Patents

Literature

30results about How to "Increased ferrite content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing

ActiveCN101649369AReduce dosageImprove toughnessProcess efficiency improvementGranularityFerrosilicon

The invention discloses a melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing, which produces the synthetic cast iron by taking scrap steel, pig iron and cast iron returns or scrap steel and cast iron returns as the main raw materials in an induction furnace by utilizing SiC as an carburizing siliconizing agent, wherein the addition of SiC is 0.5-3%, and thegranularity is 6-20mm; SiC is added to a hearth before melting or is added during the melting process, or the two modes cooperate to be used. The invention utilizes SiC to replace the pig iron and silicon iron carburizing siliconizing to reduce the pig iron and silicon iron so as to reduce the cost, and meanwhile, the tendency of the molten iron chill and the reverse chill of the produced synthetic cast iron is small; the dimensions of graphite pebbles in produced nodular cast iron are small, the sphericity or roundness is high, the content of ferrite is high, and the roughness of the nodularcast iron is improved; the organization of produced grey cast iron is refined, and the mechanical property and the abrasion resistance are obviously improved. The invention can be used for producingvarious trademarks of grey cast iron, nodular cast iron and alloy cast iron.

Owner:河南省金太阳精密铸业股份有限公司

Production method for improving surface quality of high-grade pipeline steel

InactiveCN110157978AThe proportion of surface purging and grinding is smallReduce thicknessChemical compositionSheet steel

The invention discloses a production method for improving the surface quality of high-grade pipeline steel. The steel comprises the following chemical components in percentage by mass: 0.040-0.080% ofC, 0.10-0.30% of Si, 1.50-1.90% of Mn, P not more than 0.015%, S not more than 0.0030%, 0.10-0.30% of Ni, 0.10-0.30% of Cr, Cu not more than 0.20%, 0.040-0.070% of Nb, Mo not more than 0.15%, V not more than 0.01%, 0.005-0.02% of Ti, N not more than 0.0050%, 0.001-0.003% of Ca, 0.010-0.050% of Al, and the balance of Fe and inevitable impurities. Through optimization of a smelting process, the blank surface quality is improved; and through adjustment of a rolling forming technology, the steel plate surface scale completeness is improved, and the product quality is improved.

Owner:NANJING IRON & STEEL CO LTD

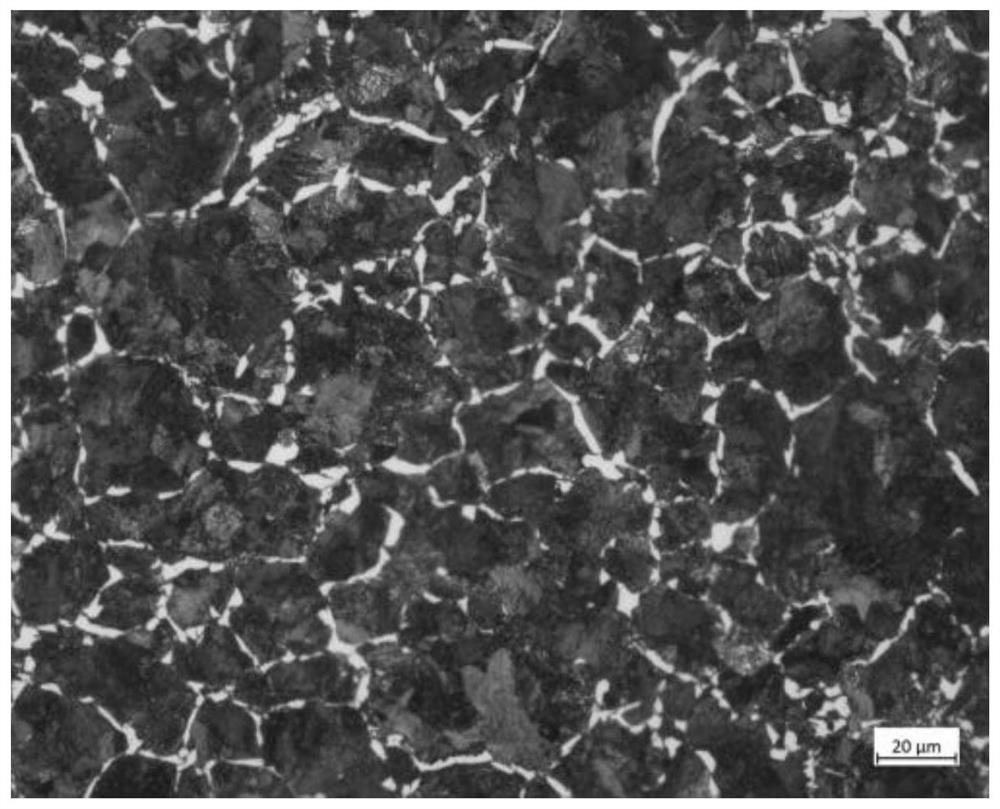

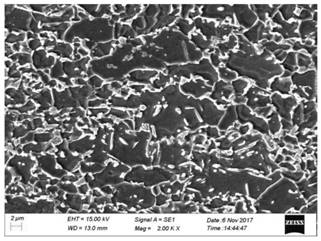

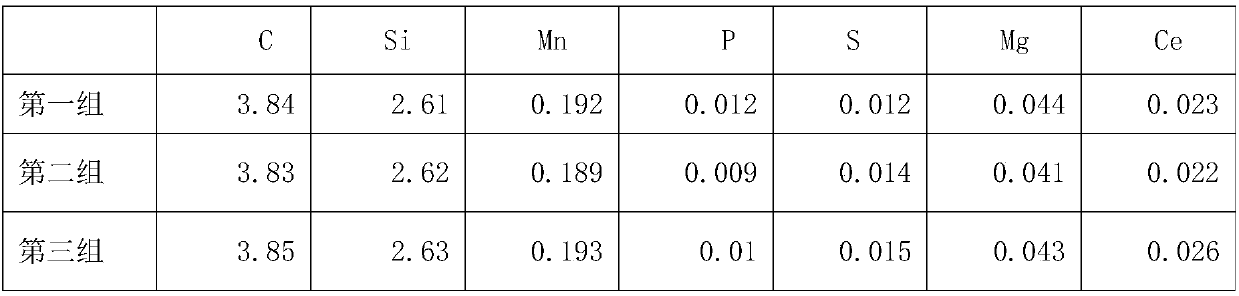

Ferritic spheroidal graphite cast iron and preparation method thereof

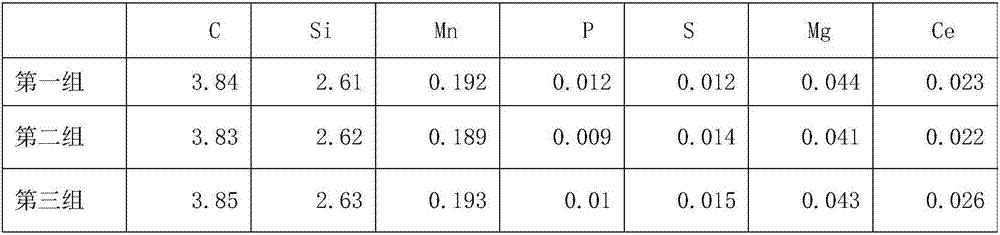

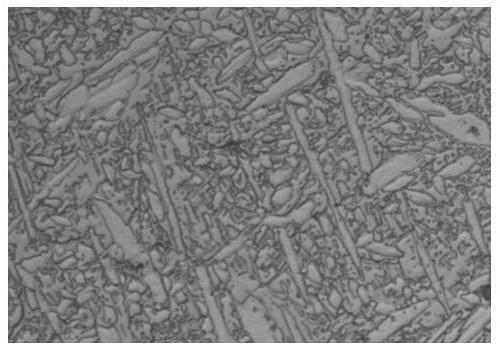

The invention relates to the field of spheroidal graphite cast iron, in particular to ferritic spheroidal graphite cast iron and a preparation method thereof. The ferritic spheroidal graphite cast iron comprises, by mass, 3.5%-3.8% of carbon, 2.4%-2.7% of silicon, 0.29%-0.35% of manganese, 0.03%-0.04% of cerium, 0.045%-0.06% of magnesium, 0.08%-0.1% of yttrium, 0.01%-0.02% of molybdenum, 0.02%-0.03% of rhenium, not more than 0.04% of phosphorus, not more than 0.018% of sulphur and the balance iron. The preparation method particularly includes the steps of (1), melting raw materials by a medium-frequency induction furnace prior to desulfurization; (2), uniformly mixing silicon carbide powder with rare earth magnesium alloy, then pouring the mixture into a spheroidizing package, covering the spheroidizing package with a first inoculant for spheroidizing and primary inoculation treatment prior to secondary inoculation treatment, and casting so as to obtain a cast; (3), subjecting the cast to heat treatment so as to obtain the ferritic spheroidal graphite cast iron. The ferritic spheroidal graphite cast iron is high in spheroidizing ratio and strength and excellent in toughness and impact plasticity, and the preparation method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

