A production method for reducing the hardness of x80m grade pipeline steel

A production method and pipeline steel technology, applied in the field of iron and steel metallurgy, can solve problems such as cold-bending cracking, cold cracks, high surface and section hardness values, and achieve the effects of reducing hardness values, improving banded structure, reducing and stabilizing hardness values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

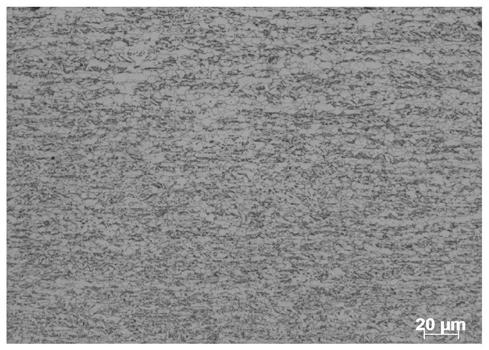

Embodiment 1

[0023] The steel plate thickness is 27.2mm, the billet heating temperature is 1229°C, the heating time is 13min / cm, and the soaking time is 42min. Rolling final pass reduction rate 28%, finish rolling temperature 785°C, final rolling temperature 751°C, steel plate theoretical Ar3 temperature 736°C, water entry temperature 715°C, red return temperature 315°C, steel throwing speed after rolling 5.0m / s , the speed of the steel plate entering the water roller table is 0.6m / s, and the acceleration of the roller table is 0.005m / s 2 .

Embodiment 2

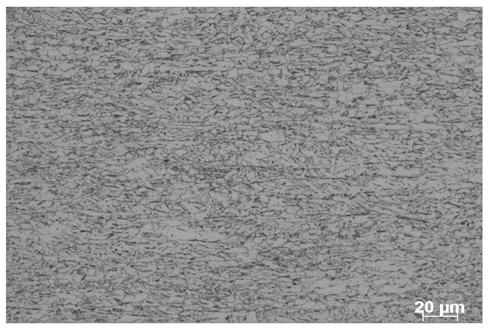

[0025] Steel plate thickness 22mm, slab heating temperature 1228 degrees, heating time 13min / cm, soaking time 45min, the first, second, fourth and fifth passes of phosphorus removal in the rough rolling process, the second pass of phosphorus removal in the finish rolling process, rough rolling The reduction rate of the final pass is 28%, the finish rolling temperature is 790 degrees, the final rolling temperature is 757 degrees, the theoretical Ar3 temperature of the steel plate is 747 degrees, the water entry temperature is 719 degrees, the redness temperature is 360 degrees, the steel throwing speed after rolling is 5.0m / s, The speed of the steel plate entering the water roller table is 1.1m / s, and the acceleration of the roller table is 0.010m / s 2 .

Embodiment 3

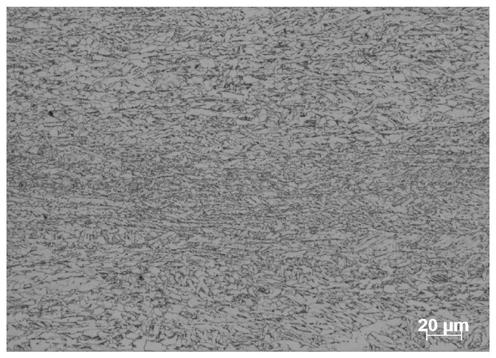

[0027] The steel plate thickness is 30.8mm, the billet heating temperature is 1210 degrees, the heating time is 13min / cm, and the soaking time is 48min. The reduction rate of the final pass is 26%, the finish rolling temperature is 810°C, the final rolling temperature is 741°C, the theoretical Ar3 temperature of the steel plate is 736°C, the water entry temperature is 712°C, the redness temperature is 453°C, and the steel throwing speed after rolling is 5.0m / s , the speed of the steel plate entering the water roller table is 0.5m / s, and the acceleration of the roller table is 0.003m / s 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com