A kind of steel structure raised floor board

A raised floor and steel structure technology, applied to local raised floors, building structures, floors, etc., can solve the problems of insufficient floor strength, affecting the heating effect of the floor, and difficult to stack and transport, so as to achieve the central bearing capacity and the overall The effect of improving bearing capacity, maintaining integrity and load performance, and increasing grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

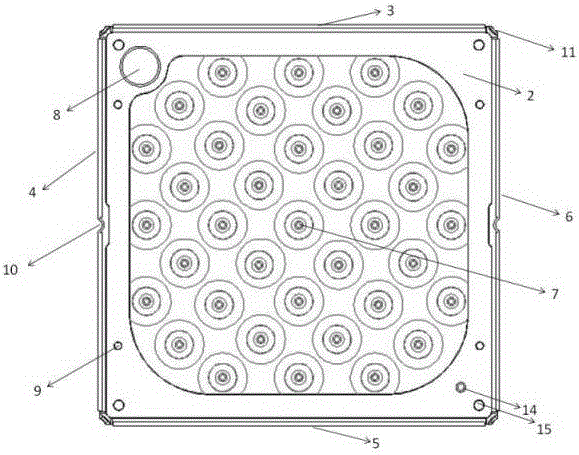

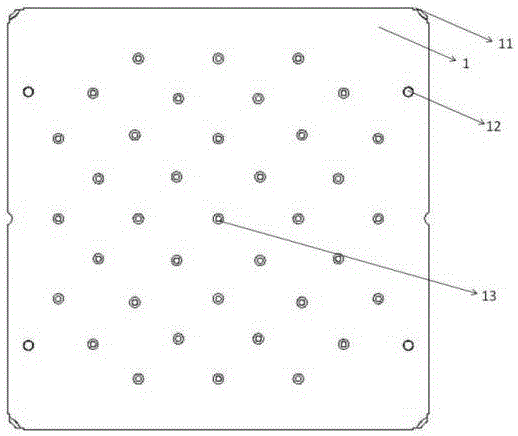

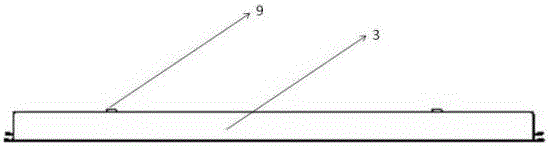

[0028] The present invention is described in further detail below by means of drawings and embodiments, as Figure 1-Figure 6 It is a schematic diagram of the six sides of the floorboard, which are the upper surface (1), the lower surface (2) and the four sides, in which the first side (3) is adjacent to the second side (4) and the third side (5) Relatively, the fourth side (6) is adjacent to the third side and opposite to the second side. The upper and lower surfaces and side surfaces of the floor board are made of steel, and the lower surface is provided with truncated spherical protrusions (7) of equal size. The center of the lower surface There is a section of spherical protrusion, and the remaining section of spherical protrusions are symmetrically arranged according to the center. There are 37 truncated spherical protrusions (7) in total, and there is a truncated spherical protrusion in the center of the lower surface, and the rest of the spheres are arranged symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com