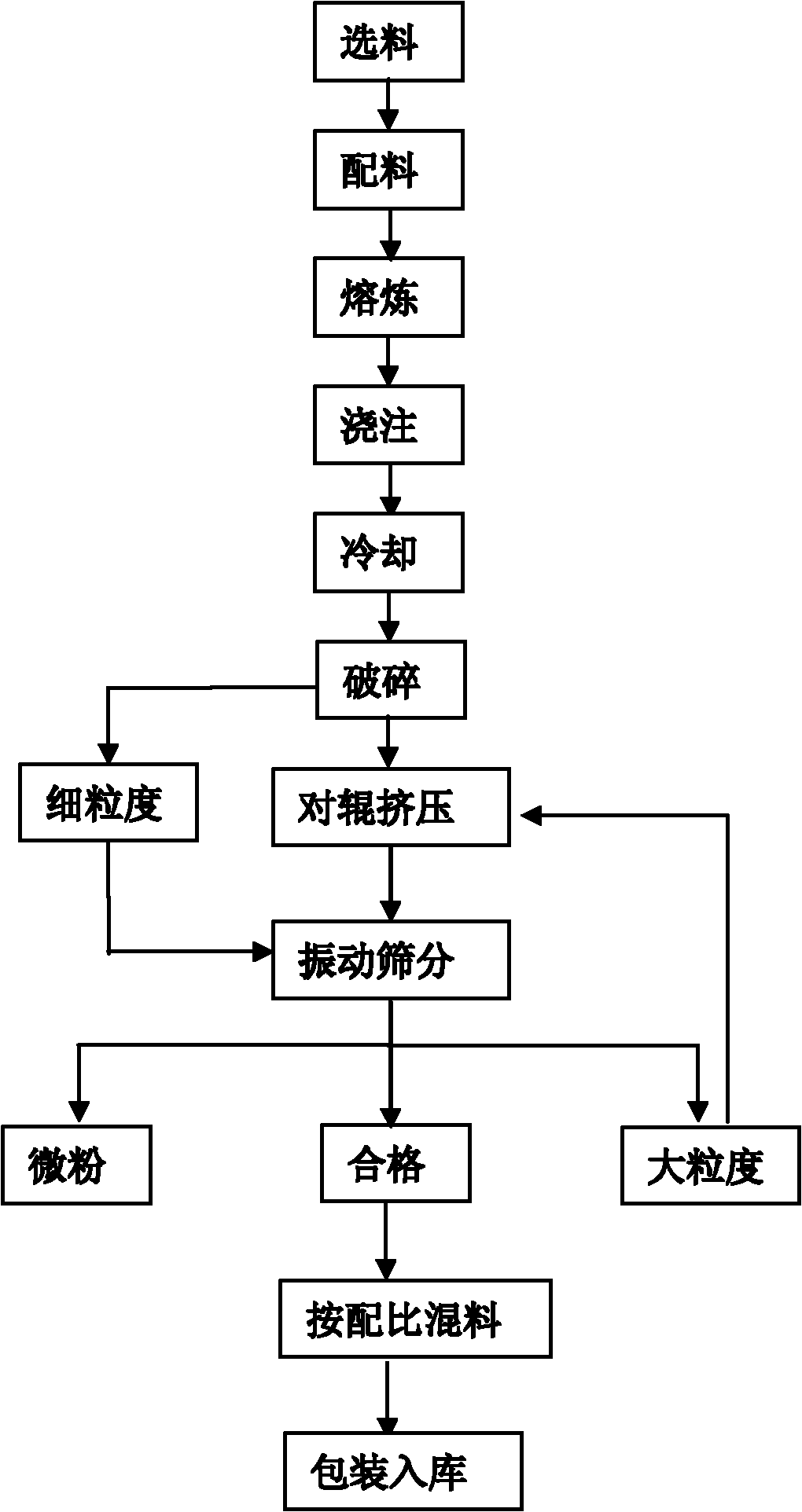

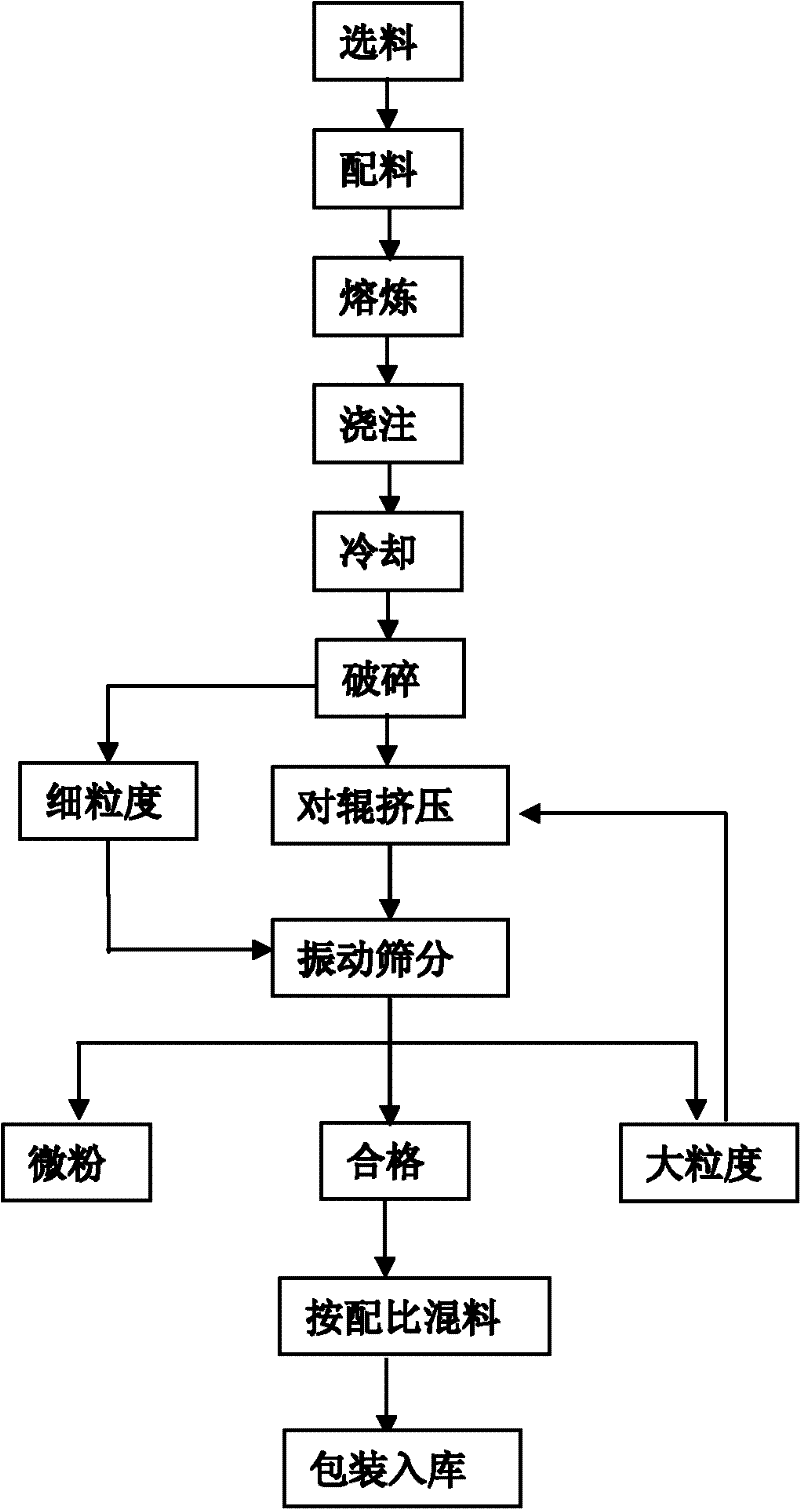

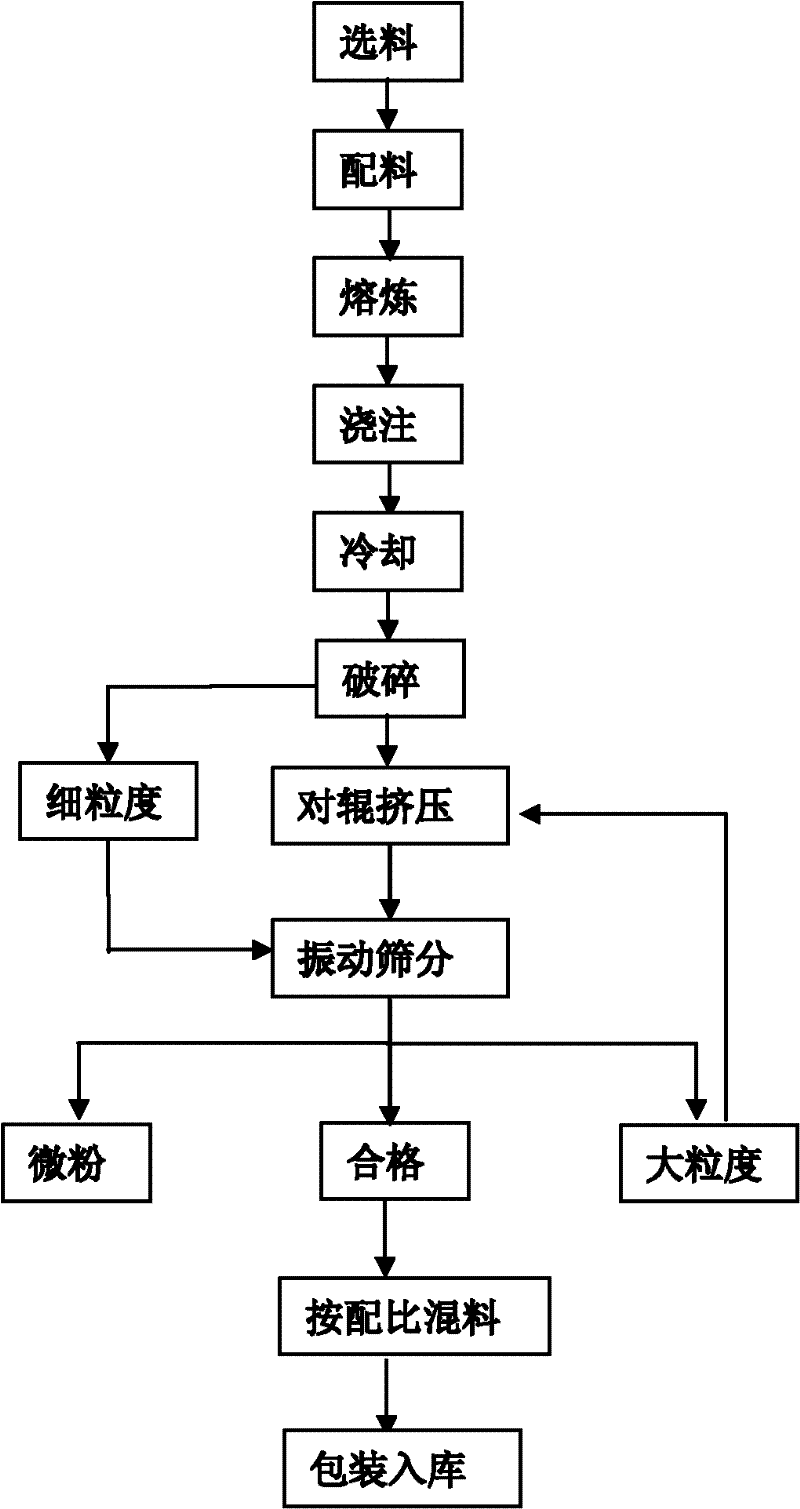

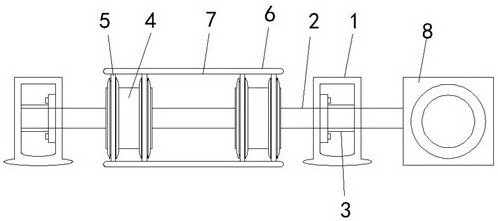

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Nodular cast iron manhole cover casting method for preventing cold shut defects

The invention discloses a nodular cast iron manhole cover casting method for preventing cold shut defects. Molten iron component selection is controlled, microelements exceeding general standards arenot allowed, reasonable nodulizing agents and nucleating agents are added, lanthanum can eliminate graphite deterioration and graphite floatation, the tendency of blooming graphite aggregation is decreased, the number of graphite nodules can be increased, nodulizing rate is increased, shrinkage porosity tendency is decreased, high-quality nodular cast iron liquid is provided, and the cold shut defects of a formed cast iron manhole cover are decreased. By strictly controlling casting temperature and casting modes, the probability of casting defects such as sand burning, shrinkage and deformation is reduced, and each casting mould is uniformly filled with molten iron. The cold shut defects are prevented by the aid of component control, casting temperature and mode control and the like in thecasting process, the nodular cast iron manhole cover is excellent in quality and mechanical property and worthy of popularization, and the process is conveniently controlled.

Owner:安徽大来机械制造有限公司

Inoculant for ferritic nodular cast iron and preparation method of inoculant

InactiveCN103146985APromote nucleationImprove the straightness effectExtensibilityChemical composition

The invention discloses an inoculant for a ferritic nodular cast iron and a preparation method of the inoculant, and the inoculant can be used for solving the problems that the nodular graphite cast iron prepared by an existing inoculant is less in graphite nodule quantity, low in ferrite content and poor in extensibility and impact ductility. The inoculant for the ferritic nodular cast iron comprises the following chemical compositions in percentage by mass: 65-70% of Si, 1.0-5.0% of Bi, 2.0-5.0% of Ca, 1.0-4.0% of Ba, less than 0.5% of Al, less than 0.05% of T1, less than 0.4% of Mn, less than 0.02% of S, less than 0.05% of P, and the balance of Fe; and the inoculant is prepared by smelting and granulating the raw materials. The ferritic nodular cast iron produced by using the inoculant can accelerate graphite nucleation, reduce the chilling tendency, increase the graphite nodule quantity, improve the graphite nodule element integration action, further improve the ferrite content under a cast condition, and improve the extensibility and impact ductility of ductile iron.

