Subsea pipeline steel L485MO with low yield ratio and low hardness and production method thereof

A subsea pipeline steel and low yield-strength ratio technology, which is applied to the low-yield-ratio and low-hardness submarine pipeline steel L485MO and its production field, can solve the problems of not reflecting the hardness value and yield ratio control level, reducing product economy, etc. To achieve the effect of increasing anti-cracking effect, strong anti-seawater corrosion ability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the thickness of the submarine pipeline steel strip produced in this embodiment is 3mm, the total reduction under light reduction at the end of continuous casting solidification is 8mm, the rough rolling in the rolling process is rolled in 3+5 passes, and the reduction rate in the final pass of R2 rough rolling is 24 %, without throwing the frame, the specific composition of the continuous casting slab, other production process parameters and performance control are shown in Table 1:

[0034] Table 1 3mm thickness composition (wt%), process and performance

[0035]

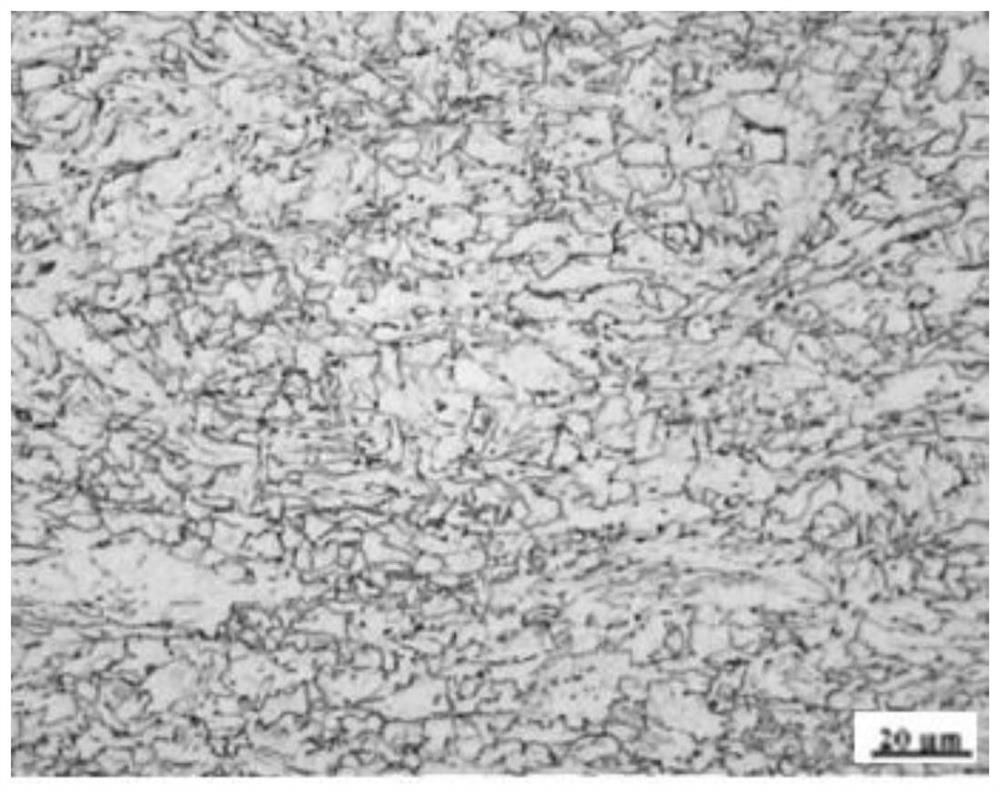

[0036] figure 1 It shows that the subsea pipeline steel L485MO structure produced in Example 1 is irregular acicular ferrite, and the grain size rating is 13 grades; Table 1 shows that the product strength is moderate, and the tensile, bending, impact, metallographic, and drop Other experimental items meet the requirements of APISpec 5L (version 46) PSL2, the yield strength ratio and...

Embodiment 2

[0038] In this embodiment, the thickness of the L485MO steel strip for the production of the seabed pipeline steel is 3 mm, and the total reduction is 8 mm under light reduction at the end of continuous casting solidification. The production rate is 24%, the frame is not thrown, the specific composition of the continuous casting slab, other production process parameters and performance control are shown in Table 2:

[0039] Table 2 3mm thickness composition (wt%), process and performance

[0040]

