A stainless steel flux cored wire

A flux-cored wire, stainless steel technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problems of poor anti-corrosion ability and poor high temperature resistance of stainless steel flux-cored welding wire, and achieve harm reduction and excellent welding process. performance, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

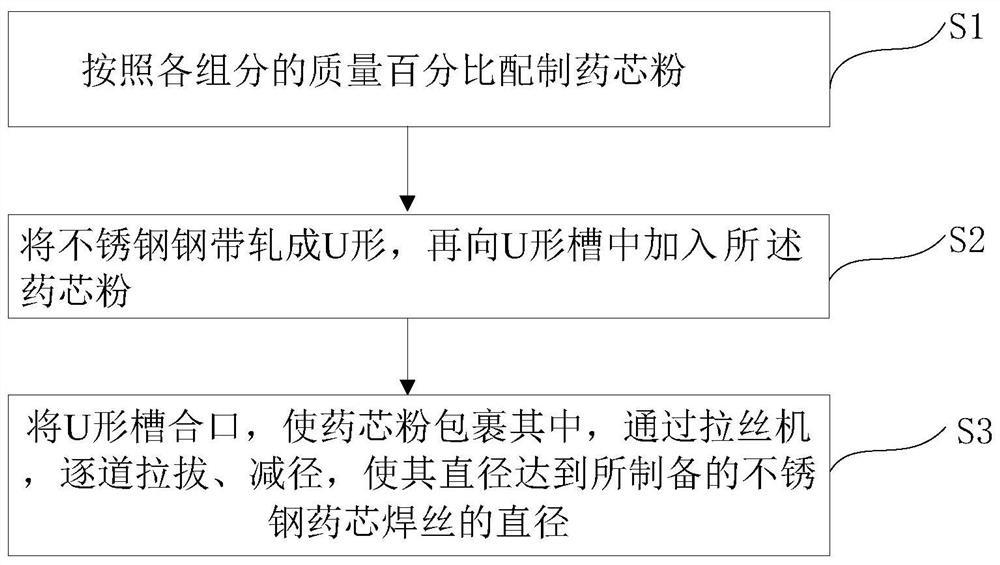

[0033] See attached figure 1 , the preparation method of the stainless steel flux-cored welding wire of the present invention comprises the following steps:

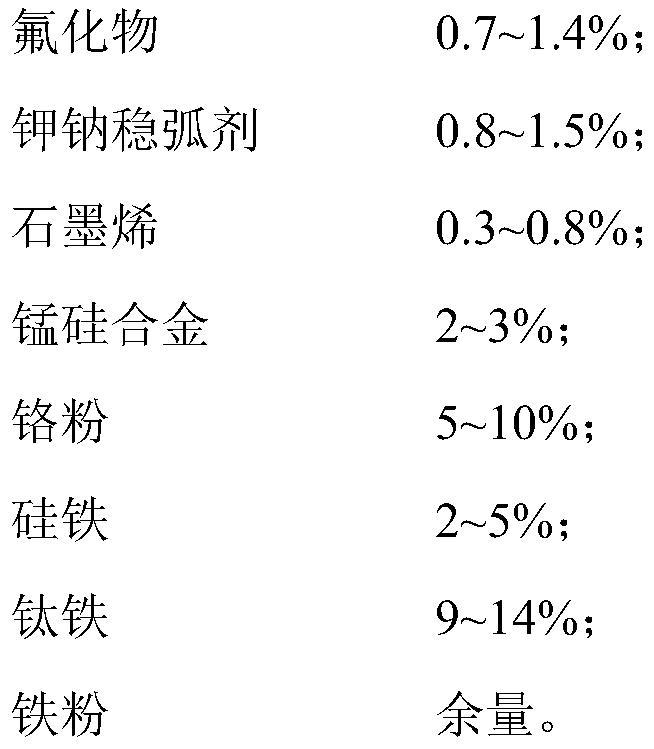

[0034] S1, prepare medicine core powder according to the mass percentage of above-mentioned each component;

[0035] S2, rolling the stainless steel strip into a U shape, and then adding the core powder to the U shape groove;

[0036] S3. Close the U-shaped groove, wrap the core powder in it, draw and reduce the diameter one by one through the wire drawing machine, so that the diameter reaches the diameter of the prepared stainless steel flux cored wire.

[0037] Wherein, each component in step S1 is in powder form, and the particle size of each component is 60-80 mesh. When batching, each component is sieved through a 60-mesh, 70-mesh or 80-mesh sieve.

[0038] In step S2, the stainless steel strip is SUS340 stainless steel, the specification of which is 0.3*10 mm in thickness*width, and the filling amount of the flux...

Embodiment 1

[0042] In this embodiment, the stainless steel flux-cored welding wire includes a SUS430 stainless steel strip and a flux core, and the flux core is filled in the SUS430 stainless steel strip. Among them, the mass percentages of the components in the drug core are as follows: 0.7% fluoride, 0.8% potassium sodium arc stabilizer, 0.3% graphene, 2% manganese-silicon alloy, 5% chromium powder, 2% ferrosilicon, 9% ferrotitanium, The balance is iron powder, the total mass percentage of each component is 100%, and the filling amount of the flux core is 18% of the total weight of the stainless steel flux cored wire.

Embodiment 2

[0044] In this embodiment, the stainless steel flux-cored welding wire includes a SUS430 stainless steel strip and a flux core, and the flux core is filled in the SUS430 stainless steel strip. Among them, the mass percentages of the components in the drug core are as follows: 1.1% fluoride, 1.1% potassium sodium arc stabilizer, 0.6% graphene, 3% manganese-silicon alloy, 7% chromium powder, 5% ferrosilicon, 12% ferrosilicon, The balance is iron powder, the total mass percentage of each component is 100%, and the filling amount of the flux core is 20% of the total weight of the stainless steel flux cored wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com