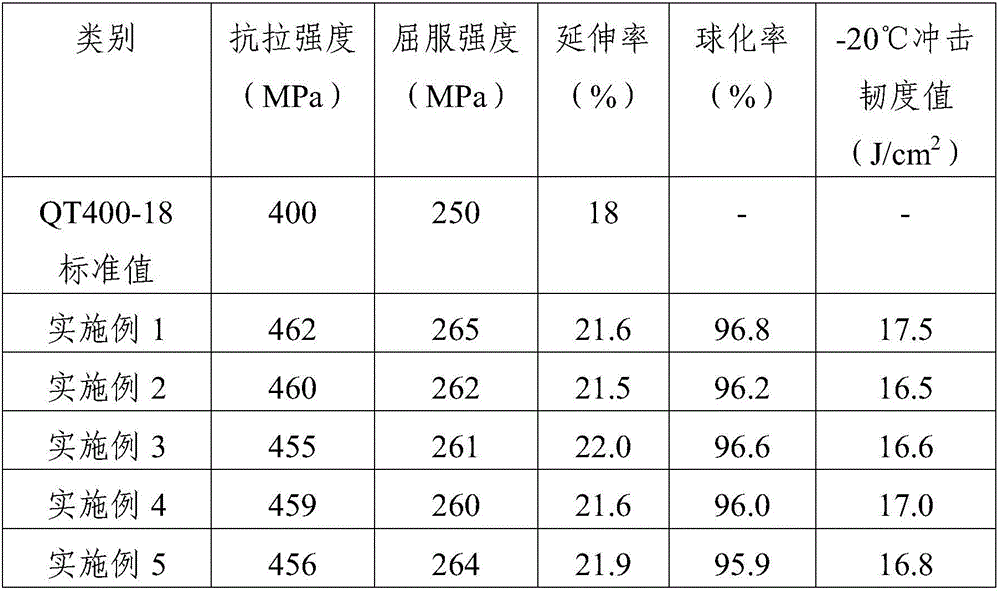

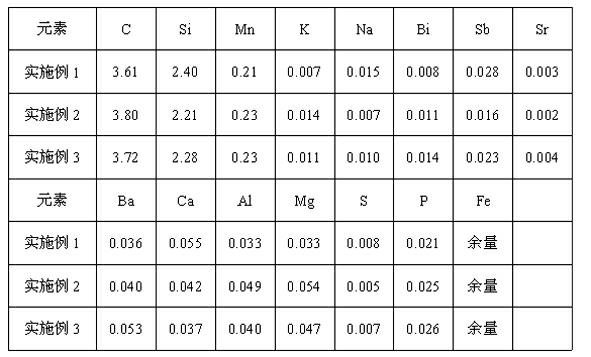

Wind-power equipment casting and manufacturing method thereof

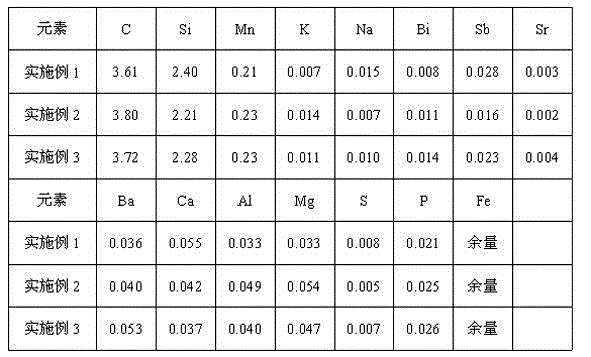

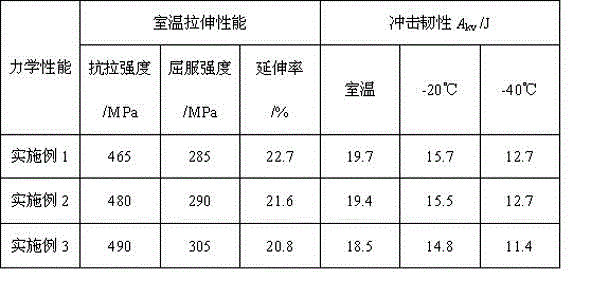

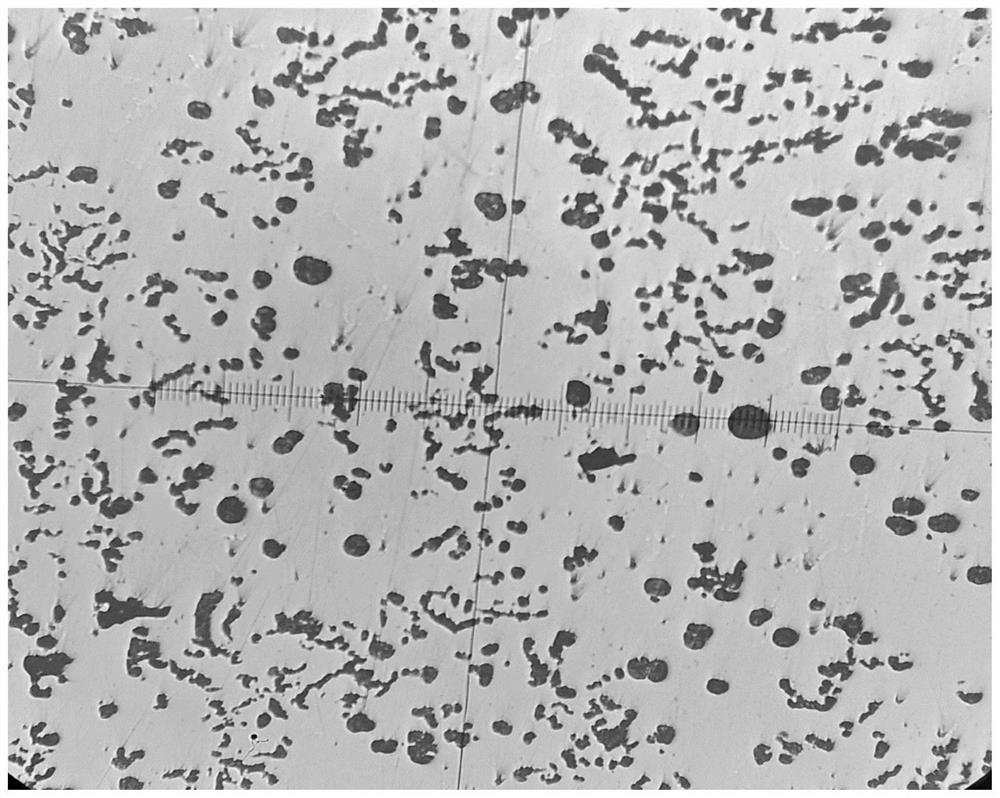

The invention relates to the technical field of manufacturing of wind-power generating equipment, in particular to a wind-power equipment casting and a manufacturing method thereof. The wind-power generating casting comprises the following chemical components in percentage by mass: 3.60-3.80 percent of C, 2.2-2.4 percent of Si, less than 0.25 percent of Mn, 0.006-0.015 percent of K, 0.006-0.015 percent of Na, 0.008-0.015 percent of Bi, 0.015-0.028 percent of Sb, 0.002-0.004 percent of Sr, 0.035-0.055 percent of Ba, 0.035-0.055 percent of Ca, 0.030-0.050 percent of Al, 0.032-0.055 percent of Mg, less than 0.03 percent of P, less than 0.01 percent of S and the balance of Fe. In the method, an electric furnace is adopted for smelting, and low-manganese waste steel and graphite are added instead of cast iron, supplementary iron and carbon for serving as major raw materials; for further improving the performance of the wind-power casting, a small quantity of micro-alloy elements such as bismuth, antimony, potassium, sodium, strontium, calcium, barium, aluminum and the like are added, so that the graphite is refined, the spheroidizing effect of the graphite is improved, and the effect of preventing degraded spheroidization is achieved; spheroidizing treatment with pure magnesium is performed; and inoculation treatment is performed by using a ferrite spheroidal graphite cast iron inoculant before casting. The wind-power equipment casting has the advantages of simple and convenient production process, low cost, high intensity and high toughness at room temperature and low temperature.

Owner:甘肃酒钢集团西部重工股份有限公司

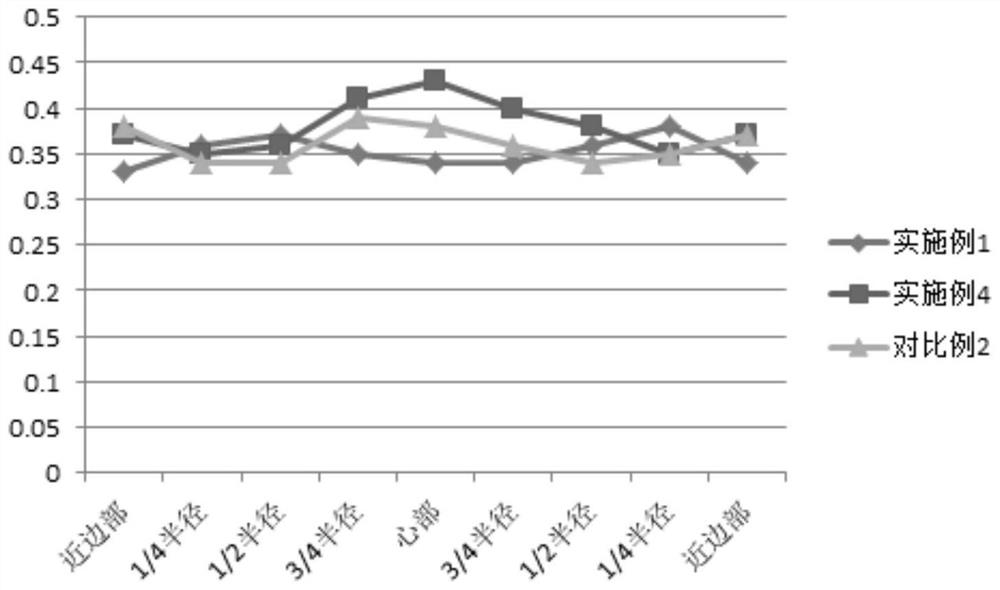

Production method for reducing hardness of X80M-grade pipeline steel

The invention discloses a production method for reducing the hardness of X80M-grade pipeline steel. Through a high-temperature rolling process, reasonable adjusting of phosphorus removal process and perfecting of rolling schedule, a laminar flow cooling process is optimized, a hybrid tissue structure is obtained, wherein the edge of the hybrid tissue structure is mainly made of quasi-polygonal ferrite, and the core of the hybrid tissue structure is mainly made of acicular ferrite, bainite and a small amount of martensite and austenite islands, it is ensured that the Wechsler hardness value ofthe surface and the section of a steel plate is stabilized within 220, the performance requirements for the steel plate are ensured, and economic benefits are remarkable.

Owner:NANJING IRON & STEEL CO LTD

Non-quenched and tempered steel for crankshaft, crankshaft forging and preparation process thereof

The invention provides a non-quenched and tempered steel for a crankshaft, a crankshaft forging and a preparation process thereof, and belongs to the technical field of the non-quenched and tempered steel. The non-quenched and tempered steel comprises the following components in percentage by weight: 0.36-0.39% of C, 0.50-0.65% of Si, 1.35-1.50% of Mn, 0-0.030% of P, 0.040-0.055% of S, 0-0.25% ofCr, 0-0.20% of Mo, 0-0.03% of Al and 0.010-0.020% of N; and the carbon equivalent Ceq is 0.75-0.81%. The hardenability of the non-quenched and tempered steel is J5mm of 47-52 HRC, J9mm of 35-42 HRC and J13mm of 30-36 HRC; the tensile strength is not lower than 760 MPa; the elongation A is not lower than 14%; the belt structure is not higher than 2.0 grade; the Brinell hardness is 220-250 HBW; andthe non-quenched and tempered steel is suitable for preparing crankshaft forgings.

Owner:SGIS SONGSHAN CO LTD

Manufacturing method of thick-wall high-strength ship plate steel for high heat input welding

InactiveCN113249638ARefined grain sizeImprove the stability of welding performanceAustenite grainAlloy

The invention discloses a manufacturing method of thick-wall high-strength ship plate steel for high heat input welding, and relates to the technical field of steel production. A high-cleanliness smelting blank is obtained through a magnesium metallurgy technology by adopting a converter and RH vacuum treatment, a high-reduction rolling deformation technology is carried out below a recrystallization temperature according to a metallurgical principle technology, by means of magnesium metallurgy, growth of austenite grains is effectively controlled in microalloy, the thick-wall high-strength ship plate with fine grains and excellent performance is obtained in cooperation with the after-rolling rapid cooling process, a yield strength ranges from 400 MPa to 600 MPa, and the requirement for high heat input welding is met.