Owner:SHANDONG HUIFENG CASTING TECH

Inoculating agent used for thin-walled ferrite nodular cast iron and preparing method of inoculating agent

The invention discloses an inoculating agent for thin-walled ferrite nodular cast iron. With the total weight of the inoculating agent for the thin-walled ferrite nodular cast iron being 100%, the inoculating agent for the thin-walled ferrite nodular cast iron comprises, by weight, 68-70% of Si, 2-4% of RE, 1-2% of Sr, 0.3-0.8% of Bi, 1.0-3.0% of Ca, 2.0-4.0% of Ba, 0.3-0.5% of Al and the balanceFe. The obtained thin-walled ferrite nodular cast iron has the functions of promoting graphite nucleation, reducing chilling tendency, increasing the number of the nodular cast iron and improving theintegrity of the nodular cast iron, the ferrite content can be remarkably improved in a casting state, and the elongation and strength of the nodular cast iron are improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Preparation method of pipe powder for nodular cast iron and application of pipe powder

The invention discloses pipe powder for nodular cast iron. The formula of the pipe powder comprises the following components in percentage by weight: 62-70% of Si, 3-10% of Ba, 1-2% of Ca, 0.8-1.8% of Al, 0.5-1.5% of Fe3O4, the balance of Fe and inevitable microelements. According to the pipe powder for the nodular cast iron disclosed by the invention, the overall performance of the nodular cast iron can be improved, and the inoculation efficiency is improved.

Owner:成都宏源铸造材料有限公司

Manufacturing method of ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting

ActiveCN108866427AMeet technical requirementsShorten the setting timeFoundry mouldsFoundry coresNuclear powerDuctile iron

The invention discloses a manufacturing method of an ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting. The spheroidal graphite iron casting is more than 50 tons in weight, is 400mm or more in wall thickness, and is prepared from the following components: 3.6 to 3.7 percent of C, 0.9 to 1.0 percent of Si<original>, 1.9 to 2.0 percent of Si<final>, less than or equal to 0.1 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 0.03 to 0.08 percent of Mg, 0.01 to 0.02 percent of RE, 0.6 to 0.8 percent of Ni and0.003 to 0.005 percent of Sb. During manufacturing, the technical measures of ''high-temperature pure base iron melt, water-cooled metal mold, cold iron, spheroidizing agent 5800, compound strengthening inoculation, alloying and low-temperature box beating'' are adopted, so that the prepared ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting can meet the quality standard of a spheroidal graphite iron casting of which the license number is QT400-18, and can meet the technical requirements of ultra-large-section spheroidal graphite iron castings applied to wind power, nuclear power and the like.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

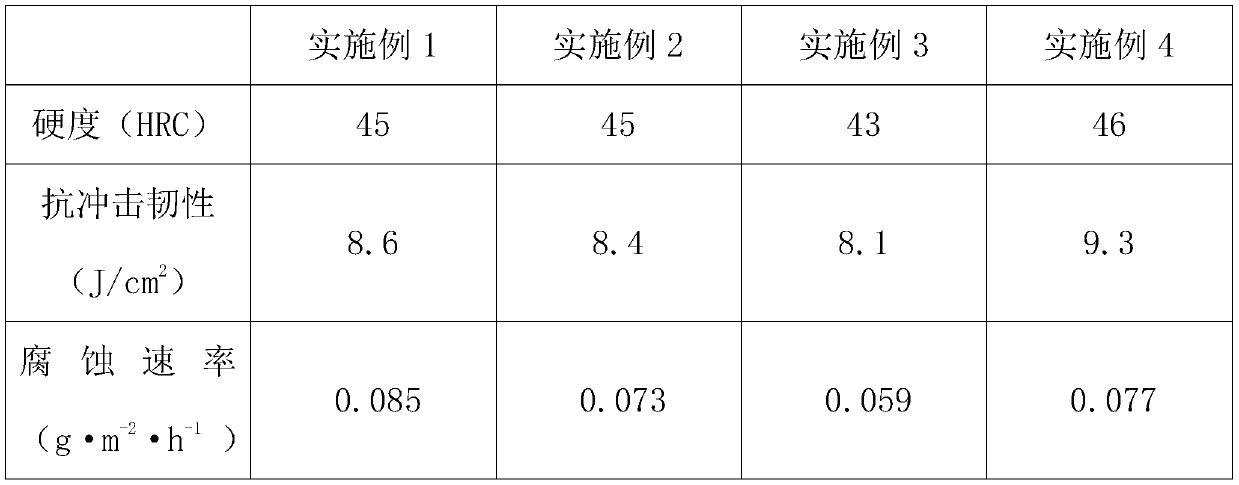

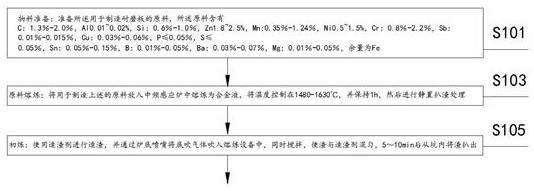

Acid-resisting, high-toughness and high-wear-resisting cast ball and preparing method thereof

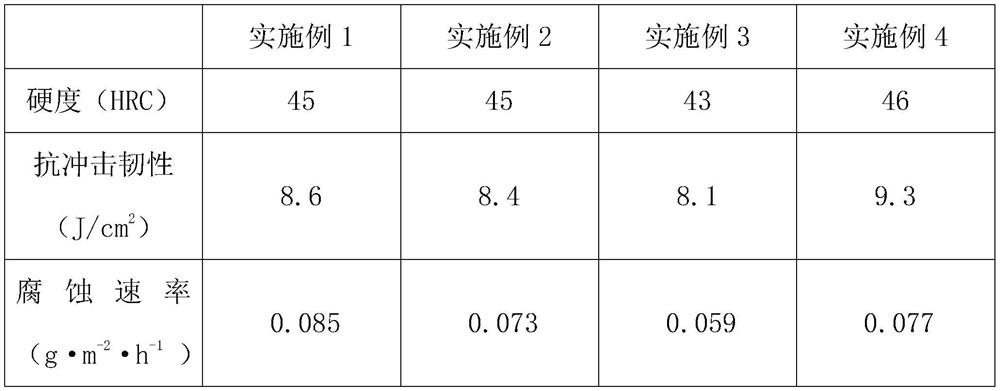

ActiveCN111074143AHigh hardnessImprove toughnessFurnace typesProcess efficiency improvementTemperingIngot

The invention discloses an acid-resisting, high-toughness and high-wear-resisting cast ball and a preparing method thereof. The preparing method includes the following steps that S1, smelting is conducted in a smelting furnace, and iron liquid is obtained; S2, an aluminum ingot is added into the iron liquid for deoxygenation before the iron liquid is discharged out of the furnace, then the iron liquid is transferred into a transferring ladle, after slagging off is conducted, the iron liquid is poured into a pouring ladle for pouring, and a cast blank is obtained after cooling; and S3, the castblank is heated to 500 DEG C to 510 DEG C for heat insulation for 2 h to 3 h, the temperature is then increased to 780 DEG C to 790 DEG C for heat insulation for 2 h to 3 h, then the temperature is increased to 940 DEG C to 950 DEG C for heat insulation for 2 h to 3 h, then the temperature is then increased to 1015 DEG C to 1030 DEG C for heat insulation for 2 h to 3 h, quenching oil is used forquenching for 10 min to 15 min, finally, tempering treatment is conducted after heat insulation is conducted for 6 h to 8 h at the temperature of 260 DEG C to 280 DEG C, and the cast ball is obtained.The cast ball prepared through the method has good acid-resisting and corrosion-resisting performance, in addition, the hardness is high, the wear-resisting performance is good, and economic benefitsare better increased.

