A high-hardness, corrosion-resistant cast stainless steel for fluid delivery

A technology of fluid transportation and stainless steel, which is applied in the field of high-hardness corrosion-resistant cast stainless steel, which can solve the problems of loss, thin thickness, waste, etc., and achieve the effect of hardness improvement and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

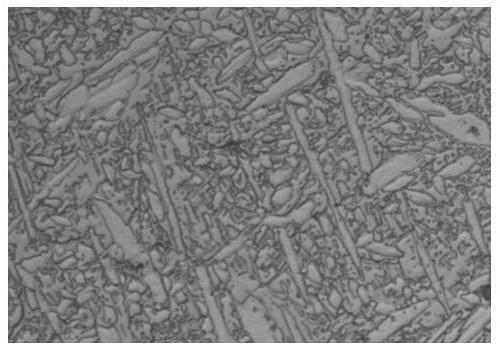

Image

Examples

Embodiment 2

[0032] The chemical composition percentage of the casting is: C: 0.028%, Si: 0.516%, Mn: 0.803%, S: 0.01%, P: 0.038%, Cr: 25.8%, Ni: 4.79%, Mo: 4.1%, Cu: 2.68% ,N:0.12%

[0033] After solution treatment at 1130 degrees and hardening treatment at 850 degrees, the casting hardness reaches 43HRC.

Embodiment 3

[0035] The chemical composition percentage of stainless steel castings is: C: 0.012%, Si: 0.43%, Mn: 1.2%, S: 0.02%, P: 0.035%, Cr: 26.1%, Ni: 4.76%, Mo: 4.6%, Cu: 1.5 %,N:0.10%

[0036] After solution treatment at 1150 degrees and hardening treatment at 850 degrees, the casting hardness reaches 46HRC.

[0037] (4) Embodiment 4

[0038]The chemical composition percentage of the casting is: C: 0.012%, Si: 0.43%, Mn: 1.2%, S: 0.02%, P: 0.035%, Cr: 26.1%, Ni: 4.76%, Mo: 4.6%, Cu: 1.5% ,N:0.10%

[0039] After solution treatment at 1170 degrees and hardening treatment at 850 degrees, the casting hardness reaches 47HRC.

[0040] (5) Example 5

[0041] The chemical composition percentage of the casting is: C: 0.014%, Si: 0.35%, Mn: 0.68%, S: 0.01%, P: 0.02%, Cr: 26%, Ni: 5.2, Mo, 4.4%, Cu: 3.5%, N: 0.05%.

[0042] After solution heat treatment at 1150 degrees and age hardening at 530 degrees, the casting hardness reaches 39HRC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com