Owner:NANJING IRON & STEEL CO LTD

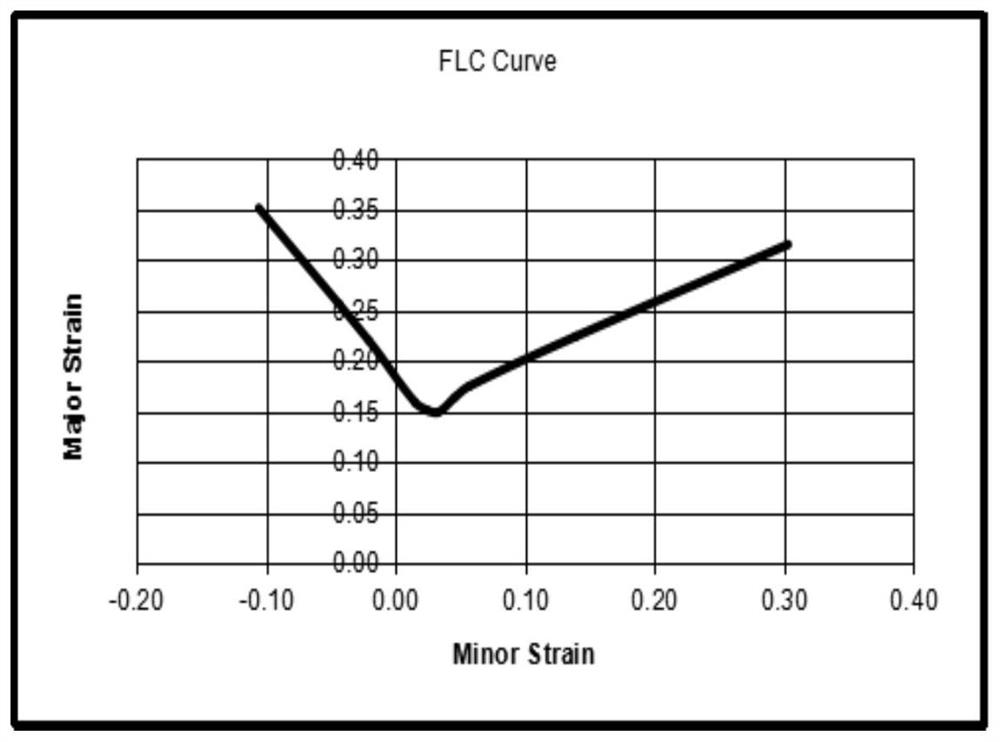

Cold-rolled dual-phase steel DP780 and flexible production method thereof

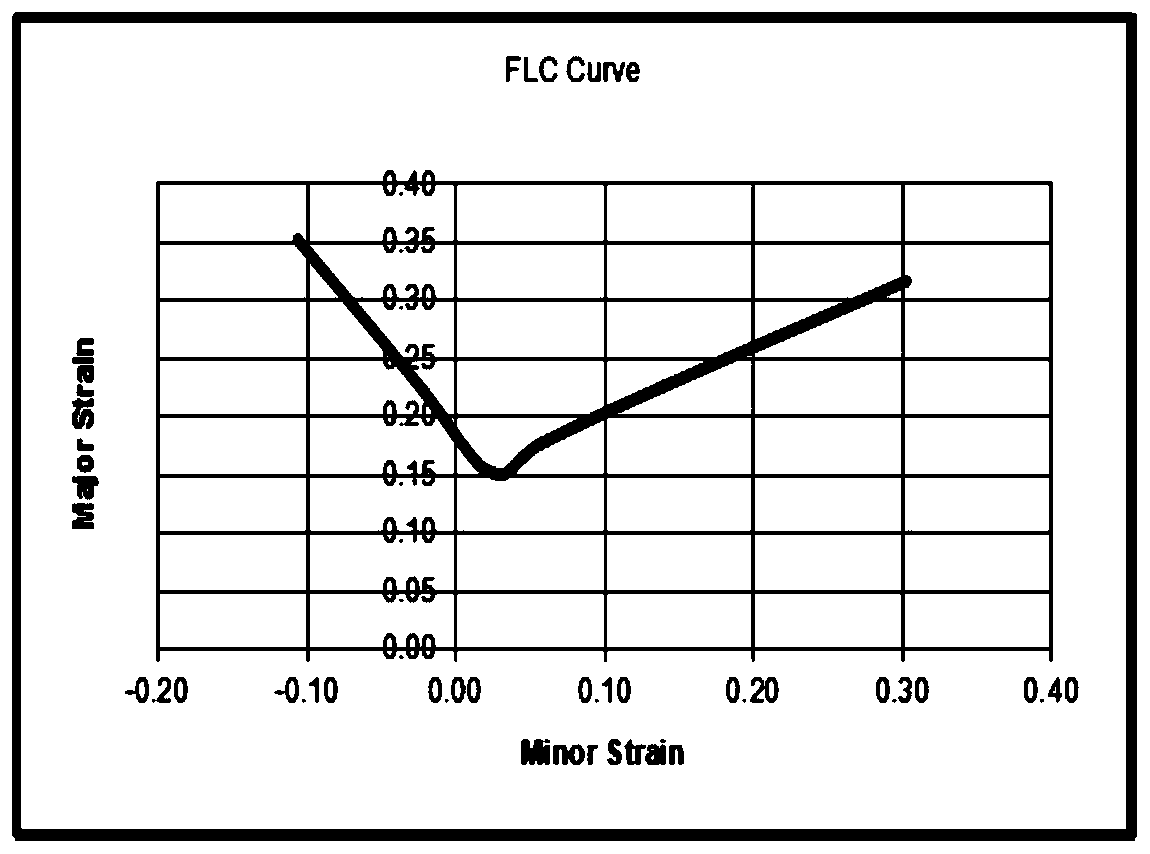

The invention belongs to the technical field of preparation of cold-rolled dual-phase steel, and relates to cold-rolled dual-phase steel DP780 and a flexible production method thereof. The cold-rolleddual-phase steel DP780 comprises the components according to the percentage by weight: 0.13 to 0.17 of C, 0.10 to 0.40 of Si, 1.0 to 1.2 of Mn, 0.01 to 0.04 of Ti, 0.10-0.20 of Cr, 0.02-0.06 of Al, less than or equal to 0.015 of P, less than or equal 0.010 of S, and the balance being Fe and inevitable impurities. The cold-rolled dual-phase steel DP780 prepared by the method has uniform tissue distribution, martensite volume fraction of less than 20%, average grain size of 3-4 micrometers, yield strength of 400-650 MPa, tensile strength of greater than or equal to 780 MPa, elongation percentage A80 of greater than or equal to 18%, n10-20 / Ag value of greater than or equal to 0.14, r90 value of greater than or equal to 0.8, and BH2 of greater than or equal to 50 MPa and can meet the requirements of automobile factories on individualization and high forming property.

Owner:BENGANG STEEL PLATES

Inoculating agent used for thin-walled ferrite nodular cast iron and preparing method of inoculating agent

The invention discloses an inoculating agent for thin-walled ferrite nodular cast iron. With the total weight of the inoculating agent for the thin-walled ferrite nodular cast iron being 100%, the inoculating agent for the thin-walled ferrite nodular cast iron comprises, by weight, 68-70% of Si, 2-4% of RE, 1-2% of Sr, 0.3-0.8% of Bi, 1.0-3.0% of Ca, 2.0-4.0% of Ba, 0.3-0.5% of Al and the balanceFe. The obtained thin-walled ferrite nodular cast iron has the functions of promoting graphite nucleation, reducing chilling tendency, increasing the number of the nodular cast iron and improving theintegrity of the nodular cast iron, the ferrite content can be remarkably improved in a casting state, and the elongation and strength of the nodular cast iron are improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Heavy-duty locomotive wheel steel resistant to surface contact fatigue and wheel production method

ActiveCN113528967AHigh yield strengthImproved resistance to surface contact fatigueFurnace typesHeat treatment furnacesMechanical engineeringMaterials science

The invention provides heavy-duty locomotive wheel steel resistant to surface contact fatigue and a wheel production method. Components of the wheel steel comprise 0.60%-0.67% of C, 0.15%-1.00% of Si, 0.60%-0.90% of Mn, 0.04%-0.15% of V, 0.10%-0.25% of Cr, not larger than 0.040% of Al, not larger than 0.015% of Als, (70-100) * 10 <-4 >% of N, not larger than 0.003% of Ti, not larger than 0.020% of P, not larger than 0.015% of S and the balance Fe and inevitable impurity elements. In wheel production, the austenitizing soaking temperature is 30-50 DEG C higher than the conventional heating temperature, and the holding time of the soaking section is not shorter than 1.5 h. Compared with the prior art, the surface contact fatigue resistance of the wheel is obviously superior to that of a traditional locomotive wheel, the non-planned turning repair frequency of the wheel is reduced, and the service life of the wheel is prolonged.