Owner:宁国东方碾磨材料股份有限公司

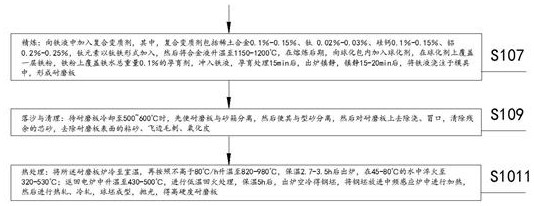

Control method for increasing the number of graphite nodules in solid solution strengthened ferritic ductile iron with thick and large section

ActiveCN109402491BEnsure consistencyStable and reliable gating systemProcess efficiency improvementPerformance indexDuctile iron

The invention discloses a control method for increasing the number of graphite nodules by solid solution strengthening ferrite nodular cast iron with a thick and large cross section, which comprises the following steps: selecting materials: 50-70 percent of pig iron and 30-50 percent of scrap steel; smelting: adding the materials into an electric furnace for smelting, wherein the tapping temperature of the molten iron is 1420-1450 DEG C; spheroidizing: adding a spheroidizing agent, adding a covering agent on the spheroidizing agent, and then spheroidizing, wherein the spheroidizing temperatureis 1420-1450 DEG C; inoculating: adding a silicon-aluminum-calcium-barium type inoculant during a primary inoculation, and respectively adding the inoculant on the surface of the covering agent and the other side of a ladle dam before tapping, wherein the distribution proportion is 50 percent; adding a trace amount of alloy Sb along with the flow of the molten iron during casting, wherein the adding amount of the alloy Sb is 0.003-0.005% of the total amount of the molten iron, molding, casting and cooling: ensuring that the casting opening temperature is controlled to be <= 300 DEG C, and thecasting is obtained by air cooling after the casting is opened. The control method has the advantages of obtaining higher number of the graphite nodules, ensuring a metallographic structure and goodconsistency of performance indexes, thereby improving the quality of the castings and prolonging the service life.

Owner:宁波日星铸业有限公司

Method for improving application performance of nodular cast iron on mine car wheel

InactiveCN111004966ASolve the problem of life and property safetyGood application effectSmelting processEconomic benefits