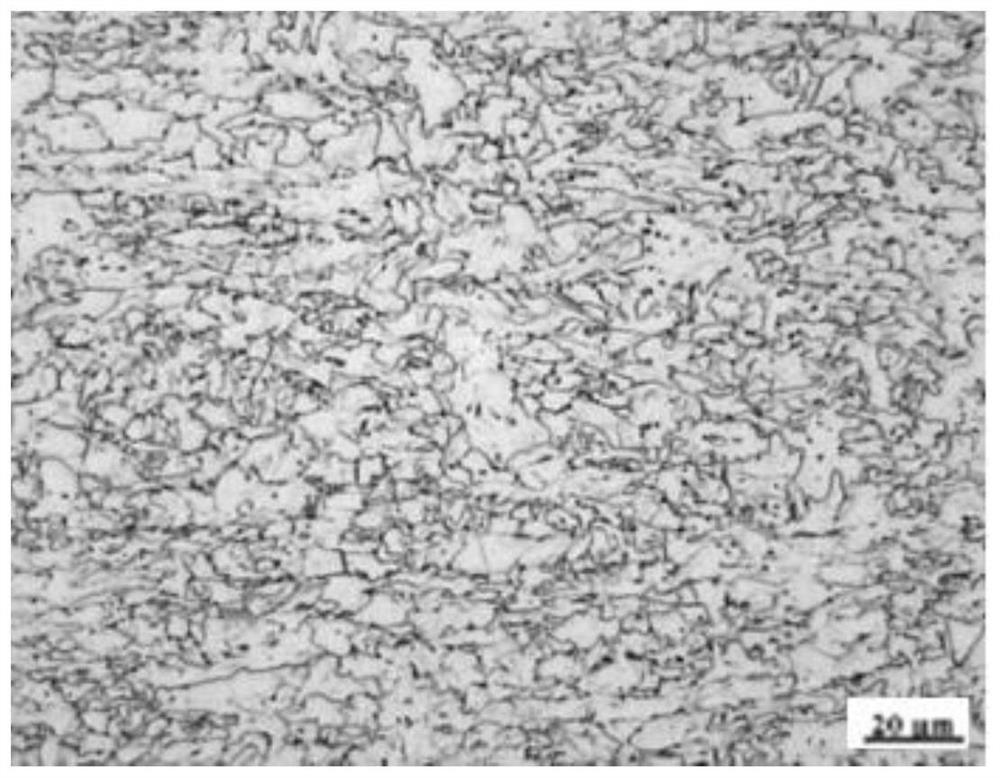

[0041] figure 2 It shows that the subsea pipeline steel L485MO structure produced in Example 2 is irregular acicular ferrite, and the grain size rating is 13 grades; Table 2 shows that the product strength is moderate, and the tensile, bending, impact, metallographic, and drop weight Other experimental items meet the requirements of APISpec 5L (version 46) PSL2, the yield strength ratio and hardness value are low and stable, and the CTOD outsourced experiment is qualified.

Embodiment 3

[0043] In this embodiment, the thickness of the L485MO steel strip for the production of the seabed pipeline steel is 3 mm, and the total reduction is 8 mm under light reduction at the end of continuous casting solidification. The specific composition of continuous casting slab, other production process parameters and performance control are shown in Table 3:

[0044] Table 3 3mm thickness composition (wt%), process and performance

[0045]

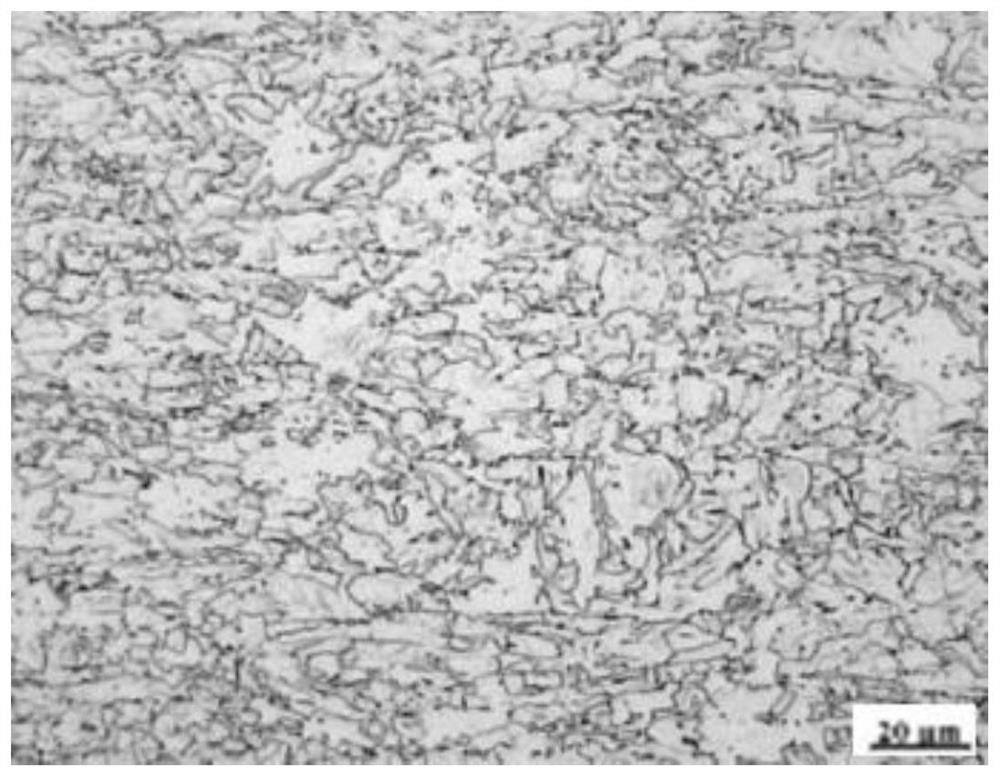

[0046] image 3 It shows that the subsea pipeline steel L485MO structure produced in Example 3 is irregular acicular ferrite, and the grain size rating is 13 grades; Table 3 shows that the product strength is moderate, and the tensile, bending, impact, metallographic, and drop weight Other experimental items meet the requirements of APISpec 5L (version 46) PSL2, the yield strength ratio and hardness value are low and stable, and the CTOD outsourced experiment is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com