Owner:MAANSHAN IRON & STEEL CO LTD

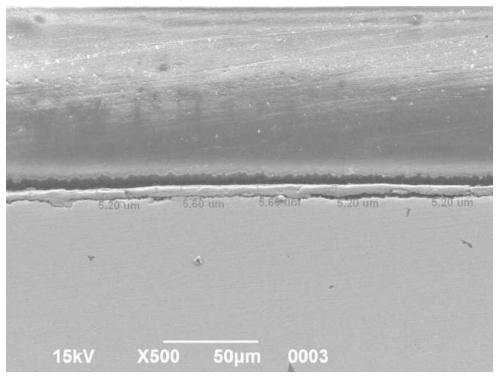

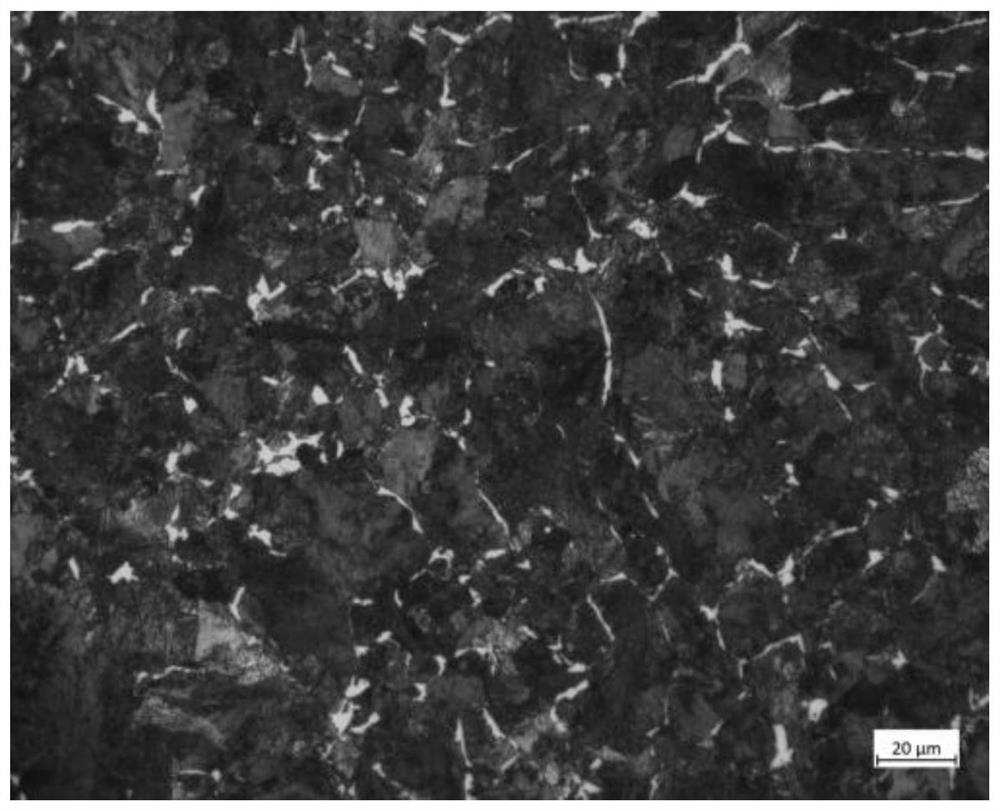

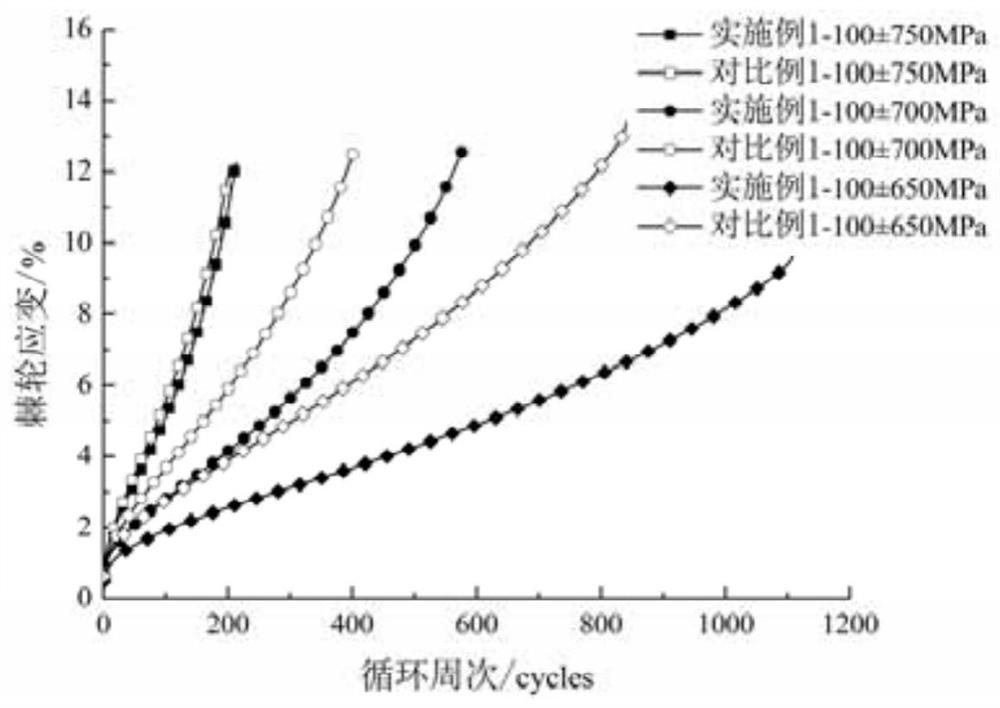

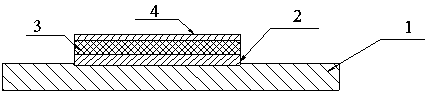

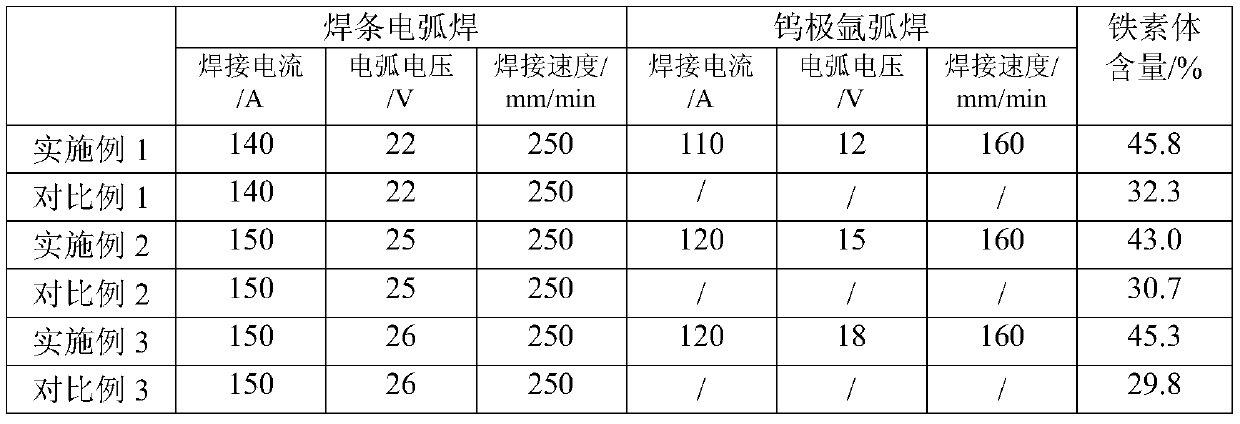

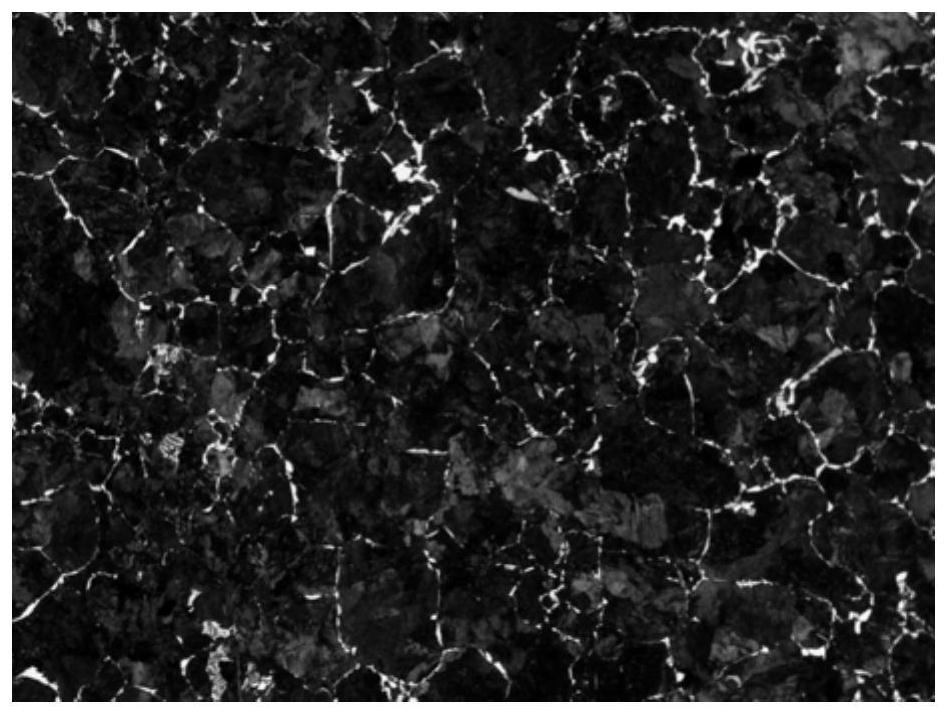

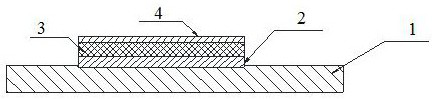

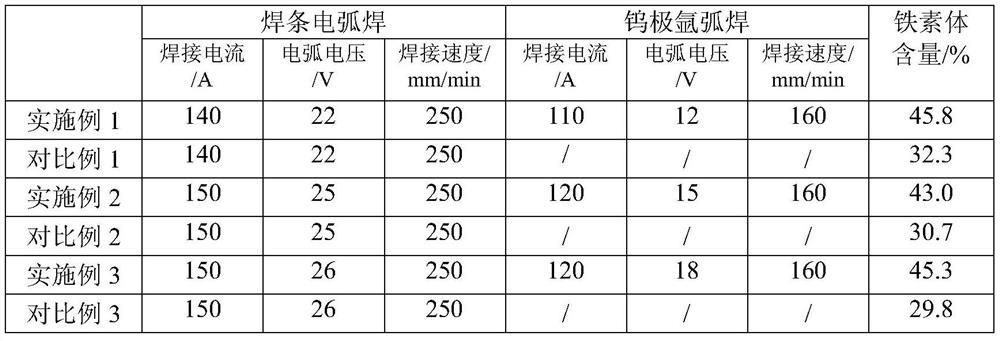

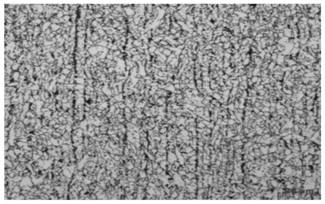

Phase proportion control method for surfacing welding of two-phase corrosion resistant layer on surface of carbon steel

ActiveCN110449692AIncreased ferrite contentImprove corrosion resistanceArc welding apparatusManufacturing cost reductionDouble phase

The invention discloses a phase proportion control method for surfacing welding of a two-phase corrosion resistant layer on the surface of carbon steel. The phase proportion control method comprises the following specific steps that a transition isolation layer, a filling layer and a cover layer are sequentially arranged on a base material through surfacing welding; the high-nickel ultra-low carbon austenitic deposited metal is adopted as the transition isolation layer; high-chromium and high-nickel stainless steel electrode is adopted for large-current and high-efficiency arc surfacing welding to form the filling layer, namely the super alloyed anti-corrosion surfacing welding layer of an austenite-ferrite double-phase structure; the interlayer temperature is controlled to be 120 DEG C orlower in the process of surfacing welding; small-current gas shielded tungsten arc welding is adopted for cover surface surfacing welding to form the cover layer; the post weld heat treatment is notneeded after surfacing welding is finished; and the penetrant inspection is carried out 24 hours after welding, and the ferrite content is measured through a ferrite tester. According to the weldingmethod, two-phase structure corrosion-resistant surfacing welding layer with approximately equal proportion can be formed, and heat treatment is not needed after welding so that the machining technology can be simplified, and the manufacturing cost can be reduced.

Owner:NANJING INST OF TECH

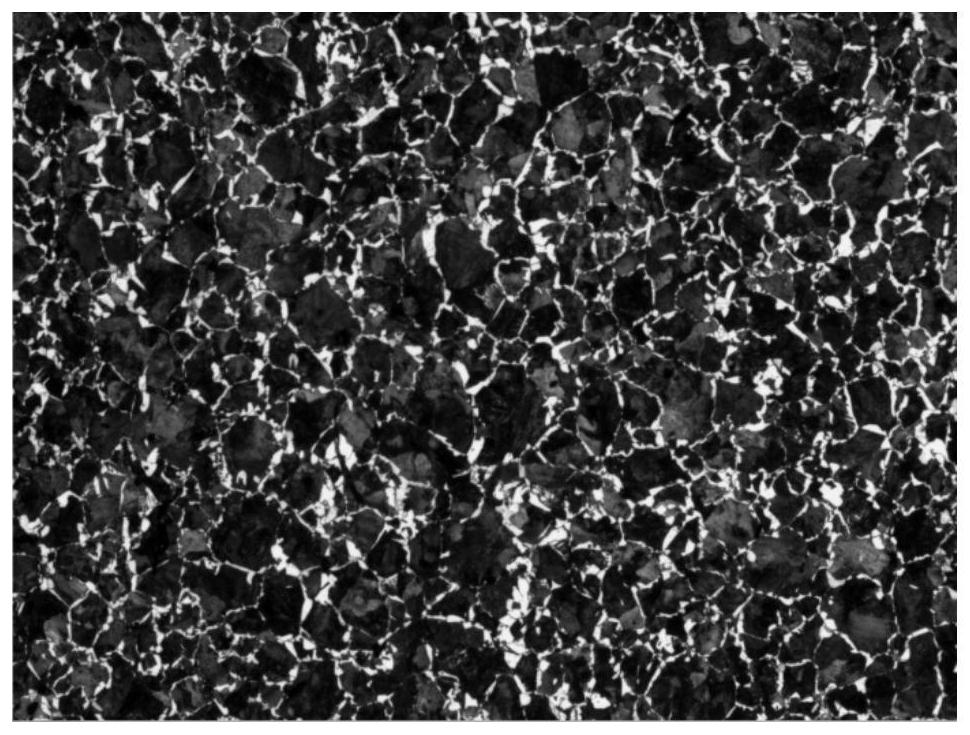

Waste-steel-smelting-ductile-iron process with carburant absorptivity reaching 95% or above

ActiveCN107058857AImprove purityLow impurity contentProcess efficiency improvementHardnessDuctile iron

The invention discloses a waste-steel-smelting-ductile-iron process with the carburant absorptivity reaching 95% or above. In a smelting furnace, furnace burdens and carburant are added at many times, and the furnace burdens comprise ductile iron chippings, foundry returns and waste steel; after the furnace burdens in the smelting furnace completely fuse, temperature rise is started, after all carburant fuses completely, a slag remover is added, and slag is picked out of the furnace with a rolling rod; after stokehole samples are tested to be qualified, spheroidizing is started, and then secondary inoculation is carried out; casting is carried out; the nodulizing stage of obtained ductile iron is 2 stage to 3 stage, and the hardness ranges from 155 HB to 165 HB; and based on the mass percent of the ductile iron, the pearlite content is 5%+ / -0.5%, the S content is smaller than 0.02%, the ferrite content is larger than 85%, and free cementite is not contained. According to the process, through creative detail treatment and furnace burden mastering in the production process, the carburant absorptivity is remarkably improved, the product quality is improved, and the production cost is reduced.