Owner:TONGLING MINGCHENG FOUNDRY

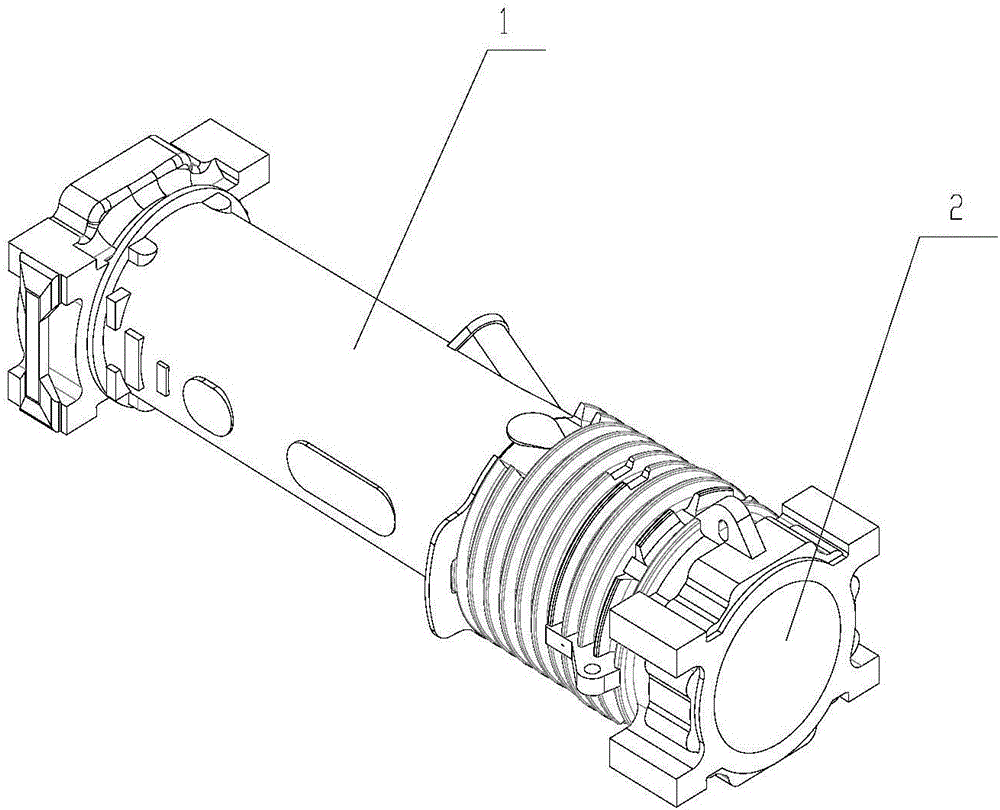

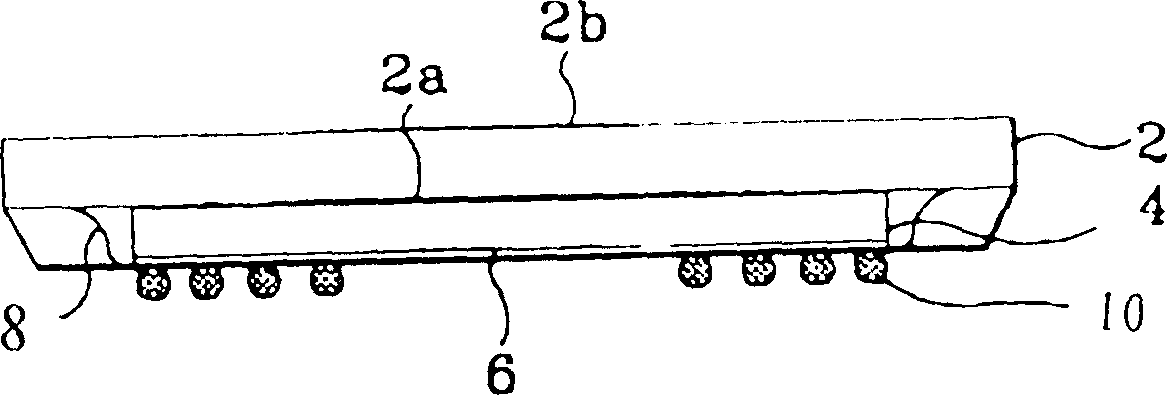

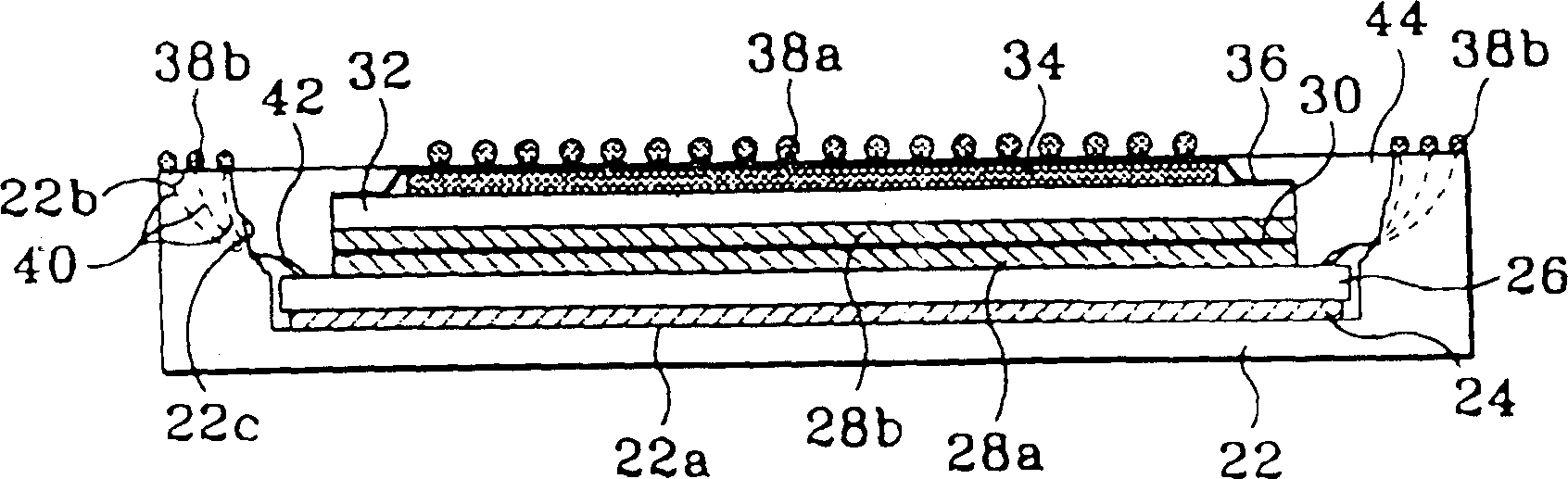

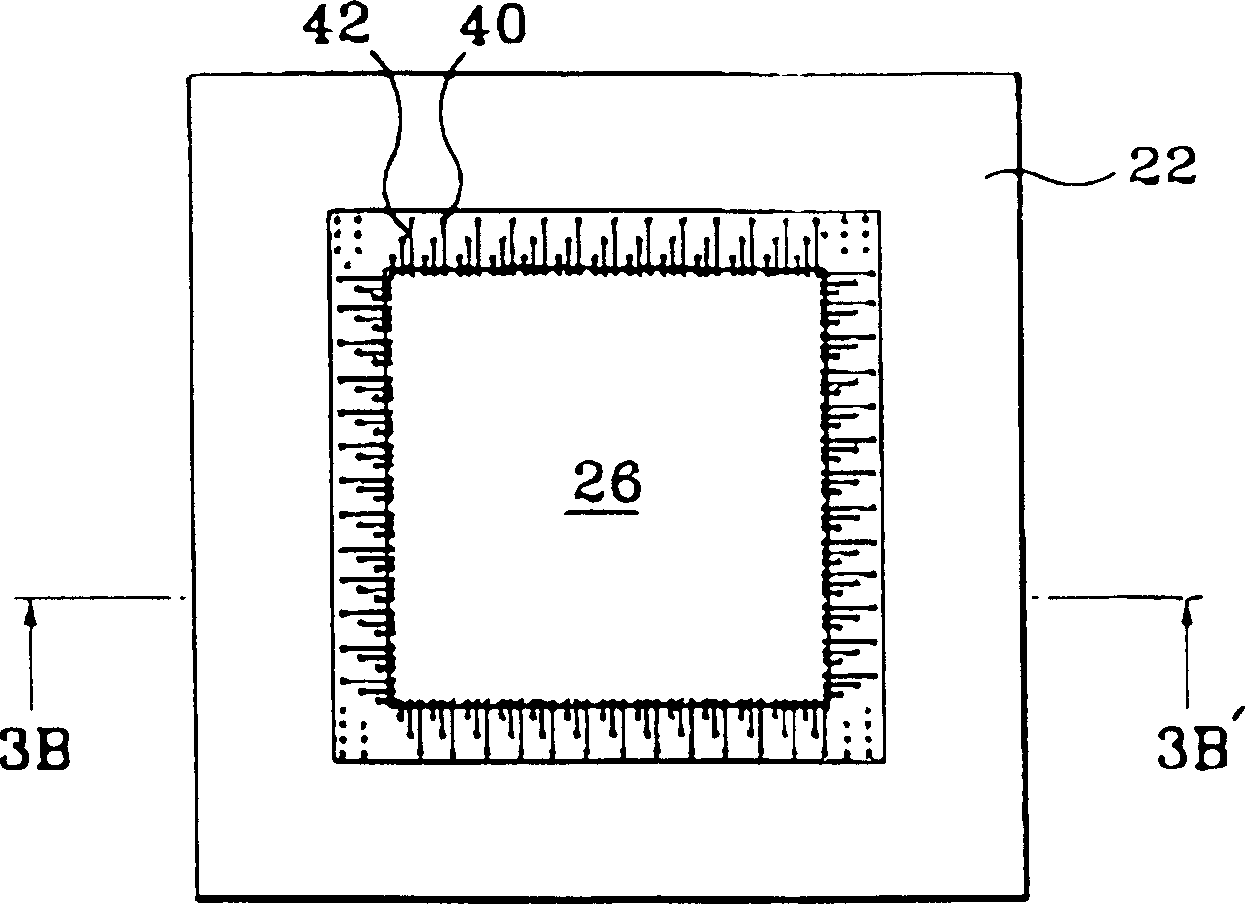

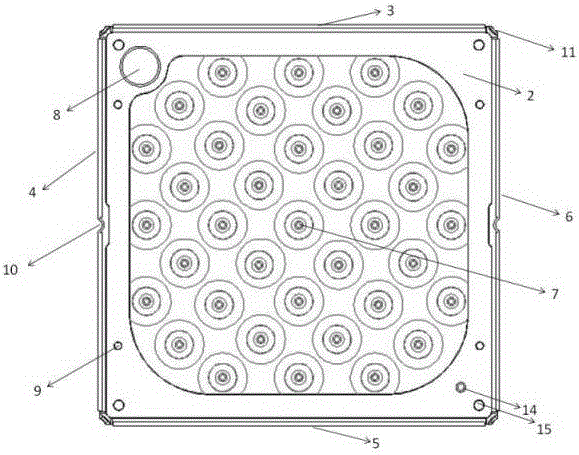

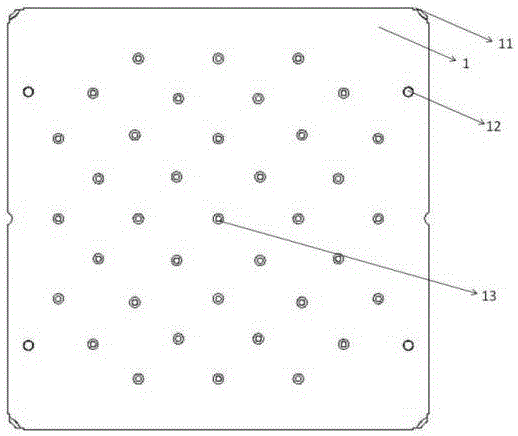

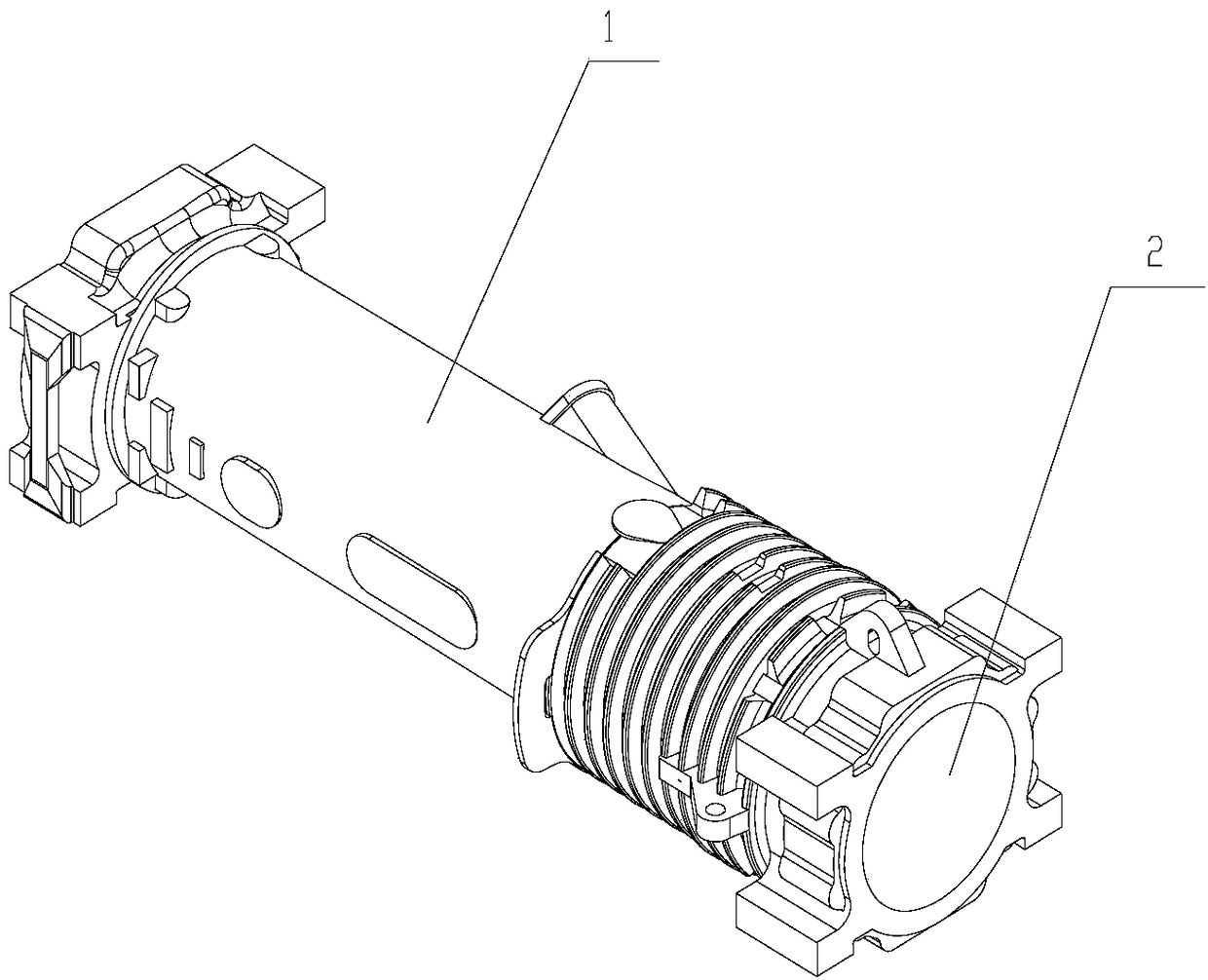

Spherical grid array package

InactiveCN1126172CHighly integratedIncrease the number of ballsSemiconductor/solid-state device detailsSolid-state devicesGate arrayElectrical connection

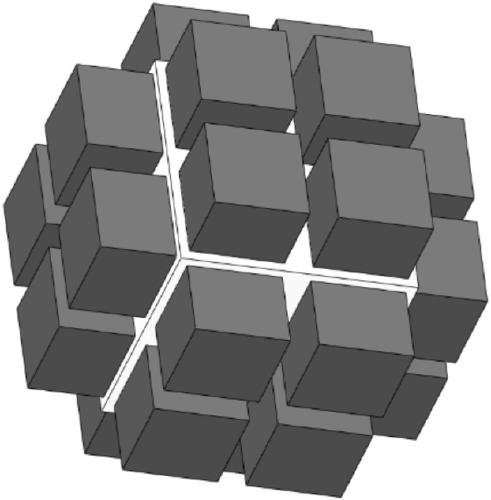

An improved ball grid array package BGA, which can prevent the impact between solder balls and improve integration, includes: a substrate with a first surface and a second surface higher than the first surface; at least one semiconductor chip, which is Stacked and arranged on the first surface, a plurality of pads are provided on the upper surface; a plurality of leads are provided on the substrate, one end of which is connected to a part of the pads of the semiconductor chip, and the other end is exposed on the second surface On: a plurality of conductive solder balls are formed on the surface of the semiconductor chip and the second surface of the substrate, and are electrically connected to the pads of the semiconductor chip and the leads exposed on the second surface of the substrate.

