Nodular cast iron with high wear resistance and long service life and preparation method of lower cylinder using the cast iron

A technology of high wear resistance and nodular cast iron, which is applied in the preparation of the lower cylinder and the processing of nodular cast iron, can solve the problems of high tensile strength, low tensile strength and low plasticity, and achieve high-quality comprehensive mechanical properties, high service life, The effect of ensuring wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

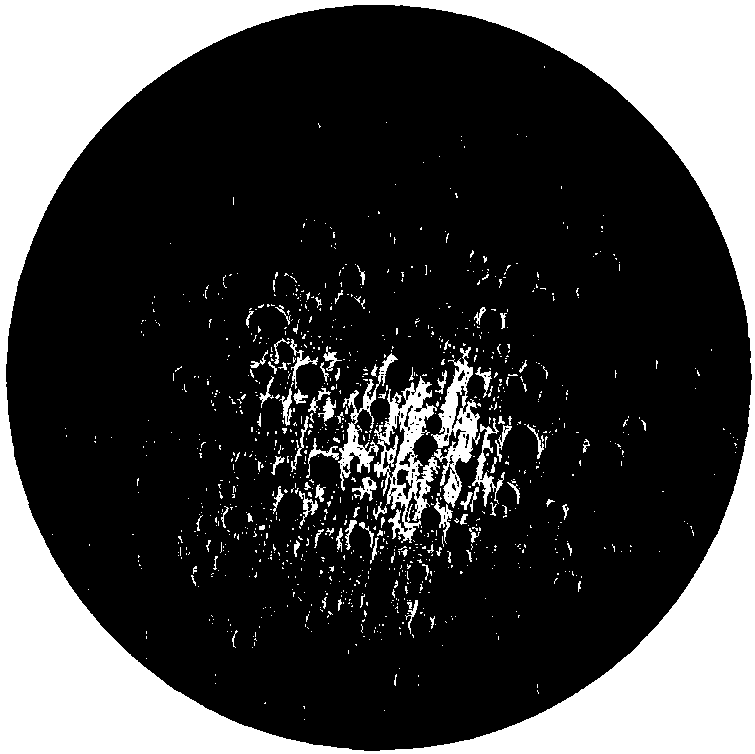

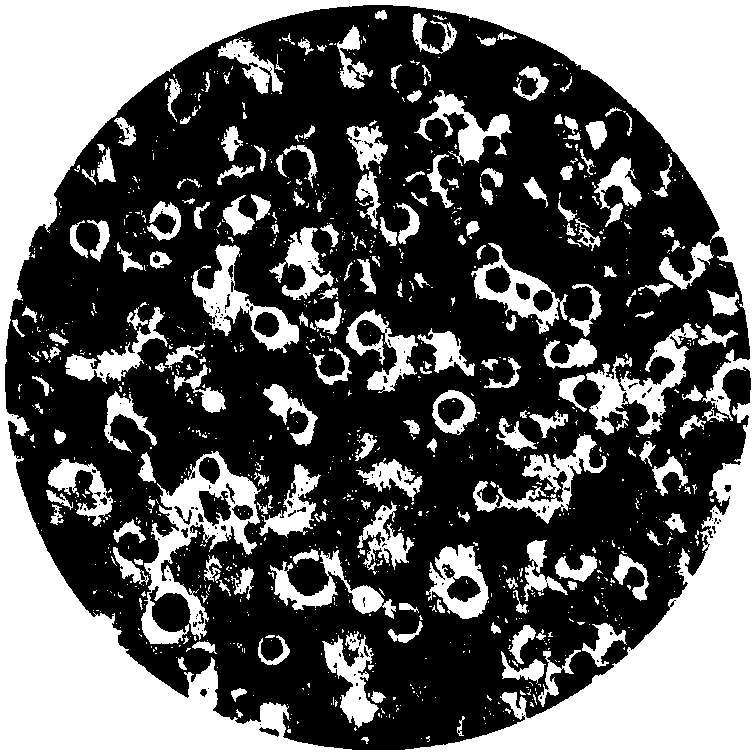

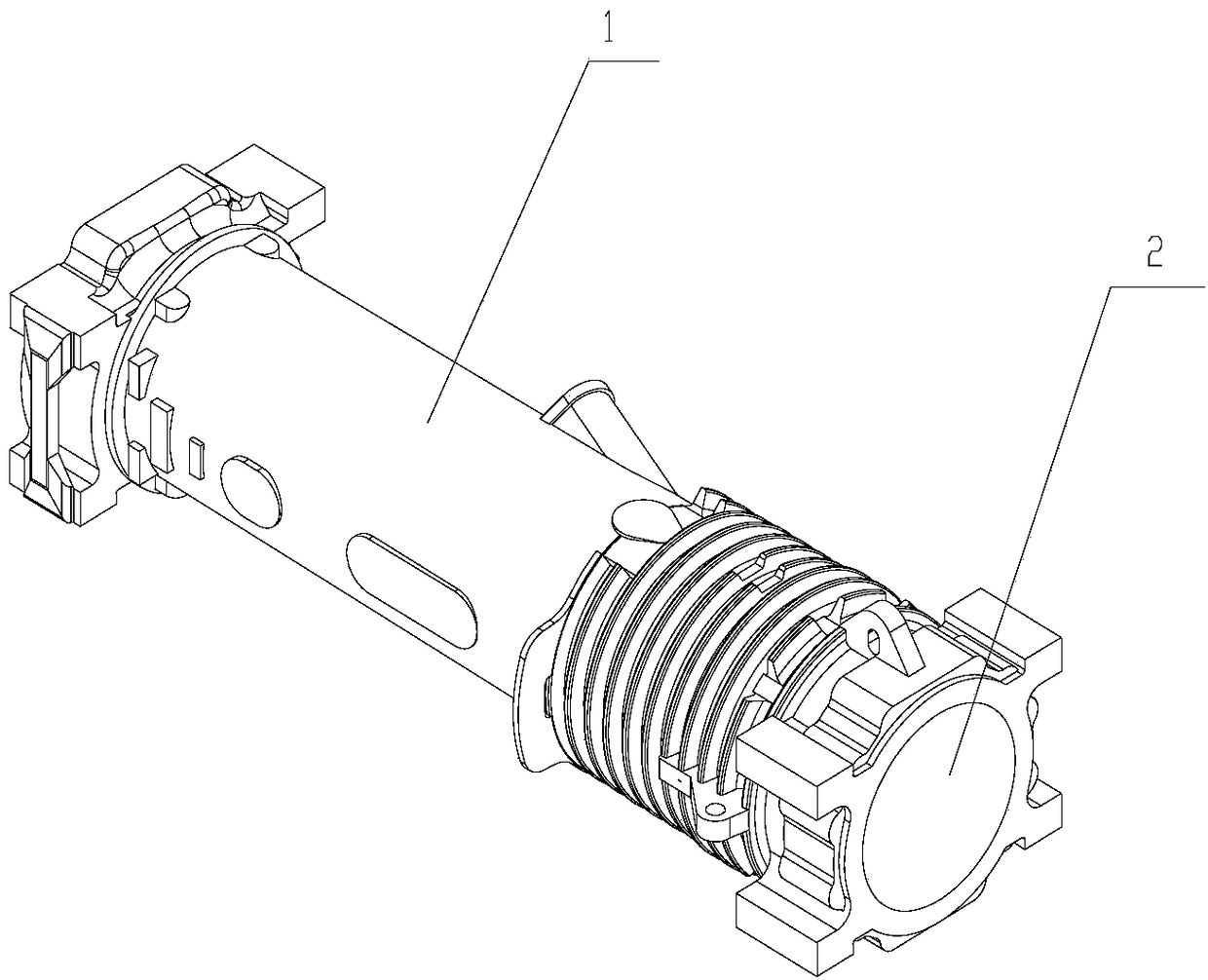

Image

Examples

Embodiment 1

[0038] Preparation method of lower cylinder of ductile iron with high wear resistance and long service life

[0039] 1.1 Raw material preparation:

[0040] The overall raw material requirements for the lower cylinder are C: 3.80%, Si: 2.20%, Mn: 0.65%, P: 0.017%, S: 0.005%, Cu: 0.55%, Mo: 0.30%, La: 0.0041%, Mg: 0.038 %, the balance of iron and non-removable impurities. In the present embodiment, in order to achieve the above-mentioned raw material requirements, the specific raw material ratio of the present invention is:

[0041] 50 parts by weight of automobile scraps, 50 parts by weight of metal stamping parts, 4.10 parts by weight of carburizers, 1 part by weight of lanthanide nodulizers, 0.6 parts by weight of high-calcium barium inoculants, 0.56 parts by weight of copper, and 0.2 parts by weight of sulfur oxide Inoculants, 1.92 parts by weight of ferrosilicon, 0.75 parts by weight of ferromanganese, and 0.54 parts by weight of ferromolybdenum.

[0042] The present inv...

Embodiment 2

[0063] Preparation method of lower cylinder of ductile iron with high wear resistance and long service life

[0064] 1.1 Raw material preparation:

[0065] The overall raw material requirements for the lower cylinder are C: 3.88%, Si: 2.30%, Mn: 0.55%, P: 0.015%, S: 0.008%, Cu: 0.45%, Mo: 0.40%, La: 0.0059%, Mg: 0.045 %, the balance of iron and non-removable impurities. In the present embodiment, in order to achieve the above-mentioned raw material requirements, the specific raw material ratio of the present invention is:

[0066] 50 parts by weight of automotive scraps, 50 parts by weight of metal stamping parts, 4.30 parts by weight of carburizers, 1 part by weight of lanthanide nodulizers, 0.6 parts by weight of high-calcium barium inoculants, 0.46 parts by weight of copper, 0.15 parts by weight of sulfur oxide Inoculants, 2.22 parts by weight of ferrosilicon, 0.50 parts by weight of ferromanganese, and 0.73 parts by weight of ferromolybdenum.

[0067] The present invent...

Embodiment 3

[0084] Preparation method of lower cylinder of ductile iron with high wear resistance and long service life

[0085] 1.1 Raw material preparation:

[0086] The overall raw material requirements for the lower cylinder are C: 3.85%, Si: 2.25%, Mn: 0.60%, P: 0.018%, S: 0.010%, Cu: 0.50%, Mo: 0.35%, La: 0.0050%, Mg: 0.0040 %, the balance of iron and non-removable impurities.

[0087] In the present embodiment, in order to achieve the above-mentioned raw material requirements, the specific raw material ratio of the present invention is:

[0088] 50 parts by weight of automobile scraps, 50 parts by weight of metal stamping parts, 4.19 parts by weight of carburizers, 1 part by weight of lanthanide nodulizers, 0.6 parts by weight of high-calcium barium inoculants, 0.51 parts by weight of copper, and 0.2 parts by weight of sulfur oxide Inoculants, 2.12 parts by weight of ferrosilicon, 0.60 parts by weight of ferromanganese, and 0.64 parts by weight of ferromolybdenum.

[0089] The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com