Owner:抚州市羊易铸业有限公司

Melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing

ActiveCN101649369BReduce dosageImprove toughnessProcess efficiency improvementFerrosiliconDuctile iron

The invention discloses a melting process for producing synthetic cast iron by utilizing SiC carburizing siliconizing, which produces the synthetic cast iron by taking scrap steel, pig iron and cast iron returns or scrap steel and cast iron returns as the main raw materials in an induction furnace by utilizing SiC as an carburizing siliconizing agent, wherein the addition of SiC is 0.5-3%, and the granularity is 6-20mm; SiC is added to a hearth before melting or is added during the melting process, or the two modes cooperate to be used. The invention utilizes SiC to replace the pig iron and silicon iron carburizing siliconizing to reduce the pig iron and silicon iron so as to reduce the cost, and meanwhile, the tendency of the molten iron chill and the reverse chill of the produced synthetic cast iron is small; the dimensions of graphite pebbles in produced nodular cast iron are small, the sphericity or roundness is high, the content of ferrite is high, and the roughness of the nodular cast iron is improved; the organization of produced grey cast iron is refined, and the mechanical property and the abrasion resistance are obviously improved. The invention can be used for producingvarious trademarks of grey cast iron, nodular cast iron and alloy cast iron.

Owner:河南省金太阳精密铸业股份有限公司

N80 steel grade oil casing and preparation method thereof

The invention relates to the technical field of oil casings and particularly discloses an N80 steel grade oil casing and a preparation method thereof. The N80 steel grade oil casing comprises the following elemental compositions of, by weight, 0.26-0.30% of C, 0.15-0.35% of Si, 1.35-1.45% of Mn, 0.06-0.08% of V, 0.10-0.30% of Cr, 0.02-0.04% of Al, less than or equal to 0.002% of S, less than or equal to 0.01% of P, less than or equal to 0.01% of N, less than or equal to 0.005% of Ti, less than or equal to 0.08% of Ni, less than or equal to 0.08% of Cu, less than or equal to 0.01% of Mo, less than or equal to 0.01% of Nb and the balance Fe and inevitable impurity elements, wherein Mn / C is greater than or equal to 4. According to the N80 steel grade oil casing provided by the invention, an alloy composition system is simple, and the N80 steel grade oil casing has high strength and high toughness by reasonably controlling the elements of C, Mn, Cr and V.

Owner:DALIPAL PIPE

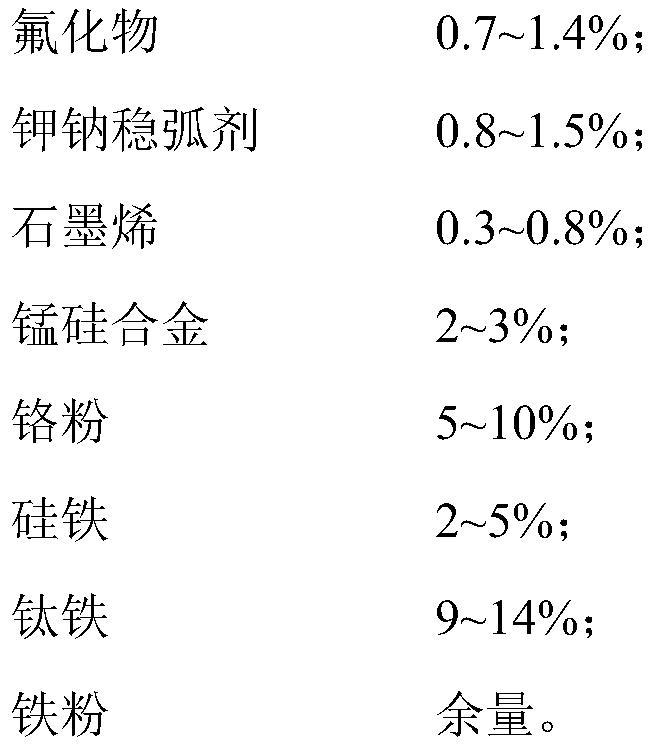

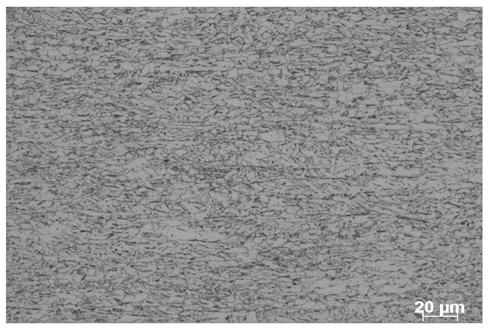

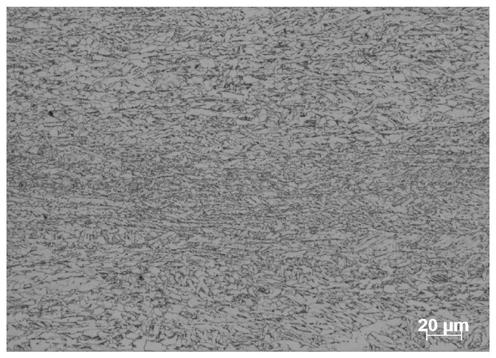

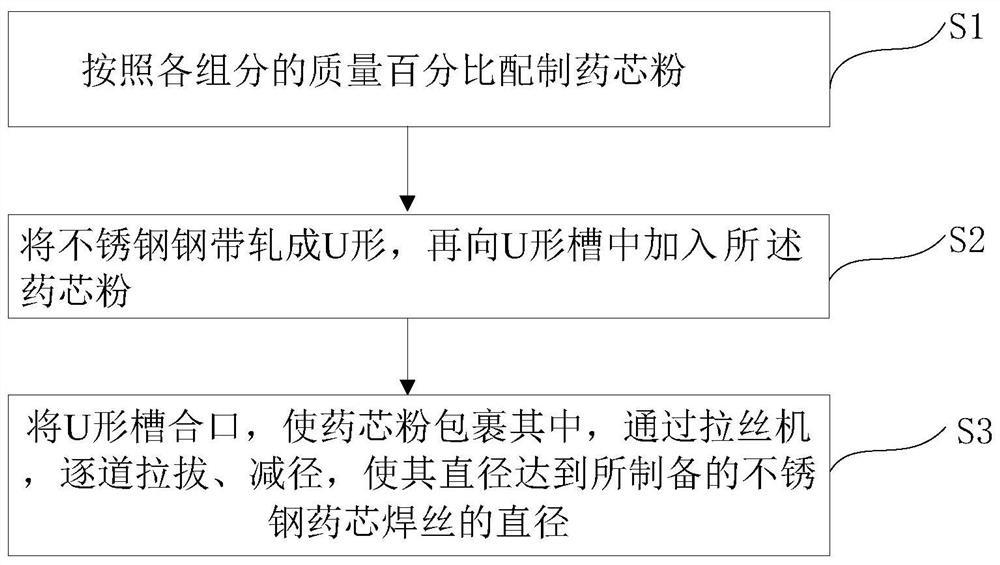

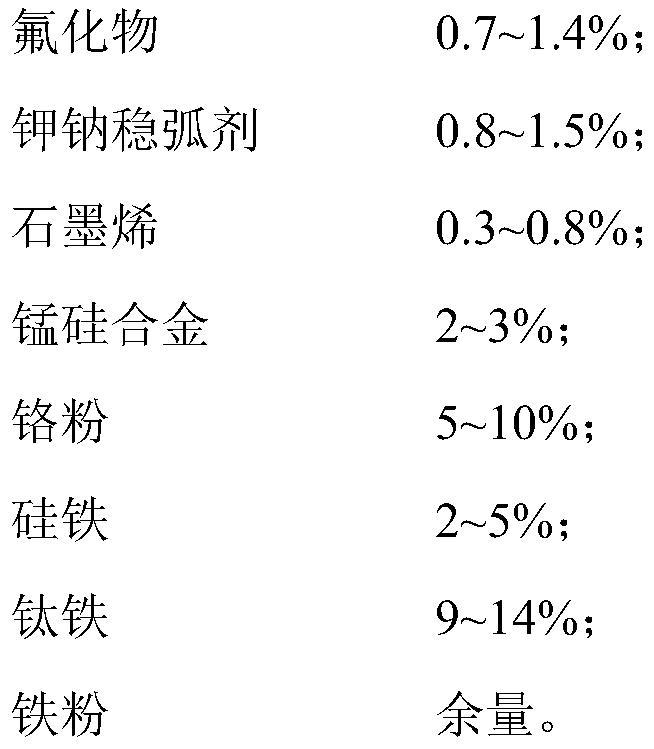

Stainless steel flux-cored wire

ActiveCN112643243ASimple welding processImprove wear resistanceWelding/cutting media/materialsSoldering mediaSilicon alloyFerrosilicon

The invention provides a stainless steel flux-cored wire. The stainless steel flux-cored wire comprises a stainless steel strip and a flux core, and the stainless steel strip is filled with the flux core. The flux core comprises, by mass, 0.7-1.4% of fluoride, 0.8-1.5% of a potassium-sodium arc stabilizer, 0.3-0.8% of graphene, 2-3% of manganese-silicon alloy, 5-10% of chromium powder, 2-5% of silicon iron, 9-14% of ferrotitanium and the balance iron powder. When the stainless steel flux-cored wire is used for welding, electric arcs are soft and stable, weld joints are attractive in appearance and small in splashing after welding, small air holes do not exist in the weld joints, and meanwhile weld joint metal has excellent abrasion resistance, corrosion resistance and high-temperature resistance.