Owner:MAGNACHIP SEMICONDUCTOR LTD

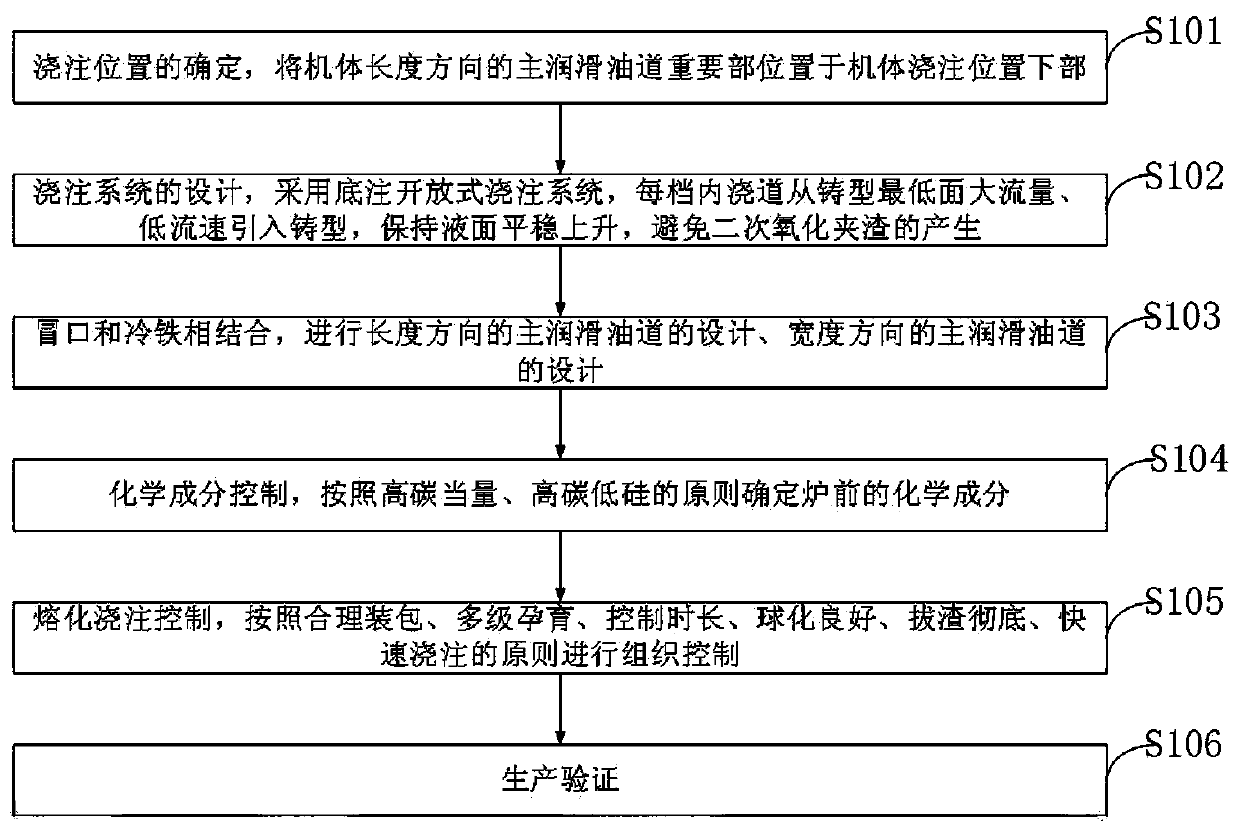

Method for forming main lubricating oil passage of nodular cast iron diesel engine body and application

The invention belongs to the technical field of cast iron casting, and discloses a method for forming a main lubricating oil passage of a nodular cast iron diesel engine body and application. A bottom-pouring open-type gating system with a filter device is adopted to purify molten iron, a feeding head is arranged at the thermal center part of the main lubricating oil passage, and cold iron is usedin cooperation to balance the temperature field of nodular cast iron; and the stokehold chemical composition, reasonable charging, multi-stage inoculation, duration control, good nodularization, thorough slagging-off and fast pouring parameters are determined according to the principles of high carbon equivalent and high carbon and low silicon, and internal compaction of the thick and large thermal center part is performed to eliminate shrinkage and slag inclusion inside the main lubricating oil passage of the engine body. The method is beneficial to realizing the basic balance of the temperature field of the nodular cast iron. The method guarantees the high quality of the molten iron, realizes the internal compaction of the thick and large thermal center part, eliminates the quality risks of shrinkage and slag inclusion defects inside the main lubricating oil passage of the engine body, and overcomes the shrinkage casting defect of the main lubricating oil passage of the complicatednodular cast iron diesel engine body.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

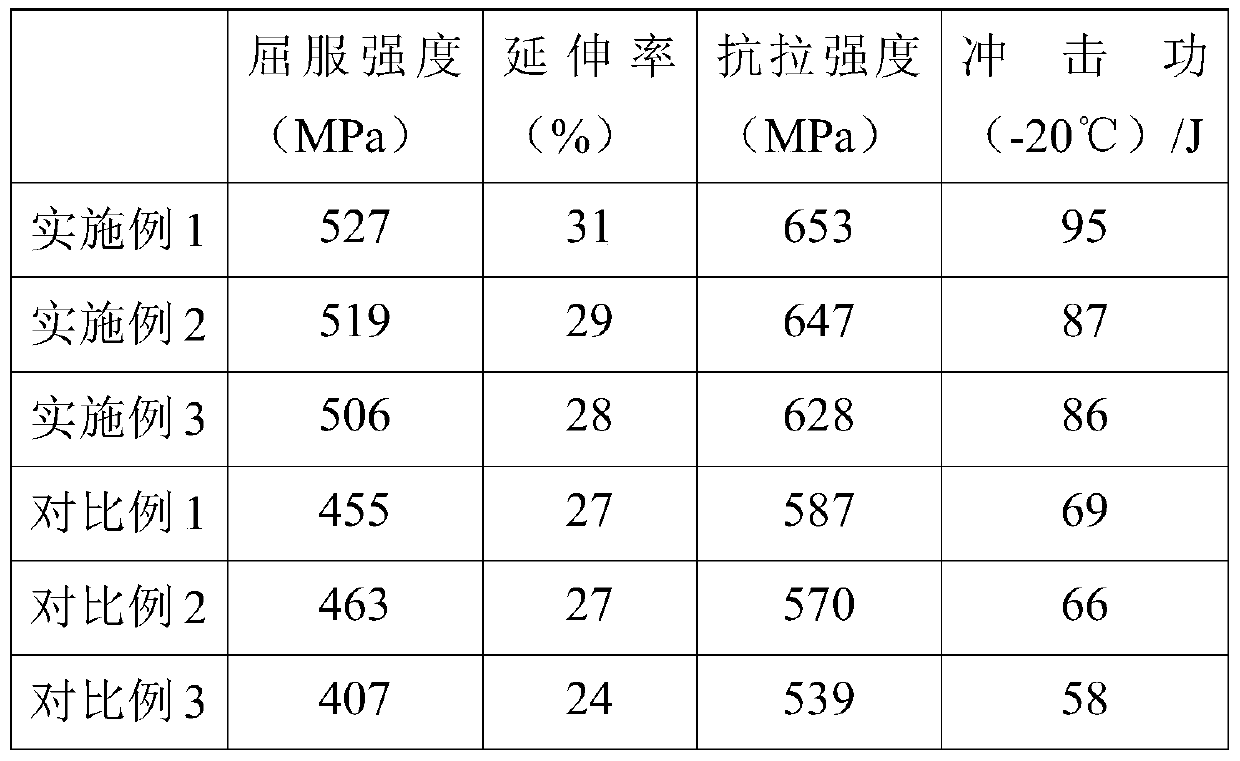

High-yield-strength hot-rolled section steel and production process thereof

InactiveCN110499468AHigh elastic limitImprove hardenabilityProcess efficiency improvementChemical compositionUltimate tensile strength

The invention discloses a high-yield-strength hot-rolled section steel. The chemical components of the hot-rolled section steel include: 0.08-0.20 wt% of C, 0.10-0.40 wt% of Si, 0.80-1.25 wt% of Mn, <= 0.02 wt% of P, <= 0.01 wt% of S, 0.25-0.40 wt% of Cu, 0.30-0.50 wt% of Cr, 0.30-0.50 wt% of Ni, 0.02-0.04 wt% of Nb, 0.01-0.03 wt% of Ti, 0.02%-0.05 wt% of V, 0.01-0.03 wt% of Ce, 0.01-0.05 wt% of Sb and the remainder being Fe and a trace of impurities. The production process of a hot-rolled H-shaped steel includes the following steps: (1) melting and deoxidizing, (2) converter smelting, (3) LFrefining, (4) VD vacuum treatment, (5) the continuous casting of a beam blank, (6) rolling, and (7) cooling to obtain the high-yield-strength hot-rolled H-shaped steel.

