Ferritic spheroidal graphite cast iron and preparation method thereof

A technology of nodular cast iron and ferrite, applied in the field of ferritic nodular cast iron and its preparation, to achieve the effects of reducing dendrites, excellent toughness and impact plasticity, increasing the number of graphite nodules and ferrite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

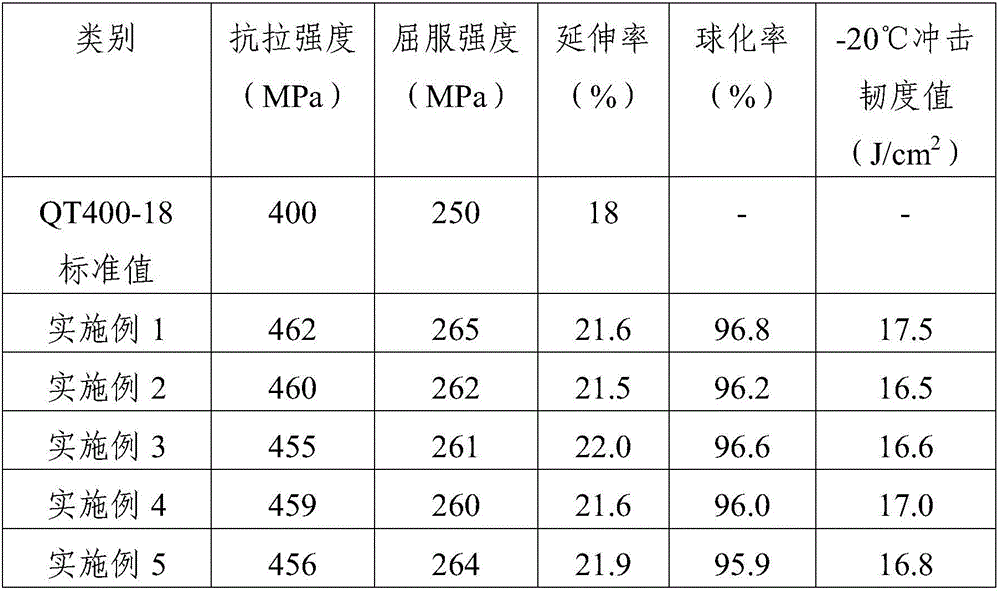

Examples

Embodiment 1

[0019] A ferritic nodular cast iron, the mass percent of each element composition in the ferritic nodular cast iron is: carbon 3.6%, silicon 2.5%, manganese 0.32%, cerium 0.035%, magnesium 0.05%, yttrium 0.09%, molybdenum 0.015% %, rhenium 0.025%, phosphorus ≤ 0.04%, sulfur ≤ 0.018%, and the balance is iron.

[0020] The preparation method of ferrite ductile iron specifically comprises the following steps:

[0021] (1) Melt low-phosphorus, low-sulfur high-quality pig iron and scrap steel in an intermediate frequency induction furnace at 1450°C, detect the content of each element in the molten iron after melting, and adjust the content of each element to meet the formula requirements, followed by desulfurization treatment ;

[0022] (2) Mix silicon carbide powder with 0.45% of the total weight of molten iron and rare earth magnesium alloy (particle size: 1.5mm) with 1.3% of the total weight of molten iron and pour it into the spheroidizing bag, compact it, and evenly cover the...

Embodiment 2

[0027] A ferritic nodular cast iron, the mass percent of each element composition in the ferritic nodular cast iron is: carbon 3.8%, silicon 2.4%, manganese 0.35%, cerium 0.03%, magnesium 0.045%, yttrium 0.08%, molybdenum 0.02% %, rhenium 0.02%, phosphorus ≤ 0.04%, sulfur ≤ 0.018%, and the balance is iron.

[0028] The preparation method of ferrite ductile iron specifically comprises the following steps:

[0029] (1) Melt low-phosphorus, low-sulfur high-quality pig iron and scrap steel in an intermediate frequency induction furnace at 1480°C, detect the content of each element in the molten iron after melting, and adjust the content of each element to meet the formula requirements, followed by desulfurization treatment ;

[0030] (2) Mix silicon carbide powder with a total weight of 0.35% of molten iron and a rare earth magnesium alloy (with a particle size of 0.5mm) of 1.5% of a total weight of molten iron, and then pour it into a spheroidizing bag, compact it, and evenly co...

Embodiment 3

[0035] A ferritic nodular cast iron, the mass percent of each element composition in the ferritic nodular cast iron is: carbon 3.5%, silicon 2.7%, manganese 0.29%, cerium 0.04%, magnesium 0.045%, yttrium 0.1%, molybdenum 0.01% %, rhenium 0.03%, phosphorus ≤ 0.04%, sulfur ≤ 0.018%, and the balance is iron.

[0036] The preparation method of ferrite ductile iron specifically comprises the following steps:

[0037] (1) Melt low-phosphorus, low-sulfur high-quality pig iron and steel scrap in an intermediate frequency induction furnace at 1460°C, detect the content of each element in the molten iron after melting, and adjust the content of each element to meet the formula requirements, followed by desulfurization treatment ;

[0038] (2) Mix the silicon carbide powder with 0.4% of the total weight of molten iron and the rare earth magnesium alloy (with a particle size of 1 mm) at 1.4% of the total weight of molten iron and pour it into the spheroidizing bag. The inoculant is pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com