Owner:山东聚力焊接材料有限公司

High-hardness corrosion-resistant cast stainless steel for fluid transportation

The invention discloses high-hardness corrosion-resistant cast stainless steel for fluid transportation. A stainless steel casting comprises the following chemical components in percentage: equal to or less than 0.03% of C, equal to or less than 1% of Si, equal to or less than 2% of Mn, equal to or less than 0.03% of S, equal to or less than 0.04% of P, 25-28% of Cr, 4-6% of Ni, 4-8% of Mo, 0-5% of Cu, 0-0.3% of N and the balance of Fe and unavoidable impurities, wherein the range of Mo / Ni is 0.75-1.5, and PREN=(Cr+3.3*Mo+16*N) is equal to or greater than 41. The manufacturing process flow isas follows: smelting, casting, solid solution and hardening treatment; through ingredient improvement, a texture is obtained, and the content of solid solution state ferrite of the texture is far greater than that of common duplex stainless steel; the phase proportion requirement of the duplex stainless steel is 30%-70%; and the content of ferrite of the high-hardness corrosion-resistant cast stainless steel is equal to or greater than 70%, so that the hardness of the stainless steel is greatly improved; and the corrosion resistance and high hardness performance are further realized through the smelting, casting, solid solution and hardening treatment.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

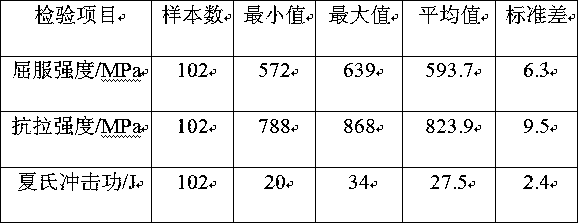

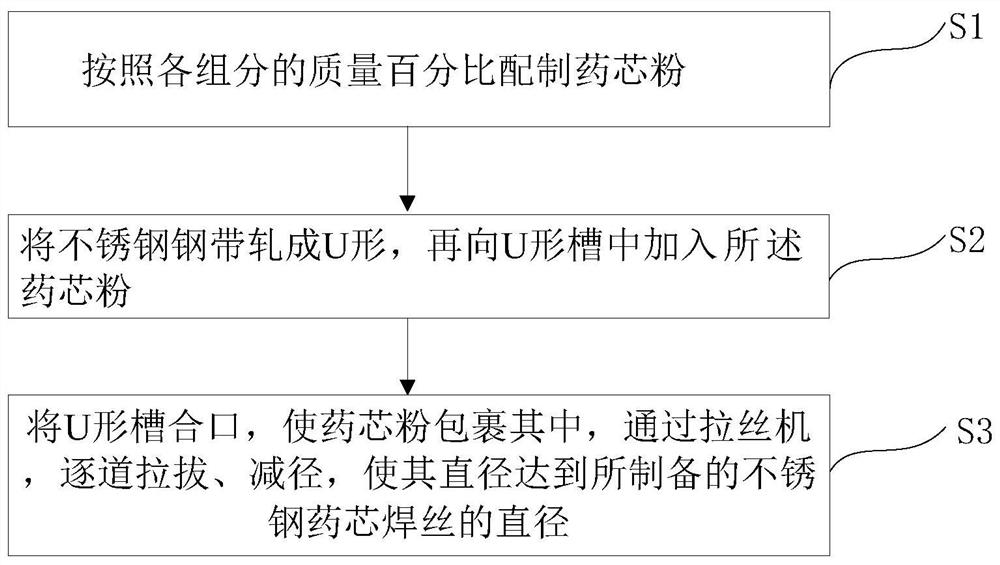

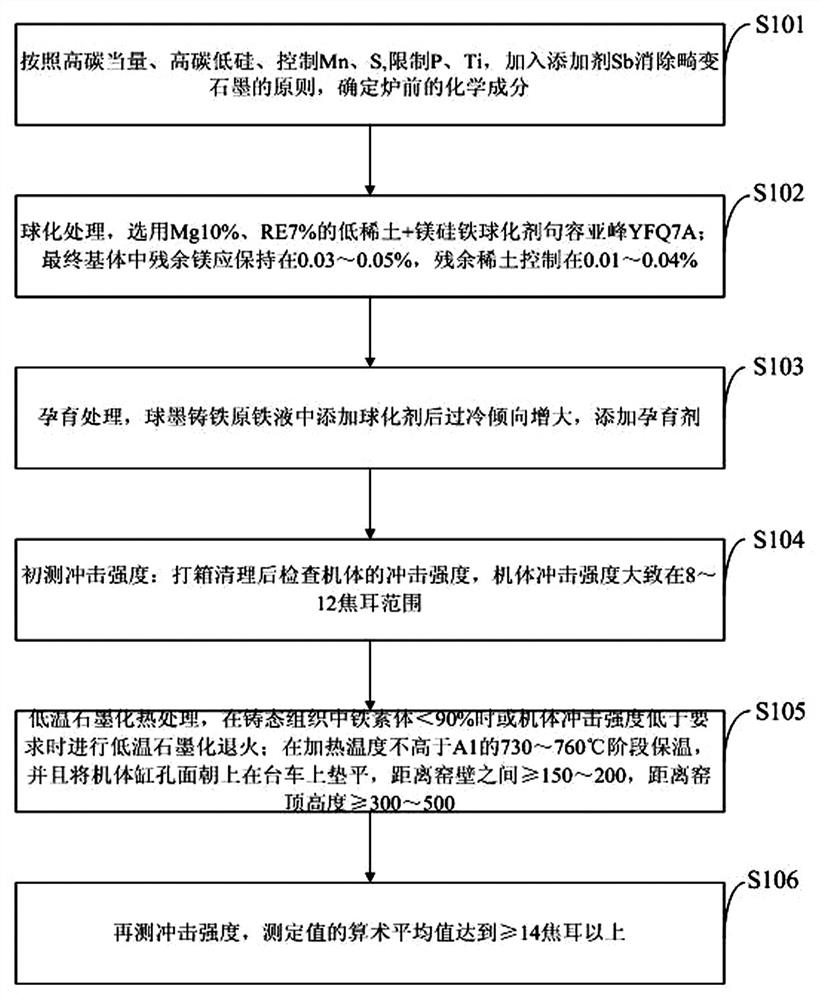

Method for improving impact strength of large high-strength high-toughness nodular cast iron diesel engine body

InactiveCN111876655AReduce generationReduce solidificationProcess efficiency improvementDieselingDuctile iron

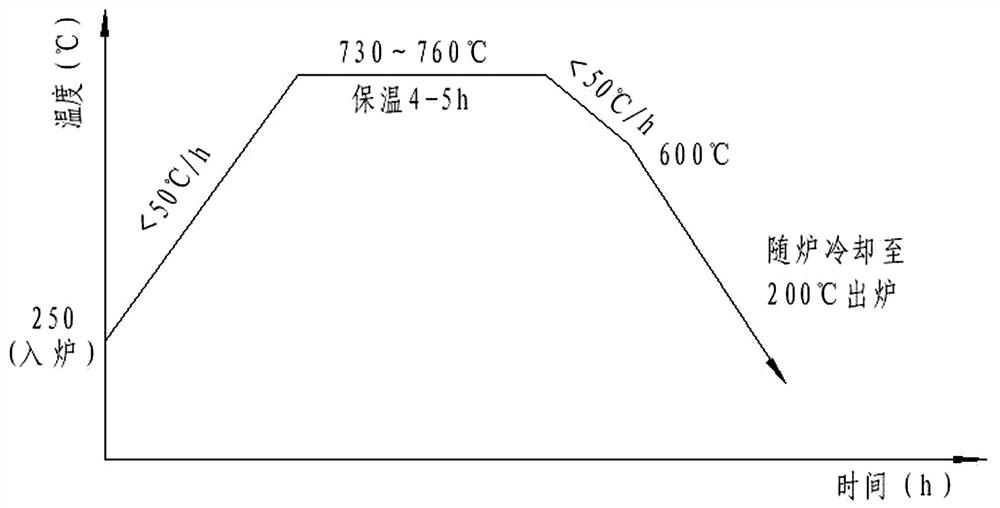

The invention belongs to the technical field of cast iron casting and heat treatment, and discloses a method for improving the impact strength of a large high-strength high-toughness nodular cast irondiesel engine body. The method comprises the following steps of determining stokehole chemical components according to the principles of high carbon equivalent, high carbon, low silicon, Mn and S control, P and Ti limitation, and addition of an additive Sb to eliminate distorted graphite; and conducting spheroidizing and inoculating again, primarily measuring the impact strength, performing low-temperature graphitization heat treatment, and measuring the impact strength again.ai According to the method, in the casting process, the principles of the high carbon equivalent, high carbon, low silicon, Mn and S control, P and Ti limitation, multi-stage inoculation and addition of the additive Sb to eliminate the distorted graphite is selected, generation of supercooled graphite and free cementite is reduced, and solidification of molten iron according to stable system eutectic is promoted; and meanwhile, pearlite is eliminated through low-temperature graphitization annealing, the ferrite content of the engine body structure is increased to 90% or above, and therefore the purpose of improving the impact strength of the engine body is achieved.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

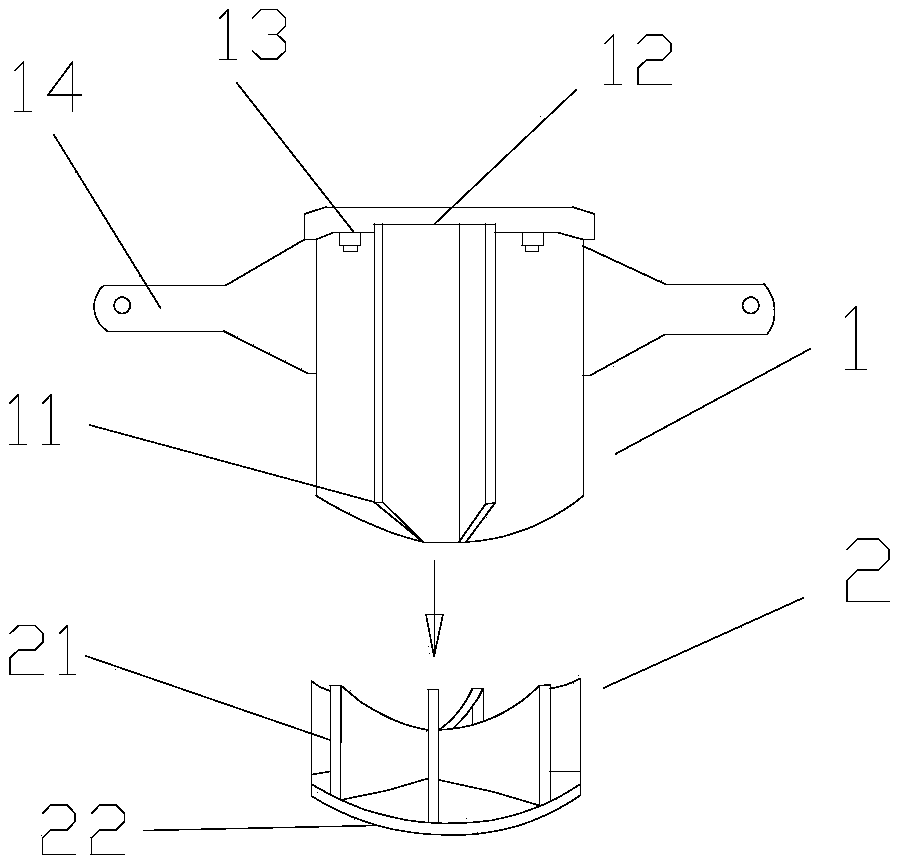

A spherical plate processing tooling

ActiveCN106282808BGuaranteed smoothnessGuaranteed ferrite contentFurnace typesAnti-corrosive paintsEngineeringMachine tool

The invention discloses a machining tool for a spherical plate. The tool comprises an upper mold and a lower mold, wherein the lower mold comprises a lower columnar structure defined through welding connection of sides of at least three lower rib plates and a seat plate arranged at the bottom of the lower columnar structure; a machining concave end surface is arranged at the top of the lower columnar structure, and the curve of the machining concave end surface is consistent with the radian of a curved surface of the to-be-machined spherical plate; the upper mold comprises an upper columnar structure defined through welding connection of sides of at least three upper rib plates and a top plate arranged at the top of the upper columnar structure; and a machining convex end surface is arranged at the lower end of the upper columnar structure and is matched with the machining concave end surface in radian. The smooth degree of the appearance of the plate can be guaranteed with the tool, assembly, electric welding and polishing in following processes can be reduced, the manufacturing period of the spherical plate can be shortened, and the manufacturing cost of the spherical plate can be saved.