Owner:江苏方圆型钢有限公司

Preparation technology of wear-resistant and high-hardness wear-resistant plate and scraper conveyor comprising wear-resistant plates

InactiveCN113699466AImprove wear resistanceImprove hardness and corrosion resistanceConveyorsFoundry mouldsDrive shaftElectric machinery

The invention discloses a preparation technology of a wear-resistant and high-hardness wear-resistant plate and a scraper conveyor comprising the wear-resistant plates. The scraper conveyor comprises two racks, a driving shaft is arranged between the two racks, bearing seats matched with the driving shaft are arranged in the racks, chain wheels are arranged in the middle of the outer surface of the driving shaft and located between the two racks, chains are arranged on the chain wheels, a plurality of scrapers are arranged on the chains, the wear-resisting plates are arranged on the scrapers, and one end of the driving shaft penetrates through one rack and is connected with the output end of a driving motor. The preparation technology and the scraper conveyor have the beneficial effects that high carbon content contributes to graphitization and promotes magnesium absorption, so that all or most of carbon is spherical graphite, and the wear-resistant effect of the wear-resistant plate is enhanced.

Owner:江苏信铬钢耐磨复合材料有限公司

A method for producing as-cast Qt950-4 crankshaft by using all scrap steel

ActiveCN109594010BSolve the problem of deformation and oxidationLow impurity contentFoundry mouldsFoundry coresMetal moldCrankshaft

The invention belongs to the technical field of material forming, and particularly relates to a method for producing a casting-state QT950-4 crankshaft through full scrap steel. The method for producing the casting-state QT950-4 crankshaft through full scrap steel comprises following steps of raw material selection, burdening, smelting, chemical part control, spheroidization and inoculation, sandlined metal mold casting and box opening. Plate-shaped steel stub bars are adopted, the raw material quality is ensured, and it is ensured that the impurity content in the raw material is low, and thesource is stable.

Owner:云南云内动力机械制造有限公司

A kind of steel structure raised floor board

ActiveCN104074336BImprove carrying capacityIncrease the number of ballsFalse floorsEngineeringSkid plate

Owner:常州华通新立地板有限公司

An acid-resistant tough high-wear cast ball and its preparation method

ActiveCN111074143BHigh hardnessImprove toughnessFurnace typesProcess efficiency improvementTemperingSlag

The invention discloses an acid-resistant, tough, high-wear cast ball and a preparation method thereof. The preparation method comprises the following steps: S1, smelting in a smelting furnace to obtain molten iron; S2, adding aluminum ingots to the molten iron before being released from the furnace Carry out deoxidation, then transfer the molten iron to the transfer ladle, pour the slag into the pouring ladle for pouring, and obtain the cast slab after cooling; S3, raise the temperature of the cast slab to 500-510°C for 2-3h, and then raise the temperature to 780‑790°C for 2‑3h, then heated to 940‑950°C for 2‑3h, then raised to 1015‑1030°C for 2‑3h, quenched with quenching oil for 10‑15min, and finally kept at 260‑280°C for 6‑ 8h for tempering treatment, that is. The casting ball prepared by the invention not only has excellent acid and corrosion resistance, but also has high hardness and good wear resistance, which is beneficial to improving economic benefits.

Owner:宁国东方碾磨材料股份有限公司

Marine valve and marine filter casting

InactiveCN112281047AIncrease the number of ballsImprove the breeding effectProcess efficiency improvementRare-earth elementCasting defect

The invention discloses a marine valve and marine filter casting in the technical field of marine castings. The marine valve and marine filter casting comprises the following raw materials in parts byweight: 70-80 parts of pig iron, 20-25 parts of scrap steel, 2-3 parts of a nodulizing agent, 10-15 parts of a carburant and 1-2 parts of an inoculant. When the calcium content of the inoculant is 1.5-2.5%, the aluminum content of the inoculant is 0.5-1% if the calcium-aluminum content of the inoculant is within the range, MgAl silicate inclusions are used as nucleation cores of the spheroidal graphite, MgCa sulfide is clamped in multi-phase nucleation of the spheroidal graphite to play an important role, the number of graphite nodules can be remarkably increased, and the inoculation effect is the best; and when the calcium content exceeds 2.5% and the aluminum content exceeds 1%, the inoculation effect is gradually reduced; and according to the marine valve and marine filter casting, pigiron, scrap steel and 90% of carburant are put into a cupola furnace to be molten and then put into an induction furnace to be molten after being poured into an iron ingot, sulfur in the pig iron andthe scrap steel is removed in advance, the casting defects of slag inclusion, air holes and the like caused by sulfide formed by excessive sulfur, magnesium and rare earth elements are avoided, and the overall performance of a casting is improved.

Owner:LIYANG XINLI MASCH CASTING CO LTD

Heat-resistant ductile cast iron and preparation method thereof

ActiveCN103820700BImprove heat resistanceImprove high temperature oxidation resistanceThermal fatigueAlloy

The invention relates to heat-resisting spheroidal graphite cast iron and a preparation method thereof. The preparation method comprises the following steps: smelting alloy, wherein the alloy comprises the following ingredients by mass: 2.7-3.5% of C, 4.0-5.0% of Si, 1.5-3.5% of W, 0.02-0.05% of Mg, 0.1-0.5% of V, Re being less than 0.03%, 0.15-0.6% of Mo, 0.05-1.0% of Mn, 0 to 0.03% of P, 0 to 0.02% of S, and the balance of iron and unavoidable impurities, discharging molten iron, inoculating the molten iron, spheroidizing, and casting. The heat-resisting spheroidal graphite cast iron prepared by the preparation method is of excellent high-temperature oxidation resistance, high-temperature anti-cracking property and thermal fatigue performance, and is good in mechanical property, low in production cost, and suitable for producing parts of an engine emission system.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Nodular cast iron with high wear resistance and long service life and preparation method of lower cylinder using the cast iron

ActiveCN106834901BCooperate wellPromote formationFoundry mouldsFurnace typesHigh wear resistanceDuctile iron

The invention discloses high-wear-resistance long-life ductile iron, comprising, by weight, 3.80-3.88% of C, 2.20-2.30% of Si, 0.55-0.65% of Mn, < / =0.020% of P, < / =0.010% of S, 0.45-0.55% of Cu, 0.30-0.40% of Mo, 0.0040-0.0060% of La, 0.035-0.045% of Mg, and the balance of iron and unavoidable impurity. The invention is intended to provide the high-wear-resistance long-life ductile iron that has high rigidity and fatigue strength and has improved tensile strength and plasticity, and a method of producing a lower cylinder with the ductile iron.

Owner:GUANGDONG ZHONGTIAN CHUANGZHAN DUCTILE IRON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com