Owner:JIANGSU DAJIN HEAVY IND

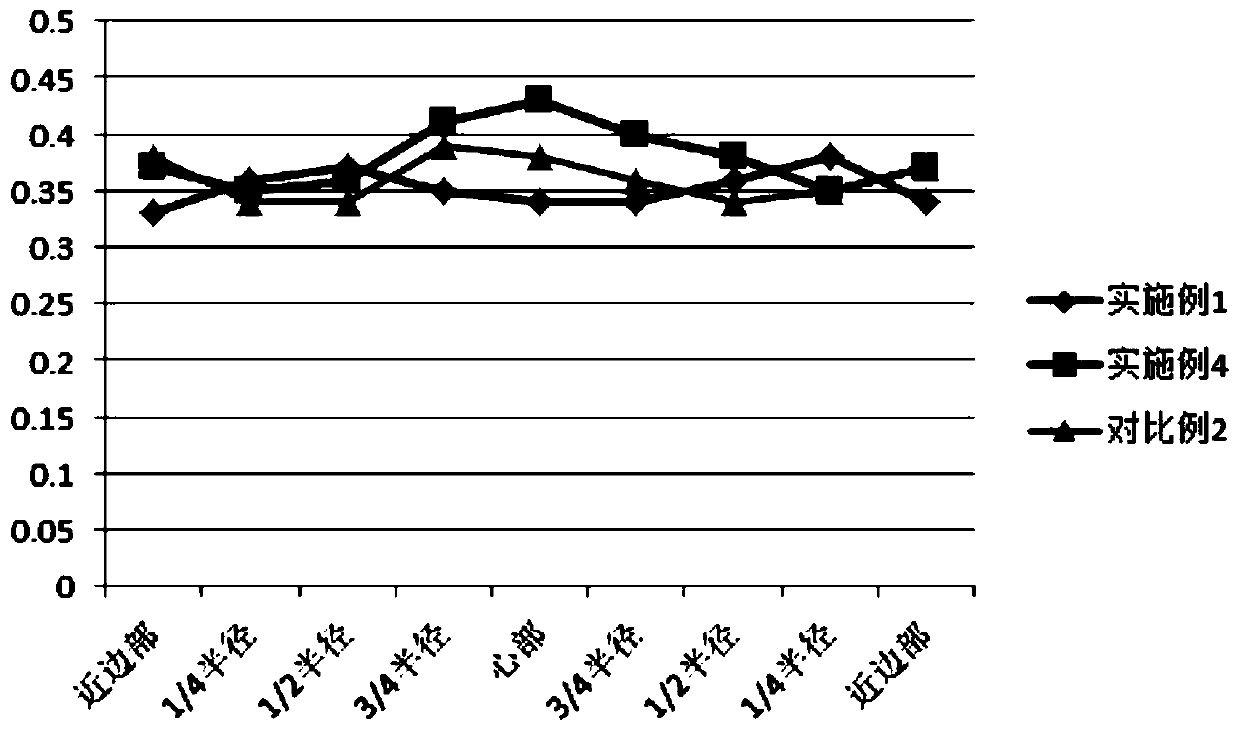

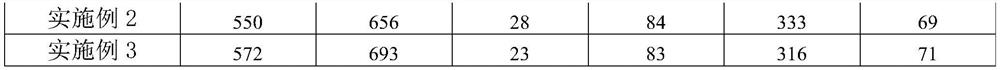

Non-quenched and tempered steel for crankshaft, crankshaft forging and its preparation process

ActiveCN110578096BIncreased ferrite contentAvoid Centrifugal Balance BurdenCrankshaftsRotary machine partsBrinellingCrankshaft

The application provides a non-quenched and tempered steel for a crankshaft, a crankshaft forging and a preparation process thereof, which belong to the technical field of non-quenched and tempered steel. Non-quenched and tempered steel by weight percentage: C 0.36‑0.39%, Si 0.50‑0.65%, Mn 1.35‑1.50%, P 0‑0.030%, S 0.040‑0.055%, Cr 0‑0.25%, Mo 0‑0.20 %, Al 0‑0.03%, N 0.010‑0.020%, carbon equivalent Ceq=0.75‑0.81%. The hardenability of non-quenched and tempered steel is: J5mm 47‑52HRC, J9mm 35‑42HRC, J13mm 30‑36HRC; tensile strength ≥ 760MPa; elongation A ≥ 14%; band structure ≤ 2.0; Brinell hardness is 220‑250HBW, suitable for making crankshaft forgings.

Owner:SGIS SONGSHAN CO LTD

A phase ratio control method of two-phase corrosion-resistant layer on carbon steel surface

ActiveCN110449692BIncreased ferrite contentImprove corrosion resistanceArc welding apparatusManufacturing cost reductionSS - Stainless steel

The invention discloses a method for controlling the phase proportion of a two-phase corrosion-resistant layer on the surface of carbon steel. Austenitic deposited metal is used as a transitional isolation layer; high-current and high-efficiency arc surfacing welding is performed with high-chromium and high-nickel stainless steel electrodes to form a filling layer, that is, corrosion-resistant surfacing welding of superalloyed austenite-ferrite dual-phase structure During the surfacing process, the interlayer temperature is controlled below 120°C; the cover surface is surfacing with low-current argon tungsten arc welding to form a cover layer; after the surfacing welding is completed, post-weld heat treatment is not required; 24 hours after welding Conduct penetrant flaw detection, and use a ferrite tester to measure the ferrite content. The welding method provided by the invention can form an approximately equal-proportion dual-phase corrosion-resistant surfacing layer, and does not require heat treatment after welding, which can simplify the processing technology and reduce the manufacturing cost.

Owner:NANJING INST OF TECH

A cold-rolled dual-phase steel dp780 and its flexible production method

The invention belongs to the technical field of cold-rolled dual-phase steel preparation, and relates to a cold-rolled dual-phase steel DP780 and a flexible production method thereof. Its composition is calculated by weight percentage, including C: 0.13-0.17, Si: 0.10-0.40, Mn: 1.0-1.2, Ti: 0.01-0.04, Cr: 0.10-0.20, Al: 0.02-0.06, P: ≤0.015, S : ≤0.010, the rest is Fe and unavoidable impurities; the cold-rolled dual-phase steel DP780 prepared by this method has a uniform structure distribution, a martensite volume fraction <20%, an average grain size of 3-4μm, and a yield strength of 400-650MPa. Tensile strength ≥ 780MPa, elongation A 80 ≥18%, n 10‑20 / Ag value ≥ 0.14, r 90 Value ≥ 0.8, BH 2 ≥50MPa, which can meet the personalized and high formability requirements of automobile factories.

Owner:BENGANG STEEL PLATES

A scrap steel smelting ductile iron process with a recarburizer absorption rate of over 95%

ActiveCN107058857BImprove purityLow impurity contentProcess efficiency improvementHardnessDuctile iron

The invention discloses a waste-steel-smelting-ductile-iron process with the carburant absorptivity reaching 95% or above. In a smelting furnace, furnace burdens and carburant are added at many times, and the furnace burdens comprise ductile iron chippings, foundry returns and waste steel; after the furnace burdens in the smelting furnace completely fuse, temperature rise is started, after all carburant fuses completely, a slag remover is added, and slag is picked out of the furnace with a rolling rod; after stokehole samples are tested to be qualified, spheroidizing is started, and then secondary inoculation is carried out; casting is carried out; the nodulizing stage of obtained ductile iron is 2 stage to 3 stage, and the hardness ranges from 155 HB to 165 HB; and based on the mass percent of the ductile iron, the pearlite content is 5%+ / -0.5%, the S content is smaller than 0.02%, the ferrite content is larger than 85%, and free cementite is not contained. According to the process, through creative detail treatment and furnace burden mastering in the production process, the carburant absorptivity is remarkably improved, the product quality is improved, and the production cost is reduced.

Owner:抚州市羊易铸业有限公司

Wind-power equipment casting and manufacturing method thereof

The invention relates to the technical field of manufacturing of wind-power generating equipment, in particular to a wind-power equipment casting and a manufacturing method thereof. The wind-power generating casting comprises the following chemical components in percentage by mass: 3.60-3.80 percent of C, 2.2-2.4 percent of Si, less than 0.25 percent of Mn, 0.006-0.015 percent of K, 0.006-0.015 percent of Na, 0.008-0.015 percent of Bi, 0.015-0.028 percent of Sb, 0.002-0.004 percent of Sr, 0.035-0.055 percent of Ba, 0.035-0.055 percent of Ca, 0.030-0.050 percent of Al, 0.032-0.055 percent of Mg, less than 0.03 percent of P, less than 0.01 percent of S and the balance of Fe. In the method, an electric furnace is adopted for smelting, and low-manganese waste steel and graphite are added instead of cast iron, supplementary iron and carbon for serving as major raw materials; for further improving the performance of the wind-power casting, a small quantity of micro-alloy elements such as bismuth, antimony, potassium, sodium, strontium, calcium, barium, aluminum and the like are added, so that the graphite is refined, the spheroidizing effect of the graphite is improved, and the effect of preventing degraded spheroidization is achieved; spheroidizing treatment with pure magnesium is performed; and inoculation treatment is performed by using a ferrite spheroidal graphite cast iron inoculant before casting. The wind-power equipment casting has the advantages of simple and convenient production process, low cost, high intensity and high toughness at room temperature and low temperature.

Owner:甘肃酒钢集团西部重工股份有限公司

High-temperature-resistant niobium-containing vermicular graphite cast iron and preparation method thereof

ActiveCN114855069AImprove high temperature resistanceEasy to useProcess efficiency improvementNiobiumGraphite

The invention provides high-temperature-resistant niobium-containing vermicular graphite cast iron and a preparation method thereof, and relates to the technical field of vermicular graphite cast iron casting. The method specifically comprises the following steps: taking pig iron, scrap steel and recirculated iron as furnace charges, adding other alloys to smelt into molten iron, and particularly adding a vanadium-iron alloy and a niobium-iron alloy, so that the molten iron contains 0.1-0.4% of V and 0.03-0.07% of Nb; the niobium-containing vermicular graphite cast iron with both high temperature resistance and use performance can be prepared by synergistic interaction with other components in molten iron and optimization and improvement of process parameters. The preparation technology is easy to operate and low in energy consumption, the production process is easy to control, the metallographic structure of the vermicular graphite cast iron prepared through the scheme is mainly ferrite, the pearlite structure is stabilized to be 5% or below, and the high-temperature stability of the matrix structure can be effectively improved. Besides, a sample with the diameter of 10.1 mm, which is prepared from the vermicular graphite cast iron disclosed by the invention, has the maximum tensile strength of 5.5 kN and the maximum tensile strength of 69 MPa at the temperature of 800 DEG C.

Owner:GUANGXI YUCHAI MASCH CO LTD

Preparation method of ferritic ductile iron

The invention relates to the field of spheroidal graphite cast iron, in particular to ferritic spheroidal graphite cast iron and a preparation method thereof. The ferritic spheroidal graphite cast iron comprises, by mass, 3.5%-3.8% of carbon, 2.4%-2.7% of silicon, 0.29%-0.35% of manganese, 0.03%-0.04% of cerium, 0.045%-0.06% of magnesium, 0.08%-0.1% of yttrium, 0.01%-0.02% of molybdenum, 0.02%-0.03% of rhenium, not more than 0.04% of phosphorus, not more than 0.018% of sulphur and the balance iron. The preparation method particularly includes the steps of (1), melting raw materials by a medium-frequency induction furnace prior to desulfurization; (2), uniformly mixing silicon carbide powder with rare earth magnesium alloy, then pouring the mixture into a spheroidizing package, covering the spheroidizing package with a first inoculant for spheroidizing and primary inoculation treatment prior to secondary inoculation treatment, and casting so as to obtain a cast; (3), subjecting the cast to heat treatment so as to obtain the ferritic spheroidal graphite cast iron. The ferritic spheroidal graphite cast iron is high in spheroidizing ratio and strength and excellent in toughness and impact plasticity, and the preparation method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

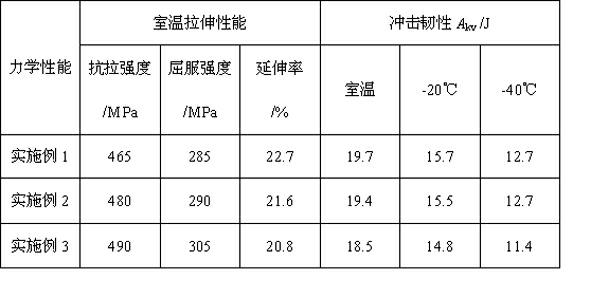

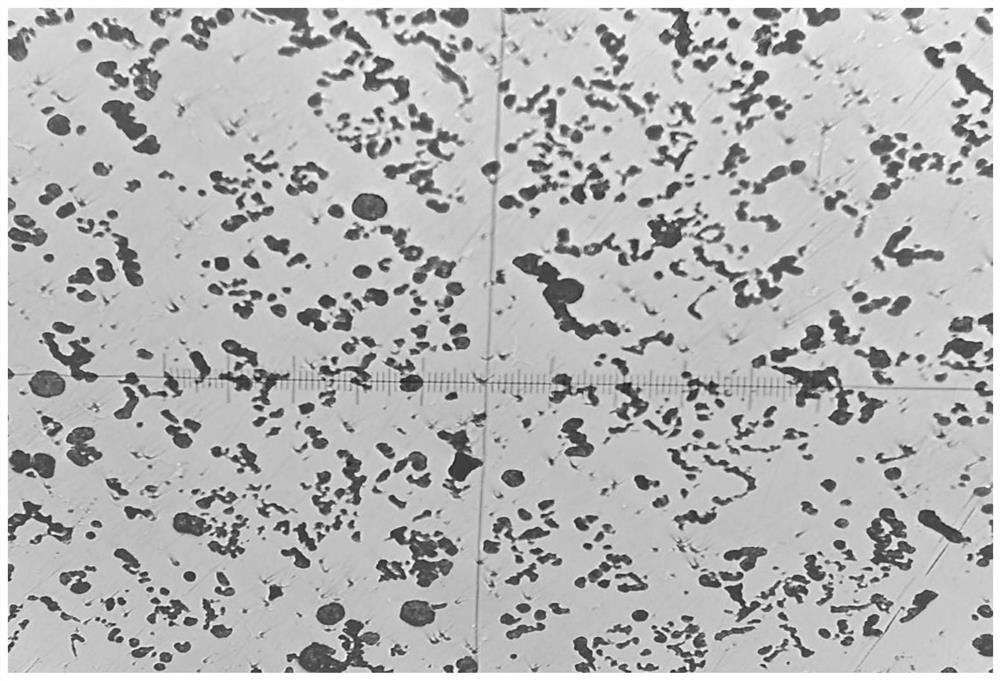

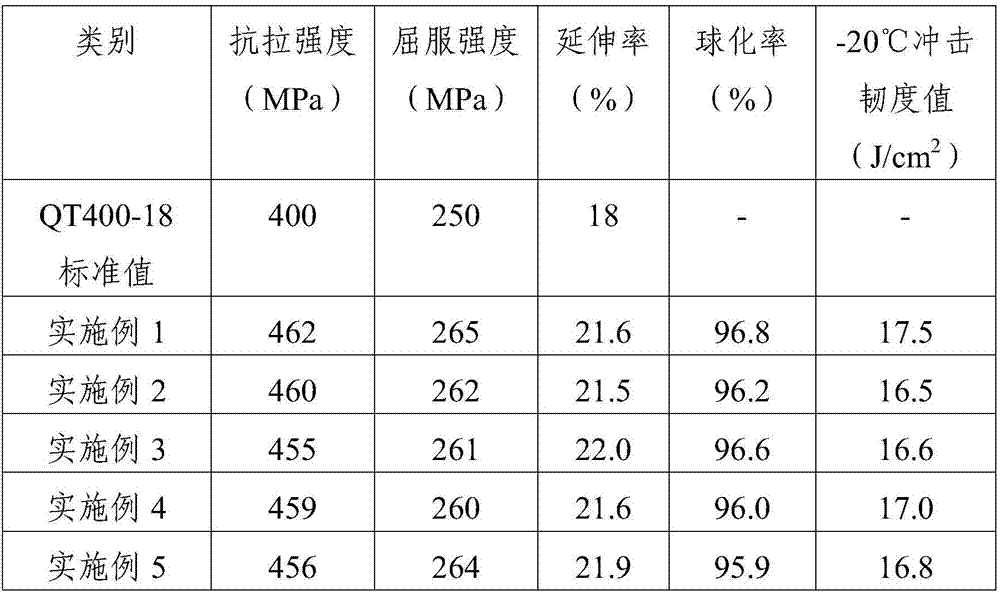

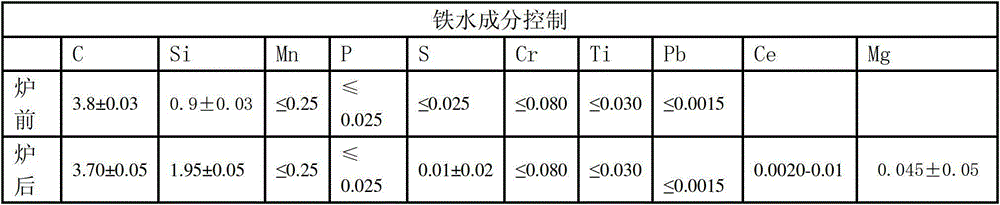

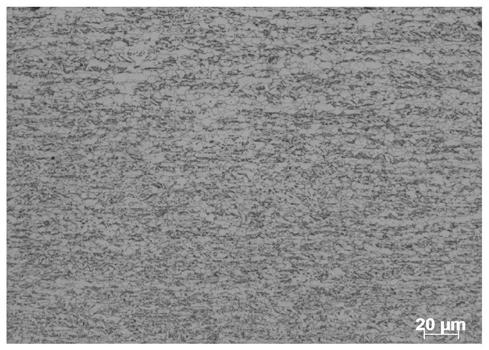

A smelting method for obtaining qualified mechanical properties at low temperature without nickel

ActiveCN103045931BAvoid burnsHigh pearlite volumeMetal recyclingProcess efficiency improvementChemical compositionNickel free

The invention relates to a smelting method, particularly a smelting method for acquiring qualified mechanical properties under low-temperature nickel-free conditions, which is characterized by comprising the following steps: melting, embedding a nodulizer and an inoculator, tapping, and casting a test block. The method provided by the invention is unique, can acquire higher tensile strength and elongation percentage, enables the matrix structure of the test block to contain less pearlite, enhances the nodularity of the test block, and ensures the quality and low-temperature impact value of the casting on the premise of reasonably selecting chemical composition.

Owner:泉州共享智能铸造产业创新中心有限公司

A production method for reducing the hardness of x80m grade pipeline steel

The invention discloses a production method for reducing the hardness of X80M-grade pipeline steel. Through a high-temperature rolling process, reasonable adjusting of phosphorus removal process and perfecting of rolling schedule, a laminar flow cooling process is optimized, a hybrid tissue structure is obtained, wherein the edge of the hybrid tissue structure is mainly made of quasi-polygonal ferrite, and the core of the hybrid tissue structure is mainly made of acicular ferrite, bainite and a small amount of martensite and austenite islands, it is ensured that the Wechsler hardness value ofthe surface and the section of a steel plate is stabilized within 220, the performance requirements for the steel plate are ensured, and economic benefits are remarkable.

Owner:NANJING IRON & STEEL CO LTD

A stainless steel flux cored wire

ActiveCN112643243BSimple welding processImprove wear resistanceWelding/cutting media/materialsSoldering mediaSilicon alloyManganese

Owner:山东聚力焊接材料有限公司

Steel for medium-carbon non-quenched and tempered crankshaft of automobile engine as well as crankshaft manufacturing method

PendingCN112575251AIncreased ferrite contentImprove comprehensive mechanical propertiesCrankshaftsAutomotive engineeringManufacturing engineering

The invention discloses steel for a medium-carbon non-quenched and tempered crankshaft of an automobile engine as well as a crankshaft manufacturing method. The crankshaft manufacturing method comprises the following steps: at first, rolling the steel for the non-quenched and tempered crankshaft into a bar of 90-100 mm finally through rolling heating, initial rolling, water-crossing cooling and final rolling, wherein the rolling heating temperature reaches 1200-1250 DEG C, the initial rolling temperature reaches 1100-1130 DEG C, and the final rolling temperature reaches 950-1000 DEG C; and then, adopting the bar as a blank, and acquiring the medium-carbon non-quenched and tempered crankshaft through blanking, forging and induction heating, roll forging, primary controlled cooling, forgingforming, trimming, and secondary controlled cooling. According to the crankshaft prepared through the crankshaft manufacturing method, the ferrite content of the medium-carbon non-quenched and tempered crankshaft is effectively controlled, crystalline grains of the medium-carbon non-quenched and tempered crankshaft are refined, the material toughness and plasticity are improved, and the comprehensive mechanical properties of the non-quenched and tempered crankshaft are improved.

Owner:NANJING IRON & STEEL CO LTD +1

A high-hardness, corrosion-resistant cast stainless steel for fluid delivery

A high-hardness corrosion-resistant cast stainless steel used for fluid transportation. The chemical composition of the stainless steel casting contains C≤0.03%, Si≤1%, Mn≤2%, S≤0.03%, P≤0.04%, Cr: 25 ~28%, Ni: 4~6%, Mo: 4~8%, Cu: 0~5%, N: 0~0.3%, the rest is Fe and unavoidable impurities, Mo / Ni range is 0.75‑1.5, PREN=(Cr+3.3*Mo+16*N)≥41; the manufacturing process is: smelting, casting, solid solution, hardening treatment, through composition improvement, the content of solid solution ferrite is much higher than that of ordinary duplex stainless steel The microstructure, duplex stainless steel phase ratio requirement (30% ~ 70%), the ferrite content of the invented material is ≥ 70%, realizes a substantial increase in the hardness of stainless steel, and further achieves high corrosion resistance and high hardness through smelting, casting, solid solution, and hardening treatments performance.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com